Super-automatic pipe reaming production line

A kind of hole production line, super-automatic technology, applied in the field of hole reaming machine, achieves the effect of fast speed, improving hole reaming efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

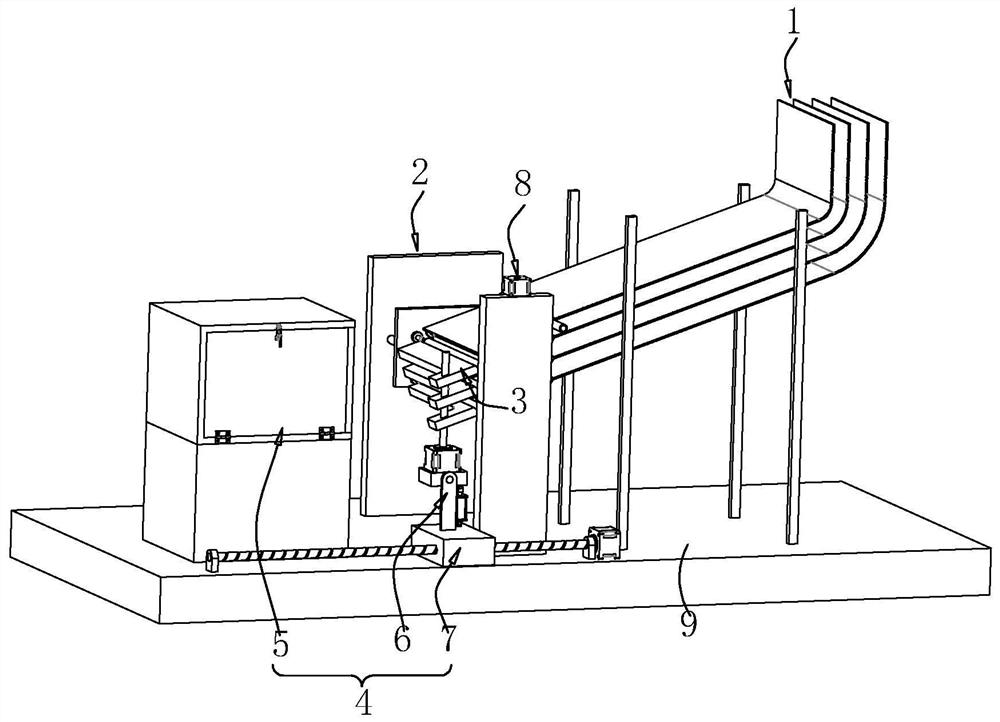

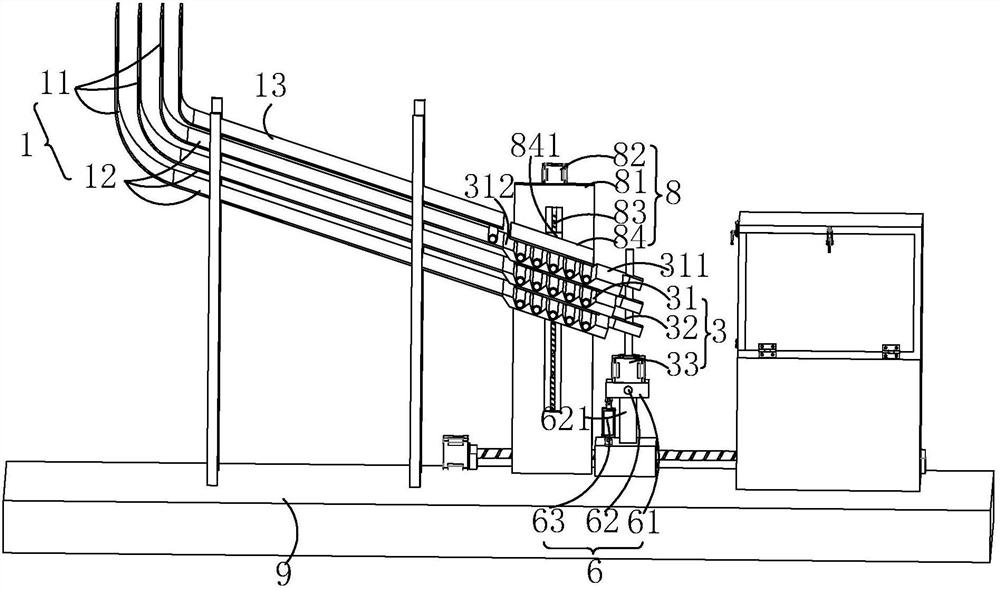

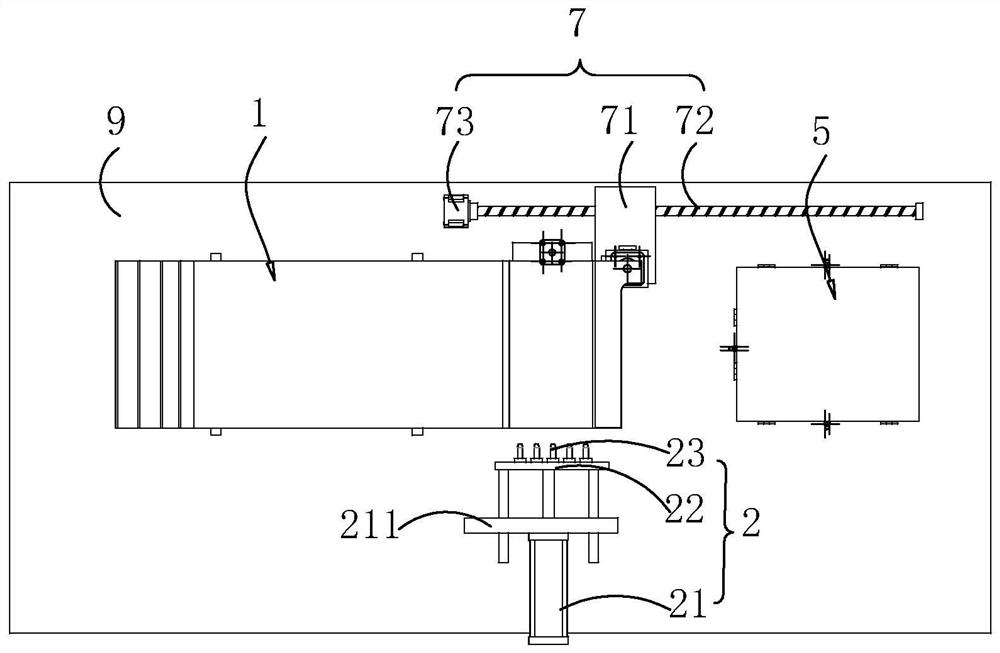

[0036] The following is attached Figure 1-4 The application is described in further detail.

[0037] The embodiment of the present application discloses a super-automated pipe fitting reaming production line. refer to figure 1, the ultra-automated pipe fitting reaming production line includes a feeding assembly 1, a reaming assembly 2, a rotating assembly 3 and a material receiving device 4. The feeding assembly 1 is located on the side of the feeding end of the reaming assembly 2 and rotating assembly 3, and the receiving device 4 is located on the other side of the discharge end of the reaming assembly 2 and the rotating assembly 3. The rotating assembly 3 is connected to the feeding assembly 1 and the receiving device 4; the receiving device 4 includes a receiving box 5, a discharging assembly 6 and a pumping plate assembly 7. The receiving box 5 is located on the side of the rotating assembly 3 away from the feeding assembly 1; the discharging assembly 6 is located belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com