Reverse circulation channel-type double stage reamer

A reverse circulation, flow channel technology, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of large inclination angle, small single crushing area, low efficiency, etc., and achieve the effect of high return speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The cutting edge of the reverse circulation channel type double-stage reamer provided in the embodiment adopts a cone-PDC composite cutting structure.

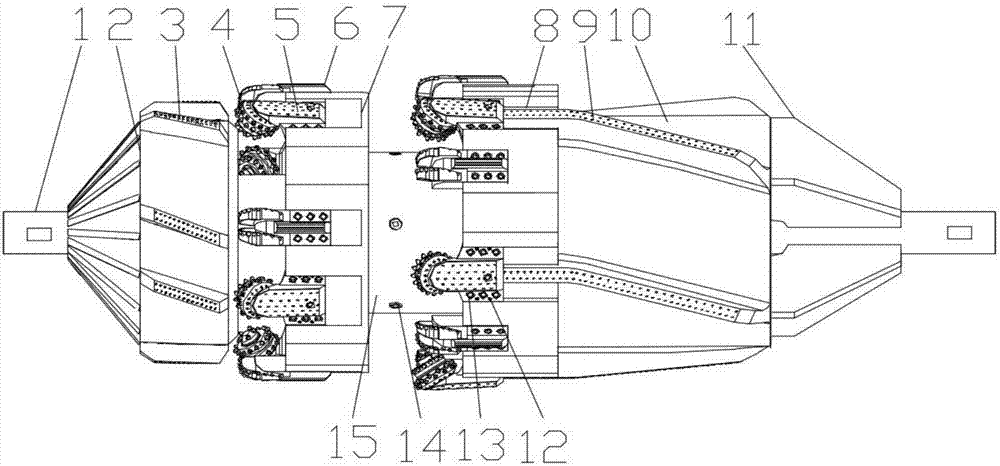

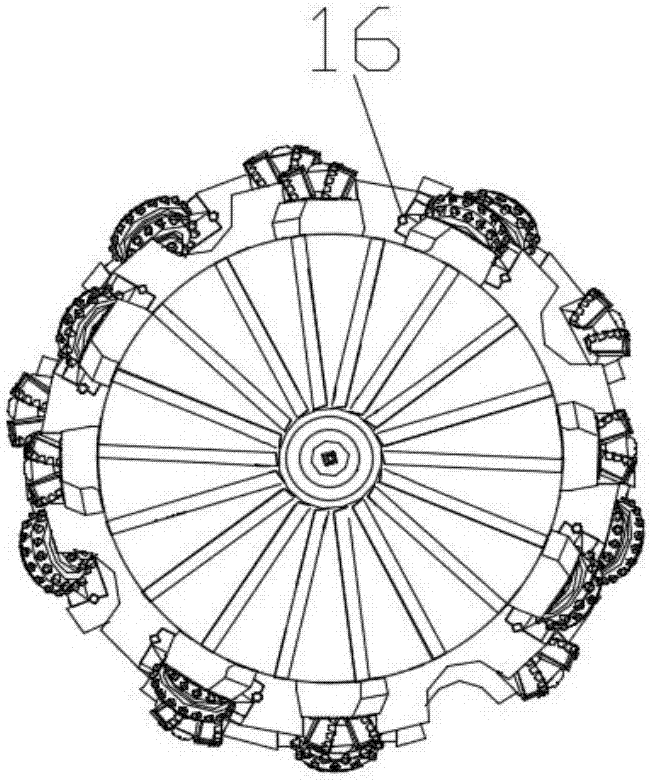

[0027] figure 1 and figure 2 The front view structure and the right view structure of the reverse circulation channel type double-stage reamer according to Embodiment 1 of the present invention are respectively shown.

[0028] Such as figure 1 and figure 2 Commonly shown, the reverse circulation channel type double-stage reamer provided by Embodiment 1 of the present invention includes: reverse circulation assembly 1, front centralizing barrel 2, front screw blade 3, cone 4, tooth palm 5, double Row of PDC (Polycrystalline DiamondCompact, polycrystalline diamond composite sheet) blade 6, primary reaming base 7, secondary reaming base 8, rear spiral blade 9, rear centralizing barrel 10, rear rib 11, limit Screw 12, fastening screw 13, slag suction pipe 14, slag suction bucket 15 and bearing pin 16; Wherein, reverse...

Embodiment 2

[0030] The cutting edge of the reverse circulation channel type double-stage compound reamer provided in the second embodiment adopts a cone-type cutting structure.

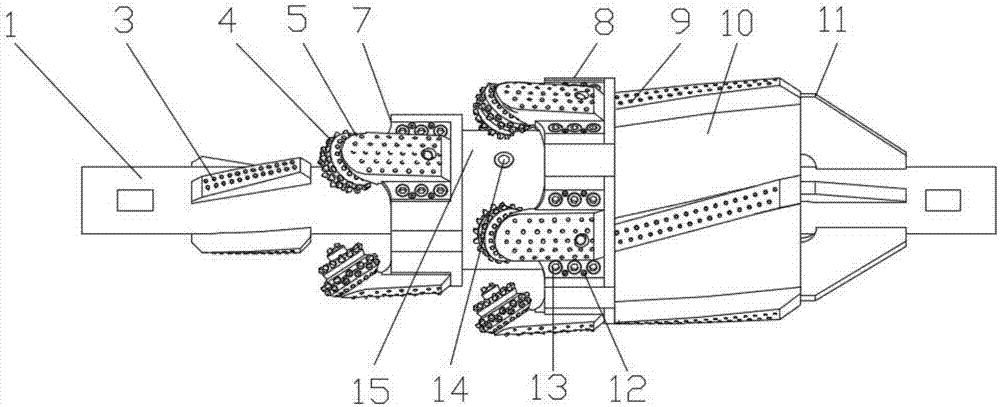

[0031] image 3 It shows the front view structure of the reverse circulation channel type double-stage reamer according to the second embodiment of the present invention.

[0032] Such as image 3 As shown, the reverse circulation channel type double-stage reamer provided by Embodiment 2 of the present invention includes: reverse circulation assembly 1, front screw blade 3, cone 4, tooth palm 5, and primary reaming base 7 , secondary reaming base 8, rear spiral blade 9, rear righting barrel 10, rear rib 11, limit screw 12, fastening screw 13, slag suction pipe 14, slag suction bucket 15 and pin 16; Wheel 4, tooth palm 5, primary reaming base 7, secondary reaming base 8, rear screw blade 9, rear righting barrel 10, rear rib 11, limit screw 12, fastening screw 13, suction The structure of the slag pipe 14, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com