Hole reaming and borehole enlarging device for exploitation of coalbed methane exploitation hole bottom

A coalbed methane and hole bottom technology, applied in earthwork drilling, drilling equipment and methods, drilling equipment, etc., can solve the problem that the hole wall of reaming cannot be guaranteed to be flat and smooth, the cutting teeth cannot be flushed and cooled, and self-sharpening cannot be realized and other problems, to achieve the effect of reducing the failure to open and retract normally, good market prospects, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

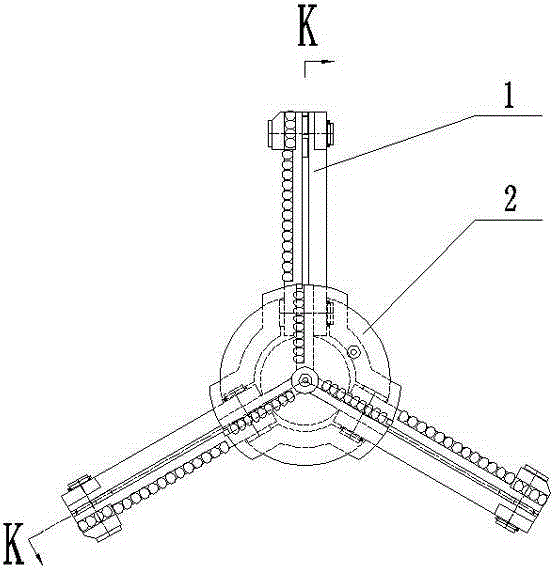

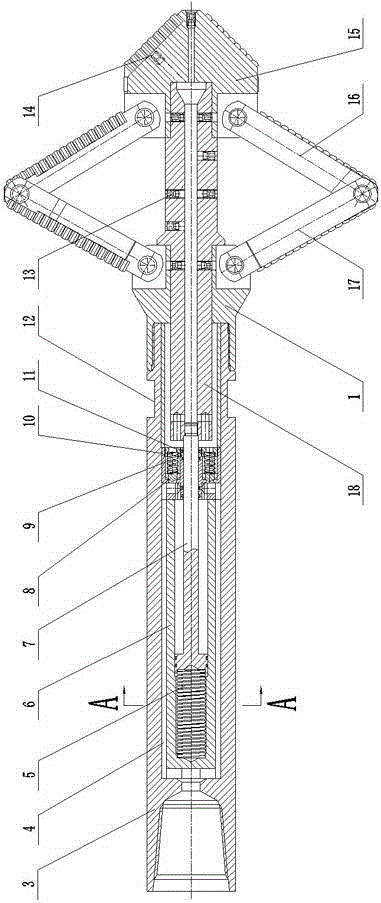

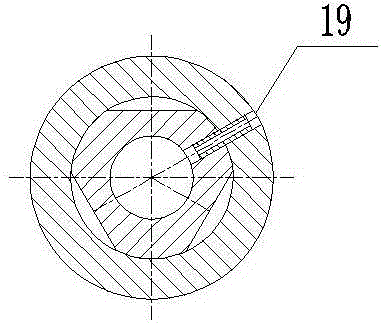

[0013] A hole-reaming and hole-digging device for the bottom of a coalbed methane exploitation hole, comprising a connecting drill pipe 3 connected with a drill pipe thread; The inner cavity is set as a flushing liquid flow channel 4 that communicates with the drill pipe cavity, a flushing liquid back pressure valve is installed in the flushing liquid flow channel 4, and a hole-digging oil cylinder is installed in the flushing liquid flow channel above the flushing liquid back pressure valve. , the hole-digging oil cylinder includes a cylinder body 6 and a piston 7 that moves up and down in the cylinder. A cylinder spring 5 is installed between the piston and the cylinder body in the rodless cavity of the hole-digging oil cylinder. The outer wall of the cylinder is provided with a flushing fluid inlet which is communicated with the flushing fluid flow passage, and a flushing fluid outlet for opening the flushing fluid backpressure valve is provided at the cylinder body of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com