Diamond grinding wheel disc for thinning silicon carbide and preparation method of diamond grinding wheel disc

A diamond grinding wheel and silicon carbide technology, which is applied in the field of abrasive tool manufacturing, can solve the problems of easy scratching on the surface, large environmental pollution, low free grinding efficiency, etc., and achieve the effect of small roughness, low fragmentation rate and good finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

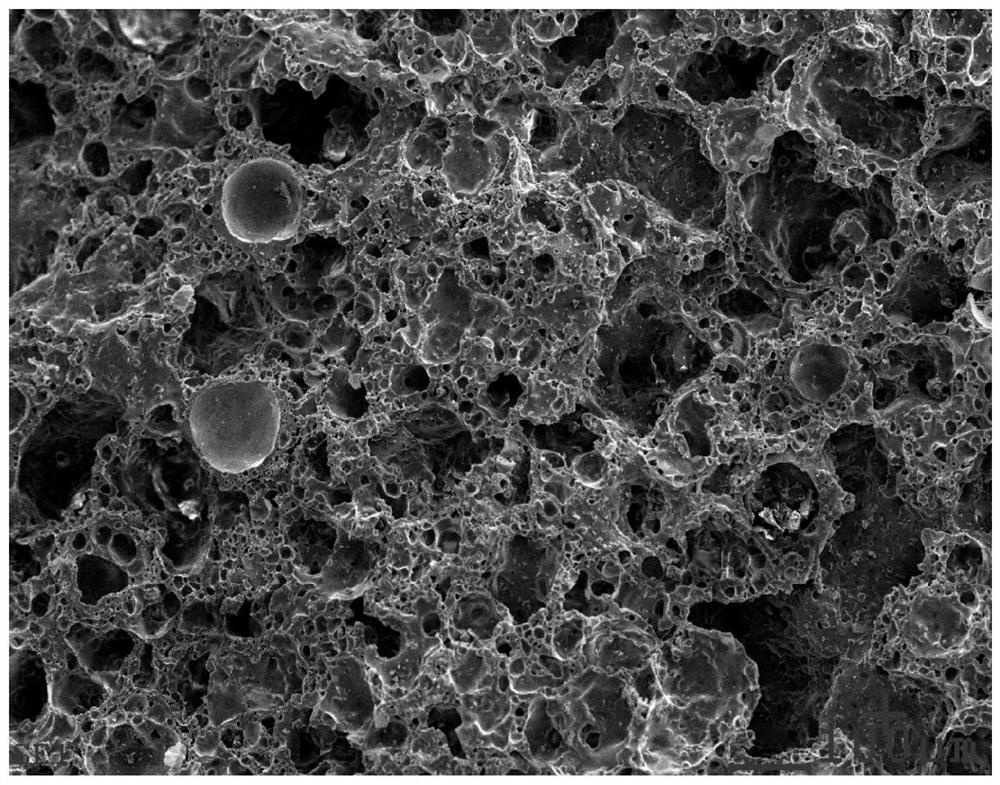

Image

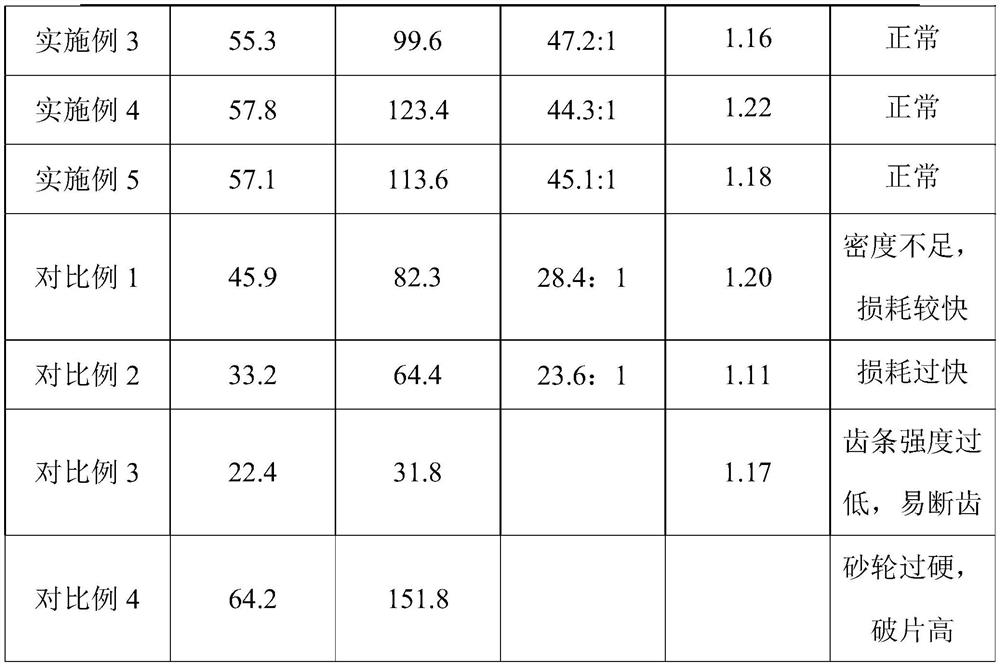

Examples

Embodiment 1

[0038] The implementation process steps are:

[0039]1. Prepare the raw materials according to the composition ratio in the table below, mix and pass through an 80-mesh sieve, take the undersize, and then mix the undersize in a V-type mixer with a ball-to-material ratio of 1:5 and a speed of 20rpm for 24 hours , to prepare a homogeneous powder mixture.

[0040] components foam diamond Ni powder Al powder Alumina Hollow Ball mass percentage 20ωt.% 50ωt.% 20ωt.% 10ωt.%

[0041] The diamond foam used is a three-type material with an average particle size of 8-10 μm, and the particle size of the aluminum oxide hollow balls used is 100-150 μm.

[0042] 2. Add 6ωt.% paraffin wax molding agent to the powder mixture, stir evenly, sieve, granulate, and put into a steel mold.

[0043] 3. Place the loaded mold in an argon atmosphere at 300°C for 40 minutes for degassing and degreasing, then raise the temperature to 750°C and hold for 90 minutes, press...

Embodiment 2

[0047] The implementation process steps are:

[0048] 1. Prepare the raw materials according to the composition ratio in the table below, mix and pass through an 80-mesh sieve, take the undersize, and then mix the undersize in a V-type mixer with a ball-to-material ratio of 1:5 and a speed of 20rpm for 24 hours , to prepare a homogeneous powder mixture.

[0049] components foam diamond Ni powder Al powder Alumina Hollow Ball mass percentage 20ωt.% 55ωt.% 15ωt.% 10ωt.%

[0050] The diamond foam used is a three-type material with an average particle size of 8-10 μm, and the particle size of the aluminum oxide hollow balls used is 100-150 μm.

[0051] 2. Add 6ωt.% paraffin wax molding agent to the powder mixture, stir evenly, sieve, granulate, and put into a steel mold.

[0052] 3. Place the loaded mold in an argon atmosphere at 300°C for 40 minutes for degassing and degreasing, then raise the temperature to 750°C and hold for 90 minutes, pres...

Embodiment 3

[0056] The implementation process steps are:

[0057] 1. Take the raw materials according to the composition ratio in the table below, mix and pass through a 80-mesh sieve, take the undersize, and then mix the undersize in a V-shaped mixer with a ball-to-material ratio of 1:5 and a speed of 20rpm 24h, a homogeneous powder mixture was prepared.

[0058] components foam diamond Ni powder Al powder Alumina Hollow Ball mass percentage 20ωt.% 60ωt.% 10ωt.% 10ωt.%

[0059] The diamond foam used is a three-type material with an average particle size of 8-10 μm, and the particle size of the aluminum oxide hollow balls used is 100-150 μm.

[0060] 2. Add 6ωt.% paraffin wax molding agent to the powder mixture, stir evenly, sieve, granulate, and put into a steel mold.

[0061] 3. Place the loaded mold in an argon atmosphere at 300°C for 40 minutes for degassing and degreasing, then raise the temperature to 750°C and hold for 90 minutes, press at 150MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com