Insulation board thermal cutting system for scraping away residues of thermal cutting wires

A heat preservation board and residue technology, which is applied in metal processing and other directions, can solve the problems of cutting effect influence, hot wire residual residue, etc., and achieve the effect of ensuring the scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

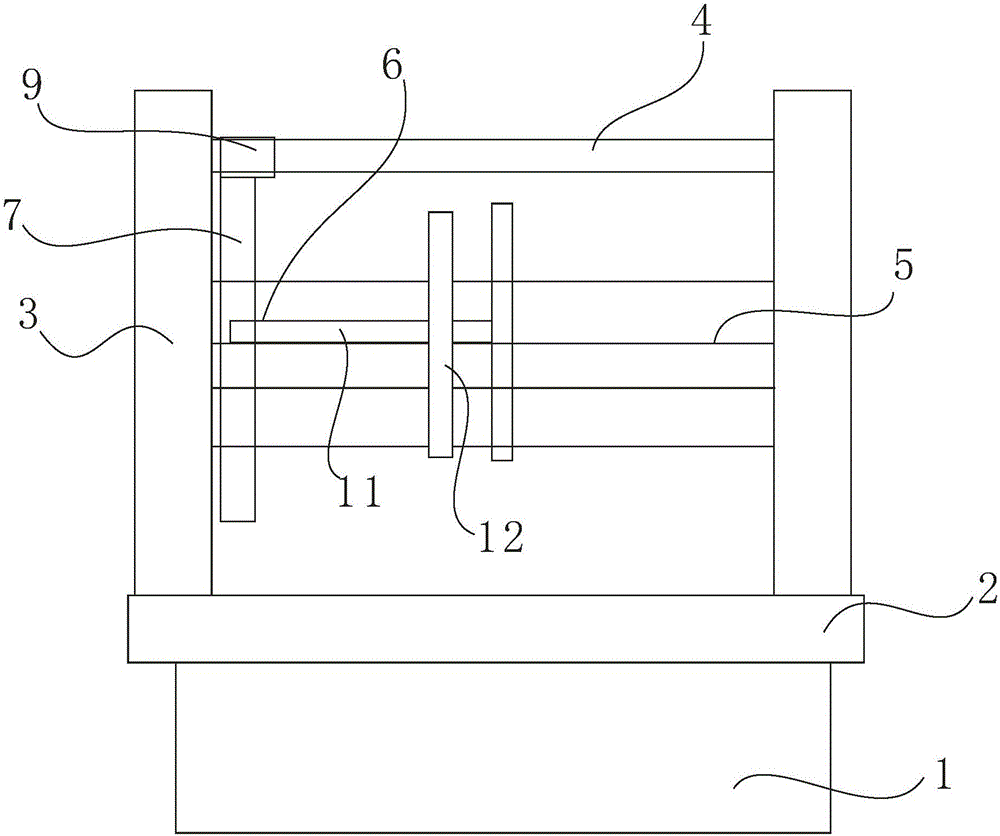

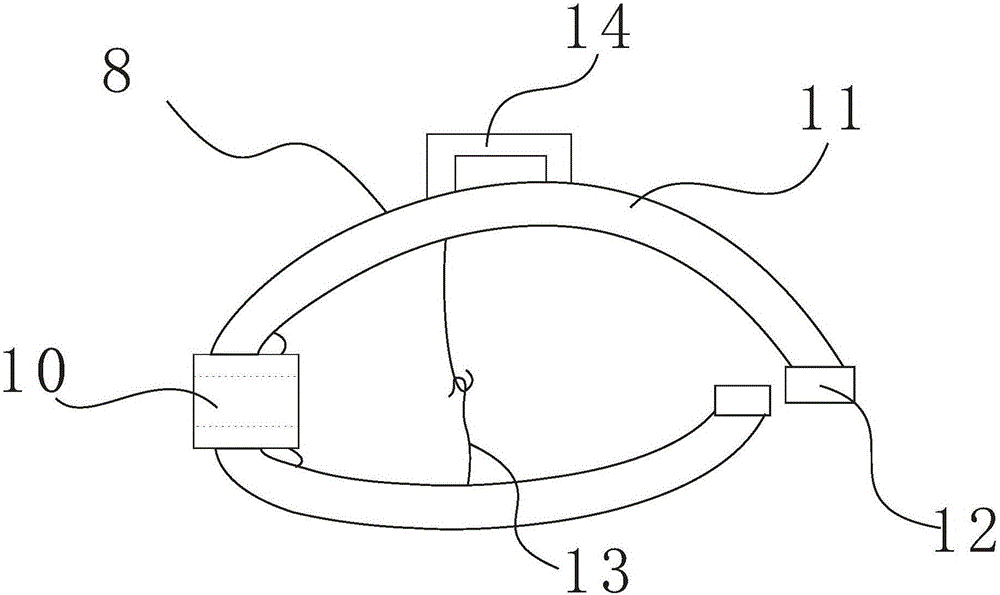

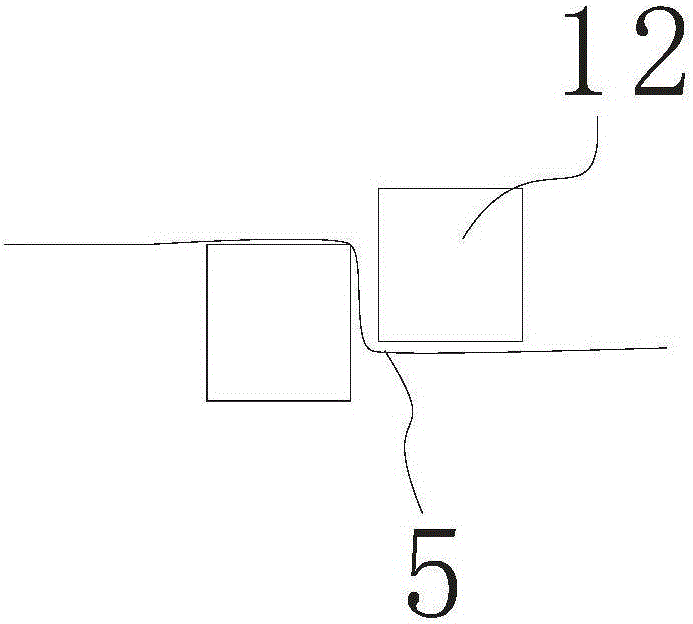

[0016] As shown in the figure, the present invention includes a frame 1, a working platform 2 arranged on the frame and a translational eager cutting frame 3 arranged on the working platform. The translational eager cutting frame includes a square translational frame 4 vertically arranged on the base, The hot-cut wire 5 evenly arranged on the square translation frame and the hot-cut wire scraping device 6 arranged on the square translation frame, the hot-cut wire scraper device includes a vertical hot-cut wire setting translation push rod 7 and a scraper fixedly connected with the translation push rod. In addition to the head 8, one end of the translation push rod is provided with a translation suspension block 9 that tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com