Chamber for heat treatment equipment and heat treatment equipment

A heat treatment device and chamber technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of labor and time, and achieve the effect of reducing labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, a mode for implementing the present invention will be described with reference to the drawings. In addition, the present invention can be widely applied to heat treatment devices that heat treatment objects to be processed.

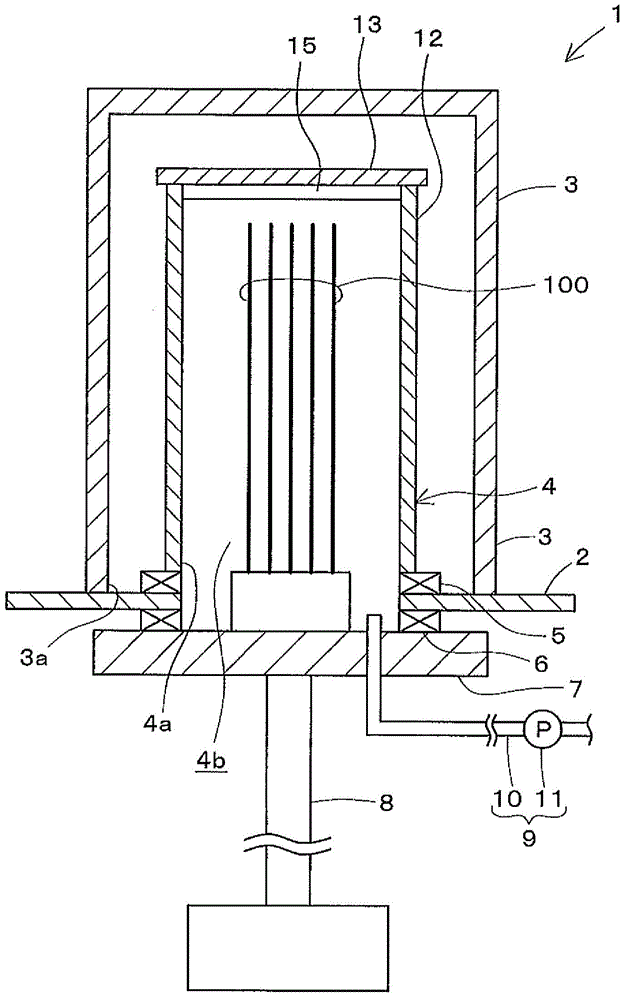

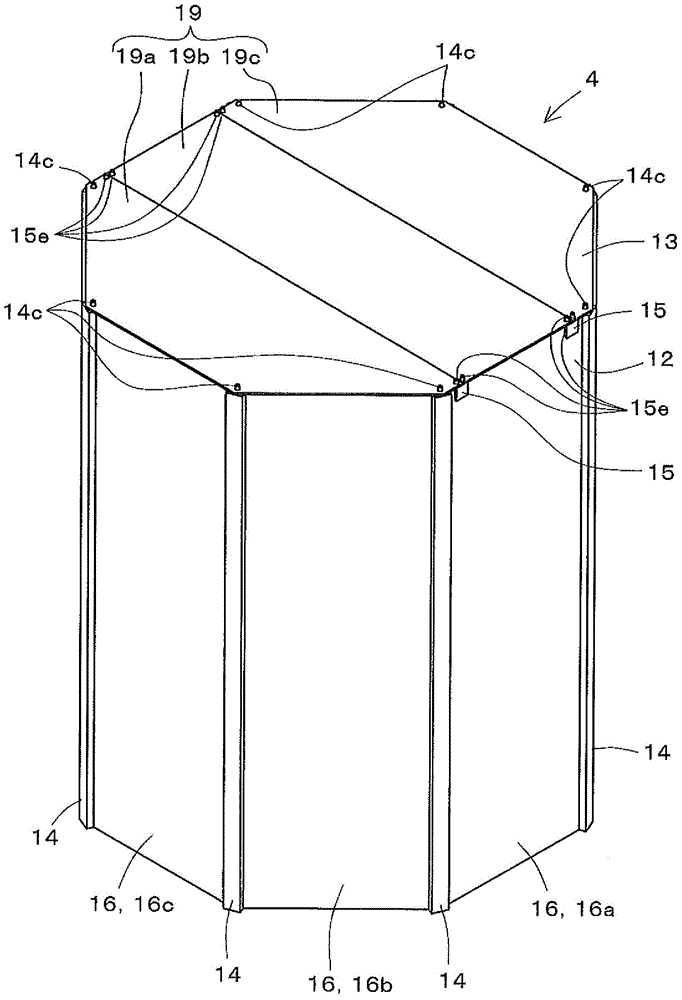

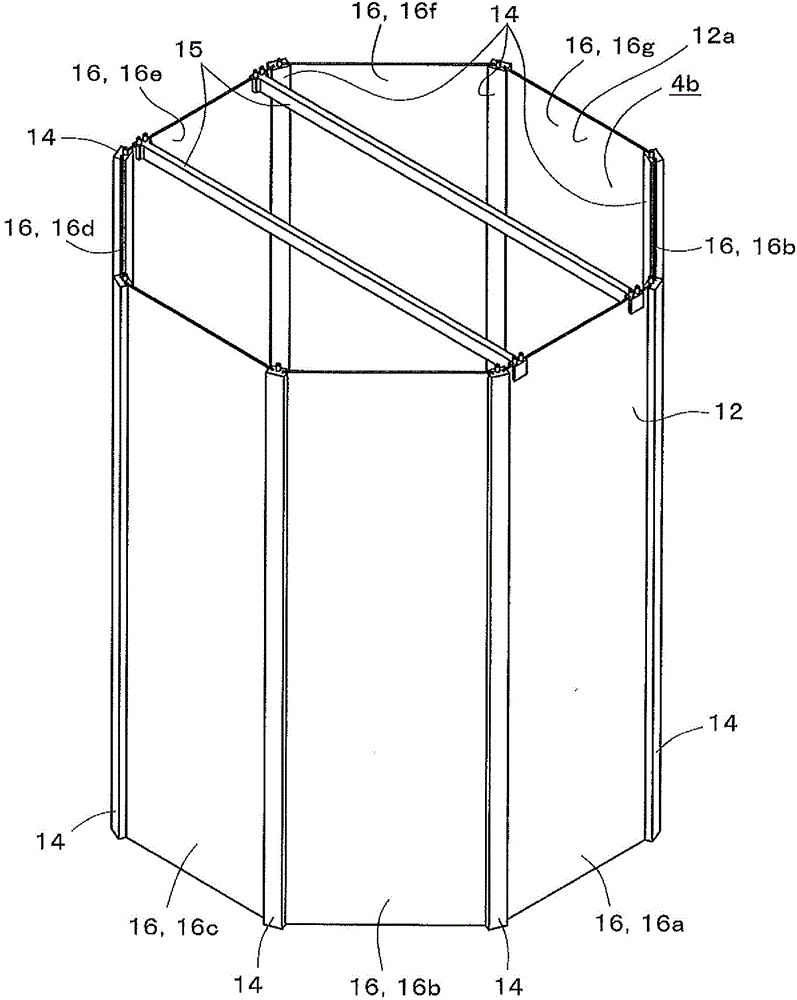

[0039] figure 1 This is a cross-sectional view of the heat treatment apparatus 1 according to the embodiment of the present invention, and shows a state of the heat treatment apparatus 1 viewed from the side. figure 2 It is a perspective view of the chamber 4 of the heat treatment apparatus 1. image 3 It is an exploded perspective view of the chamber 4. Figure 4 It is a cross-sectional view of the chamber 4, and shows a state in which the chamber 4 is viewed from above.

[0040] Reference figure 1 The heat treatment apparatus 1 is configured to be able to perform heat treatment on the surface of the object 100 to be processed. More specifically, the heat treatment apparatus 1 is configured to be able to perform heat treatment on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com