Mixing mechanism for gluing device for glass fiber cloth

A technology of glass fiber cloth and stirring mechanism, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, and devices for coating liquid on surfaces, etc. Low-level problems, to achieve the effect of improving the quality of gluing, the best impregnation effect, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

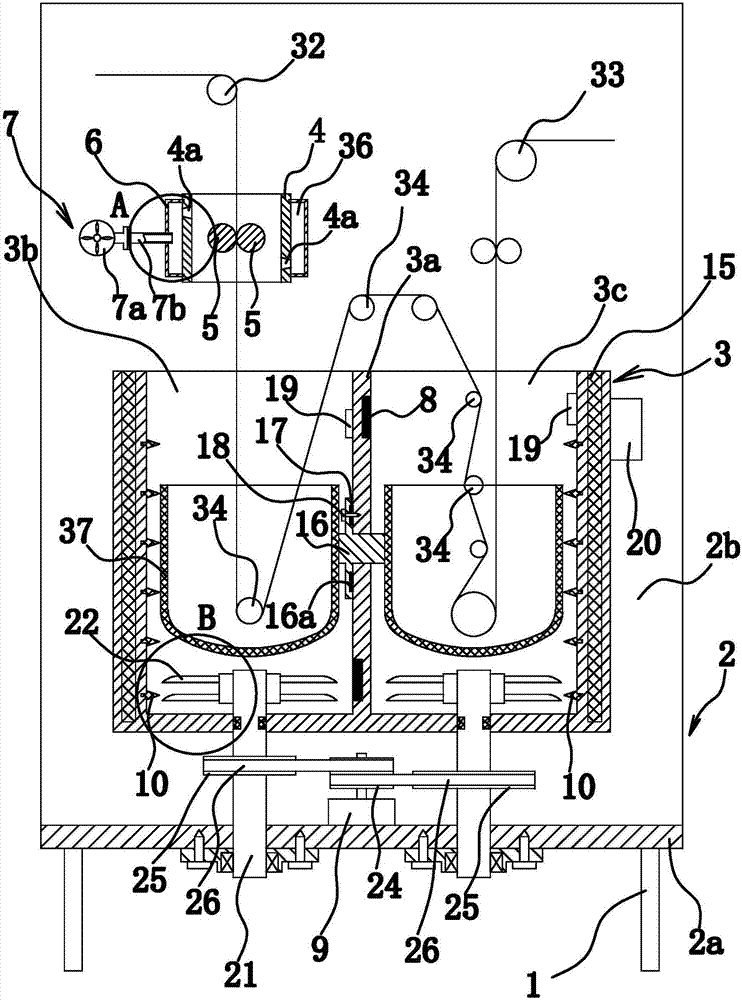

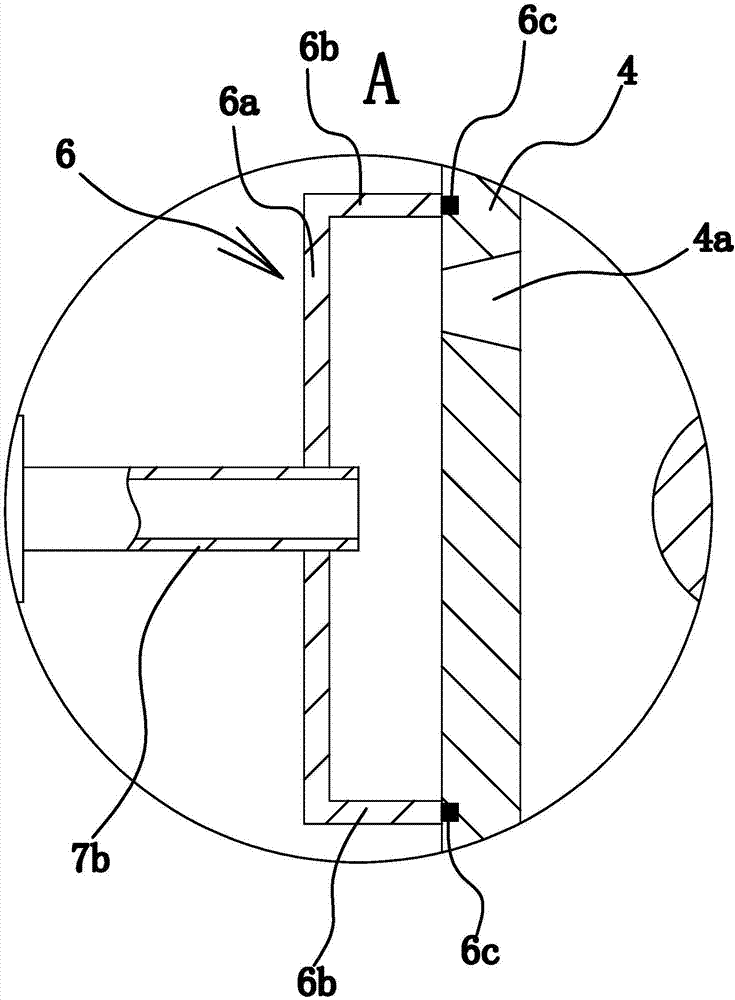

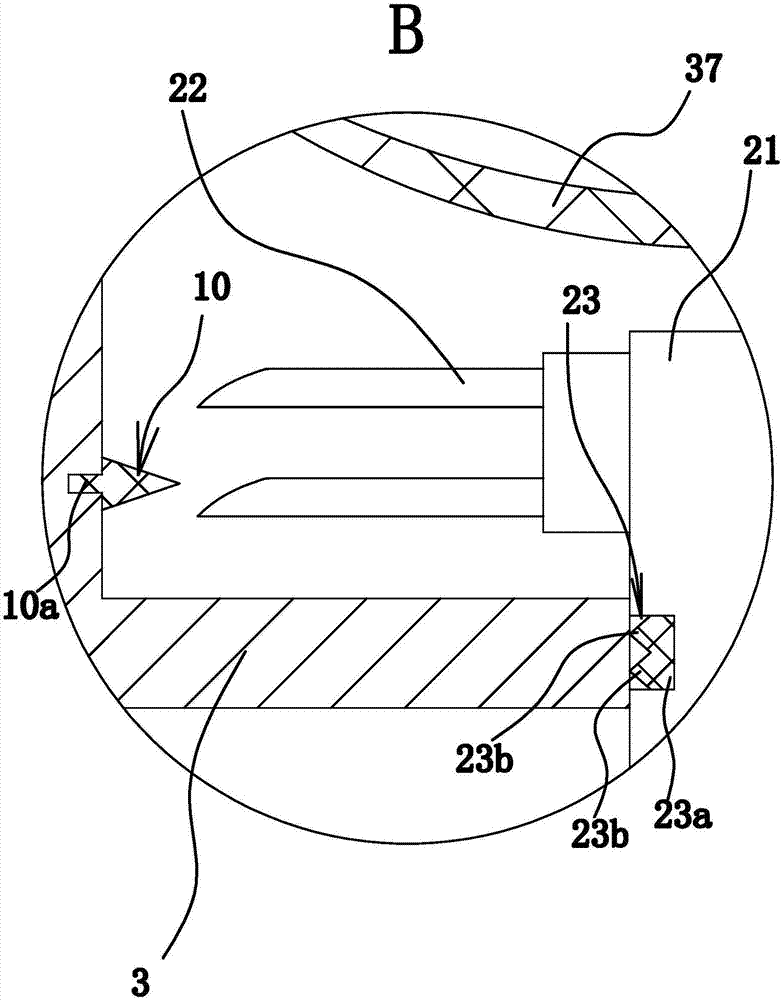

[0031] Such as Figure 1 to Figure 6 As shown, the glass fiber cloth gluing device consists of a bracket 1, a workbench 2, a tank body 3, an air suction ring 4, a roller shaft 5, a sealing ring 6, a negative pressure piece 7, an electric heating plate 8, a motor 9, and a crushing head 10. Composition of support block 11, piston 12, push plate 13, spring 14, etc. Wherein, the electric heating plate 8 is an existing product, which can be bought in the market.

[0032] Specifically, the workbench 2 is located on the support 1, such as figure 1 As shown, the workbench 2 is L-shaped, and the workbench 2 includes a horizontally arranged support part 2a and a vertically arranged support part 2b. Both the support part 2a and the support part 2b are plate-shaped, and the support part 1 2a is fixed to the bracket 1 by welding.

[0033] The tank body 3 is arranged on the front side of the workbench 2, and the notch of the tank body 3 faces upward. The tank body 3 and the supporting p...

Embodiment 2

[0058] The structure and principle of the present embodiment three are basically the same as those of the first embodiment, except that the motor 9 is located between the two stirring shafts 21, and the transmission mechanism includes a main gear fixed on the main shaft of the motor 9 and fixed on the two stirring shafts respectively. Two secondary gears on the 21, and both secondary gears are meshed with the main gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com