Automatic waste collecting and lifting mechanism

A waste collection and elevator technology, applied in conveyors, loading/unloading, containers, etc., can solve the problems of high input cost, long construction period, inconvenient movement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

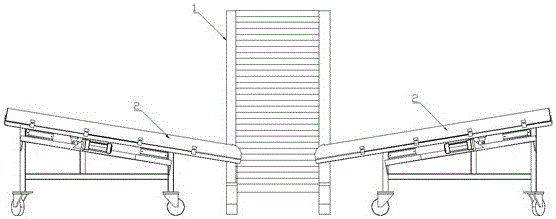

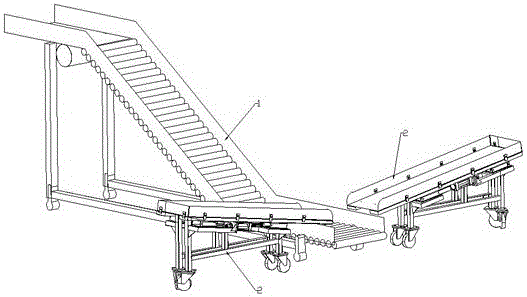

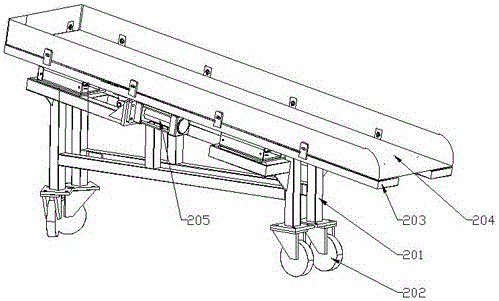

[0010] like figure 1 , figure 2 and image 3 As shown, an automatic waste collection and lifting mechanism includes a waste conveying hoist 1 and a waste collection shaking machine 2 that are independent of each other. The two waste collecting shaking machines 2 are respectively located on the left and right sides of the waste conveying elevator 1. The discharge end of the shaker 2 and the feed end 1 of the waste conveying hoist are set up and down correspondingly; the structure of the waste collection shaker 2 is: including a frame 201, a universal wheel 202, a slideway 203, a hopper 204 and a cylinder 205, the universal wheel 202 is fixed on the bottom of the frame 201, the universal wheel 202 is convenient for the frame to move, the slideway 203 provided with an inclination is fixed on the top of the frame 201, the hopper 204 is arranged in the slideway 203, the hopper 204 and the slideway Road 203 is slidingly connected, cylinder 205 is fixed on the frame, and the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com