Steel crushing device

A crushing device and steel technology, applied in grain processing, spring/shock absorber, vibration suppression adjustment, etc., can solve problems such as machine loosening, surrounding building damage, production safety issues, etc., to reduce vibration amplitude, reduce noise, The effect of protecting and stabilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

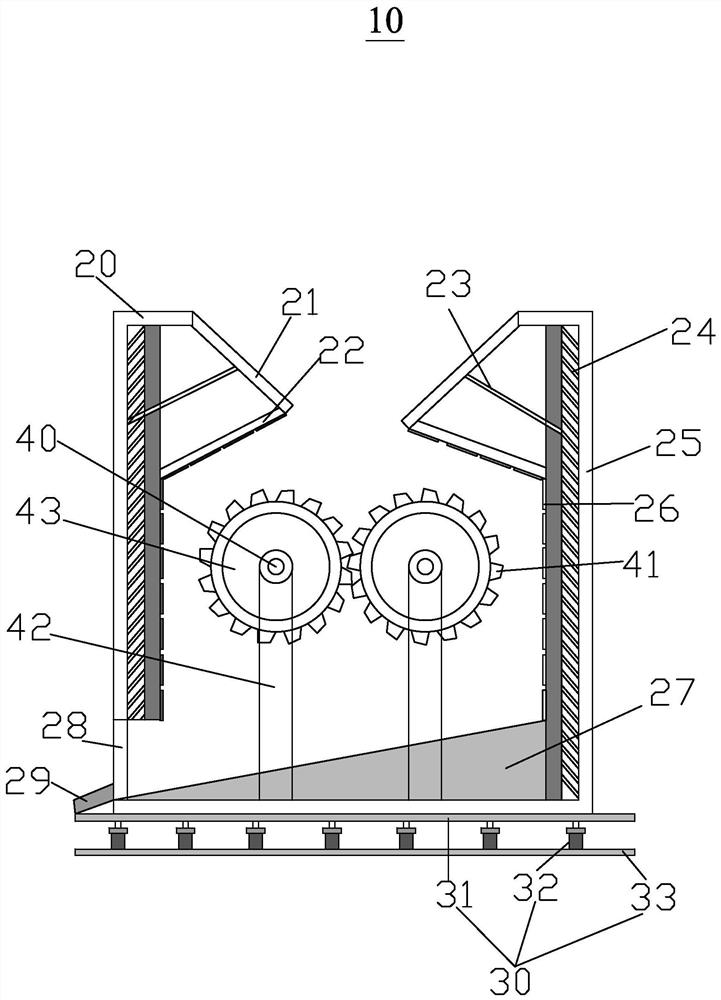

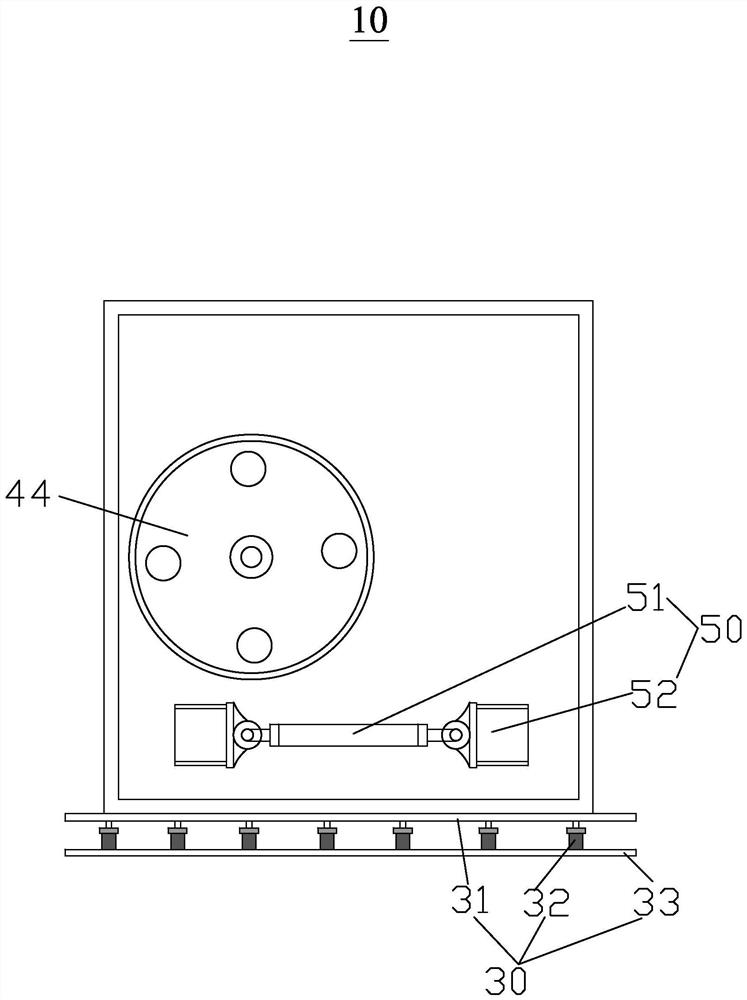

[0017] Through the following examples, combined with the attached figure 1 And attached figure 2 , further specifying the technical characteristics of the present invention.

[0018] A steel crushing device 10, comprising a cutting mechanism 40 inside the machine, a crusher frame 20 and an elastic shockproof structure 30 at the bottom; the cutting mechanism 40 includes two cutting wheels 43, the surface of the cutting wheels is provided with a cutting piece 41, and the two cutting wheels The end of the bearing is provided with a support rod 42; the crusher frame 20 includes a feed inlet slide plate 21, a feed inlet slide plate support rod 23, an anti-rebound plate 22, a shock absorbing layer 24, a slope 27, a discharge port 28 and an outer steel plate layer 25. The bottom elastic damping structure 30 includes three parts, the upper support plate 31, the lower support plate 33 and the middle spring vibration isolator 32; the outside of the crusher is provided with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com