A grounding wire method and isolated grounding tool for high-voltage transmission lines

A high-voltage transmission line, isolated technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing work intensity, unable to control the clip, time-consuming and labor-intensive, etc., to improve work efficiency, ensure work quality, shorten The effect of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

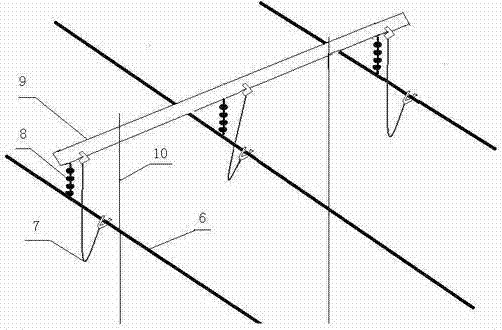

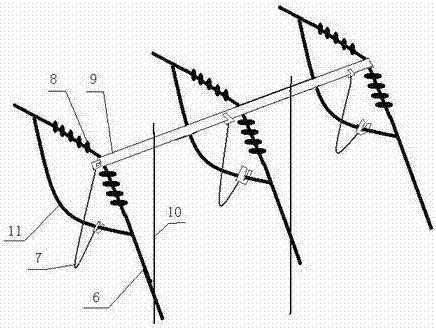

[0030] combine figure 1 , 2 , Shown in 3, a kind of ground wire method that is used for high voltage transmission line, its steps are as follows:

[0031] 1. Assemble and adjust the isolated grounding tool,

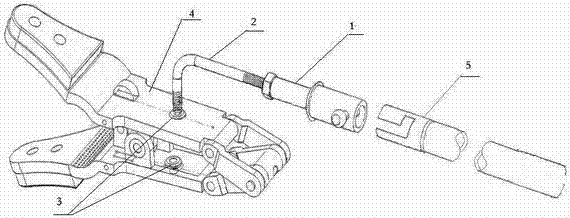

[0032] 1) The operator screws one end of the L-shaped screw joint 2 into the screw connection hole 3 beside the grounding wire clamp 4, and adjusts the screw operation chuck hanging on the high-voltage transmission line according to the working position of the operator. 1, adjust the direction of the screw head of the L-shaped screw, and then tighten it;

[0033] 2) The operator connects the other end of the L-shaped screw joint 2 to the operating rod 5 with the screw joint, and then adjusts the working angle of the screw operating chuck 1 and fixes it.

[0034] 2. Use the isolated grounding tool to connect the transmission line to the crossarm - grounding;

[0035] The operator on the pole tower 10 first fixedly connects one end of the ground wire 7 to the cross arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com