Pipe expander

A pipe expander and pipe cone technology, which is applied in the field of pipe expanders, can solve the problems of inadequate processing, affecting the quality of pipe expansion, and easy installation errors, etc., to achieve the effects of improving efficiency, reducing scrap rate, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

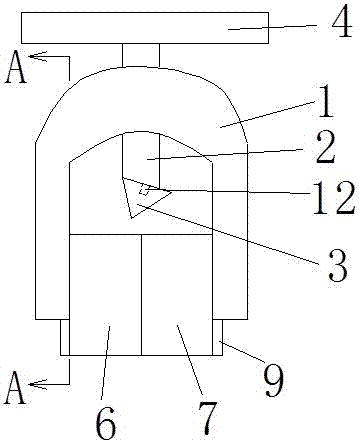

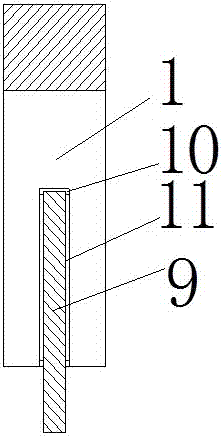

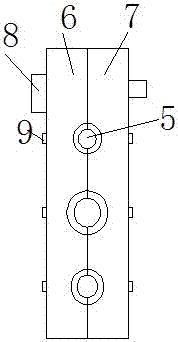

[0014] The preferred technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0015] As shown in the figure, the pipe expander of the present invention includes a clamp, a bracket 1, a top pressing screw 2, a pipe expansion cone 3 and a handle 4. The bracket 1 is installed on both sides of the clamp, and the bracket 1 is installed with a top Pressing screw 2, the lower part of the top pressing screw 2 is connected to the pipe expanding cone 3, the upper end of the top pressing screw 2 extends out of the arch 1 and is connected to the handle 4, the handle 4 is arranged perpendicular to the top pressing screw 2, and there is a row in the middle of the clamp for clamping Tighten the middle hole 5 of the metal tube, and set a fine-tuning mechanism at the connection between the bracket 1 and the clamp to fine-tune the concentricity of the top pressing screw 2 on the bracket 1 and the middle hole 5 .

[0016] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com