Patents

Literature

34results about How to "Strong chip removal ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

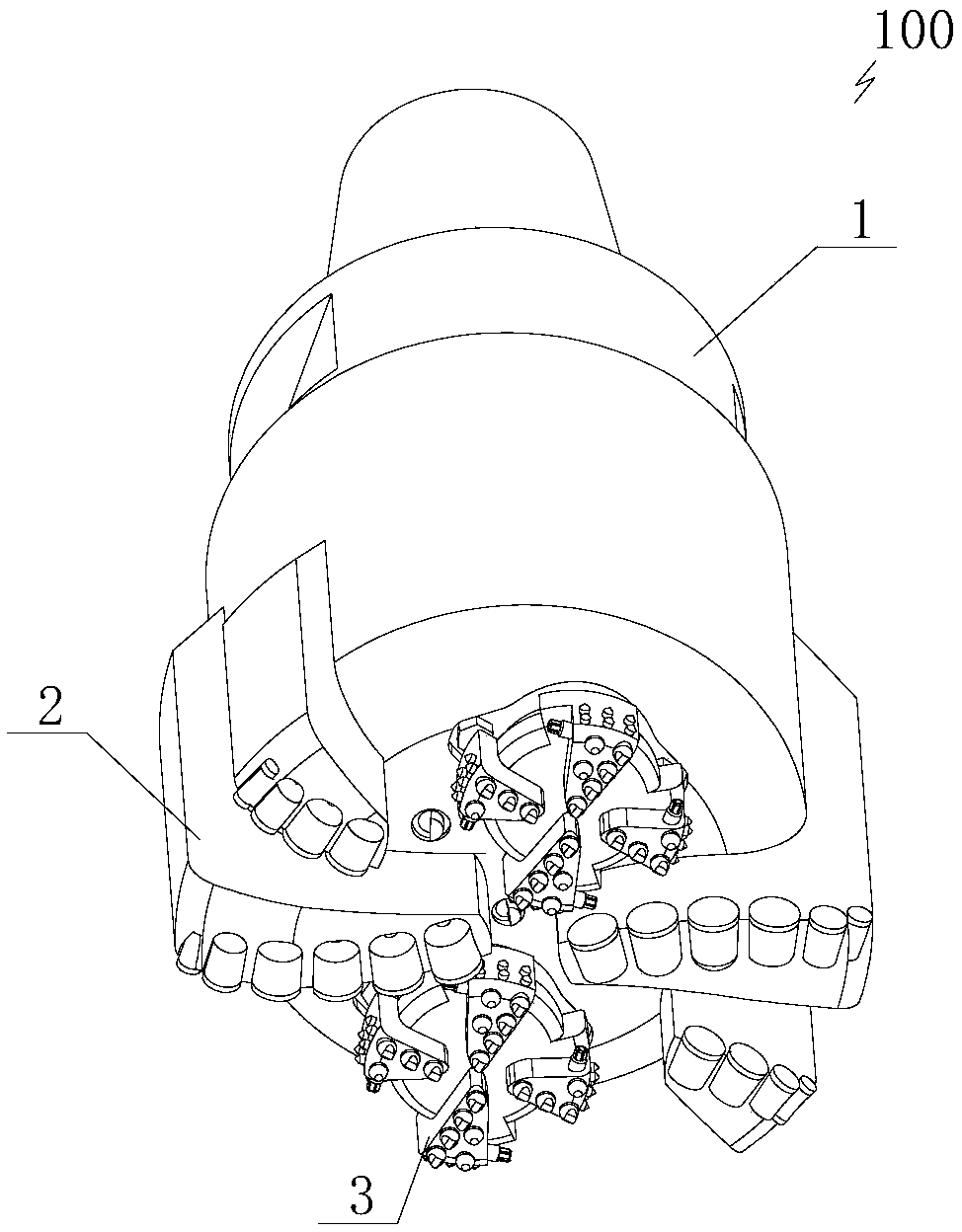

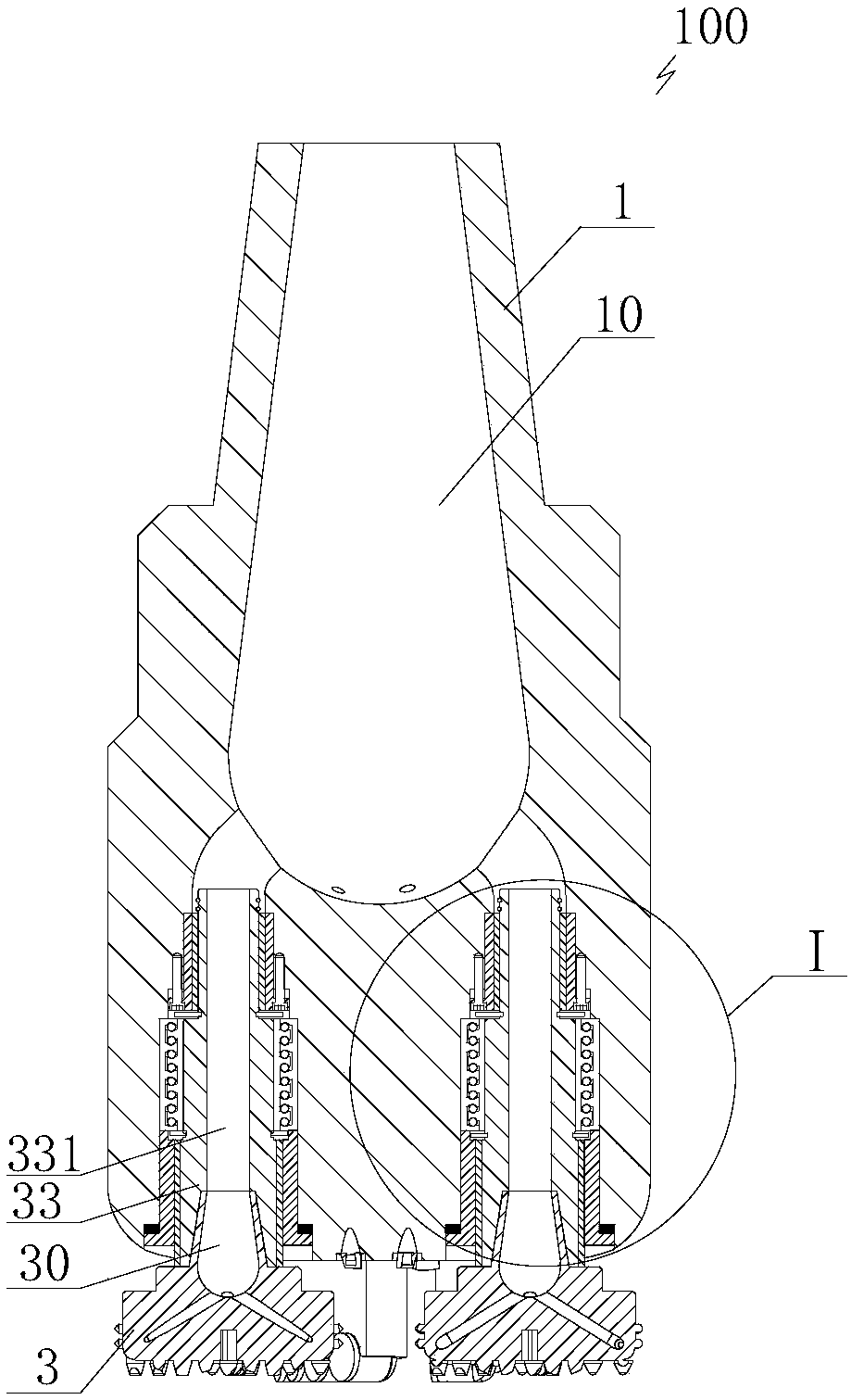

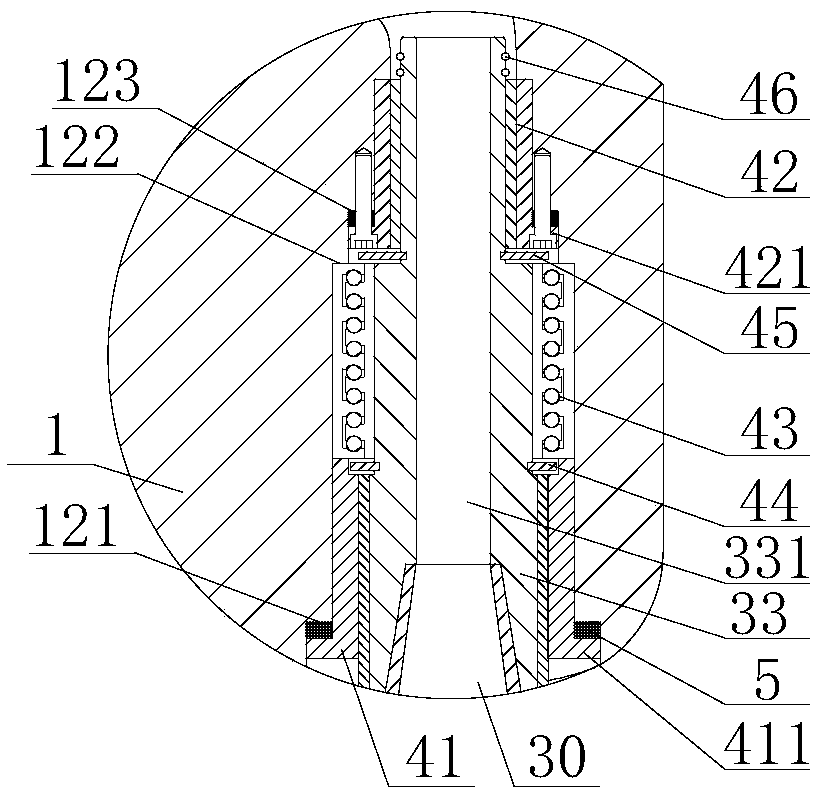

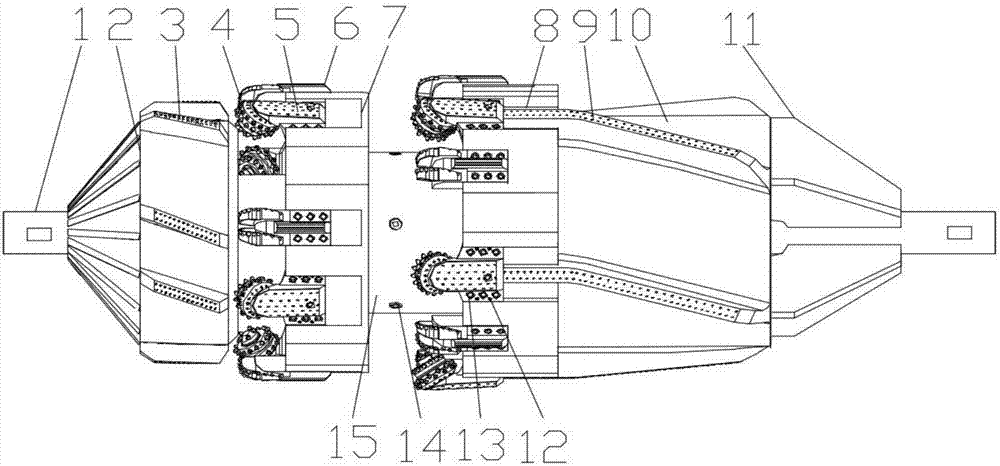

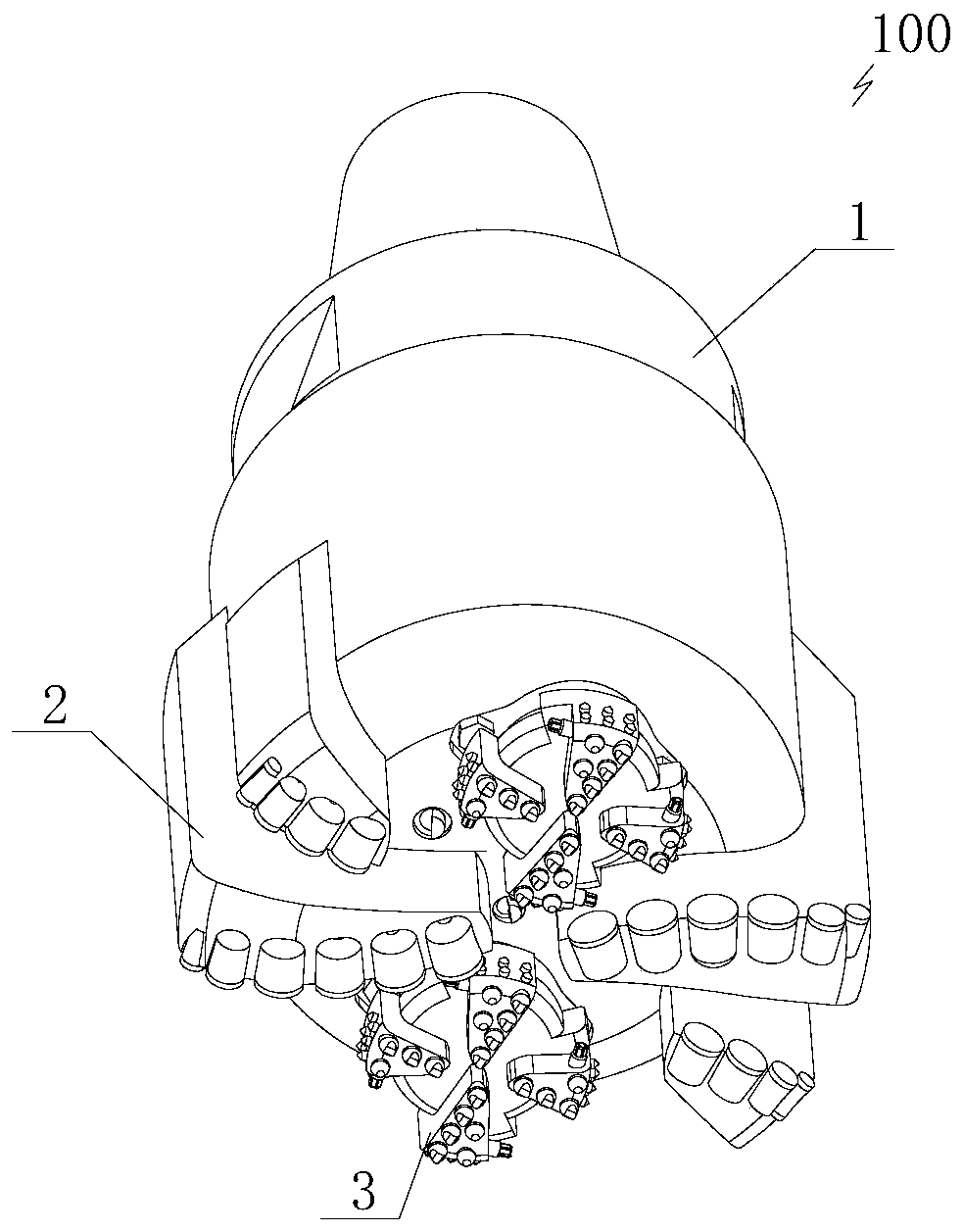

Hybrid power PDC drill bit based on jet flow technology

InactiveCN109025831AExtended service lifeImprove adaptabilityDrill bitsConstructionsWell drillingHigh pressure

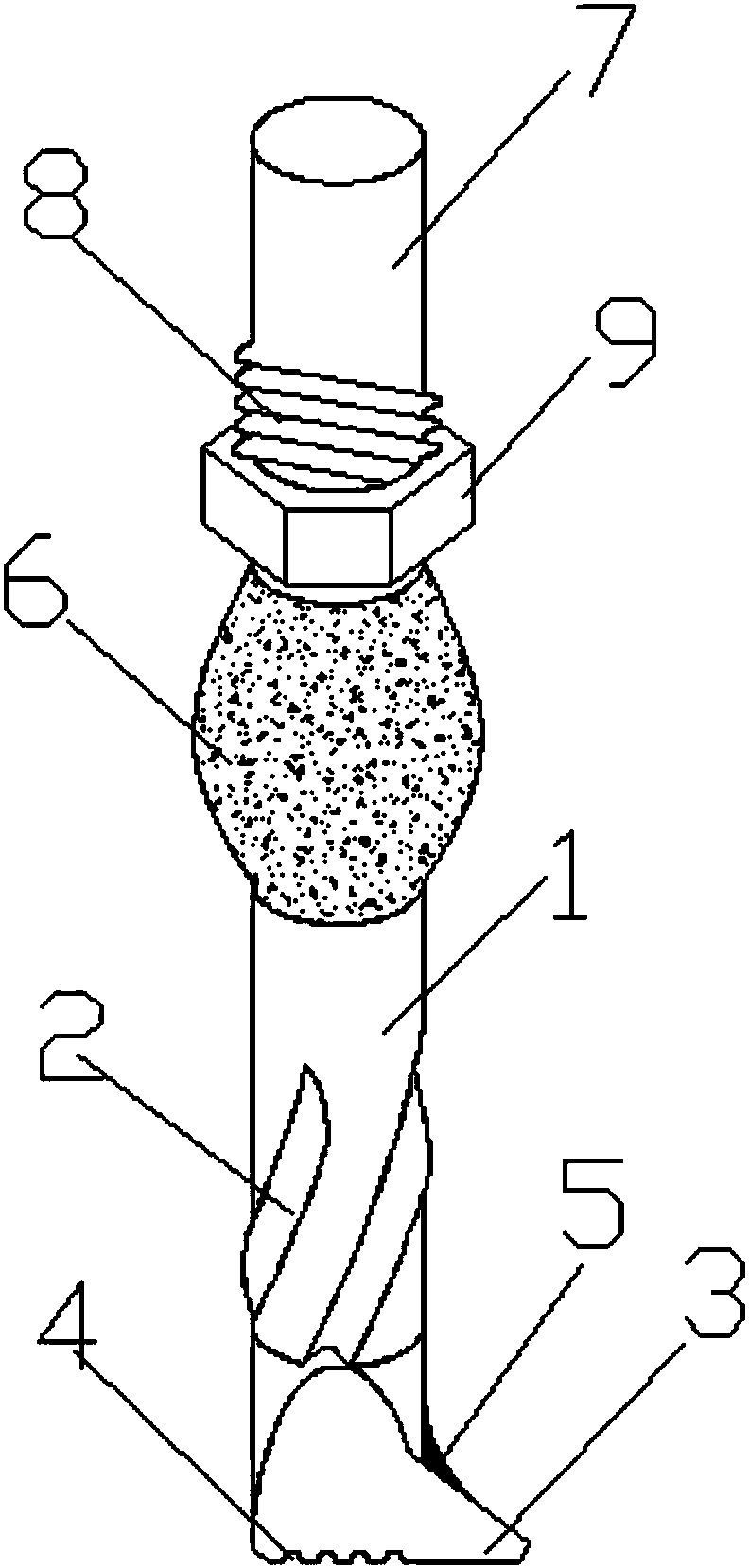

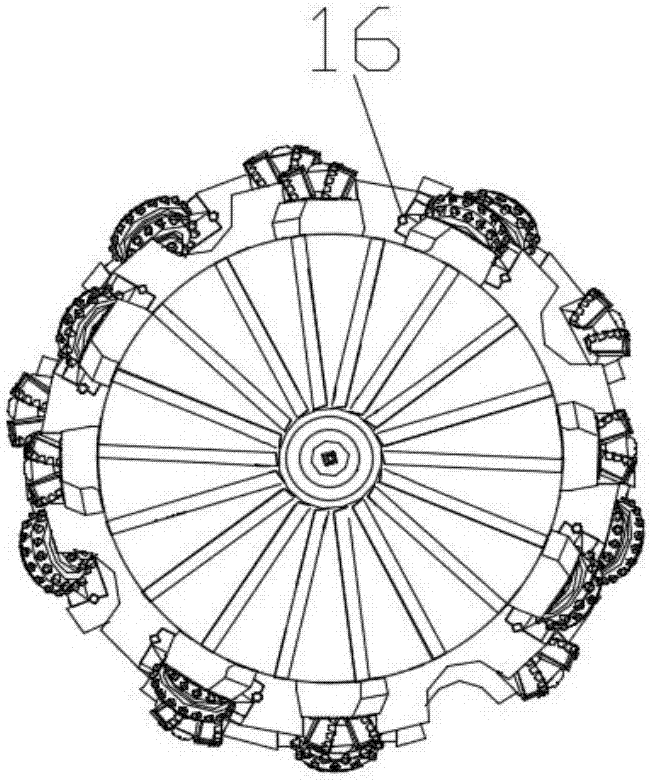

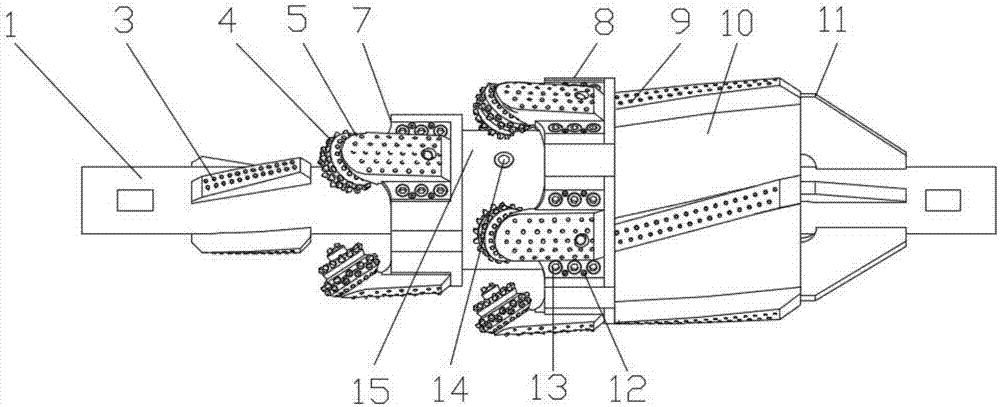

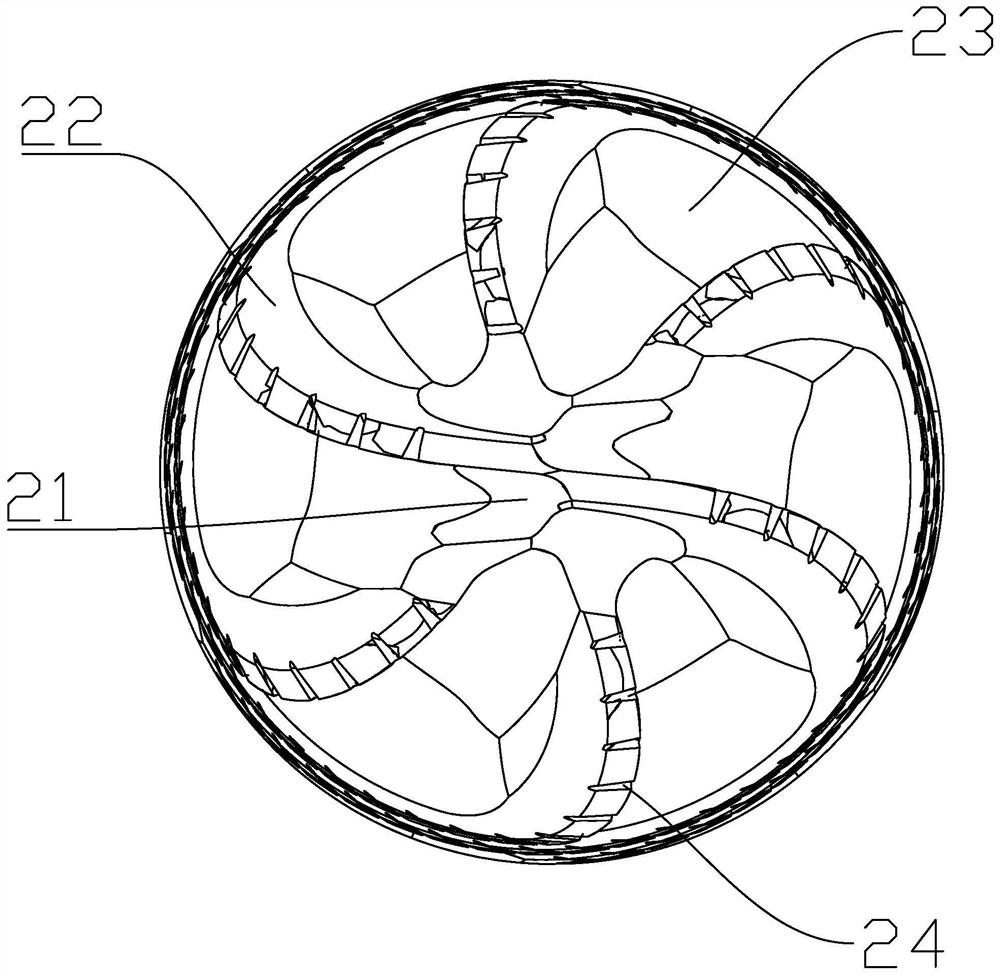

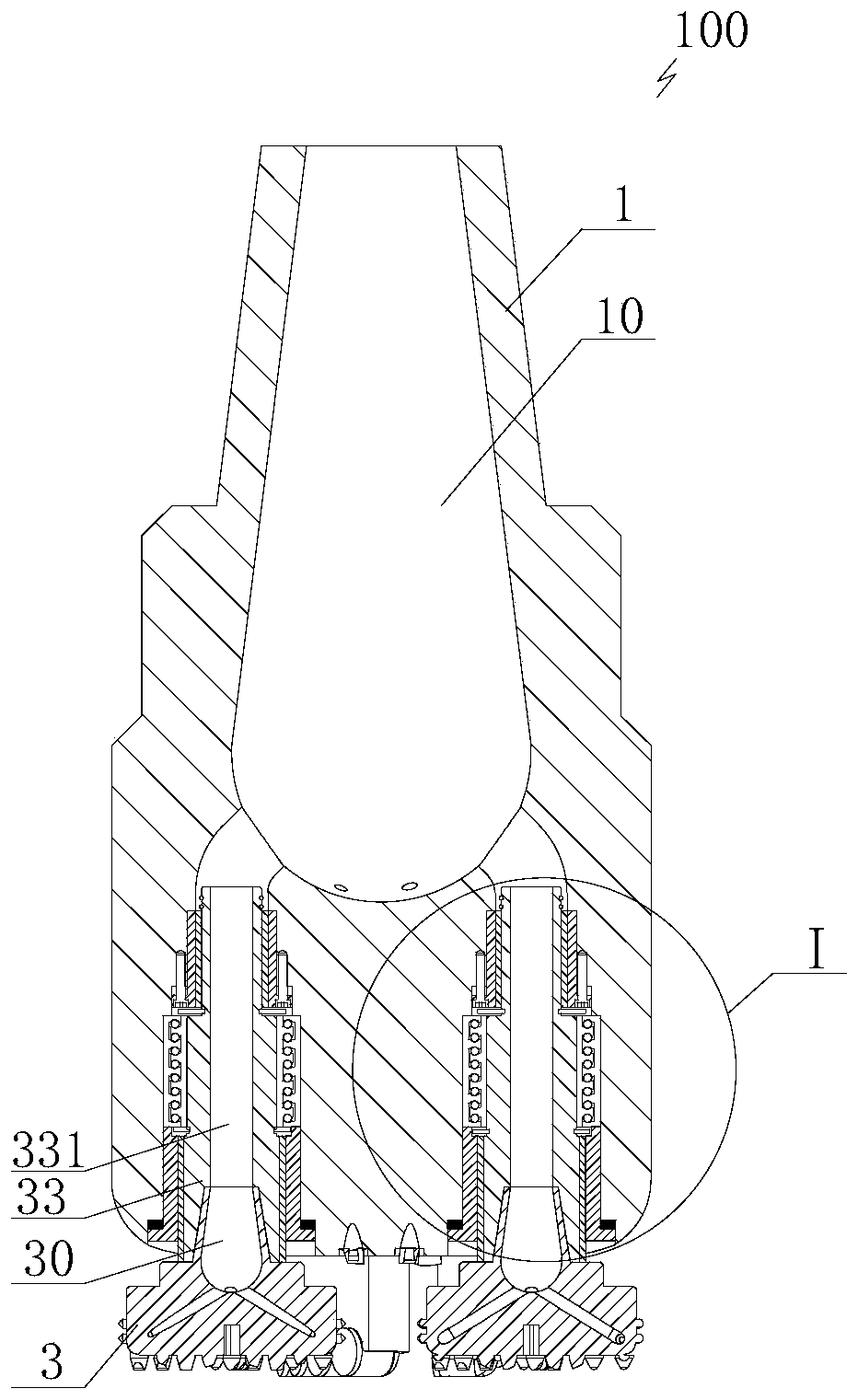

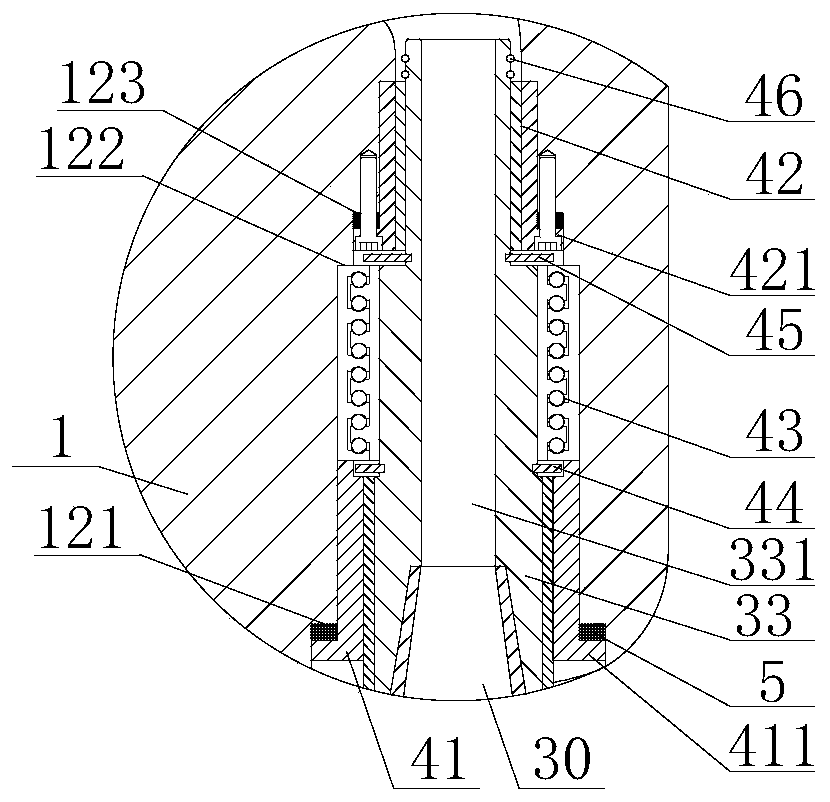

The invention relates to a hybrid power PDC drill bit based on jet flow technology, which comprises a drill bit body, one end of the drill bit body is provided with a plurality of drilling fluid nozzles, one end of the drill bit body is provided with at least two drill bit cutter wings, the drill bit cutter wings can rotate in the same direction as the bit body for cutting a rock layer. At least two jet flow power cutter heads are arranged at one end of the drill bit body, the jet flow cutter heads and the drill bit cutter wings are evenly and alternately arranged in the circumferential direction, and a plurality of cutter head cutter wings are evenly arranged on the jet flow power cutter heads at intervals in the circumferential direction, and jet flow nozzles are respectively disposed onone side of each cutter head cutter wing. The jet flow power cutter heads can rotate in the same direction as the drill bit body and can reversely rotate under the driving of a high-pressure jet flow; each cutter head wing can impact the grinding rock formation for a second time and the high pressure jet flow generated by the jet flow nozzle can spray the fracture the rock formation. The drill bit can avhieve mechanical and hydraulic cross rock breaking under the complex and changeable stratum, improves the adaptability of the drill bit to various formations, improves the rock breaking efficiency, shortens the drilling period, reduces the drilling cost and improves the exploration and development benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

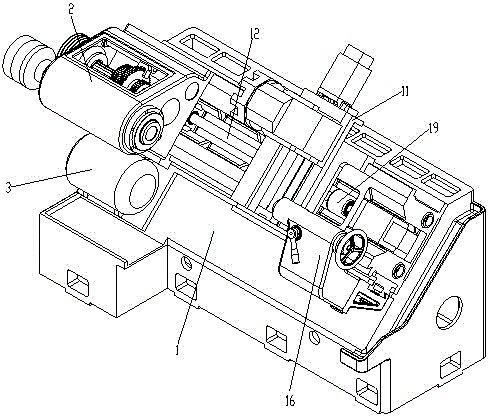

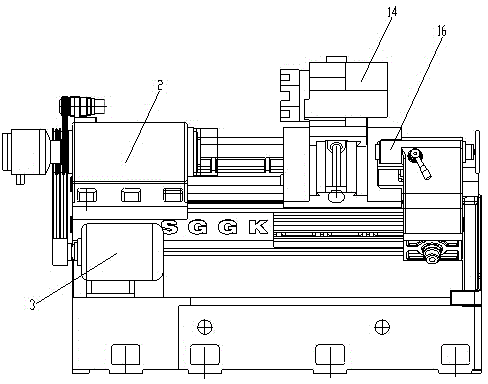

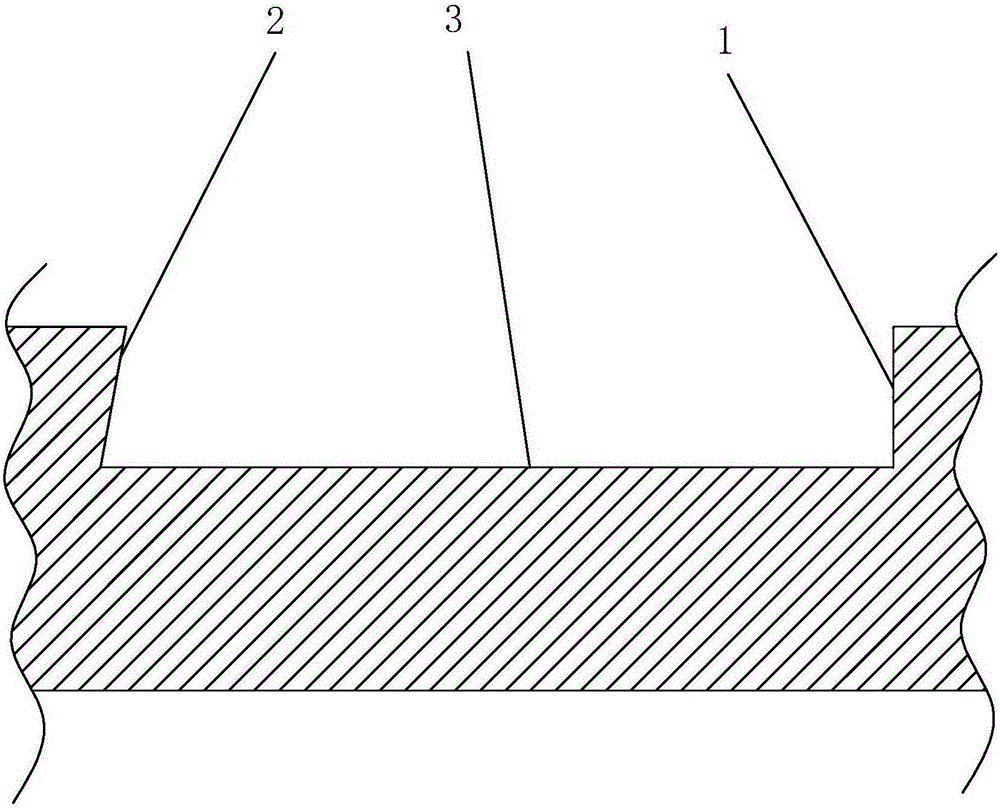

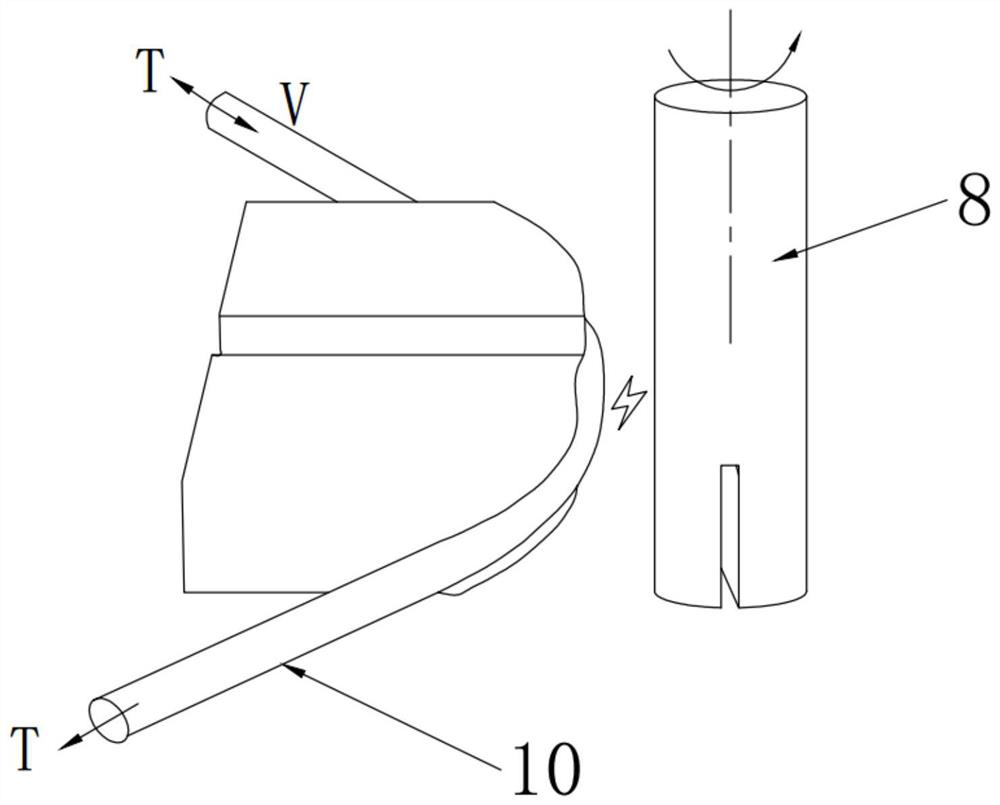

High-rigidity hard-guide-rail inclined numerical control lathe

InactiveCN104475767AImprove rigidityImprove processing efficiencyAutomatic/semiautomatic turning machinesFeeding apparatusNumerical controlEngineering

The invention relates to a high-rigidity hard-guide-rail inclined numerical control lathe which comprises a lathe body, a spindle box device, a main motor, a hydraulic tailstock device and a power tool turret mechanism. The lathe body is a split lathe body inclining by 45 degrees, the spindle box device is arranged at one end of the lathe body and connected with the main motor arranged on the lathe body in an inclined manner, the hydraulic tailstock device is arranged at the other end of the lathe body, and the power tool turret mechanism is arranged between the spindle box device and the hydraulic tailstock device. The high-rigidity hard-guide-rail inclined numerical control lathe is high in rigidity, machining efficiency and chip removing capability, easy in tensioning of a belt and capable of automatically programming rotating speed of a spindle for automatic gear shifting according to a machining process, meets needs on machining high-accuracy parts well, is suitable for most machining enterprises and has high practical value and popularization value.

Owner:YANCHENG SUGONG GAOKE MACHINERY CO LTD

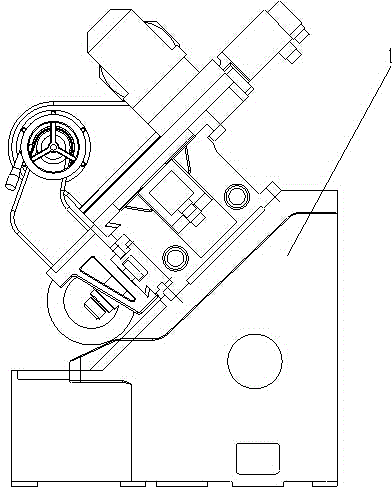

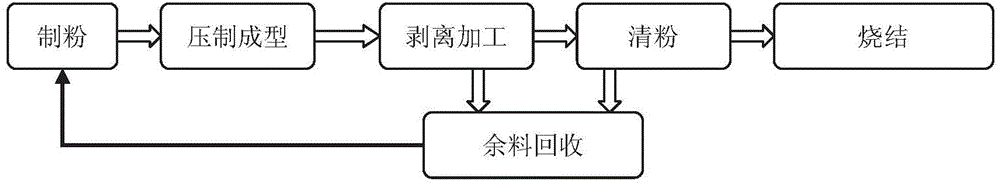

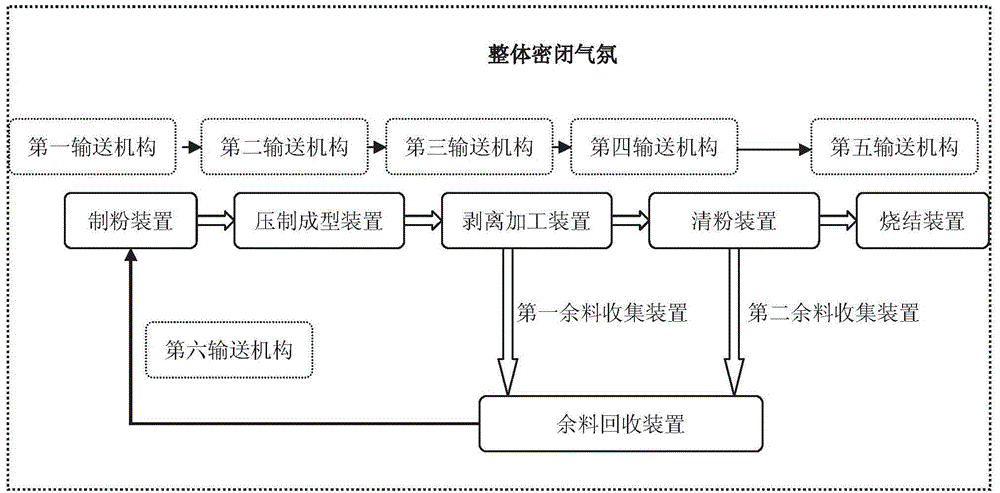

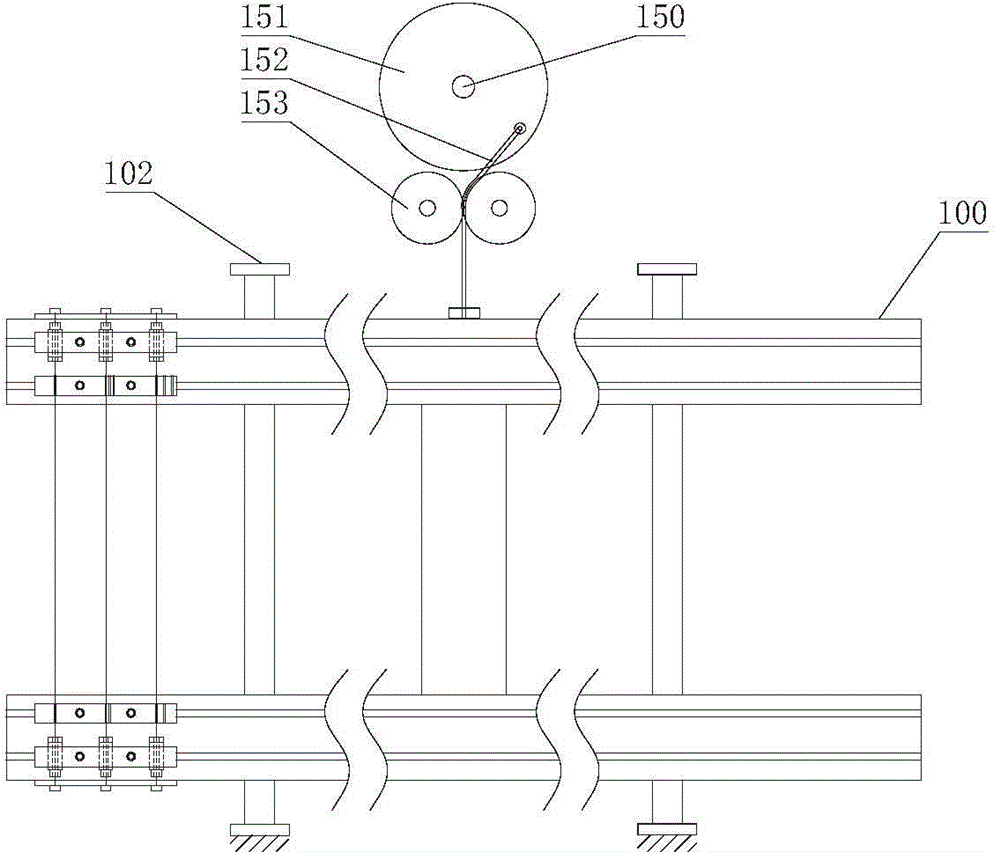

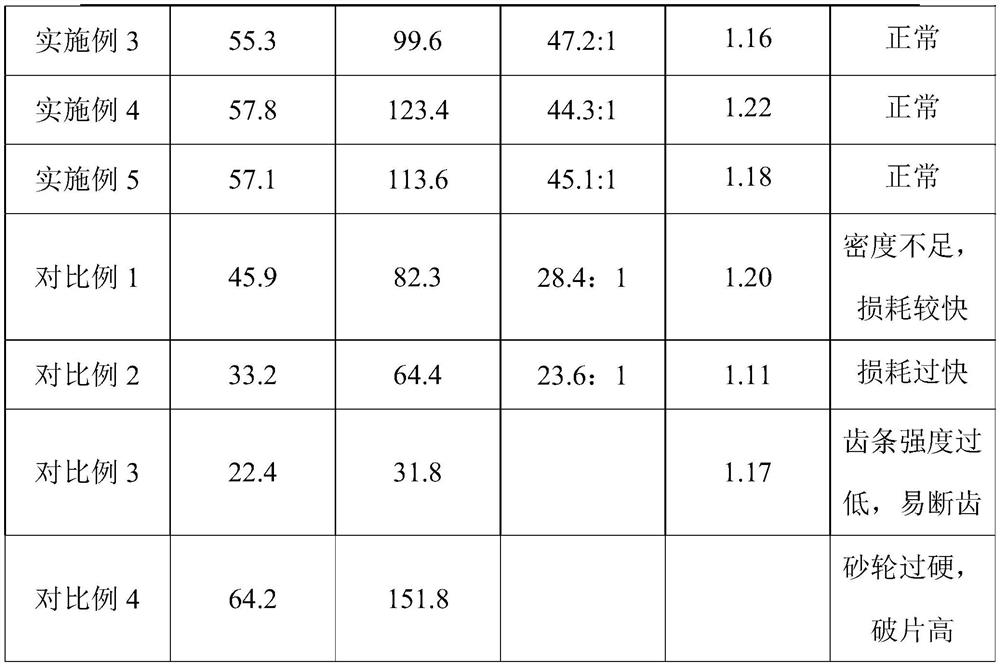

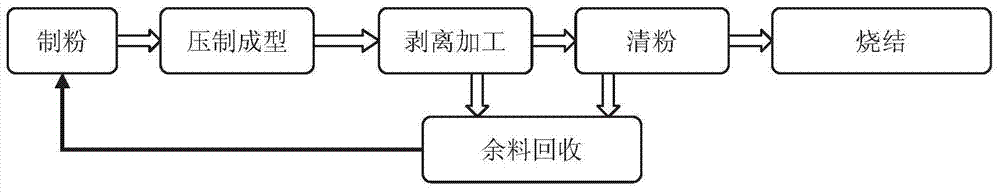

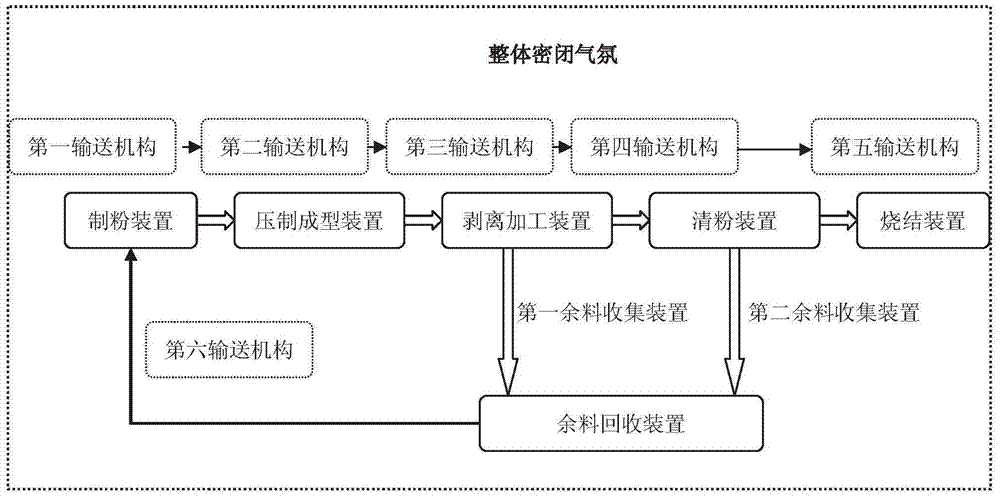

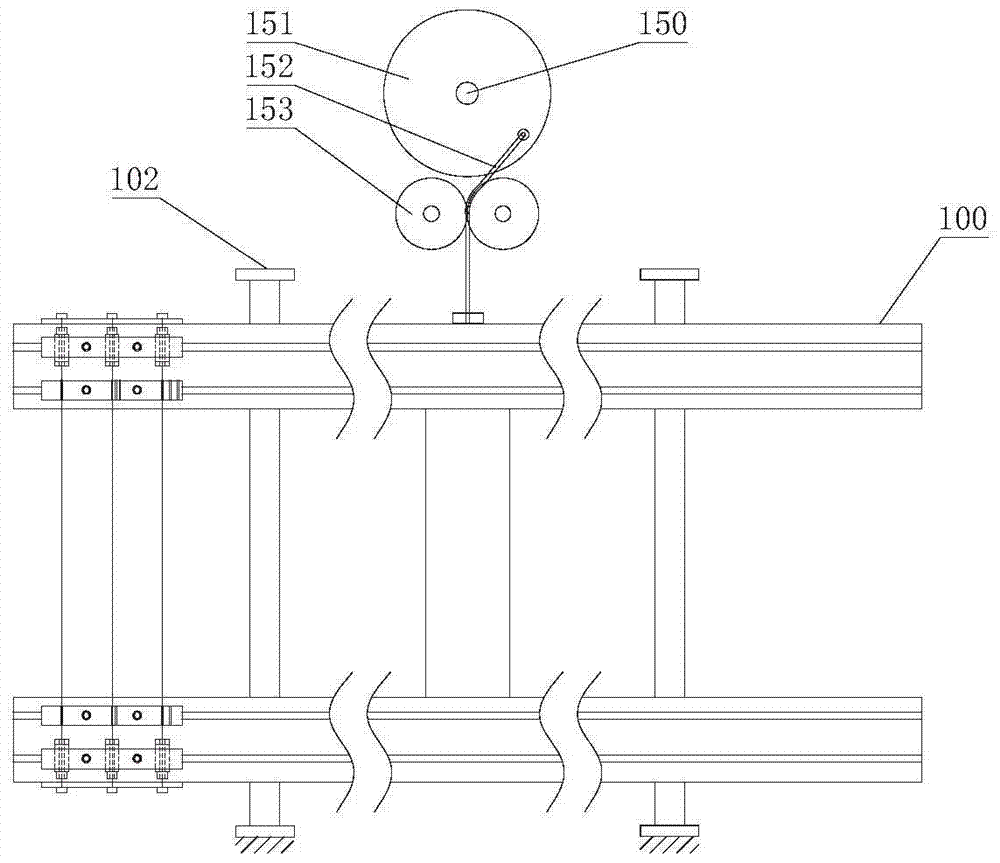

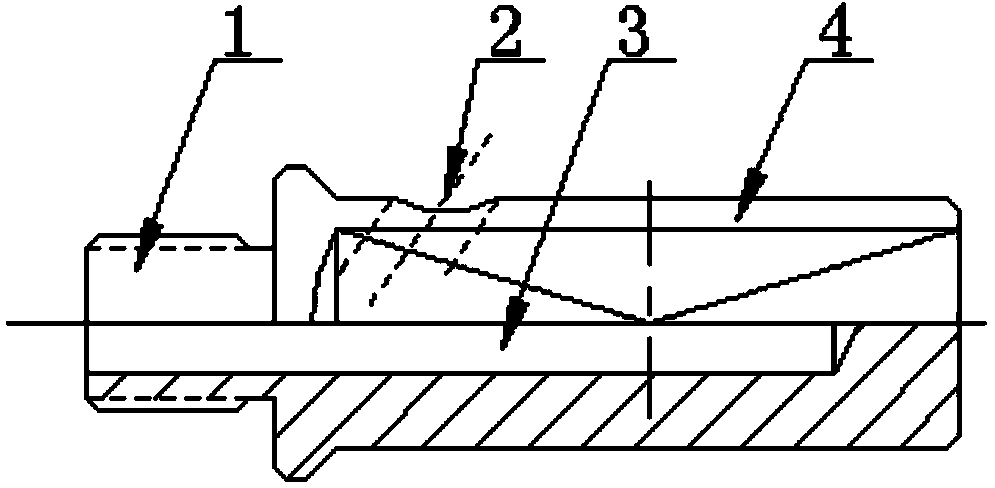

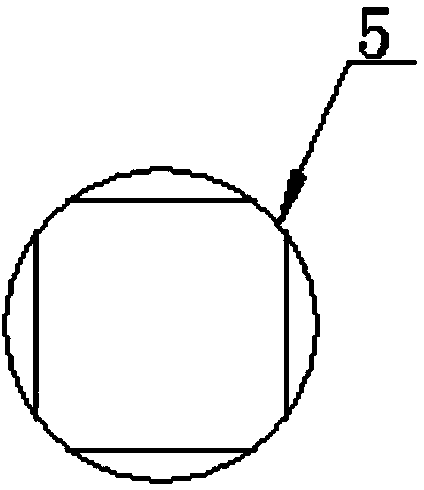

A rare earth permanent magnetic material preparing method

ActiveCN104907558AReduce lossEliminate finishing processMagnetic materialsRare earthSintered magnets

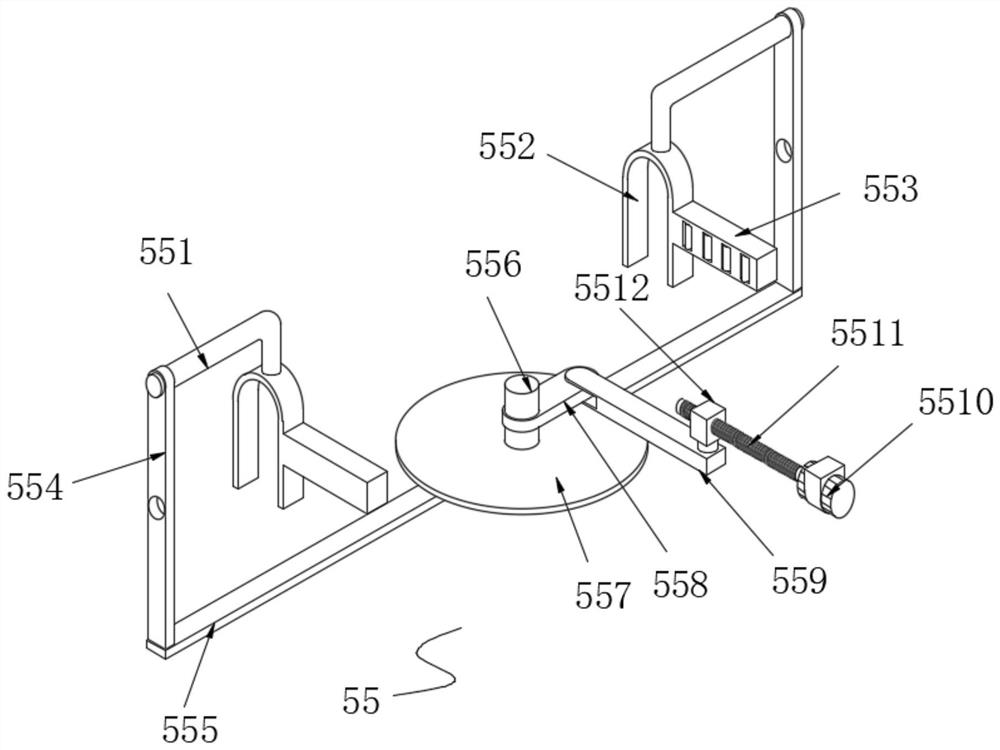

The invention relates to a rare earth permanent magnetic material preparing method comprising the steps of preparing a press blank of powder of sintered magnets, using row wires to machine the press blank and then performing sintering. All the steps are performed in a wholly sealed atmosphere. The row wire machining means line machining for the press blank formed by pressing; after the press blank is clamped and located, a driving mechanism drives the row wires to move back and forth linearly; the press blank is machined according to a preset path along with the rotation of a locating clamp and finally forms a block body or a sheet body with a preset shape and size, an arched body or other specially-shaped bodies; the final forming size contains the sintering shrinkage allowance. The rare earth permanent magnetic material preparing method has the advantages of short preparation technological process, high machining efficiency, low magnetic powder loss, and high rare earth utilization rate. The machining is near net machining, so that a finish machining procedure performed after sintering is saved.

Owner:浙江三环康盈磁业有限公司

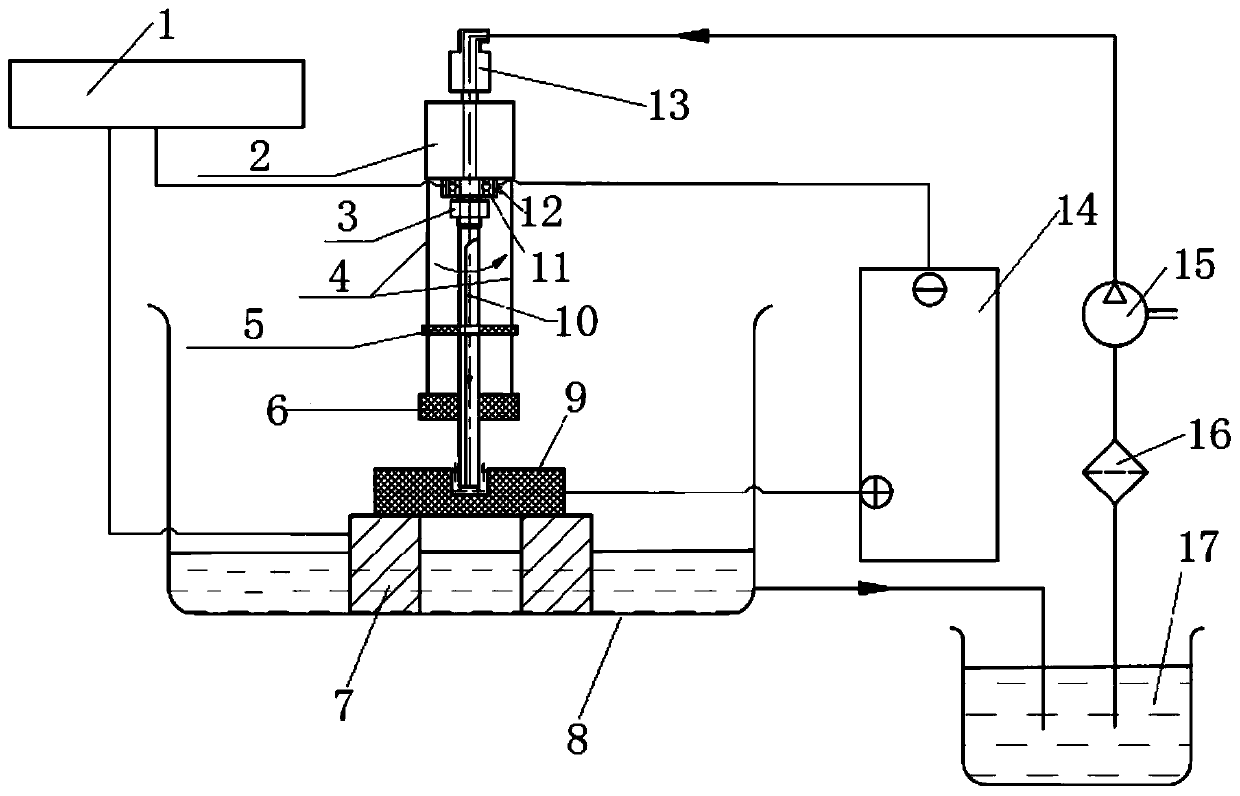

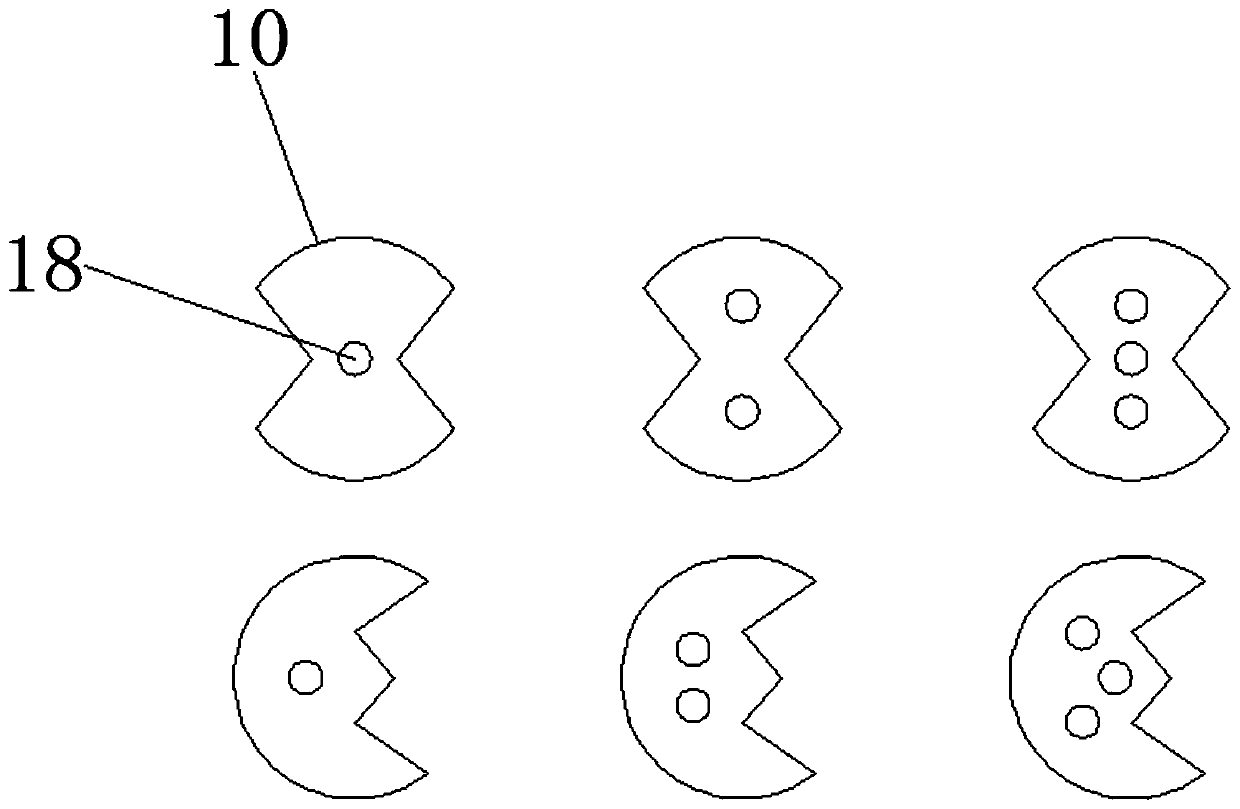

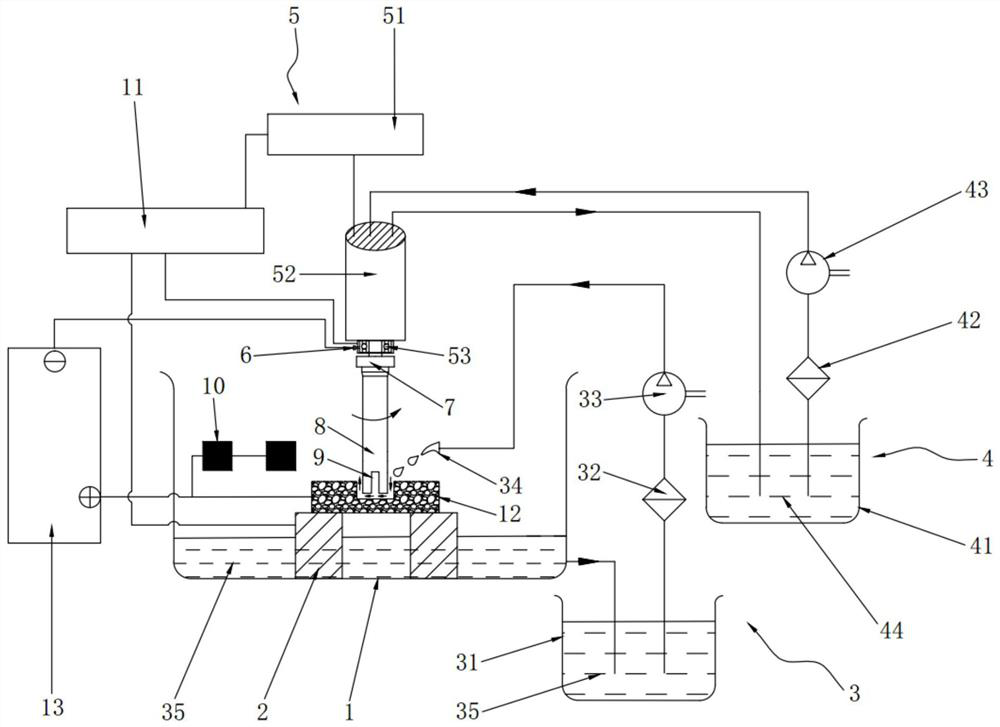

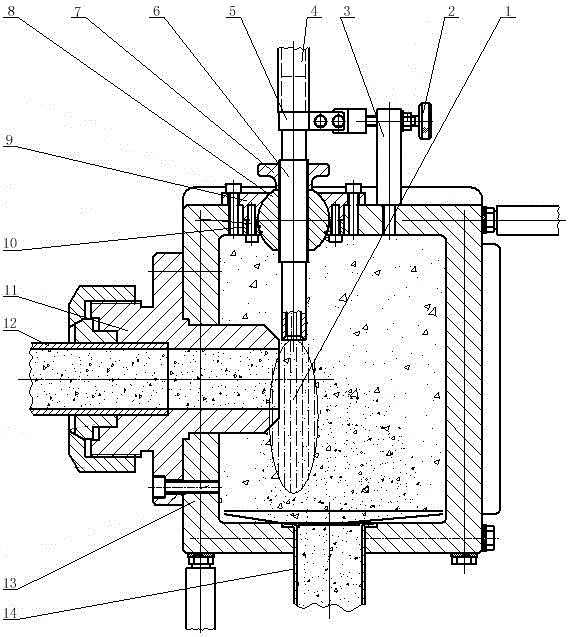

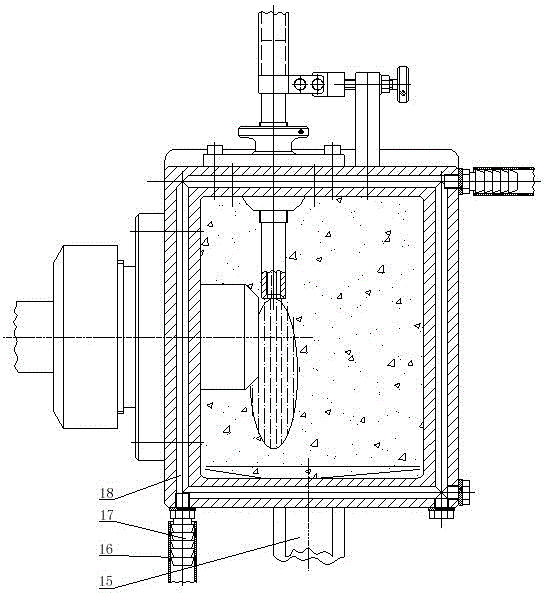

Particle reinforcement metal-matrix composite machining device and machining method

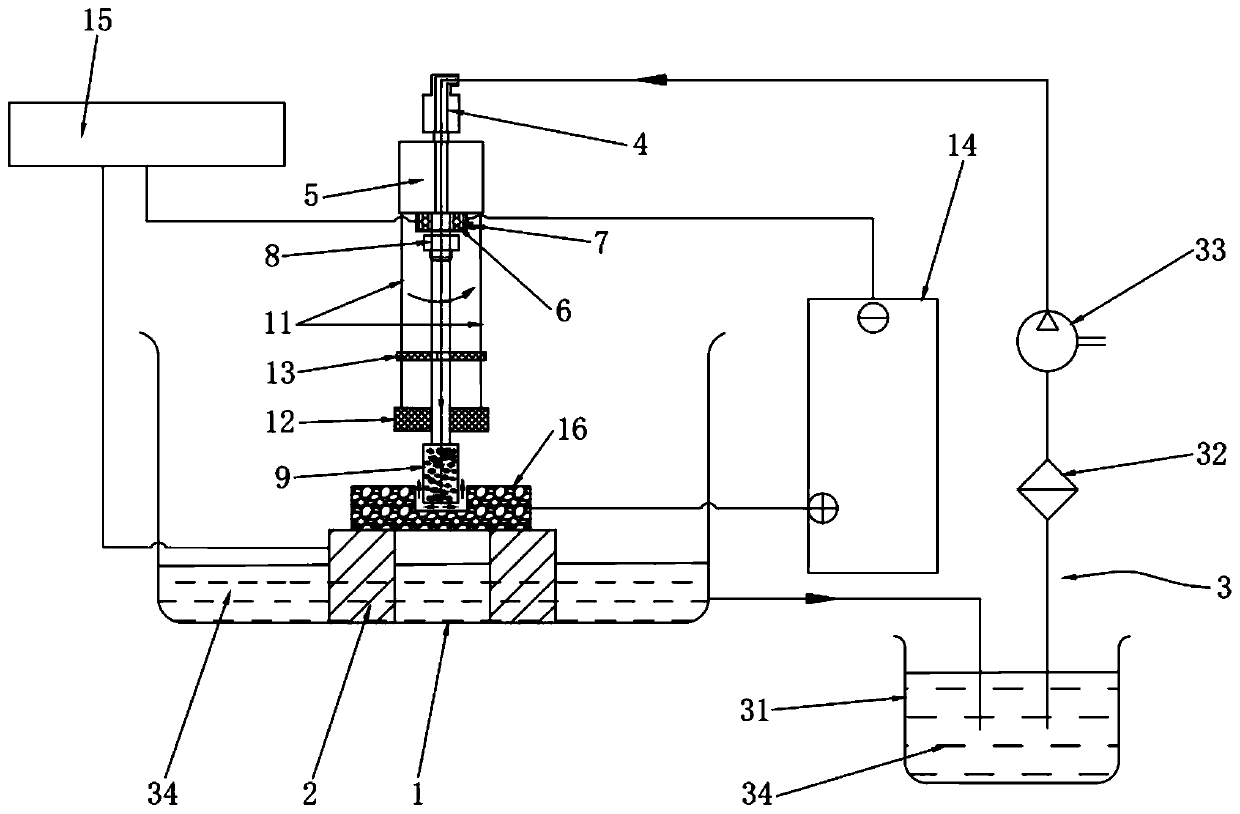

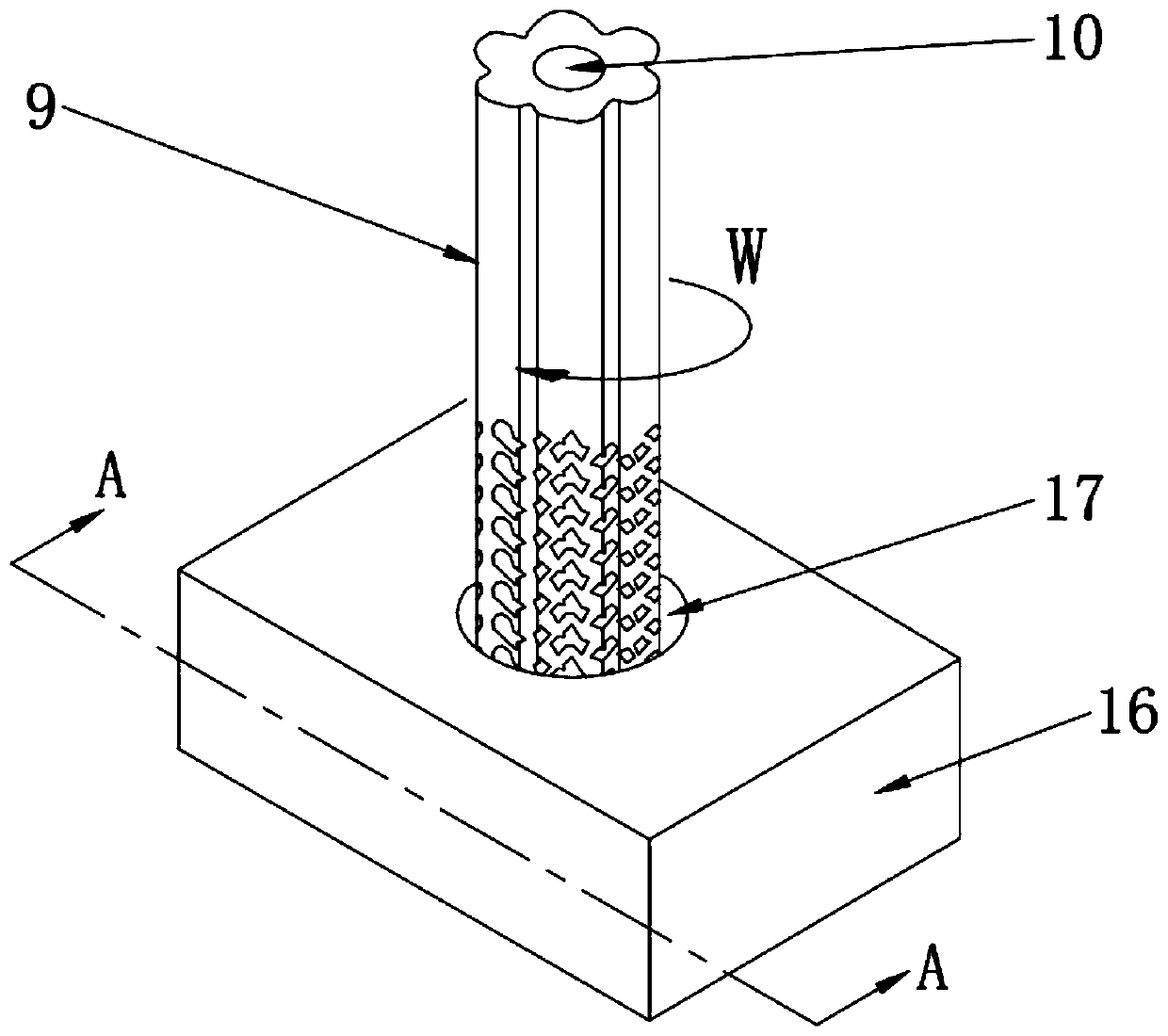

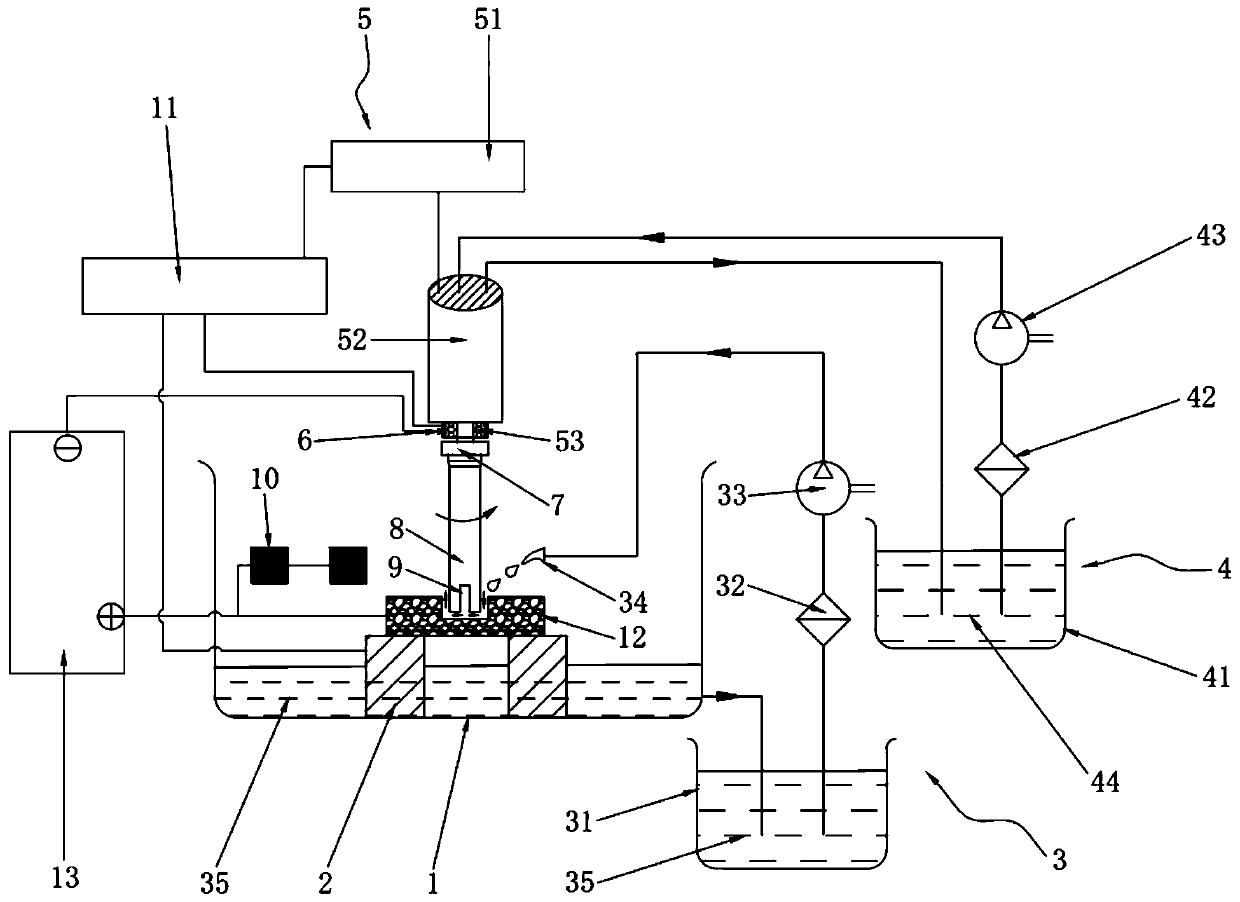

PendingCN110102840AImprove flushing abilityImprove processing statusElectrical-based auxillary apparatusMetal matrix compositeMachining process

The invention discloses a particle reinforcement metal-matrix composite machining device and machining method. The particle reinforcement metal-matrix composite machining device and machining method comprises a machining tank, a spindle motor, a chuck, a guide column, a fixed base, a guide device, a workpiece placing base, a workpiece and a tool electrode; work liquid in the machining tank entersa liquid storage tank through a liquid guide pipe, circular flowing of the work liquid is achieved, the interpolar workpiece liquid can be updated in time, machining stability in the discharge machining process can be effectively improved, machining efficiency is improved, machining quality is improved, in the deep small hole machining process, compared with a traditional chip removal manner, themachining effect is more obvious, meanwhile, when work liquid is replaced with an electrolyte with conductivity, the chip removal manner is used for electrolytic machining, electrochemical discharge machining and the like, the device is suitable for high-precision and high-quality deep small hole machining of various materials, the guide device and the fixed base are arranged, and the rotating precision of a tool electrode during high-speed rotation is ensured.

Owner:GUANGDONG UNIV OF TECH +1

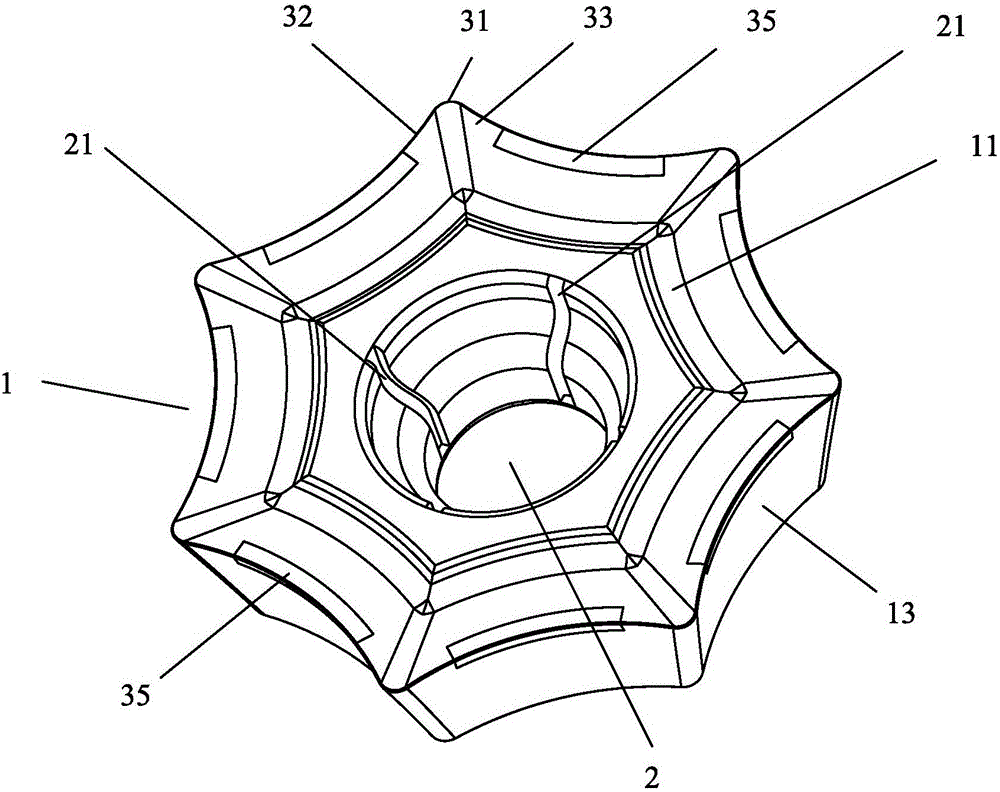

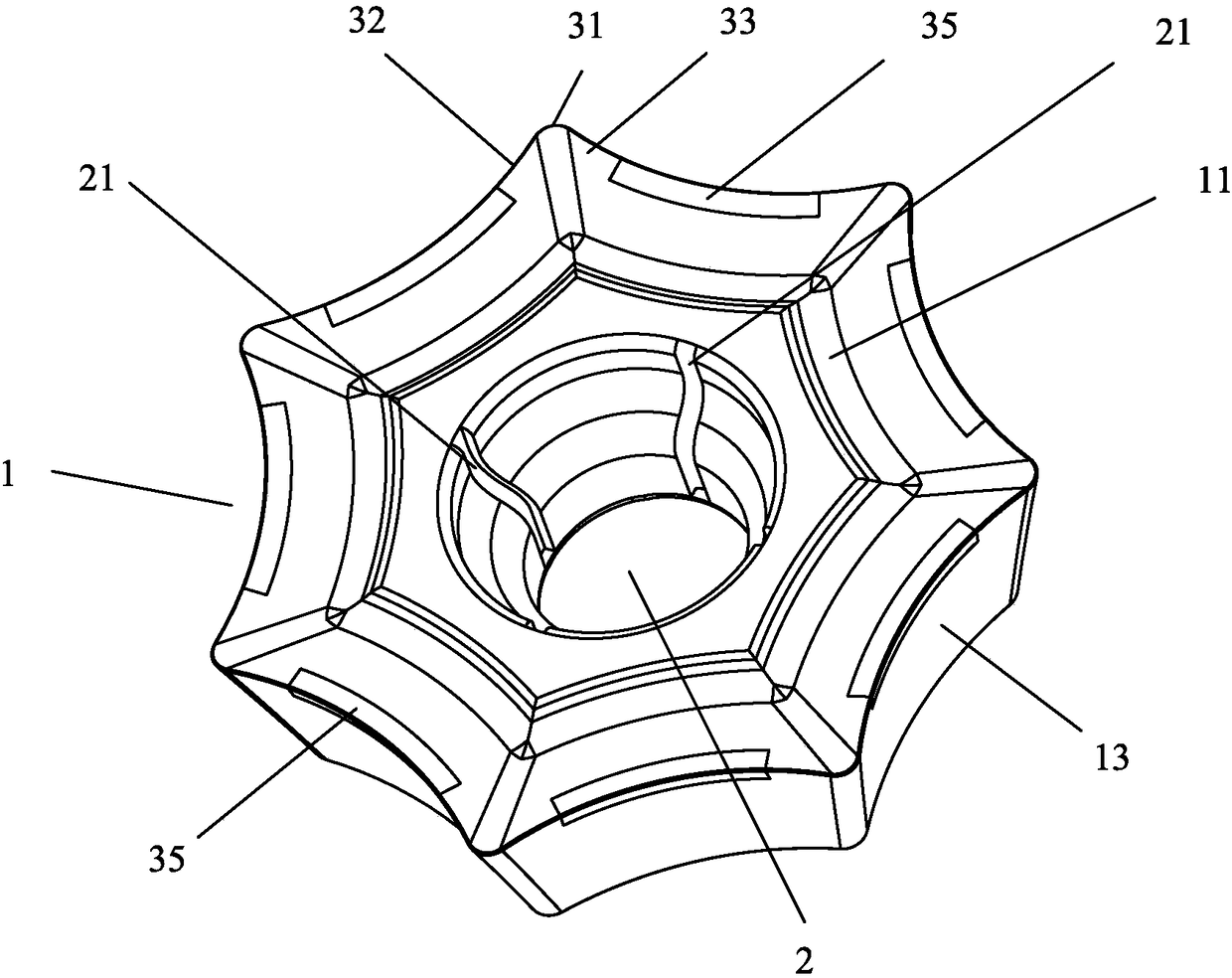

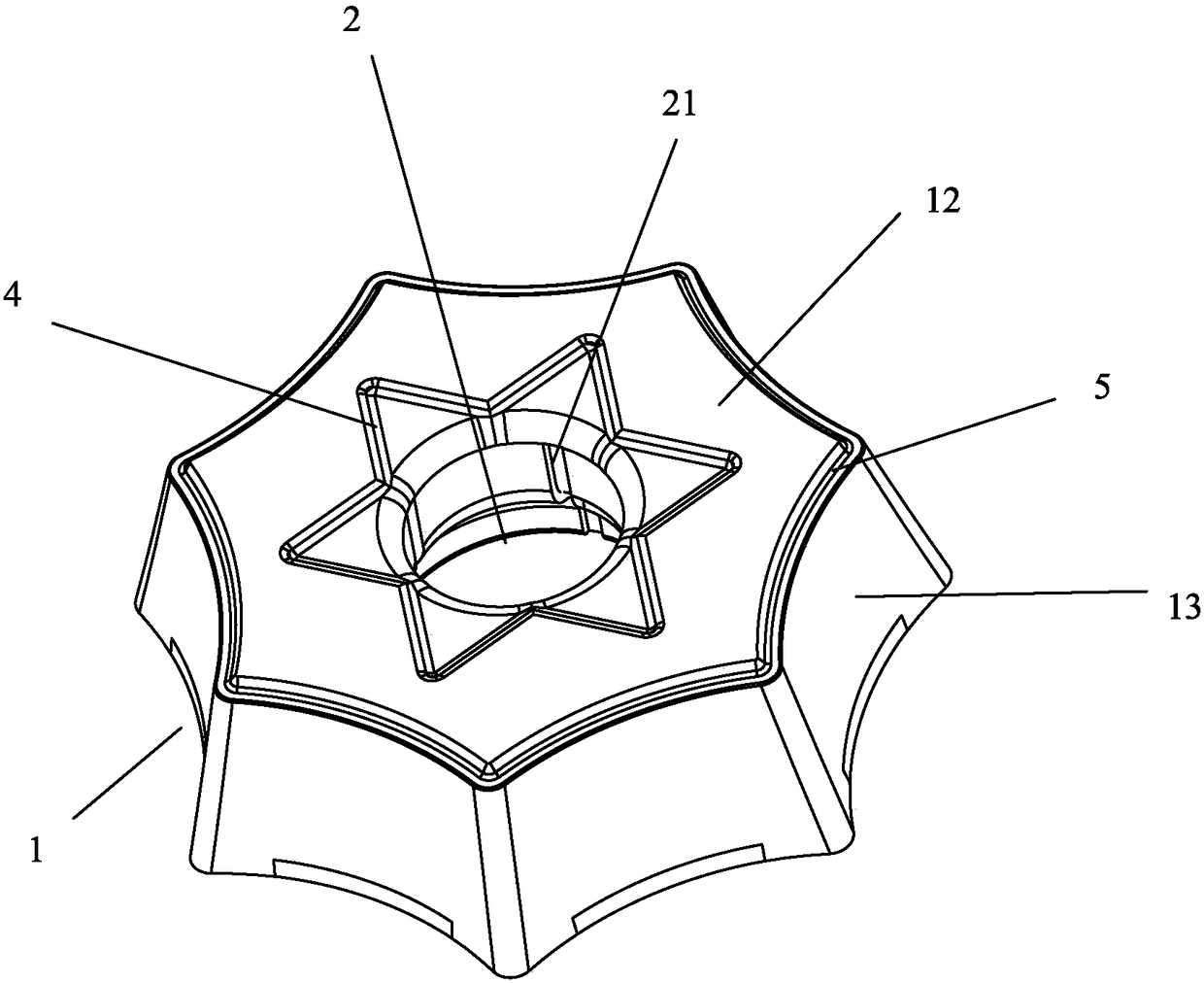

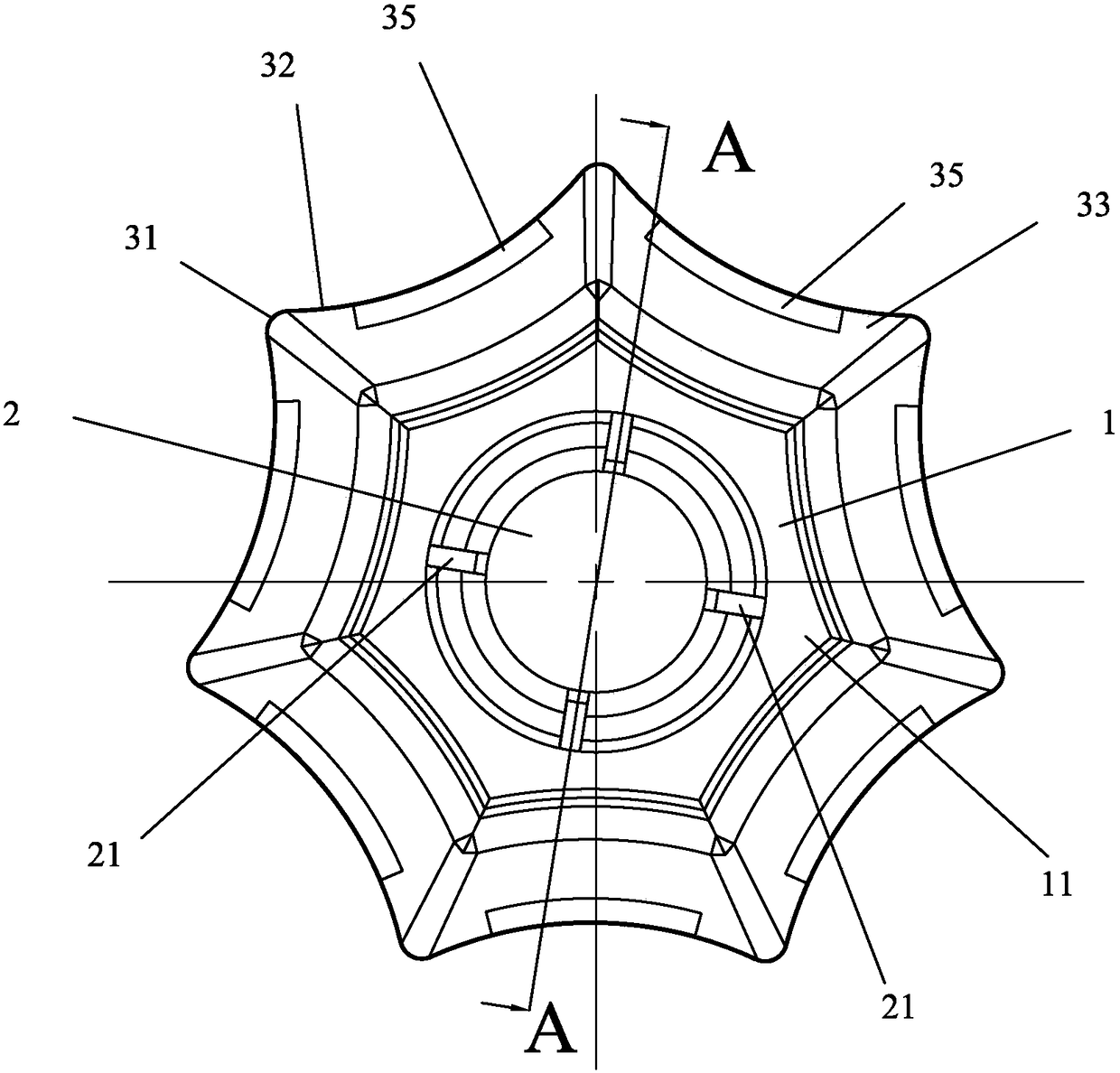

Turning/milling blade for machining dead-hard steel special-shaped part

ActiveCN106001648AHigh strengthEfficient decompositionTransportation and packagingMilling cuttersHardnessWear resistance

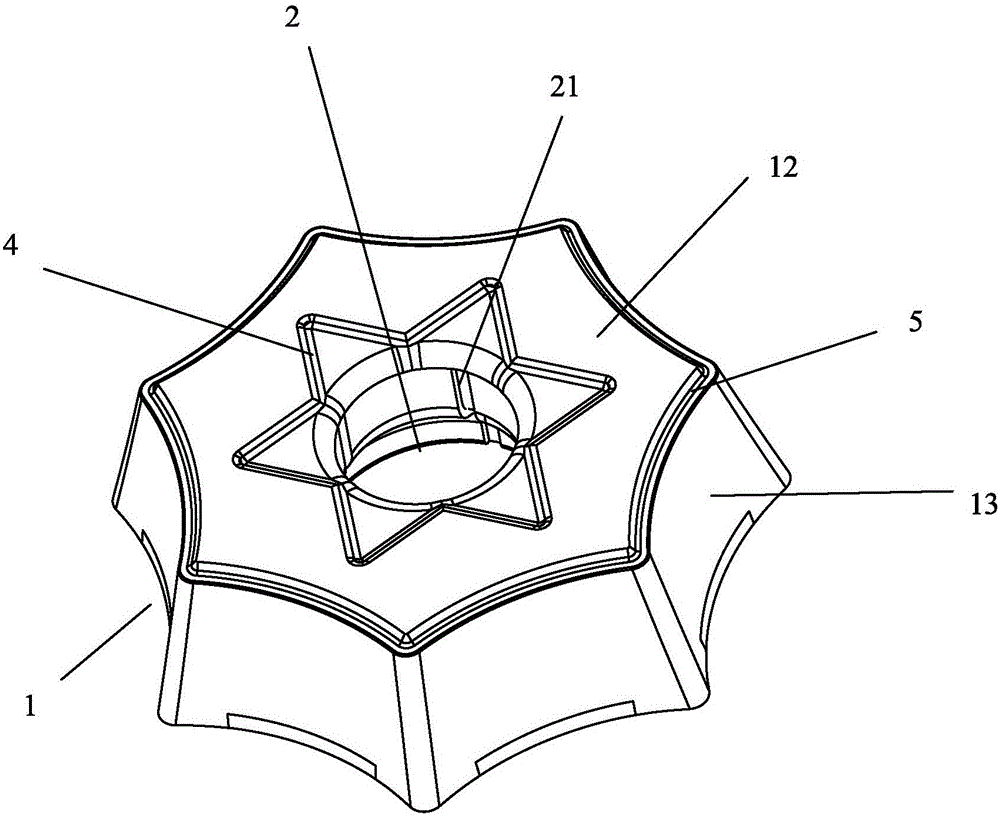

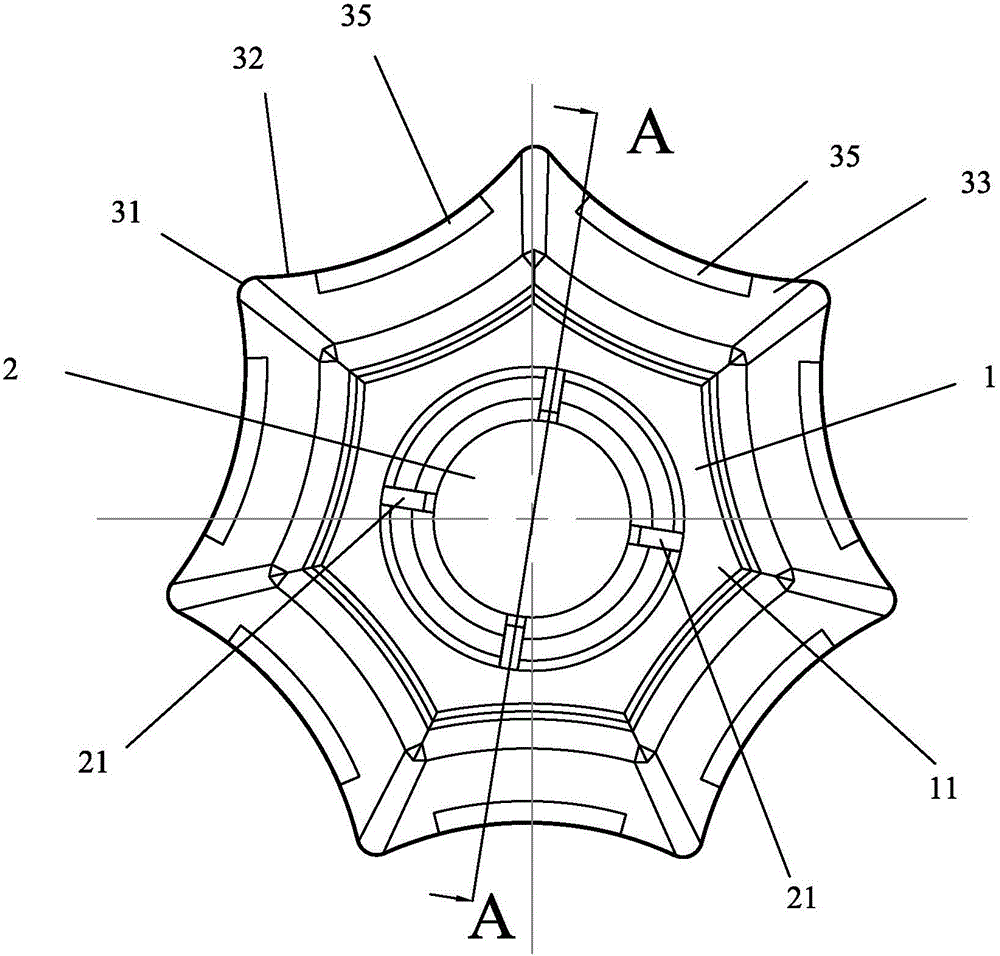

The invention discloses a turning / milling blade for machining a dead-hard steel special-shaped part. The blade comprises a blade body roughly in a right heptagonal shape. The blade body is provided with an upper surface, a lower surface and side faces; the geometric center of the blade body is provided with a fastening screw hole penetrating the upper surface and the lower surface, and the upper surface of the blade body and the crossing line of the side faces form a cutting part of the blade; the cutting part comprises a blade point located on the top corner of the right heptagon and cutting edges located on the side edges of the right heptagon; the cutting edges are sunken inwards in an arc shape to form fishtail-shaped cutting edges; the upper surface of the blade body extends inwards along the fishtail-shaped cutting edges to form a fishtail-shaped front blade face; and according to the structure, the problems that according to the profile manufacturing special-shaped face obtained after one-time postfire, the hardness of a workpiece is high, and it is required that wear resistance, blade breaking resistance, and structural precision of a tool are high, and the hard cutting performance of the tool is good are solved, and the technical problem that at present, one tool cannot meet the comprehensive machining requirement under the extreme condition is solved.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

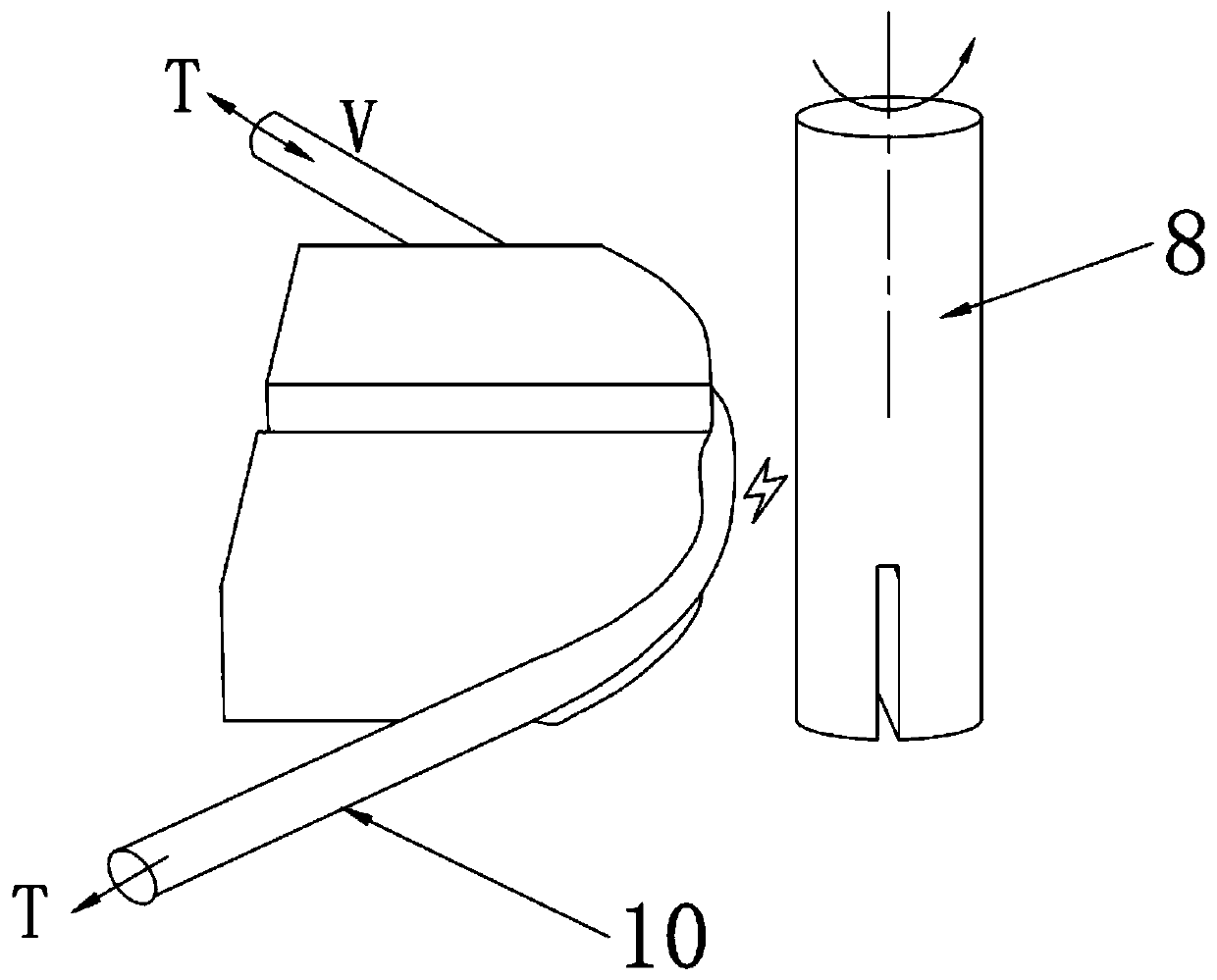

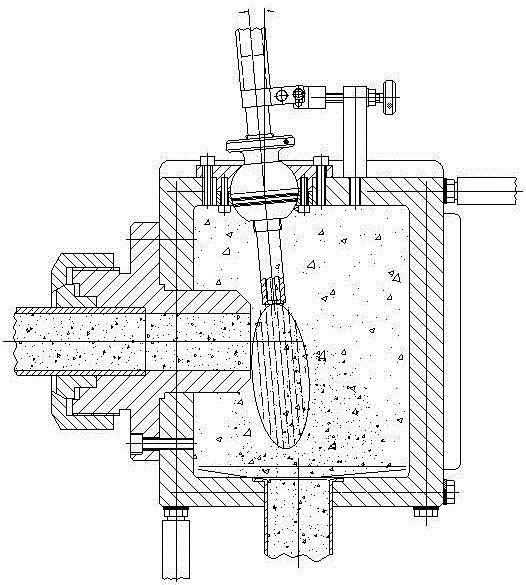

Novel electrode compound electric machining device and machining method

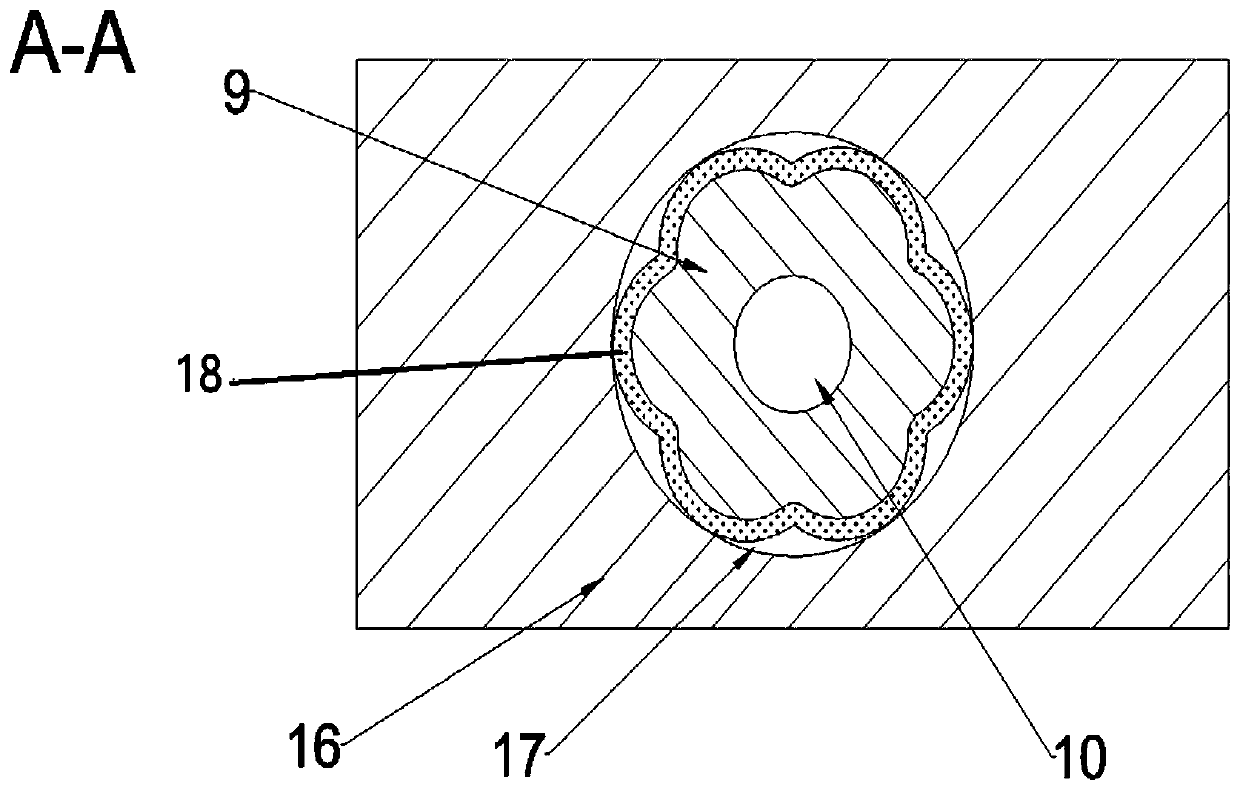

InactiveCN111215709AImprove machined surface qualityIncrease chip removal spaceElectrical-based machining electrodesRotational axisWorking fluid

The invention discloses a novel electrode compound electric machining device and machining method. The novel electrode compound electric machining device comprises a machining tank, the inner side ofthe machining tank is provided with workpiece supporting seats for placing a workpiece, one side of the machining tank is provided with a working fluid system, the working fluid system comprises a working tank, a filter and a high-pressure pump, the working tank is internally provided with a fluid guide pipe immersed in working fluid, the bottom side of a rotating connection head is provided witha main shaft motor, the output end of the main shaft motor is provided with a high-speed rotary bearing, the high-speed rotary bearing is provided with an electric lead bolt, the output end of the main shaft motor is connected with one end of a tool electrode through a clamping head, the outer side of the tool electrode is wrapped with a grinding material layer, and the cross section of the tool electrode is in an annular wave shape. According to the novel electrode compound electric machining device and the machining method, the tool electrode of the novel electrode compound electric machining device has a grinding effect in the machining process and the wave-shaped cross section of the tool electrode makes the tool electrode have a larger chip discharge space, meanwhile, in coordinationwith a fluid rushing hole and the rushing pressure formed under the action of the high-pressure pump, the rushing ability between poles is improved, and the novel electrode compound electric machiningdevice has strong chip discharge ability and is especially suitable for machining of particle reinforced metal matrix composite materials.

Owner:GUANGDONG UNIV OF TECH

Boring cutter with arc structure

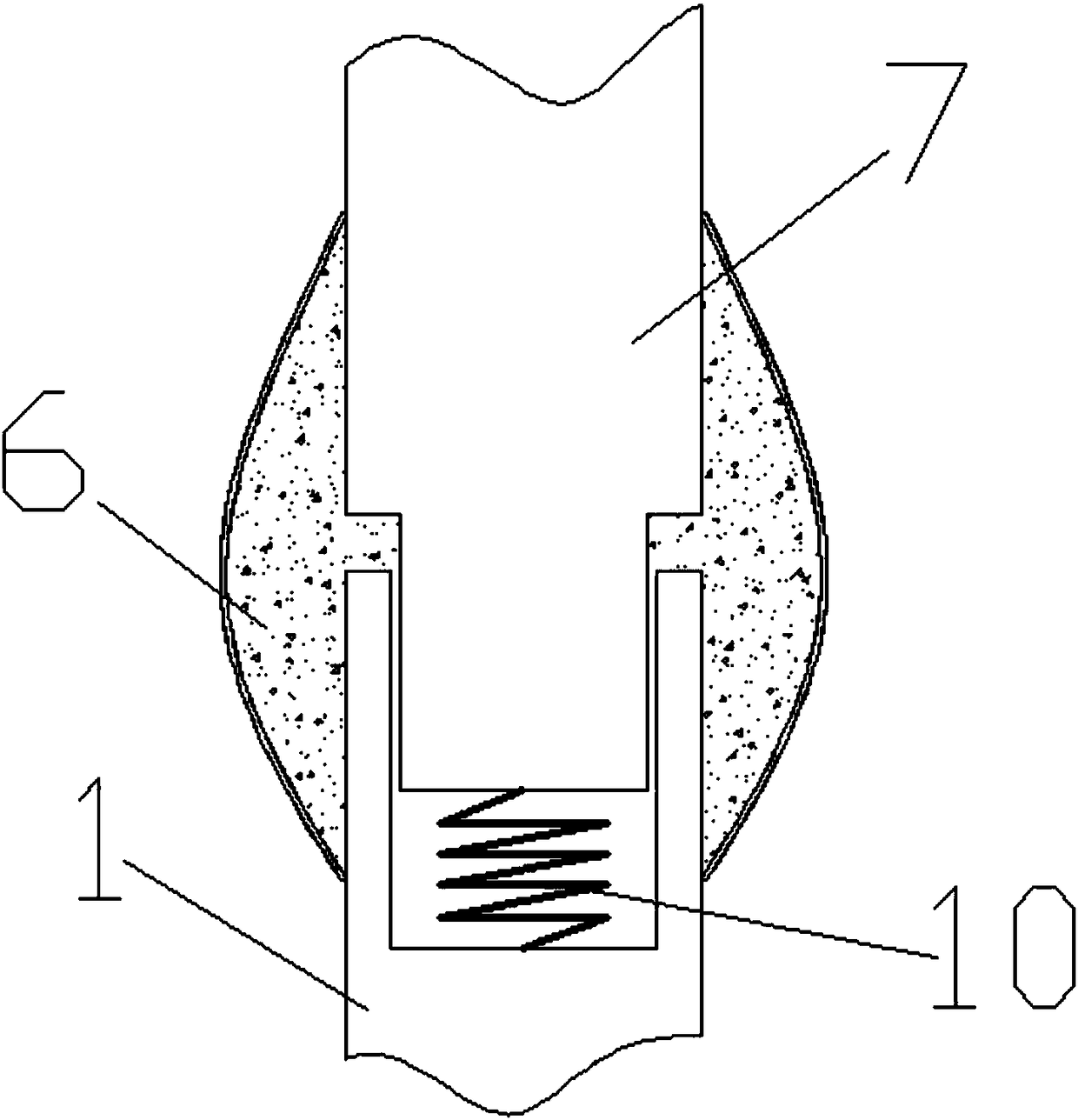

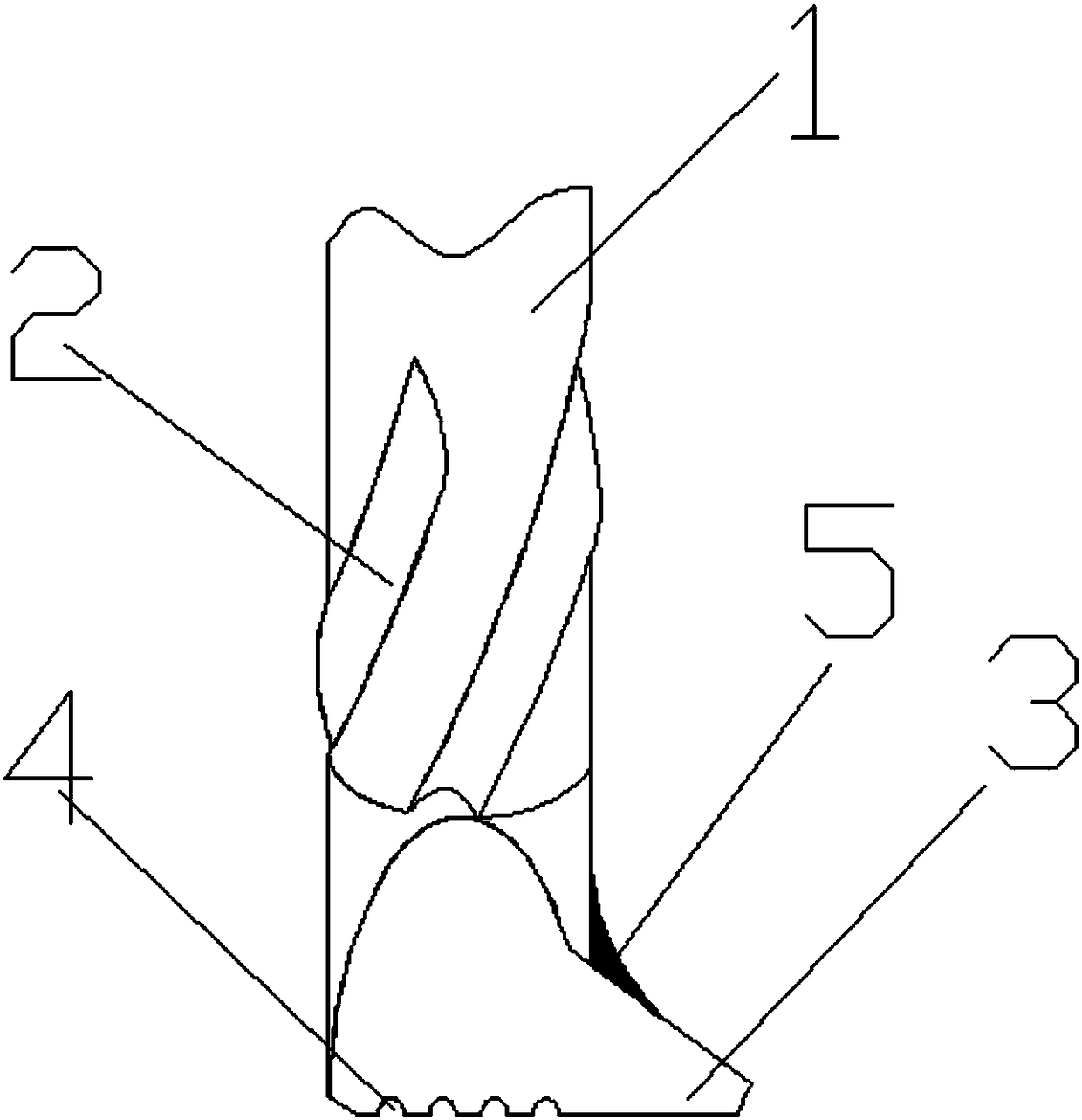

InactiveCN108380912ACompact connectionEasy to useCutting insertsTurning toolsTool bitStress strength

The invention discloses a boring cutter with an arc structure. The boring cutter comprises a connecting rod, chip removing grooves, a tool bit, pressure relief ports, reinforcing ribs, a protective rubber block, a knife handle, threads, an extrusion nut and a spring. The boring cutter with the arc structure has the beneficial effects that the bottom of the tool bit is uniformly provided with a plurality of inward-concave arc-shaped pressure relief ports, and the impact force borne by the tool bit when boring hole is carried out and when the tool bit makes contact with a workpiece can be reasonably dispersed, the vibration of the tool bit is reduced, so that the process of the hole boring is stable; the connecting part between the connecting rod and the tool bit is fixedly provided with thereinforcing ribs with the arc surfaces on the surfaces, so that the pressure borne by the tool bit can be dispersed to the connecting rod through the reinforcing ribs, and the stress strength of thetool bit can be improved; the number of the chip removal grooves are symmetric four, and the tangent plane of each chip removal groove is of the inward-concave arc shape which is provided with a largechip removal space, so that the chip removal effect of the boring cutter is good; the knife handle can move up and down inside the connecting rod, the knife handle is provided with a certain deformability, so that the large impact force cannot be generated between the tool bit and the workpiece when the tool bit is just in contact with the workpiece.

Owner:常州思智行睿精密机械有限公司

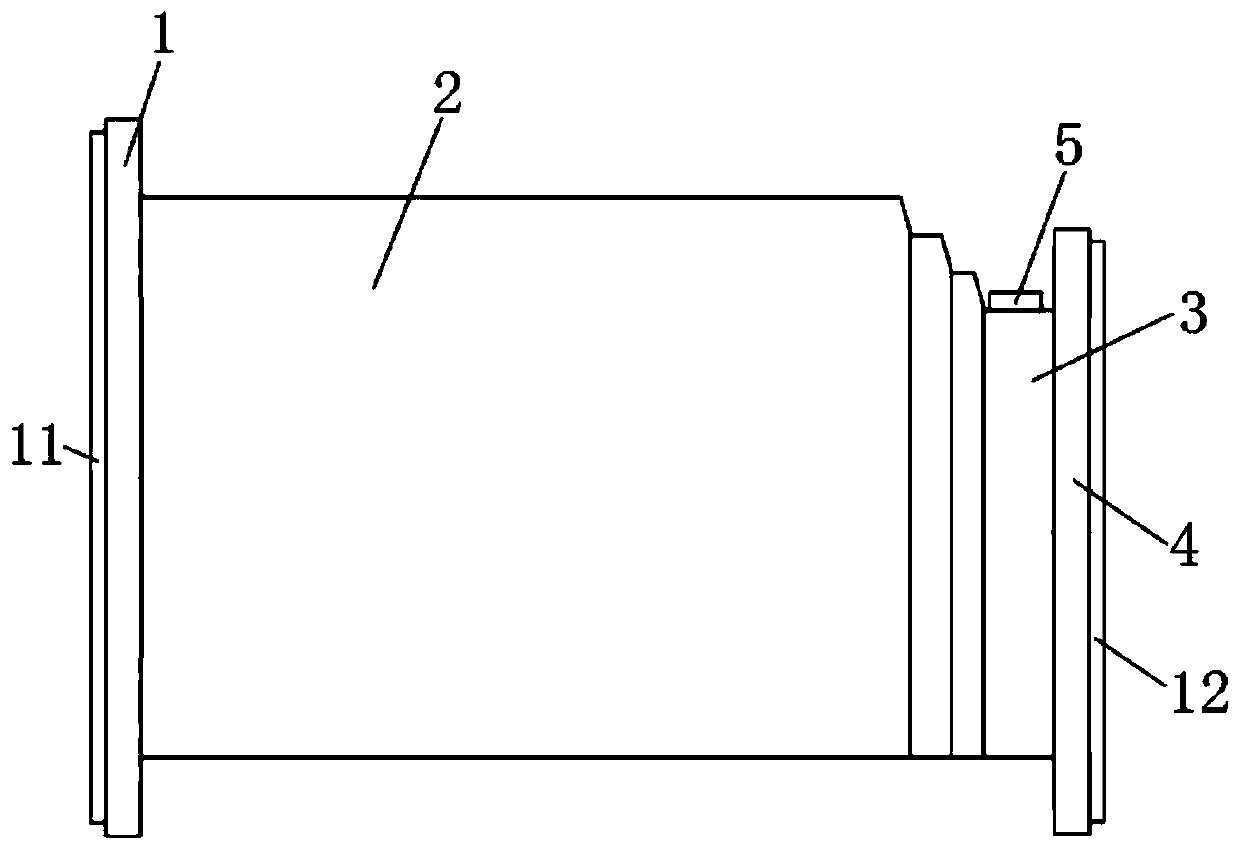

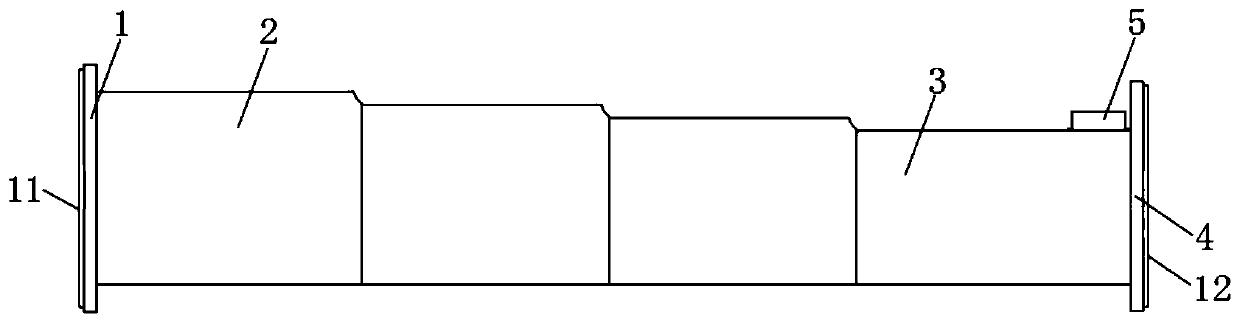

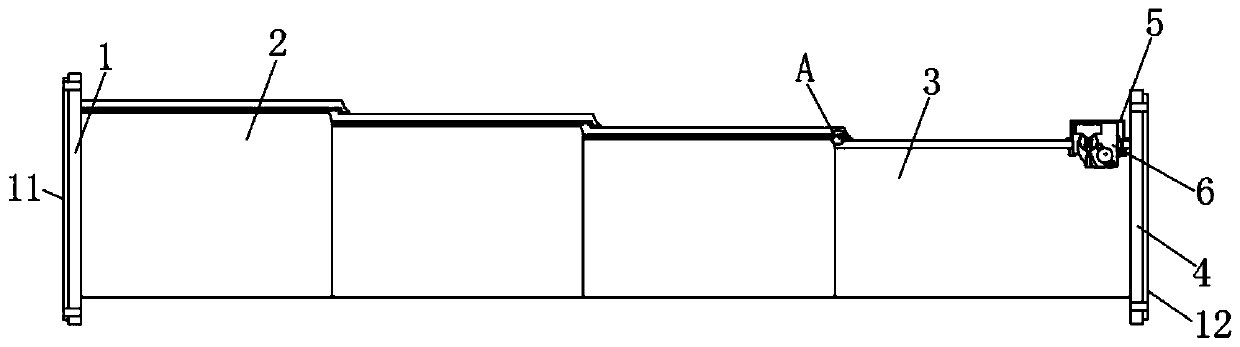

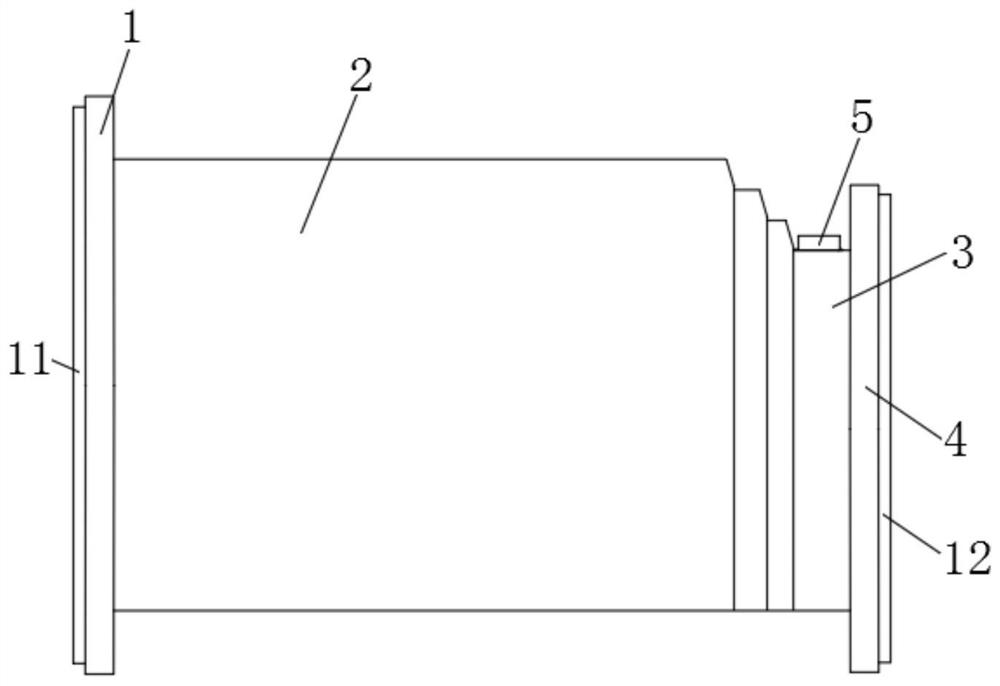

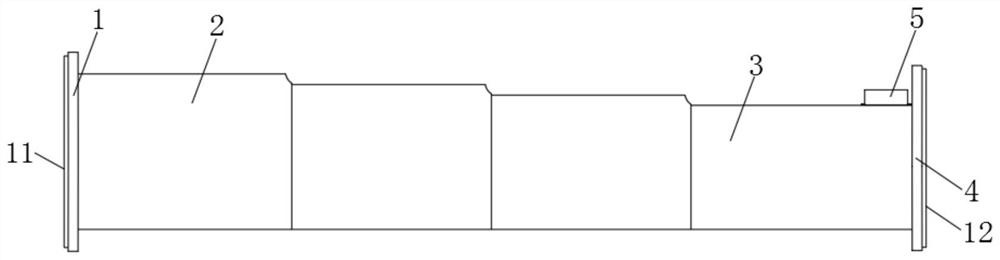

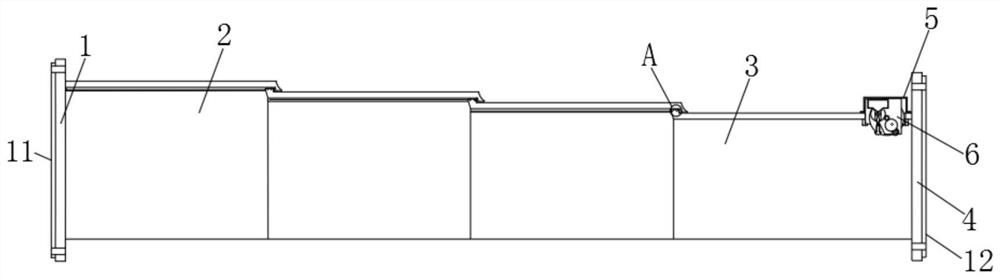

Guide rail protective cover for machine tool with efficient chip cleaning function

ActiveCN110625432AEfficient chip removal structureImprove chip removal effectMaintainance and safety accessoriesMachine toolArchitectural engineering

The invention discloses a guide rail protective cover for a machine tool with an efficient chip cleaning function. The guide rail protective cover comprises a fixed seat; a telescopic cover body is welded to the right side of the fixed seat; the inner side of the telescopic cover body is provided with a telescopic cover head in an inserting manner; a connecting seat is welded to the right side ofthe telescopic cover head; a through groove is formed in the upper surface of the right side of the telescopic cover head in a penetrating manner; a protective cover is arranged above the through groove and is connected and fixed with the telescopic cover head through a bolt; a connecting box is arranged below the through groove; the top end of the connecting box is welded and fixed with the innersurface of the telescopic cover head; a cleaning structure is inserted into the inner side of the connecting box; grooves are formed in the outer surfaces of the two ends of the left side of the telescopic cover head respectively; balls are arranged on the inner sides of the grooves respectively; and chutes are formed in the inner surface of the telescopic cover body and are distributed at the two ends of the telescopic cover head respectively. The guide rail protective cover has the advantages that with an efficient chip cleaning structure, the chip cleaning effect is improved; and with a quantitative oil supplementing structure, the surface of the guide rail is kept lubricant.

Owner:常州禾川机械有限公司

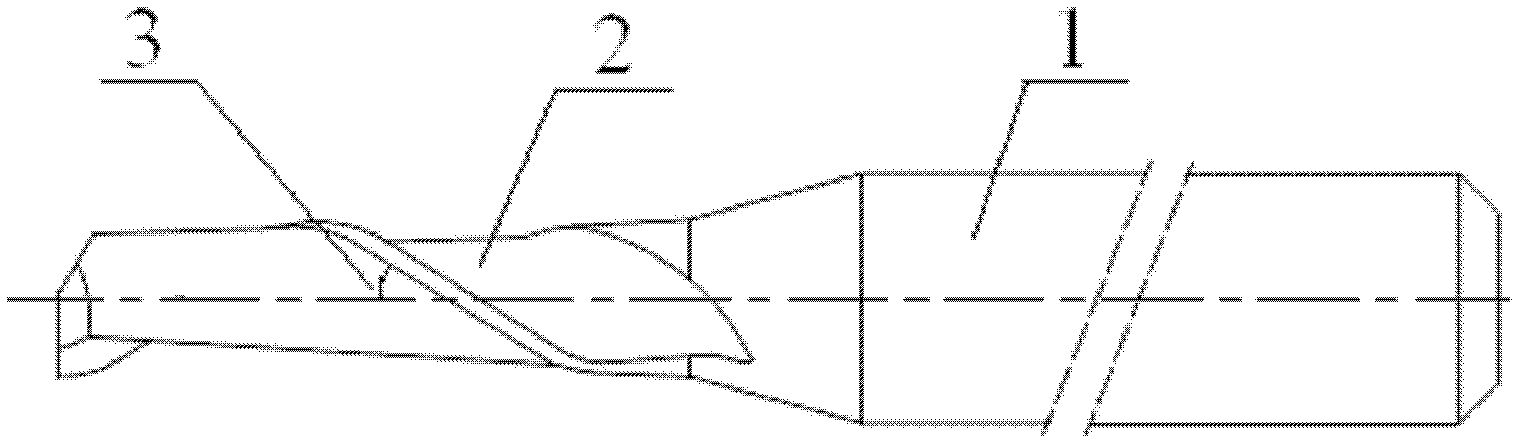

Reverse circulation channel-type double stage reamer

The invention provides a reverse circulation channel-type double stage reamer comprising a reverse circulation assembly. The reverse circulation channel-type double stage reamer is characterized in that the reverse circulation assembly comprises a mandrel whose inner portion is provided with a reverse circulation structure; both ends of the mandrel are internal thread joints; a front centralizer,a first level reaming base, a second level reaming base, a rear centralizer and a slag suction bucket are welded on the shell of the mandrel; a front spiral blade is welded on the shell of the front centralizer while a rear spiral blade is welded on the shell of the rear centralizer; the slag suction bucket is welded on the shell of the mandrel and located between the first level reaming base andthe second reaming base; the slag suction bucket is communicated with the mandrel through a slag suction pipe; a reinforcing rib is respectively welded on the shell of the mandrel and the end surfaceof the rear centralizer; tooth palms and double rows of PDC (polycrystalline diamond compact) blades are respectively fixed on the first level reaming base and the second level reaming base; the end portion of the tooth palms is connected with a cone. The reverse circulation channel-type double stage reamer has the advantages of being applicable to different geology, having large cross section insingle reaming and high reaming efficiency, and achieving the effects of quick replacement of cutting edges, reducing costs and prolonging service life.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

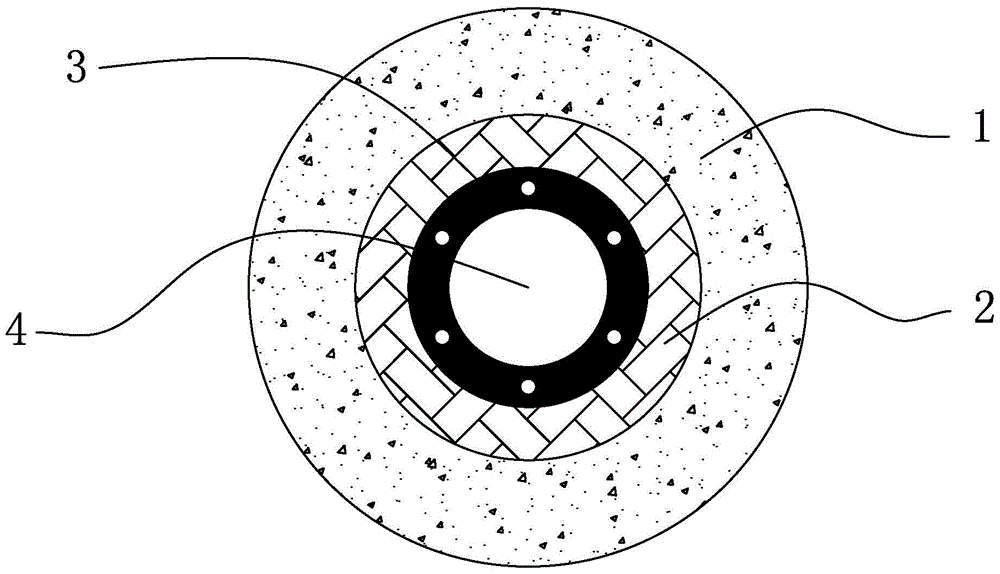

Resin grinding disc

The invention discloses a resin grinding disc which comprises a base body layer and an abrasive material layer. The base body layer and the abrasive material layer are bonded through a binder. Raw materials of the abrasive material layer comprise, by weight part, 25-35 parts of diamond, 10-15 parts of CBN, 15-35 parts of aluminum oxide hollow ball, 9-28 parts of modified phenolic resin, 5-7 partsof graphite, 2-4 parts of polytetrafluoroethylene powder, 0.5-3 parts of walnut shell flour, 1-3 parts of stearic acid and 0.5-1.5 parts of dibutyl phthalate. The resin grinding disc is good in self-sharpening performance and heat resisting property, the grinding efficiency is high, the falling probability of abrasive particles can be reduced, and the abrasive material can obtain good surface quality.

Owner:安徽全兆光学科技有限公司

Drill with coating at flat base of straight groove, blind hole and single groove

ActiveCN103252520ASolve the problem of injusticeReduce heat transferTransportation and packagingTrepanning drillsEngineeringPrinted circuit board

The invention relates to a drill with a coating at a flat base of a straight groove, a blind hole and a single groove. The back part of the drill is a clamping part; the front part is a cutting part; a chip groove is arranged at the back cutter face of the cutting part; the main body of the cutting part is a big helical angle of 25-30 DEG; the cutting edge of the drill passes through the center of the drill; and a coating layer is plated at the outer part of the drill. Compared with the prior art, the single chip groove is utilized, so that a drill tip having the same angle as the drill rather than a transverse blade exists when the drill drills a printed circuit board; the chip groove is great in size and great in chip containing capability and achieves a good chip removal effect; the length of a blade is greater than a radius, that is to say, a cutting edge goes beyond a core-bit, so that the unevenness problem of a hole bottom is solved; in addition, the TiAlN coating with the heat transfer coefficient much lower than that of a drill base body and a work-piece material is additionally arranged. Therefore, the heat energy absorbed by the drill is relatively low, a relatively high drilling temperature can be borne, and the service life of the cutter is prolonged by up to 40%.

Owner:SHANGHAI UNIV OF ENG SCI +1

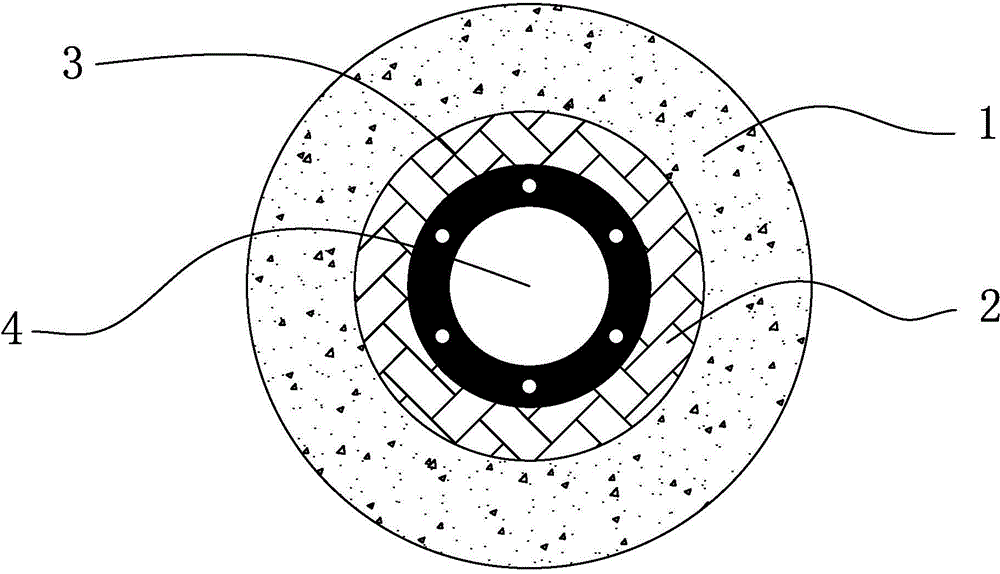

Scouring pad drawing wheel and manufacturing method thereof

ActiveCN104440612AGuaranteed StrengthGood self-sharpeningBonded abrasive wheelsGrinding devicesAdhesiveEngineering

The invention relates to a scouring pad drawing wheel which comprises a wheel body. A central hole is formed in the middle of the wheel body, the wheel body comprises a base body, a strengthening layer and a scouring pad layer, the strengthening layer is arranged between the base body and the scouring pad layer, the scouring pad layer is mainly made of bottom cloth, adhesive and grinding particles, and the grinding particles are arranged on the surface of the bottom cloth through the adhesive. A manufacturing method of the scouring pad drawing wheel comprises the steps that the base body, the strengthening layer and the scouring pad layer are manufactured, and then the strengthening layer is arranged between the base body and the scouring pad layer, wherein the manufacturing process of the scouring pad layer comprises the steps that firstly, nylon materials are made into the bottom cloth; secondly, the adhesive is arranged on all the faces of the bottom cloth, and the drying process needs to the conducted after the adhesive is arranged on each face; thirdly, the grinding particles are prepared, and the grinding particles and the adhesive are then evenly mixed to obtain a bonding material; finally, an even material layer is formed on the surface of the bottom cloth and dried, and the scouring pad layer is obtained. The scouring pad drawing wheel manufacture through though the manufacturing method is stable in performance, good in grinding effect, durable in use and superior in comprehensive performance.

Owner:NINGBO DAHUA GRINDING WHEEL

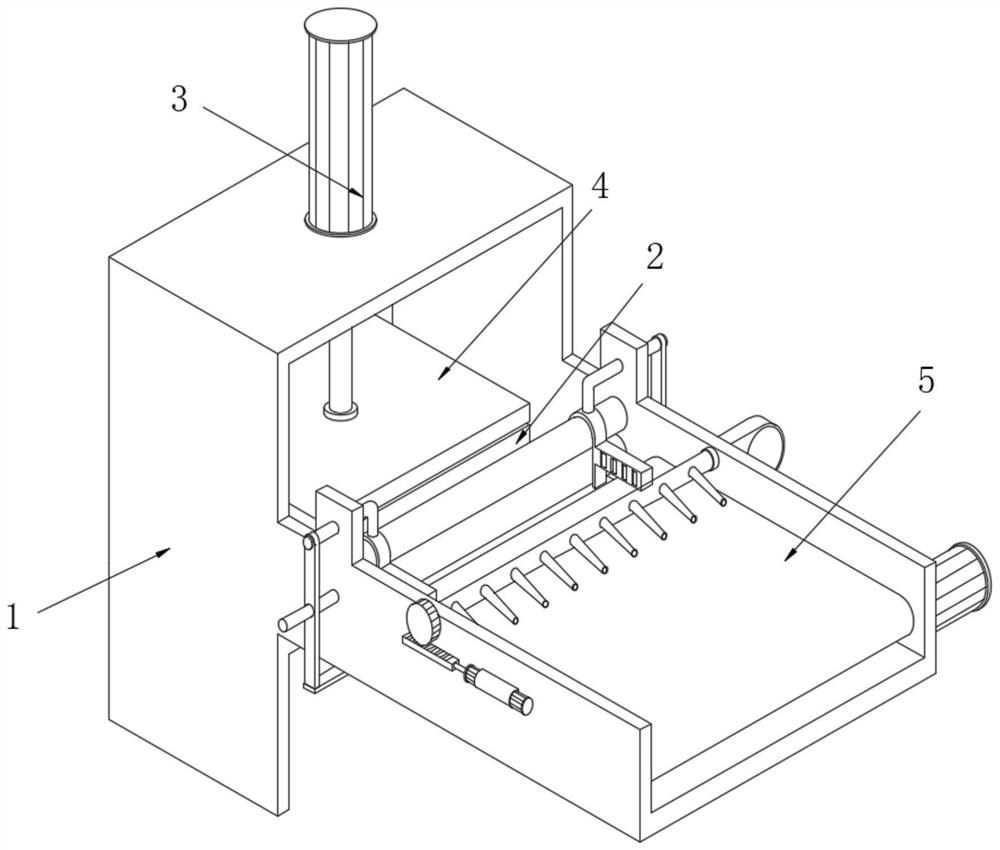

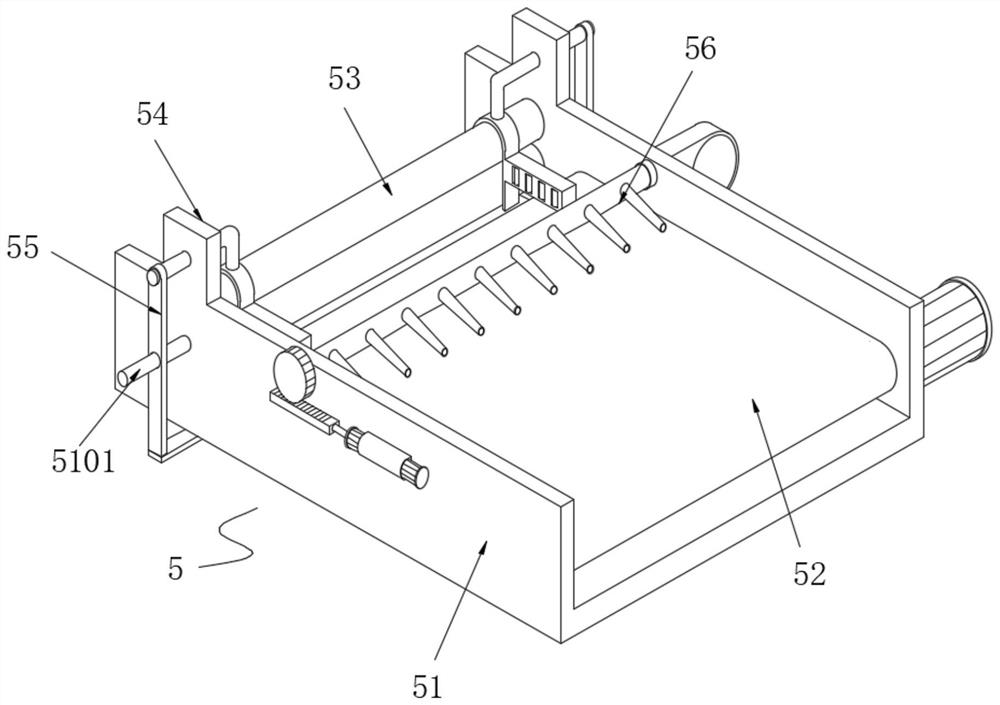

Rapid mask assembling mold and assembling method

PendingCN114734676AFacilitates stamping and forming assembly workMovement is accurateCleaning using gasesPressesHydraulic cylinderManufactured material

The invention discloses a mask rapid assembly die and an assembly method, and relates to the technical field of mask machining, the mask rapid assembly die comprises a concave base, a die cavity is formed in the concave base, a stamping hydraulic cylinder is mounted at the top of the concave base, and an upper die corresponding to the die cavity is connected to the position, located in the concave base, of an output shaft of the stamping hydraulic cylinder; and a material conveying assembly is arranged on the front side of the concave base and comprises a concave table, a conveying belt is installed in the concave table, and two guide rollers are horizontally and rotationally installed at the positions, located on the rear side of the conveying belt, in the concave table. According to the mask rapid assembly mold and the assembly method, when a mask is assembled, under the work of a servo motor, the two limiting blocks can clamp the two sides of a raw material, the conveyed mask raw material can be kept at a designated position to move, the deviation condition is avoided, and the assembly efficiency is improved. Therefore, the mask raw material can be accurately moved to the position of the die cavity.

Owner:仙桃市美凯尔防护用品有限公司

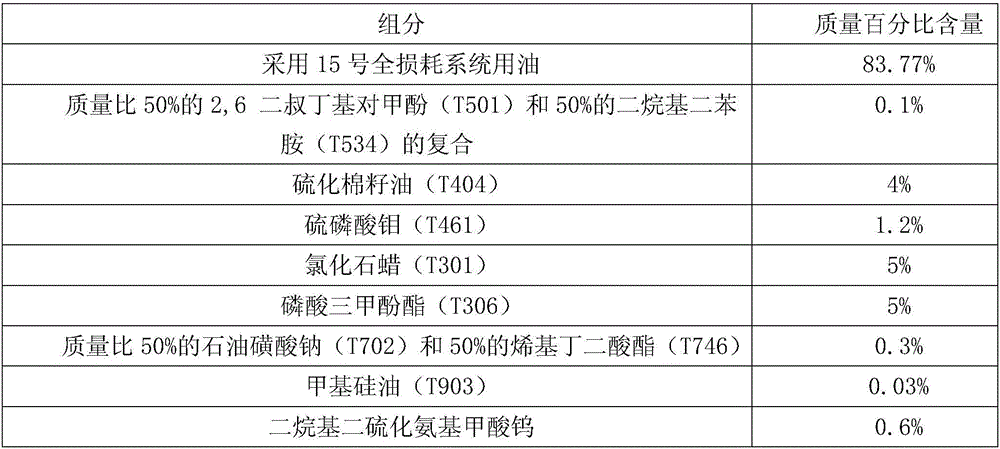

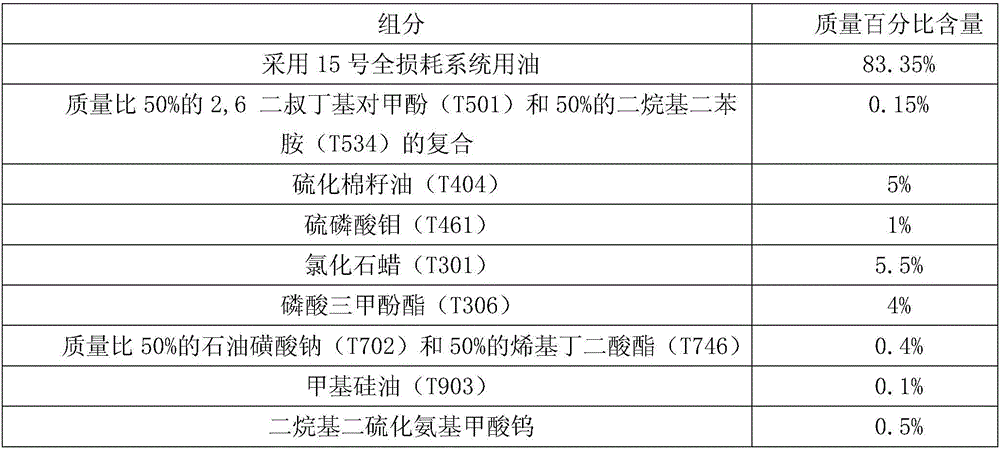

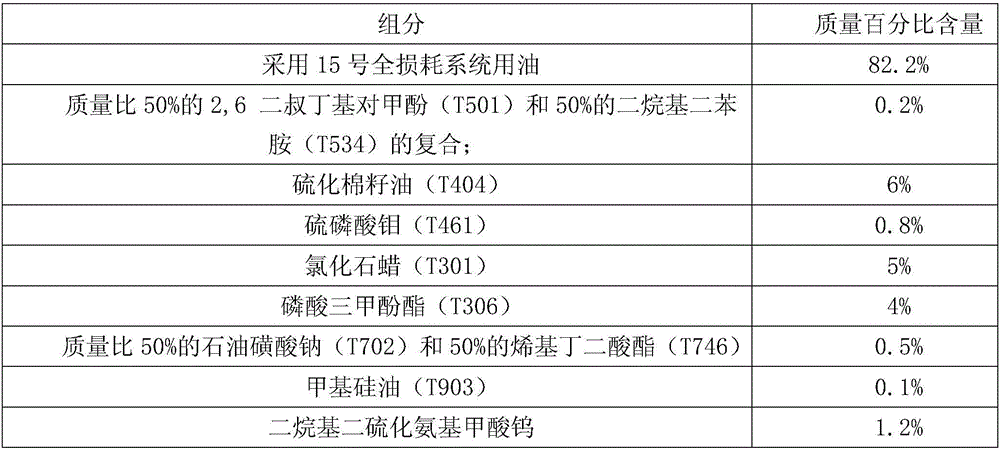

Lubricant composition for cutting machining of ordinary carbon structure steel gear

InactiveCN106433920AGood coolingStrong chip removal abilityLubricant compositionRust converterAntioxidant

The invention discloses lubricant composition for cutting machining of an ordinary carbon structure steel gear. No.15 total loss system oil is adopted as base oil and matched with multiple composite additives including an antioxidant, an oily agent, a friction modifier, an extreme pressure agent, an antiwear agent, an antirust agent, an anti-foaming agent and an oxidation and corrosion inhibitor. The composition is good in cooling performance, lubricating property, cleaning performance and diffusibility and high in chip removal capacity, can reduce phenomena such as accumulated burl, scratching and bruising produced during machining and has the advantages of resisting wear, reducing friction and preventing rust.

Owner:GUANGXI UNIV

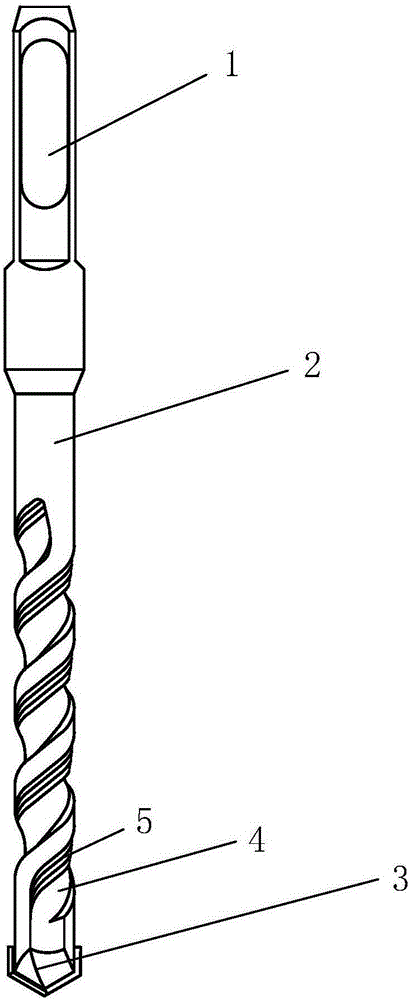

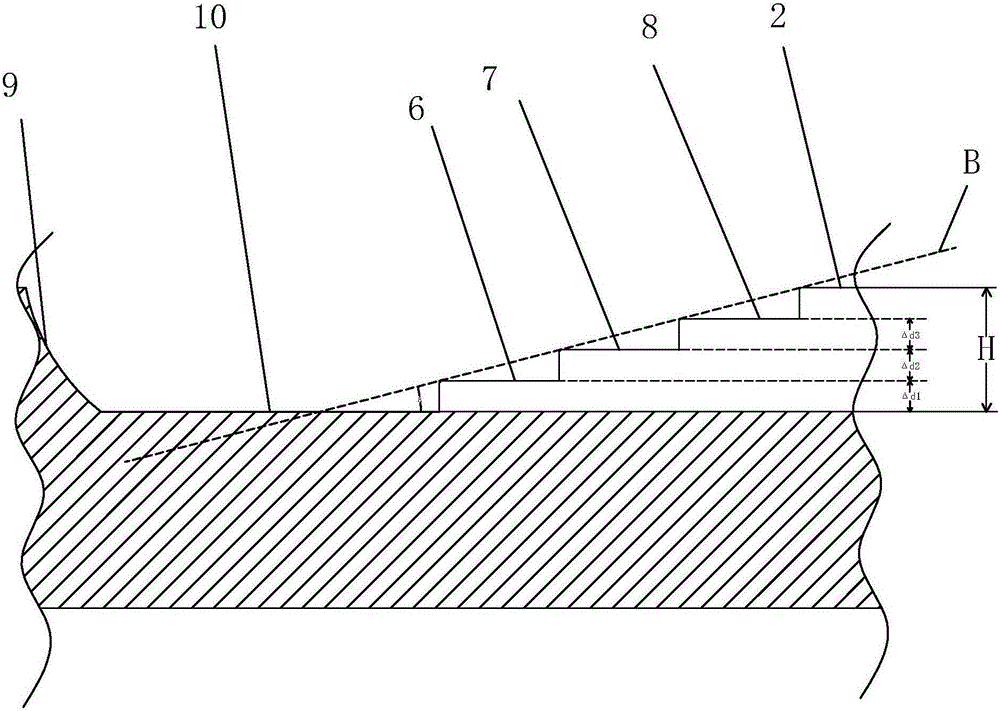

Drill bit

ActiveCN105215434AEasy to processReduce recoilTransportation and packagingTrepanning drillsEngineeringFlange

The invention discloses a drill bit which comprises a drill handle, a drill body and a drill tip. The drill body is provided with a spiral scrap guide groove. A scrap guide portion is arranged on the bottom face of the spiral scrap guide groove and extends from the initial position of the spiral scrap guide groove to the terminal position of the spiral scrap guide groove along the spiral scrap guide groove. The left side of the scrap guide portion is close to the spiral center line of the spiral scrap guide groove. The right side of the scrap guide portion is attached to the right side wall of the spiral scrap guide groove. The scrap guide portion is composed of at least N flanges with different heights, and therefore the bottom face of the spiral scrap guide groove, the scrap guide portion and the outer surface of the drill body can form a gradually-heightened step shape, wherein N is larger than or equal to 2. The drill bit has the advantages that the scrap discharge speed is high, and the cooling performance of the drill tip is improved.

Owner:乐清市天中天五金工具有限公司

A guide rail protective cover with high-efficiency chip removal function for machine tools

ActiveCN110625432BEfficient chip removal structureGuaranteed lubrication effectMaintainance and safety accessoriesStructural engineeringMachine tool

The invention discloses a guide rail protective cover for machine tools with efficient chip removal function, which comprises a fixing seat, a telescopic cover body is welded on the right side of the fixing seat, and a telescopic cover head is inserted into the inner side of the telescopic cover body, so that The right side of the telescoping head is welded with a connecting seat, and the upper surface of the right side of the telescoping head is penetrated with a through groove, and a protective cover is provided above the through groove, and the protective cover is connected with the telescoping head through bolts fixed, a connection box is provided below the through groove, and the top of the connection box is welded and fixed to the inner surface of the telescoping head, a cleaning structure is inserted inside the connection box, and the left two ends of the telescoping head The outer surfaces are all provided with grooves, the inside of the grooves are provided with balls, and the inner surface of the telescopic cover body is provided with chute, and the chute is arranged at both ends of the telescopic hood head. The invention has an efficient debris removal structure, improves the debris removal effect, and has a quantitative oil replenishment structure to keep the surface of the guide rail lubricated.

Owner:常州禾川机械有限公司

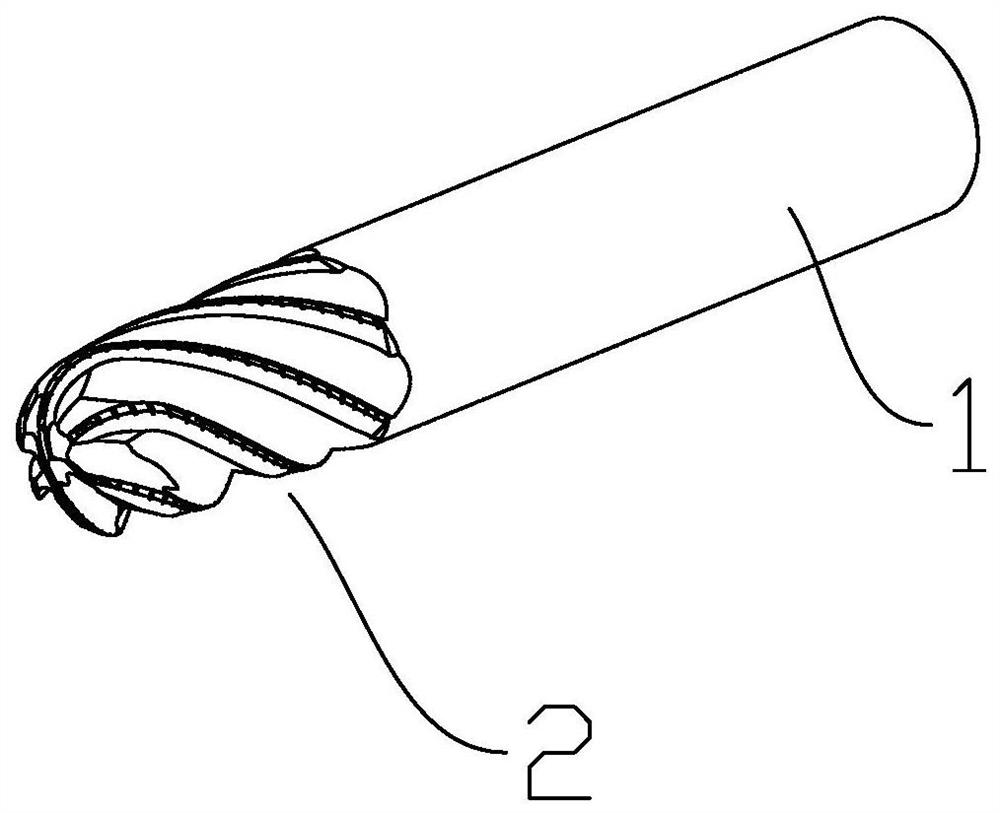

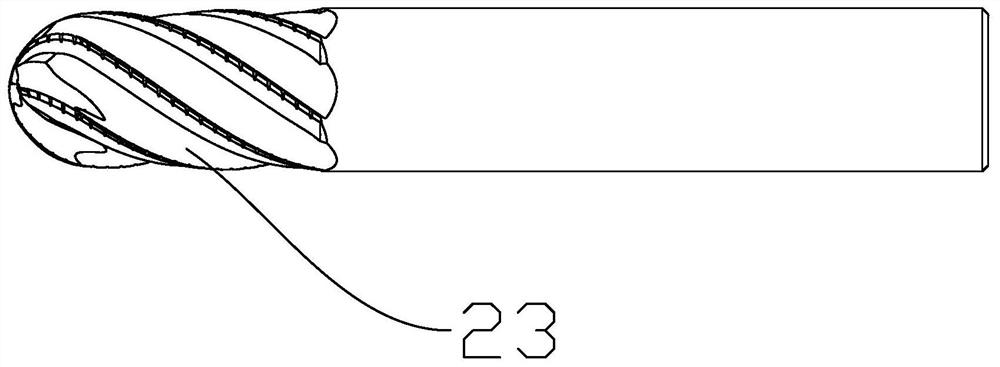

Heat-resistant alloy high-efficiency milling cutter

The invention discloses a heat-resistant alloy high-efficiency milling cutter and solves the problems of easy chip removal and cutter breaking, short service life, low processing efficiency and the like of a conventional ball cutter during rough machining of a blade disc. According to the technical scheme, the heat-resistant alloy high-efficiency milling cutter is characterized by comprising a cutter bar, wherein a cutter head is formed at one end of the cutter bar; a central boss is formed on the cutter head; cutting edges and a chip groove are formed in the cutter head; the central boss is fixedly connected with the center of the cutter bar; the central boss and the cutter bar are coaxially arranged; the number of the cutting edges is at least four; the cutting edges are evenly distributed on the side periphery of the central boss and circumferentially arranged with the central boss as the center; the chip groove is formed between the two cutting edges; the top of the central boss serves as a base face; every two cutting edges, symmetrical about the central axis of the central boss, on the base face are in an S shape; the cutting edges and the chip groove extend to the side body of the cutter bar in the same spiral direction; and the cutting edges and the cutter bar are connected into a whole.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

A kind of manufacturing process of die-cutting knife plate

ActiveCN107379116BExtended service lifeImprove cutting accuracyMetal working apparatusLaser cuttingEngineering

Owner:郑州华美彩印纸品有限公司

A kind of Baijie brass wheel and its preparation method

ActiveCN104440612BGood self-sharpeningImprove cooling effectBonded abrasive wheelsGrinding devicesAdhesiveMechanical engineering

Owner:NINGBO DAHUA GRINDING WHEEL

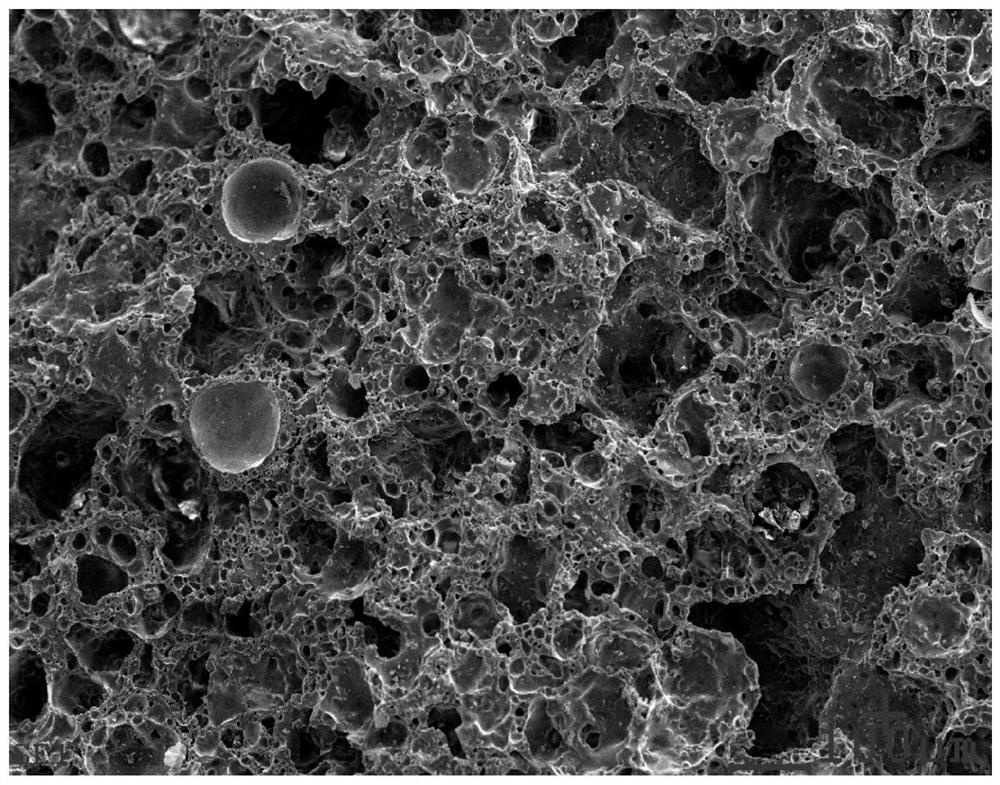

Diamond grinding wheel disc for thinning silicon carbide and preparation method of diamond grinding wheel disc

PendingCN114516001ARealize self-sharpeningShallow specific surface areaAbrasion apparatusGrinding devicesCarbide siliconAl powder

The invention discloses a diamond grinding wheel disc for silicon carbide thinning and a preparation method thereof.The diamond grinding wheel disc is composed of diamond grinding wheel teeth and an aluminum matrix, and the diamond grinding wheel teeth are prepared from, by mass, 15%-25% of foam diamond, 45%-65% of Ni powder, 10%-30% of Al powder and 5%-15% of aluminum oxide hollow balls; the particle size of the foam diamond is 8-10 microns. The diamond grinding wheel tooth prepared through the method is high in porosity, high in chip containing and discharging capacity, good in sharpness, high in machining efficiency and long in service life, and after silicon carbide is thinned, the surface smoothness is good, the fragment rate is low, and a damaged layer is shallow. Therefore, the problems of low efficiency, easy surface scratch, large environmental pollution and the like when the silicon carbide crystal is subjected to free grinding are solved.

Owner:长沙市萨普新材料有限公司

A kind of preparation method of rare earth permanent magnet material

ActiveCN104907558BReduce lossEliminate finishing processMagnetic materialsRare earthSintered magnets

The invention relates to a rare earth permanent magnetic material preparing method comprising the steps of preparing a press blank of powder of sintered magnets, using row wires to machine the press blank and then performing sintering. All the steps are performed in a wholly sealed atmosphere. The row wire machining means line machining for the press blank formed by pressing; after the press blank is clamped and located, a driving mechanism drives the row wires to move back and forth linearly; the press blank is machined according to a preset path along with the rotation of a locating clamp and finally forms a block body or a sheet body with a preset shape and size, an arched body or other specially-shaped bodies; the final forming size contains the sintering shrinkage allowance. The rare earth permanent magnetic material preparing method has the advantages of short preparation technological process, high machining efficiency, low magnetic powder loss, and high rare earth utilization rate. The machining is near net machining, so that a finish machining procedure performed after sintering is saved.

Owner:浙江三环康盈磁业有限公司

Water-in-oil Nano Working Fluid for EDM

The invention relates to oil pocket water type nano working fluid in the field of electric spark forming machining. The working fluid is composed of white mineral oil, deionized water and compound emulsifier. During preparing, dehydration sorbitol aliphatic ester and lauryl alcohol polyoxyethylene ether are mixed according to the proportion requirement, stirring is conducted till uniform mixing, and accordingly the compound emulsifier is formed. Then, the deionized water, the white mineral oil and the compound emulsifier are mixed according to the proportion requirement, stirring is conductedat the normal temperature till uniform mixing, and accordingly oil pocket water type rough emulsion is formed. Then, the oil pocket water type rough emulsion is arranged in a constant-temperature water bath kettle at the temperature of 80 DEG C, stirring is conducted for 15 min, self-emulsifying of the oil pocket water type rough emulsion is achieved, and finally mixed liquid is arranged at the normal temperature to be naturally cooled. The electric spark forming machining oil pocket water type nano working fluid has the advantages that stability is high, environment friendliness is achieved,usage is safe, the scrap discharging capability is high, machining is efficient, and dielectric strength is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

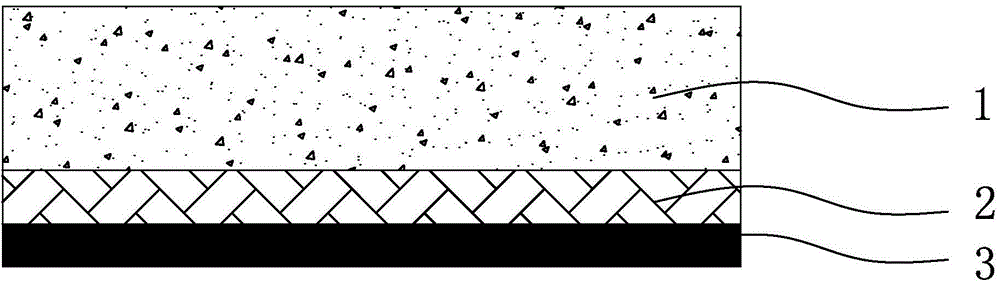

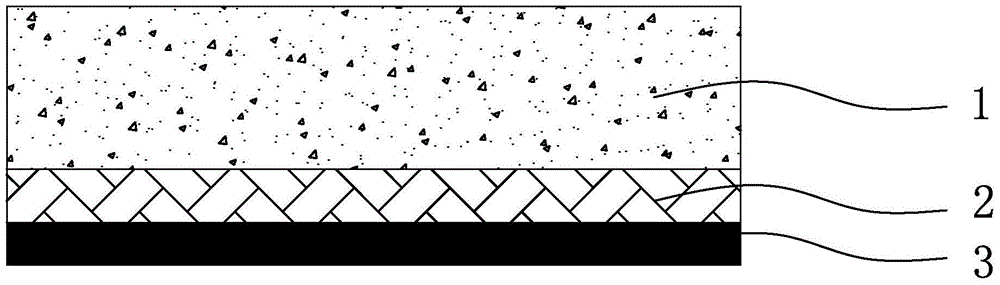

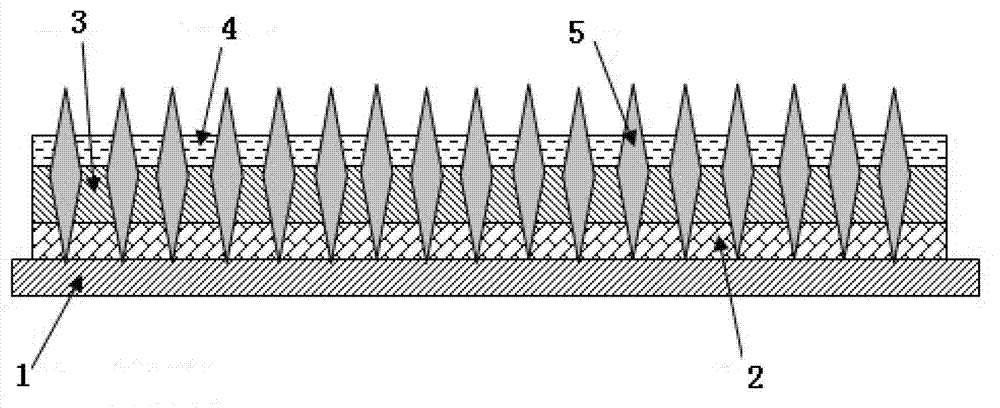

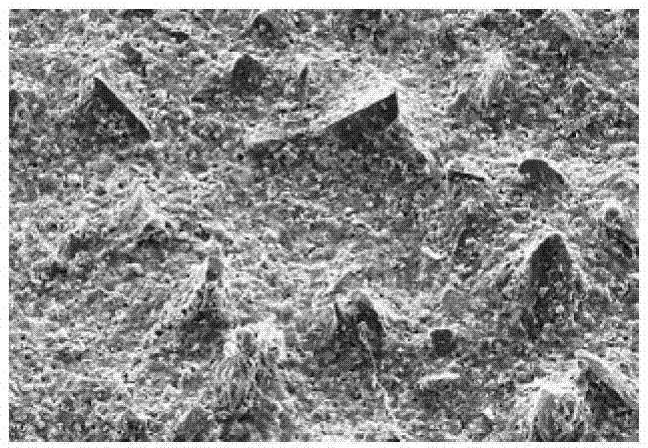

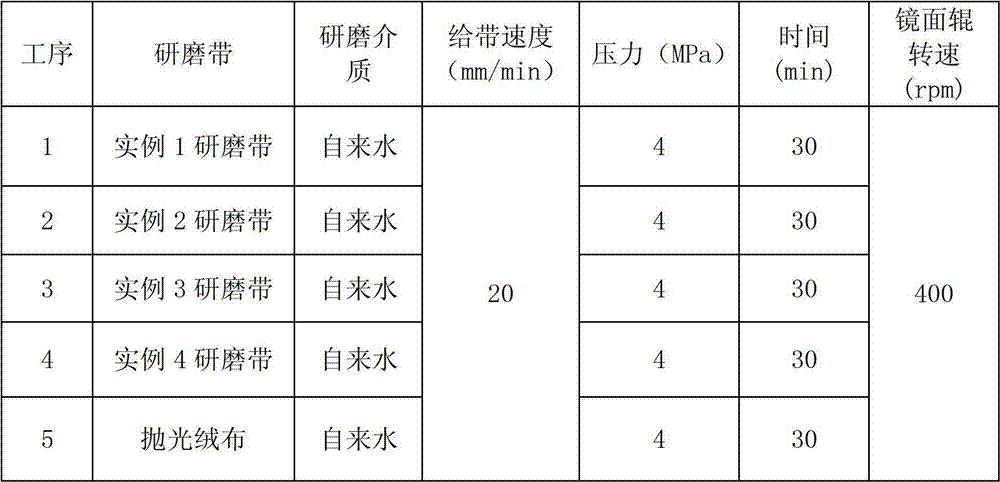

Film-based electrostatic sand-planting grinding belt and preparation method thereof

ActiveCN102729159BStrong chip removal abilityImprove cooling effectAbrasion apparatusGrinding devicesAdhesiveSolvent based

The invention provides a film-based electrostatic sand-planting grinding belt and a preparation method thereof. The film-based electrostatic sand-planting grinding belt has the advantages of good chip removal capability, high cutting force, low possibility of blockage and sand drop, long life and the like, thus more efficiently polishing metal sticks, crankshafts and the like to meet the requirement of surface roughness. The grinding belt is characterized in that the grinding belt comprises a film base material, coating layers coated on the surface of the film base material and micron-sized grinding materials embedded in the coating layers; the coating layers include a primer layer and a compound adhesive layer which are stacked in sequence; the primer layer comprises primer layer fillers and a solvent adhesive; the primer layer fillers are selected from one of or the mixture of more than one of the following substances: calcium oxide, calcium carbonate and talcum powder; the grain sizes of the fillers are 5-30mu m; the compound adhesive layer comprises compound adhesive layer fillers and a solvent adhesive; the compound adhesive layer fillers are selected from one of or the mixture of more than one of the following substances: calcium oxide, calcium carbonate and talcum powder; and the grain sizes of the fillers are 5-30mu m.

Owner:BEIJING GRISH HITECH

Hybrid pdc drill bit based on jet technology

InactiveCN109025831BExtended service lifeImprove adaptabilityDrill bitsConstructionsTool bitJet flow

The invention relates to a hybrid power PDC drill bit based on jet flow technology, which comprises a drill bit body, one end of the drill bit body is provided with a plurality of drilling fluid nozzles, one end of the drill bit body is provided with at least two drill bit cutter wings, the drill bit cutter wings can rotate in the same direction as the bit body for cutting a rock layer. At least two jet flow power cutter heads are arranged at one end of the drill bit body, the jet flow cutter heads and the drill bit cutter wings are evenly and alternately arranged in the circumferential direction, and a plurality of cutter head cutter wings are evenly arranged on the jet flow power cutter heads at intervals in the circumferential direction, and jet flow nozzles are respectively disposed onone side of each cutter head cutter wing. The jet flow power cutter heads can rotate in the same direction as the drill bit body and can reversely rotate under the driving of a high-pressure jet flow; each cutter head wing can impact the grinding rock formation for a second time and the high pressure jet flow generated by the jet flow nozzle can spray the fracture the rock formation. The drill bit can avhieve mechanical and hydraulic cross rock breaking under the complex and changeable stratum, improves the adaptability of the drill bit to various formations, improves the rock breaking efficiency, shortens the drilling period, reduces the drilling cost and improves the exploration and development benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

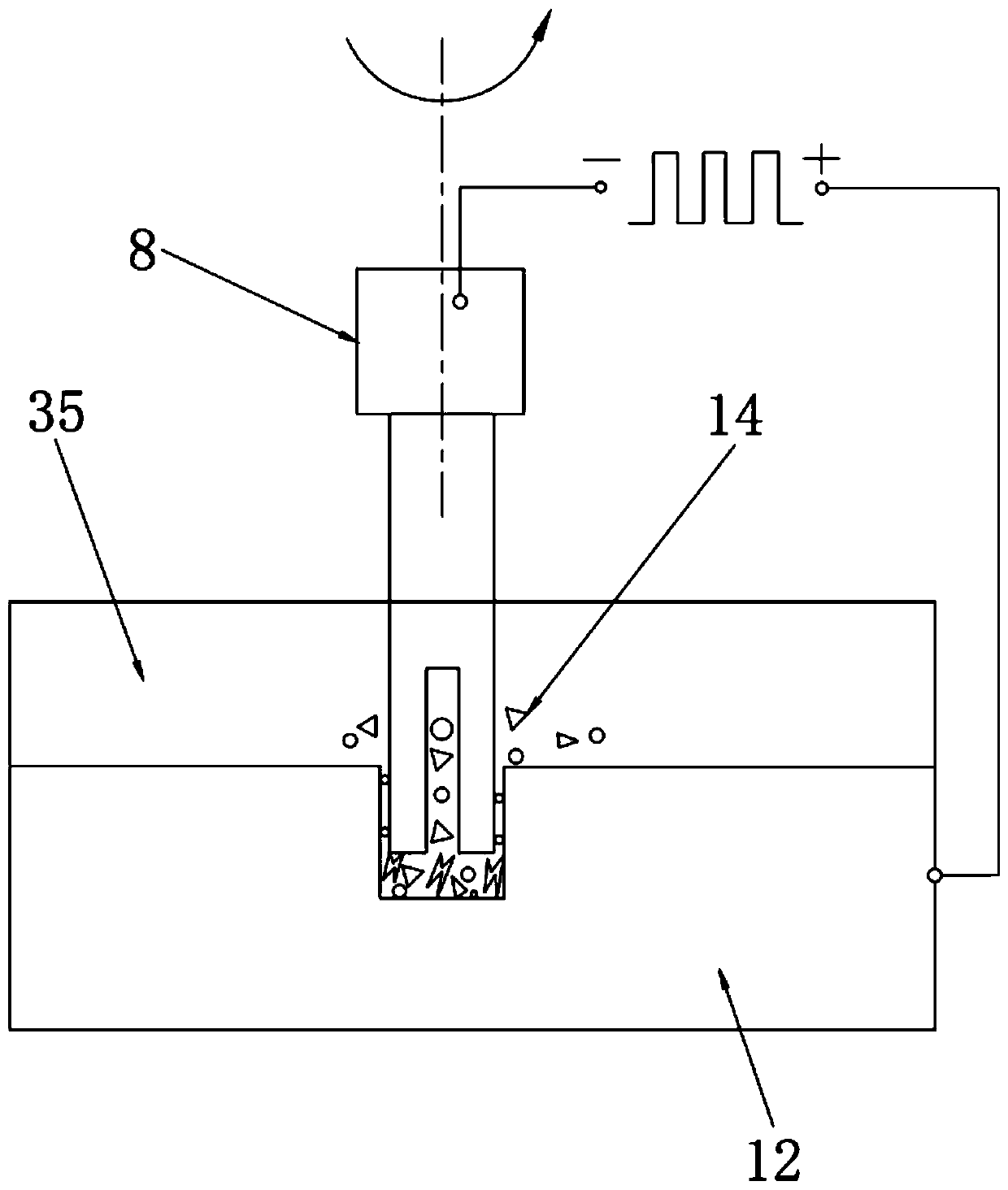

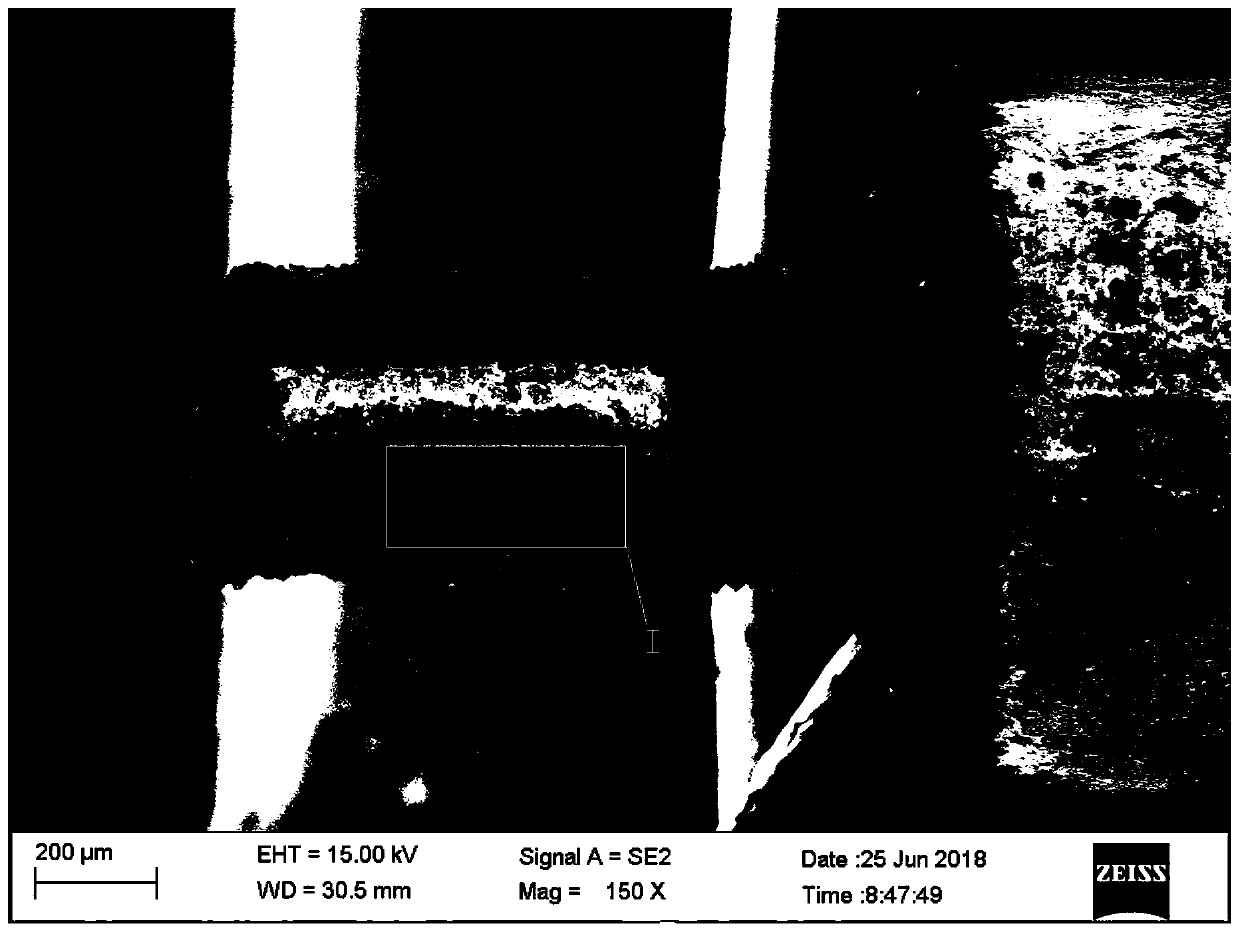

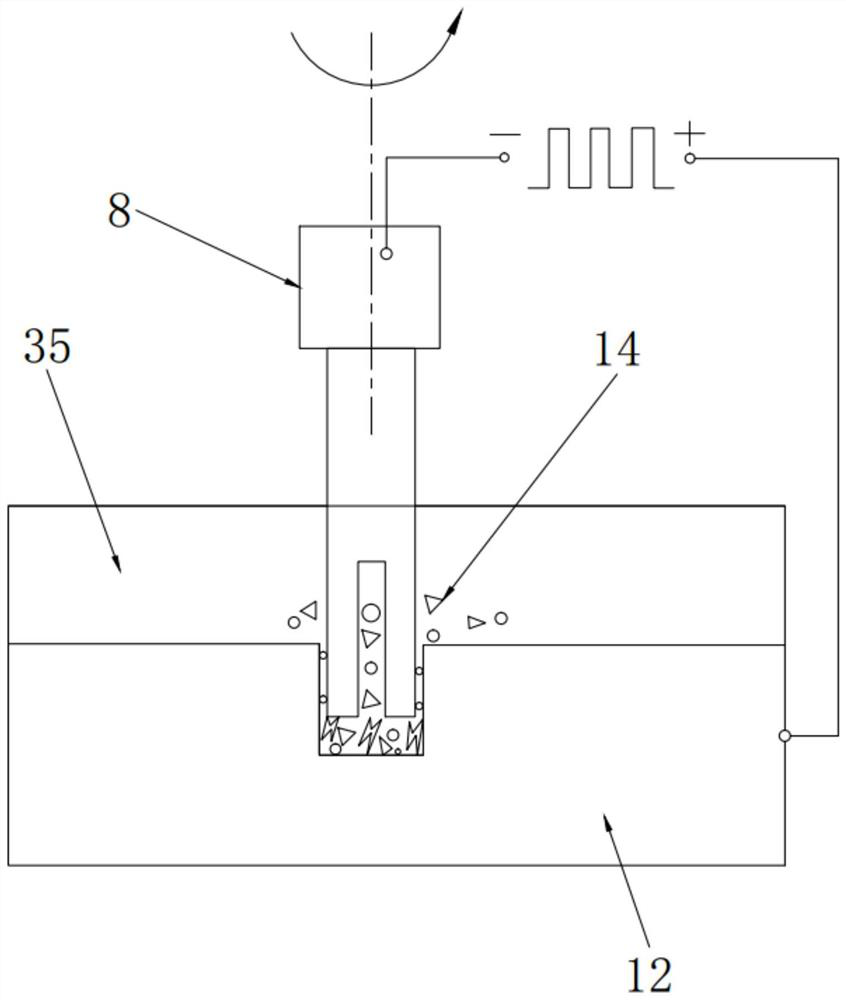

Online finishing cutting groove electrode fine discharge machining device and method

ActiveCN111215710AStrong chip removal abilityStrong size flexibilityElectrical-based machining electrodesWorking fluidHigh surface

The invention discloses an online finishing cutting groove electrode fine discharge machining device and method, and relates to the technical field of electromachining. A work fluid system comprises awork groove, a first filter, a first high-pressure pump and a nozzle. A cooling fluid system is arranged on one side of the work fluid system and comprises a cooling groove, a second filter and a second high-pressure pump. A transmission system is arranged on one side of the cooling fluid system and comprises a servo motor, a motor main shaft and a high-speed bearing. The motor main shaft is connected with one end of a tool electrode through a chuck. A groove is formed in the bottom of the tool electrode. A wire electrode for finishing the tool electrode is arranged on one side of the tool electrode. The online finishing cutting groove electrode fine discharge machining device and method break through the bottleneck of the existing particle enhancing metal-based composite material fine discharge machining technology; meanwhile, the tool electrode of the new method has online finishing performance, excellent scrap discharging capability and work fluid updating capability, and the high-precision and high-surface-quality manufacturing bottleneck during existing metal-based composite material fine discharge machining is expected to be broken through.

Owner:GUANGDONG UNIV OF TECH

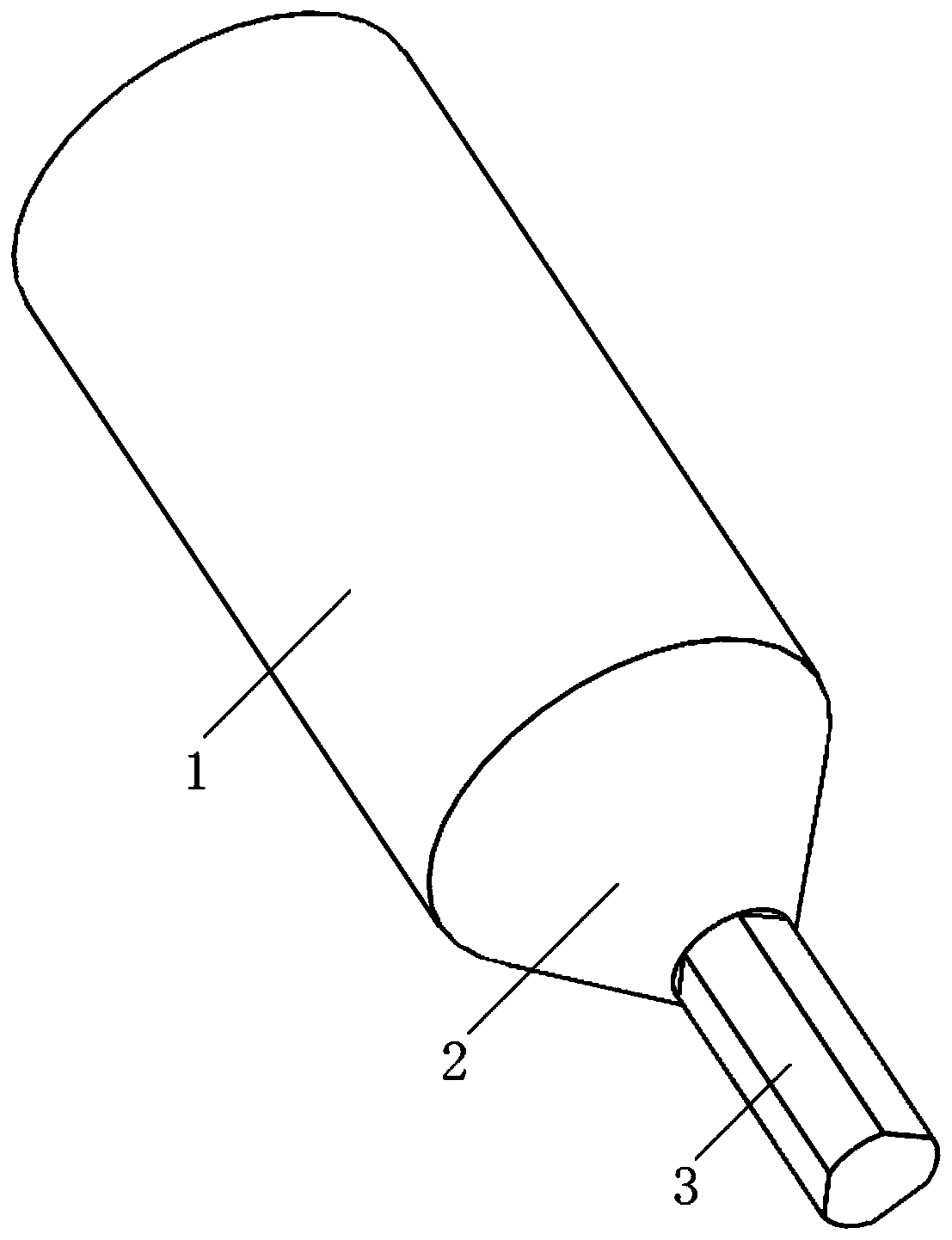

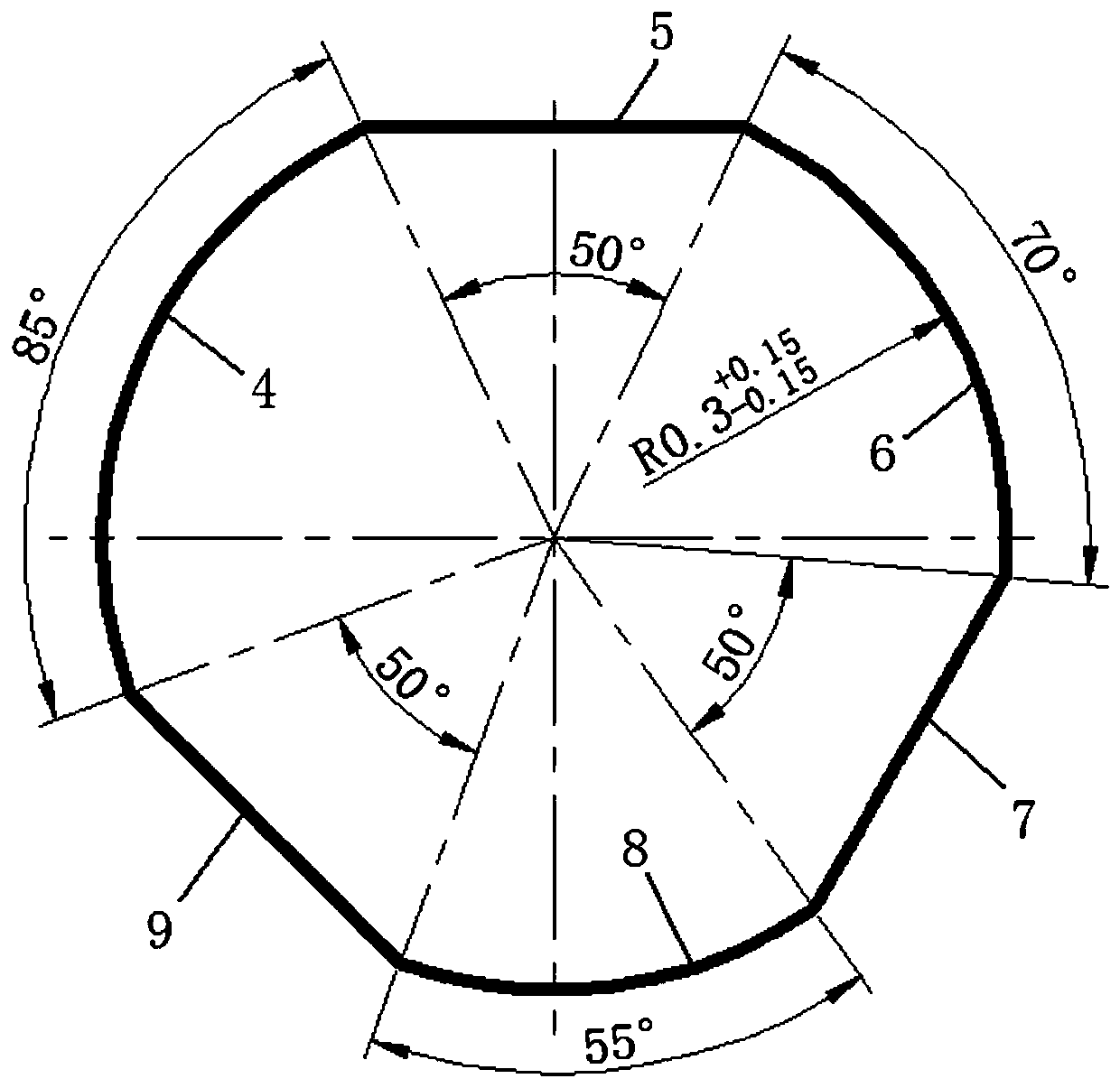

Diamond intermittent micro-grinding cutter

InactiveCN110125823AReduce wearGrinding heat dissipation is goodBonded abrasive wheelsCircular coneEngineering

A diamond intermittent micro-grinding cutter comprises a cutter handle section, a transition section and a cutter head section. The cutter handle section is of a cylindrical structure, the transitionsection is of a conical frustum structure, the cutter head section is of a polygonal cylindrical structure, the cutter handle section is located at the large-diameter end of the transition section, the cutter head section is located at the small-diameter end of the transition section, the cross section of the cutter head section is in a hexagonal shape and is divided into three arc edges and threelinear edges, and the first arc edge, the first linear edge, the second arc edge, the second linear edge, the third arc edge and the third linear edge are sequentially connected end to end. Diamond abrasive particles are electroplated on the surface of the transition section, diamond abrasive particles are electroplated on the portions, corresponding to the three arc edge, on the surface of the cutter head section, no diamond abrasive grain coating is arranged on the portions, corresponding to the three linear edges, of the surface of the cutter head section, no diamond abrasive grain coatingis arranged on the surface of the cutter handle section, the length of the first arc edge is larger than that of the second arc edge, the length of the second arc edge is larger than that of the third arc edge, circle centers of the three arc edges coincide, the linear lengths of the three linear edges are equal, and the thickness of the diamond abrasive grain coating is 0.03-0.06mm.

Owner:NORTHEASTERN UNIV

Central water outlet scrap crushing water nozzle for numerical control lathe

InactiveCN103480868ABrokenEasy to washAuxillary equipmentMaintainance and safety accessoriesNumerical controlInlet channel

The invention relates to a central water outlet scrap crushing water nozzle for a numerical control lathe. The central water outlet scrap crushing water nozzle is formed by a water nozzle mounting handle and a water nozzle main body; a central water inlet channel is made in the axis parts of the water nozzle mounting handle and the water nozzle main body; a water outlet bevel hole communicated with the central water inlet channel is formed in the water nozzle main body; the central water outlet scrap crushing water nozzle is characterized in that the water nozzle main body is shaped like a square post body. The central water outlet scrap crushing water nozzle for the numerical control lathe is scientific and reasonable in structural design and convenient to mount, and the scrap crushing effect is realized while rinsing is realized, so the scrap removing capacity of the water nozzle is improved. The central water outlet scraping crushing water nozzle belongs to a central water outlet scrap crushing water nozzle with higher innovation for the numerical control lathe.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

A micro electric discharge machining device and processing method for a slotted electrode that can be trimmed on-line

ActiveCN111215710BStrong chip removal abilityStrong size flexibilityElectrical-based machining electrodesWorking fluidHigh surface

The invention discloses a slotted electrode fine electric discharge machining device capable of online trimming and a machining method, and relates to the technical field of electrical machining. The working fluid system includes a working tank, a first filter, a first high-pressure pump and a nozzle. The working fluid system includes a There is a coolant system on one side, the coolant system includes a cooling tank, a second filter and a second high-pressure pump, and a transmission system is provided on one side of the coolant system, and the transmission system includes a servo motor, a motor shaft and a high-speed bearing; the motor shaft passes through the clip The head is connected with one end of the tool electrode, the bottom of the tool electrode is provided with a groove, and one side of the tool electrode is provided with a wire electrode for trimming the tool electrode. The invention breaks through the bottleneck of the existing particle-reinforced metal matrix composite micro-discharge machining technology. At the same time, the tool electrode of the new method has the ability to be trimmed online, as well as the excellent chip removal ability and the renewal ability of the working fluid. It is also expected to break through the existing metal matrix composite material. The manufacturing bottleneck of high precision and high surface quality in micro electric discharge machining of materials.

Owner:GUANGDONG UNIV OF TECH

A turning/milling insert for processing special-shaped parts of high-hardness steel

ActiveCN106001648BHigh strengthEfficient decompositionTransportation and packagingMilling cuttersHardnessEngineering

The invention discloses a turning / milling insert for processing high-hardness steel special-shaped parts, which comprises a roughly regular heptagonal insert body; the insert body has an upper surface, a lower surface and side surfaces; the geometric center of the insert body is provided with a The fastening screw holes on the upper and lower surfaces; the intersection line between the upper surface and the side of the blade body constitutes the cutting portion of the blade, and the cutting portion includes a knife point at the vertex of a regular heptagon and a side of the regular heptagon The cutting edge is concave inward in an arc shape so that the cutting edge forms a fishtail-shaped cutting edge; the upper surface of the blade body extends inwardly along the fishtail-shaped cutting edge to form a fishtail-shaped rake face. The structure of the present invention can solve the problems of one-time post-fire profiling processing of special-shaped surfaces, the high hardness of the workpiece requires tool wear resistance, chipping resistance, high structural precision and good hard cutting performance, and solves the problem that the current tool cannot meet the requirements. Technical difficulties of comprehensive processing requirements under extreme conditions.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Pneumatic negative pressure chip removal double cooling system for deep hole machine tools

ActiveCN103707122BStrong chip removal abilityImprove cooling effectMaintainance and safety accessoriesCooling effectPneumatic tool

The invention belongs to the technical field of equipment for chip removal and deep hole processing in small diameter, and specifically relates to a pneumatic negative pressure chip removal double cooling system for deep hole machine tools, which solves the problem of the traditional DF system in the field of deep hole processing in the process of batch deep hole processing. The problem of accumulating thermal effects and thus affecting the processing quality. It includes a self-cooling negative pressure chip removal box installed on the tool holder mounting seat of the deep hole machine tool. The bottom of the self-cooling negative pressure chip extraction box is equipped with a large-diameter pressure relief port, and the top is equipped with an air duct. nip. The invention has good chip removal ability and cooling effect.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com