Complete equipment for transverse large-diameter hole forming in soft coal seam coal pillar area and hole forming technology

A technology of soft coal seam and large diameter is applied to complete sets of equipment and pore forming technology for horizontal large diameter hole forming in the coal pillar area of soft coal seam, which can solve the problems of difficult hole forming and low efficiency, and achieve high force transmission efficiency and equipment structure. It is compact and realizes the effect of torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

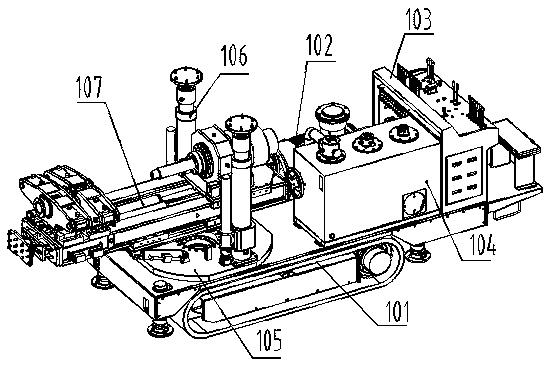

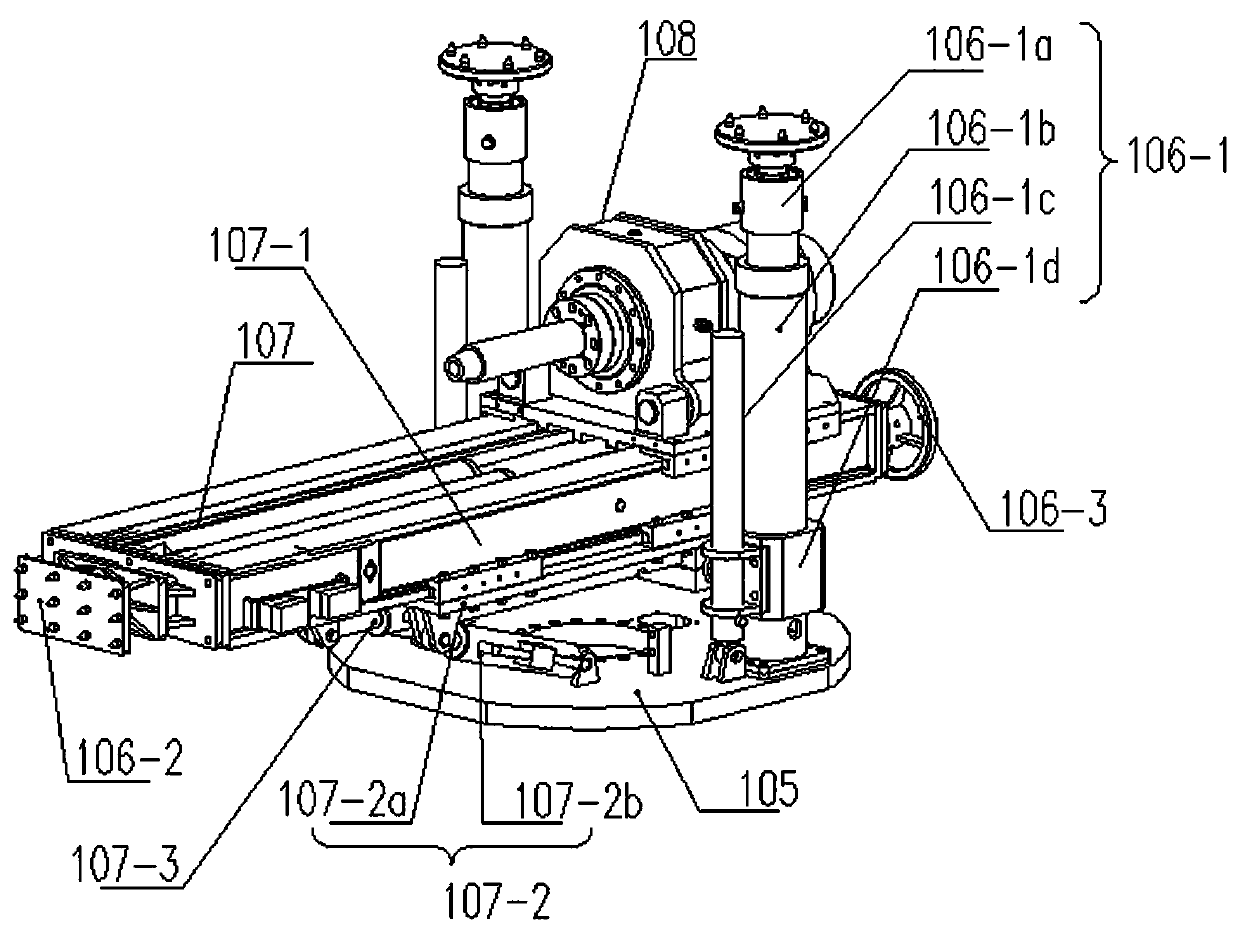

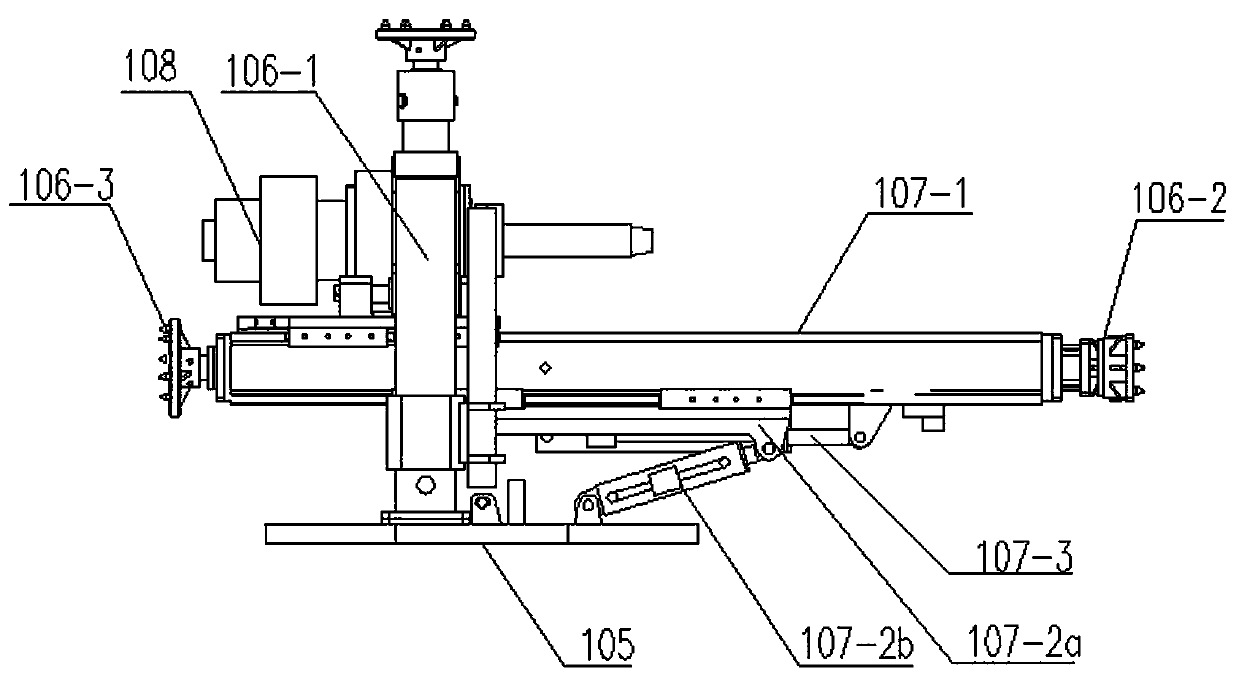

[0048] Referring to the accompanying drawings, a complete set of equipment for forming large-diameter holes laterally in the coal pillar area of soft coal seams, including a high-torque drilling rig 1, a crawler-type elevating vehicle 2, a drilling tool set and a gas drainage pipe 5, the drilling tool set includes a guide The hole drilling tool 3 and the reaming drilling tool 4, the pilot hole drilling tool 3 is used for the small-diameter pilot hole operation, and the reaming drilling tool 4 is used for the small-diameter back-expansion after the pilot-hole operation is completed, to obtain a large-diameter hole.

[0049] Such as Figure 1~6 It is a structural schematic diagram of the whole and each component of the high-torque drilling rig. The high-torque drilling rig 1 includes a craw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com