Patents

Literature

33results about How to "Broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

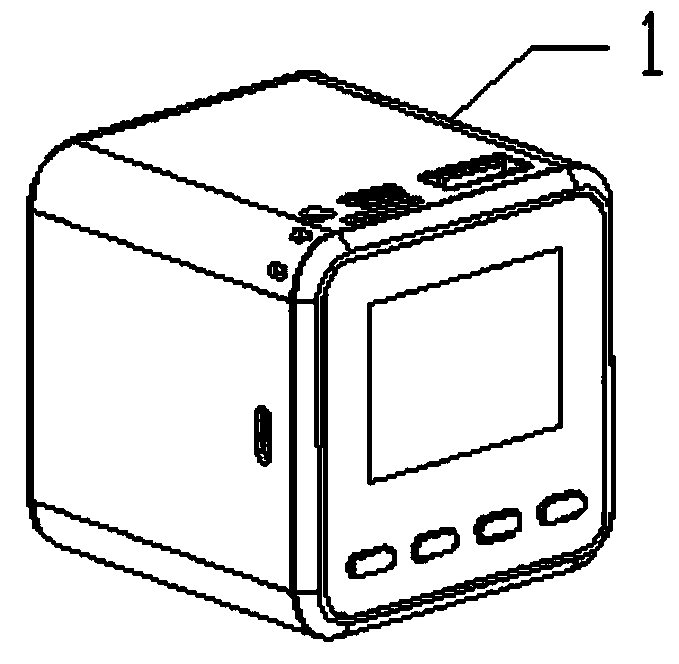

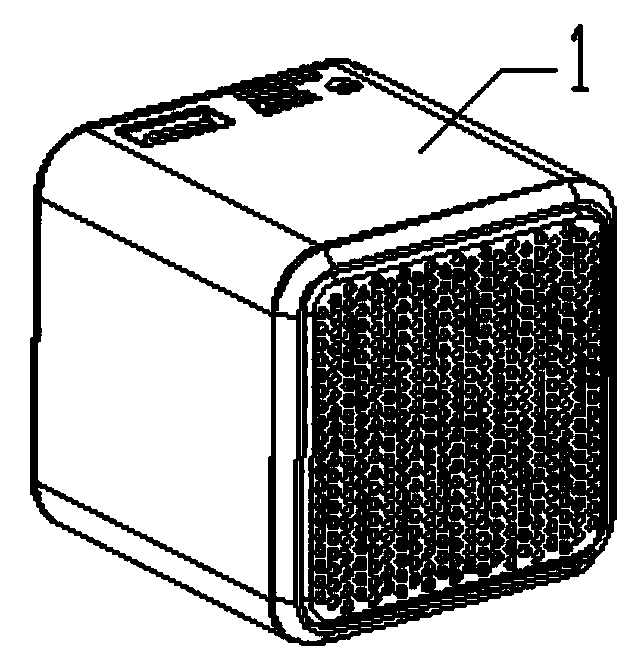

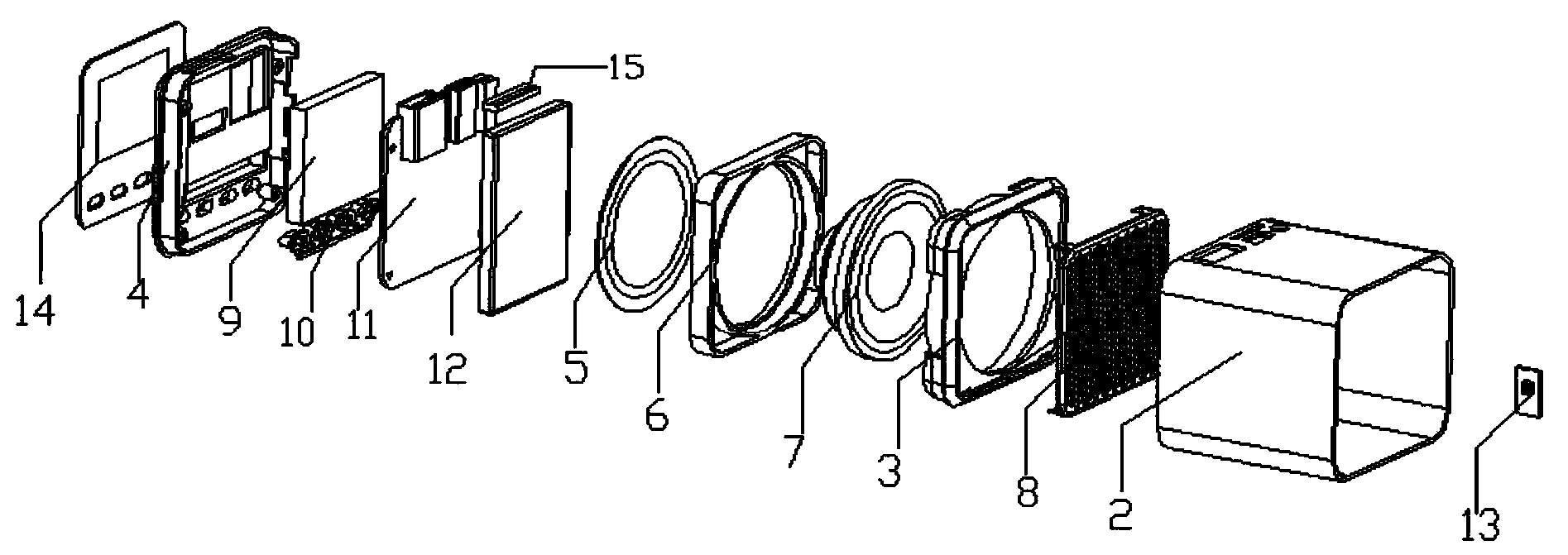

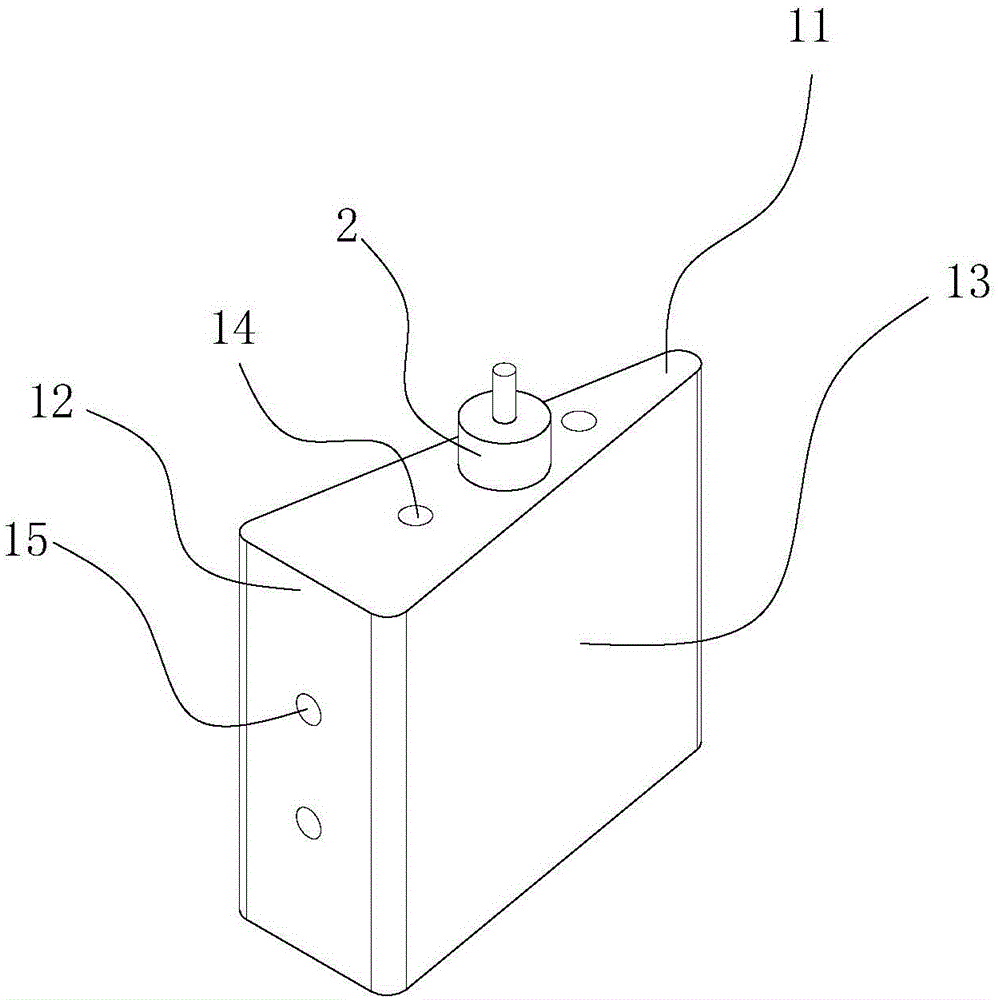

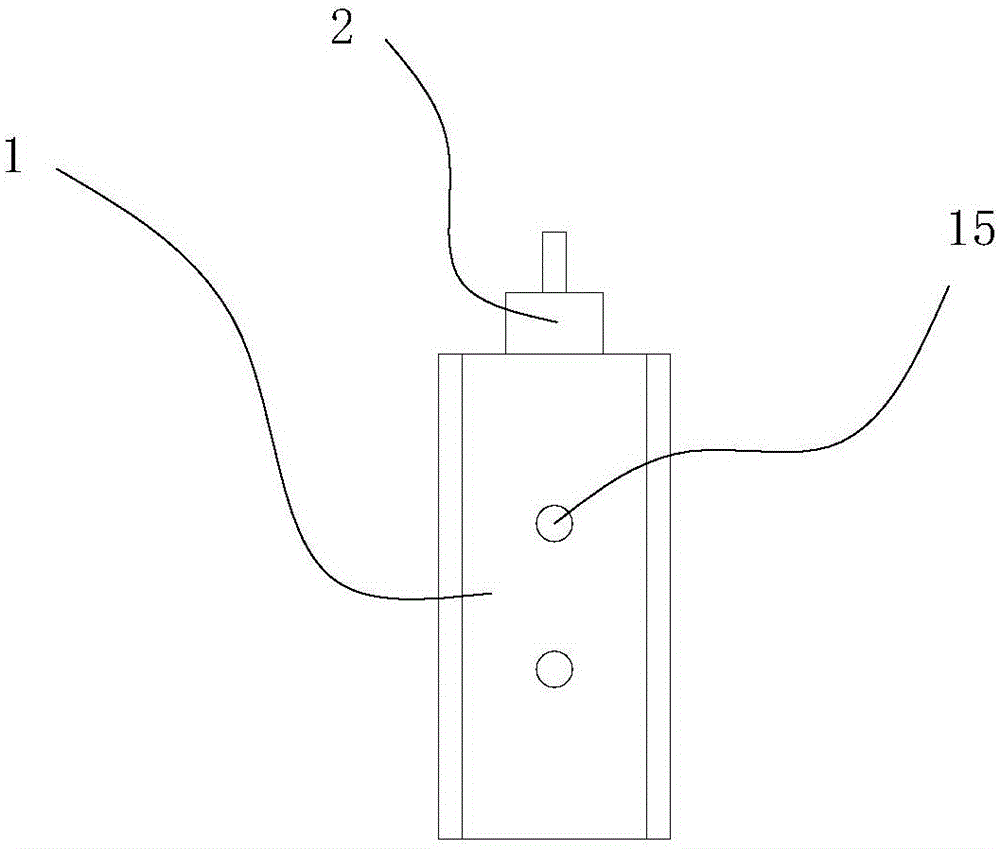

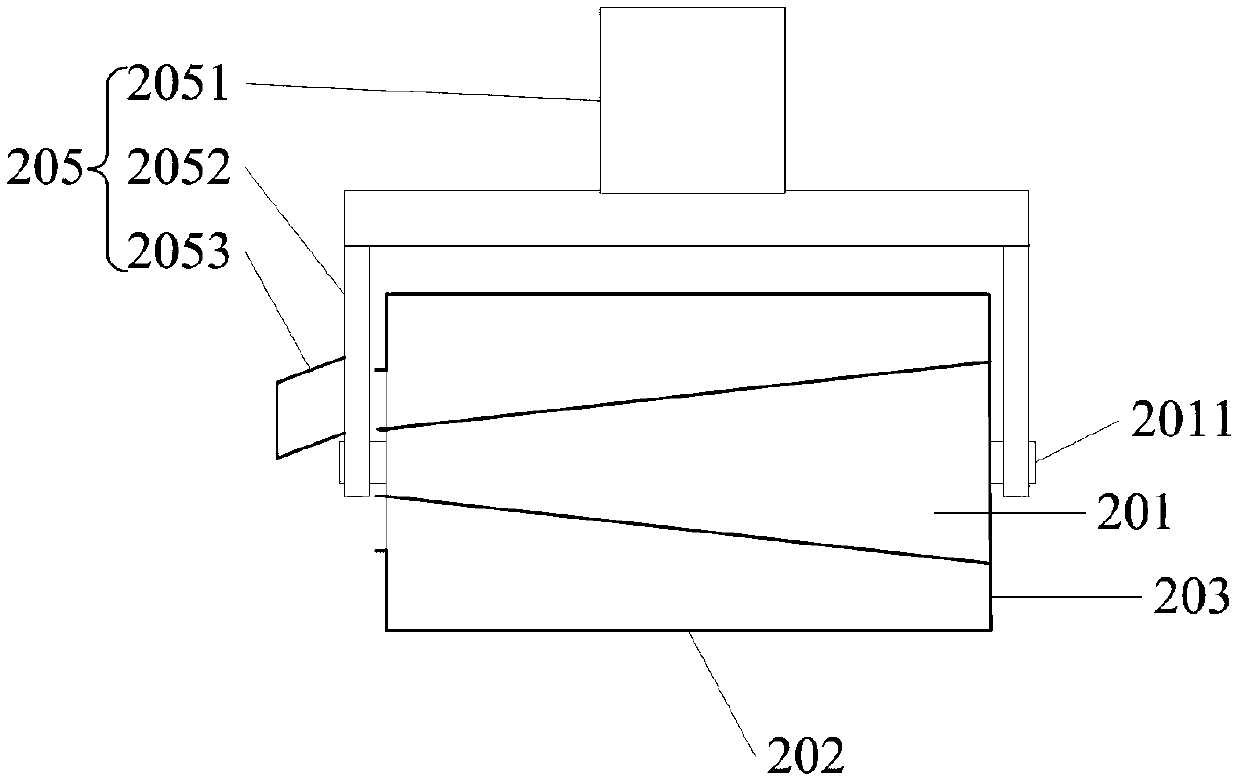

Miniature sound box

The invention discloses a miniature sound box. The miniature sound box comprises a face shell, a display screen and a lens, wherein the display screen is fixed to the face shell and is flush with the face shell, and the lens is matched with the display screen in shape. A sunken lens containing table which is matched with the lens in shape is arranged on the face shell, and the lens is fixed to the inner portion of the lens containing table through glue. Due to the fact that the lens is arranged on the display screen, namely, a protection film is installed on the display screen, a user or other objects cannot directly make contact with the display screen. Therefore, the display screen cannot be scratched or crushed.

Owner:刘骏涛

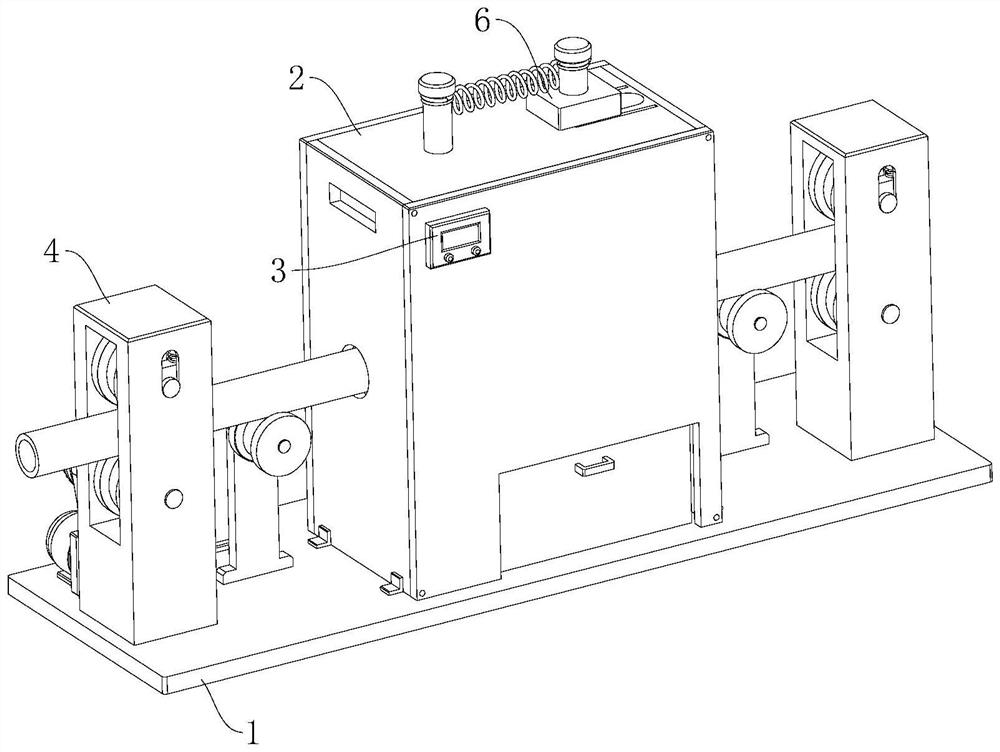

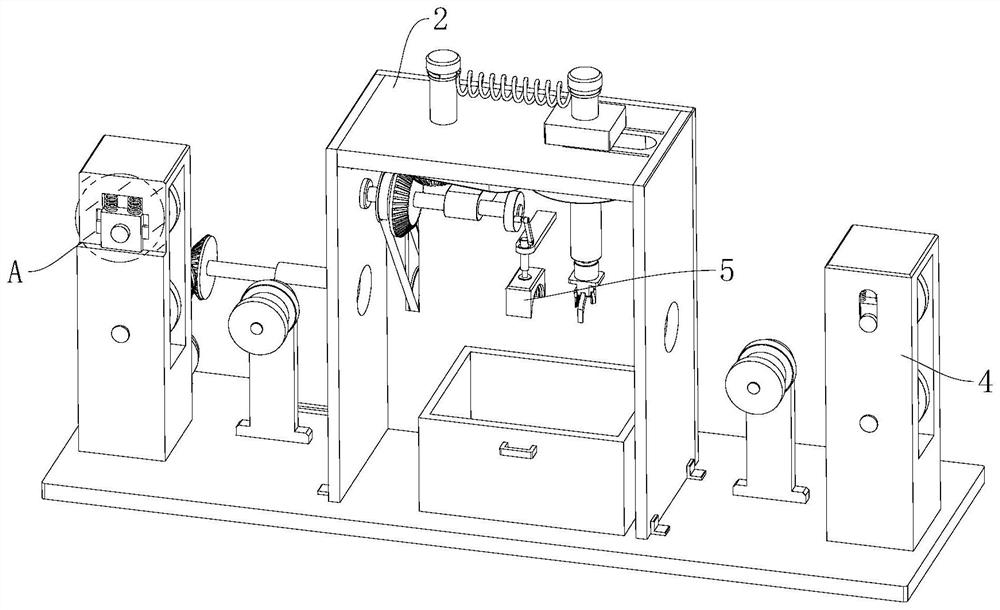

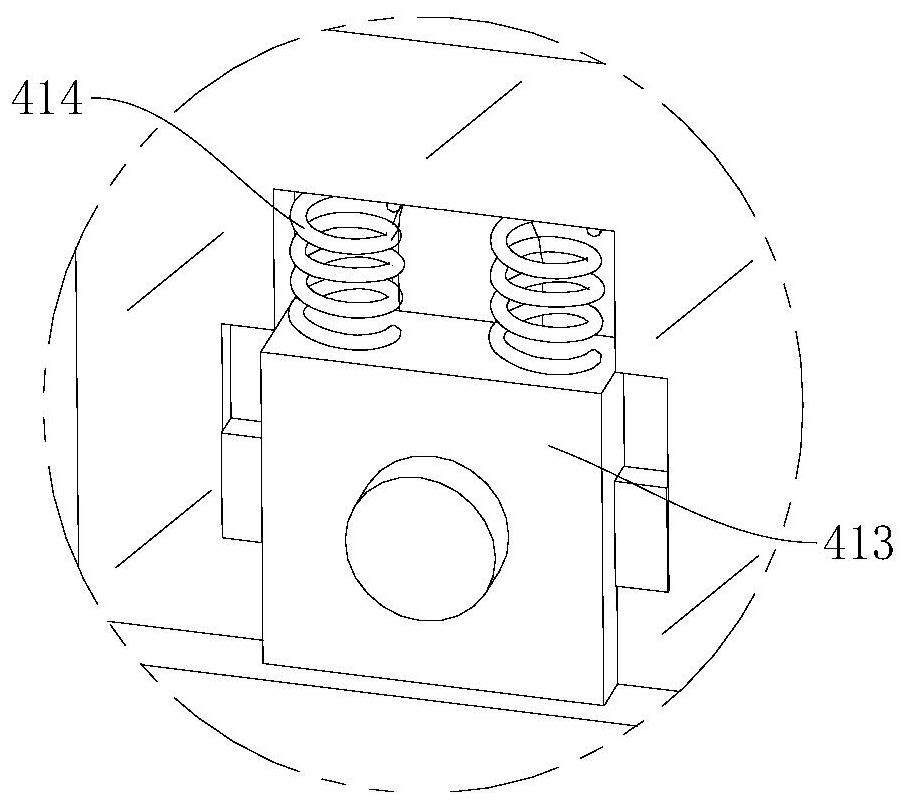

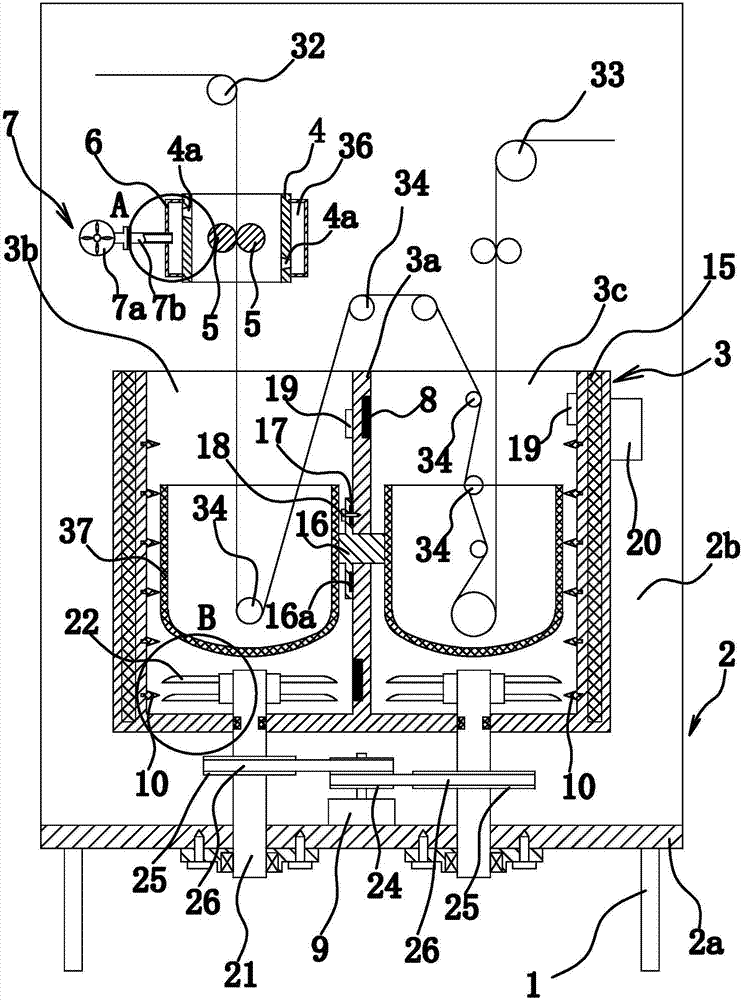

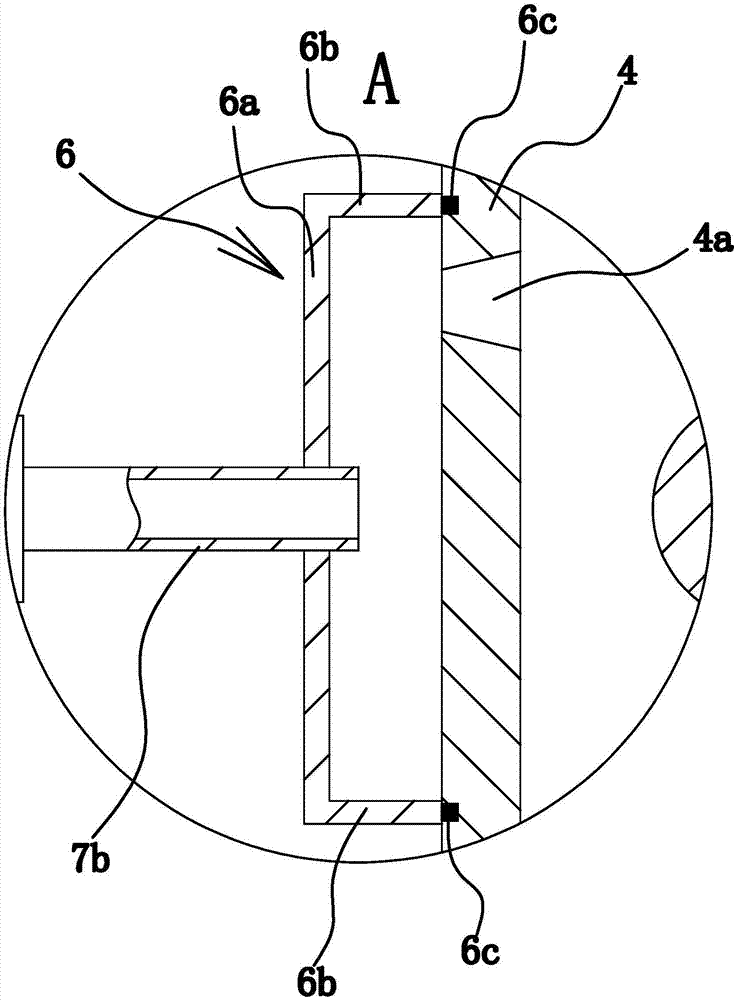

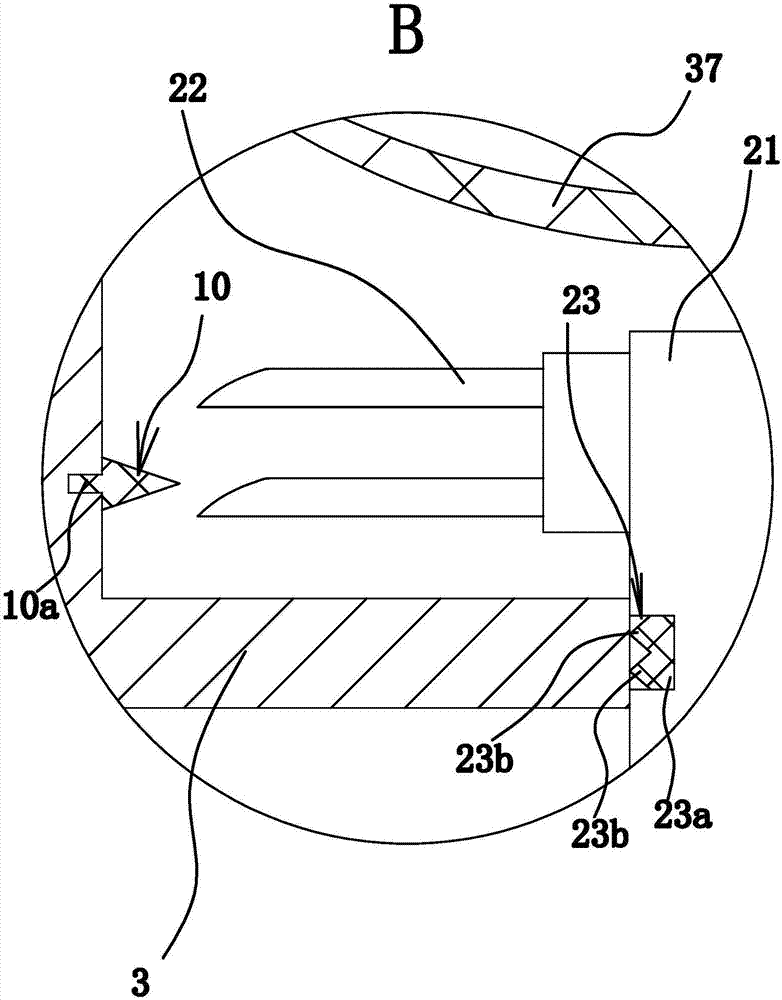

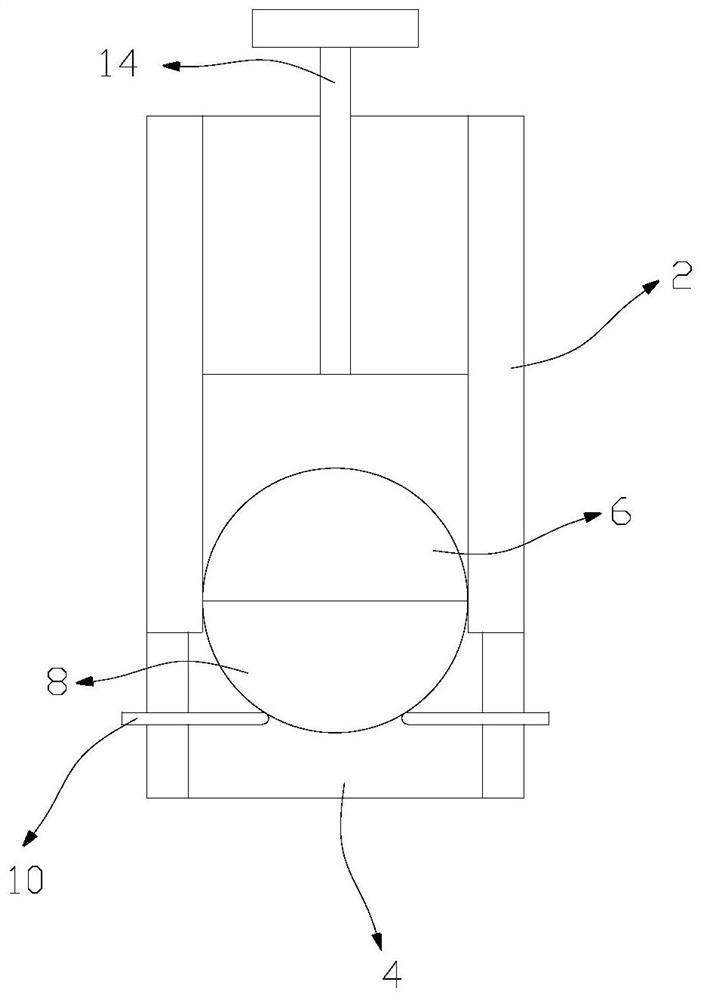

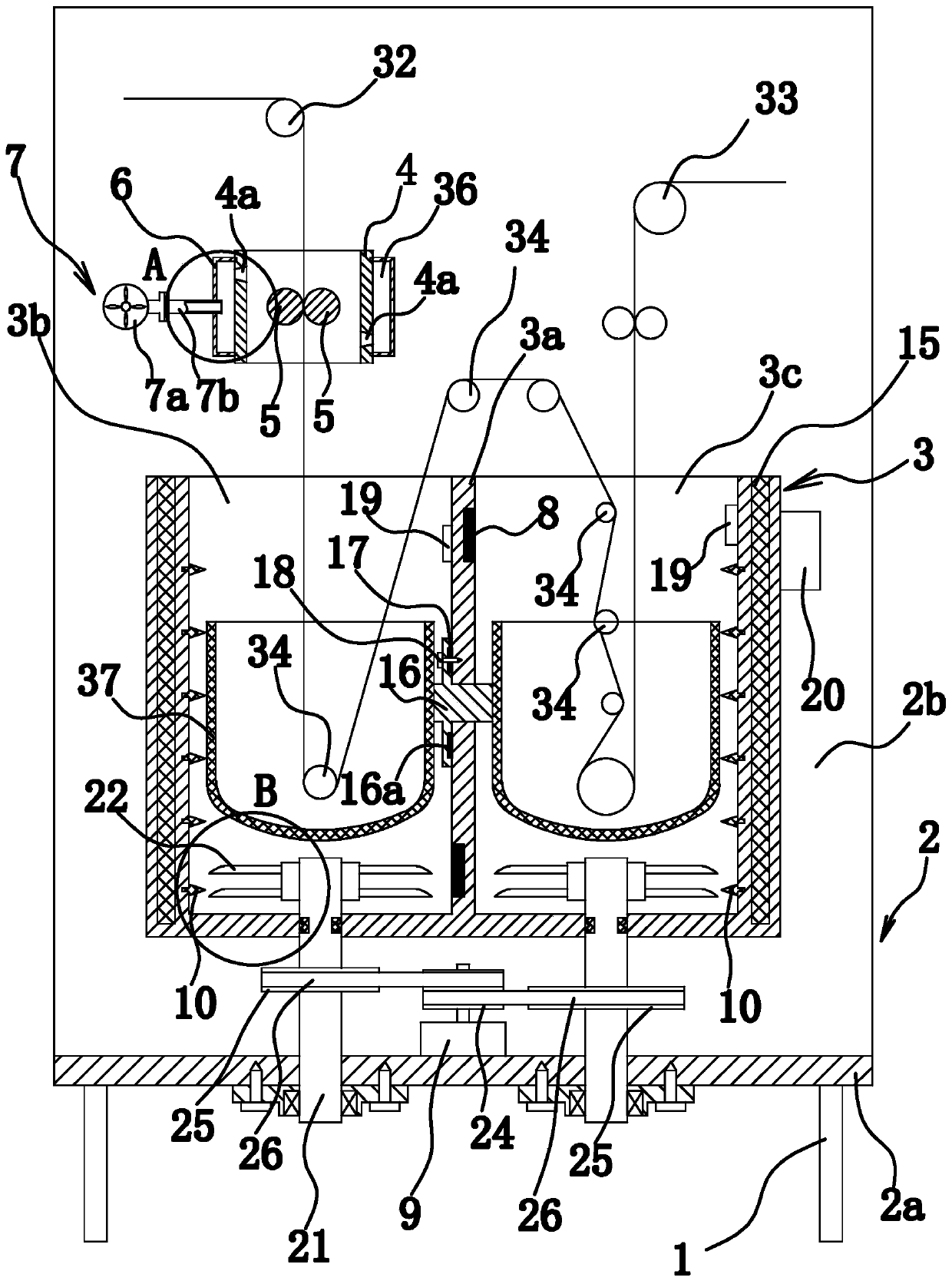

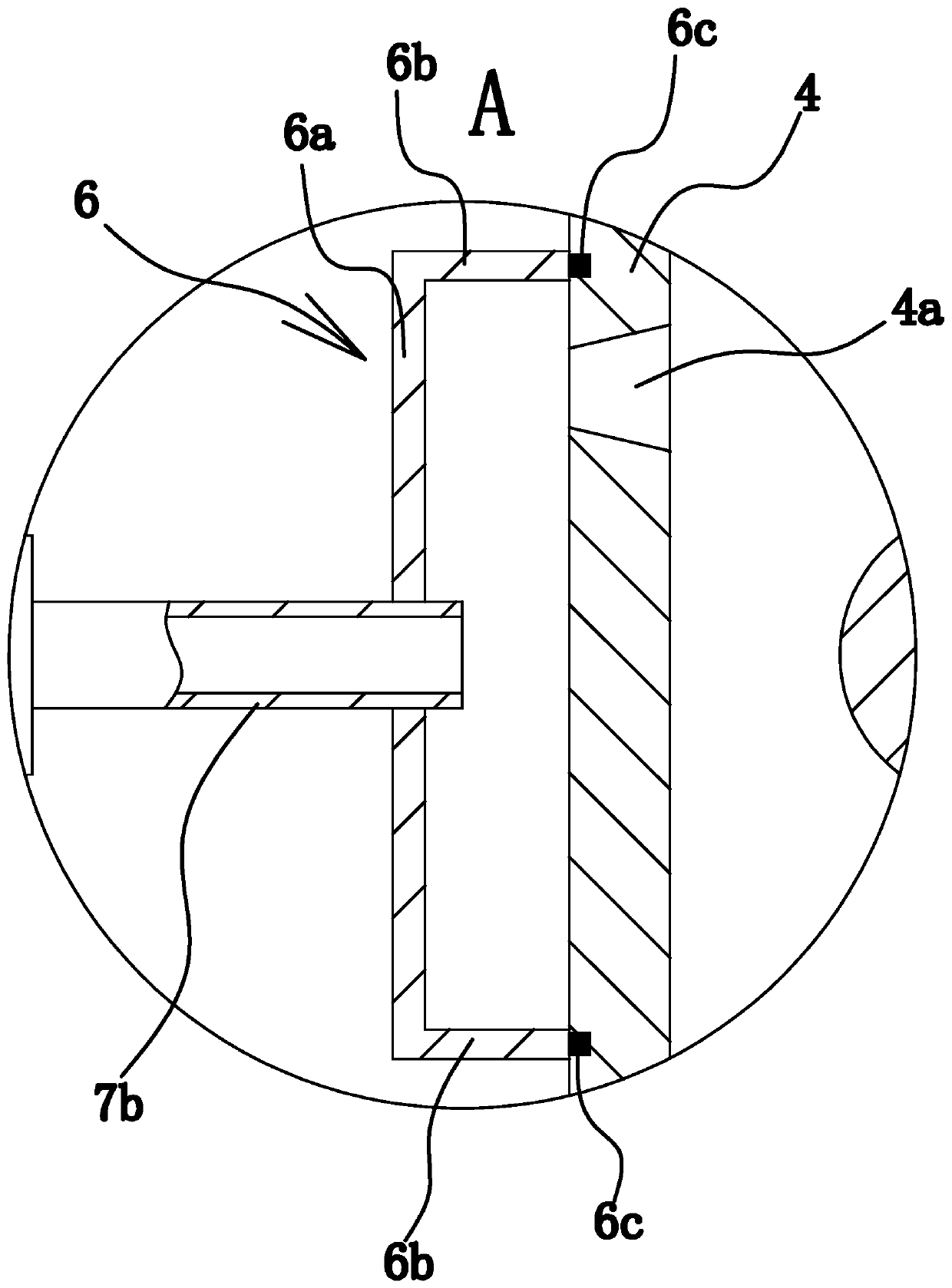

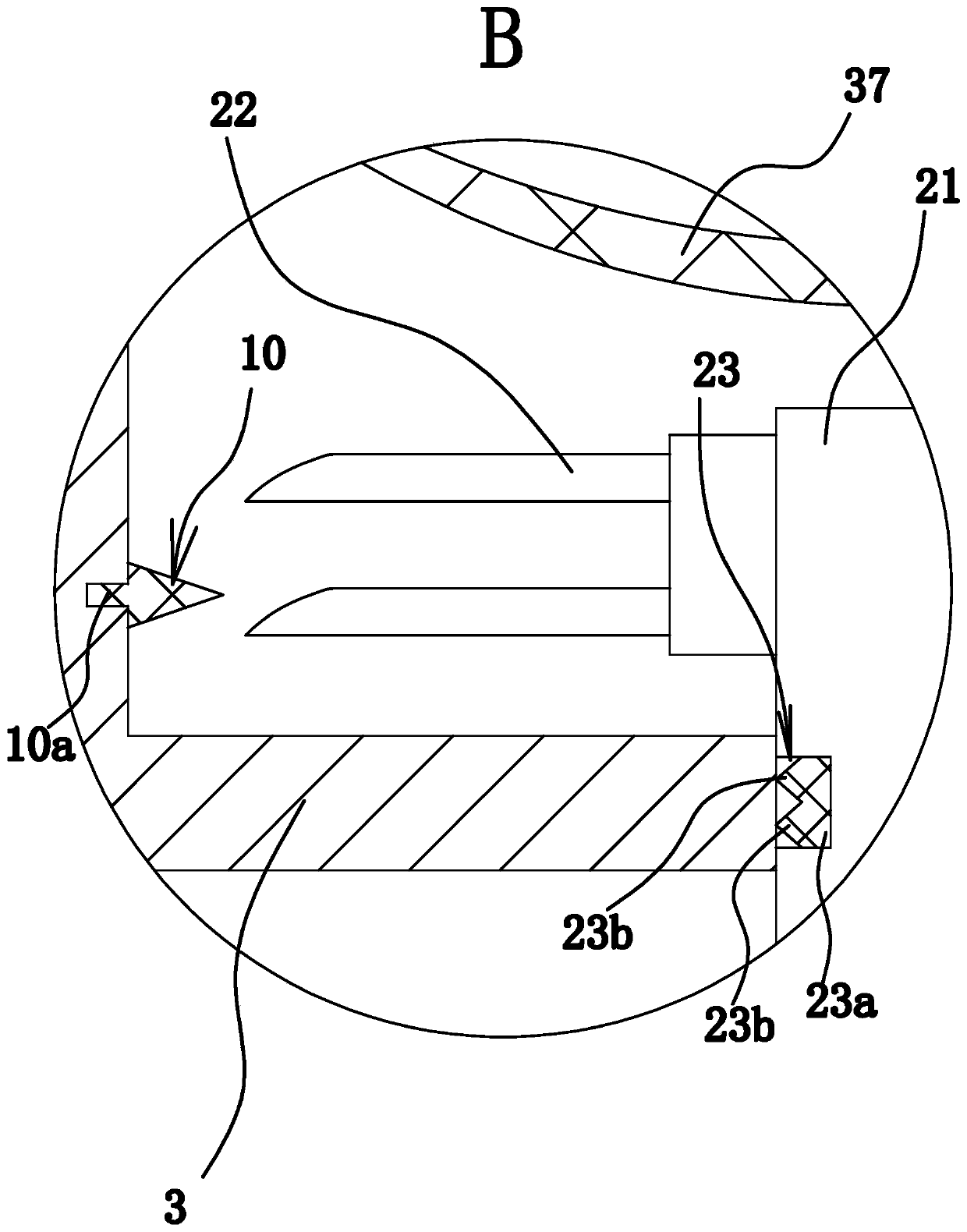

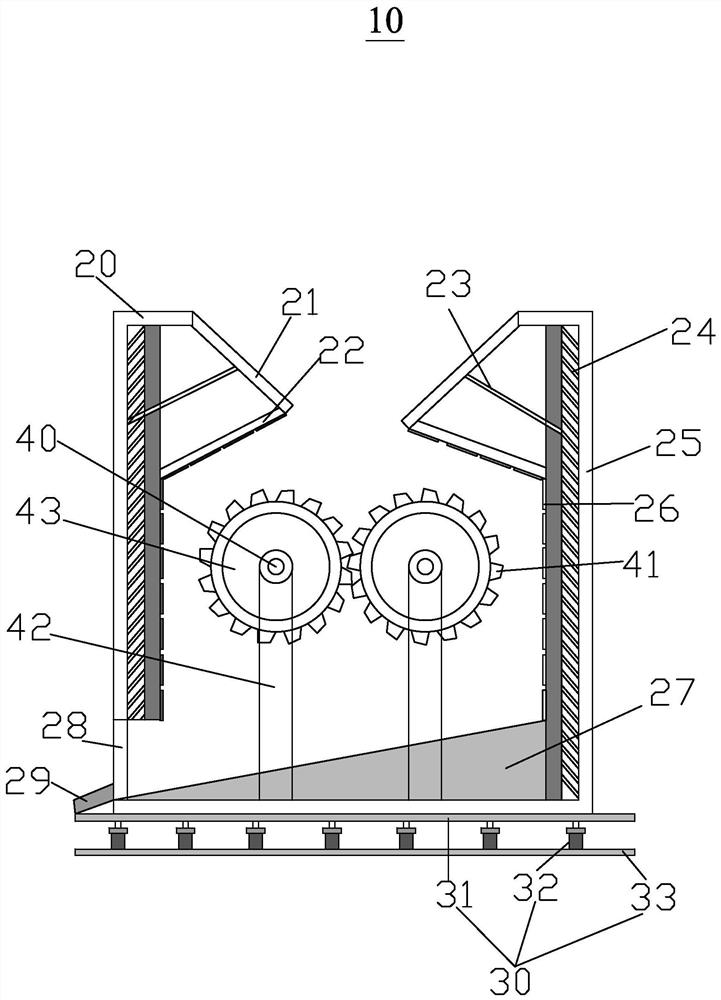

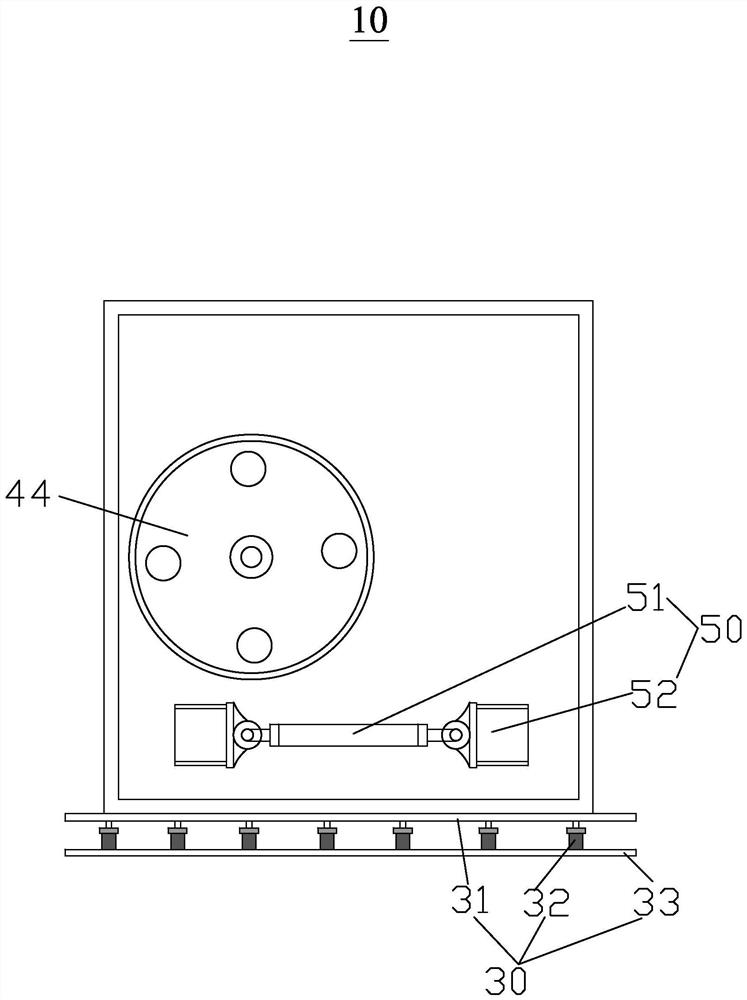

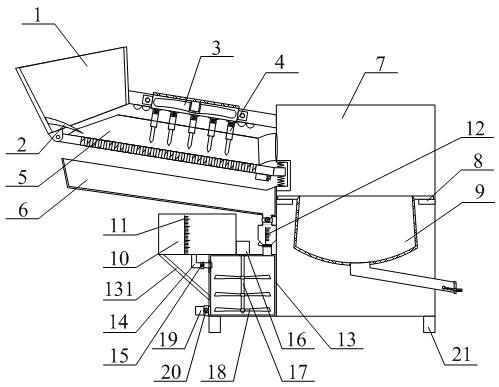

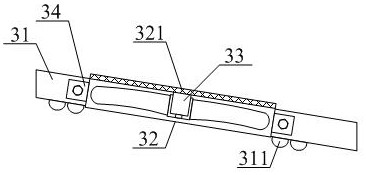

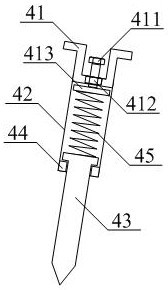

Construction site steel pipe surface cleaning equipment

ActiveCN112354979AReduce labor intensityReduce cleanup stepsHollow article cleaningDirt cleaningSurface cleaningPipe

The invention relates to the field of cleaning devices, in particular to construction site steel pipe surface cleaning equipment. The equipment comprises a base and a cleaning box and further comprises a controller, a conveying mechanism, a beating mechanism and a scraping mechanism. The conveying mechanism is arranged at the top of the base to be used for conveying steel pipes and comprises a transmission assembly and two conveying tables. The beating mechanism is arranged at the top of the inner side of the cleaning box and used for beating the steel pipes, the beating mechanism comprises ahammer head and a rotating assembly, the scraping mechanism is arranged at the top of the inner side of the cleaning box and used for scraping impurities such as concrete on the surfaces of the steelpipes, the scraping mechanism comprises a scraping head, a pushing assembly and a limiting assembly, and the transmission assembly is electrically connected with the controller. According to the construction site steel pipe surface cleaning equipment, manpower is automatically replaced, the cleaning efficiency is high, the labor intensity is low, the noise is low, meanwhile, the power consumptionis low, the cleaning cost can be reduced, the cleaned impurities can be effectively collected, and pollution is avoided.

Owner:巢湖市鼎力铁塔有限公司

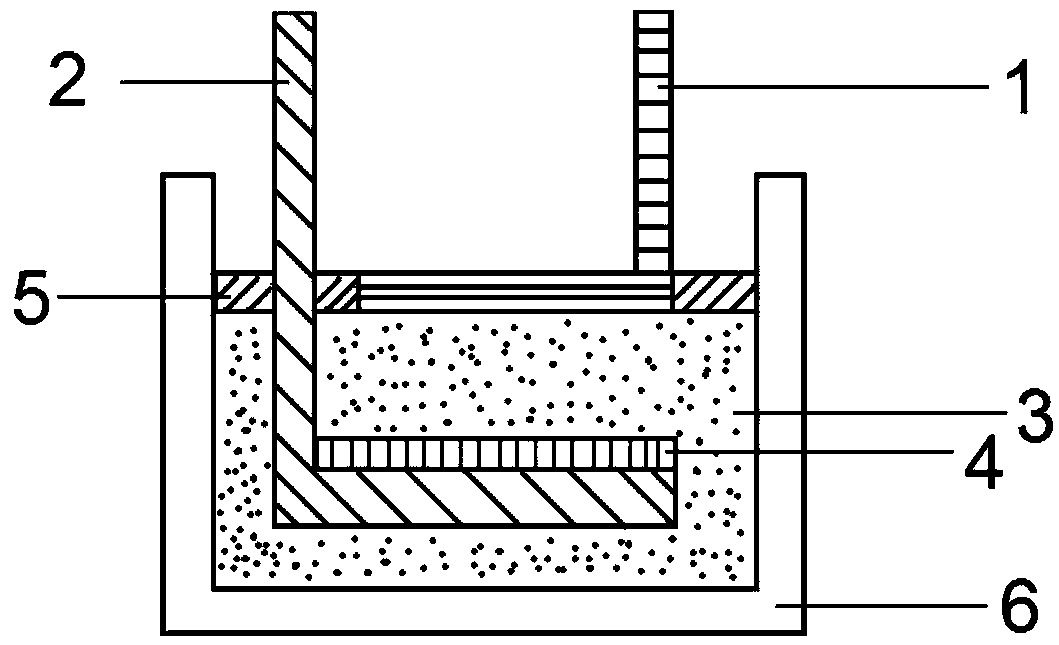

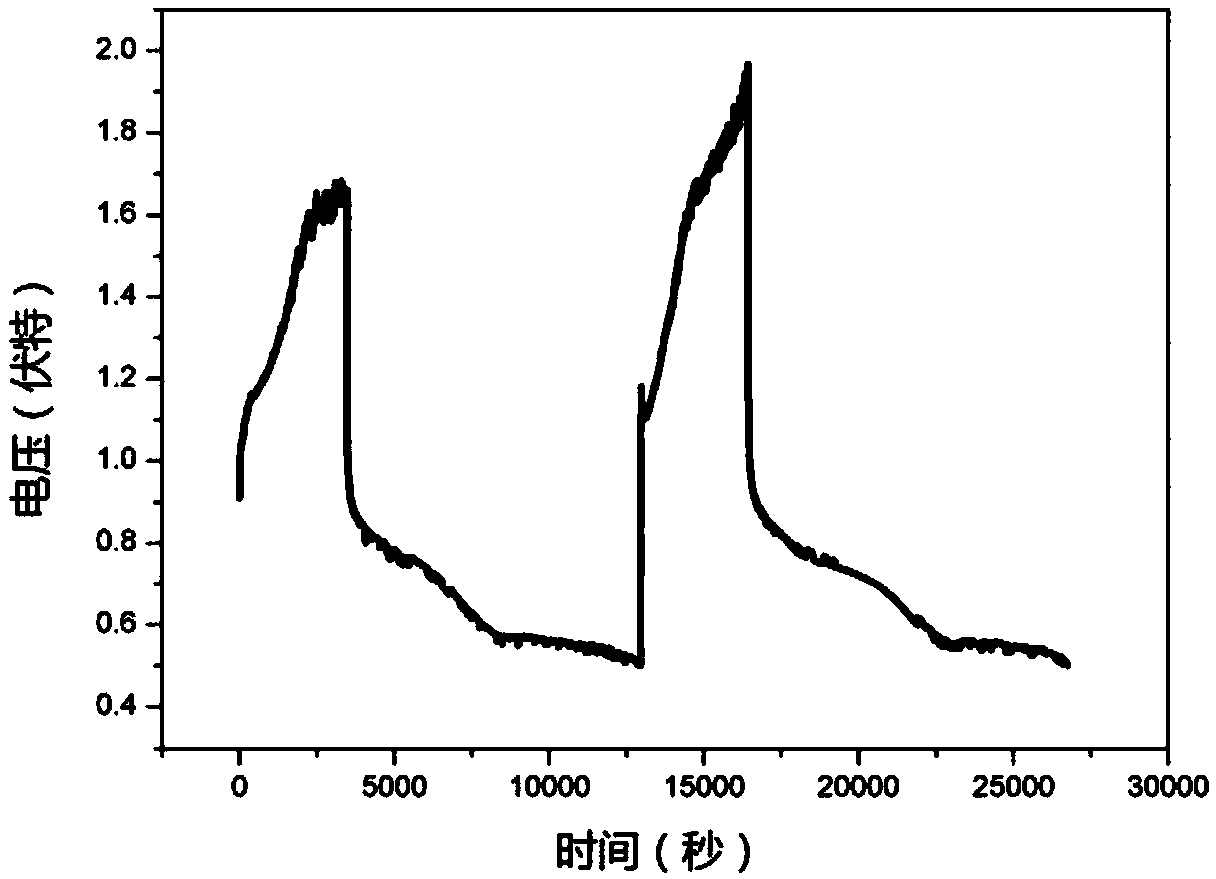

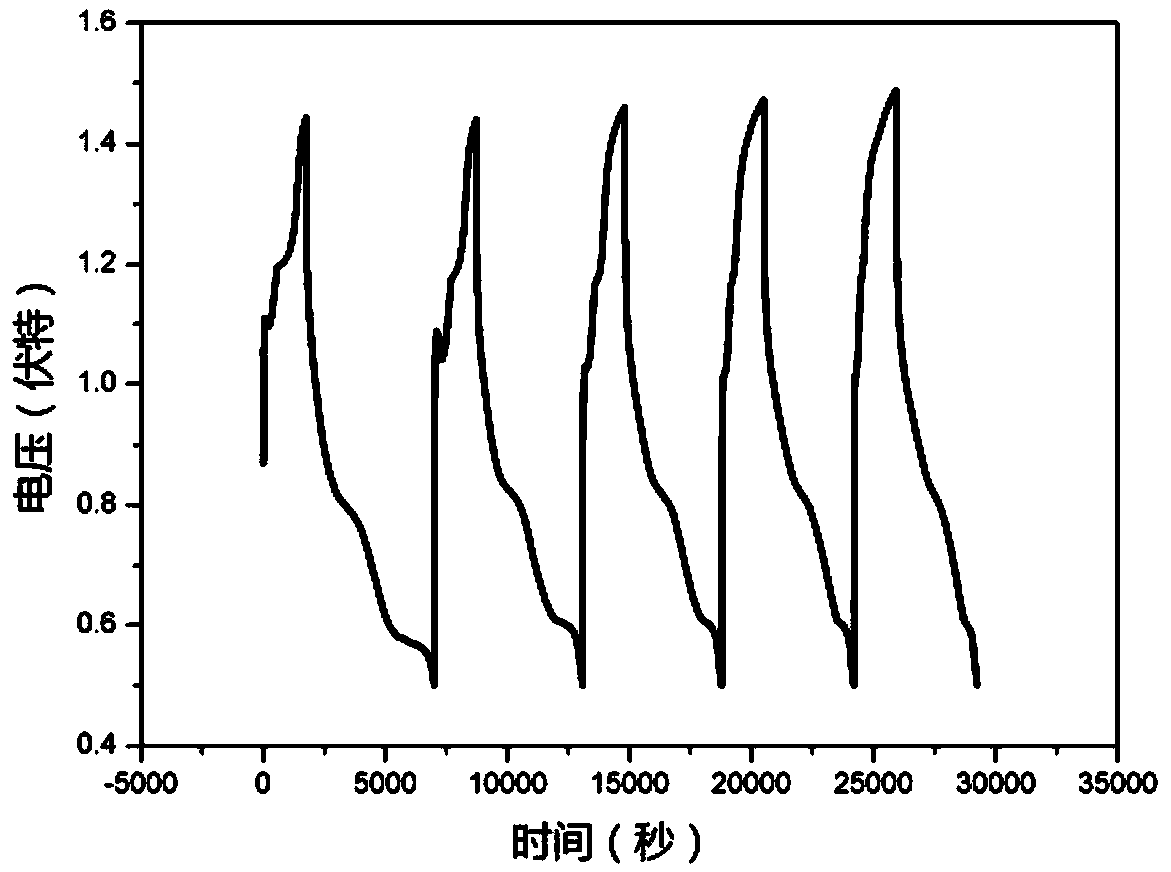

High-temperature fused salt battery

The invention relates to a high-temperature fused salt battery which comprises a positive pole, pasty dual electrolyte and a negative pole, wherein the positive pole is exposed in air, the pasty dualelectrolyte is prepared from fused salt and solid electrolyte powder by mixing, the fused salt is potassium carbonate and / or sodium carbonate, the solid electrolyte powder is zirconium oxide micron powder containing yttrium oxide, and the negative pole is separated from the positive pole by the pasty dual electrolyte. The high-temperature fused salt battery disclosed by the invention is a high-temperature fused salt battery which can be applied to large-scale power grid energy storage and is based on the fused salt and the solid electrolyte powder material. The pasty dual electrolyte disclosedby the invention can be easily prepared from the fused salt and the solid electrolyte powder through direct mixing, so that the pasty dual electrolyte has the advantages of higher oxygen ion conductivity, lower fluidity and good filling ability; furthermore, the short circuit and open circuit phenomena between the positive pole and the negative pole of the battery are effectively avoided, circular charge-discharge property of the battery is remarkably improved, and the processing manufacturing cost of the high-temperature fused salt battery is obviously reduced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

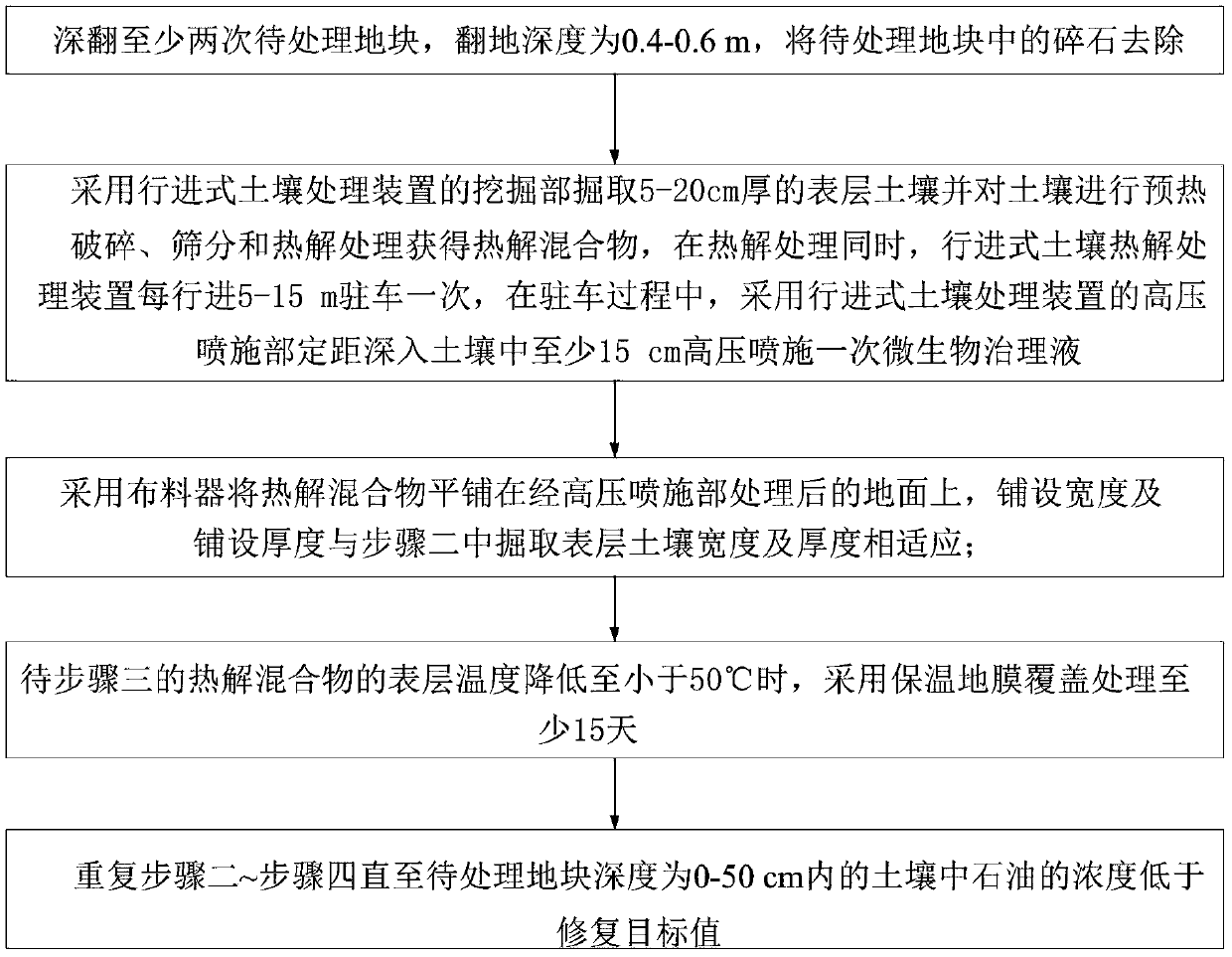

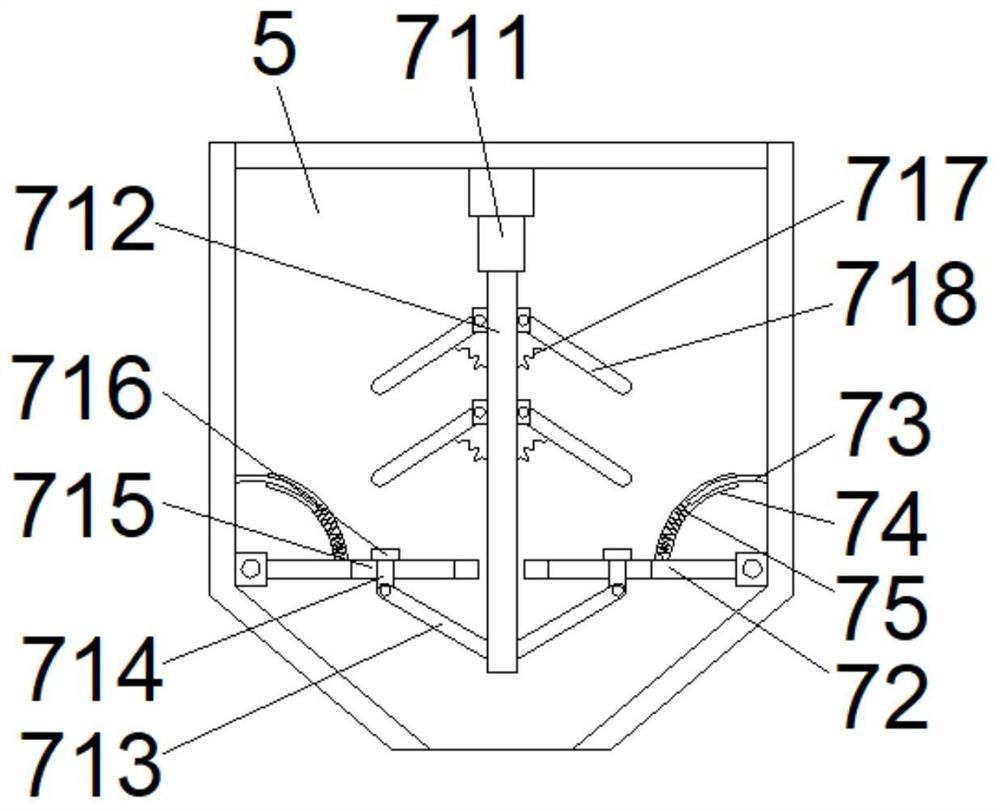

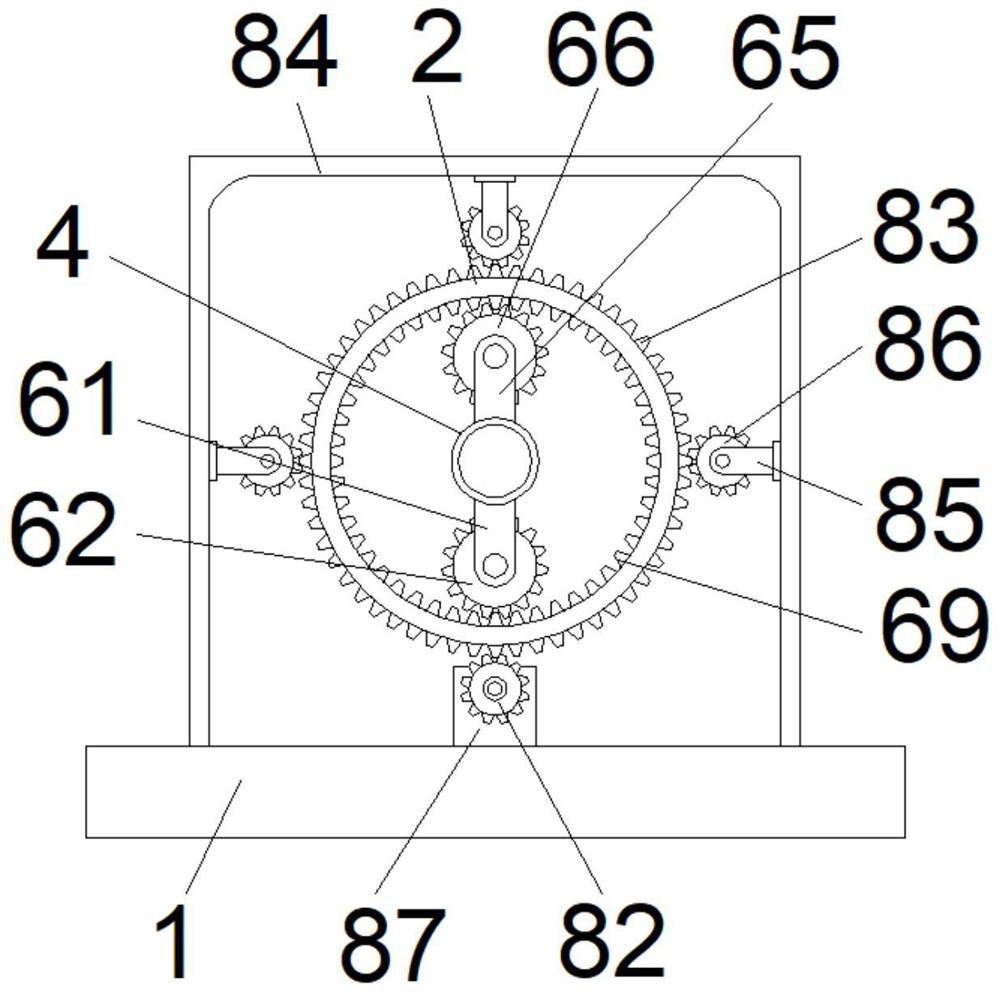

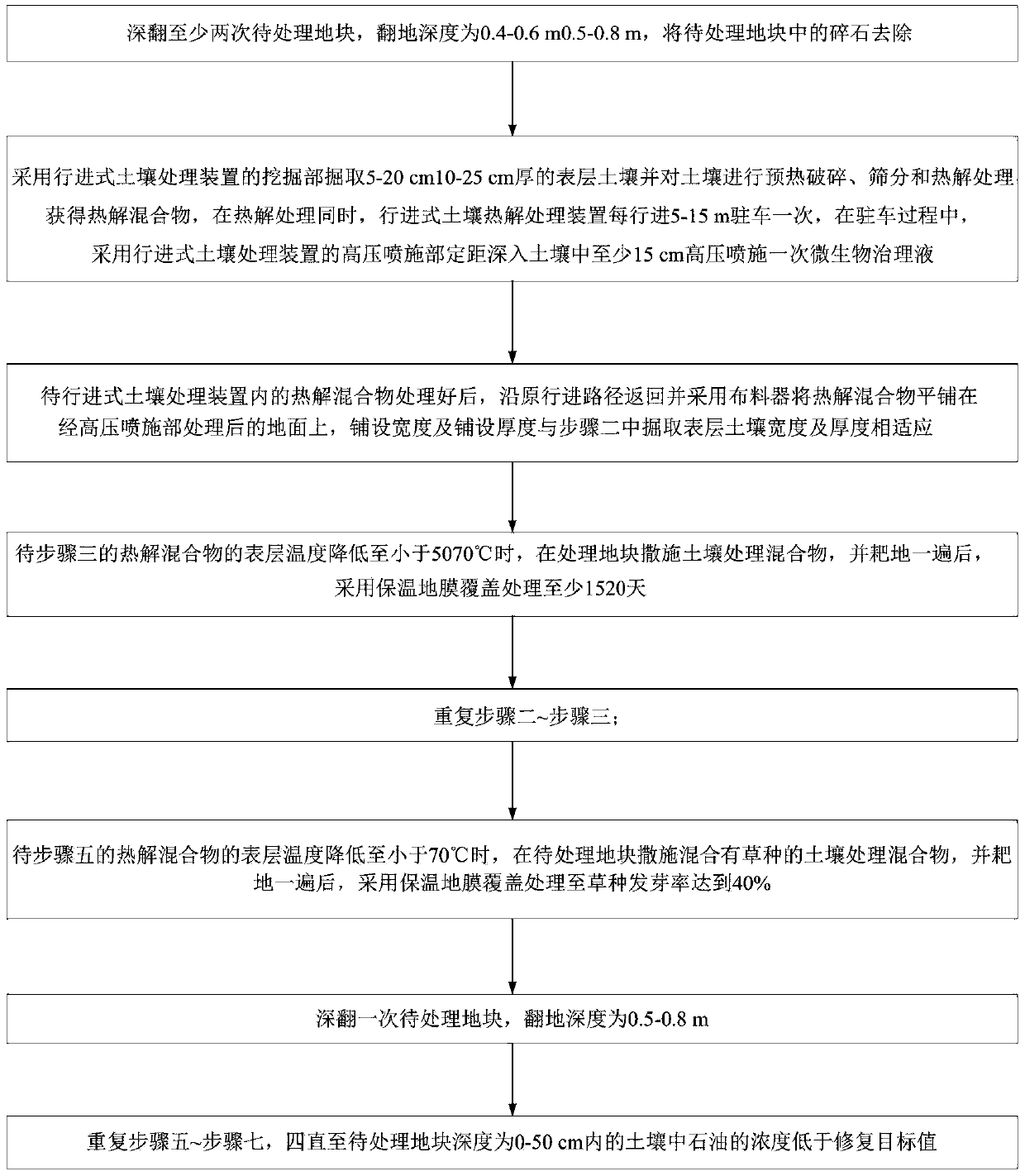

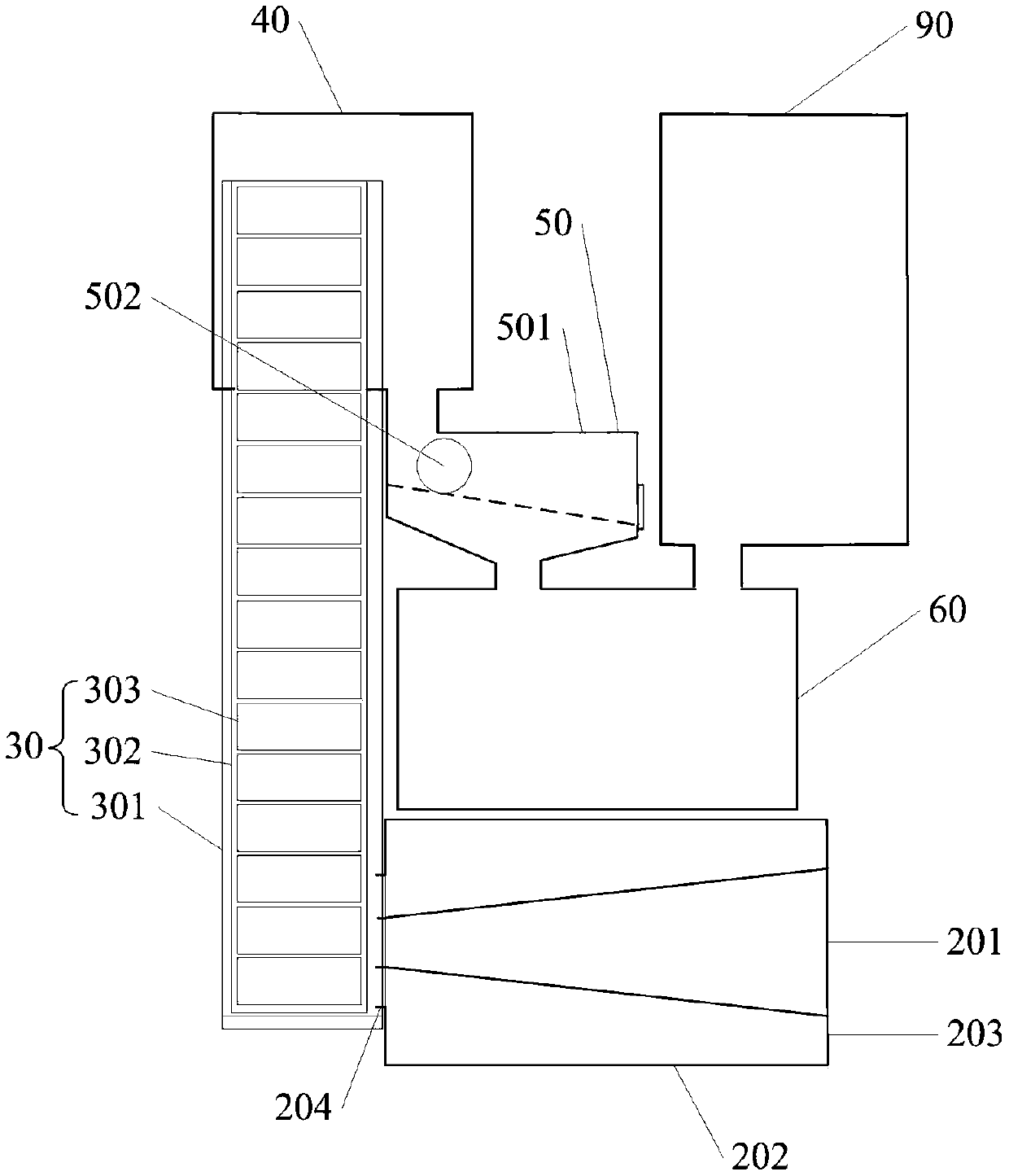

In-situ remediation method for petroleum-contaminated soil

InactiveCN111495955AImprove the effectImprove governance effectContaminated soil reclamationContaminated soilsSheet mulching

The invention discloses an in-situ remediation method for petroleum-contaminated soil. The in-situ remediation method comprises the following steps: 1, deeply ploughing a to-be-treated land parcel forat least two times, and removing gravels in the to-be-treated land parcel; 2, digging surface soil, carrying out pyrolysis treatment on the soil to obtain a pyrolysis mixture, and simultaneously carrying out fixed-distance deep soil high-pressure spraying once by adopting a high-pressure spraying part of an advancing type soil treatment device while carrying out pyrolysis treatment; 3, flatly laying the pyrolysis mixture on the ground treated by the high-pressure spraying through a distributing device; 4, when the surface layer temperature of the pyrolysis mixture in step 3 is reduced to be lower than 50 DEG C, carrying out heat preservation plastic film mulching treatment for at least 15 days; and 5, repeating steps 2-4 until the concentration of petroleum in the soil with the depth of 0-50 cm of the to-be-treated land parcel is lower than a restoration target value. According to the in-situ remediation method for the petroleum-contaminated soil, a physical method and a biological method can be combined to carry out layered treatment on the petroleum-contaminated soil, so the treatment effect is effectively improved.

Owner:尤宝旺

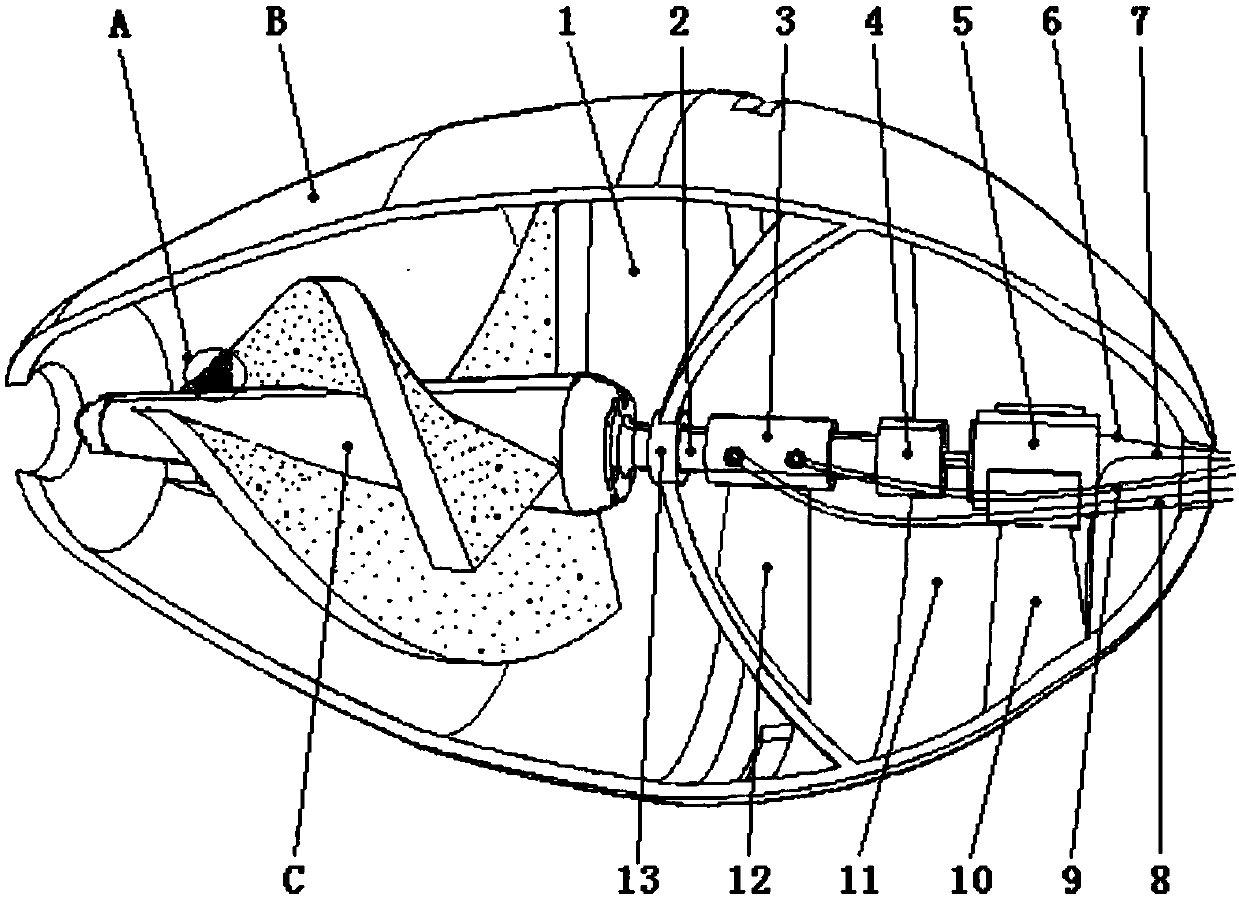

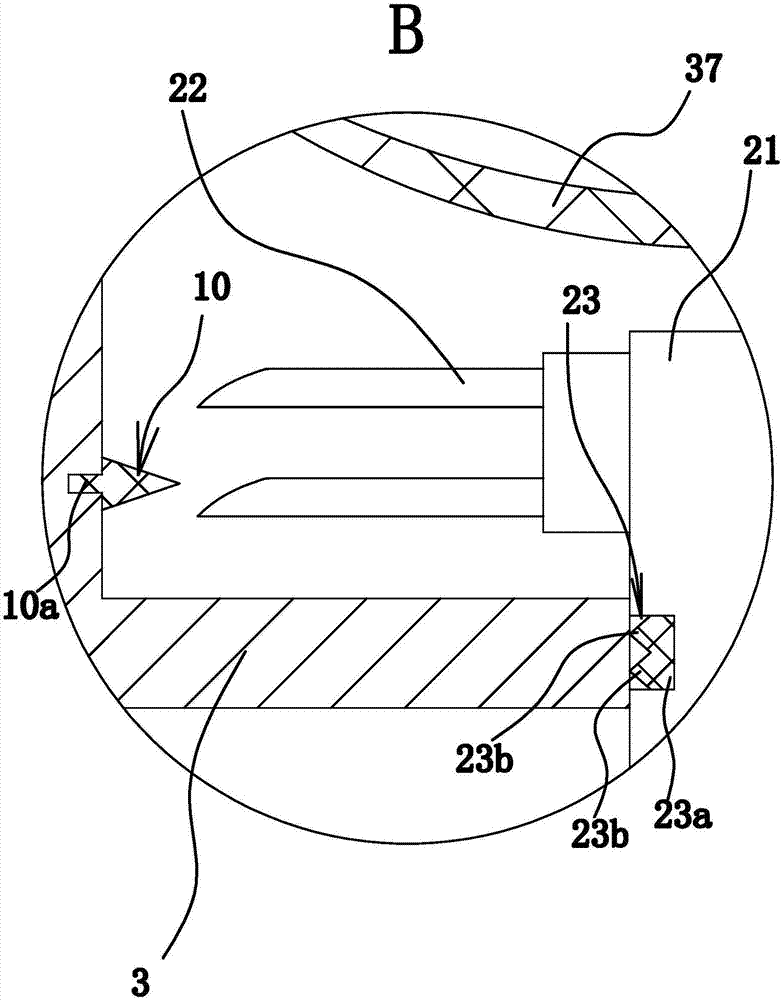

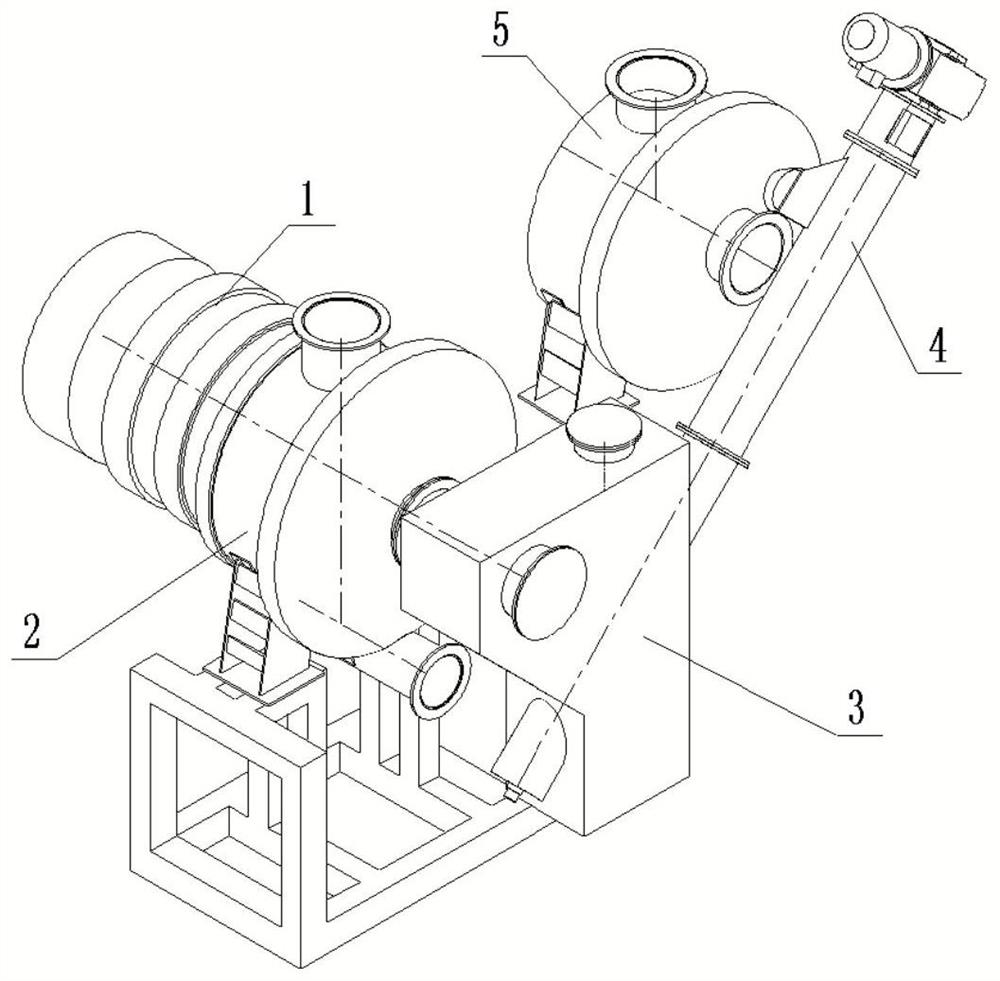

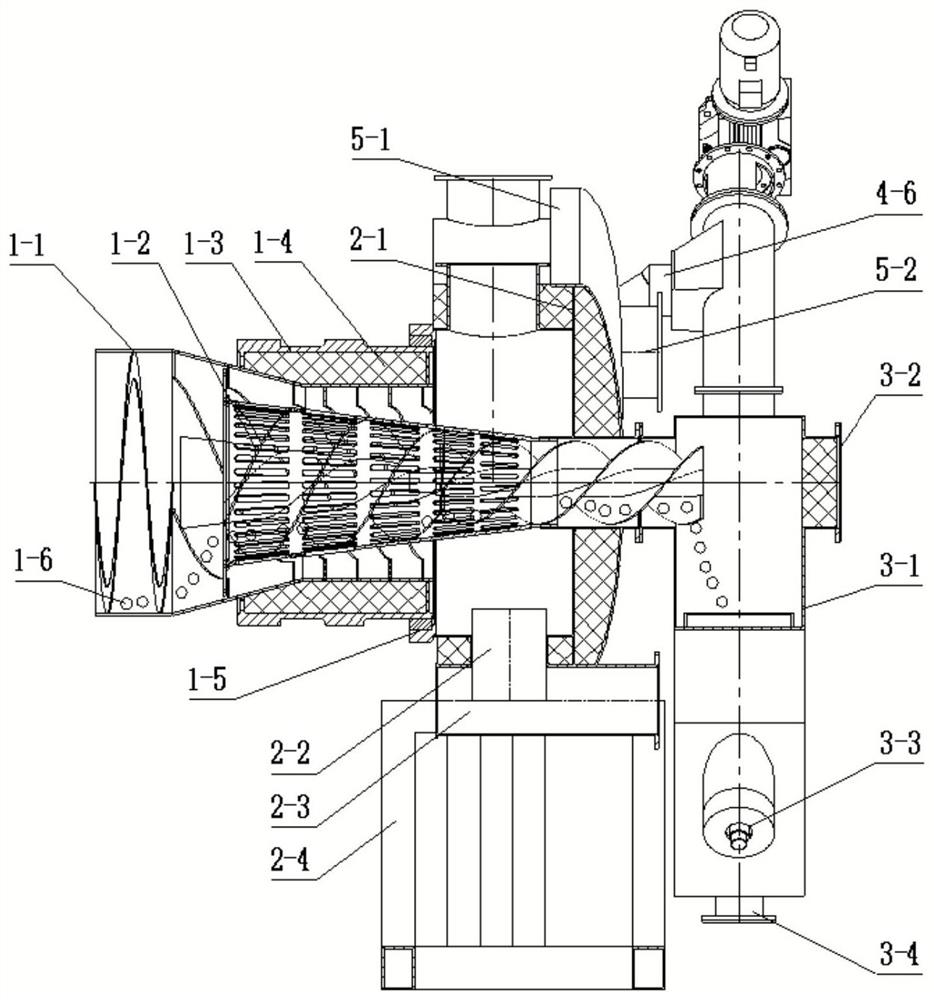

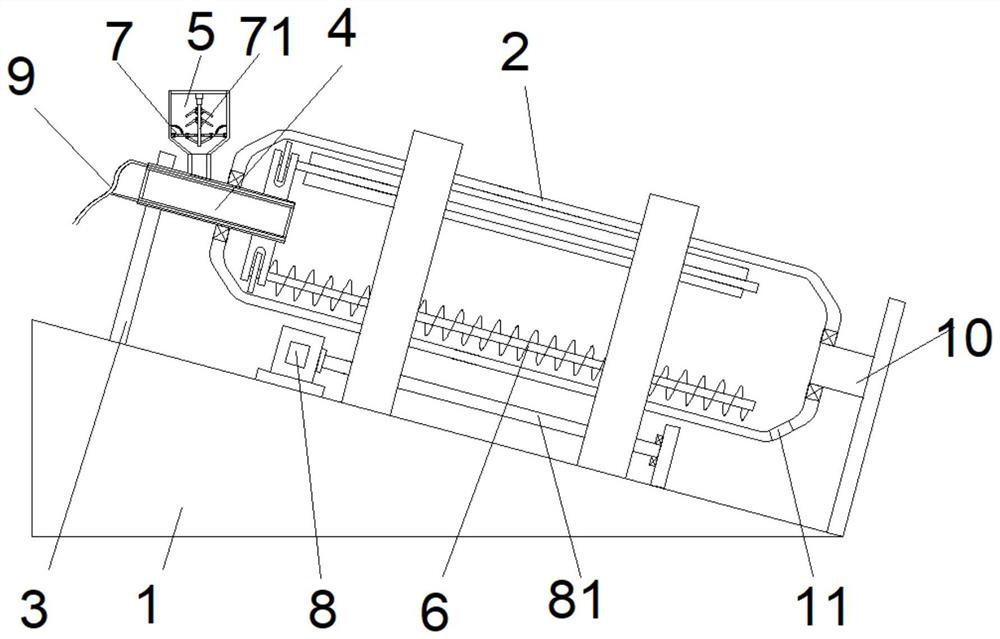

A degasser for gas logging based on semi-permeable membrane

ActiveCN105735924BFew influencing factorsReduce flow rateLiquid degasificationFlushingDegasserSpiral blade

The invention relates to a degasser for gas logging based on a semi-permeable membrane and belongs to the technical field of oil and gas exploration. The degasser comprises a housing, a conical spiral oil and gas separator and a transmission device, wherein the housing comprises an outer shell and a partition, the front end of the outer shell is open for allowing drilling fluid to enter, symmetrical liquid-discharging openings are formed in the rear edge at a position where the radius of the outer shell is maximum, and the outer shell is divided into a front cavity and a rear cavity by the partition; the conical spiral oil and gas separator positioned in the front cavity consists of a hollow shaft and three spiral blades; the inside of each spiral blade is hollow, the spiral blade is communicated with a gas collecting chamber in the hollow shaft, embedded membrane structures are densely distributed on the front surface and the rear surface of the spiral blade, and each embedded membrane structure is formed by embedding the semi-permeable membrane in a regularly-hexagonal ring-shaped boss; the conical spiral oil and gas separator is fixedly connected with a rotating shaft, and the other end of the rotating shaft is connected with a speed reducing motor through a coupling, a gas passage inside the rotating shaft is connected with a carrier gas inlet pipe and a sample gas outlet pipe through a sleeve. According to the degasser provided by the invention, the service life of the device can be effectively prolonged, the oil and gas separation efficiency, the gas logging precision and the accuracy are significantly improved, and the work is reliable.

Owner:JILIN UNIV

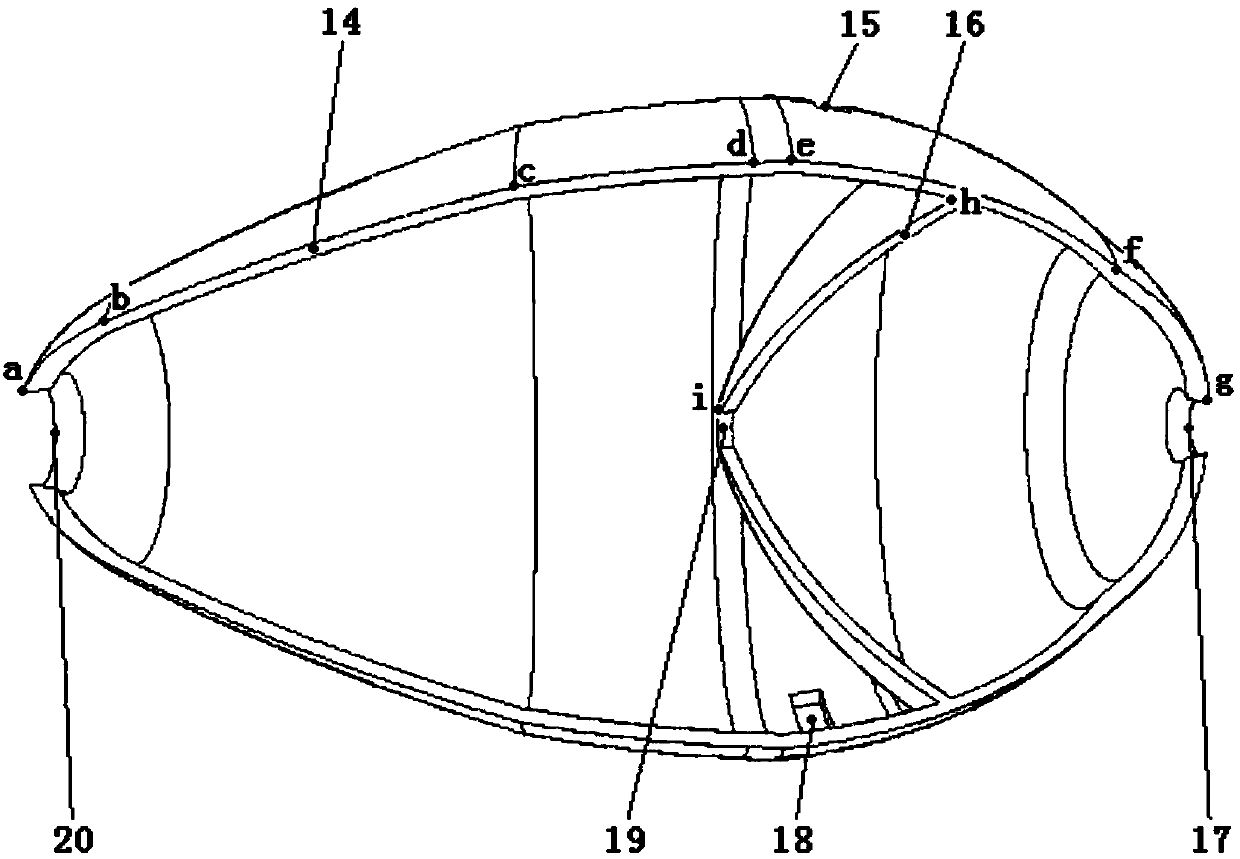

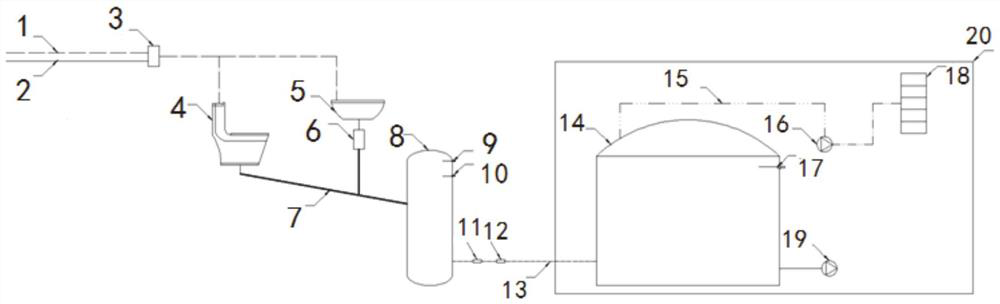

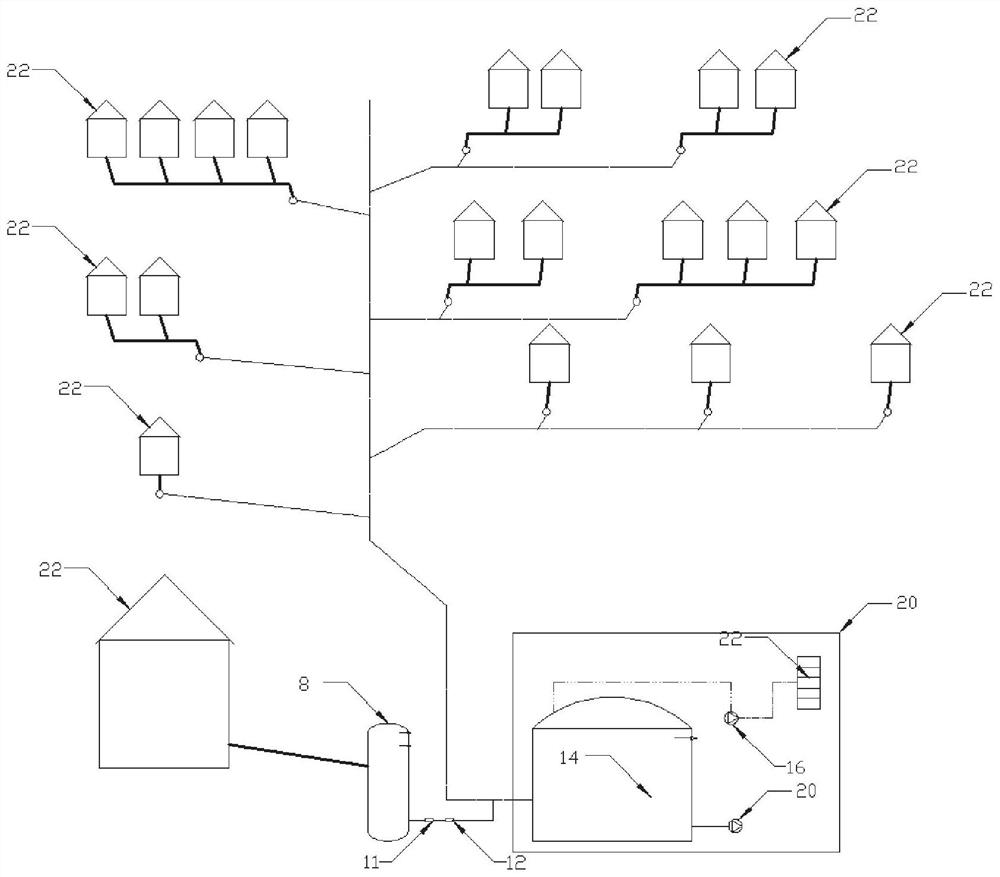

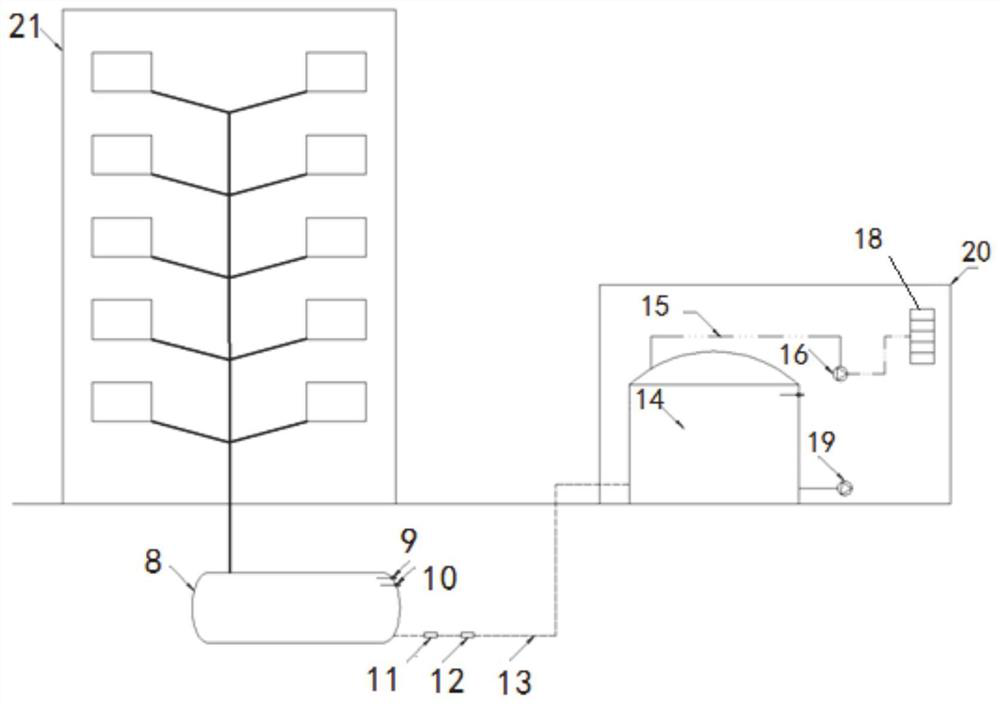

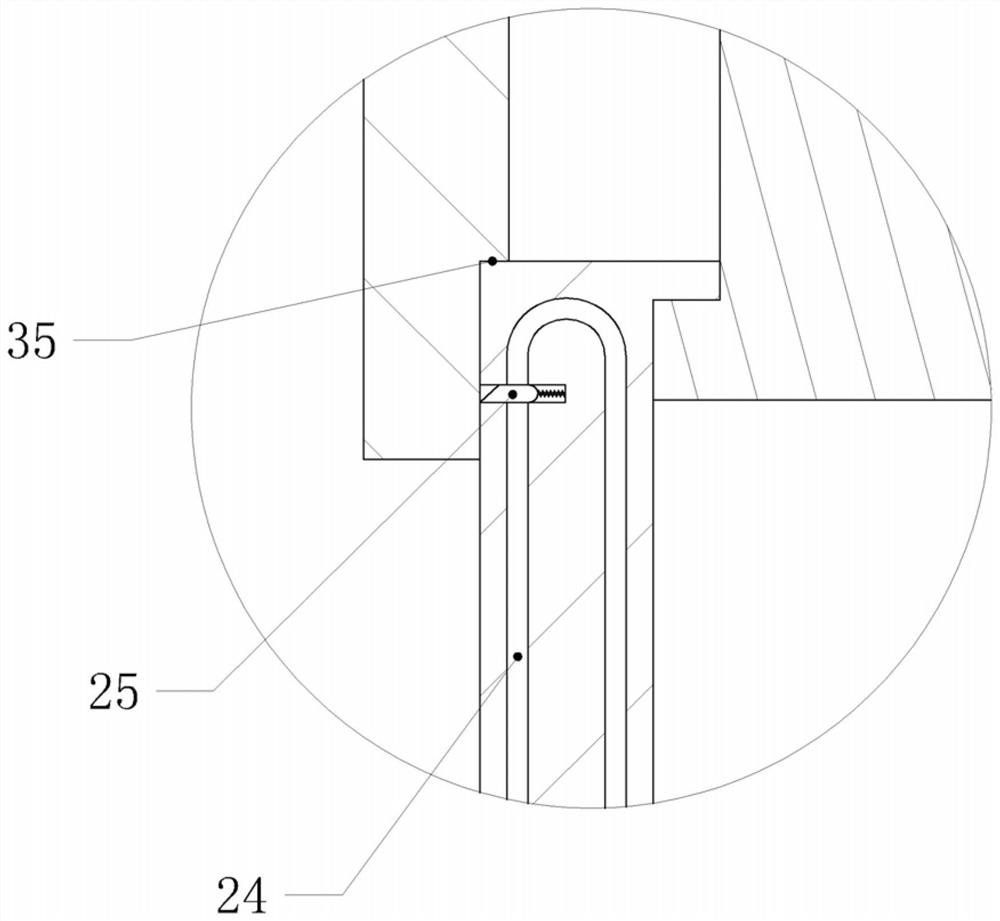

Water-saving type excrement and kitchen waste collaborative vacuum collecting system

InactiveCN111997158AEffective flushingBrokenGeneral water supply conservationDomestic plumbingWater sourceCollection system

The invention relates to a water-saving type excrement and kitchen waste collaborative vacuum collecting system. The water-saving type excrement and kitchen waste collaborative vacuum collecting system comprises a water pressurization system, a gravity drainage system, vacuum collection devices and vacuum pump stations. The water pressurization system comprises a plurality of water pressurizers. The water pressurizers are connected with a compressed air source through compressed air pipes. The water pressurizers are connected with a water source through water supply pipes. The water pressurizers are connected with the gravity drainage system. The gravity drainage system is connected with the vacuum collection devices through a plurality of gravity drainage pipes. The vacuum collection devices are connected with the vacuum pump stations through vacuum drainage pipes. By the adoption of the water-saving type excrement and kitchen waste collaborative vacuum collecting system, the flushingwater amount is saved, the pollution discharging problem of rural and towns is solved, and the problem that the garbage in the pipeline cannot be completely removed is solved.

Owner:SHANDONG XIANGHUAN ENVIRONMENTAL TECH CO LTD +2

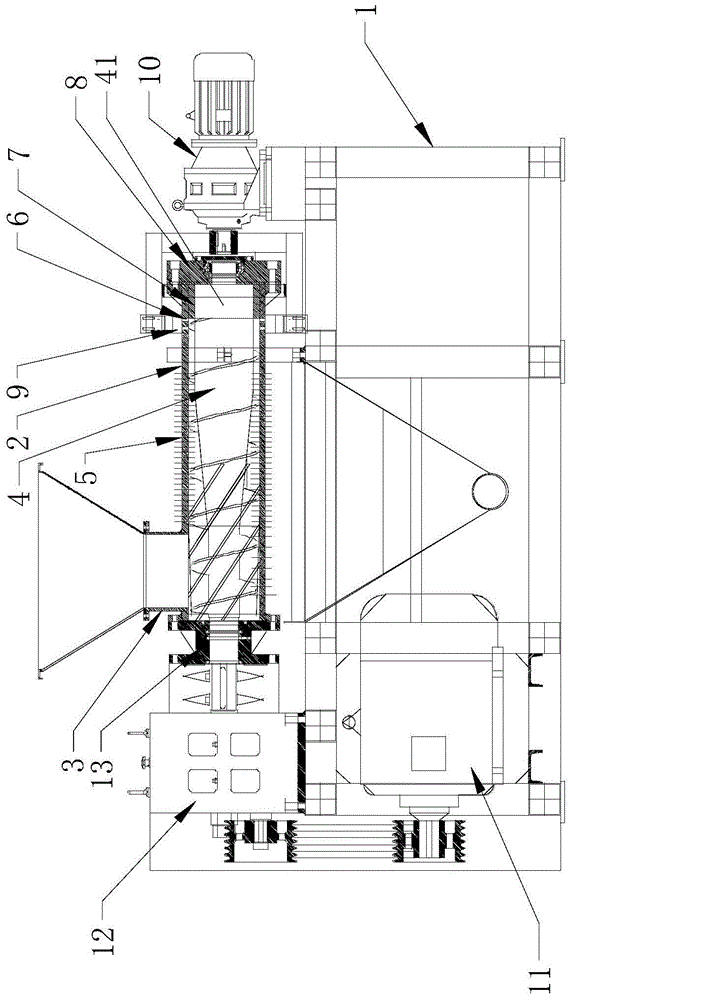

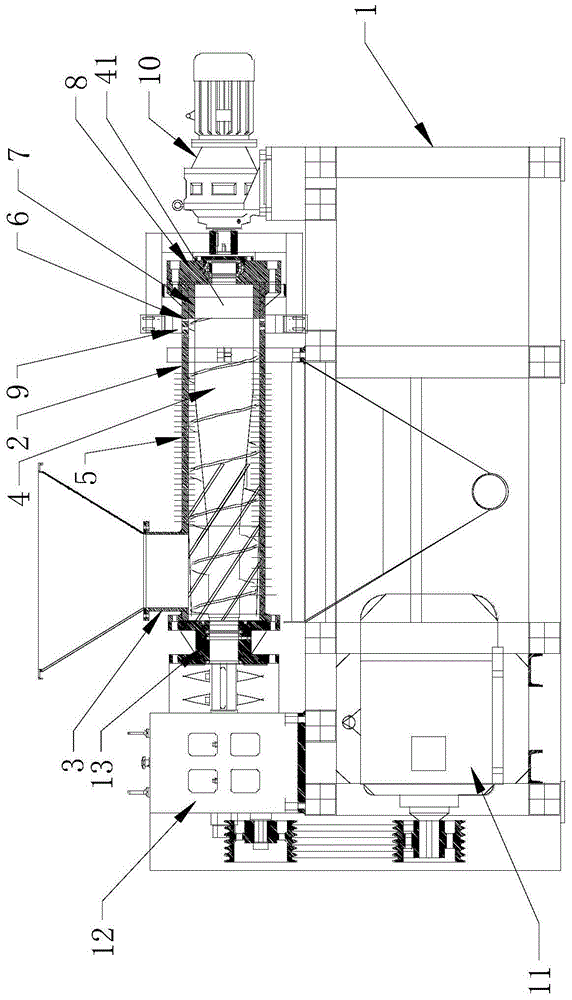

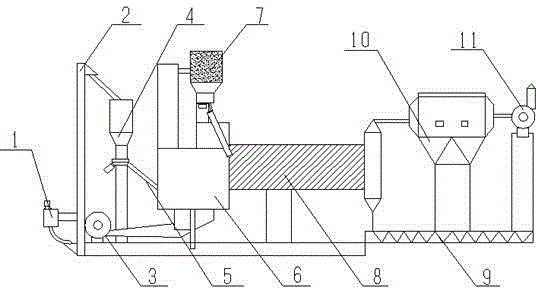

Squeezing pre-grain-cutting machine for plastic recovery

ActiveCN104441328AImprove work efficiencyExtended service lifePlastic recyclingWater filterEngineering

The invention discloses a squeezing pre-grain-cutting machine for plastic recovery. The squeezing pre-grain-cutting machine comprises a rack, a squeezing barrel, a heating and cooling device and a pre-grain-cutting device, wherein an upstream bearing pedestal and a downstream decompression seal are arranged on the rack, two ends of the squeezing barrel are fixed between the upstream bearing pedestal and the downstream decompression seal, a feeding hole is formed in the squeezing barrel, an extruding screw rod is arranged between the upstream bearing pedestal and the downstream decompression seal, the extruding screw rod is positioned in the squeezing barrel and is connected with a screw rod power device, the heating and cooling device is arranged at the downstream of the squeezing barrel, a water filter hole is formed in the upstream section of a squeezing barrel body, a discharge hole is also formed in the downstream section of the squeezing barrel body, a downstream decompression sealing base comprises a decompression sealing barrel and a sealing bearing pedestal, the decompression sealing barrel stretches into the downstream opening of the squeezing barrel, an optical axis part is arranged at the downstream of the extruding screw rod, the optical axis part is arranged in the decompression sealing barrel to be in clearance fit with the decompression sealing barrel, the pre-grain-cutting device is arranged on the rack and is located at the downstream end of the squeezing barrel, and the pre-grain-cutting device comprises a grain cutter and a grain cutter power device. The squeezing pre-grain-cutting machine has high working efficiency and long service life.

Owner:ZHANGJIAGANG LIANDA MACHINERY

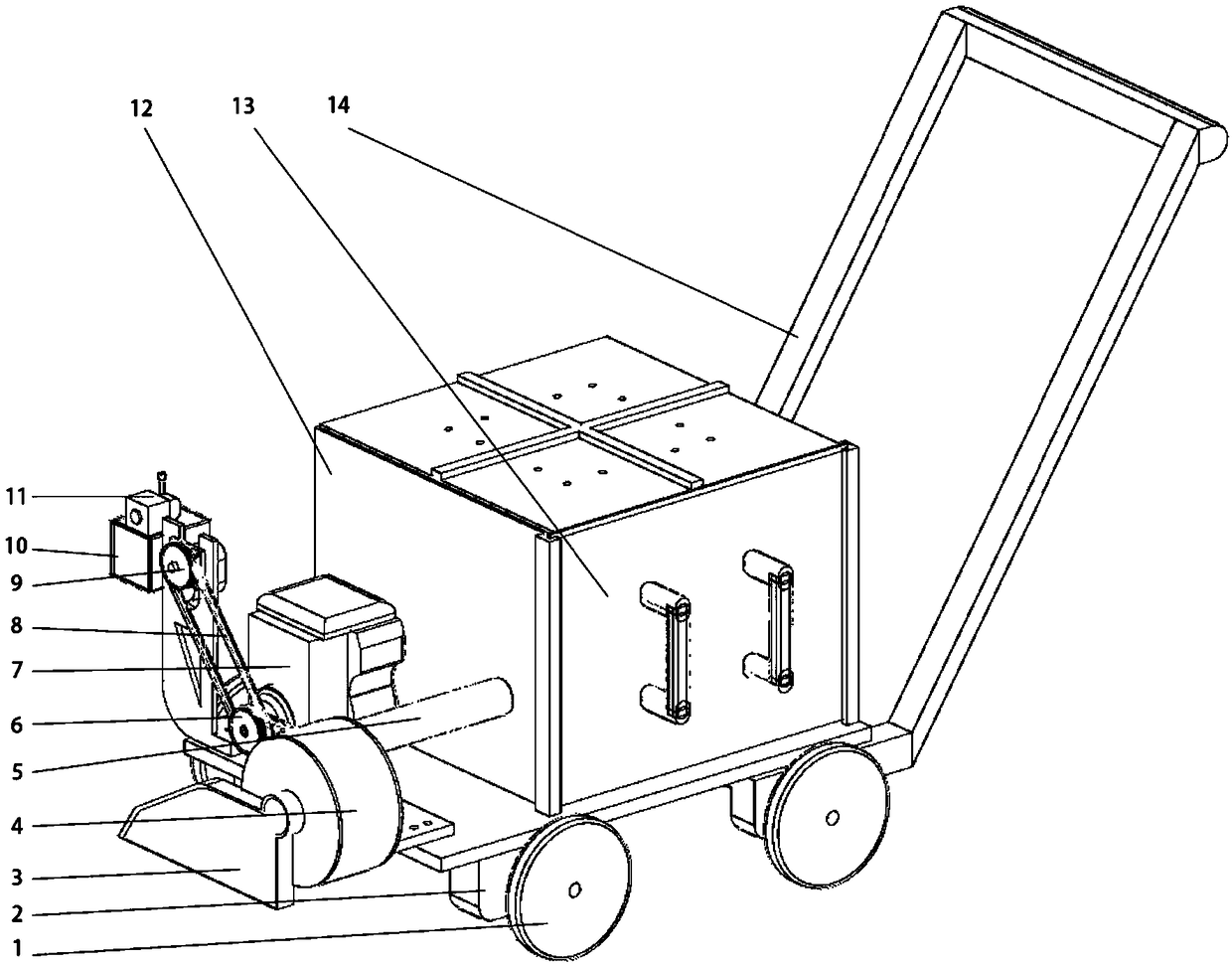

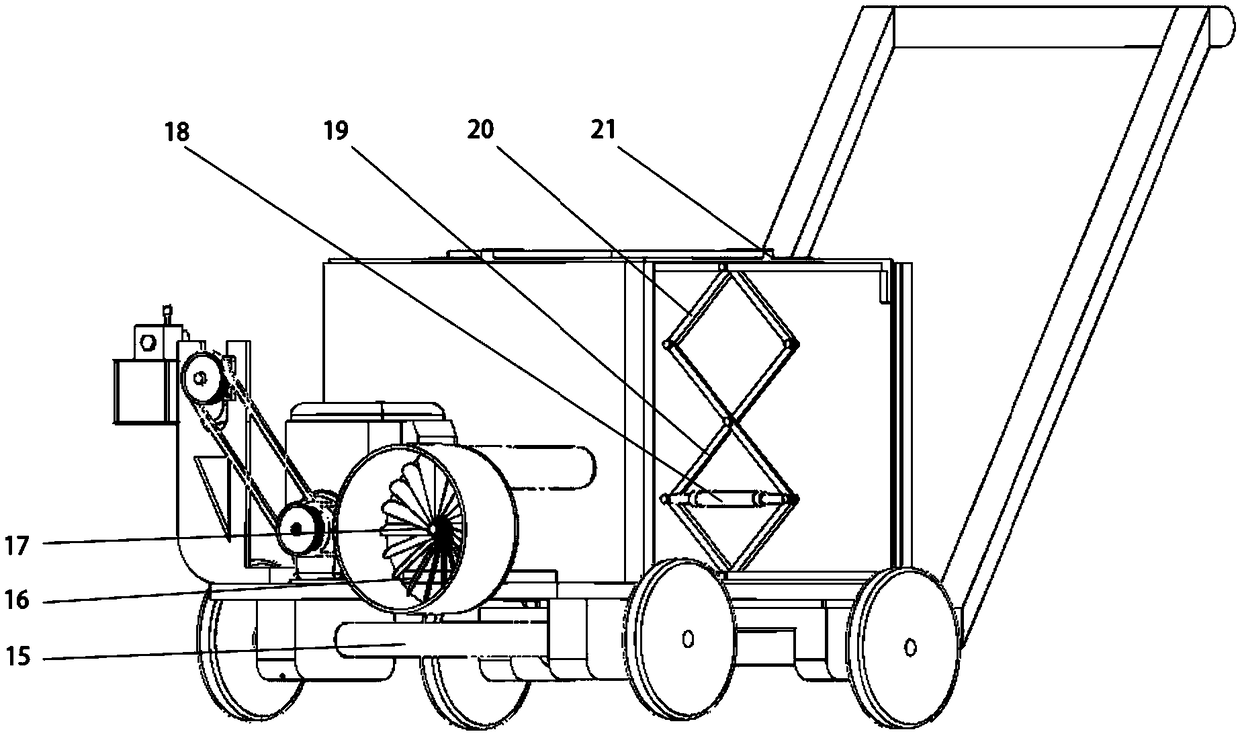

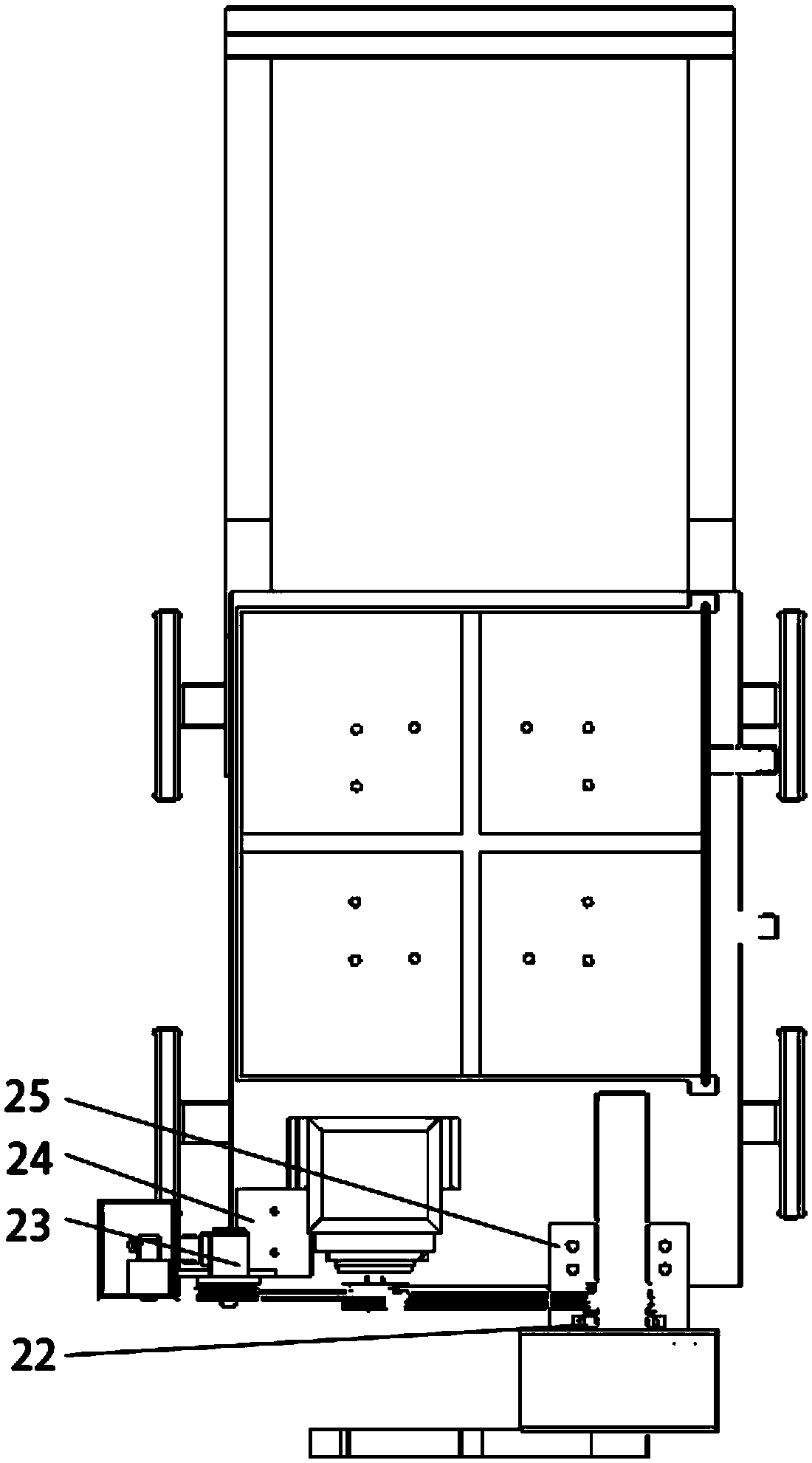

Fallen-leaf cleaning device

The invention discloses a Fallen-leaf cleaning device which is characterized by comprise a vehicle frame, wherein that vehicle frame is fixed with a suction part and a power source of the suction part, the suction part is connected with the pow source of the suction part, and the suction section of the suction part is provided with a suction port; The frame is also fixedly connected with the pumpbody; The bottom of the frame is fixed with a walking device; A box body is also fixed on the vehicle frame, One side of the box body is provided with an opening, and one side of the box body providedwith the opening is hinged with a first cover body, the first cover body can rotate relative to the box body to open or close the box body, a second cover body is also provided in the box body, the second cover body is connected with a telescopic assembly, and the second cover body can move in the box body under the driving of the telescopic assembly to compress the substance in the box body. Theinvention adopts a fan as a suction power source, which is favorable for improving the efficiency of falling leaves entering the box body and simplifying the structure of the box body; the combination of the telescopic assembly and the second cover body is adopted to realize the method of compressing the fallen leaves in the box body can carry more fallen leaves.

Owner:LIAOCHENG UNIV

Mixing mechanism for gluing device for glass fiber cloth

ActiveCN107029950AImprove work efficiencyAvoid cakingLiquid surface applicatorsRotary stirring mixersGlass fiberMechanical engineering

The invention provides a mixing mechanism for a gluing device for glass fiber cloth and belongs to the technical field of machines. The mixing mechanism solves the problem that an existing gluing device is poor in quality. According to the mixing mechanism for the gluing device for the glass fiber cloth, the gluing device for the glass fiber cloth comprises a bracket and a workbench fixed to the bracket. A groove body with an upward groove opening is fixedly formed in the workbench. A partition for partitioning an inner cavity of the groove body into an independent first glue solution groove and an independent second glue solution groove is arranged in the groove body. The mixing mechanism comprises two mixing shafts which are correspondingly and vertically arranged in the first glue solution groove and the second glue solution grove. Through holes are formed in the bottom of the groove body in a penetrating manner. The two through holes are formed. Each of the upper ends of the two mixing shafts is fixedly provided with a mixing blade. The lower ends of the two mixing shafts correspondingly penetrate the two through holes and are fixed to the workbench in the axial direction. A motor is fixedly arranged on the workbench. The motor can drive the two mixing shafts to rotate at the same time through a transmission mechanism. Each of the inner side walls of the first glue solution groove and the second glue solution groove is fixedly provided with multiple breaking heads. Each breaking head is conical. The mixing mechanism has the beneficial effect that the gluing quality can be improved.

Owner:浙江凯澳新材料有限公司

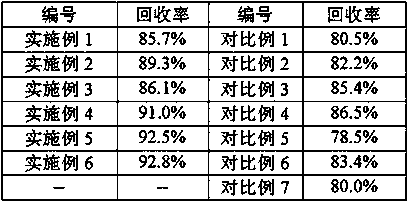

Extraction process for improving recovery rate of fagaramides

The invention discloses an extraction process for improving the recovery rate of fagaramides, and relates to an extraction method of food spices. The method specifically comprises the following steps:(1) Chinese prickly ash pretreatment: tabletting a Chinese prickly ash raw material, wherein the tablet thickness is 0.1-0.5mm; (2) supercritical CO2 fluid extraction: putting Chinese prickly ash slices into an extraction tank, introducing supercritical CO2 fluid with an entrainer when the pressure of the extraction tank is increased to 30-35MPa and the extraction temperature is 45-55 DEG C, andperforming extraction for 2-3h to obtain extraction liquid; (3) separation: allowing the extraction liquid to enter a separation tank for separation, wherein the separation pressure is 6-8MPa and theseparation temperature is 50-55 DEG C so as to obtain prickly ash crude oil and gaseous CO2; and (4) molecular distillation treatment: separating out the entrainer from the extracted prickly ash peelcrude oil to finally obtain oleoresin containing fagaramides. The process has high recovery rate, and is simple.

Owner:郑州雪麦龙食品香料有限公司

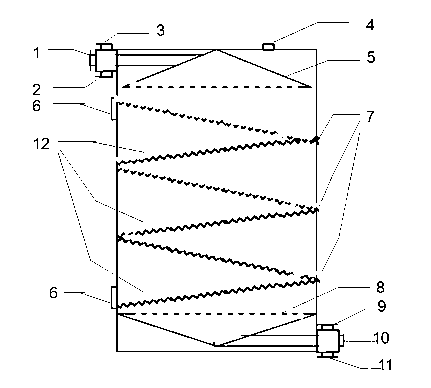

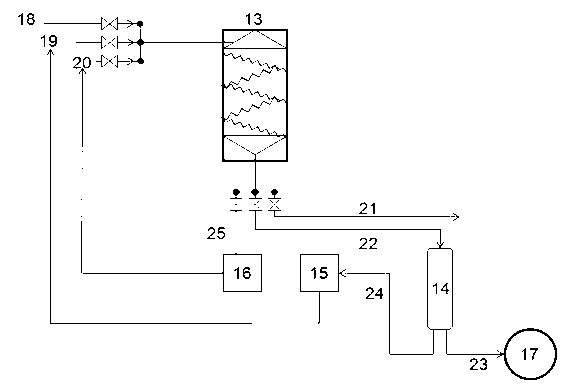

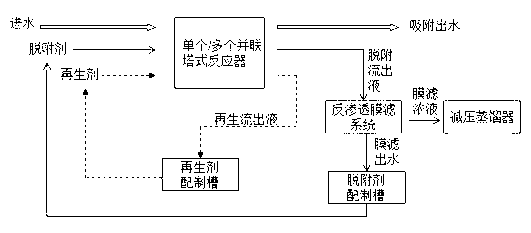

Tower-type adsorption reactor and system and method thereof for removing heavy metal ions in water

ActiveCN103058315ABrokenNo churnWater contaminantsWater/sewage treatment bu osmosis/dialysisFiberPhysical chemistry

The invention discloses a tower-type adsorption reactor and a system and a method thereof for removing heavy metal ions in water, belonging to the water treatment filed. The tower-type adsorption reactor comprises a tower body, a water distributor [5] and a water collector [8], and further comprises a screw-type porous pleated sheet [7] and a fiber adsorbing material [12], wherein the water distributor [5] is arranged at the inner top end of the tower; the screw-type porous pleated sheet [7] is arranged in the tower body; the fiber adsorbing material [12] is coated in the groove of the screw-type porous pleated sheet [7]; and the water collector [8] is arranged at the inner bottom of the tower; the system comprises one or more tower-type adsorption reactors which are in parallel connected; the method for removing the heavy metal ions in the water comprises the following steps of: feeding water, adsorbing and discharging water, desorbing fibers, recycling desorption effluent and recycling fiber, wherein the concentration of heavy metal ions in the desorption outlet water is lower than the heavy metal ion concentration limit value of national drinking water hygienic standard; and the heavy metal ions can be in-situ desorbed, regenerated and recycled after the fiber adsorption is saturated. The system is simple in structure, convenient to operate, stable in operation, and capable of quickly removing the plurality of heavy metal ions in the water.

Owner:NANJING UNIV

Glass fiber cloth gluing device

The invention provides a glass fiber cloth gluing device and belongs to the technical field of machines. The problem that existing gluing devices are poor in quality is solved through the glass fiber cloth gluing device. The glass fiber cloth gluing device comprises a bracket and a workbench fixed to the bracket. A first glue solution tank and a second glue solution tank are parallelly fixed to the workbench. The workbench is further provided with a cloth guiding mechanism. An air suction ring allowing glass fiber cloth to penetrate through is arranged over the first glue solution tank and fixed to the workbench. Roller shafts are rotationally installed in the air suction ring. The number of the roller shafts is two, and the roller shafts are parallel. A clamping opening is formed between the two roller shafts. A sealing ring is arranged and fixed outside the air suction ring in a sleeving mode. An annular dust removing cavity of a closed structure is formed between the air suction ring and the sealing ring. The air suction ring is provided with dust collection openings enabling an inner cavity of the air suction ring to communicate with the dust removing cavity. The number of the dust collection openings is two. The glass fiber cloth gluing device further comprises a negative pressure piece which can form negative pressure in the dust removing cavity. The glass fiber cloth gluing device has the advantage of being good in quality.

Owner:浙江凯澳新材料有限公司

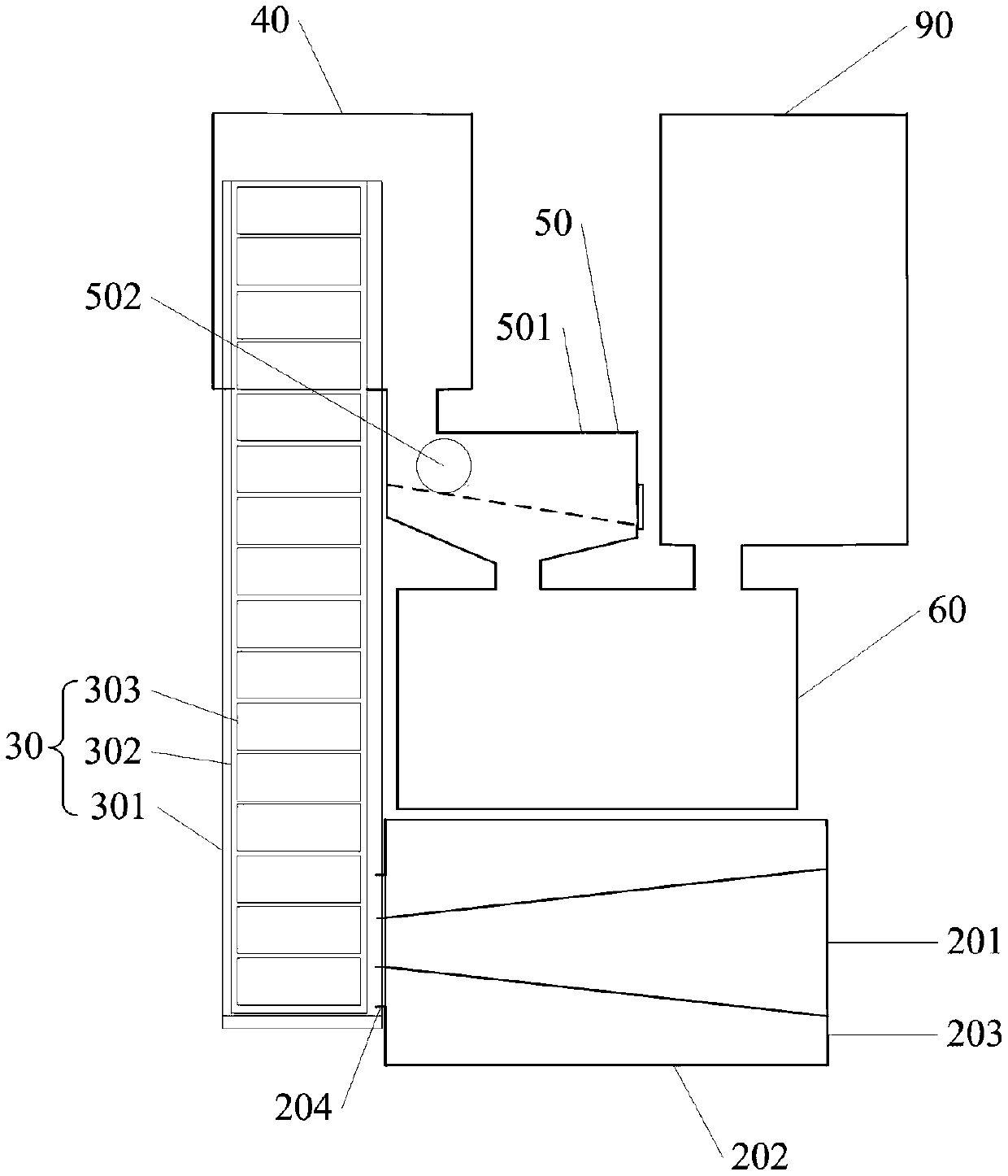

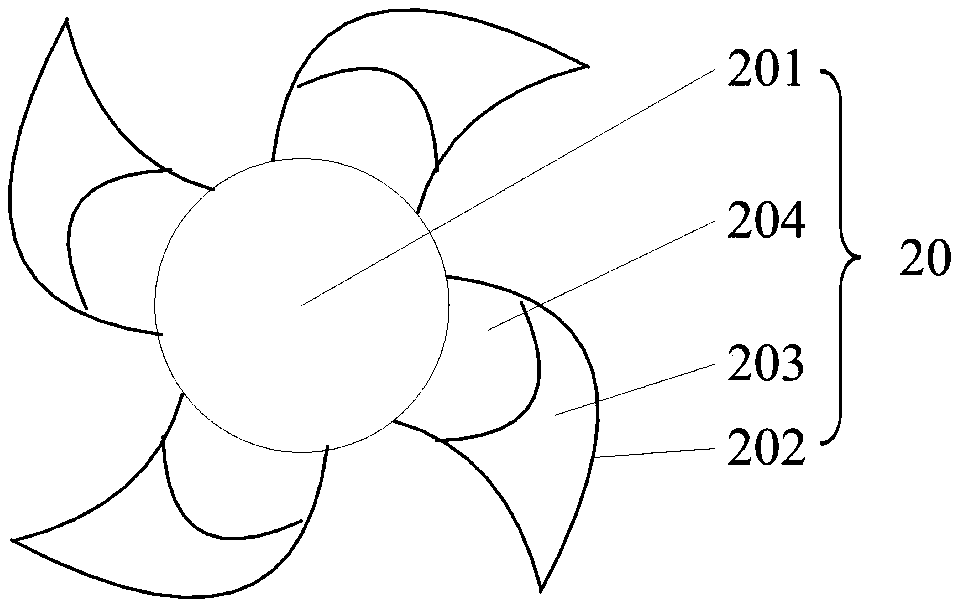

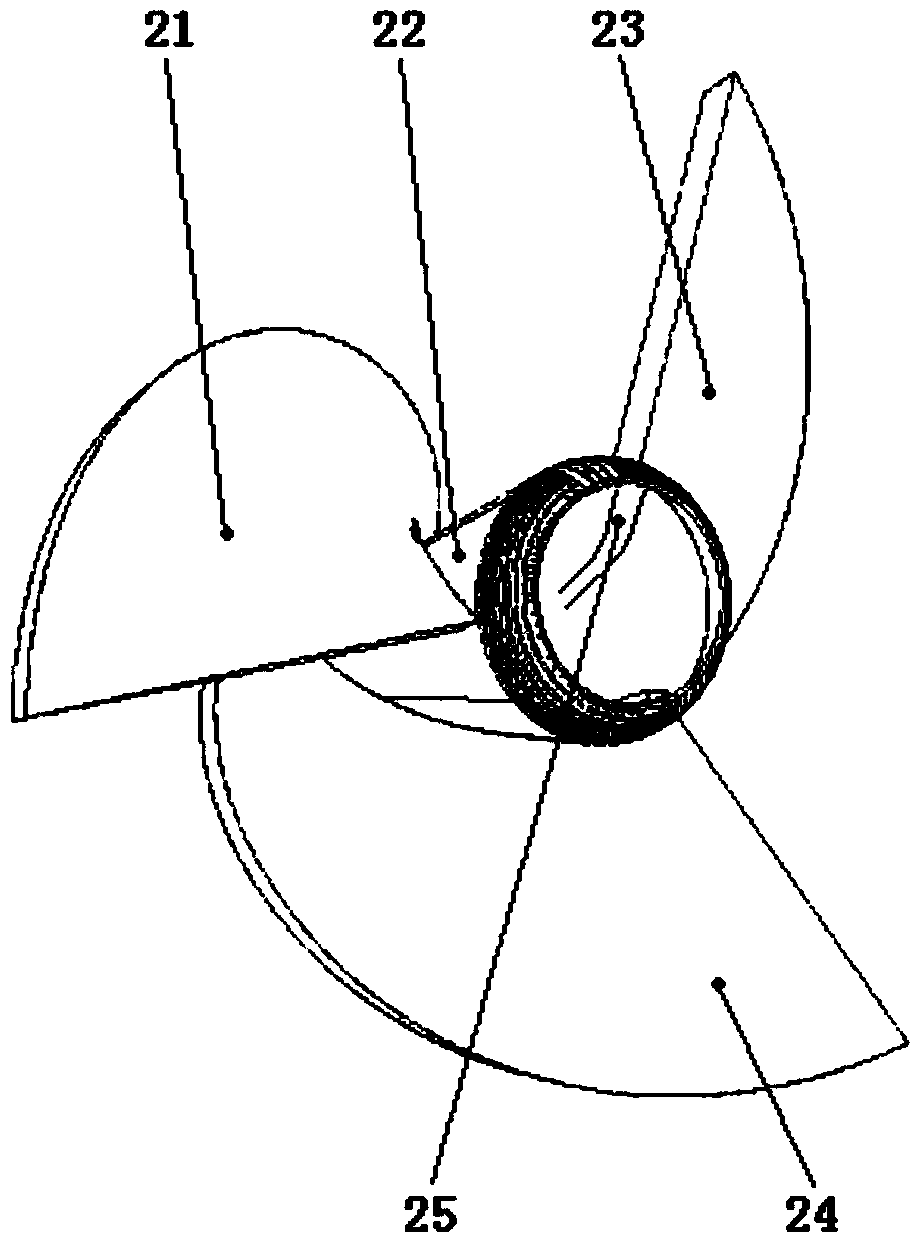

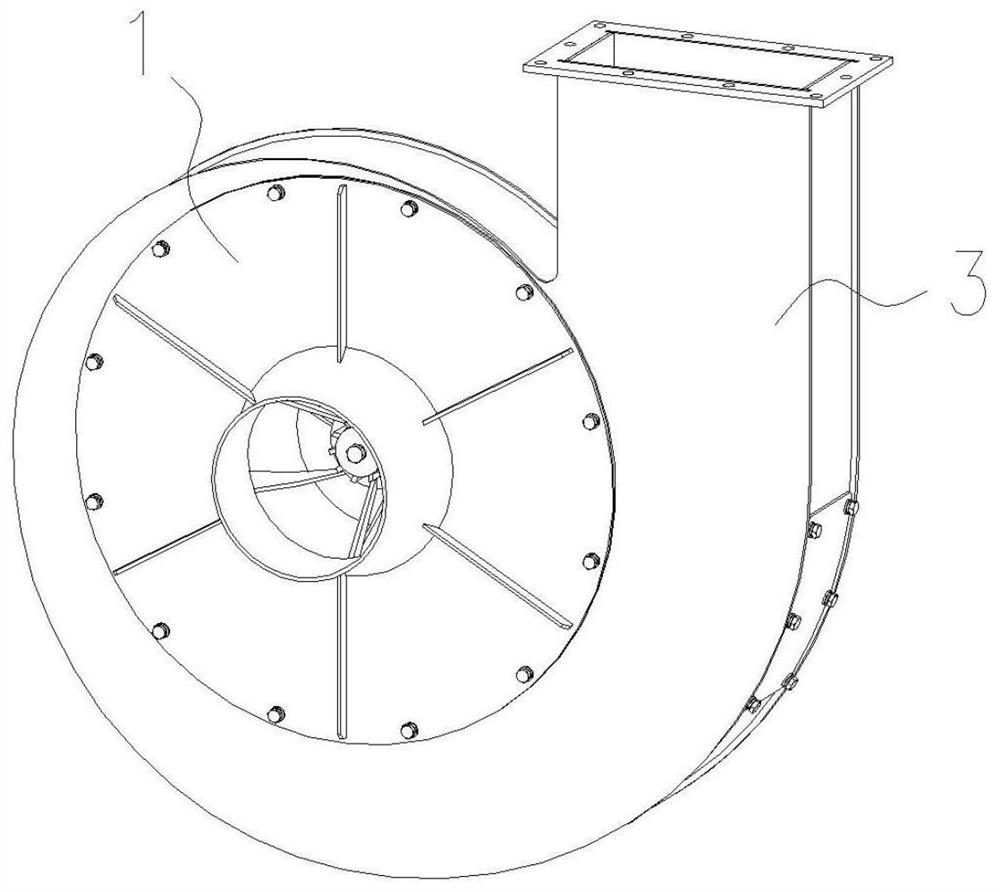

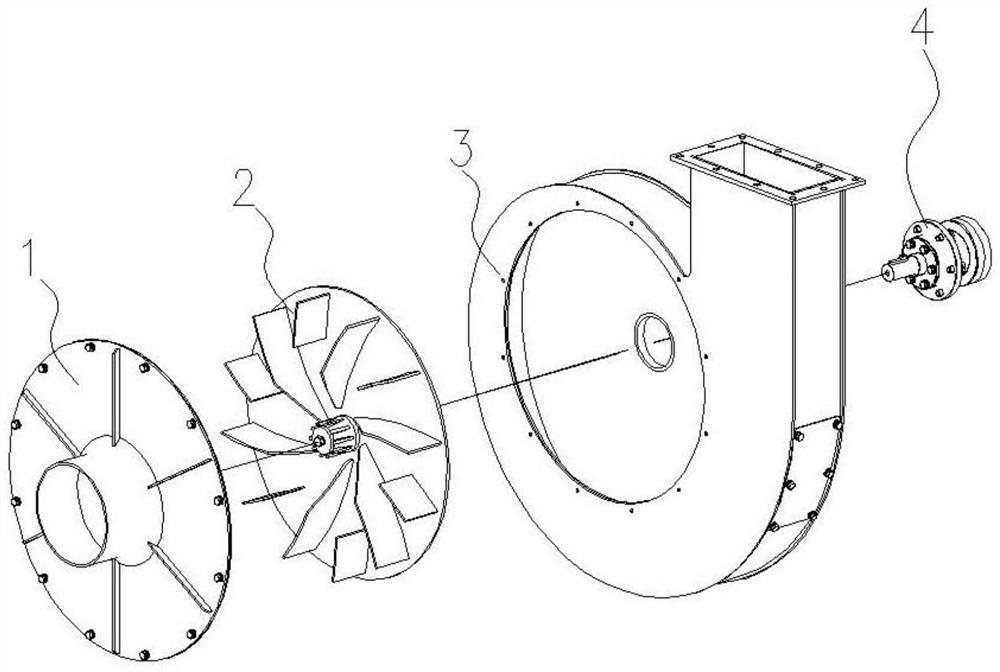

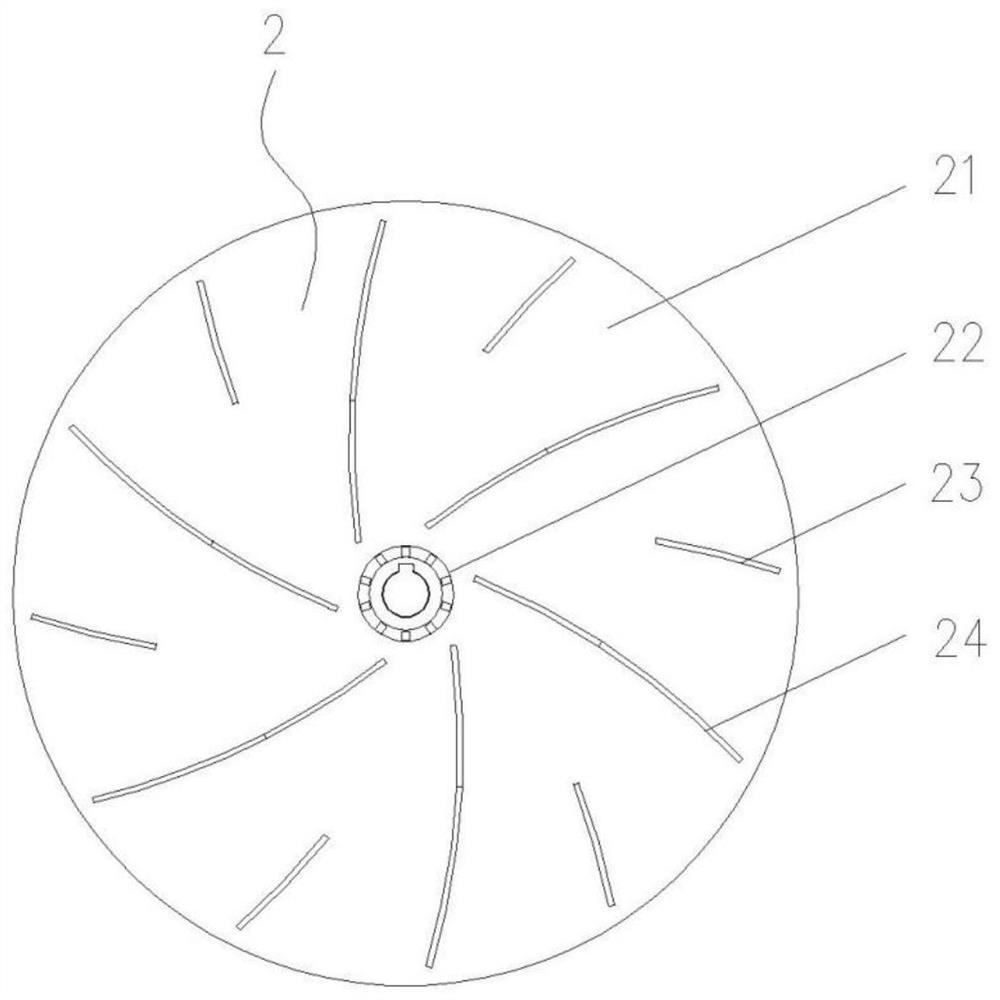

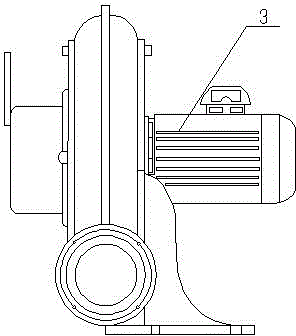

Volute type centrifugal fan

PendingCN113565770AImprove crushing effectIncrease the gapPump componentsPump installationsStructural engineeringKnife blades

The invention relates to a volute type centrifugal fan. The volute type centrifugal fan comprises a volute, an air inlet cover, an impeller and a power assembly. The cover plate is provided with a stationary knife cutterhead, the stationary knife cutterhead comprises a blade fixing ring and a plurality of blades, the plurality of blades are uniformly distributed, the two ends of each blade are connected with the cover plate and the blade fixing ring correspondingly, the cutting edge of each blade is outwards inclined, and the impeller, an output shaft, the blade fixing ring and an air inlet pipe are coaxial; and the blade fixing ring sleeves an impeller shaft in a gap, a plurality of long blades are arranged on the other face, corresponding to the cover plate, of an impeller disc, are evenly distributed around the impeller shaft and spirally spread along the outer side of the impeller shaft, and inclined edges are arranged at the ends, close to the impeller shaft, of the plurality of long blades and correspond to the cutting edges of the blades of the stationary knife cutterhead. The cutting edges of the blades and the inclined edges of the long blades form gap shearing edges. According to the technical scheme, the inclined edges of the blades relatively move at a high speed relative to the blades of the stationary knife cutterhead, and when the gaps of the shearing edges are smaller, garbage is sheared to be smaller, and the crushing effect of the centrifugal fan is better.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

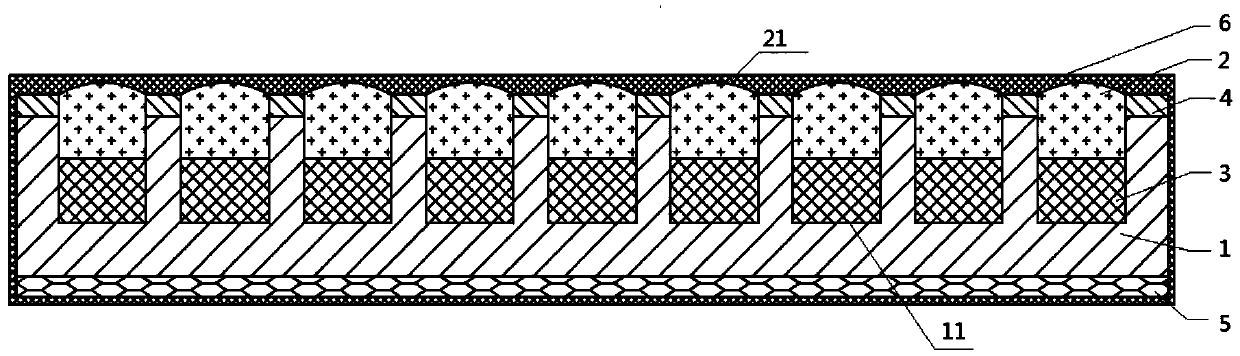

Composite material and preparation method thereof

ActiveCN110274521AExcellent Ballistic PerformanceHigh impact strengthSynthetic resin layered productsArmour platesEpoxyMetallurgy

The invention discloses a composite material and a preparation method thereof. The composite material comprises an aluminum alloy substrate, ceramic columns, rubber sheets, a steel wire mesh, a honeycomb plate and epoxy resin, wherein a plurality of flat bottom holes are formed in the upper surface of the aluminum alloy substrate, and the distances between the axes of every two adjacent flat bottom holes are equal; the ceramic columns are nested in grids of the steel wire mesh and are fixed in the flat bottom holes; the rubber sheets are fixed in the flat bottom holes, located below the ceramic columns and in contact with the hole bottoms of the flat bottom holes; the honeycomb plate is fixed on the lower surface of the aluminum alloy substrate; and the epoxy resin coats the outermost layer of the composite material. The composite material has the advantages of being good in elasticity resistance, light in weight, and capable of improving the comprehensive performance of armors.

Owner:WUXI YINBANG DEFENSE TECH CO LTD +1

Density-controllable hail preparation method and extrusion device for hail manufacturing

ActiveCN111928549AEffective simulationNo cracksLighting and heating apparatusIce productionMechanical engineeringMaterials science

The invention discloses a density-controllable hail preparation method and an extrusion device for hail manufacturing. The density-controllable hail preparation method comprises the following steps: S1, manufacturing ice; S2, crushing the manufactured ice into crushed ice by using an ice crusher; S3, weighing M (unit: g) of the above crushed ice by mass and putting the crushed ice into the extrusion device; S4, extruding the above crushed ice through the extrusion device till the volume of the crushed ice is compressed to L (unit: cm<3>), wherein the ratio of M to L reaches 0.6-0.9 (unit: g / cm<3>); S5, taking out the above crushed ice and spraying at least one layer of water mist onto the surface of the crushed ice; and S6, storing the above crushed ice in a frozen state. According to themethod, the crushed ice can be extruded to form hail with a set density as required; the hail manufactured through the density-controllable hail preparation method can be prevented from cracking or breaking during the high-speed flight process; the simulation of hail in nature can be effectively achieved; and then the problems encountered in the prior art can be solved.

Owner:江苏心源航空科技有限公司

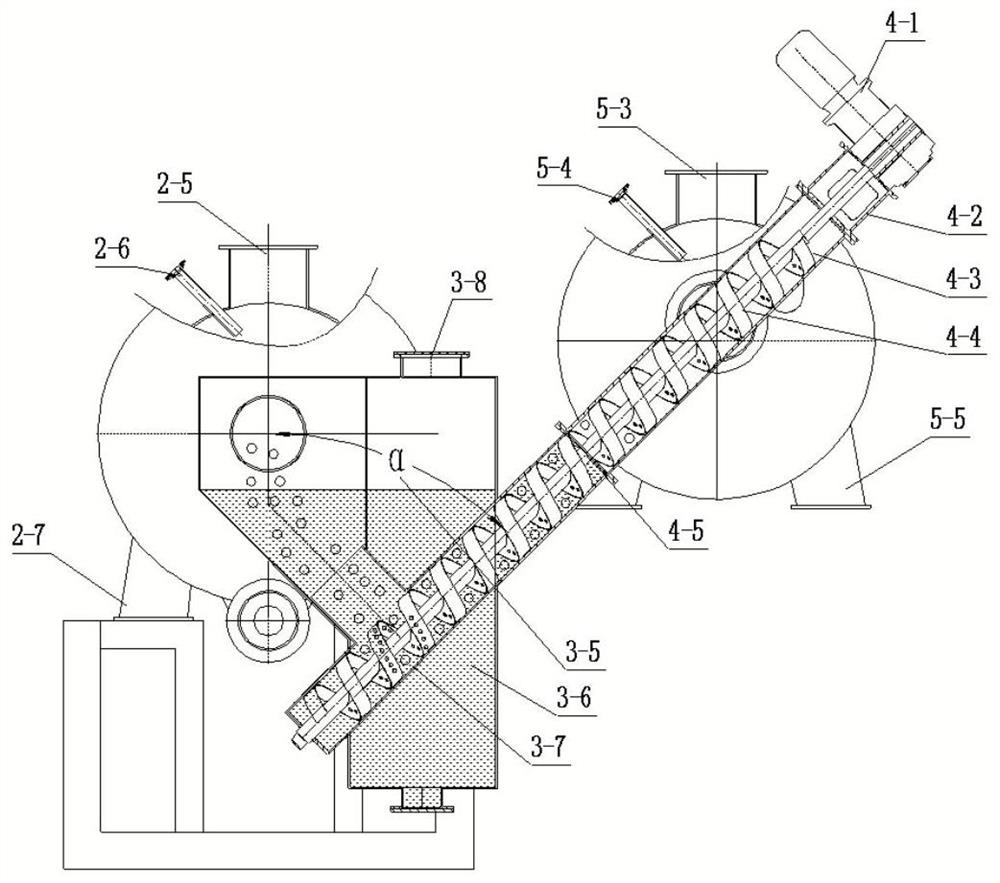

Ball circulation screening powder sealing and discharging integrated device and method

The invention relates to a ball circulating screening and powder sealing discharging integrated device which comprises a pyrolyzing furnace rotary cylinder, and the pyrolyzing furnace rotary cylinder is sequentially connected with a pyrolyzing furnace discharging end cover, a powder sealing box, a ball circulating screw elevator and a drying furnace feeding end cover. A ball screening structure is arranged in the pyrolyzing furnace rotary cylinder and comprises a ball screening fixing plate, a ball screening net is arranged on the ball screening fixing plate, and a ball screening spiral structure is arranged in the length direction of the inner wall of the pyrolyzing furnace rotary cylinder. The side, close to the discharging end cover of the pyrolyzing furnace, of the ball screening spiral structure is connected with a ball pushing spiral structure, and circulating balls are arranged in the pyrolyzing furnace rotary shell. And the ball screening structure is utilized to ensure the separation of pyrolysis product high-temperature carbon powder and circulating balls, so that the phenomenon of adhesion of pyrolysis tar and coke is avoided, and the safety of equipment operation is further ensured. The powder sealing box is combined with the ball circulating screw elevator, so that the dynamic sealing performance of powder materials in the ball circulating conveying process is realized.

Owner:SHANDONG XIANGHUAN ENVIRONMENTAL TECH CO LTD +1

Dynamic material temperature measurement device

ActiveCN105067149BBrokenAvoid Temperature Sensing ErrorsTemperature measurement of moving solidsTemperature measurement of flowing materialsData processing systemProcess systems

The invention discloses a dynamic material temperature measuring device capable of improving the temperature detection accuracy of flowing materials and having a simple structure. The dynamic material temperature measuring device includes a bracket, a dynamic material temperature measuring instrument and a data processing system; at least two rows of dynamic material temperature measuring instruments are arranged on the support, and there is a distance between two adjacent rows of dynamic material temperature measuring instruments. And there are at least two dynamic material thermometers in each row; there is a distance between two adjacent dynamic material thermometers in each row of dynamic material thermometers, and the material feeding ends of all heat conductors point to the same direction; the dynamic The signal output end of the material temperature measuring instrument is electrically connected with the data processing system. The adoption of the dynamic material temperature measuring device can improve the accuracy of material temperature detection, and avoid large errors in temperature detection and failure to detect the temperature in the material block when material blocks appear in the material.

Owner:四川华宇瑞得科技有限公司

Extrusion inter-granulator for plastic recycling

ActiveCN104441328BImprove work efficiencyExtended service lifePlastic recyclingWater filterOptical axis

Owner:ZHANGJIAGANG LIANDA MACHINERY

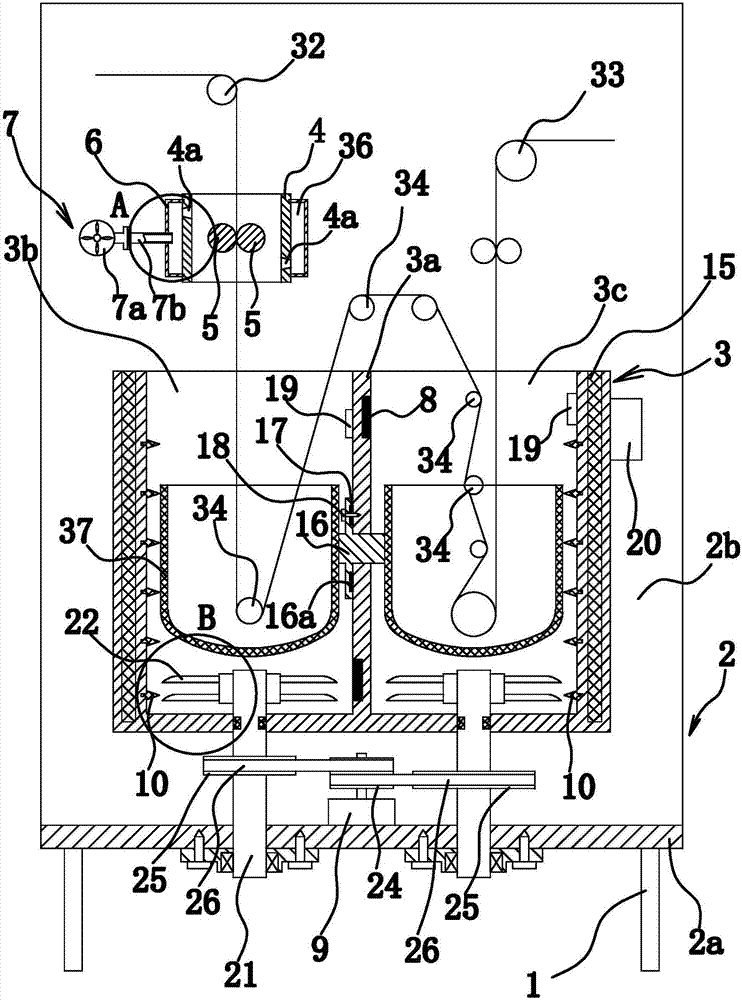

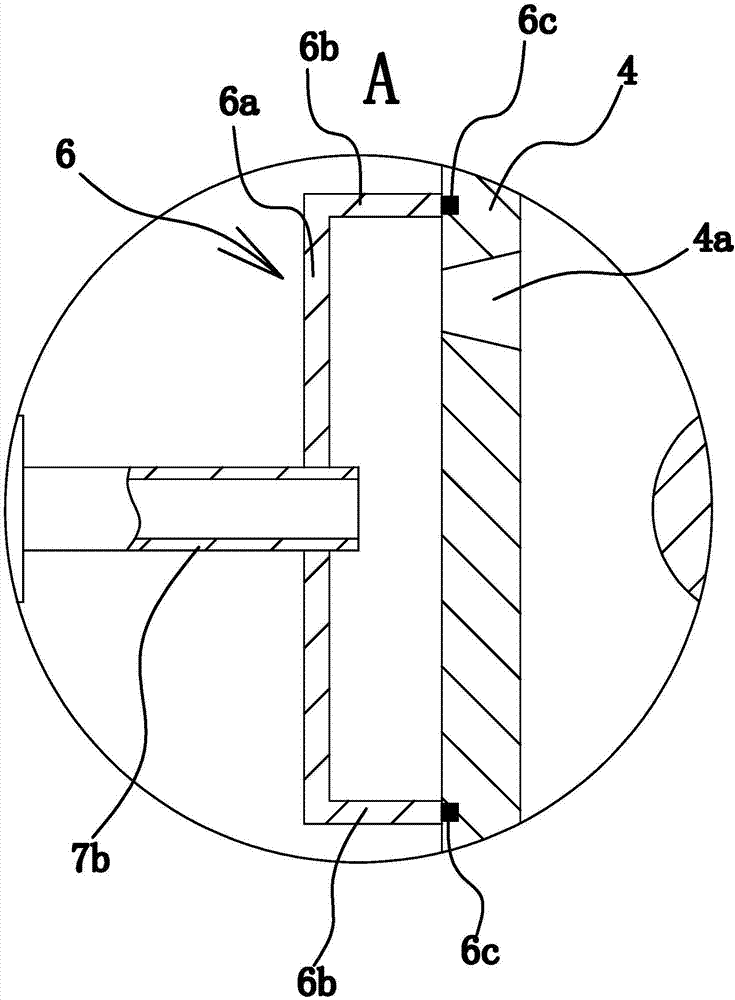

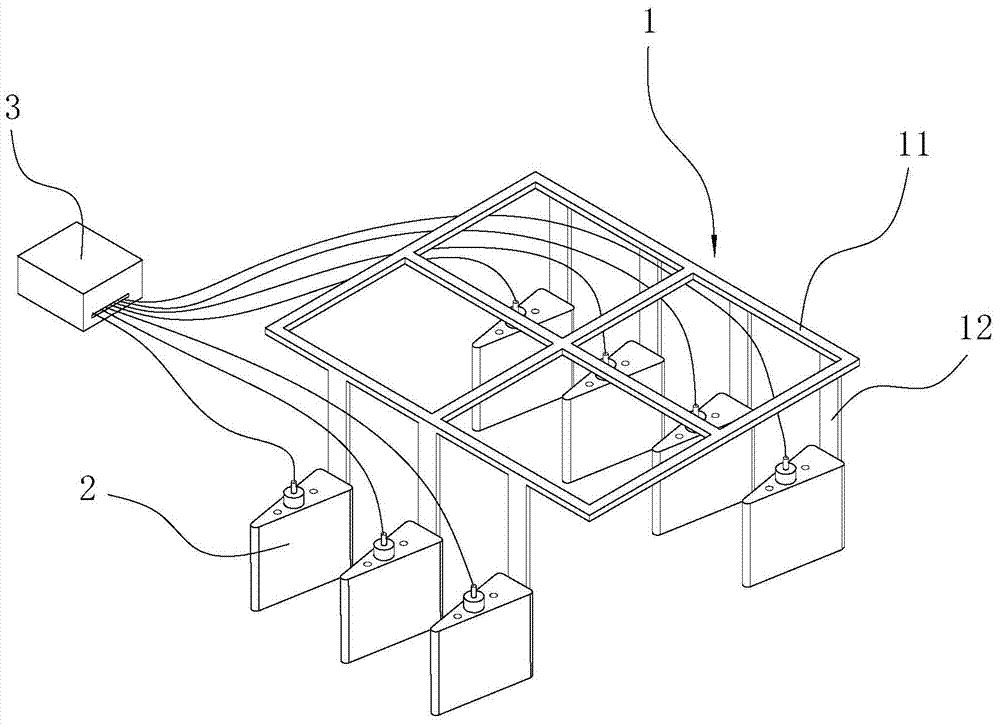

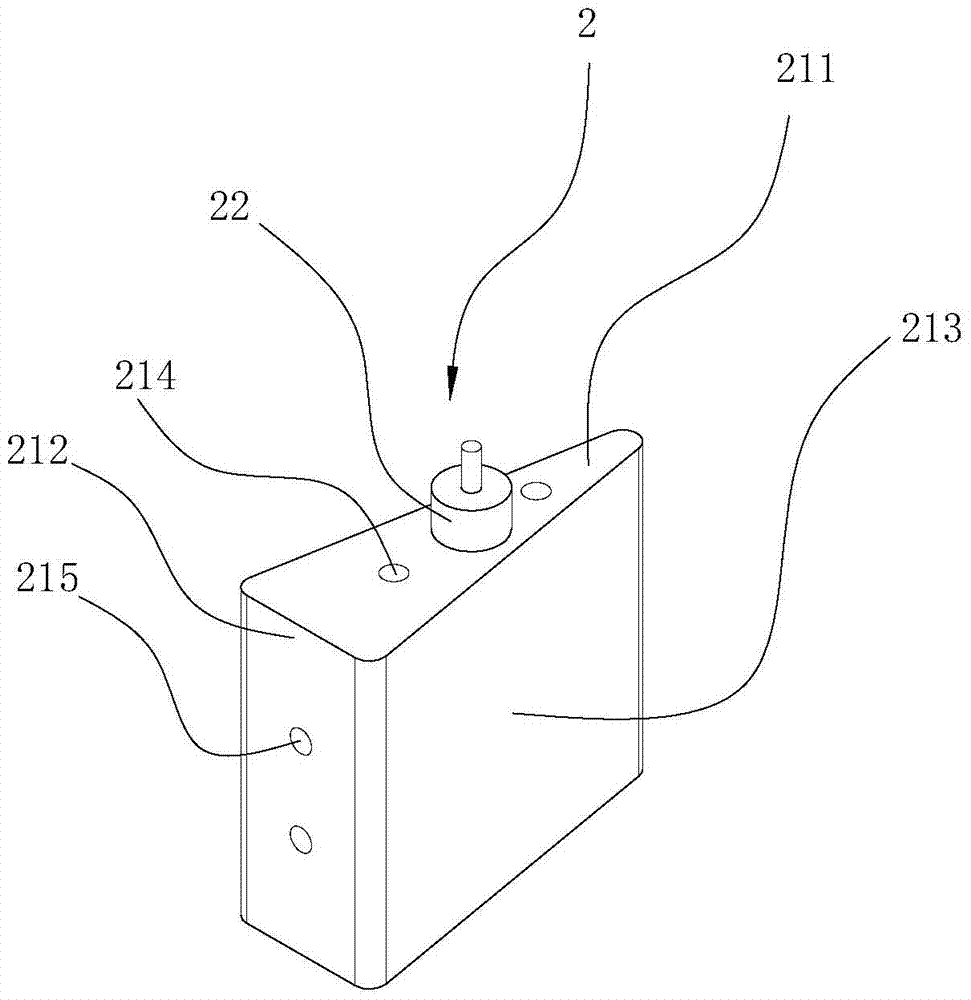

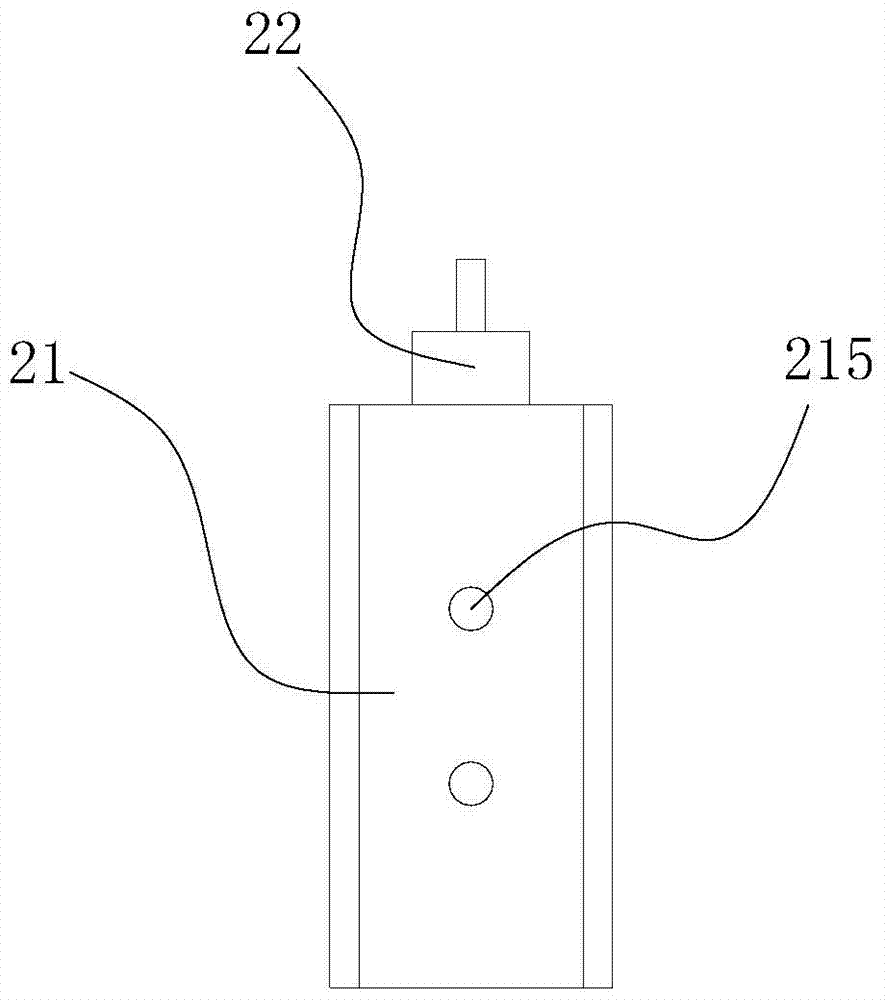

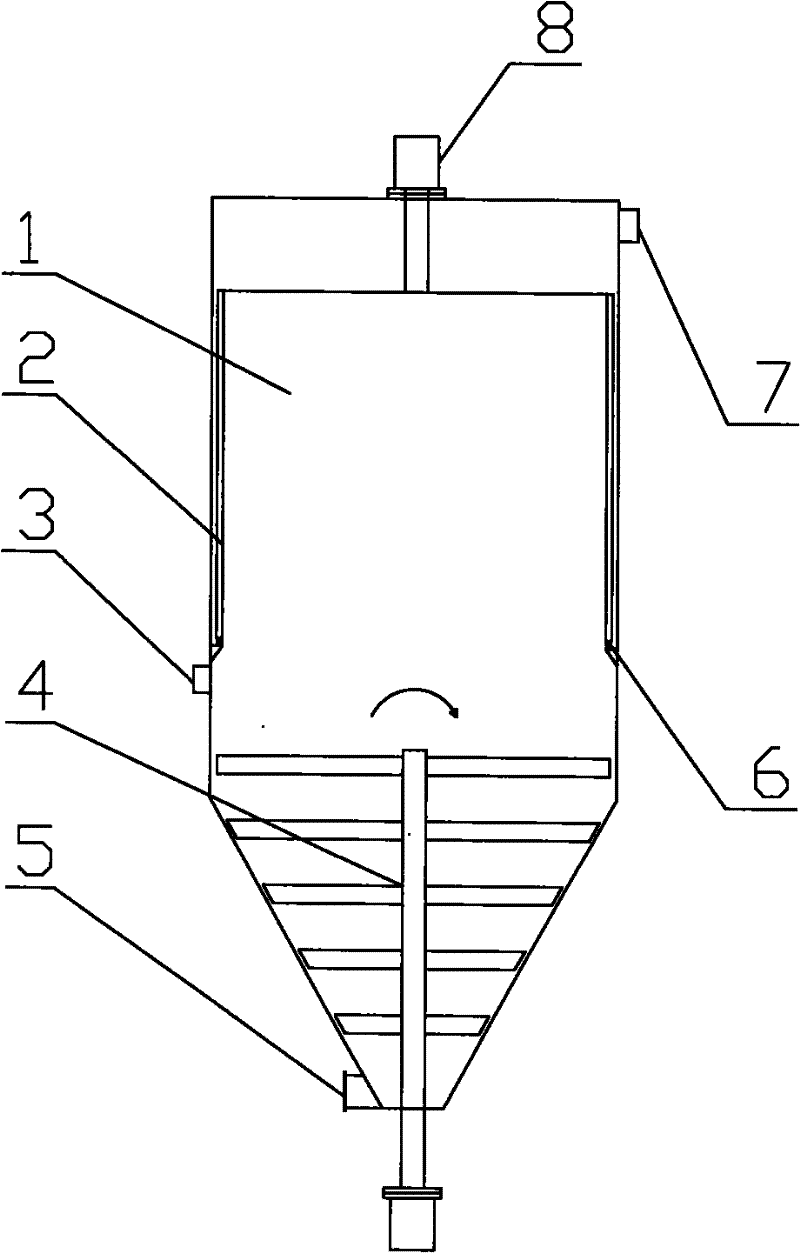

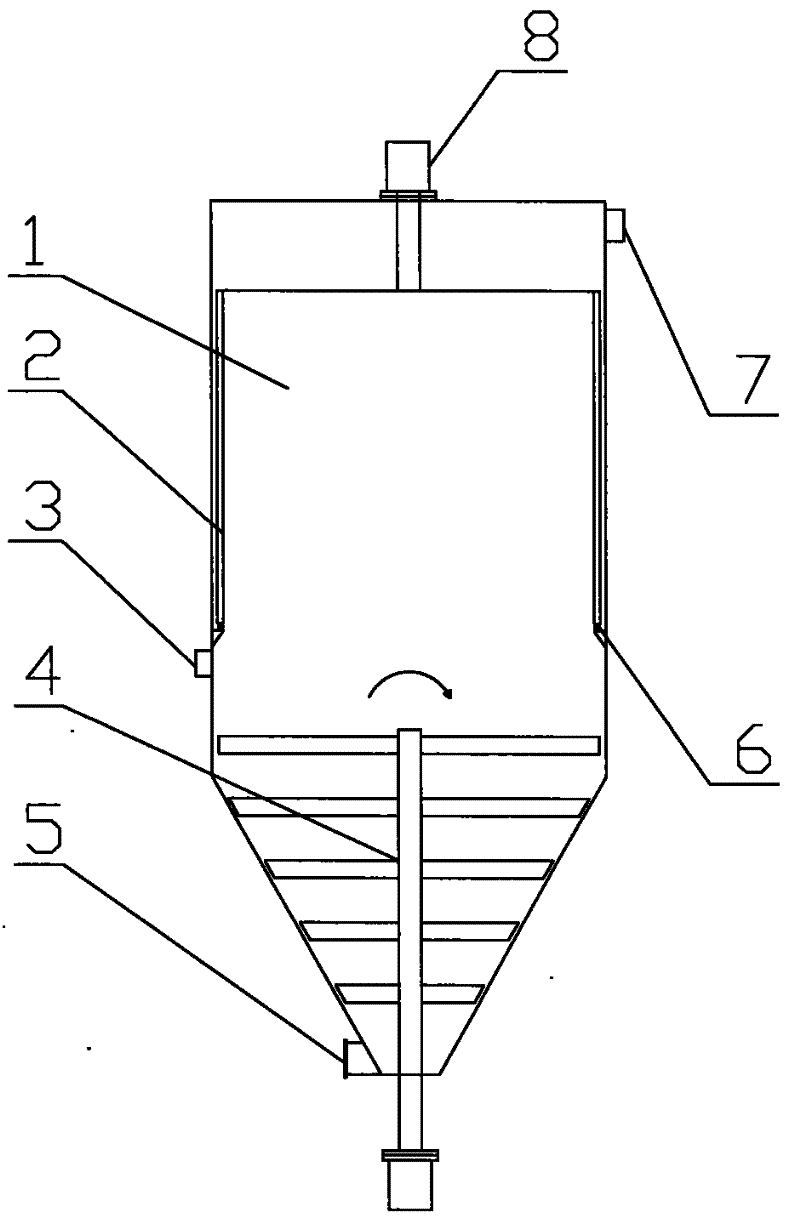

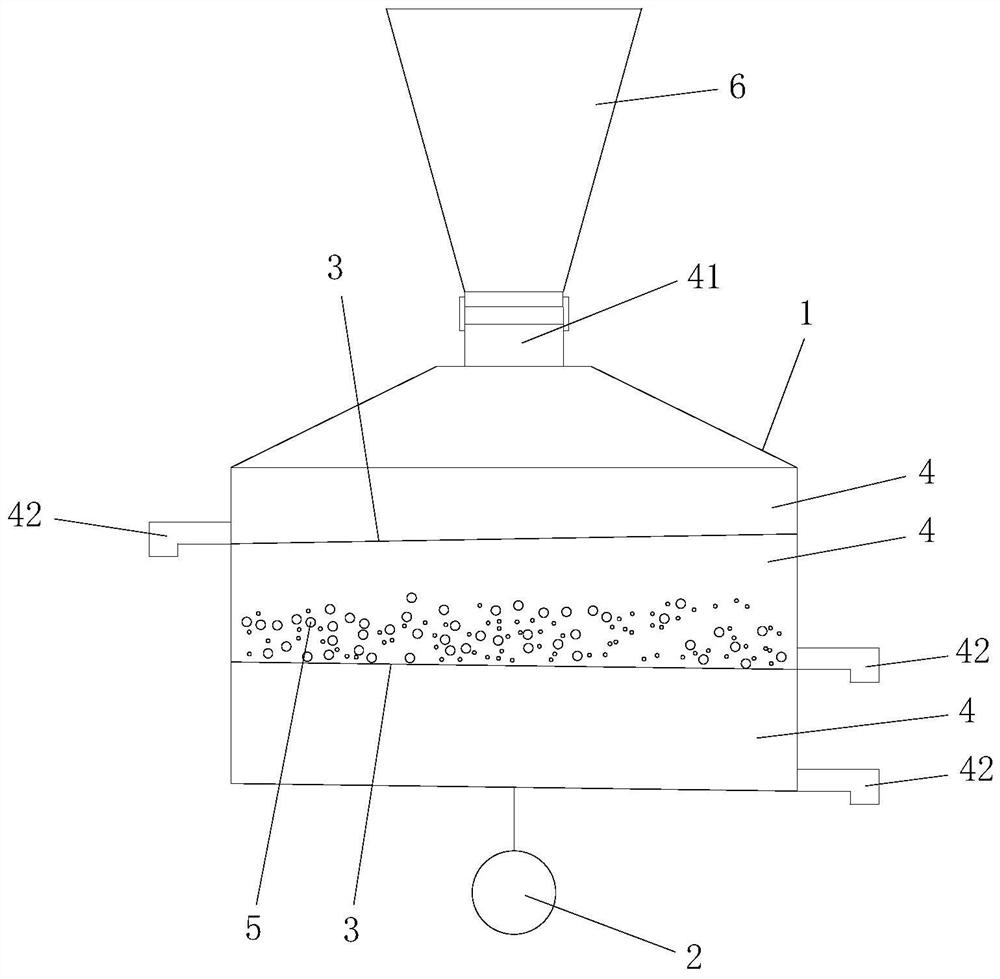

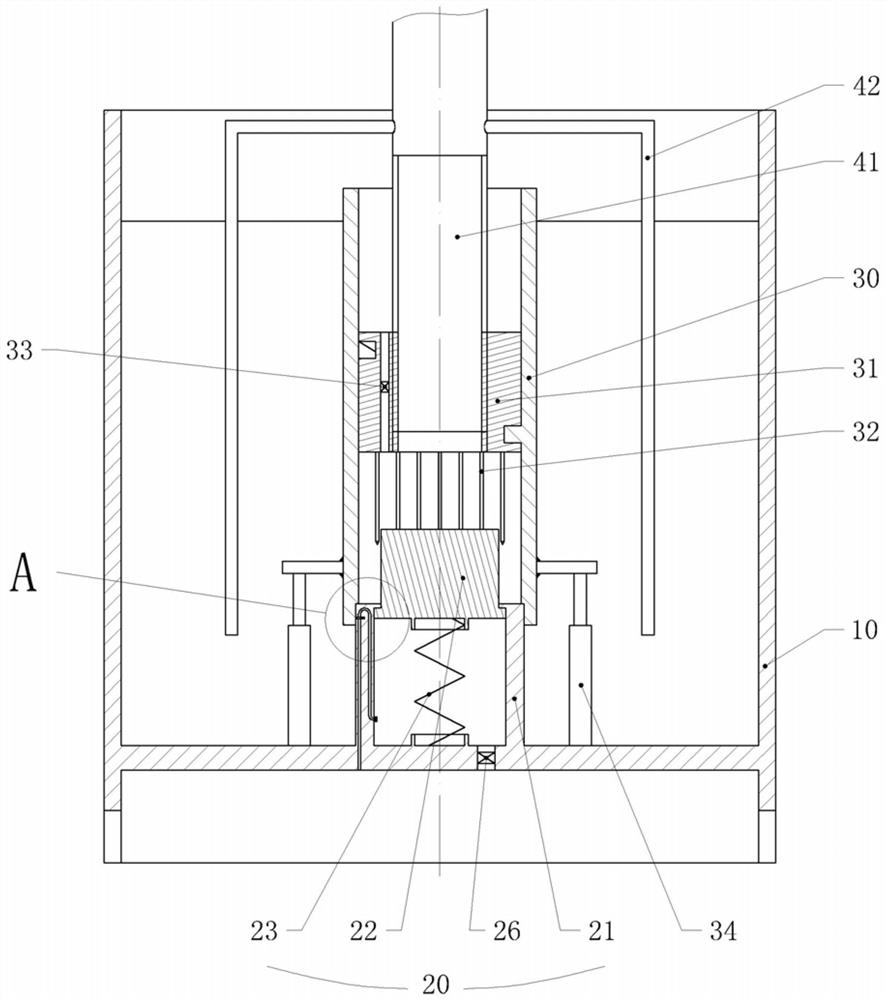

Sludge vibrating mixing spouted bed drying device and method

InactiveCN101830627BExtended stayReduce the possibility of sticking to the wallSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention relates to a sludge vibrating mixing spouted bed drying device and a sludge vibrating mixing spouted bed drying method. The sludge vibrating mixing spouted bed drying device provided by the invention comprises a dryer body (1), an inner cylinder (2), a mixing device (4), a spring component (6), a vibrating motor (8), a wet sludge inlet (3) and a heat medium inlet (5), wherein the dryer body (1) is divided into an upper part, a middle part and a lower part and provided with a top wall; the inner cylinder (2) is arranged on the upper section in the dryer body (1); the mixing device (4) is arranged on the lower part in the dryer body (1); the spring component (6) is used for connecting the dryer body (1) with the inner cylinder (2); the vibrating motor (8) is arranged outside the top wall of the dryer body (1); the wet sludge inlet (3) is used for inputting wet sludge into the dryer body (1) and is formed in the middle of the dryer body (1); and the heat medium inlet (5) isused for inputting heat media into the dryer body (1) and is formed on the lower part of the dryer body (1). The device has the advantages of continuous operation, low labor intensity, high production efficiency and low heat dissipation.

Owner:SOUTHEAST UNIV

Crushed lithium battery screening and recycling device

PendingCN112827799ACompact structureLow costSievingScreeningStructural engineeringMechanical engineering

The invention discloses a crushed lithium battery screening and recycling device which comprises a shell and a vibration driving assembly used for driving the shell to vibrate, wherein the shell is provided with a screening cavity; a plurality of layers of screening meshes which are sequentially arranged at intervals from top to bottom are mounted in the screening cavity; the hole diameters of screening holes in the multiple layers of screening meshes are reduced layer by layer in the direction from top to bottom; the screening cavity is divided by the multiple layers of screening meshes into a plurality of cavities which are sequentially arranged from top to bottom; the top cavity is provided with a feeding port; each cavity is provided with a discharging port; and a plurality of crushing components capable of jumping under the action of the vibrating screen meshes are mounted in at least one cavity positioned between every two adjacent layers of screening meshes. The crushed lithium battery screening and recycling device has the advantages of being simple and compact in structure, low in cost, high in screening efficiency, and good in screening effect.

Owner:HUNAN JINLU TECH CO LTD

A kind of extraction process that improves the recovery rate of anthocyanin

The invention discloses an extraction process for improving the recovery rate of prickly ash, and relates to a method for extracting food spices. The specific method includes: (1) Zanthoxylum bungeanum pretreatment: compressing Zanthoxylum bungeanum raw materials into tablets, the thickness of which is 0.1-0.5mm; 2) Supercritical CO 2 Fluid extraction: Put the pepper flakes into the extraction tank, when the pressure of the extraction tank rises to 30-35MPa, and the extraction temperature is 45-55°C, feed supercritical CO 2 At the same time, the entraining agent is introduced into the entraining agent, extracted for 2-3 hours, and the extract is obtained; (3) Separation: the extract enters the separation tank for separation, the separation pressure is 6-8MPa, and the separation temperature is 50-55°C to obtain Zanthoxylum bungeanum crude oil and gaseous CO 2 (4) Separating the entrainer from the extracted Zanthoxylum bungeanum crude oil, and finally obtaining the oleoresin containing pianopianin. The process has high recovery rate and simple process.

Owner:郑州雪麦龙食品香料有限公司

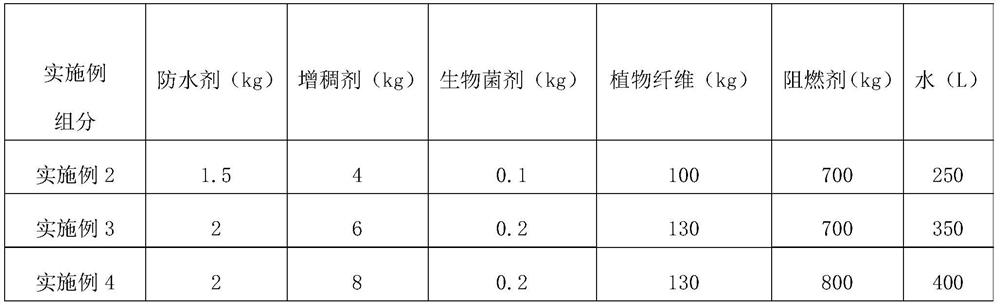

Production method of soilless spray coating material

ActiveCN113304672BBrokenGood adhesionMixing methodsLandfill technologiesPlant fibreAgricultural engineering

Owner:GUIZHOU OURUIXIN ENVIRONMENTAL PROTECTION TECH

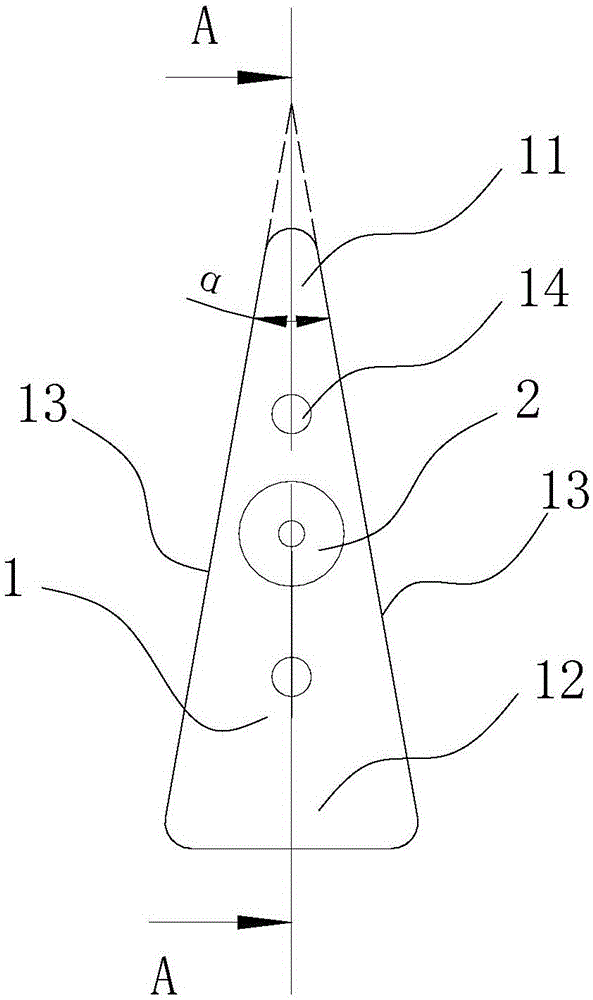

Dynamic material thermometer

ActiveCN105067135ABrokenImprove accuracyThermometer detailsTemperature measurement of flowing materialsEngineeringAngle alpha

The invention discloses a dynamic material thermometer which can fully detect material temperature and improve material temperature detection precision. The dynamic material thermometer comprises a temperature sensor and a thermal conductor having a material charging end and a discharging end, wherein two material contacting planes are arranged between the material charging end and the discharging end and intersect with each other to form a material charging end. The included angle alpha between the two material contacting planes satisfies 0<alpha<180 degrees. The temperature sensor has a sensing terminal and a signal output terminal and is installed on the thermal conductor, and the sensing terminal of the temperature sensor extends into the thermal conductor. When the dynamic material thermometer is employed, the material temperature detection accuracy is improved, and great temperature detection error when material blocks appear can be prevented. The temperature sensor can detect the temperature of flowing material on a real-time basis.

Owner:四川华宇瑞得科技有限公司

Cement processing drying device

InactiveCN104930829AImprove heat exchange efficiencyExtended stayDrying gas arrangementsDrying solid materialsSocial benefitsFluidized bed

The invention discloses a cement processing drying device. The device comprises a coal crusher, an elevator, a high-pressure draught fan, a coal bunker, a coal feeding electric vibrating machine, a high-temperature fluidized bed furnace, a feeding device, a lifting board, a discharging reamer, a dust remover and a dustproof draught fan. The coal crusher is disposed on one side of the elevator, and a crushed coal bucket is arranged at an outlet of the coal crusher; the coal bunker is disposed at one end of the high-temperature fluidized bed furnace; the coal feeding electric vibrating machine is arranged at one end of the coal bunker; the high-temperature fluidized bed furnace is arranged on one side of the lifting board; the feeding device is installed at one end of the high-temperature fluidized bed furnace; the high-pressure draught fan is arranged at one end of the high-temperature fluidized bed furnace; the discharging reamer is arranged at one end of the dust remover; and the dustproof draught fan is arranged on one side of the dust remover. The heat efficiency of the lifting board of the cement processing drying device is high, the rotation speed of a motor is appropriate, the cooling capacity of a drying machine is high, and the cement processing drying device has good economic benefits and social benefits and is suitable for application and popularization.

Owner:郑鹏飞

Intermittent comburent rotary kiln for garbage incineration treatment

The invention is applicable to the technical field of garbage disposal, in particular to an intermittent comburent rotary kiln for garbage incineration treatment. The rotary kiln comprises a kiln body and a base, the kiln body is obliquely arranged, side plates which are oppositely distributed are arranged on the surface of the base, one of the side plates is rotatably connected with the upward inclined end of the kiln body through a hollow pipe, the hollow pipe extends into the kiln body, the other side plate is rotatably connected with the downward inclined end of the kiln body through a supporting column, a discharging opening is formed in the downward inclined end of the kiln body, the hollow pipe is connected with a feeding hopper, a feeding mechanism is arranged in the feeding hopper, and a driving mechanism and a conveying mechanism are arranged outside the kiln body. A crushing mechanism is arranged in the kiln body. According to the kiln, garbage is controlled to intermittently enter the kiln body through the feeding mechanism, the phenomenon that the kiln body is blocked due to the fact that excessive garbage enters the kiln body at a time is avoided, and garbage combustion sufficiency is guaranteed.

Owner:佛山市科恒博环保技术有限公司

Layering treatment method for petroleum-contaminated soil

InactiveCN111495954AImprove governance effectMaintain structureContaminated soil reclamationSoil scienceSoil treatment

The invention discloses a layering treatment method for petroleum-contaminated soil. The layering treatment method comprises the following steps: deeply ploughing a to-be-treated land parcel for at least two times; digging surface soil, carrying out preheating crushing, screening and pyrolysis treatment on the soil to obtain a pyrolysis mixture, carrying out fixed-distance deep penetration into the soil, and carrying out high-pressure spraying of a microbial treatment solution once; paving the pyrolysis mixture on the ground; after the temperature of the surface layer of the pyrolysis mixtureis reduced, spreading the soil treatment mixture on the treated land parcel, raking once, and carrying out heat preservation plastic film mulching treatment; repeating the above steps once; spreadingthe soil treatment mixture mixed with grass seeds on the to-be-treated land parcel, raking the land once, and covering the land with a heat preservation plastic film; and repeating the above steps until the concentration of petroleum in the soil with the depth of 0-50 cm of the to-be-treated land parcel is lower than a restoration target value. According to the layering treatment method for the petroleum-contaminated soil, a physical method and a biological method can be combined to carry out layering treatment on the petroleum-contaminated soil, so the treatment effect is effectively improved.

Owner:尤宝旺

Stirring mechanism of glass fiber cloth gluing device

ActiveCN107029950BImprove work efficiencyAvoid cakingLiquid surface applicatorsTransportation and packagingGlass fiberLiquid tank

The invention provides a stirring mechanism of a glass fiber cloth gluing device, which belongs to the technical field of machinery. It solves the problem of poor quality of existing gluing devices. In the present invention, the glass fiber cloth gluing device includes a bracket and a workbench fixed on the bracket. The workbench is fixed with a tank body with a notch upward, and the tank body has a glue tank that divides its inner cavity into mutually independent glue tanks and glue tanks. The separator of liquid tank 2, the stirring mechanism includes two stirring shafts vertically arranged in glue tank 1 and glue tank 2 respectively, the bottom of the tank body has a through hole, and there are two through holes, and the upper ends of the two stirring shafts are fixed There are stirring blades, the lower ends of the two stirring shafts pass through the two through holes respectively and are fixed axially with the workbench. The motor is also fixed on the workbench. The motor can drive the two stirring shafts to rotate through the transmission mechanism at the same time; A plurality of crushing heads are fixed on the inner wall of the second groove, and the crushing heads are conical. The stirring mechanism has the advantage of improving the gluing quality.

Owner:浙江凯澳新材料有限公司

Steel crushing device

PendingCN113083468AReduce vibrationReduce the sound of vibration noiseNon-rotating vibration suppressionGrain treatmentsSlide plateCrusher

The invention relates to waste steel recycling equipment, and provides a steel crushing device which comprises a cutting mechanism in a machine, a crusher frame and an elastic shockproof structure at the bottom. The cutting mechanism comprises two cutting wheels, cutting blades are arranged on the surfaces of the cutting wheels, and supporting rods are arranged at the tail ends of bearings of the two cutting wheels; the crusher frame comprises a feed port sliding plate, a feed port sliding plate supporting rod, an anti-rebound plate, an shock absorption layer and an external steel plate layer; and the bottom elastic shock absorption structure comprises three parts, namely an upper-layer bearing plate, a lower-layer bearing plate and a middle spring vibration isolator. The steel crushing device is designed on the basis of the concept of shock absorption and noise reduction, the bottom shock absorption structure and the shock absorption layer in a crusher are formed, noise is greatly reduced when the machine runs, meanwhile, the shapes of the cutting blades on the cutting wheels can be matched with each other, and waste steel is cut to be smaller.

Owner:江西先峰钢结构有限公司

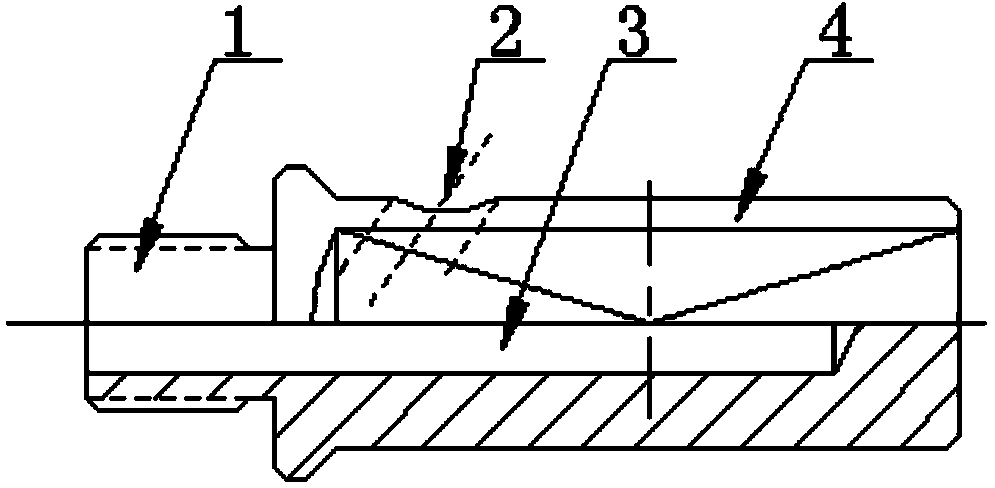

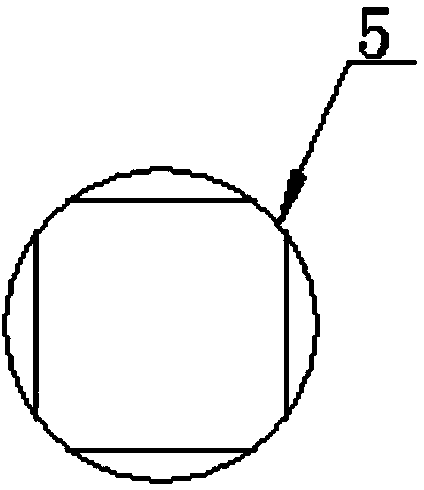

Central water outlet scrap crushing water nozzle for numerical control lathe

InactiveCN103480868ABrokenEasy to washAuxillary equipmentMaintainance and safety accessoriesNumerical controlInlet channel

The invention relates to a central water outlet scrap crushing water nozzle for a numerical control lathe. The central water outlet scrap crushing water nozzle is formed by a water nozzle mounting handle and a water nozzle main body; a central water inlet channel is made in the axis parts of the water nozzle mounting handle and the water nozzle main body; a water outlet bevel hole communicated with the central water inlet channel is formed in the water nozzle main body; the central water outlet scrap crushing water nozzle is characterized in that the water nozzle main body is shaped like a square post body. The central water outlet scrap crushing water nozzle for the numerical control lathe is scientific and reasonable in structural design and convenient to mount, and the scrap crushing effect is realized while rinsing is realized, so the scrap removing capacity of the water nozzle is improved. The central water outlet scraping crushing water nozzle belongs to a central water outlet scrap crushing water nozzle with higher innovation for the numerical control lathe.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

A kind of organic fertilizer processing equipment

ActiveCN108413760BPlay a piercing functionBrokenTransportation and packagingRotary stirring mixersAgricultural scienceWater storage tank

The invention provides an organic fertilizer processing equipment, including a hopper, a material guide plate, a dehumidification, air-drying and drying device, a material block buffer crushing frame structure, a fertilizer particle vibration separation device, a hopper, a protective outer cover, a mounting plate, and finished fertilizer storage. Discharge frame structure, water storage tank, water level scale line, powder fertilizer quantitative dosing pipe structure, stirring box, catheter, stirring motor, stirring shaft, stirring blade, liquid material outlet pipe, outlet pipe regulating valve and supporting legs, all The above-mentioned feeding hopper is installed on the upper left side of the dehumidifying, air-drying and drying device. The arrangement of the T-shaped pin, vibrating plate and vibrating motor of the eccentric wheel in the present invention is beneficial to pierce the lumped fertilizer on the vibrating plate, and then facilitate the crushing of the agglomerated fertilizer; The horizontal baffle, the transparent quantitative storage box and the setting of the powder height scale line are conducive to observing the capacity of the fertilizer powder in the transparent quantitative storage box, and then it is convenient to quantitatively add fertilizer powder to the mixing box.

Owner:滨州农一电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com