Layered frozen fixed abrasive polishing pad and preparation method thereof

A technology of fixed abrasive and layered freezing, used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of low removal rate, low precision, and change of processing positioning benchmarks, achieving simple preparation and improved processing. Efficiency and effect of preventing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

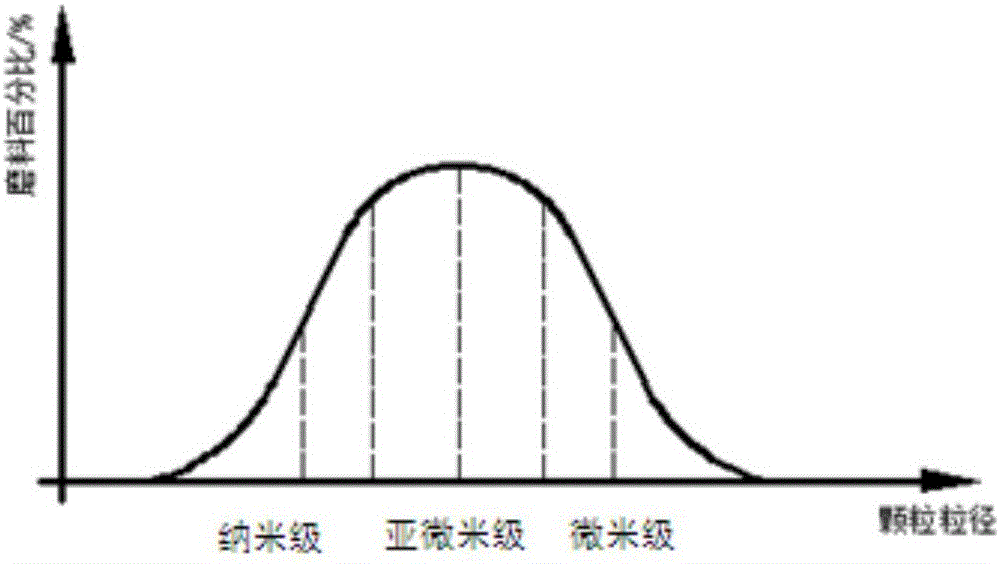

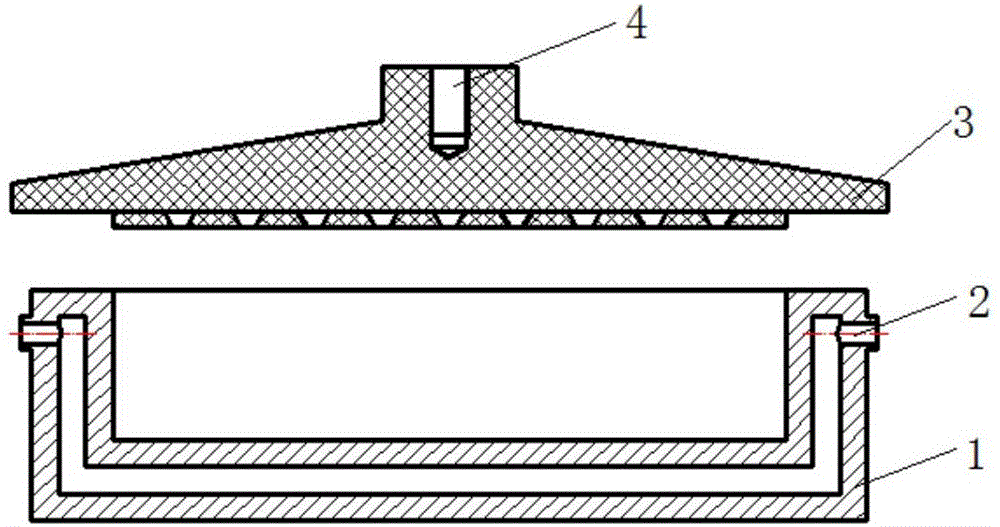

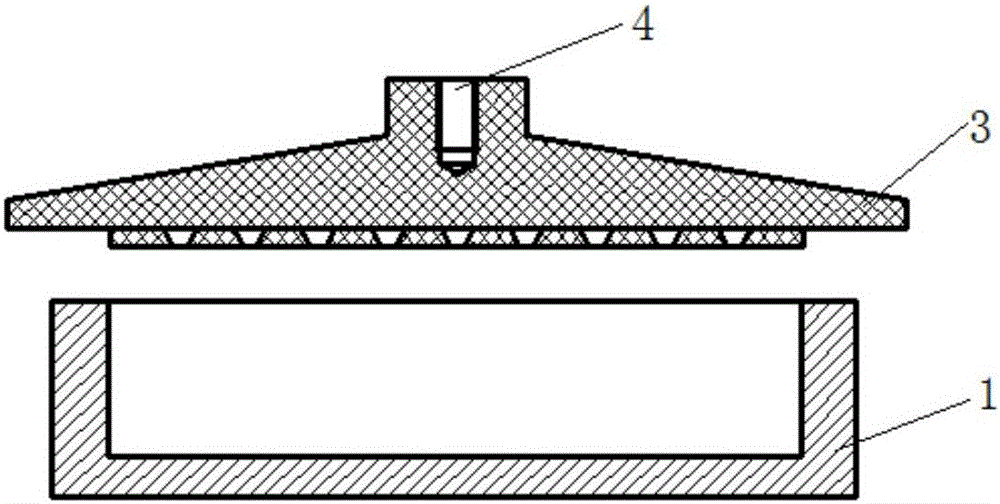

Embodiment 1

[0045] A CMP frozen polishing pad for polishing ultra-thin materials, made of 350 grams of micron SiC (or micron Cr 2 o 3、 SiO 2 、Al2 o 3 , CeO 2 ) abrasive and deionized water with a balance of 650. Stir the two evenly before use, and then mechanically disperse to obtain a colloidal mixture in which the abrasive is dispersed and suspended, and put it into a polishing pad mold. Since the particle size of micron-sized abrasives obeys the normal distribution, such as figure 1 As shown, the settling speed of abrasive particles with large particle size is faster, and the settling speed of abrasive particles with small particle size is slower, so after standing for 7-8 minutes, the suspension will appear obvious stratification, and the abrasive particles will become larger from top to bottom. , wherein the total weight of the nano-scale and micron-scale abrasives is about 35 grams each, and the particle diameters of the remaining 280 grams of abrasives after dispersion are all ...

Embodiment 2

[0047] A CMP frozen polishing pad for ultra-soft material polishing, made of 250 grams of micron SiC (or micron Cr 2 o 3、 SiO 2 、Al 2 o 3 , CeO 2 ) abrasive and deionized water with a balance of 750. Stir the two evenly before use, and then mechanically disperse to obtain a colloidal mixture in which the abrasive is dispersed and suspended, and put it into a polishing pad mold. Since the particle size of micron-sized abrasives obeys the normal distribution, such as figure 1 As shown, the total weight of the nano-scale and micron-scale abrasives is about 12.5 grams each, and the particle diameters of the remaining 225 grams of abrasives after dispersion are all in the submicron order. Abrasive particles settle slowly, so the suspension will be clearly stratified after standing for 7-8 minutes, and the abrasive particles become larger from top to bottom, and the top layer is the deionized water layer. Feed liquid nitrogen into the liquid inlet 2 of the lower mold 1 until t...

Embodiment 3

[0049] A CMP frozen polishing pad for polishing superhard materials, made of 450 grams of micron SiC (or micron Cr 2 o 3、 SiO 2 、Al 2 o 3 , CeO 2 ) abrasive and deionized water with a balance of 550. Mix the two evenly before use, and then mechanically disperse to obtain a colloidal mixture in which the abrasive is dispersed and suspended, and put it into a polishing pad mold. Since the particle size of micron-sized abrasives obeys the normal distribution, such as figure 1 As shown, the settling speed of abrasive particles with large particle size is faster, and the settling speed of abrasive particles with small particle size is slower, so after standing for 7-8 minutes, the suspension will appear obvious stratification, and the abrasive particles will become larger from top to bottom. , wherein the total weight of nano-scale and micron-scale abrasives is about 36 grams each, and the remaining 378 grams of abrasives are dispersed in sub-micron size, and the top layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com