Packaging method and packaging body

An encapsulation method and encapsulation technology, which are applied in the manufacturing of electrical solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of overflowing glue, affecting product performance, and difficult to control frame deformation, so as to improve the arrangement density and improve the Service life, the effect of solving operational difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

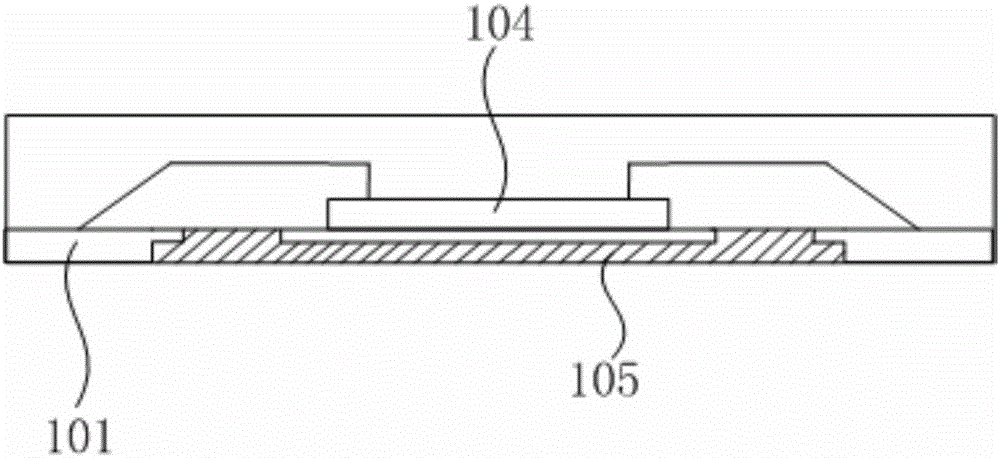

[0047] The packaging method of the present invention also provides a second specific embodiment, the difference between the second specific embodiment and the first specific embodiment is that the materials used to form the pre-filled layer are different. In a second specific implementation manner, the material forming the pre-fill layer is liquid photo-soldering resist. The steps of the second specific embodiment are as follows.

[0048] The method for forming the welding pad in the second embodiment is the same as that in the first embodiment, please refer to the above description and attached Figures 4A-4B . For the method of forming the pre-filled layer, please refer to the following steps.

[0049] See step S60 and Figure 7A1. Coating a pre-fill layer 702 on the surface of the carrier 400 and the welding pad 401, the material of the pre-fill layer 702 is liquid photo-solder resist, and the liquid photo-solder resist is commonly known as green paint. In this specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com