Central water outlet scrap crushing water nozzle for numerical control lathe

A central water outlet, CNC lathe technology, applied in the field of CNC lathes, can solve problems such as the inability to flush out iron chips, and achieve the effects of improving chip removal ability, ensuring processing accuracy and processing efficiency, and scientific and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

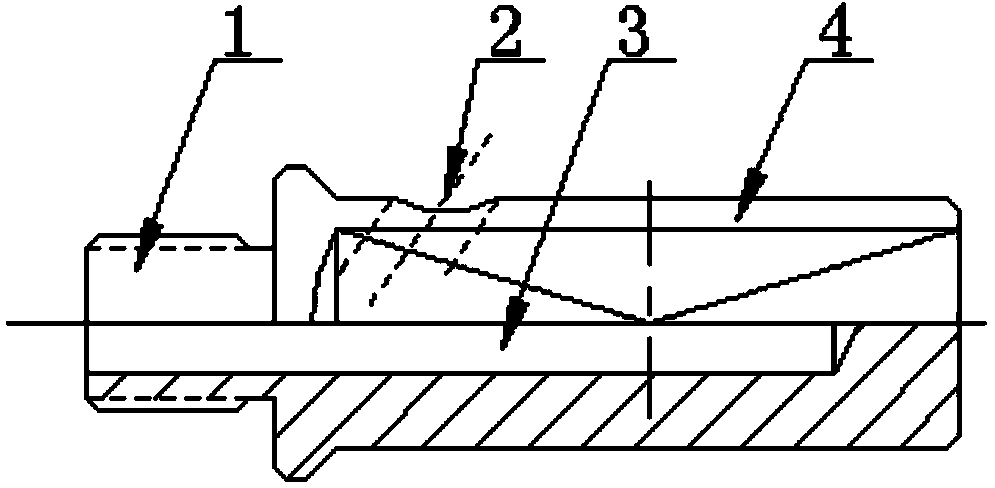

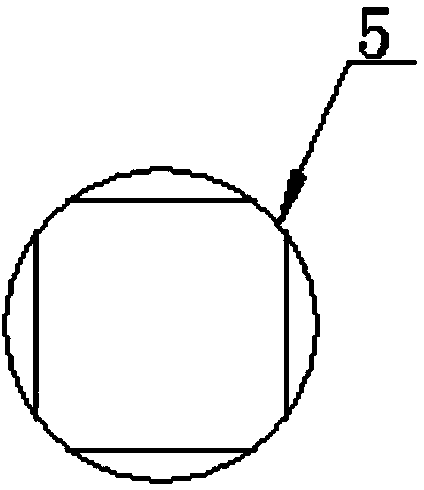

[0013] A kind of numerically controlled lathe center water outlet chip water nozzle, is made up of water nozzle installation handle 1 and water nozzle main body 4, and water nozzle installation handle and water nozzle main axis part are formed with central water inlet channel 3, and water nozzle main body is made There is a water outlet inclined hole 2 communicating with the central water inlet channel, and its innovation is that the shape of the main body of the water nozzle is a square cylinder. Chamfers 5 are formed on the four edges of the square cylinder.

[0014] Since the main body of the water nozzle is a square cylinder, during the relative rotation of the water nozzle and the workpiece, the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com