Pneumatic negative pressure chip removal double cooling system for deep hole machine tools

A pneumatic, dual-cooling technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of DF system accumulation of heat effect and affecting processing quality, etc., and achieve good chip removal ability and heat dissipation effect Excellent, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

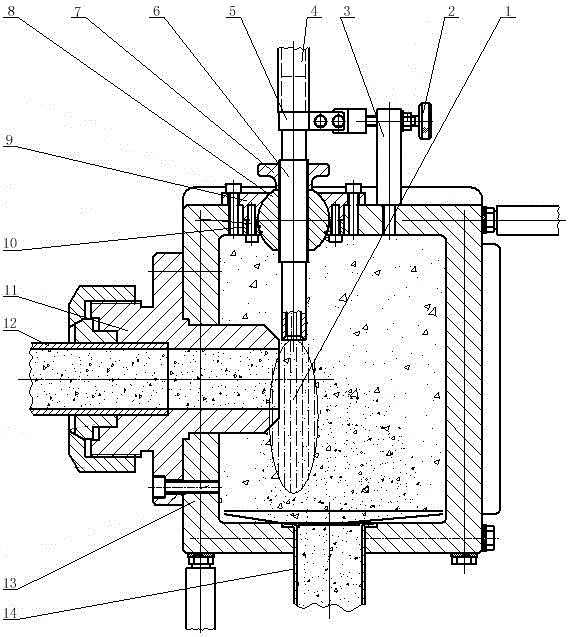

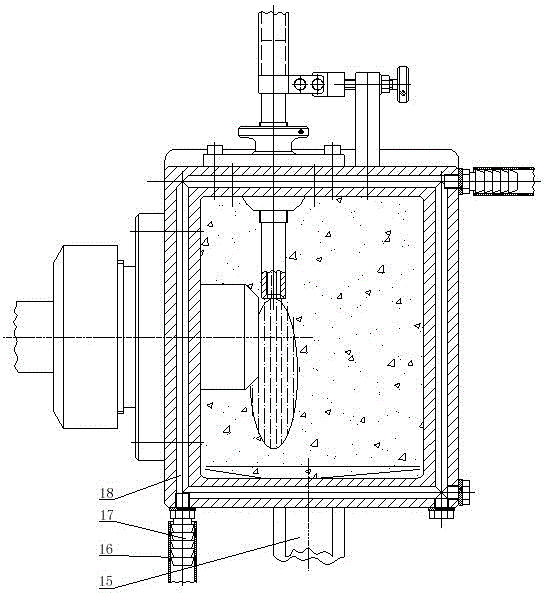

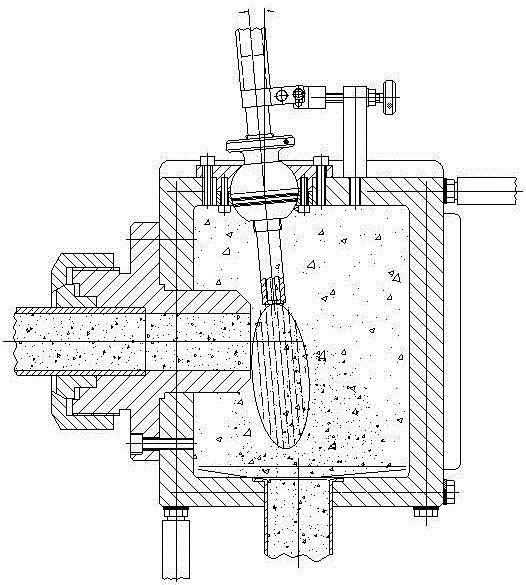

[0022] The invention has a pneumatic negative pressure chip extraction part, a water circulation part and a self-cooling negative pressure chip extraction box heat dissipation part.

[0023] Such as figure 1 As shown, the air-operated negative pressure chip extraction dual cooling system of the deep hole machine tool includes a self-cooling negative pressure chip extraction box 13 installed on the tool bar mounting base of the deep hole machine tool. The self-cooling negative pressure chip extraction box 13 is hollow inside. The outlet of the cutter bar mounting base 11 is set inside the self-cooling negative pressure chip extraction box 13, the bottom of the self-cooling negative pressure chip extraction box 13 is provided with a large-diameter pressure relief port 14, and the top is provided with an air guide tube 4, the inlet of the air guide tube 4 The end is connected with the air compression pump, and the outlet end of the air guide pipe 4 is arranged at the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com