Patents

Literature

111results about How to "Guaranteed scraping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

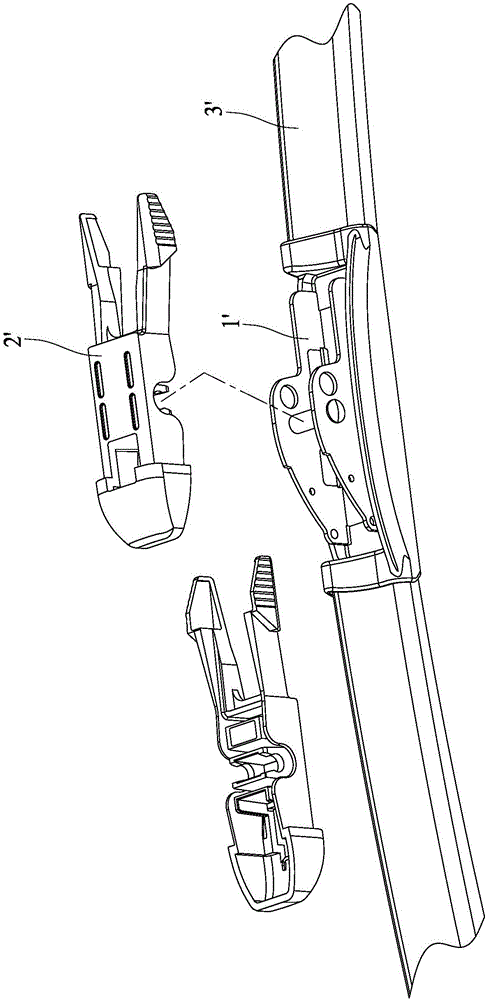

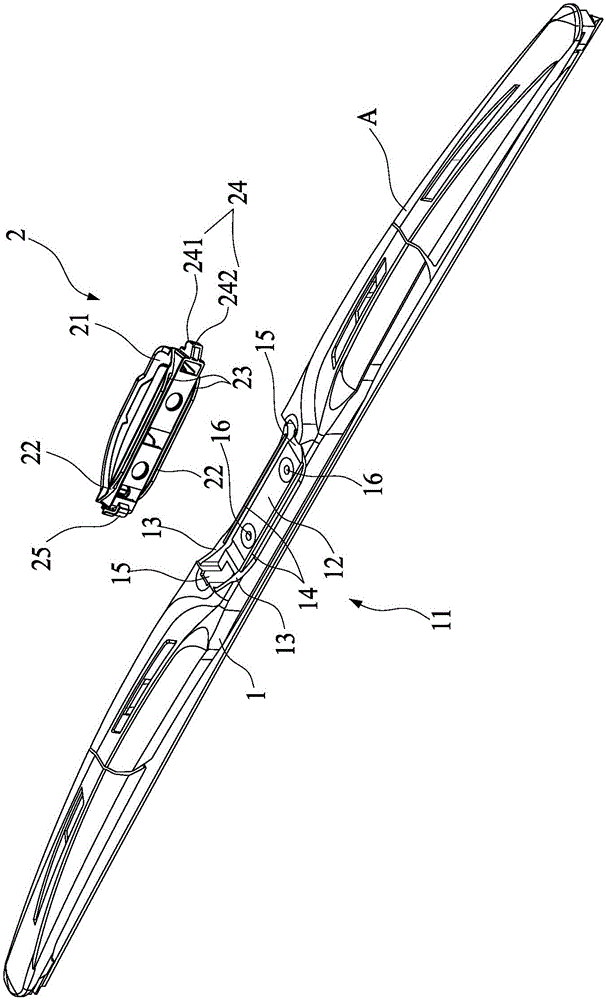

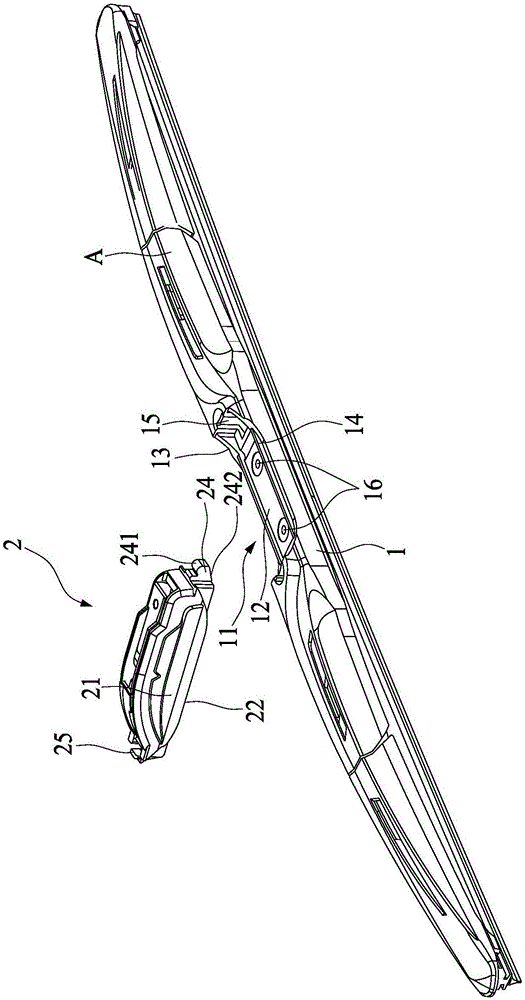

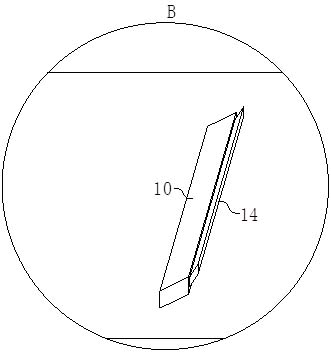

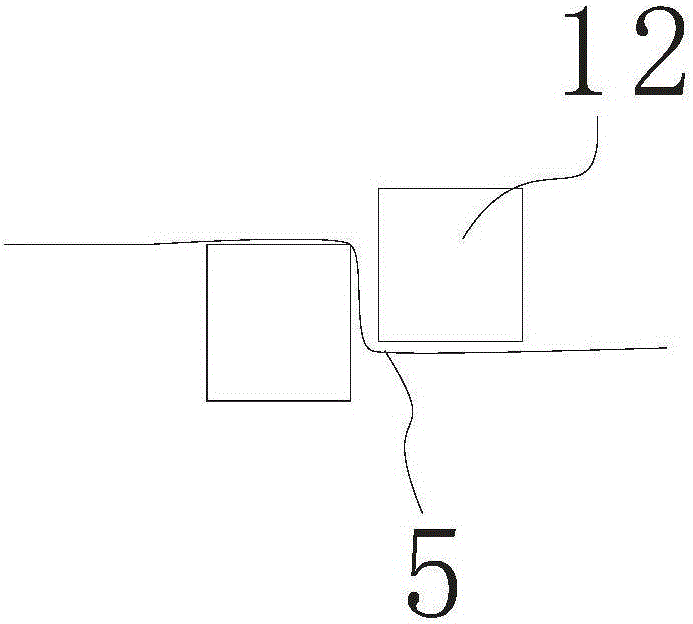

Windshield wiper connecting assembly

The invention discloses a windshield wiper connecting assembly which comprises a connecting seat and a windshield wiper connector. An open sunken groove is formed in the middle of the connecting seat along the length direction of the connecting seat and is provided with a horizontal bottom surface and cambered surfaces, the cambered surfaces extend from two ends of the horizontal bottom surface to the top of the connecting seat in a transition manner, two parallel positioning ribs are arranged on the bottom surface along the length direction of the bottom surface at intervals, and positioning slots are formed in the two cambered surfaces; the windshield wiper connector is detachably mounted on the sunken groove of the connecting seat and is provided with a base, bottom edges are arranged at the bottom of the base, the contour shapes of the bottom edges are matched with the contour shape of the sunken groove of the connecting seat, clamp grooves which are correspondingly matched with the positioning ribs of the sunken groove are formed in the bottom of the base, and clamping structures which are matched with the positioning slots are arranged at two ends of the base.

Owner:XIAMEN FUKE CAR ACCESSORIES

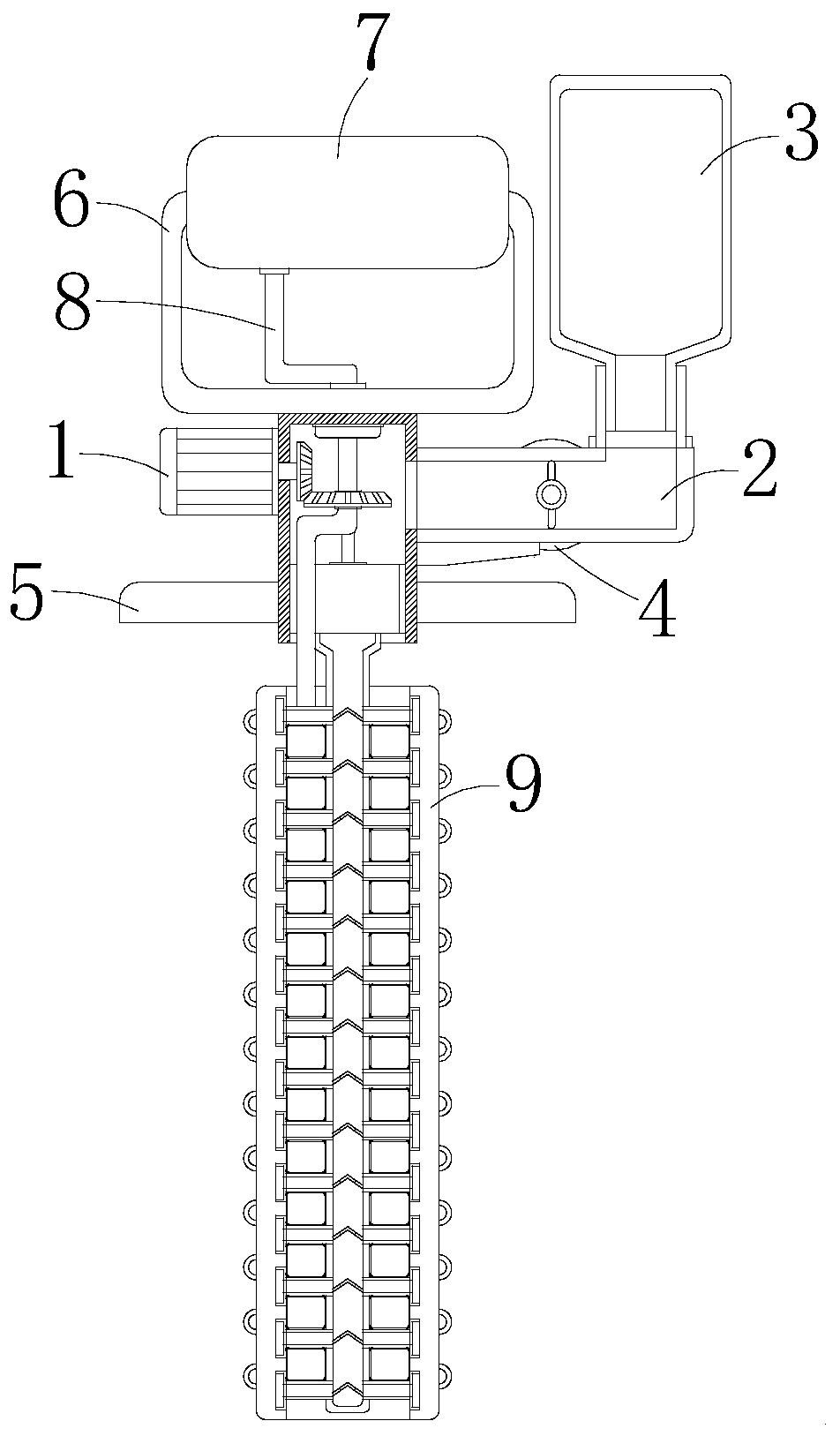

Fuel cylinder block cleaning device

The invention discloses a fuel cylinder block cleaning device, and relates to the technical field of fuel cylinder cleaning. The fuel cylinder block cleaning device comprises a driving mechanism, a holding handle, an inflation bag, a gas transmission pipe and a cleaning mechanism; the middle part of the bottom of the holding handle is fixedly connected to the top of the driving mechanism; the inflation bag is fixedly mounted in the middle part of the top of the holding handle; an exhaust port of the inflation bag is connected with and communicates with the top end of the gas transmission pipe;the bottom end of the gas transmission pipe penetrates through the top of the driving mechanism, and extends into the driving mechanism; and the cleaning mechanism is fixedly mounted under the driving mechanism. The fuel cylinder block cleaning device discharges cleaning liquid into the cleaning mechanism through the driving mechanism, drives the cleaning mechanism to rotate through the driving mechanism to discharge the cleaning liquid, can perform rotary brushing when the cleaning liquid is uniformly coated on the walls of intake manifolds, effectively removes accumulated cartons attached in the intake manifolds, and guarantees normal use of fuel cylinders.

Owner:王治军

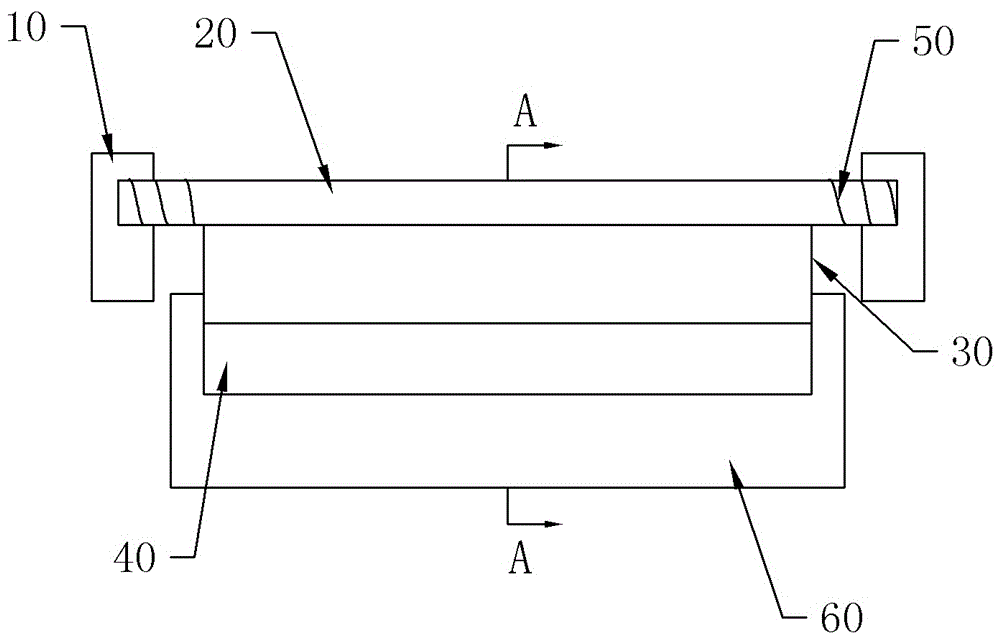

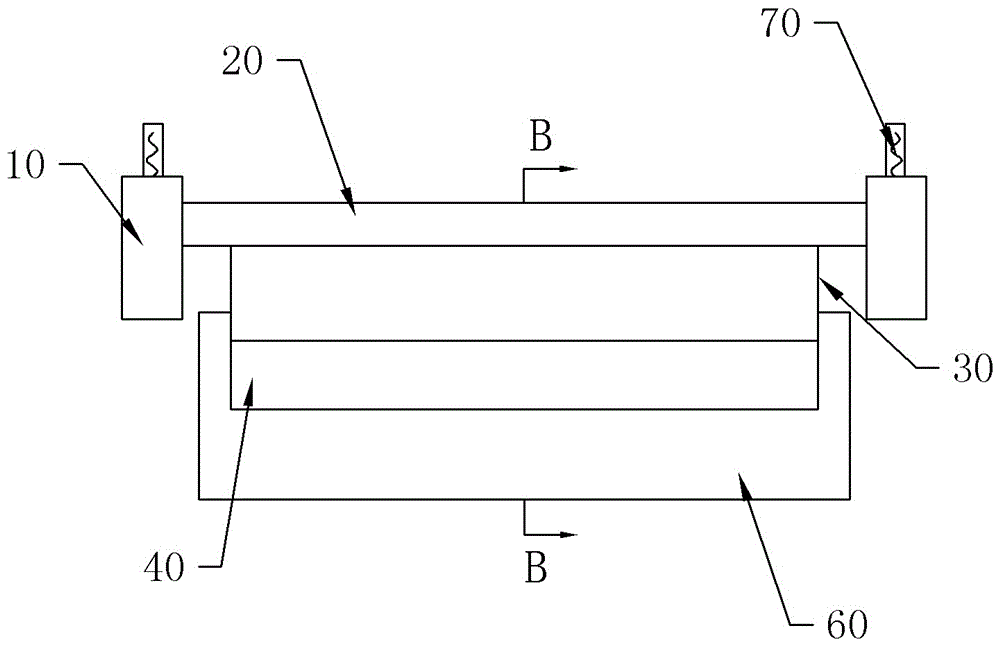

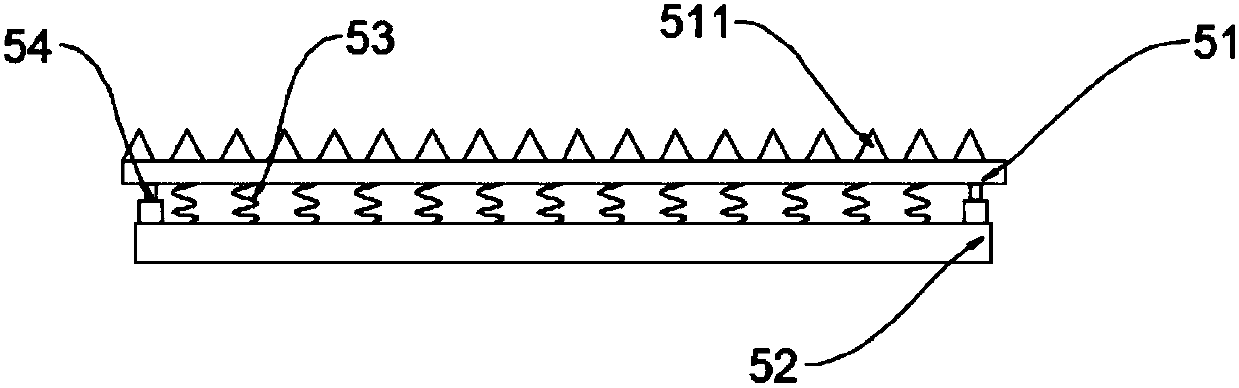

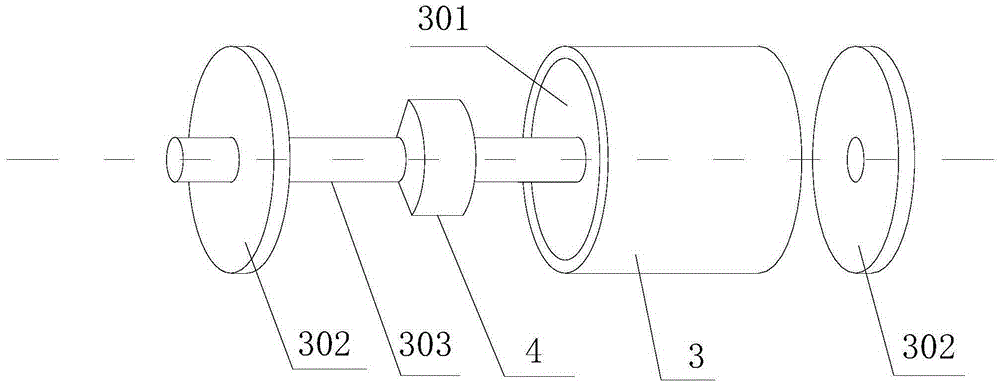

Scraping structure for rollers

ActiveCN106689245ASimple structureGuaranteed scraping effectDough-sheeters/rolling-machines/rolling-pinsEngineering

Owner:CHONGQING ZHOUYI FOOD CO LTD

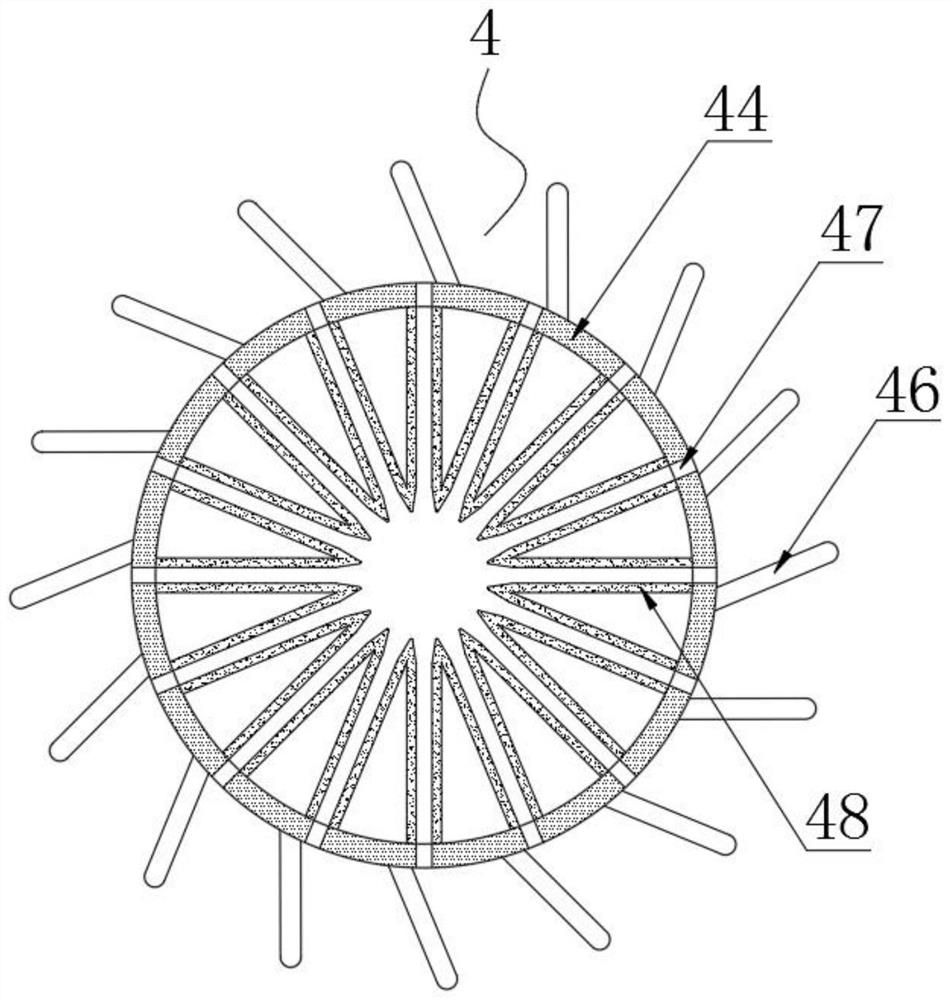

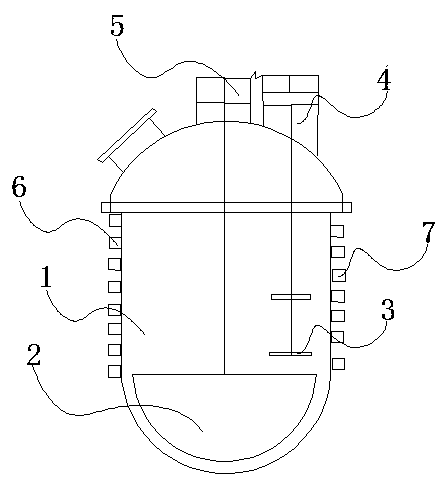

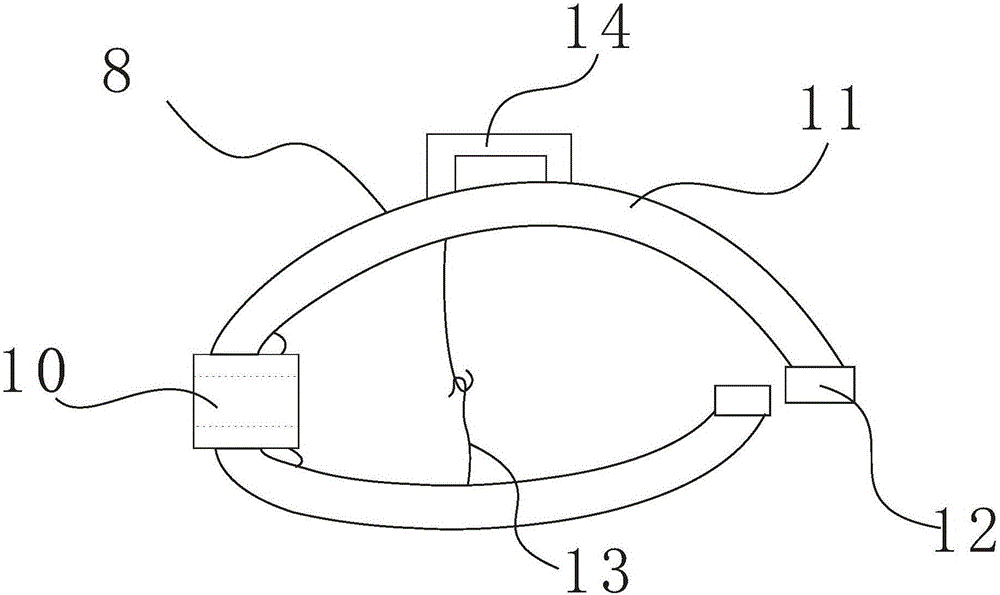

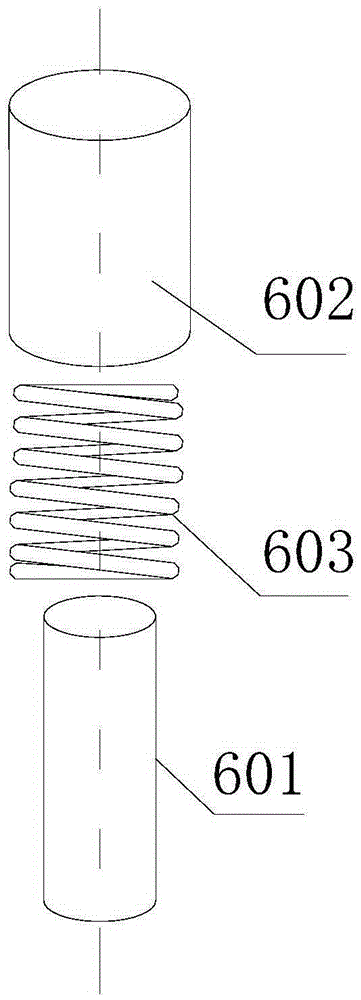

Scaler

InactiveCN103931731ASweep the scales thoroughlyPlay a buffer roleFish washing/descalingMotor driveAquatic product

The invention discloses a scaler, belonging to aquatic product processing machinery. The scaler mainly comprises a support, wherein a shell is fixed on the support, a motor and a rotating shaft are arranged at the bottom of the support, and the motor drives the rotating shaft to rotate; a fish feed inlet and a fish discharge outlet are formed in the shell, and a water outlet is formed in the bottom of the shell; a baffle plate is arranged in the shell, a turnplate is arranged on the rotating shaft, a certain clearance is left between the turnplate and the shell, and a steel wire brush is arranged on the turnplate; a scale cleaning device is arranged on the turnplate movably, and consists of a scale cleaning body, and flexible scale cleaning strips are arranged on the scale cleaning body. The occurrence of fish injury phenomenon can be prevented while the scaling effect can be guaranteed, so that the scaled fish is thoroughly scaled and complete without injury, the scaling mechanization can be realized so as to entirely replace the traditional manual scaling mode, the labor intensity can be lowered and the working efficiency can be greatly improved. The scaler is mainly used for scaling fish.

Owner:曹培银

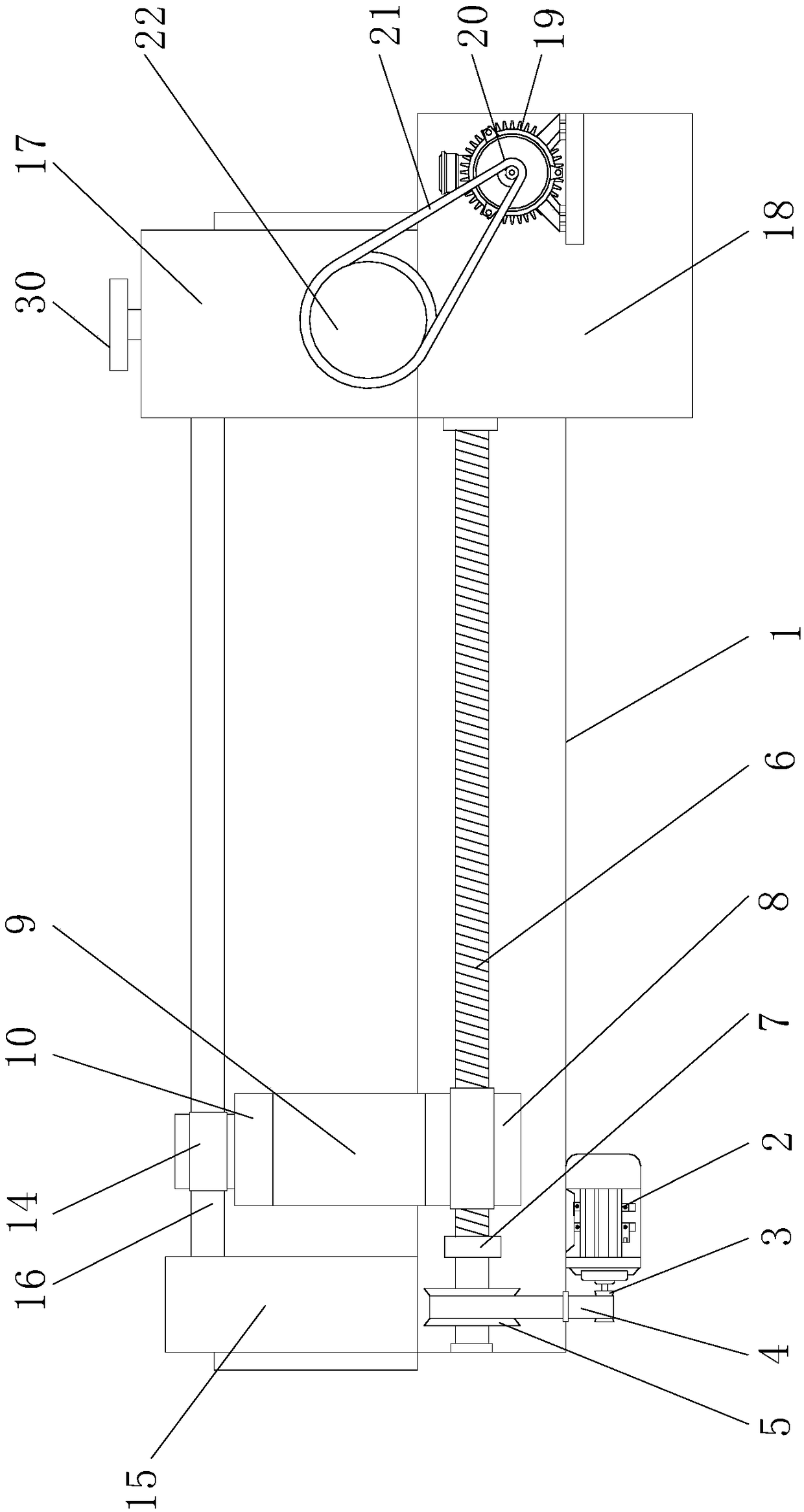

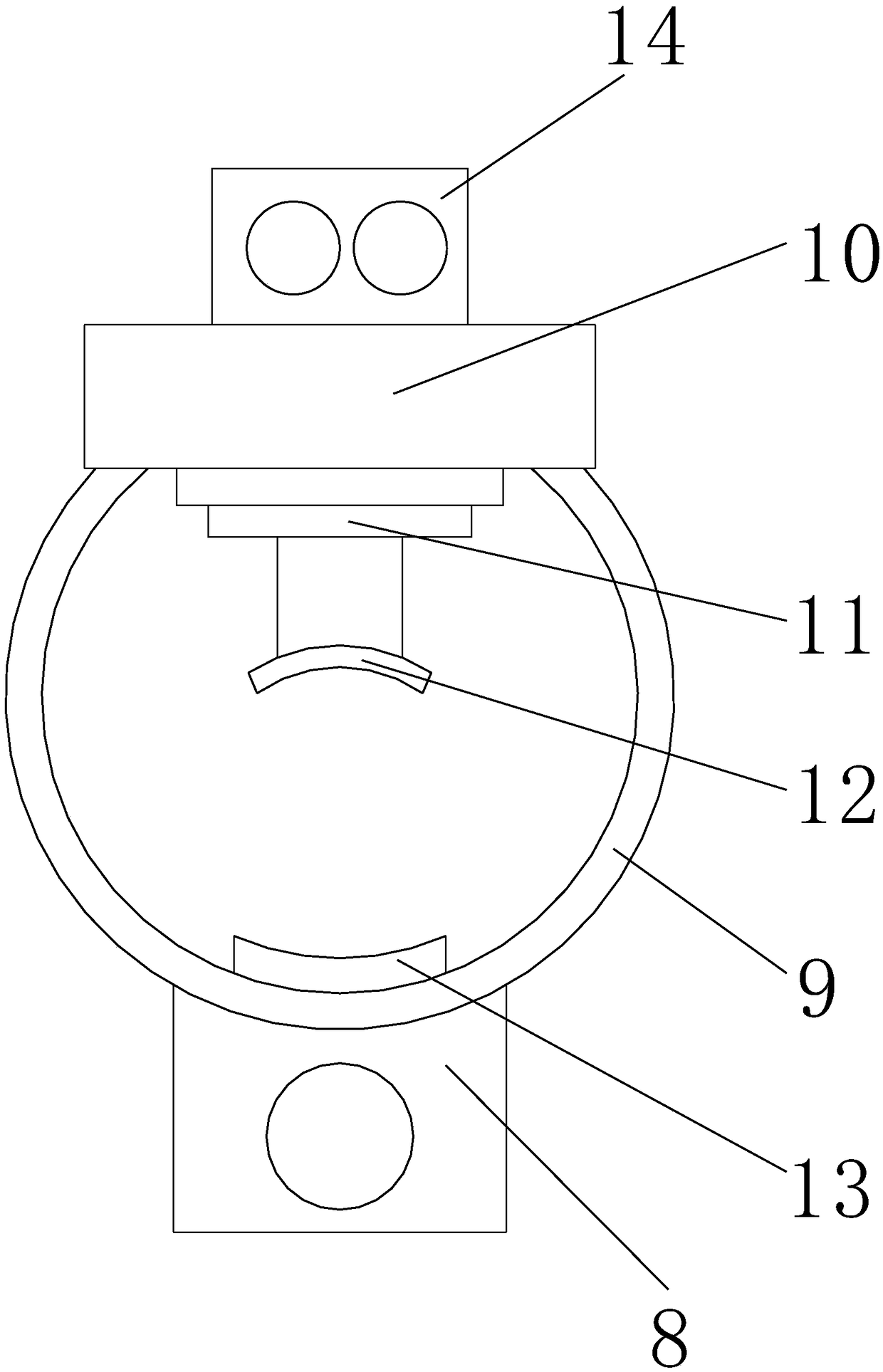

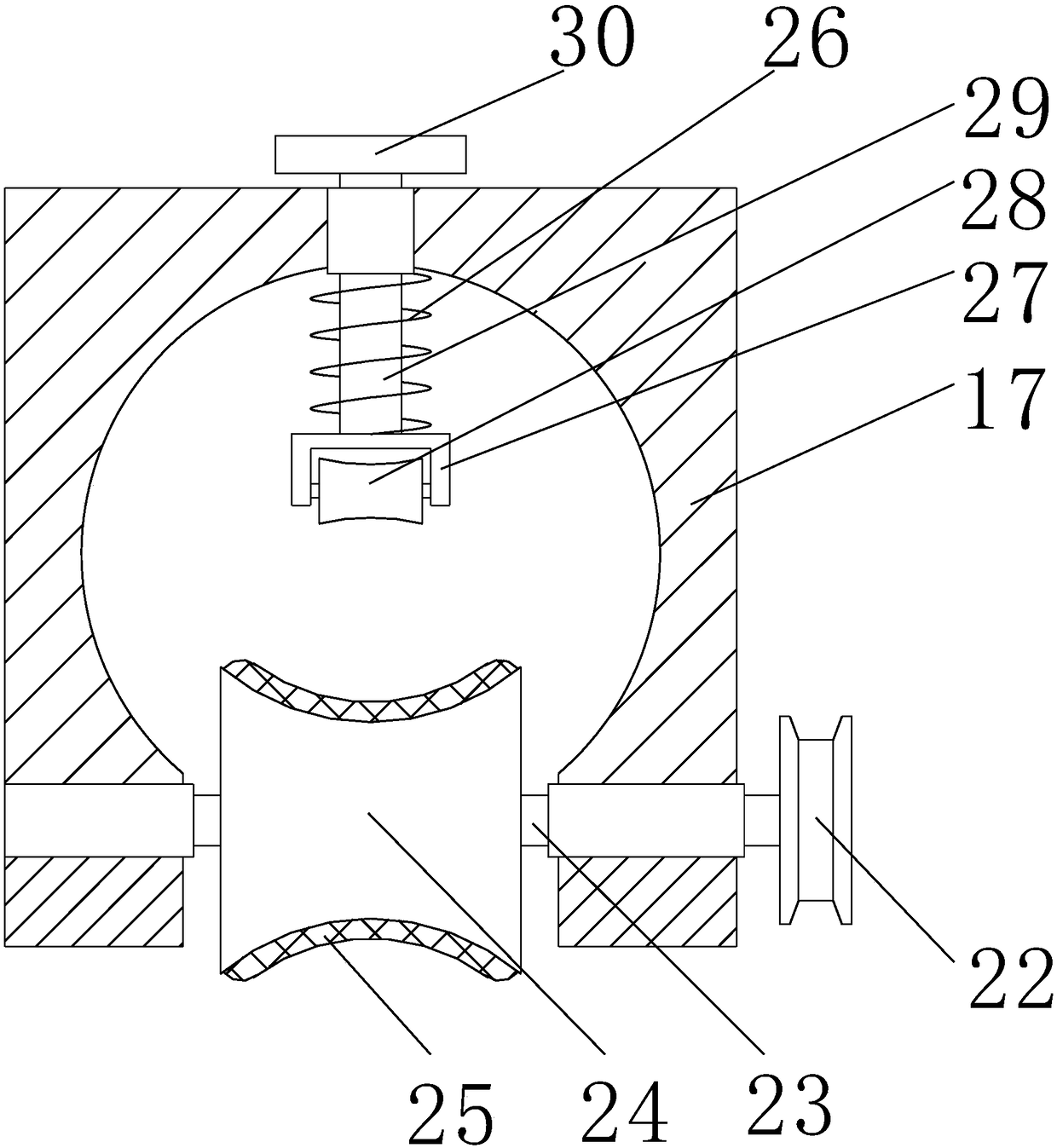

Bamboo green removing device for bamboo processing

The invention discloses a bamboo green removing device for bamboo processing and relates to the technical field of bamboo machinery. The bamboo green removing device for bamboo processing comprises abase. A first motor is fixedly connected to the bottom of the left side of the base. A first rotating wheel is fixedly connected to an output shaft of the first motor. The first rotating wheel is in driving connection with a second rotating wheel through a first belt. A rotary lead screw is fixedly connected to the axis of the second rotating wheel. The rotary lead screw is rotatably connected with the inner wall of the base. The bamboo green removing device for bamboo processing can conduct fixing and automatic feeding on bamboos and achieves the effects of improving the bamboo green removingeffect in place of manual feeding, reducing the workload of workers and improving the processing efficiency, and the bamboos are automatically pressed through a tensioning wheel so that the operationstability of a cutting tool can be guaranteed; meanwhile, a wheel of the cutting tool rotates to conduct scraping on bamboo green on the surfaces of the bamboos; the bamboo green scraping effect is effectively guaranteed, the processing efficiency is improved, and labor force is reduced.

Owner:安吉县怡成竹木工艺品厂

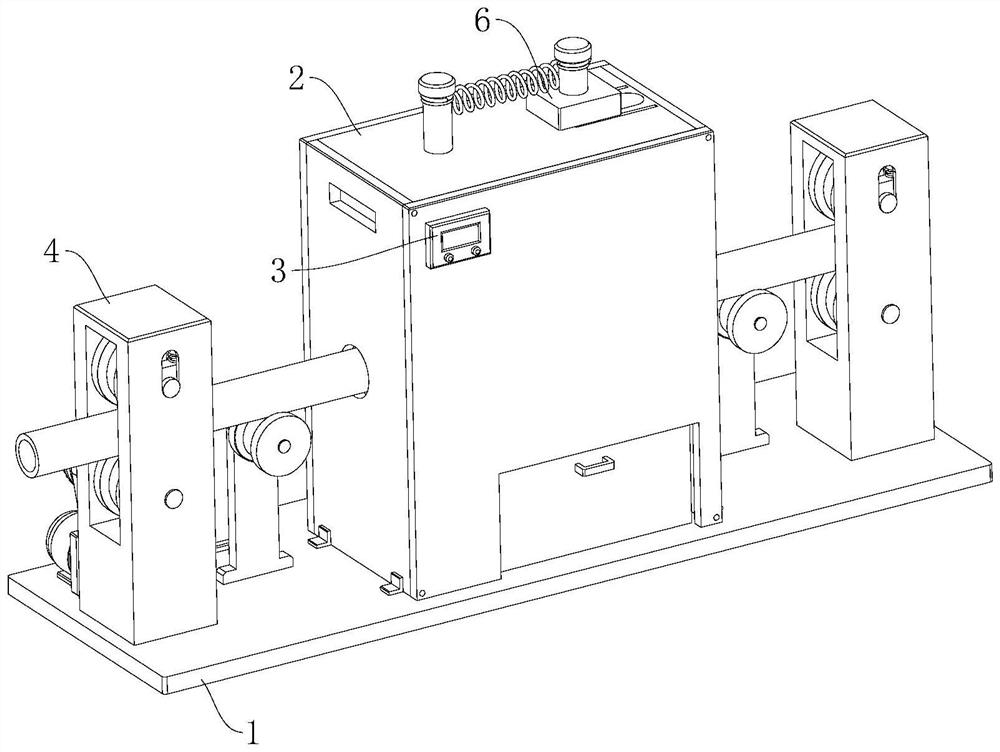

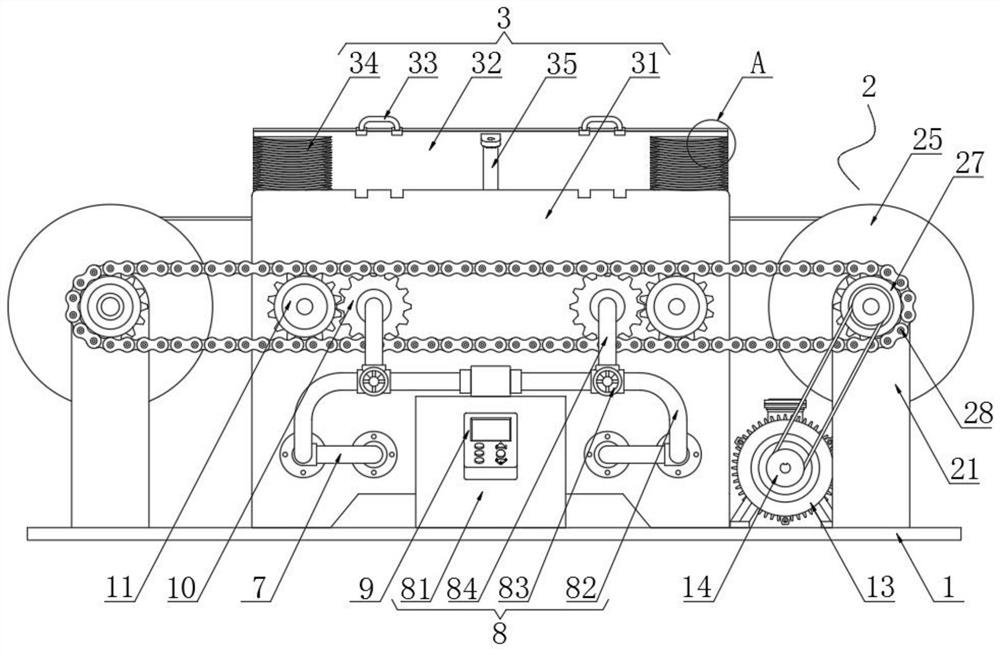

Construction site steel pipe surface cleaning equipment

ActiveCN112354979AReduce labor intensityReduce cleanup stepsHollow article cleaningDirt cleaningSurface cleaningPipe

The invention relates to the field of cleaning devices, in particular to construction site steel pipe surface cleaning equipment. The equipment comprises a base and a cleaning box and further comprises a controller, a conveying mechanism, a beating mechanism and a scraping mechanism. The conveying mechanism is arranged at the top of the base to be used for conveying steel pipes and comprises a transmission assembly and two conveying tables. The beating mechanism is arranged at the top of the inner side of the cleaning box and used for beating the steel pipes, the beating mechanism comprises ahammer head and a rotating assembly, the scraping mechanism is arranged at the top of the inner side of the cleaning box and used for scraping impurities such as concrete on the surfaces of the steelpipes, the scraping mechanism comprises a scraping head, a pushing assembly and a limiting assembly, and the transmission assembly is electrically connected with the controller. According to the construction site steel pipe surface cleaning equipment, manpower is automatically replaced, the cleaning efficiency is high, the labor intensity is low, the noise is low, meanwhile, the power consumptionis low, the cleaning cost can be reduced, the cleaned impurities can be effectively collected, and pollution is avoided.

Owner:巢湖市鼎力铁塔有限公司

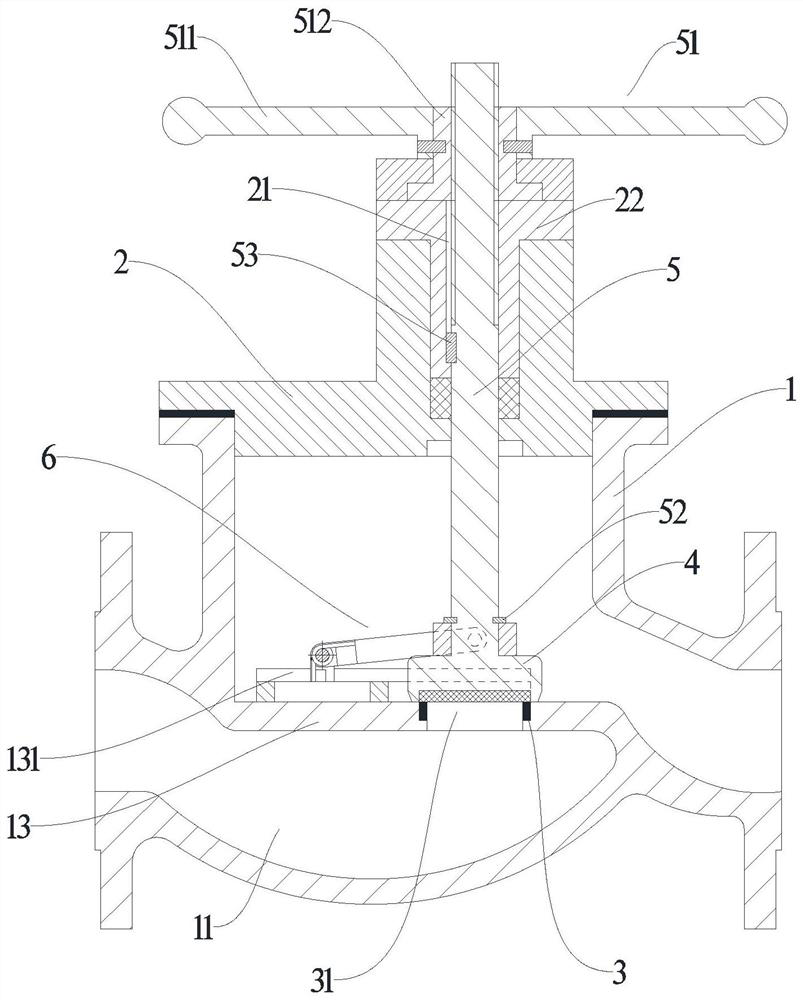

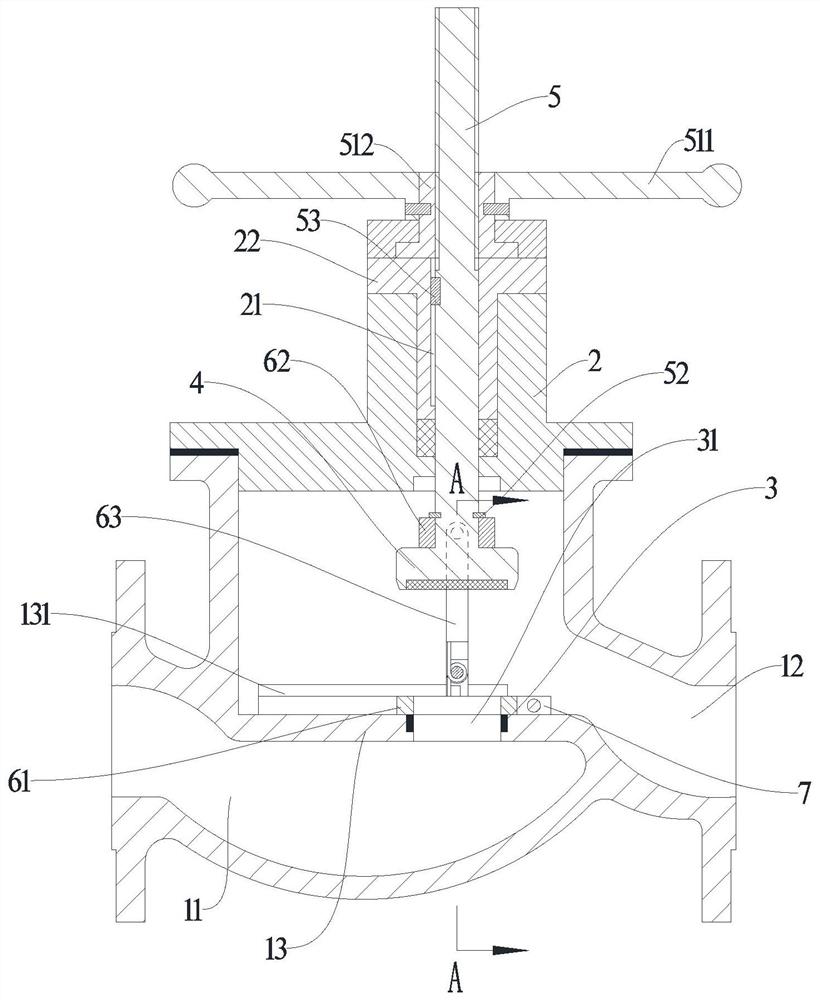

Stop valve

InactiveCN111720564APlay a role in cleaning upHas a barrier effectOperating means/releasing devices for valvesCleaning using toolsStructural engineeringMechanics

The invention relates to a stop valve which comprises a valve body and a valve cover. An inlet runner and an outlet runner are arranged in the valve body. A division plate is arranged between the inlet runner and the outlet runner. A valve seat is arranged on the side, located on the inlet runner, in the valve body. The stop valve further comprises a clearing mechanism and a protection plate cleaning part. The clearing mechanism is connected with the valve body, and media deposited on the surface of the valve seat can be cleaned away. The clearing mechanism comprises a protection plate, a connecting plate and a hinged part. Through ascending and descending of a valve clack, the protection plate can be controlled to clear the sealing face of the valve seat, and the protection plate cleaningpart can clean the protection plate. The stop valve has the advantages that through the arrangement of the clearing mechanism and the protection plate cleaning part, the clearing mechanism can be used for clearing the valve seat and can be cleared, and therefore the sealing effect of the valve clack and the valve seat is guaranteed, and maintenance cost is reduced.

Owner:张文波

Polyurethane waterproof coating production and processing equipment

InactiveCN113213407AGuaranteed cleanlinessImprove filling efficiencyConveyorsCleaningChemistryManufacturing engineering

The invention relates to the field of waterproof coating production and processing equipment, in particular to polyurethane waterproof coating production and processing equipment. The equipment comprises a support, a conveying structure, a sweeping structure, a scraping structure, a circulating structure and a dewatering structure. When the conveying structure continuously conveys packaging barrels, the sweeping structure can be synchronously driven to work, through work of the sweeping structure, a coating adhering to a conveying assembly on the conveying structure can be swept, and therefore the cleanliness of the conveying structure is guaranteed; and by installing the scraping structure at the bottom end of the support, the coating adhering to the conveying assembly can be scraped and cleared, the scraped coating can be collected, the cleanliness of the conveying assembly can be guaranteed, the scraped coating can be prevented from polluting the workshop ground, and the sweeping structure can synchronously drive the dewatering structure to work while working, so that the cleaned conveying assembly is wiped and dried, and a wiped assembly can be extruded and dehydrated.

Owner:汤健

Ceramic tile seam beautifying device

PendingCN110565914AEasy to moveImprove construction efficiencyBuilding constructionsMaterials scienceCeramic tiles

The invention relates to the field of ceramic tile seam beautifying, and discloses a ceramic tile seam beautifying device. The ceramic tile seam beautifying device is provided with a glue gun, guide wheels, a roller pressing ball and a scraping plate. When the device slides along a seam between ceramic tiles, the guide wheels can play a guiding role, so that the device is prevented from deviatingfrom the seam, and the seam beautifying efficiency is guaranteed; the glue gun extrudes a seam beautifying agent into the seam, the roller pressing ball squeezes the seam beautifying agent in the seam, and the scraping plate scrapes the seam beautifying agent attached to the ceramic tiles; and therefore, the multiple steps of seam beautifying can be completed through one-time operation, and the use is convenient.

Owner:成都生活家网络科技有限公司

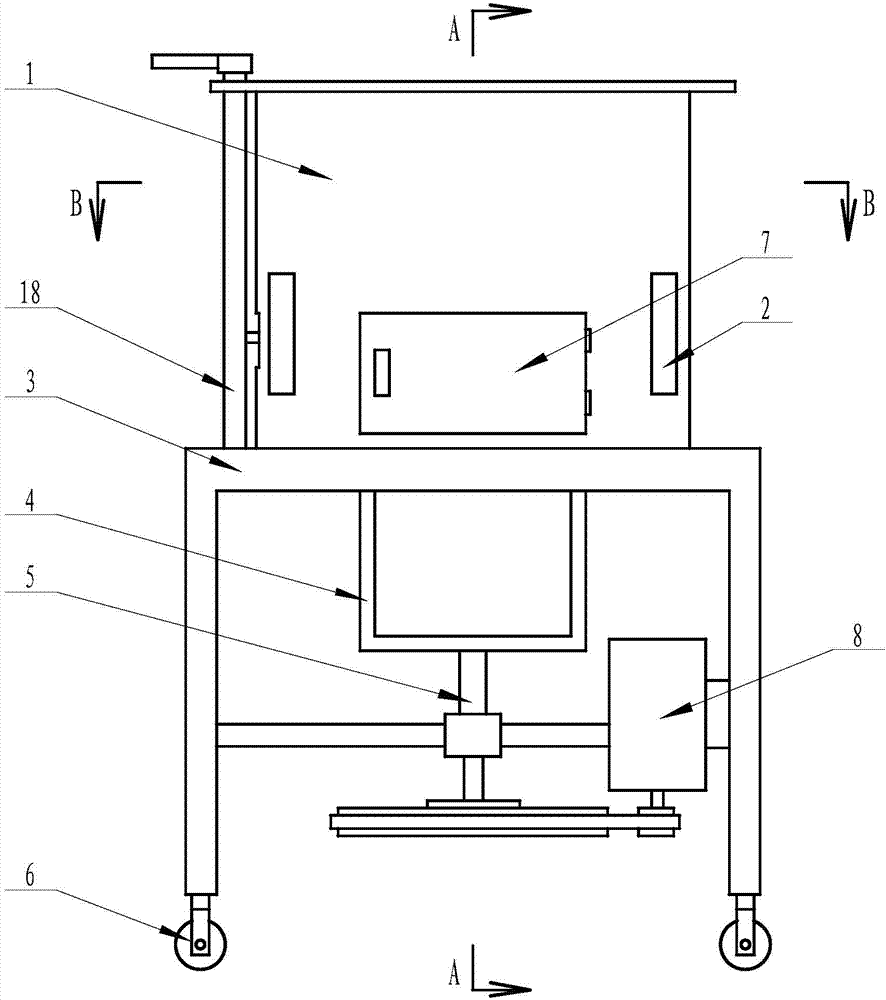

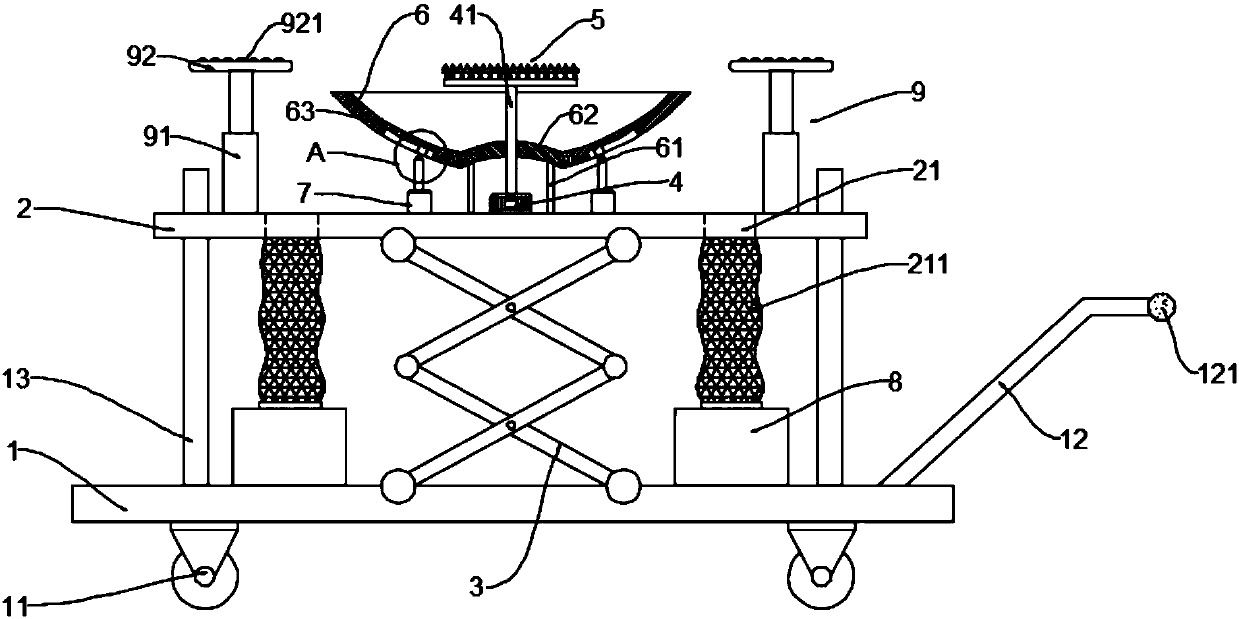

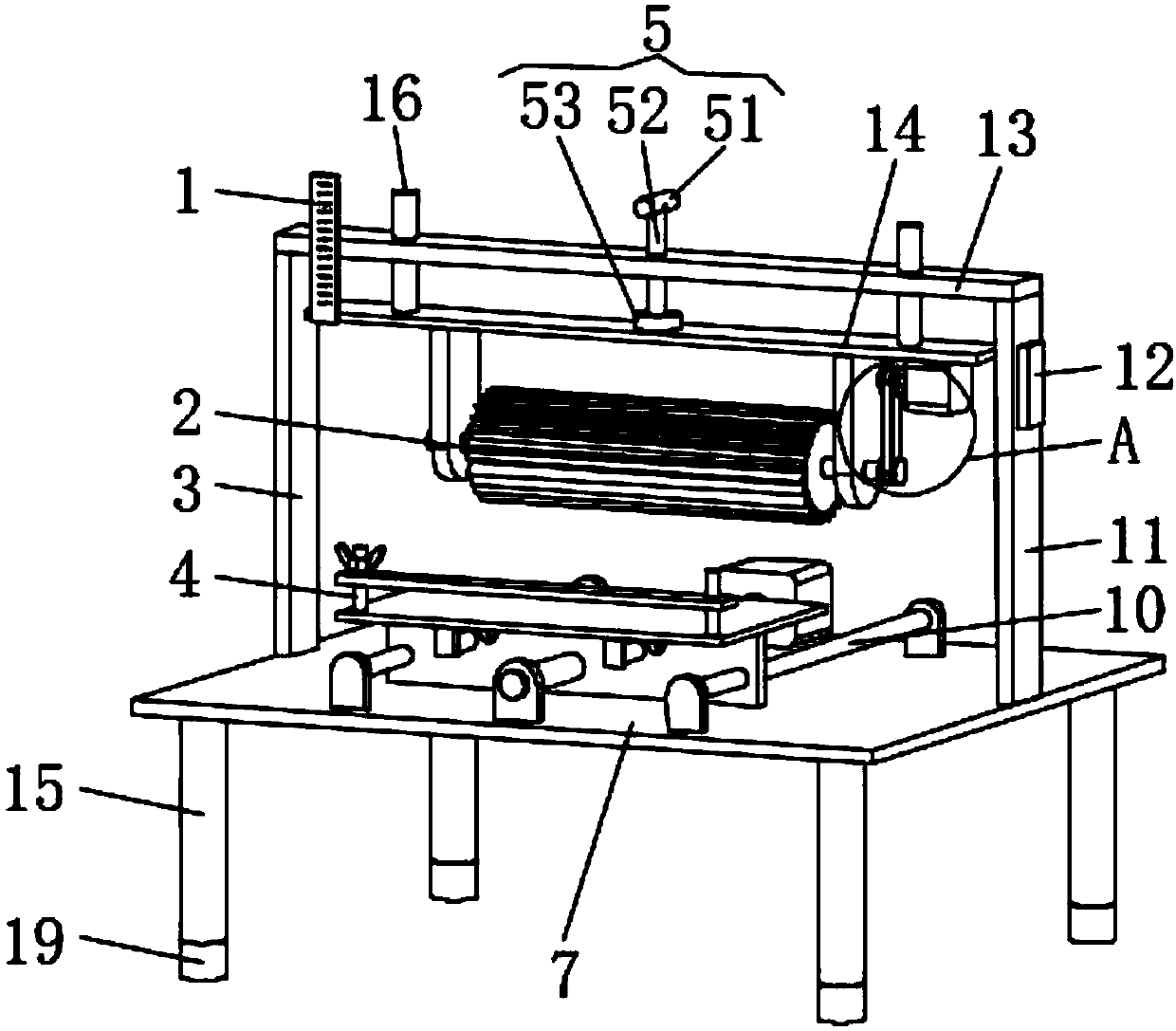

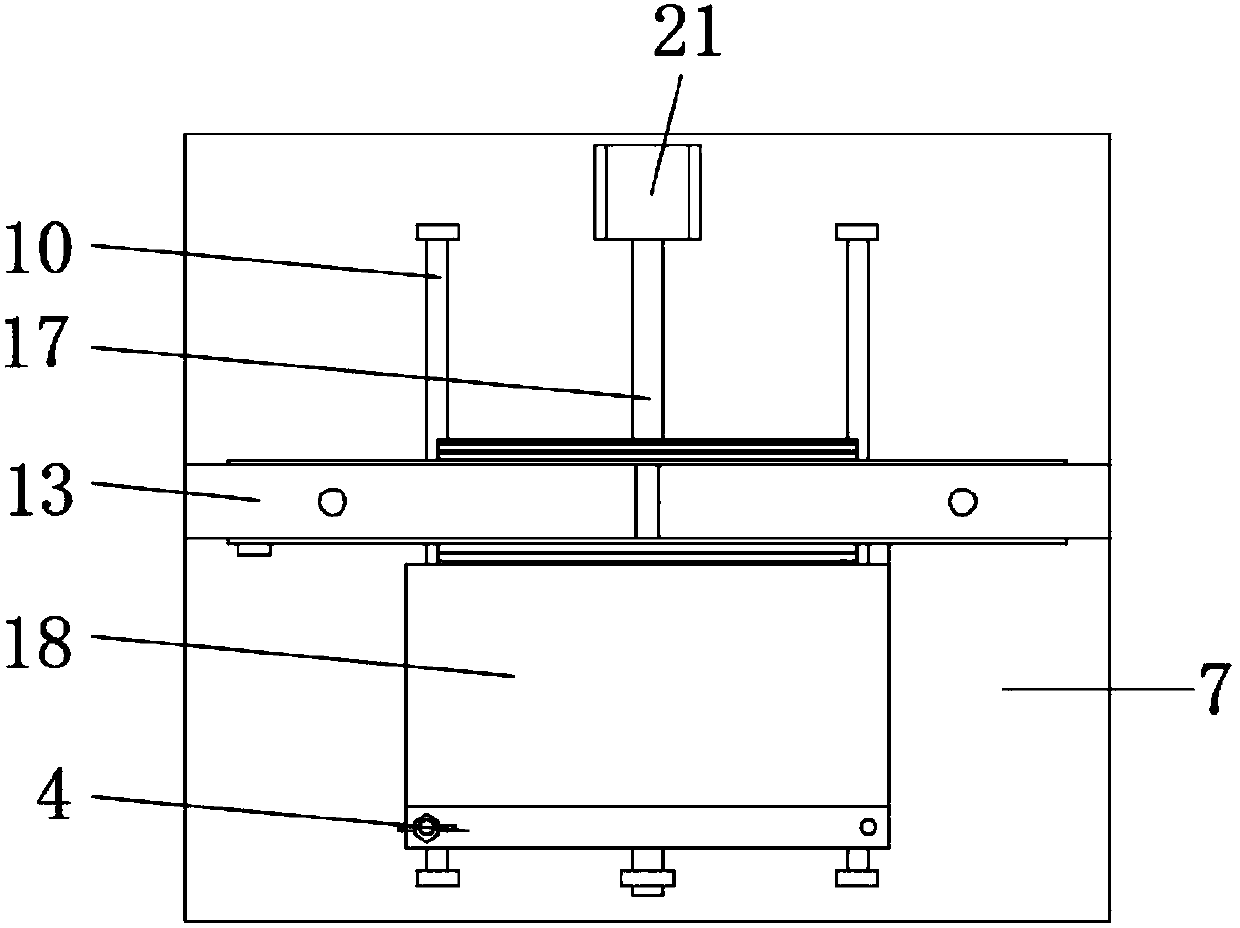

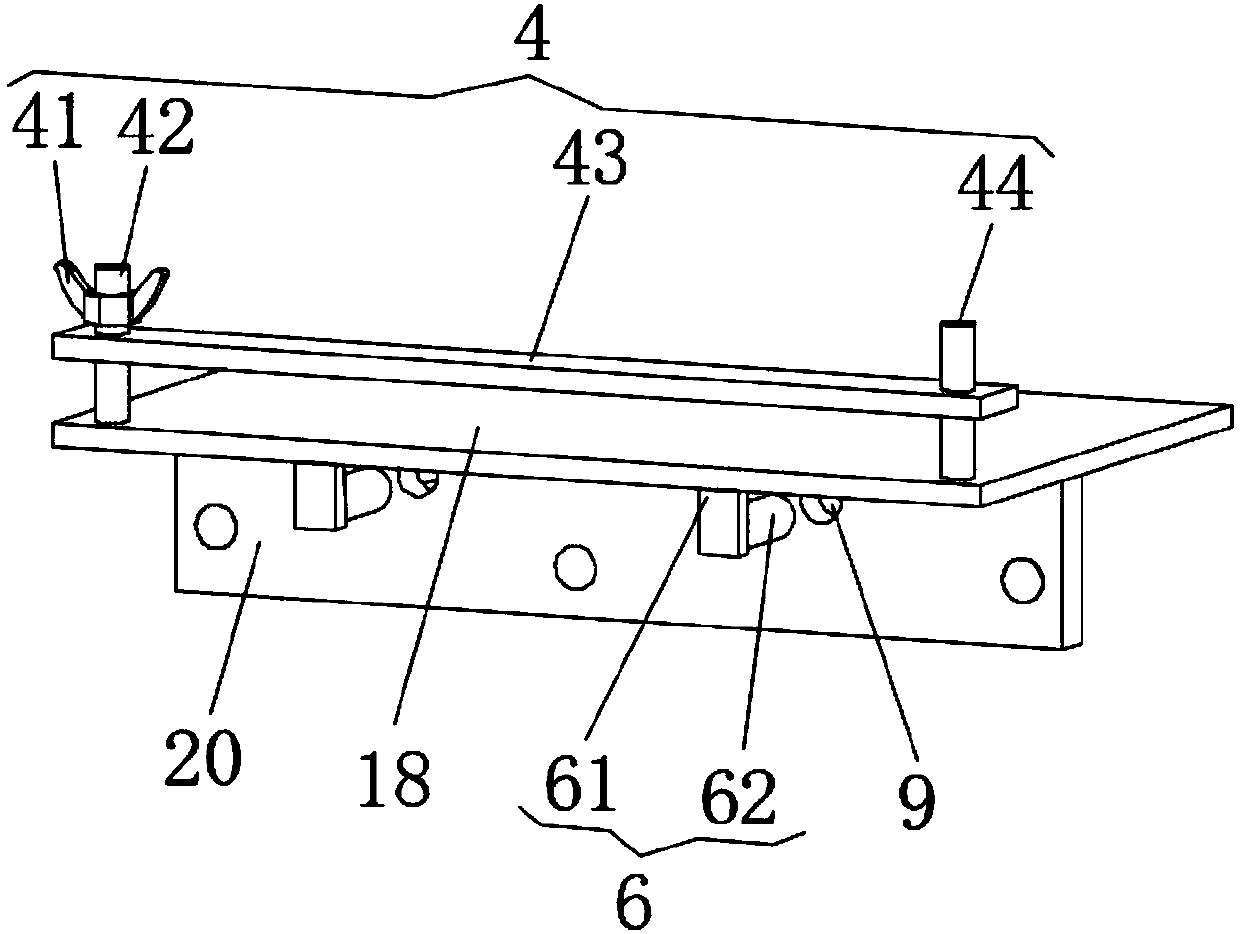

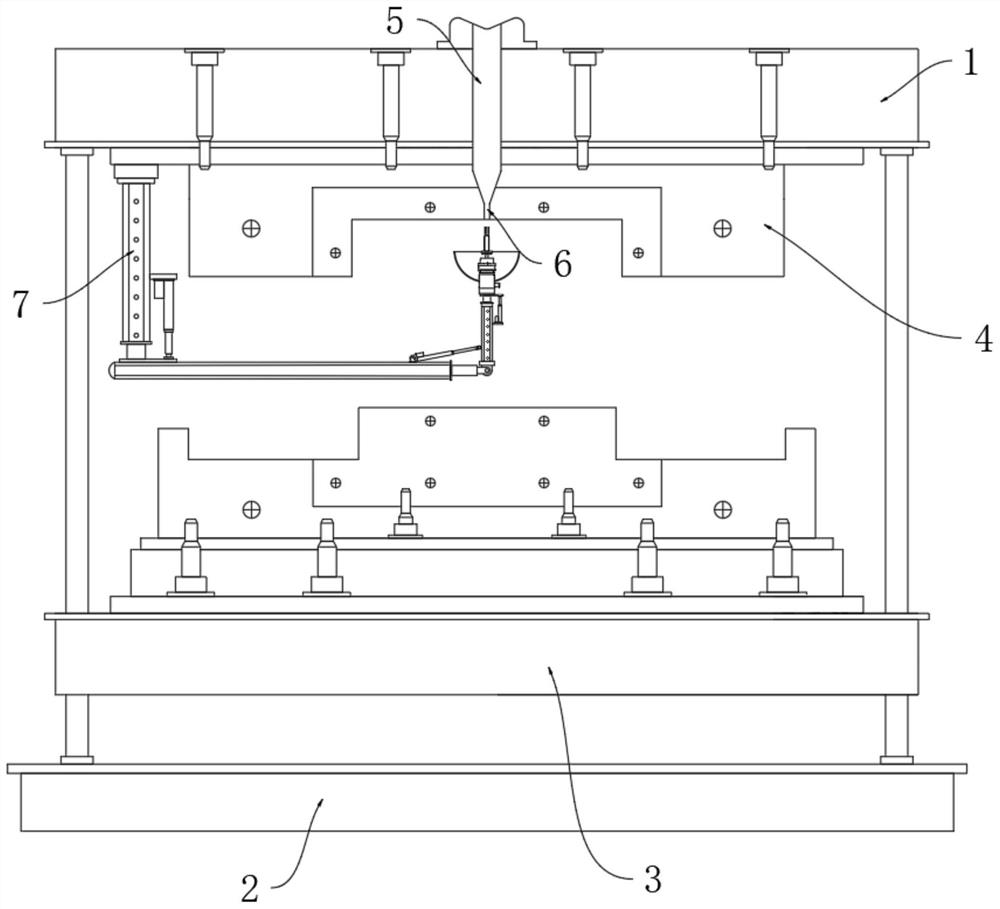

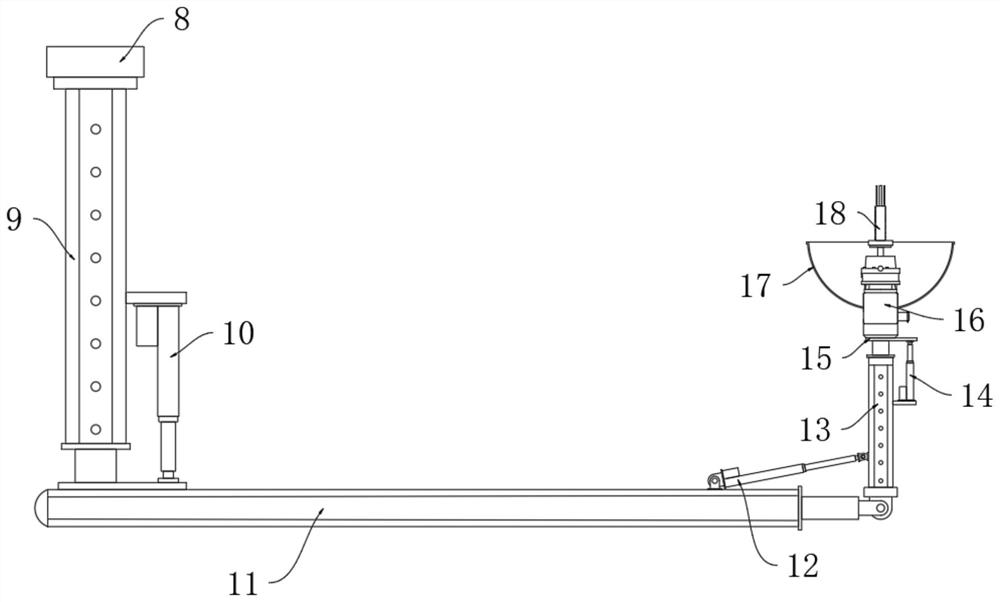

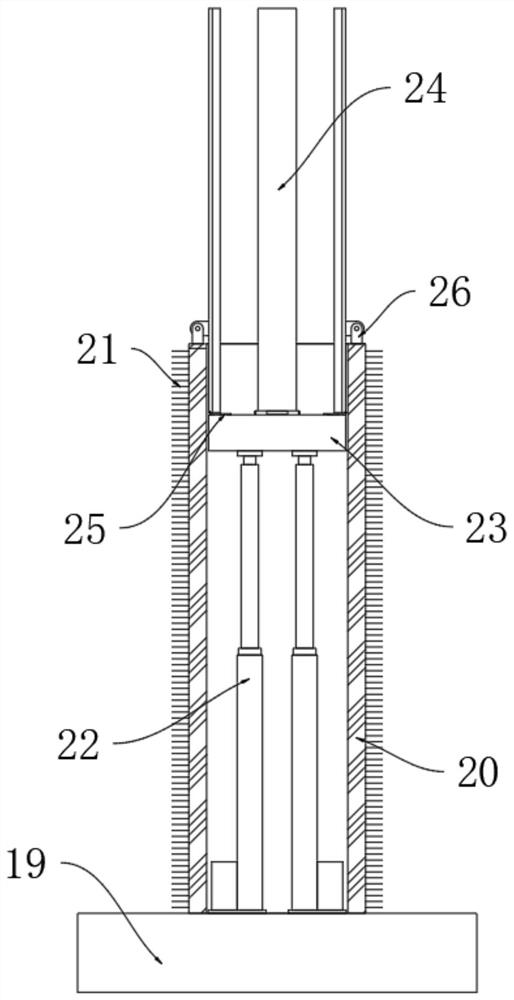

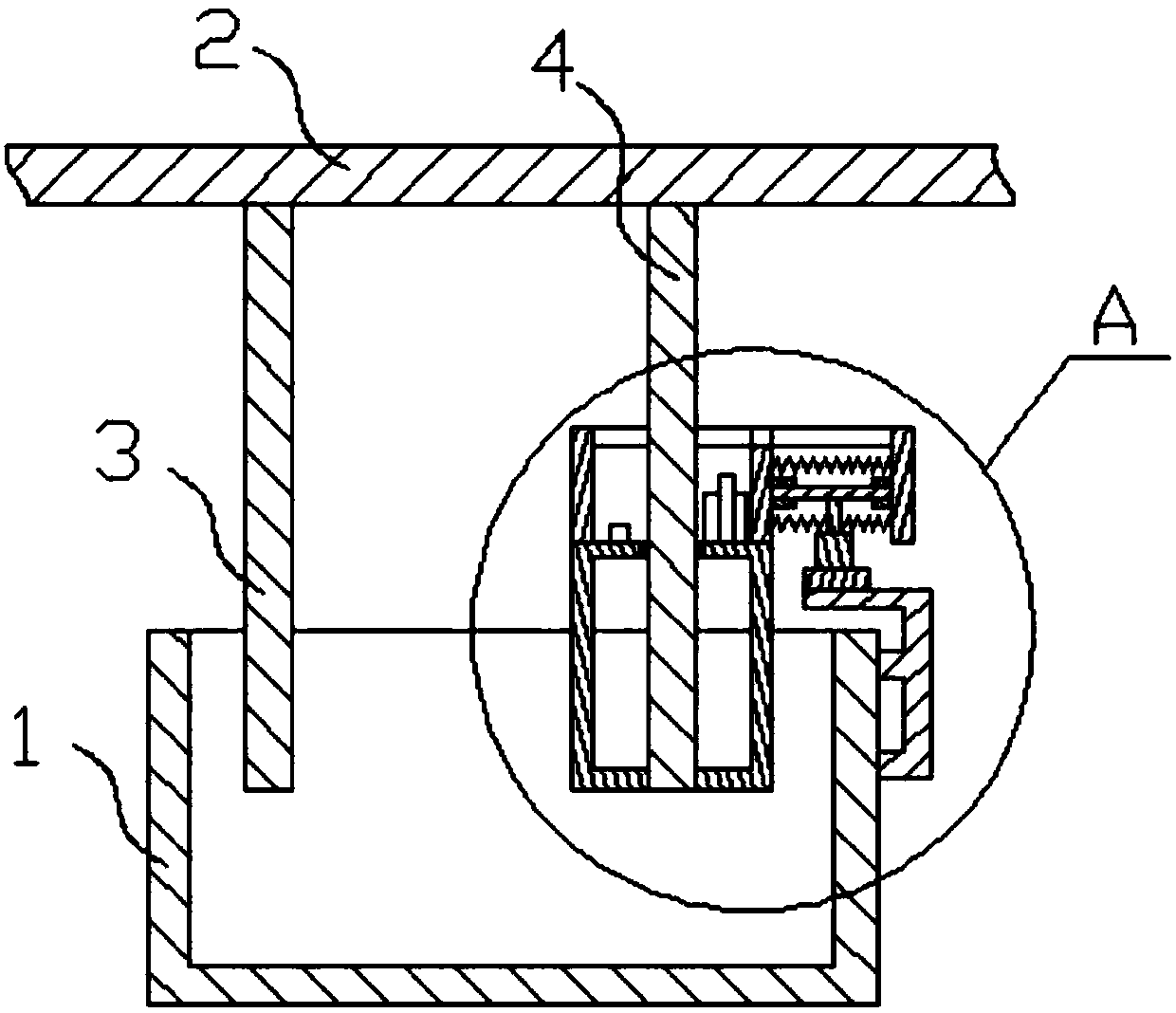

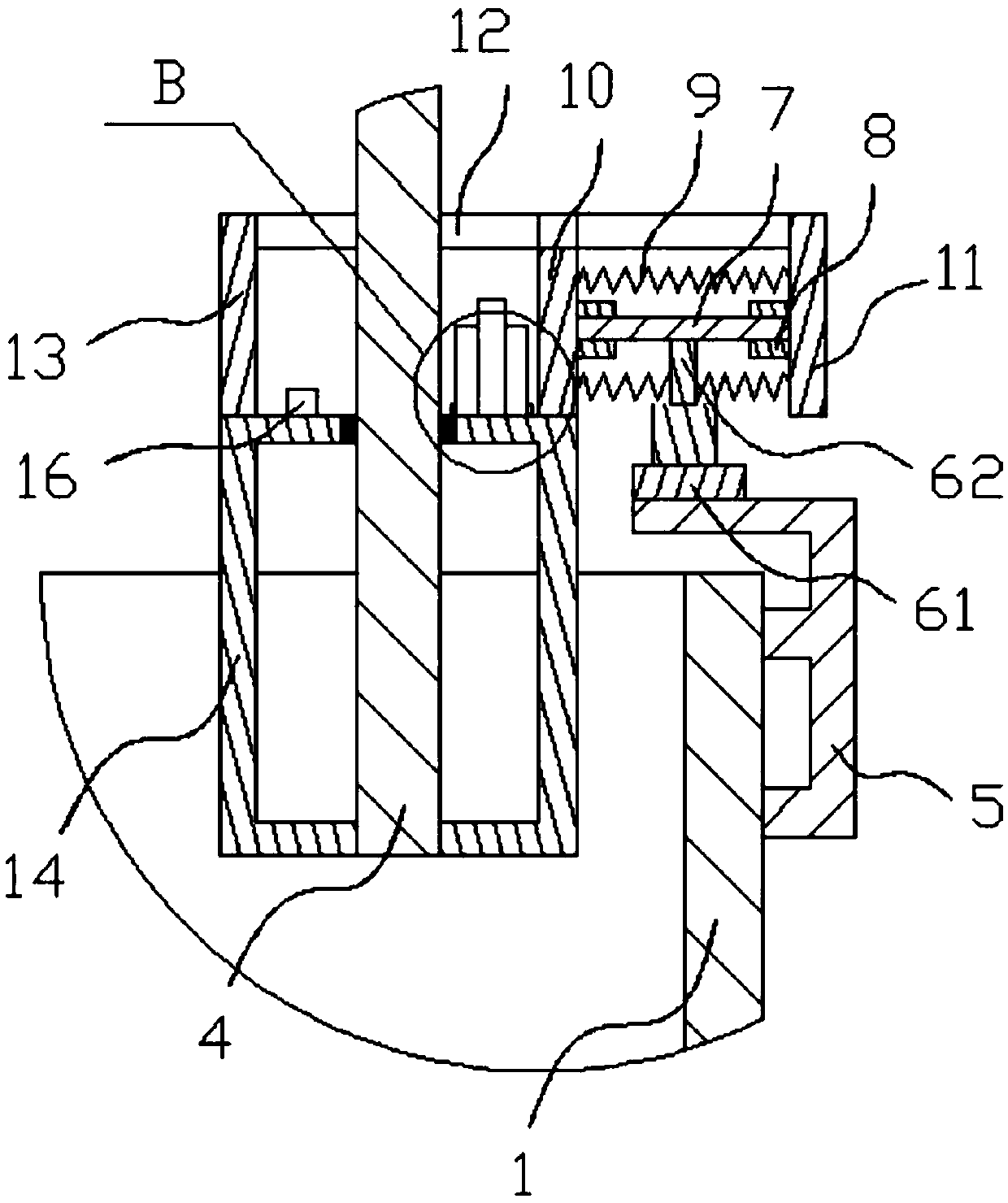

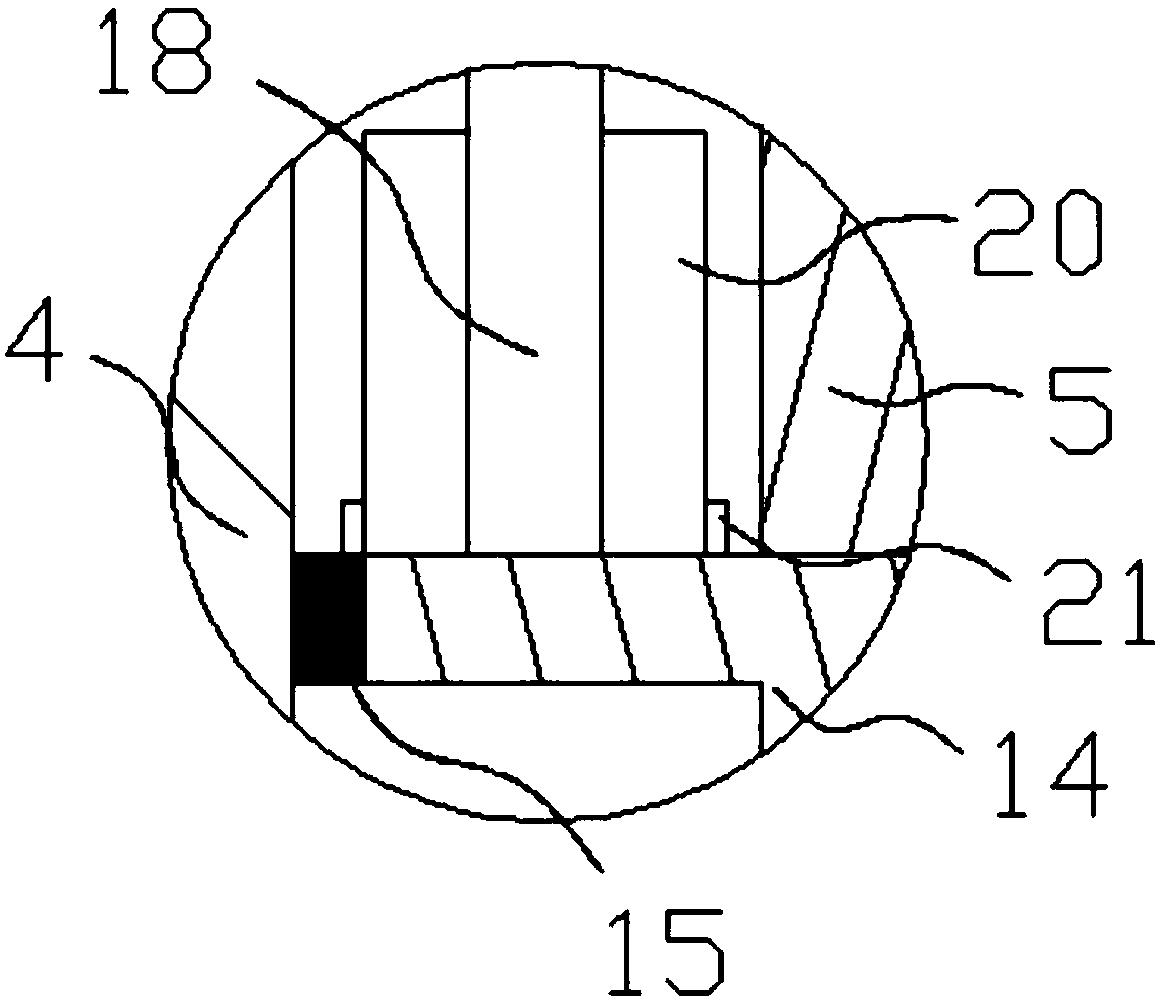

Wall skin stripping device for top wall

InactiveCN108019050AGuaranteed scraping effectProtect your healthBuilding repairsArchitectural engineering

The invention discloses a wall skin stripping device for a top wall. The wall skin stripping device comprises a base, a top plate, a smashing disc and an impurity collecting frame. The top plate is arranged above the base, and the top plate is connected with the base through a shear-fork lifting machine. A motor is fixed to the center of the top of the top plate, a rotary shaft is connected to theoutput end of the motor, and the smashing disc is fixed to the other end of the rotary shaft. The impurity collecting frame is arranged below the smashing disc, the rotary shaft penetrates through the impurity collecting frame, the impurity collecting frame is designed to be open, the impurity collecting frame is composed of a base part and rotating parts located on the two sides of the base part, and one sides of the rotating parts are rotatably connected with the base part through pin shafts. Through holes are symmetrically formed in the left side and the right side of the top plate correspondingly, telescopic hoses are connected to the positions, corresponding to the through holes, of the bottom of the top plate, and the other ends of the telescopic hoses are connected to a collectionbox. The wall skin stripping device can effectively complete stripping work of wall skin of the top wall, operation is easy, the working efficiency can be effectively improved, and convenience is provided for decoration workers.

Owner:丁勇剑

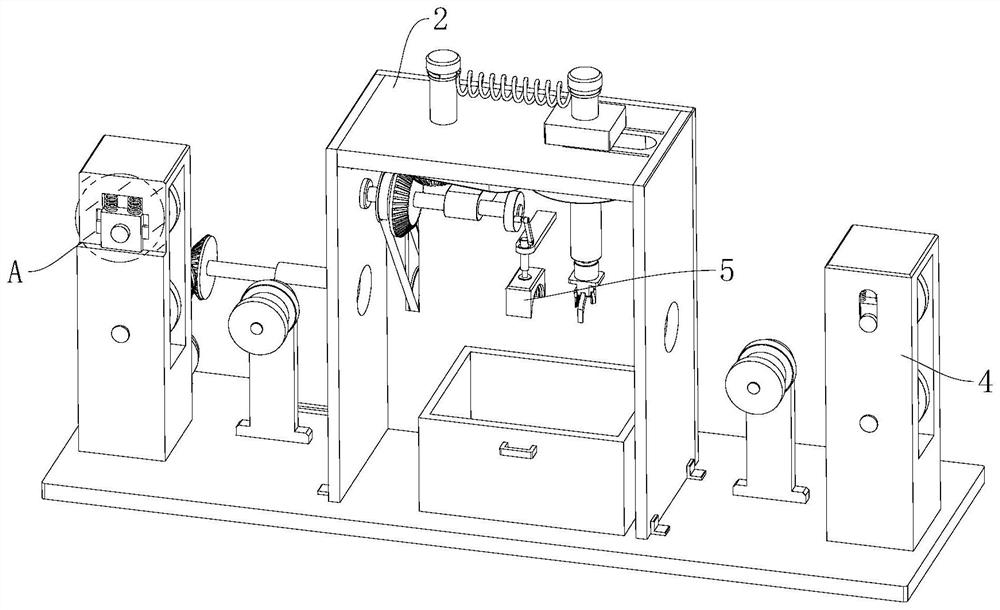

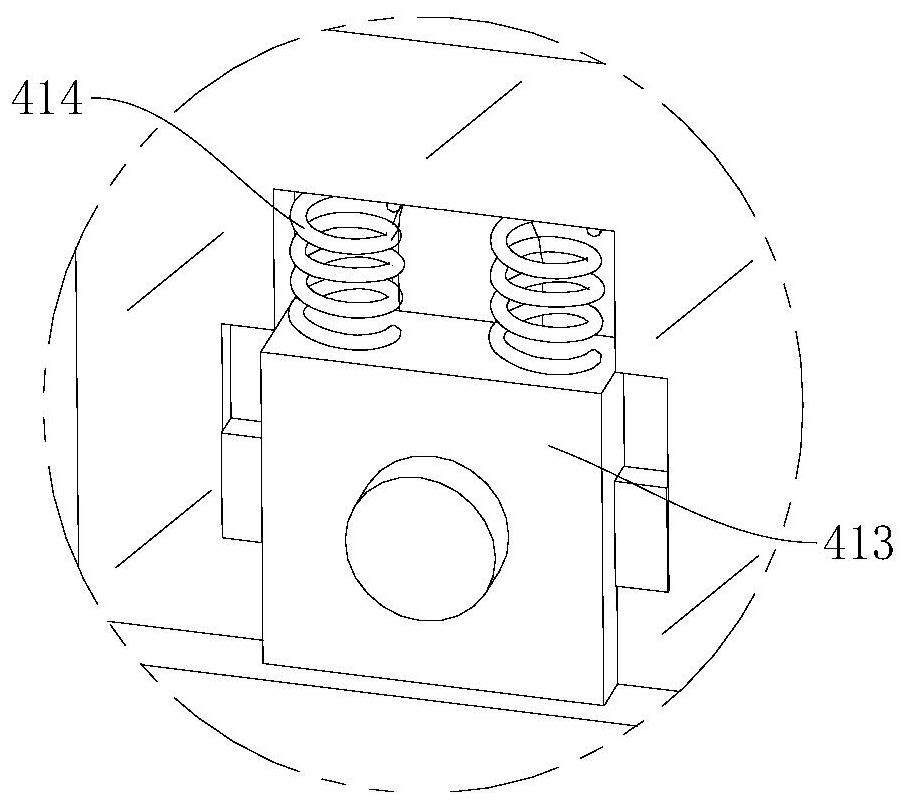

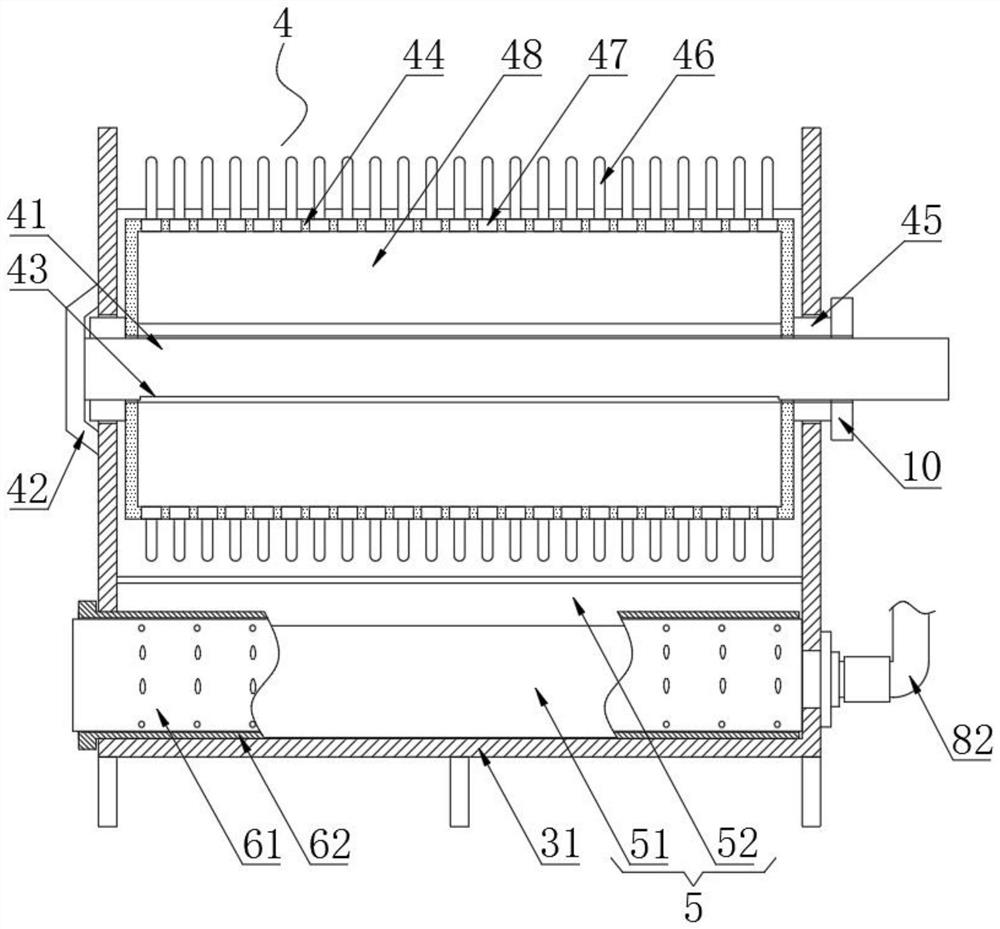

Textile yarn carding processing system

InactiveCN112391714AEasy to recycleRandom driftFibre cleaning/openingTextile yarnIndustrial engineering

The invention discloses a textile yarn carding processing system. The system comprises a base; winding mechanisms are arranged at the left side and the right side of the top of the base correspondingly; a carding box is fixedly connected with the middle of the top of the base and comprises a bottom box and a gland rotationally connected with the rear side of the top of the bottom box; and yarn removing mechanisms are rotationally arranged at the left side and the right side in the bottom box correspondingly. The textile yarn carding processing system relates to the technical field of textile processing. According to the textile yarn carding processing system, broken fluff and the like on yarn can be scraped off through the yarn removing mechanisms, discharged into a guiding mechanism through airflow and then blown into a collecting pipe through airflow, and the fluff can be blocked by flexible thin strips in the collecting pipe, so that the effect of centralized collection is achieved;and the flexible thin strips can be withdrawn only by rotating a rotary drum, so that broken yarn fluff can be taken out integrally and conveniently, the broken yarn fluff can be recycled conveniently, the broken yarn fluff cannot drift away randomly while the broken yarn fluff on the yarn is removed, and the textile yarn carding processing system is environmentally friendly.

Owner:广州培慧纺织业有限公司

Device for scraping oil on inner surface of fur

InactiveCN109971897AQuality improvementQuality assuranceFur mechanical treatmentSkins/hides/leather/fur manufacturing apparatusEngineering

Owner:安徽省卓创信息科技服务有限公司

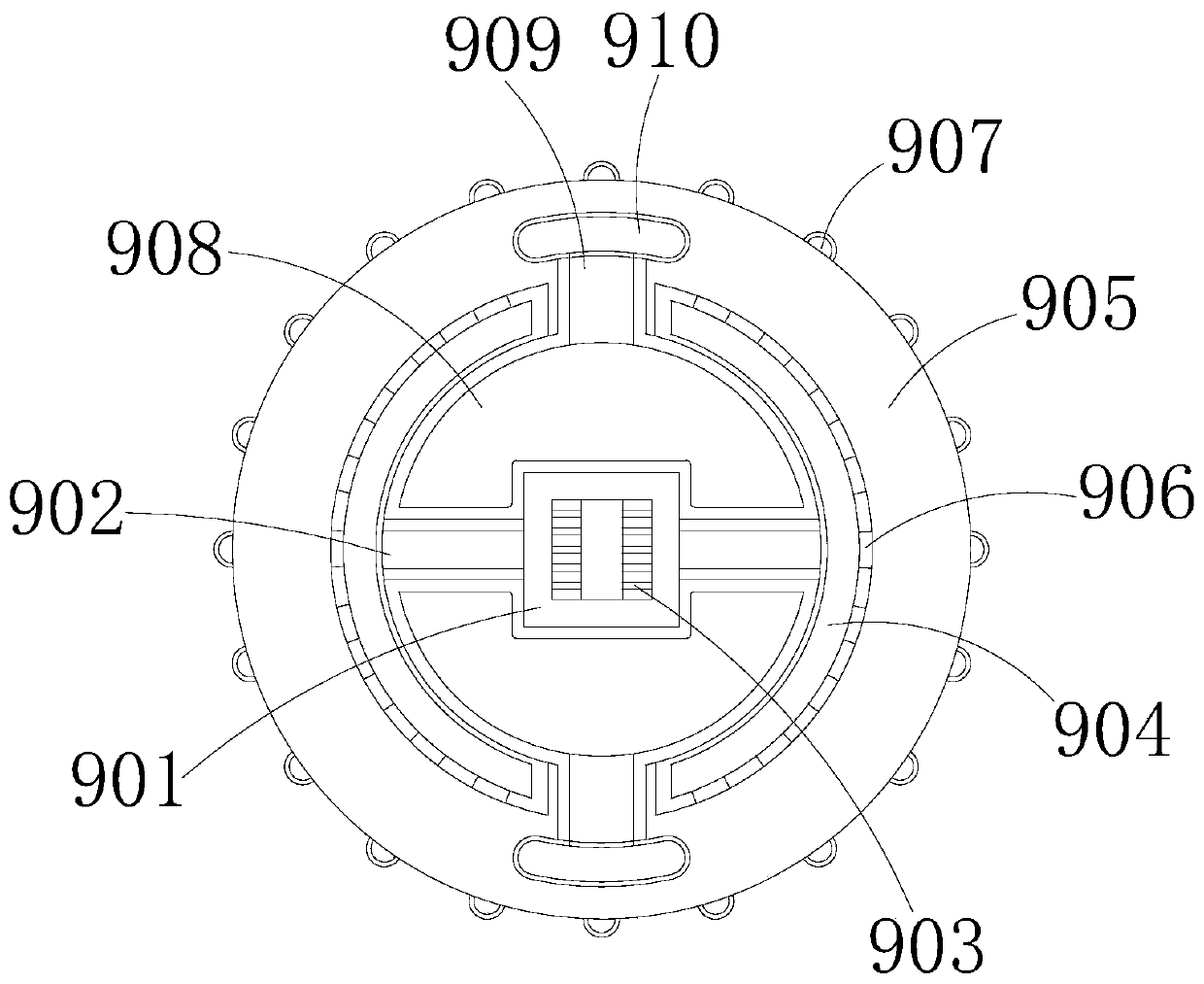

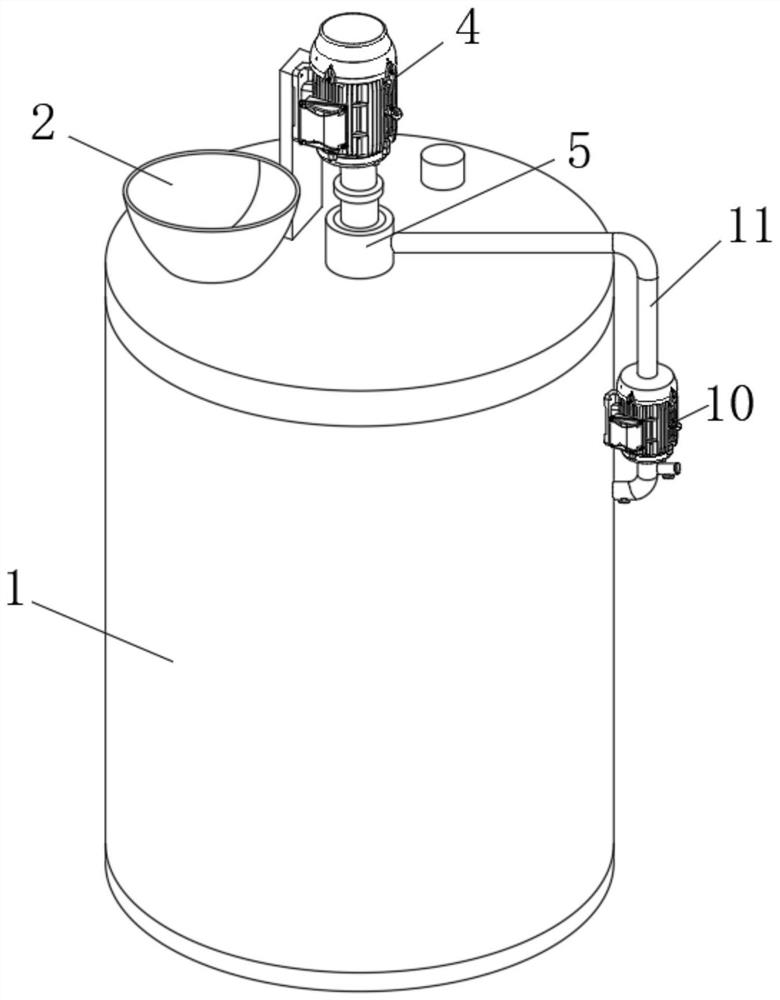

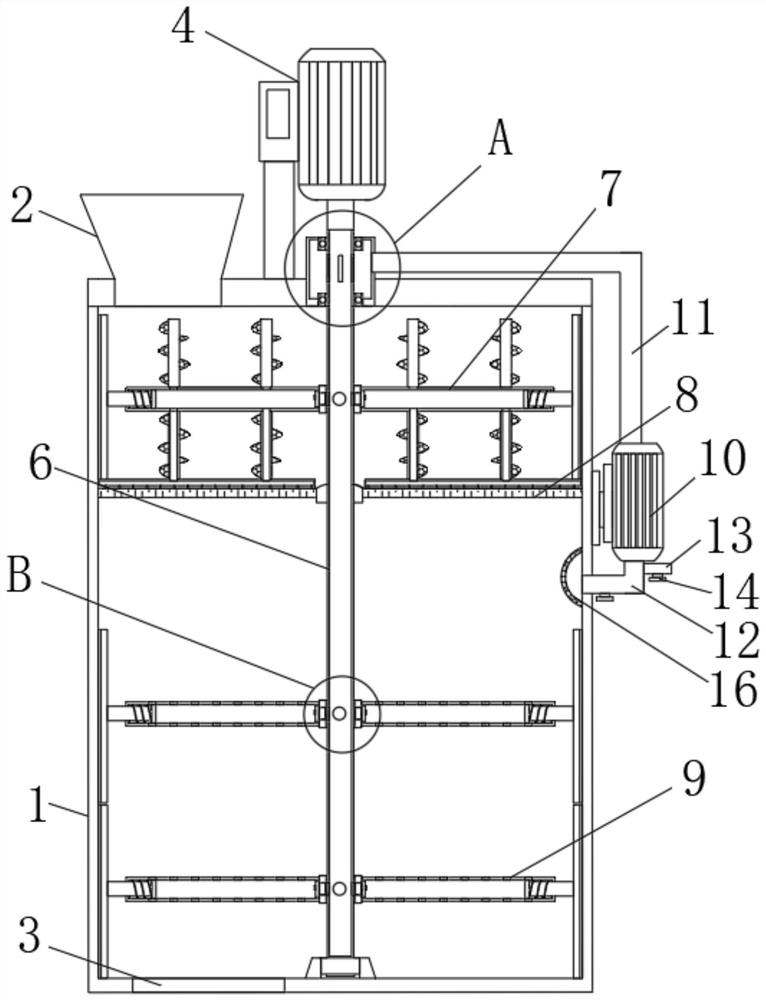

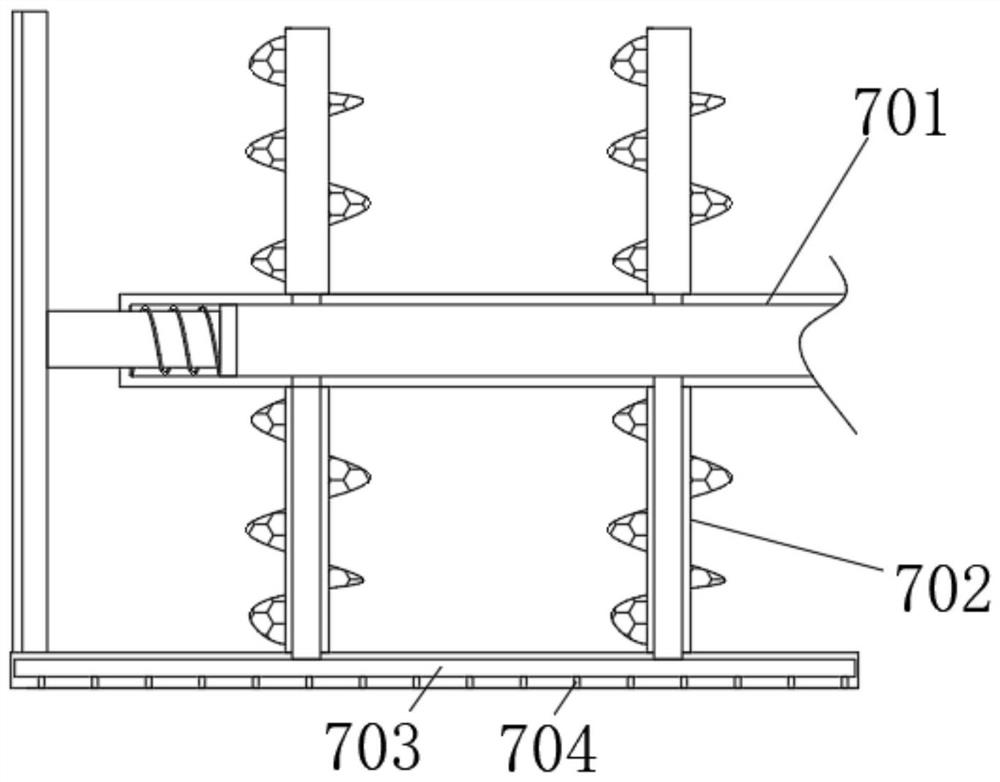

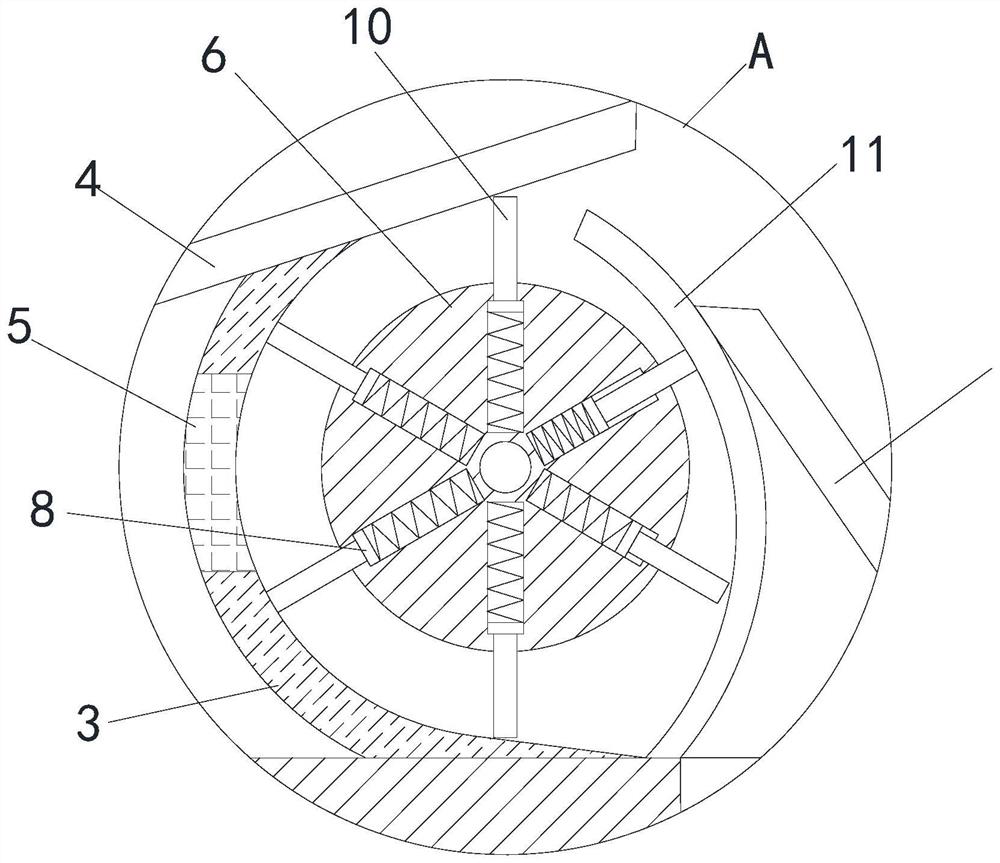

Intelligent reactor for microbial fermentation and using method

PendingCN113355215AGuaranteed fermentation effectGuaranteed screening effectBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention discloses an intelligent reactor for microbial fermentation and a using method, and belongs to the technical field of microbial fermentation. The intelligent reactor is characterized by comprising a fermentation box body, a feeding port is formed in the top of the fermentation box body, a discharging port is formed in the bottom of the fermentation box body, and a driving motor is arranged at the center of the upper portion of the fermentation box body; an output shaft of the driving motor is connected with an air inlet assembly, an air extracting pump is fixedly mounted on one side of the fermentation box body, an air outlet end of the air extracting pump is connected with an air inlet pipe, the air inlet pipe is communicated with the air inlet assembly, the bottom of the air inlet assembly is rotatably connected with a hollow shaft, and a stirring device is arranged at the upper end of the surface of the hollow shaft; a screen located below the stirring device is arranged on the inner wall of the fermentation box body, the bottom end of the hollow shaft rotatably penetrates through the screen, and at least two groups of oxygen supply assemblies are arranged at the lower end of the surface of the hollow shaft. According to the invention, the screen mesh can be prevented from being blocked, and oxygen is uniformly supplied to materials in all directions, so that the materials are more fully fermented.

Owner:张奇林

Intelligent sorting device for construction waste

PendingCN113751197AImprove sorting efficiencyImprove sorting qualitySievingGas current separationEngineeringStructural engineering

Owner:王晶晶

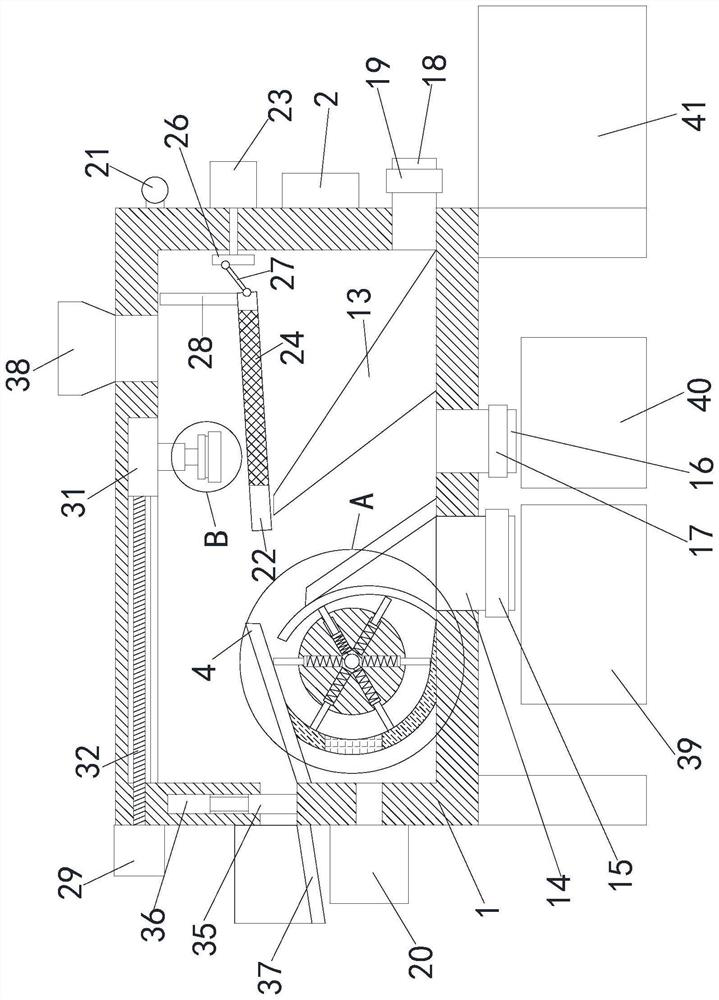

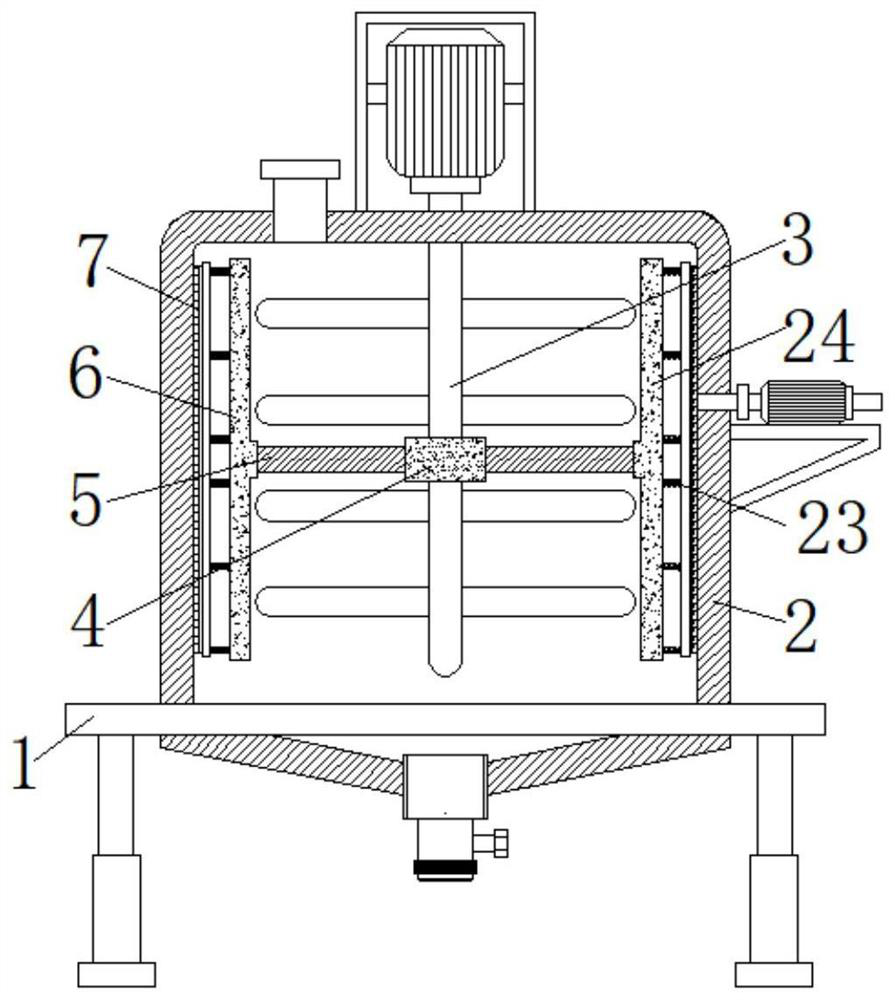

Double-helix and double-stirring reaction device for producing water-proof coating

InactiveCN104289164AEasy to operateGuaranteed outputMixersChemical/physical/physico-chemical stationary reactorsTemperature controlLow speed

The invention relates to the technical field of water-proof coating production devices, in particular to a double-helix and double-stirring reaction device for producing a water-proof coating. An anchor type low-speed scraping stirrer is arranged at the bottom of a kettle body; the anchor type low-speed scraping stirrer is connected with a low-speed variable-frequency speed regulating motor; the low-speed variable-frequency speed regulating motor is arranged at the top end of the kettle body; high-speed paddle stirrers are arranged on the side face of the anchor type low-speed scraping stirrer; the high-speed paddle stirrers are connected with the high-speed variable-frequency speed regulating motor; helical heat conducting oil heating pipes are arranged on the outer side of the kettle body; and helical cooling water pipes are arranged on the outer sides of the helical heat conducting oil heating pipes. According to the double-helix and double-stirring reaction device, the variable-frequency speed-regulating high-speed paddle stirrer is arranged on a reaction kettle, and meanwhile the anchor type low-speed scraping stirrer is provided, so that the scraping effect is ensured. A double-helix heating and cooling way is adopted, and heat conducting oil is helically introduced into one path for heating while cooling water is helically introduced into the other path for cooling in order to meet the requirements of process conditions, so that the requirement of temperature control as well as heating and cooling speeds at each stage of production are well ensured.

Owner:JIANGSU CANLON BUILDING MATERIALS

Stirring device for preparing acid-resistant coating

InactiveCN111804228AEasy to depositPromote rapid accumulationRotary stirring mixersTransportation and packagingEngineeringScrew thread

The invention discloses a stirring device for preparing an acid-resistant coating. The device comprises a supporting table, and a stirring tank body is arranged on the supporting table; an inner cavity of the stirring tank body is rotationally connected with a stirring shaft; the outer wall of the stirring shaft is fixedly sleeved with a fixed sleeve seat; threaded grooves are formed in the surfaces of the two sides of the fixed sleeve seat; the inner sides of the threaded grooves are in threaded connection with fixing screws; fixing plates are fixed to the surfaces of one sides of the fixingscrews; and a plurality of sets of fixing springs distributed at equal intervals are fixed to the surfaces of one sides of the fixing plates. Through the arrangement of a scraping plate, the coating accumulated on the inner wall of the stirring tank body can be conveniently and rapidly scraped, and the utilization rate of the coating is guaranteed; by arranging a cleaning brush head, the inner wall of the stirring tank body can be conveniently and rapidly cleaned, and the working efficiency of the device is improved; and through the arrangement of plug pins and buckles, the scraping effect ofthe scraping plate on the coating is guaranteed, and the cleaning effect of the cleaning brush head on the inner wall of the stirring tank body is also guaranteed.

Owner:青岛格林沃德新材料科技有限公司

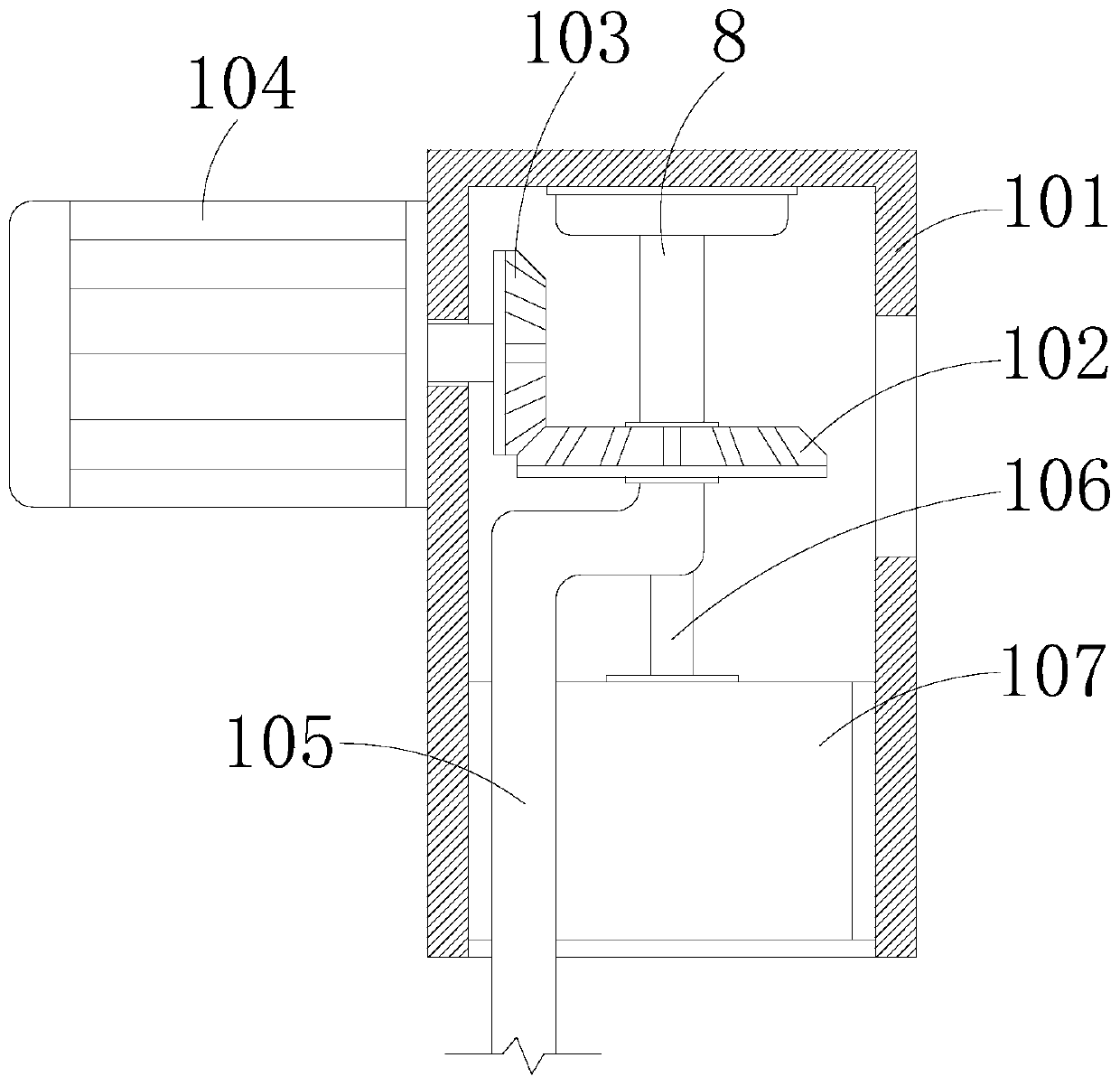

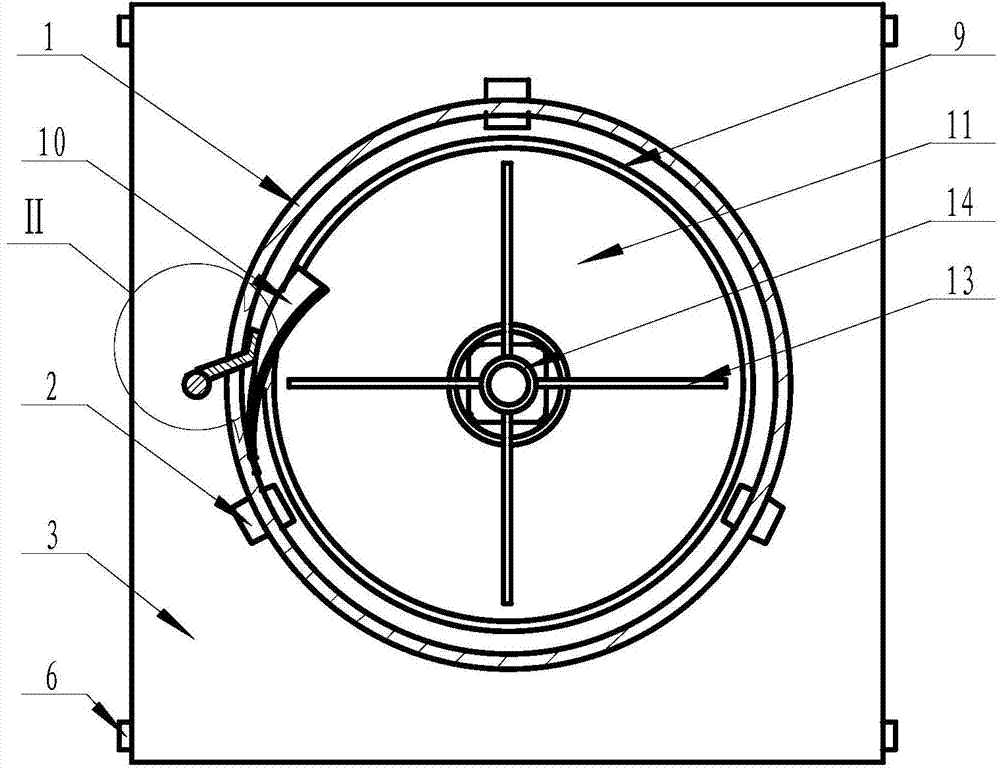

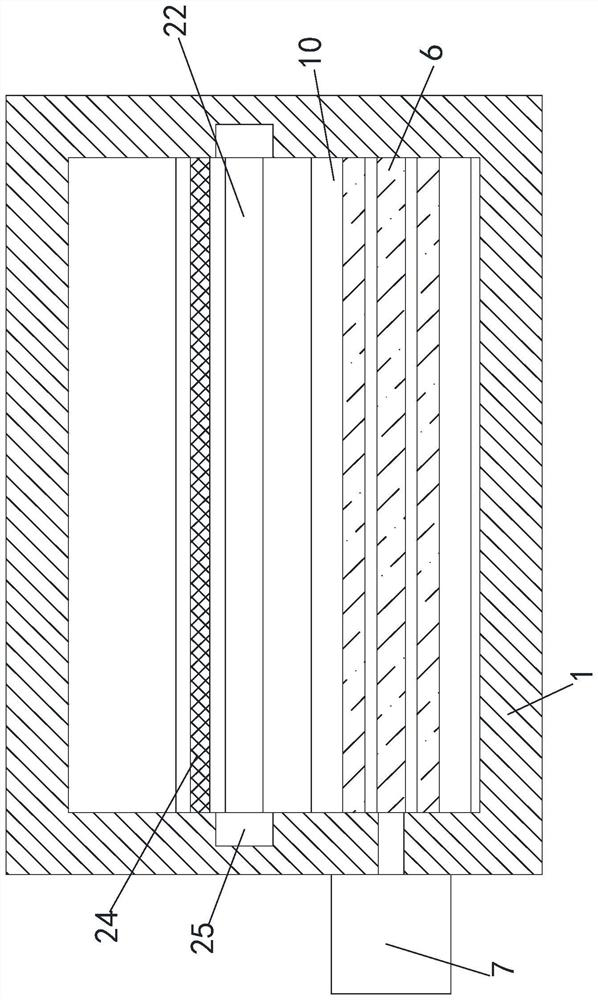

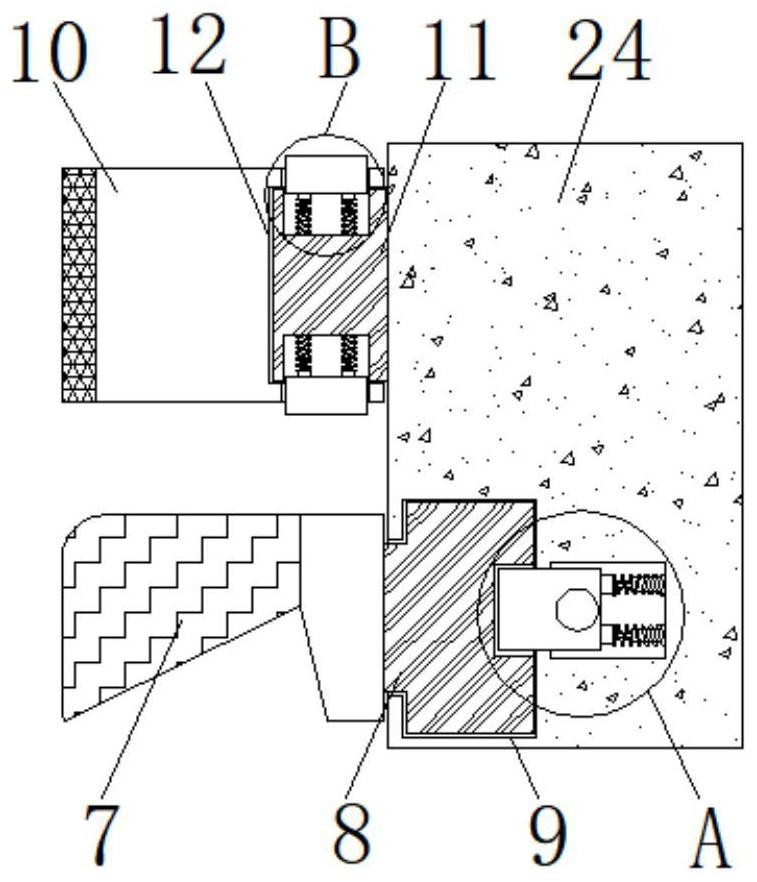

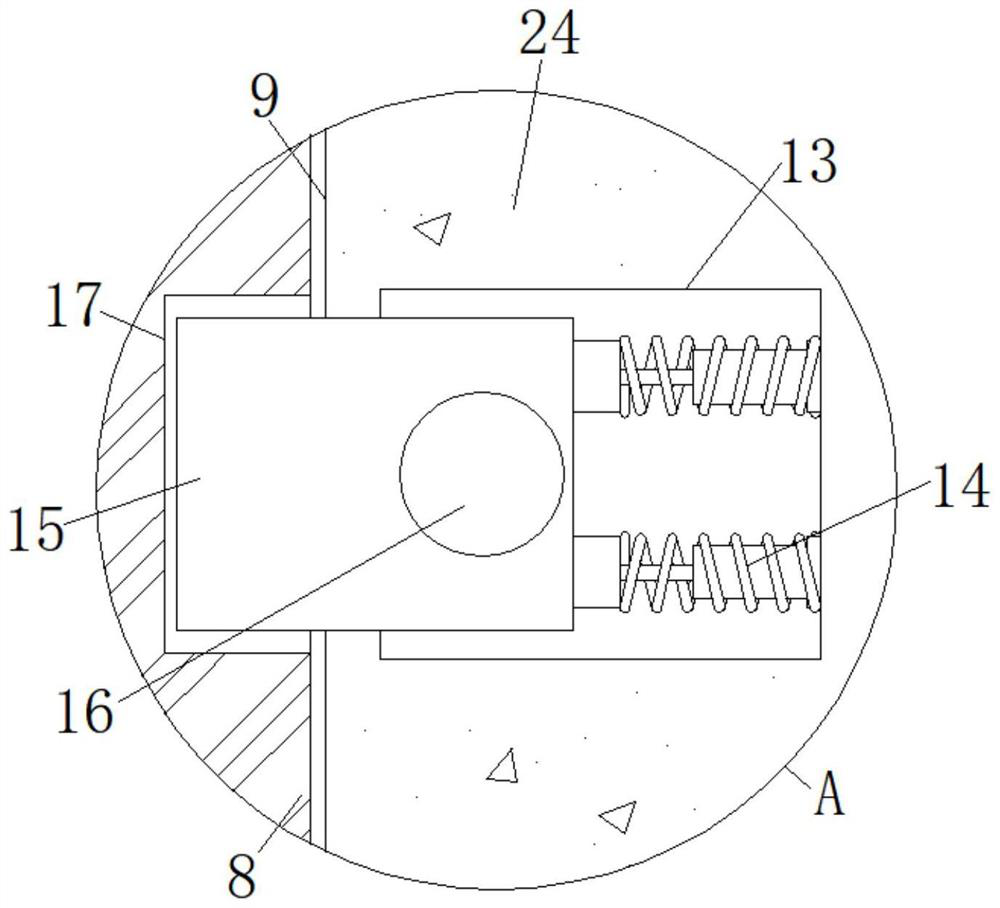

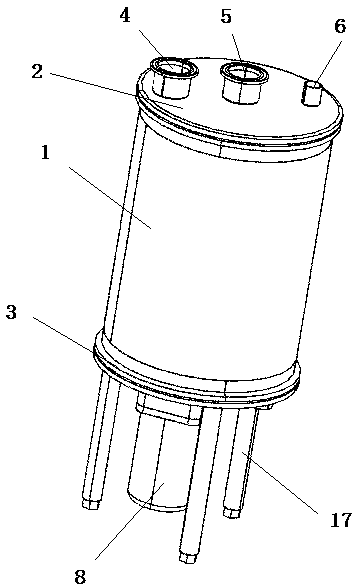

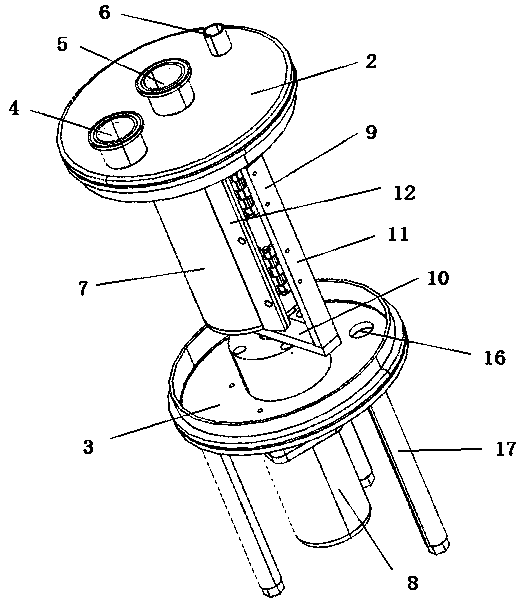

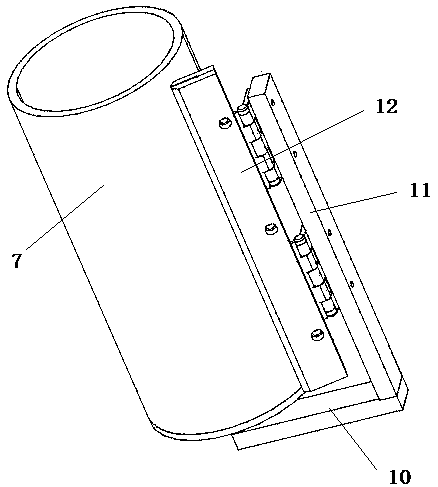

Dynamic filter unit

PendingCN107754406AAvoid scratchesGuaranteed service lifeStationary filtering element filtersElectric machineDrive motor

The invention relates to a dynamic filter unit, which comprises a cylindrical tank. The upper end of the tank is equipped with a cover body for packaging the upper part of the tank. The lower end of the tank is provided with a base for packaging the lower part of the tank. The cover body is provided with a feed inlet, a discharge port and an exhaust vent. The bottom of the cover body is equipped with a cylindrical filter core, an outlet of which is communicated with the discharge port. A scraping component which is corresponding to the external circumference of the filter core is arranged inside the tank. The bottom of the base is provided with a driving motor which drives the scraping component to rotate along the external circumference of the filter core. According to the invention, thefilter core is arranged in the tank to filter a coating liquid; and with the arrangement of the scraping component and the driving motor, the driving motor drives the scrapping component to rotate around the filter core such that impurities on the outer side of the filter core is scrapped off so as to prevent the impurities from blocking the filter core and then ensure normal operation of production.

Owner:张世珍

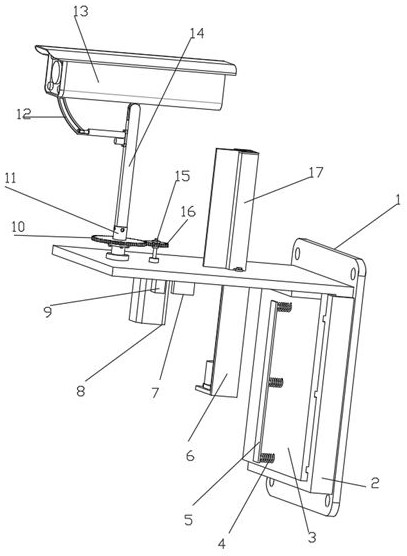

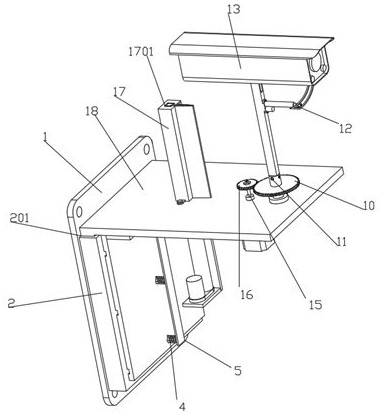

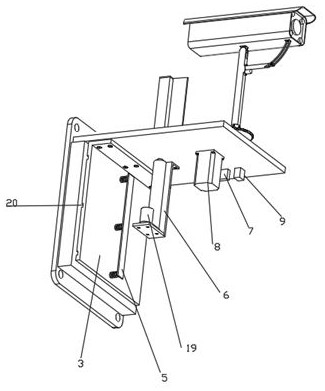

Video monitoring device based on 5G network

InactiveCN112212190AEasy to rotate and monitorEasy to monitorTelevision system detailsColor television detailsVideo monitoringElectric machinery

The invention relates to a video monitoring device based on a 5G network in the technical field of monitoring equipment. The video monitoring device comprises an installation plate and a camera, the installation plate is provided with a connection plate, the connection plate is provided with a jack, the connection plate is provided with a second L-shaped plate, the second L-shaped plate is provided with a limiting structure, the second L-shaped plate is provided with a horizontal rotating structure, the horizontal rotating structure comprises a driving motor, the driving motor is connected with the second L-shaped plate, the driving motor is provided with a rotating shaft, the rotating shaft is provided with a second gear ring, the second gear ring is provided with a first gear ring, the first gear ring is provided with a first rotating rod, the first rotating rod is provided with a straight rod, the straight rod is provided with an angle adjusting structure, and the angle adjusting structure comprises a protruding block and an arc-shaped plate, the arc-shaped plate and the protruding block are connected with the camera, and the protruding block is connected with the straight rod,a first electric push rod is provided with a connecting block, the connecting block is provided with a round rod, and an arc-shaped groove is formed in the arc-shaped plate and connected with the round rod. According to the video monitoring device, the monitoring direction of the camera is convenient to adjust, and the camera is convenient to flexibly adjust the direction for monitoring.

Owner:夏喜明

Oil scraping device for wastewater treatment

InactiveCN104944518AImprove collection effectChange the tightnessFatty/oily/floating substances removal devicesLiquid separationWastewaterPulp and paper industry

The invention discloses an oil scraping device for wastewater treatment. The device comprises a device shell, a motor, a driving roll, a driven roll, a driving belt, an oil scraping belt, an oil scraper and a bracket, wherein the motor, the driving roll and the driving belt are arranged on the device shell; the motor is connected with the driving roll through the driving belt; the driving roll is connected with the driven roll through the oil scraping belt; the device shell is mounted at the upper part of the bracket; the driven roll is fixed at the lower part of the bracket; the oil scraper comprises two scraping blades positioned on the two sides of the oil scraping belt; a knife rest is correspondingly fixed at the bottom of each scraping blade; a distance regulating mechanism is arranged between the two knife rests. The device overcomes the defects that the oil scraping belt and the scraping blades need replacing frequently, and oil contamination is collected not thoroughly.

Owner:XUZHOU UNIV OF TECH +1

Scraper blade assembly and coating device with same

ActiveCN111395720AImprove adaptabilityConstant coating thicknessBuilding constructionsStructural engineeringMechanical engineering

The invention provides a scraper blade assembly and a coating device with the same. The scraper blade assembly comprises a connector, a scraper blade, a first elastic part and a supporting part. The scraper blade is connected with the connector. The first elastic part is arranged between the connector and the scraper blade, and thus when the scraper blade scrapes a coating material, the scraper blade moves back and forth in the first preset direction under the effect of the first elastic part. The supporting part is connected with the scraper blade and movably arranged opposite to the scraperblade in the second preset direction. The second preset direction and the first preset direction are arranged at a preset angle. The scraper blade assembly solves the problem of low adaptability of ascraper blade in the prior art.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

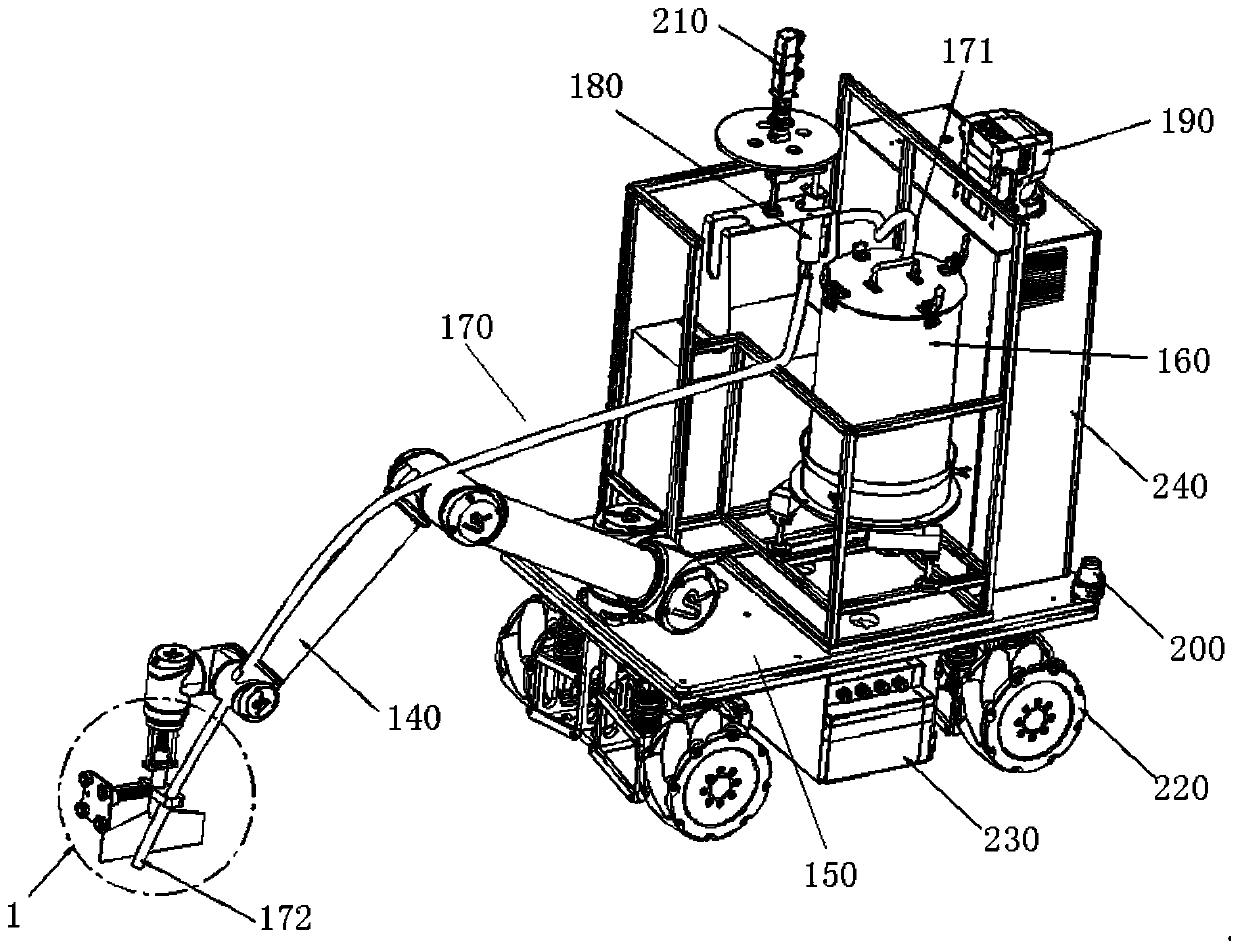

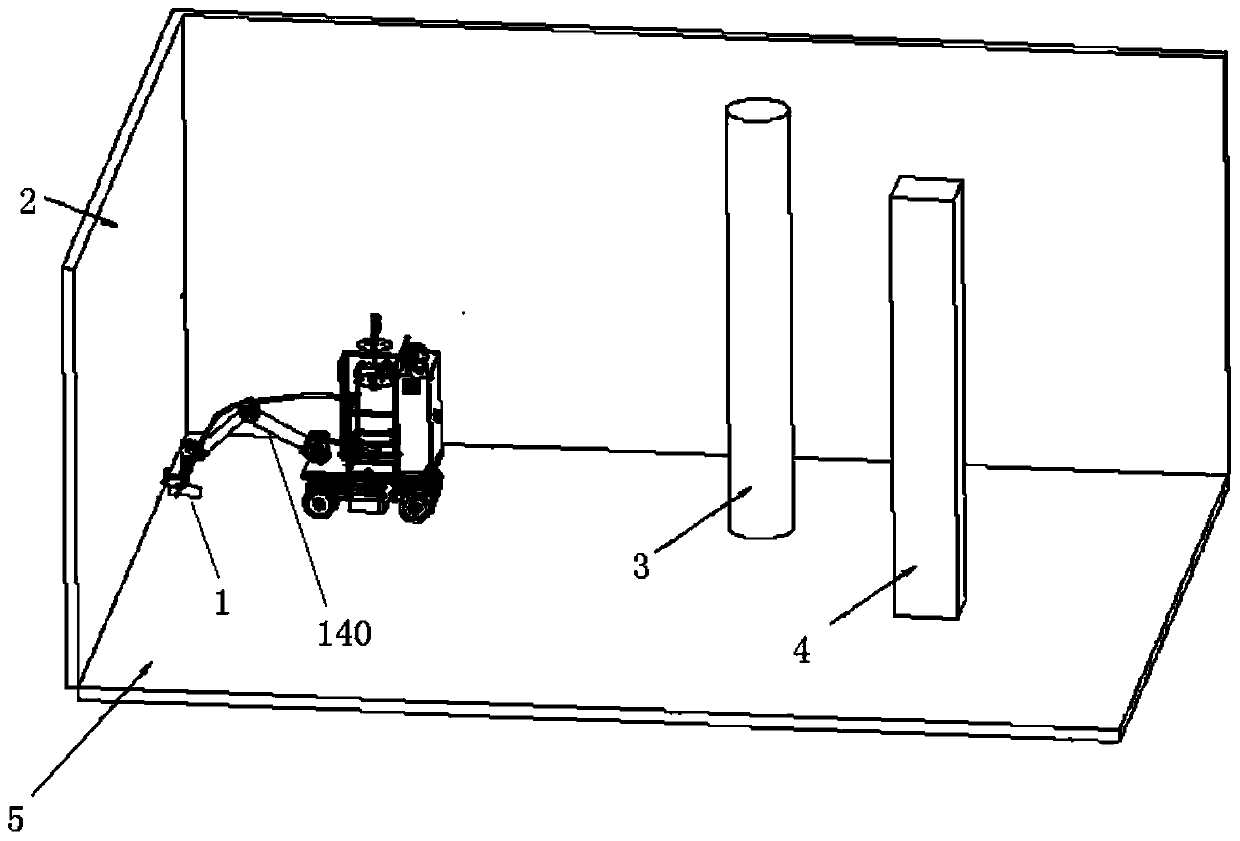

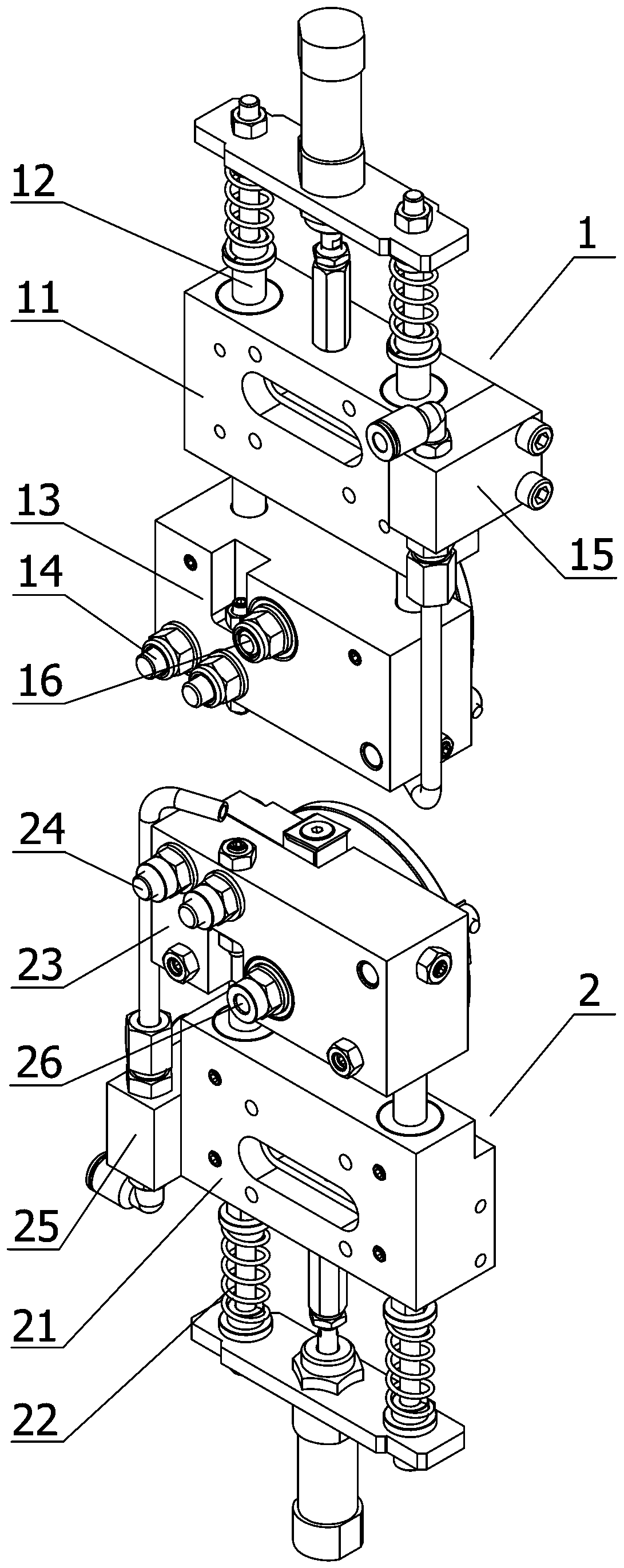

Mechanical arm capable of automatically taking out residues in pouring gate

ActiveCN112810050ASatisfy the role of automatic processingGuaranteed scraping effectFoundry mouldsCasting apparatusRobot handElectric machinery

Owner:JINGZHOU AOKELAN PLASTIC

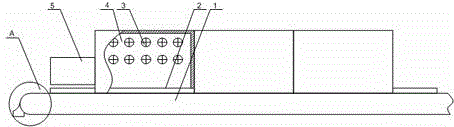

Shaving board lumber drier

InactiveCN104654761AReduce wearEliminate residueDrying machines with progressive movementsDrying solid materialsEngineeringMicrowave

The invention discloses a shaving board lumber drier, which comprises a support frame and a conveying belt matched with the support frame, wherein a plurality of drying cavities which are in parallel arrangement and are mutually communicated are fixedly arranged above the conveying belt, two sides of the conveying belt are fixedly provided with U-shaped grooves, the output ends of two air cylinders are glidingly arranged in the U-shaped grooves, bulges are also arranged on the inner walls of two sides of each drying cavity, in addition, the bulges are in contact with the upper surface of the two end parts of the conveying belt, the conveying belt is arranged on the outer circumferential wall of a roller tube, the top end of a stop block is provided with an inwards sunk material falling surface, the upper part of the stop block is fixedly provided with a contact head, and the contact head is in contact with the outer wall of the conveying belt. The two air cylinders are fixedly arranged in the support frame, in addition, the two ends of the conveying belt are provided with the U-shaped grooves, the output ends of the air cylinders are glidingly arranged in the U-shaped grooves, and the two air cylinders respectively do contraction and expansion in the opposite directions, so that the conveying belt can realize the leftward and rightward swinging, the contact frequency of microwaves with the outer wall of broken material shavings in the unit area is increased, and the drying effect of the broken material shavings is improved.

Owner:CHENGDU NONDO FURNITURE

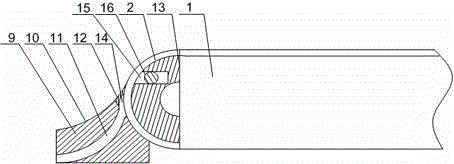

Collecting mechanism for electrolysis production of metal powder

ActiveCN108048881ADoes not affect normal electrolysisRealize automatic collectionElectrolysis componentsElectrolysisMetal powder

The invention relates to a collecting mechanism for electrolysis production of metal powder. The collecting mechanism comprises an electrolysis box and an electrolysis support, a positive pole bar anda negative pole bar which are connected to a power source and vertically penetrate into the electrolysis box are arranged on the electrolysis support, the two sides of the negative pole bar are provided with matched scrapped material collecting half barrels, semicircular openings are formed in the parts, matched with the negative pole bar, of the scrapped material collecting half barrels, movement devices capable of moving left and right and capable of being lifted are connected to the outer sides of the scrapped material collecting half barrels, a material sucking pipe communicated with thecorresponding scrapped material collecting half barrel is fixedly connected to the upper portion of one scrapped material collecting half barrel and is connected with a material sucking air pump, andthe scrapped material collecting half barrels are insulating barrels. The collecting mechanism is provided with the two scrapped material collecting half barrels which are matched with the negative pole bar and can be opened and closed, a lifting device is used in cooperation, scraping of the metal powder on the negative pole bar can be achieved, material sucking devices are arranged at the upperportions of the scrapped material collecting half barrels, automatic collecting of the metal powder on the negative pole bar can be achieved, meanwhile, normal electrolysis of the negative pole bar cannot be influenced, collection of the metal powder is facilitated, and the electrolysis efficiency is improved.

Owner:南京弘瑞机械制造有限公司

Edge sealing machine flat edge scraping mechanism with flat scraping tool assembly

InactiveCN109571704ASimple structureSmall shapeWood working apparatusDomestic articlesEngineeringWood plank

Owner:FOSHAN CITY WEHO MASCH CO LTD

A drill pipe mud scraper

Owner:SHENGLI OILFIELD DONGRUN MACHINERY ENG

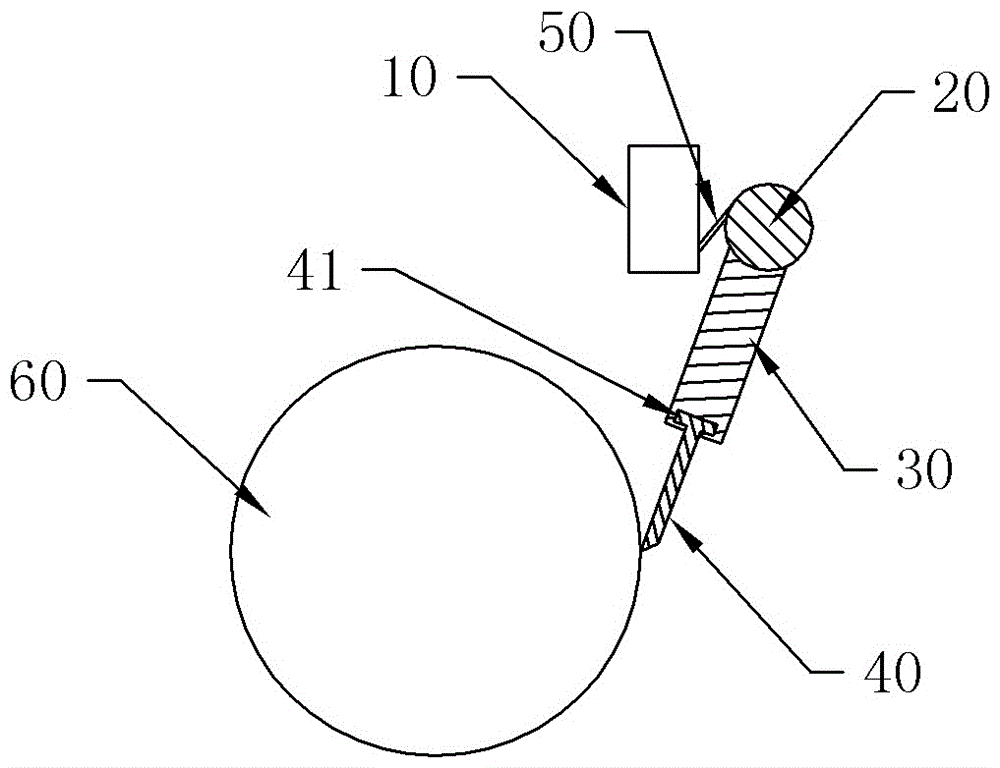

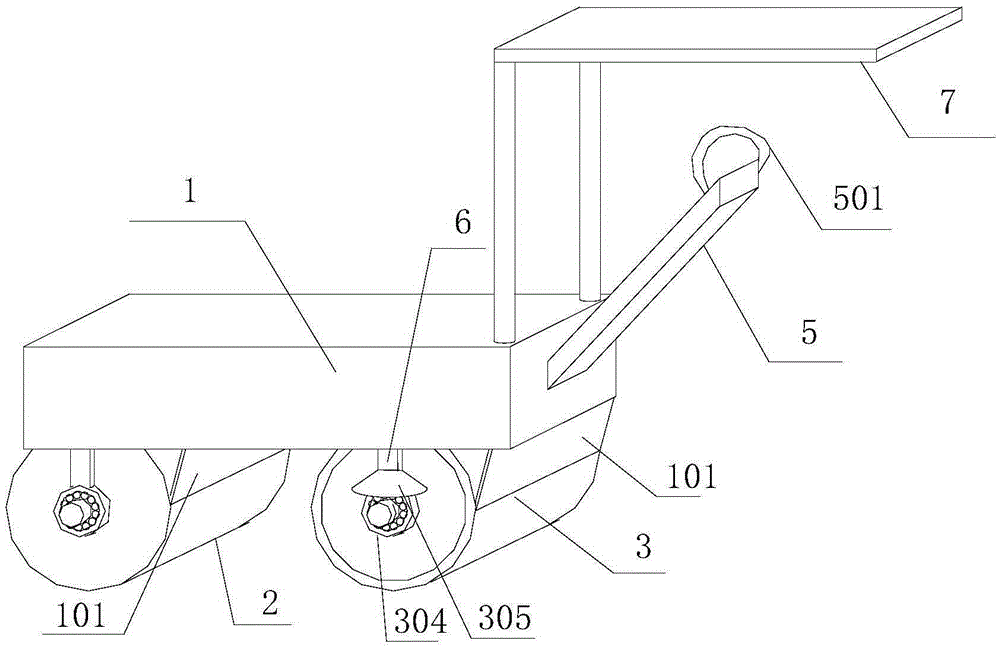

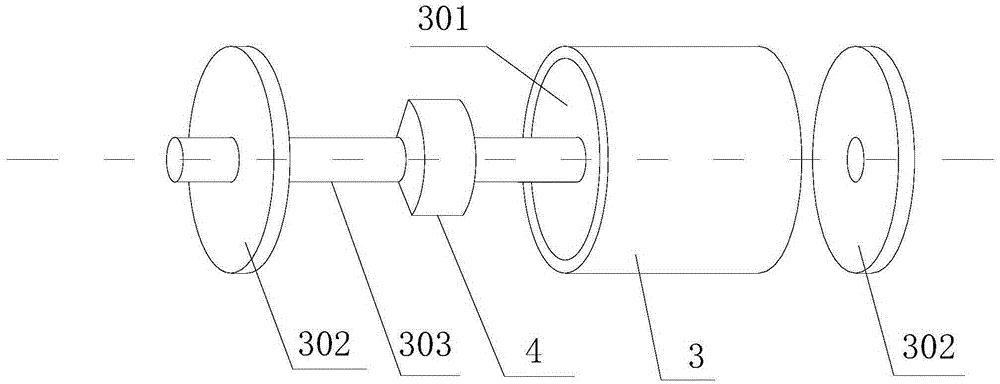

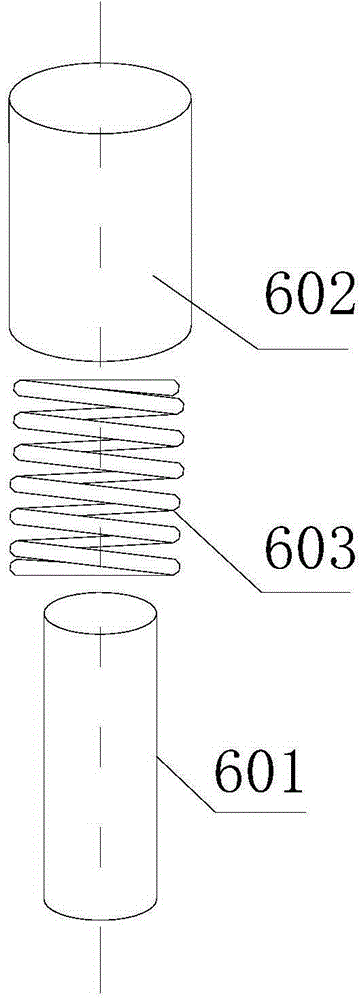

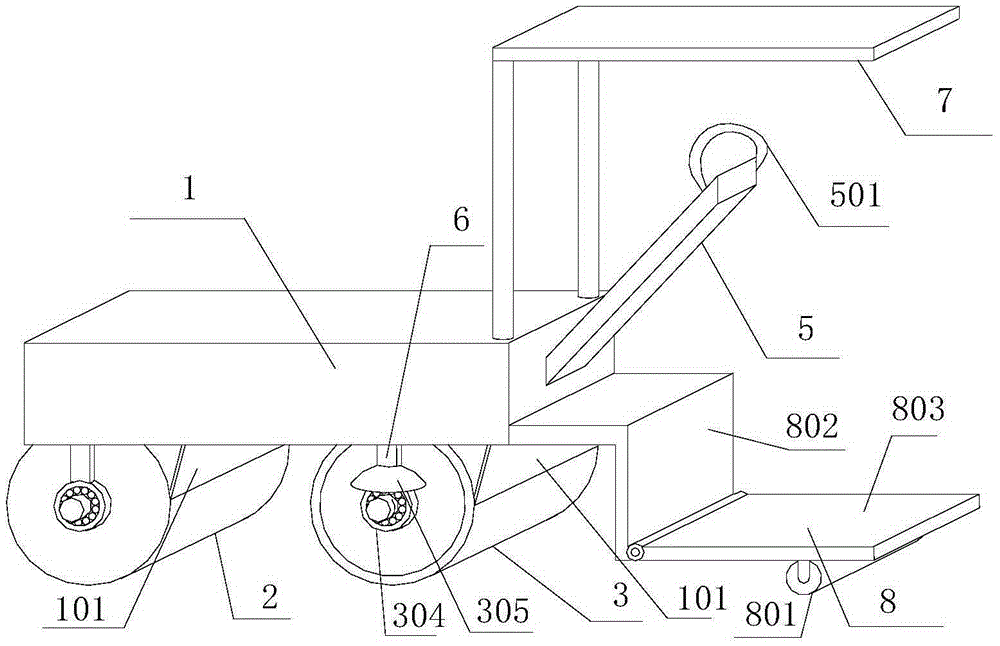

Sunshade road roller for construction engineering

InactiveCN106677022AGuaranteed scraping effectImprove climbing abilityRoads maintainenceWorking environmentArchitectural engineering

The invention discloses a sunshade road roller for construction engineering. The sunshade road roller for construction engineering comprises a machine body, and a front machine wheel and a back machine wheel which are arranged below the machine body and consistent in size, wherein a mud scraping board is arranged above each of the front machine wheel and the back machine wheel; the length of the mud scraping board is consistent with that of the back machine wheel; each mud scraping board is arranged on a mounting plate of the machine body; the mounting plate is parallel with the mud scraping board; two screw rods are arranged on the mounting plate; two long strip-shaped holes corresponding to the positions of the screw rods are formed in the mud scraping boards; the width of each long strip-shaped hole is consistent with the diameter of each screw rod; the length direction of each long strip-shaped hole is vertical to the extending direction of each mud scraping plate; a handrail is arranged on the machine body; a sun shield is arranged on the machine body and positioned over the handrail. The sunshade road roller for construction engineering has the beneficial effects that the sun shield is arranged above a driver, so that sunlight is shielded when the driver operates, and the working environment of the driver is optimized.

Owner:重庆特安建筑消防工程质量检测有限公司

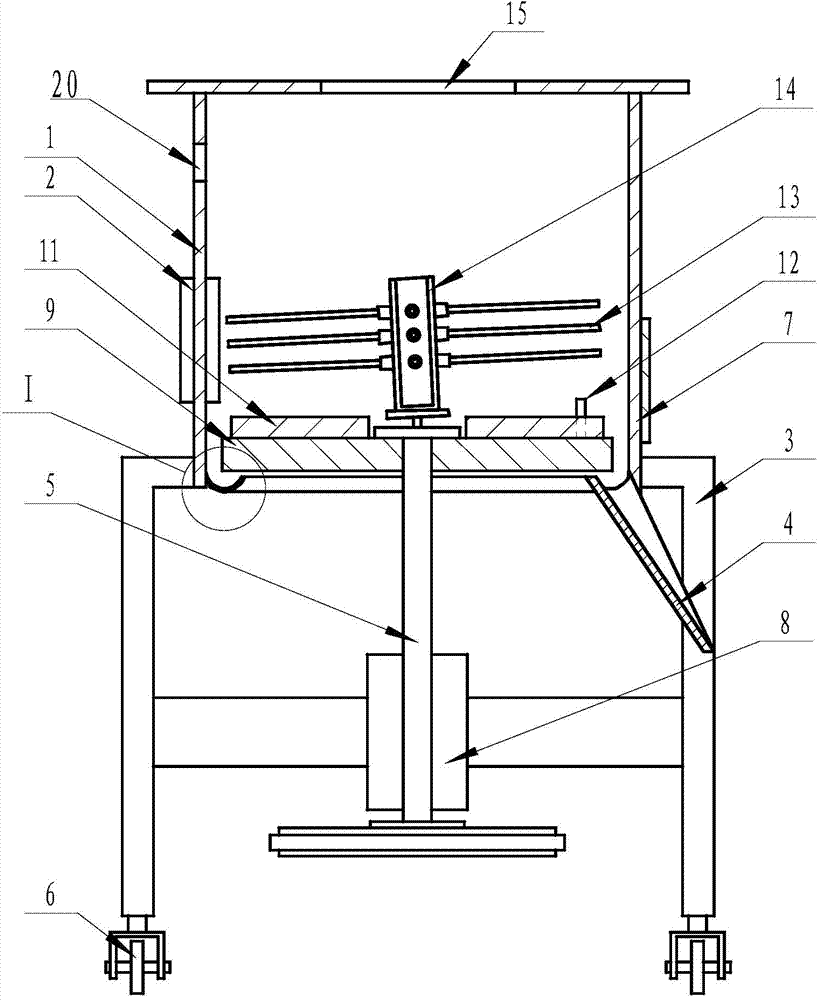

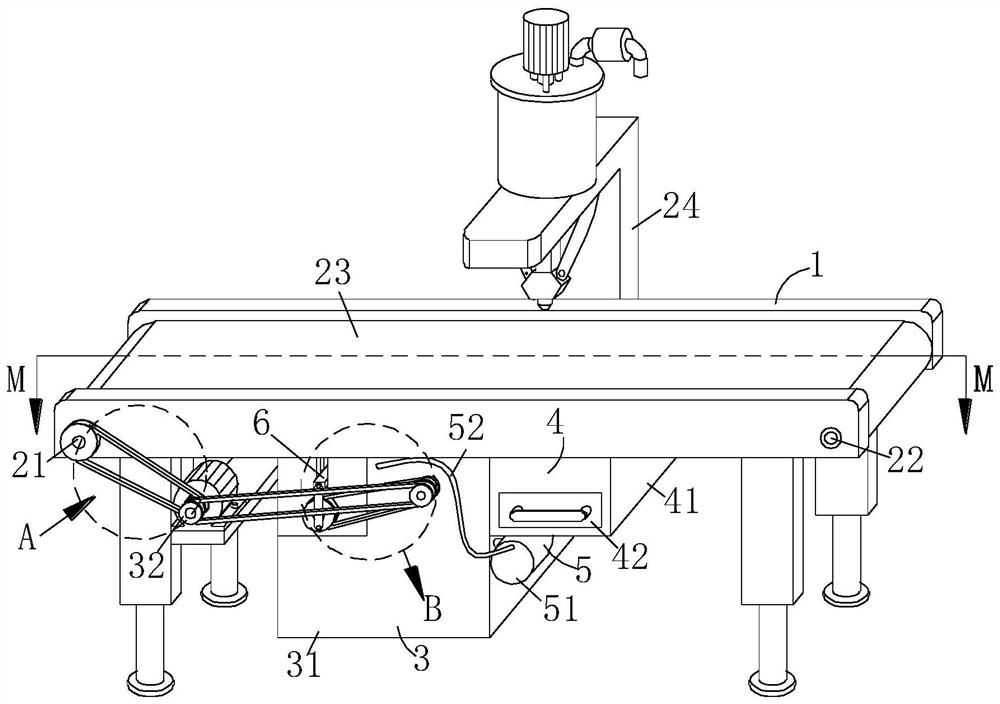

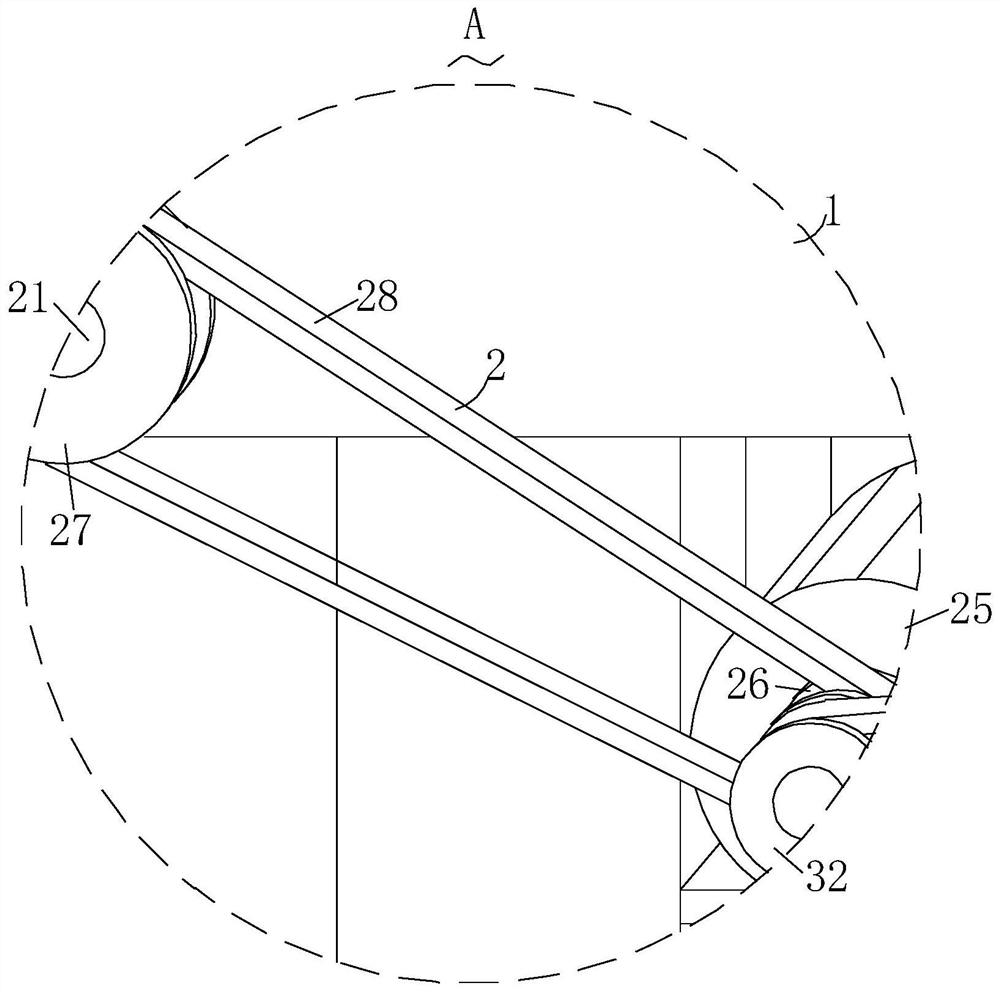

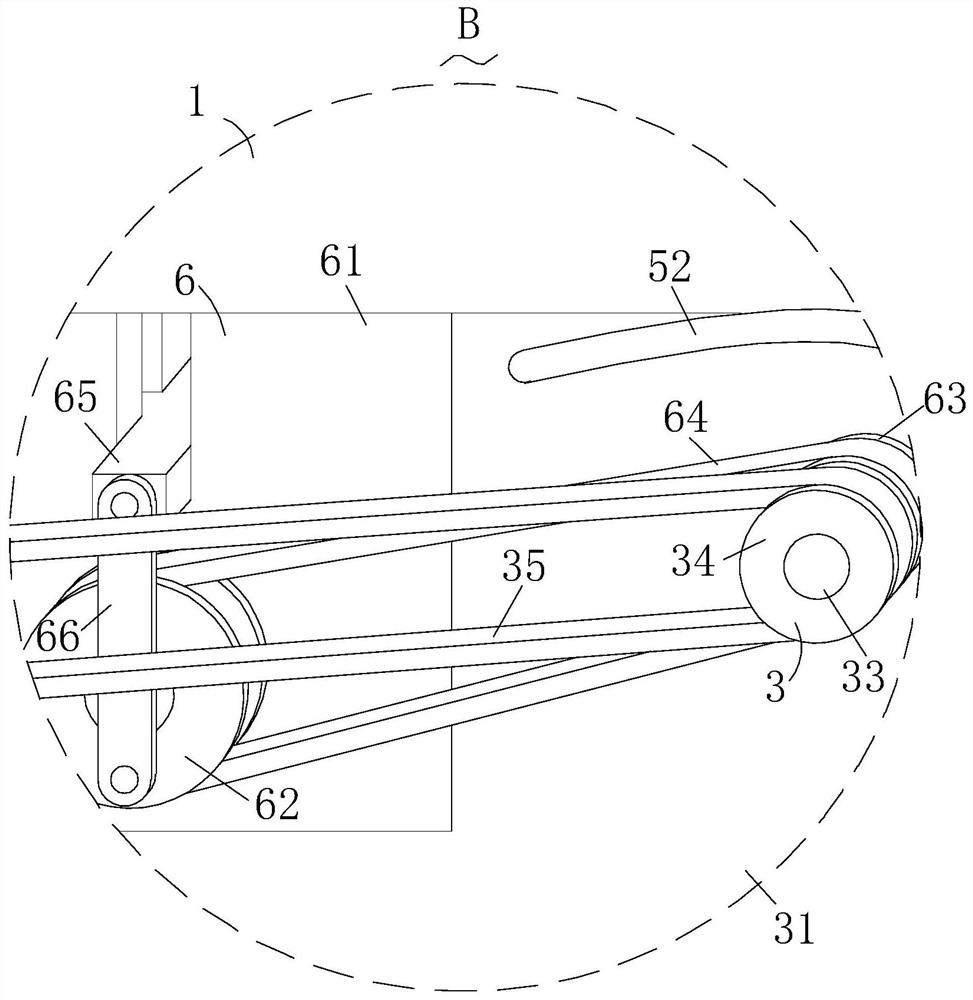

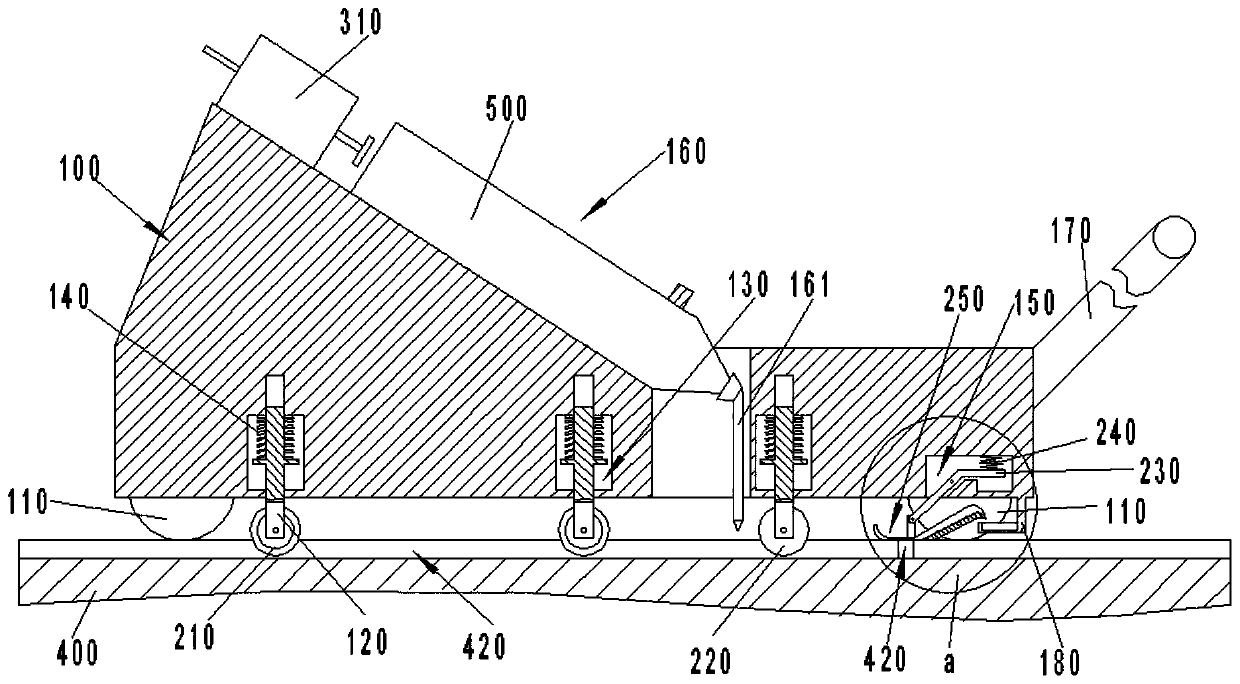

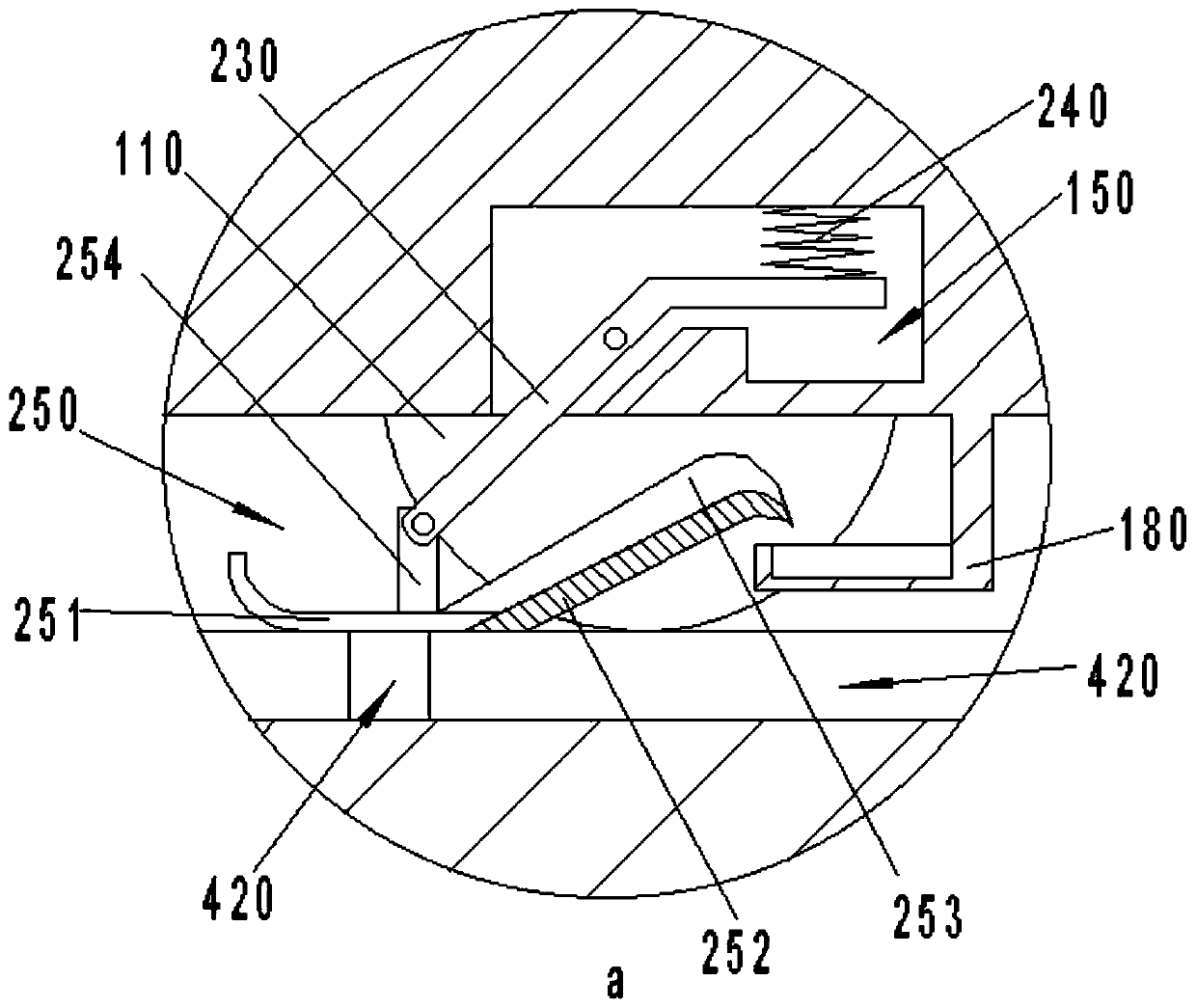

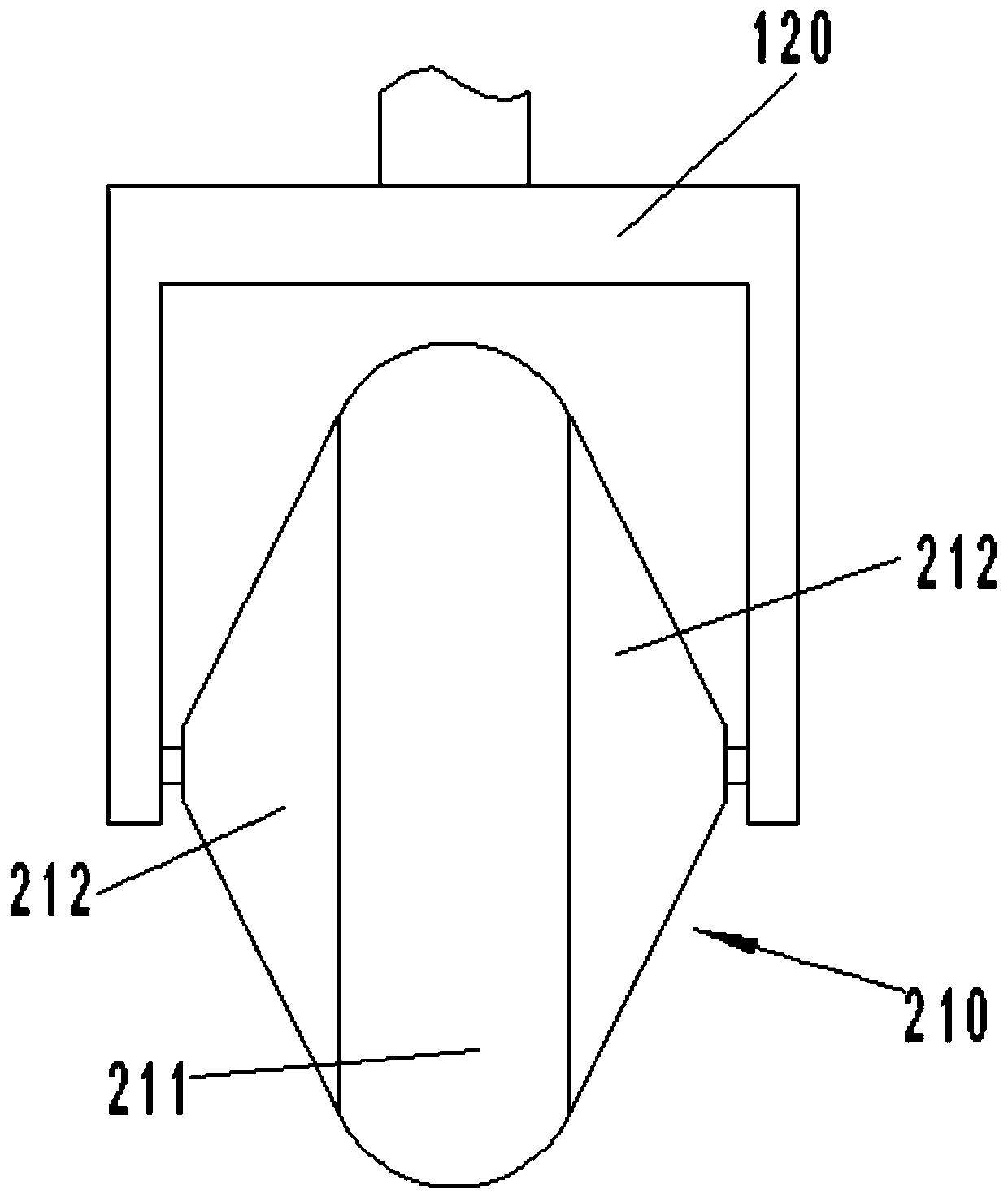

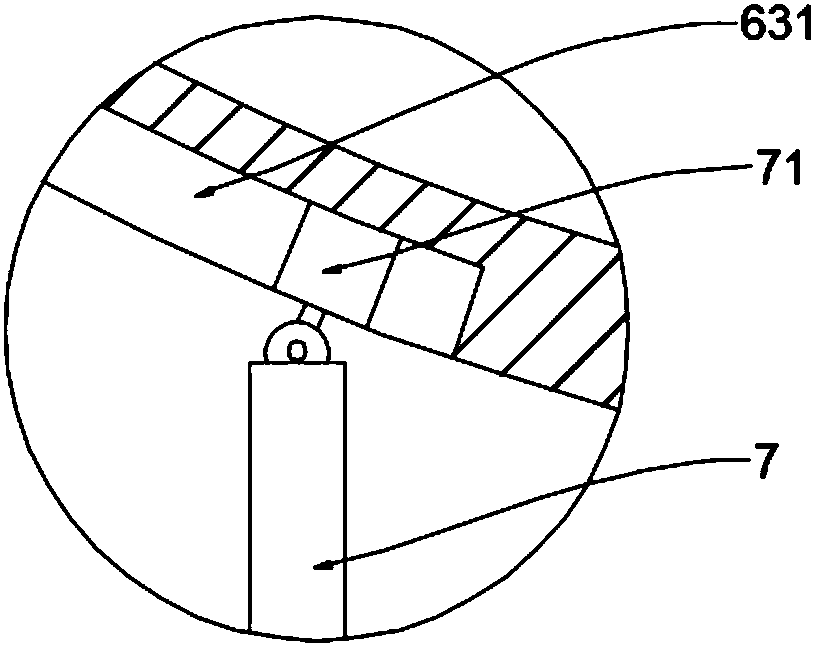

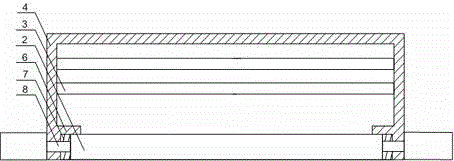

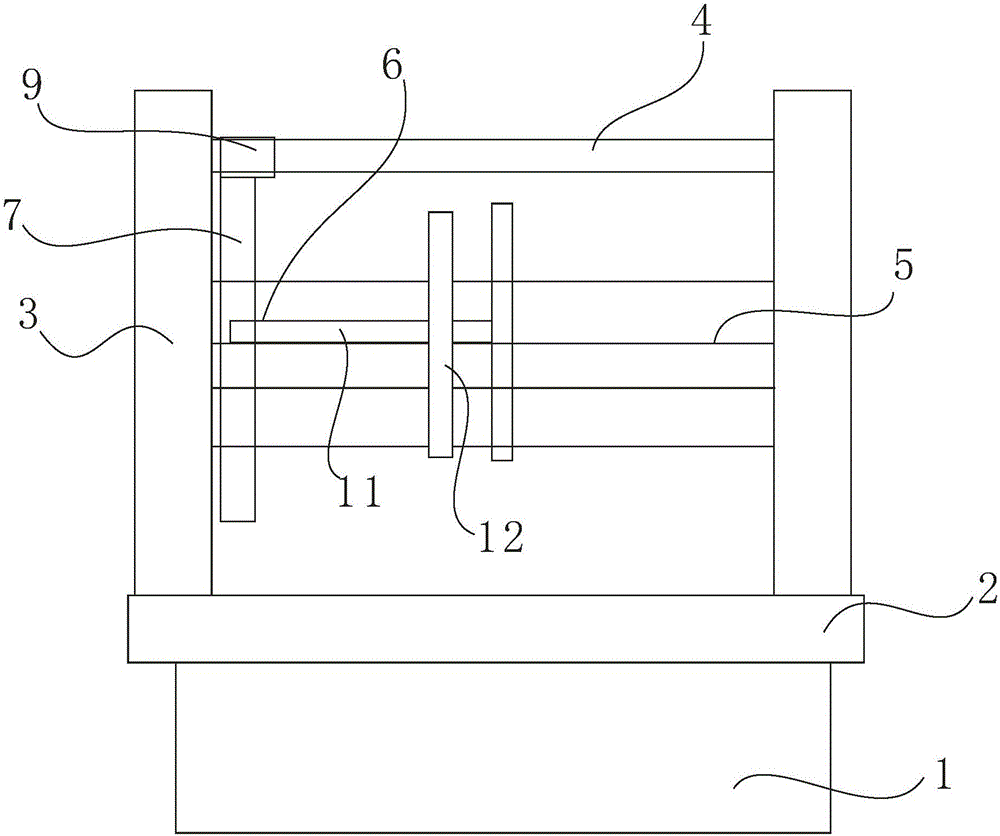

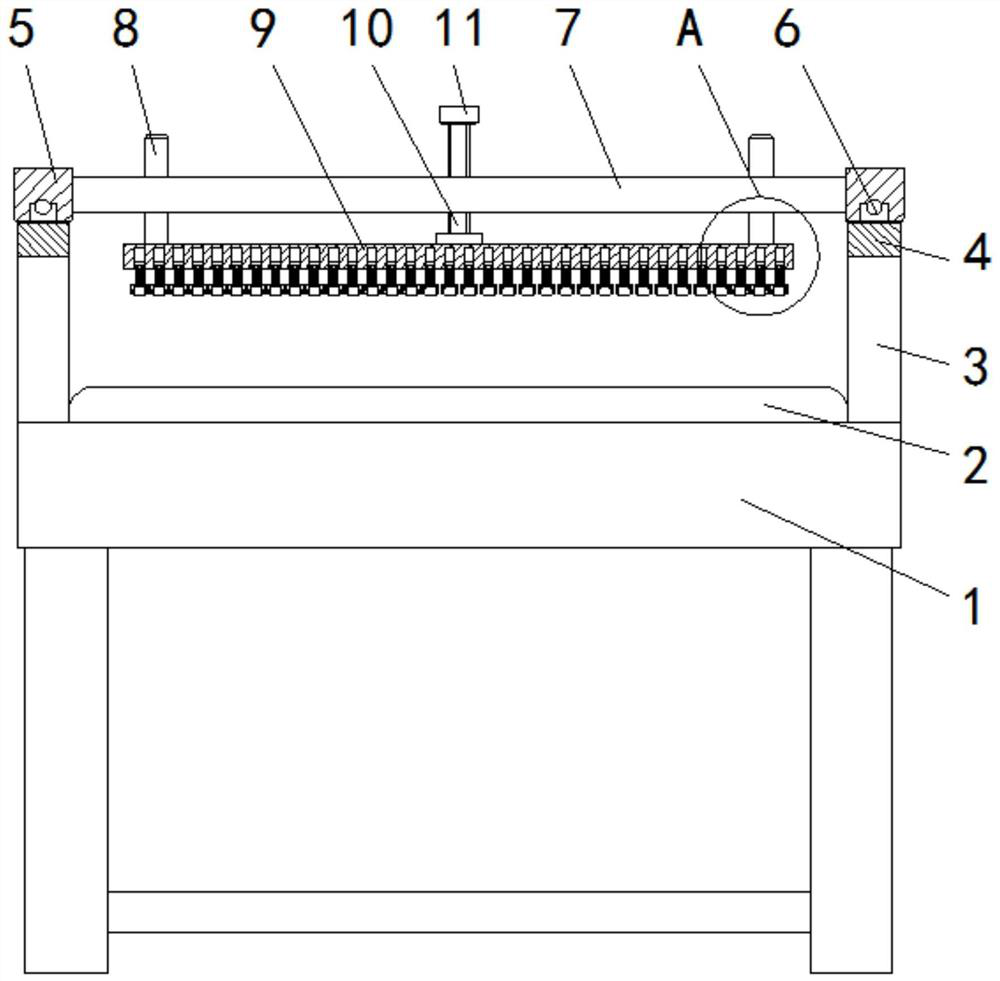

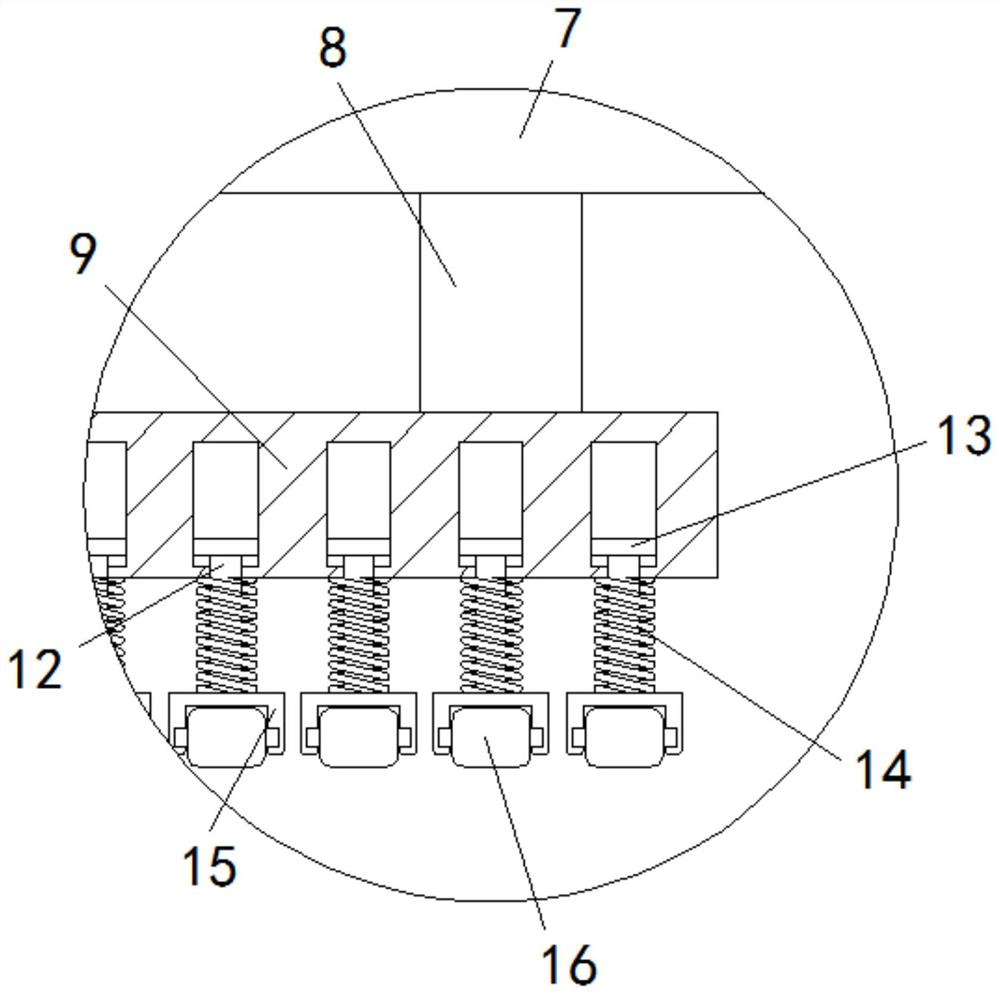

Insulation board thermal cutting system for scraping away residues of thermal cutting wires

InactiveCN105904518AGuaranteed scraping effectEasy to scrapeMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of insulation board production, in particular to an insulation board thermal cutting system for scraping away residues of thermal cutting wires. The insulation board thermal cutting system comprises a rack, a work platform arranged on the rack, and a horizontal movement thermal cutting frame arranged on the work platform; and the horizontal movement thermal cutting frame comprises a square horizontal movement frame perpendicularly arranged on a base, the thermal cutting wires evenly arranged on the square horizontal movement frame, and a thermal cutting wire scrape-away device arranged on the square horizontal movement frame; and due to the arrangement of the thermal cutting wire scrape-away device, the thermal cutting residues on the surfaces of the thermal cutting wires can be conveniently scraped away, and the scraping effect of the thermal cutting wires is guaranteed.

Owner:TIANJIN YUSHEN ENERGY SAVING THERMAL INSULATION MATERIAL

Pedal foldable road roller for constructional engineering

InactiveCN106677025AImprove climbing abilityImprove cleanlinessRoads maintainenceEngineeringUltimate tensile strength

The invention discloses a pedal foldable road roller for constructional engineering. The pedal foldable road roller for constructional engineering comprises a roller body, a front roller wheel and a rear roller wheel, wherein the front roller wheel and the rear roller wheel are arranged below the roller body and are identical in size. A handrail is arranged on the roller body. A sun shield is arranged on the roller body and located over the handrail. A pedal is arranged on the roller body and located under the handrail. A supporting wheel is arranged below the pedal. The length of the supporting wheel is identical to that of the rear roller wheel. The pedal comprises a connecting plate connected with the roller body and a supporting plate hinged to the connecting plate. The pedal foldable road roller for constructional engineering has the beneficial effects that the pedal is arranged under the handrail of the road roller and used for a driver to stand, the labor intensity is reduced, and the labor efficiency is improved; the supporting wheel is arranged below the pedal, so that the phenomenon that the pedal is broken due to the fact that the pedal supports the driver for a long time is avoided; and when the driver operates the road roller to make a turn, the pedal can be folded upwards, and the driver cannot be affected.

Owner:重庆特安建筑消防工程质量检测有限公司

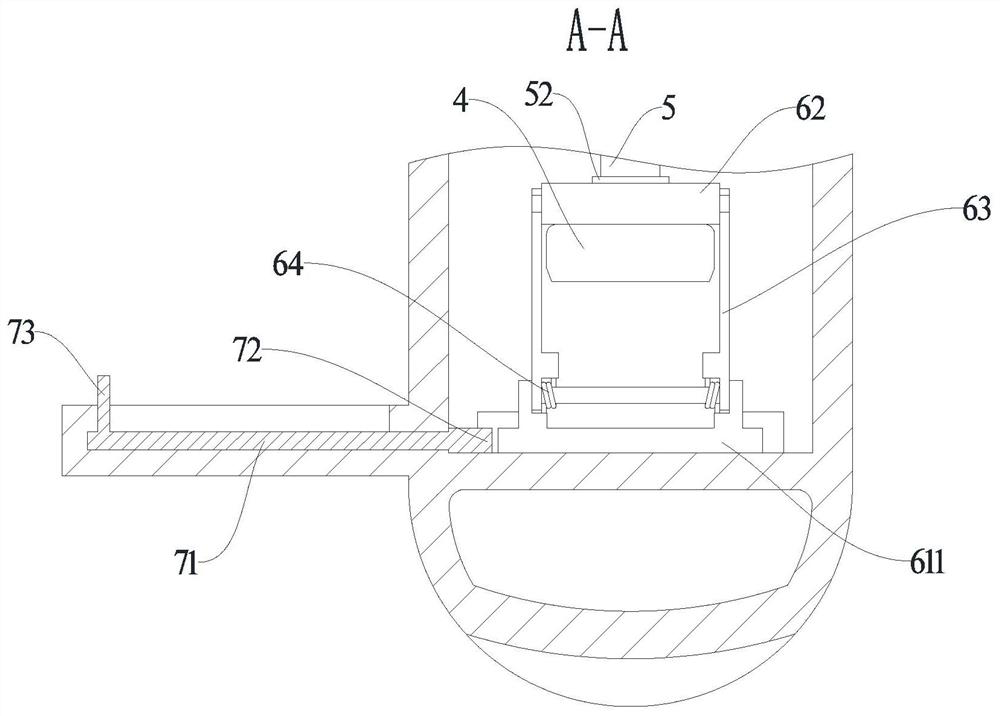

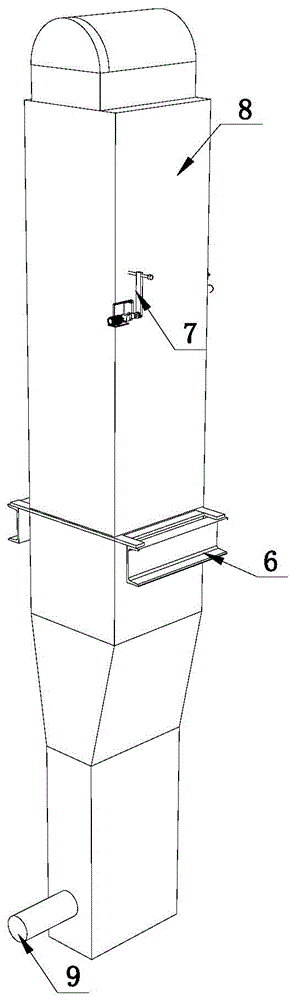

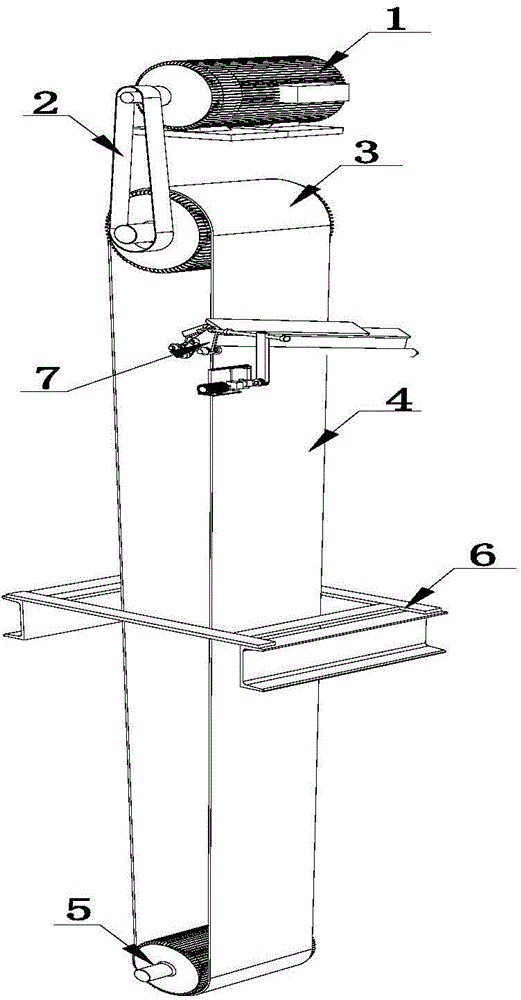

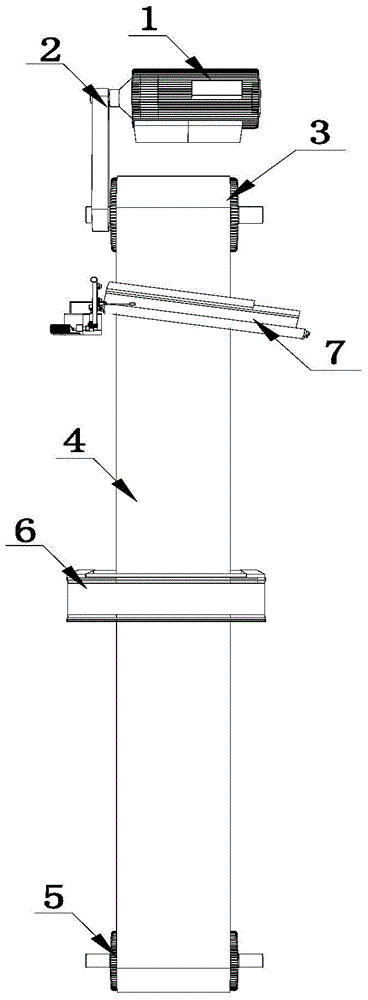

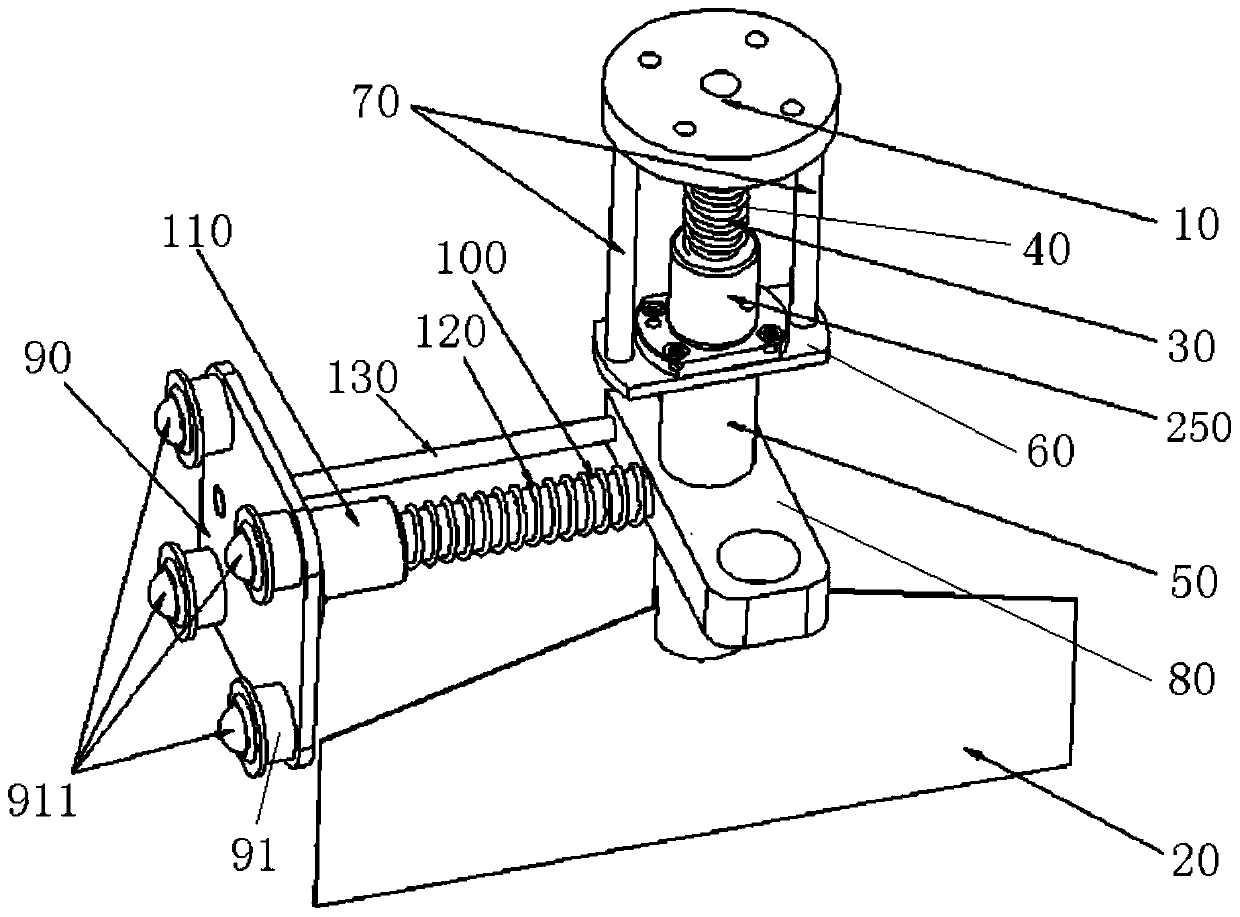

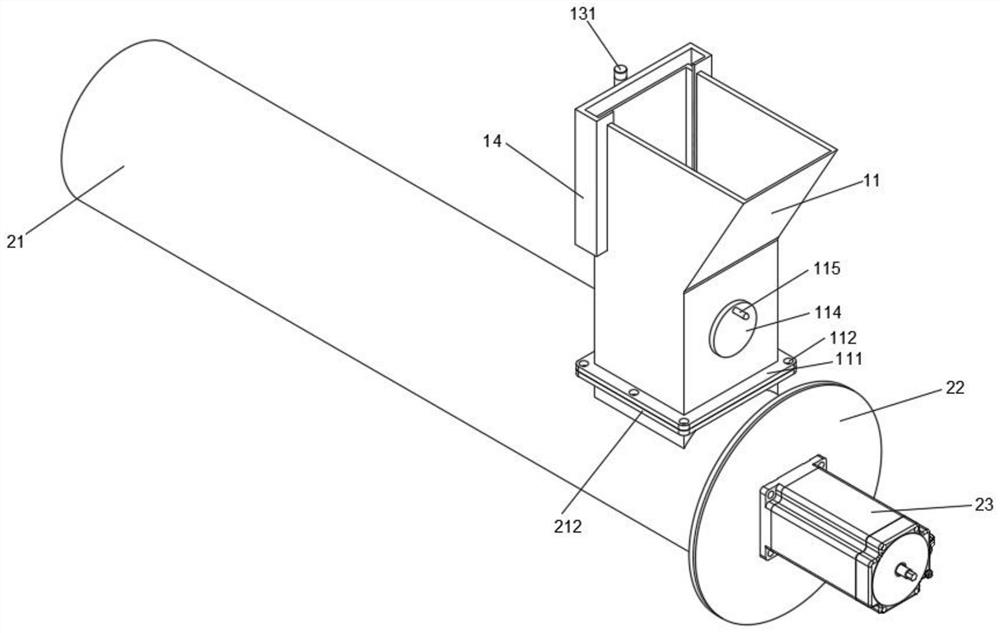

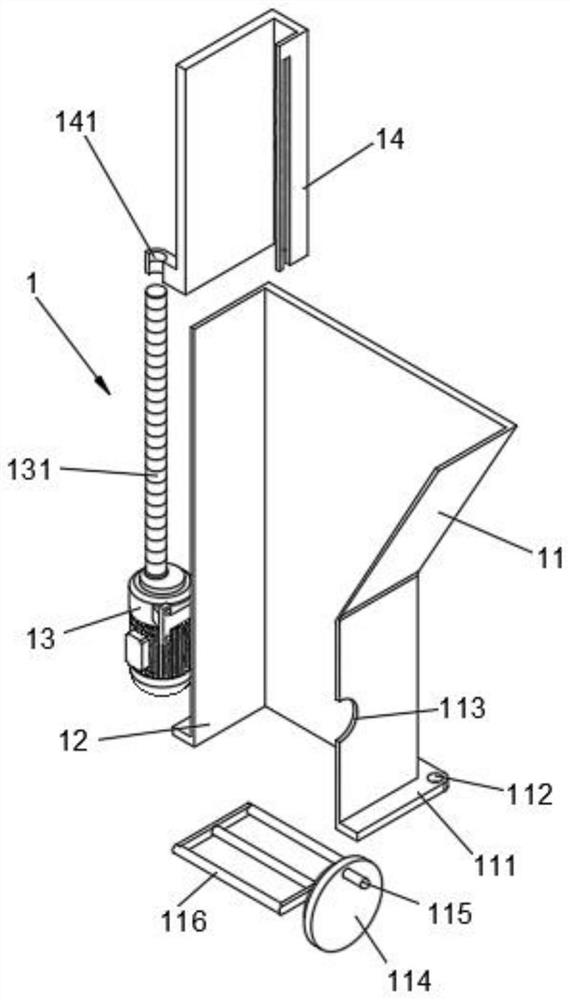

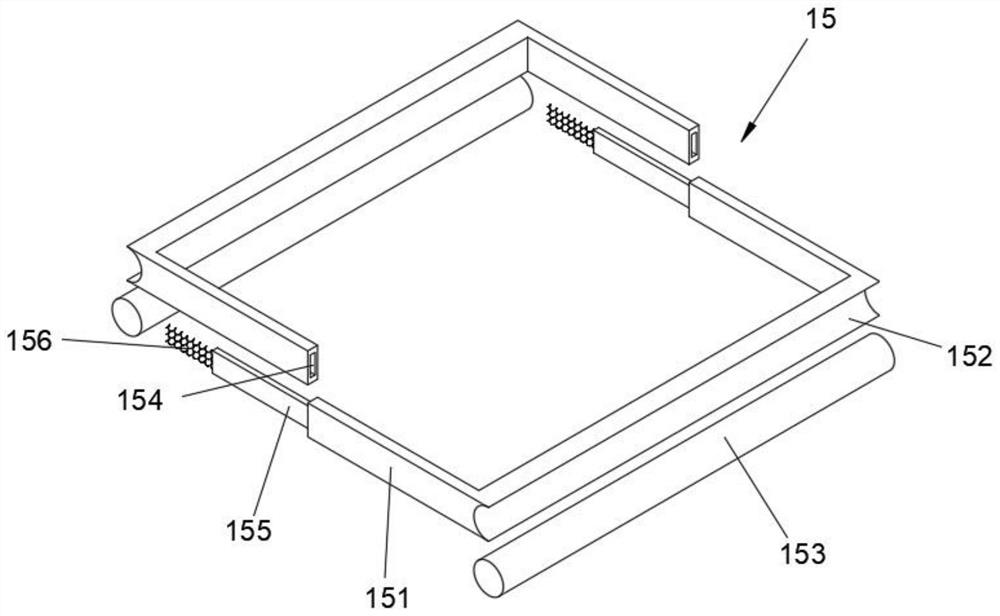

Blanking screw sleeve hot drawing film forming square opening feeding structure

PendingCN114274420AAvoid cloggingGuaranteed scraping effectHollow article cleaningElectric machineryStructural engineering

The invention relates to the technical field of screw blanking, in particular to a blanking screw sleeve hot drawing film forming square opening feeding structure which comprises a feeding body and a feeding body communicated with the bottom of the feeding body, the feeding body comprises a hopper, the hopper is provided with a material opening, the feeding body comprises an outer barrel, the outer barrel is provided with an outer opening, the outer barrel is provided with an inner barrel, and the inner barrel is provided with an inner opening. A through opening is formed in the inner cylinder, and a second motor is arranged on one side of the through opening and penetrates through the through opening to be in transmission connection with a screw. The powder feeding device has the advantages that the material circulation sectional area is increased by adopting a square opening butt joint mode, the probability of material bridging is reduced, so that powder materials are conveniently discharged, in addition, the upper opening and the lower opening are formed, the feeding body and the feeding body are conveniently combined and installed, the side opening is formed, a handle is held, and the side disc is rotated in the side opening, so that the powder feeding device is convenient to use. And the stirring body is driven to rotate in the hopper, so that materials can be stirred, and blockage of the materials is avoided.

Owner:常德科炜自动化技术有限公司

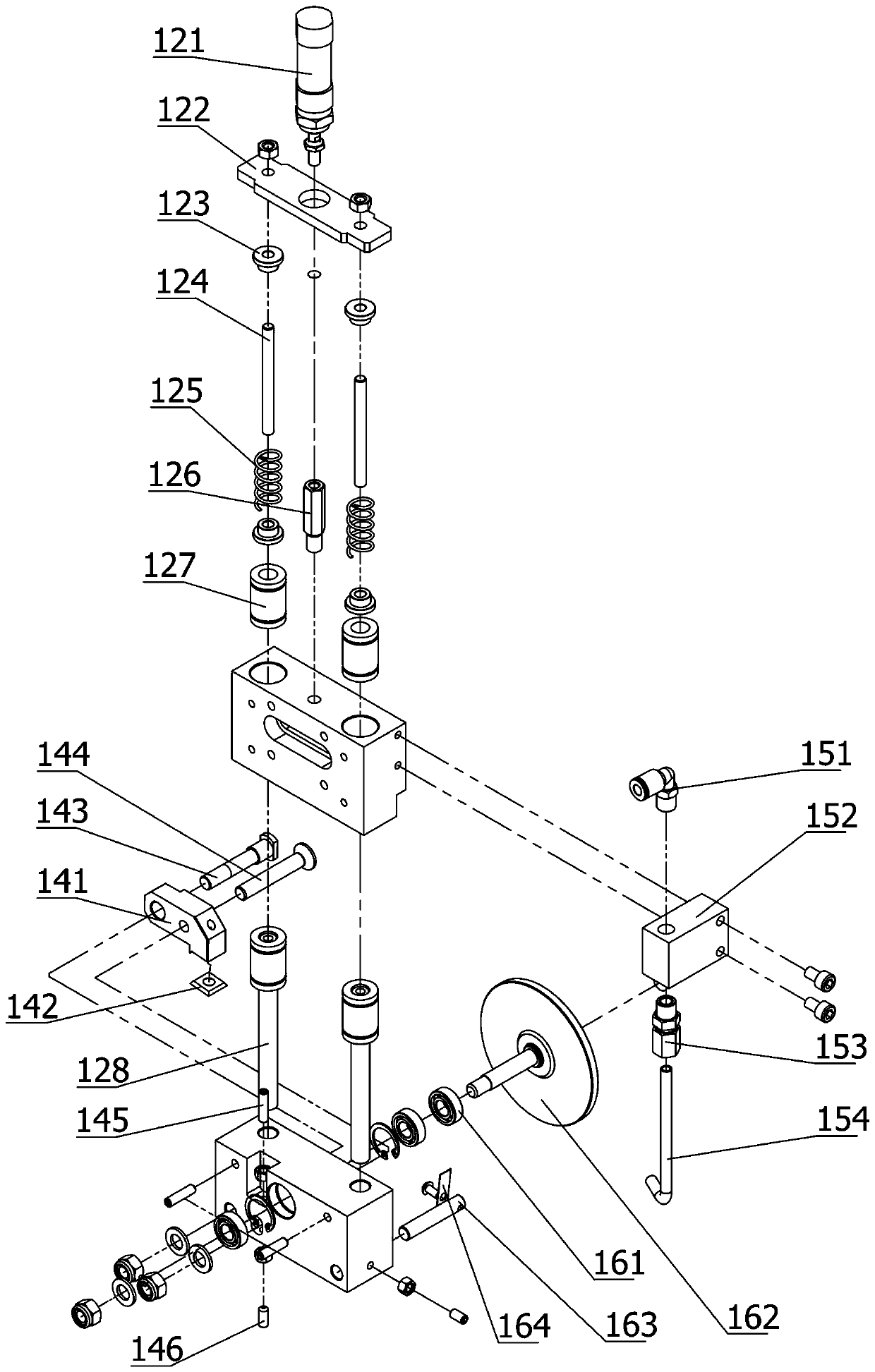

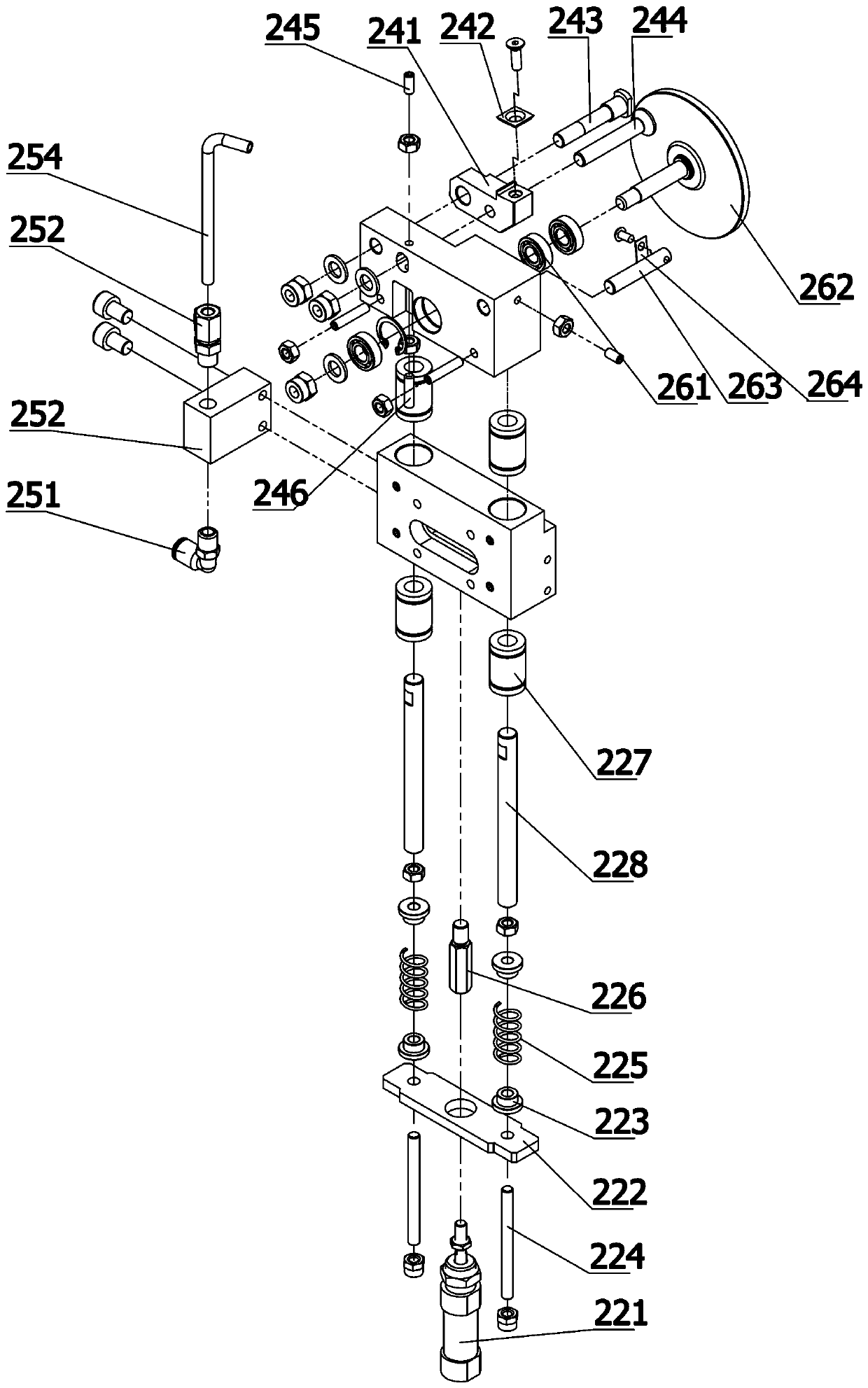

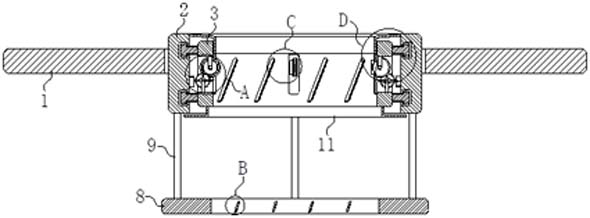

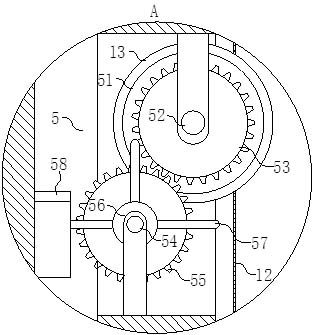

Scraping device for exercise rehabilitation

PendingCN112603784AEasy to scrapeAvoid getting hurtSuction-kneading massagePhysical medicine and rehabilitationMedizinische rehabilitation

The invention relates to the technical field of medical rehabilitation devices, and discloses an exercise rehabilitation scraping device. The device comprises a base, a soft cushion is fixedly installed at the top of the base, supporting rods are fixedly installed on the left side and the right side of the top of the base, and guide rods are fixedly installed at the top of the supporting rod on the left side and the top of the supporting rod on the right side. Movable seats are movably mounted at the tops of the two guide rods correspondingly, guide rails extending into the movable seats are fixedly mounted at the tops of the guide rods, the two movable seats are fixedly connected through a connecting rod, a stabilizing rod extending to the lower portion of the connecting rod is movably mounted at the top of the connecting rod, and a movable plate is fixedly mounted at the bottom of the stabilizing rod; and a threaded rod extending to the upper part of the connecting rod is movably mounted at the top of the movable plate. The scraping therapy device for the rehabilitation department is easy to operate, a user can conduct scraping therapy operation more conveniently, the scraping therapy effect is guaranteed, and the scraping therapy effect is better.

Owner:NANJING INST OF RAILWAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com