Reamer with anti-drag reaming type belt

A hole reamer and reaming technology, which is applied in the field of reamers, can solve the problems of small welding area, insufficient crushing force of soil and gravel, and damage of reamers, so as to improve connection strength, improve reaming efficiency, Effect of Reducing Reaming Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

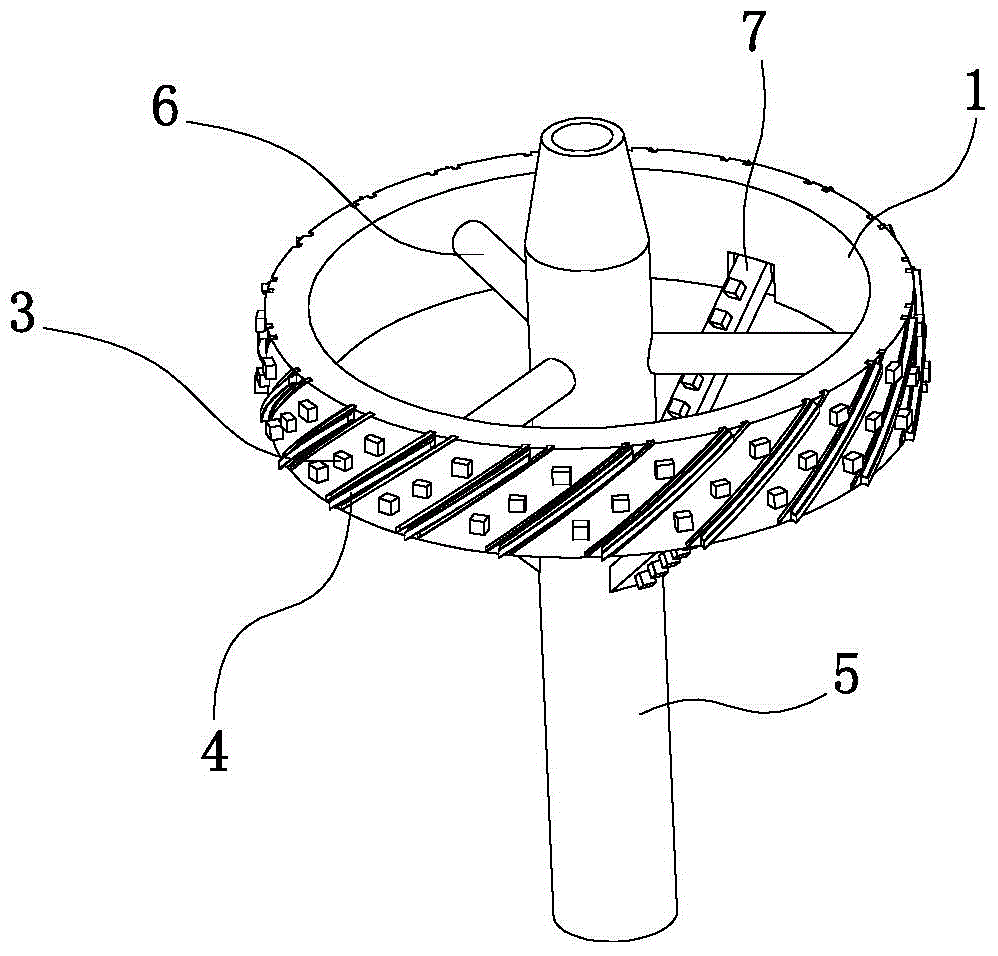

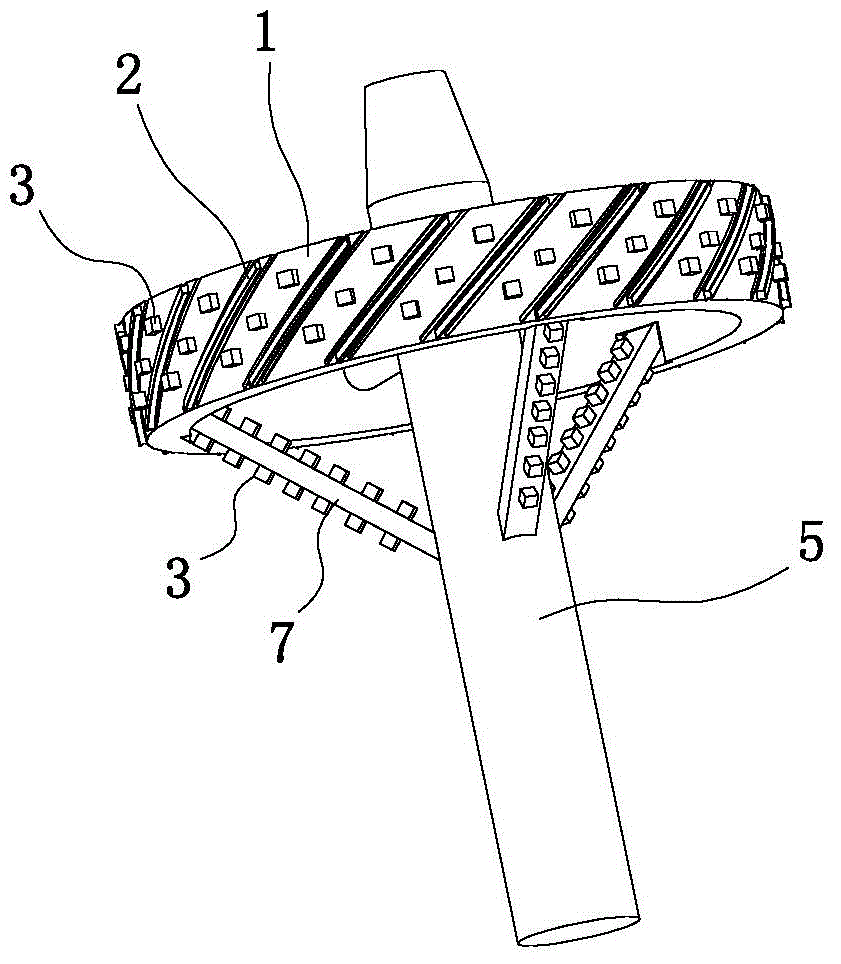

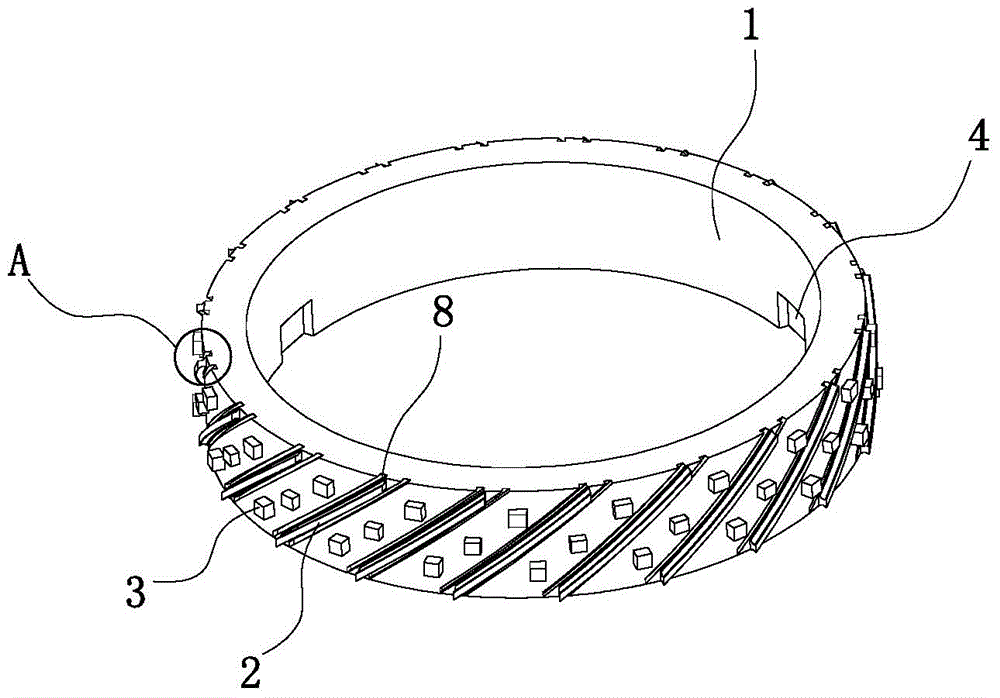

[0019] Such as figure 1 , figure 2 and image 3 As shown, the reamer of the band drag-reducing reaming type waistband of the present embodiment comprises the waistband 1 of annular shape structure, and the center of waistband 1 is fixedly connected drill rod 5 by cross bar 6, and the inner wall of waistband 1 and drill rod 5 A plurality of reaming rods 7 are fixedly connected between the side walls, and the reaming rods 7 are symmetrically arranged relative to the center of the drill rod 5. The reaming rods 7 are square rod structures, which are beneficial to crushing mud. The rods 6 are all hollow structures, the inner cavities of the three are connected, and the outer walls are evenly distributed with water outlet holes (not shown); the inner wall of the belt 1 is symmetrically provided with a plurality of welding grooves 4, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com