Centralizing and cutting integrated two-stage cone reamer

A reamer, an integrated technology, applied in the direction of drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of easy shaft breakage, low reaming efficiency, heavy reaming drilling tool weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

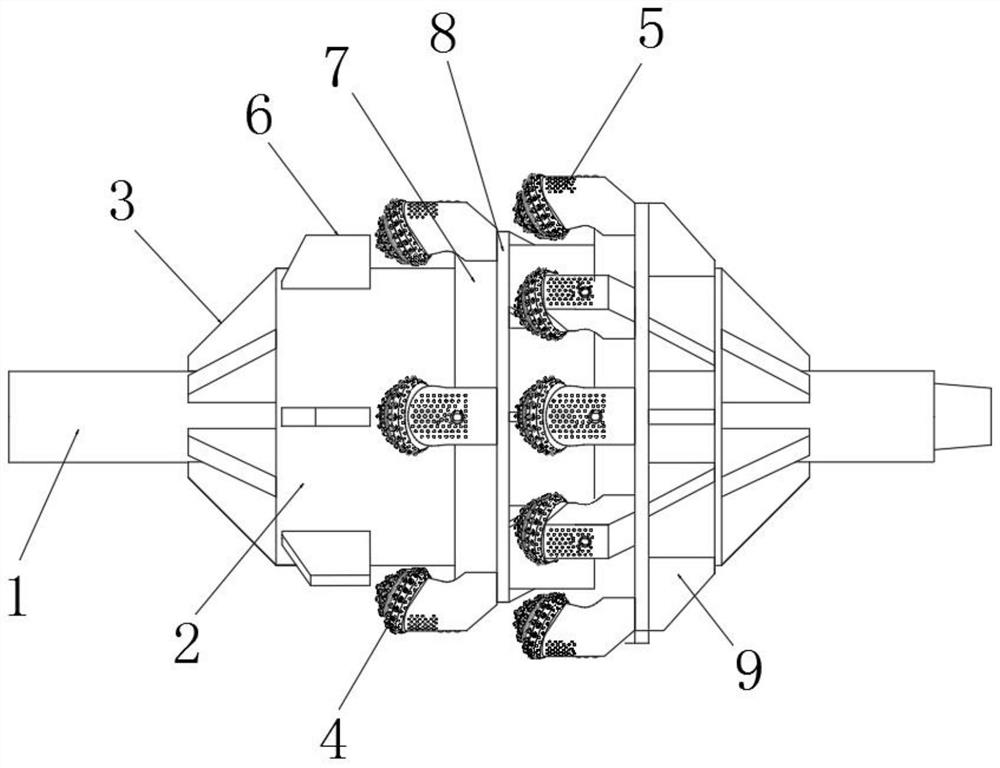

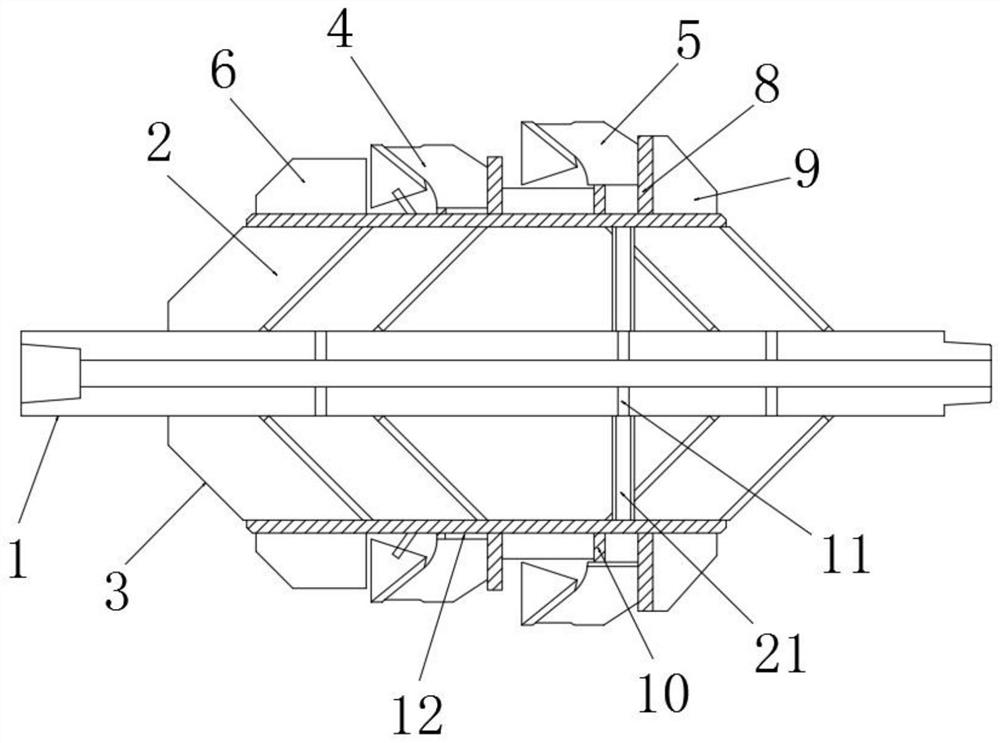

[0021] see Figure 1-2 , the embodiment of the present invention provides a technical solution: an integrated two-stage cone reamer, including a reamer body 2, a mandrel 1 is arranged at the axis of the reamer body 2, and the mandrel 1 It is a hollow structure, and one end of the mandrel 1 is a female button, and the other end is a male button. The outer side of the mandrel 1 is covered with a straight cylinder, and between the straight cylinder and the mandrel 1, there are square rigids arranged in a staggered front and rear. The reamer body 2 It is provided with a first-stage centralizing cone set 4 and a second-stage cutting cone set 5, the first-stage centralizing cone set 4 is used for centering, and the second-stage cutting cone set 5 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com