Fuel cylinder block cleaning device

A technology for cleaning devices and cylinders, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of idling jitter, fuel consumption, weak acceleration, poor cleaning effect, etc., so as to ensure normal use and ensure scraping. Removal effect, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

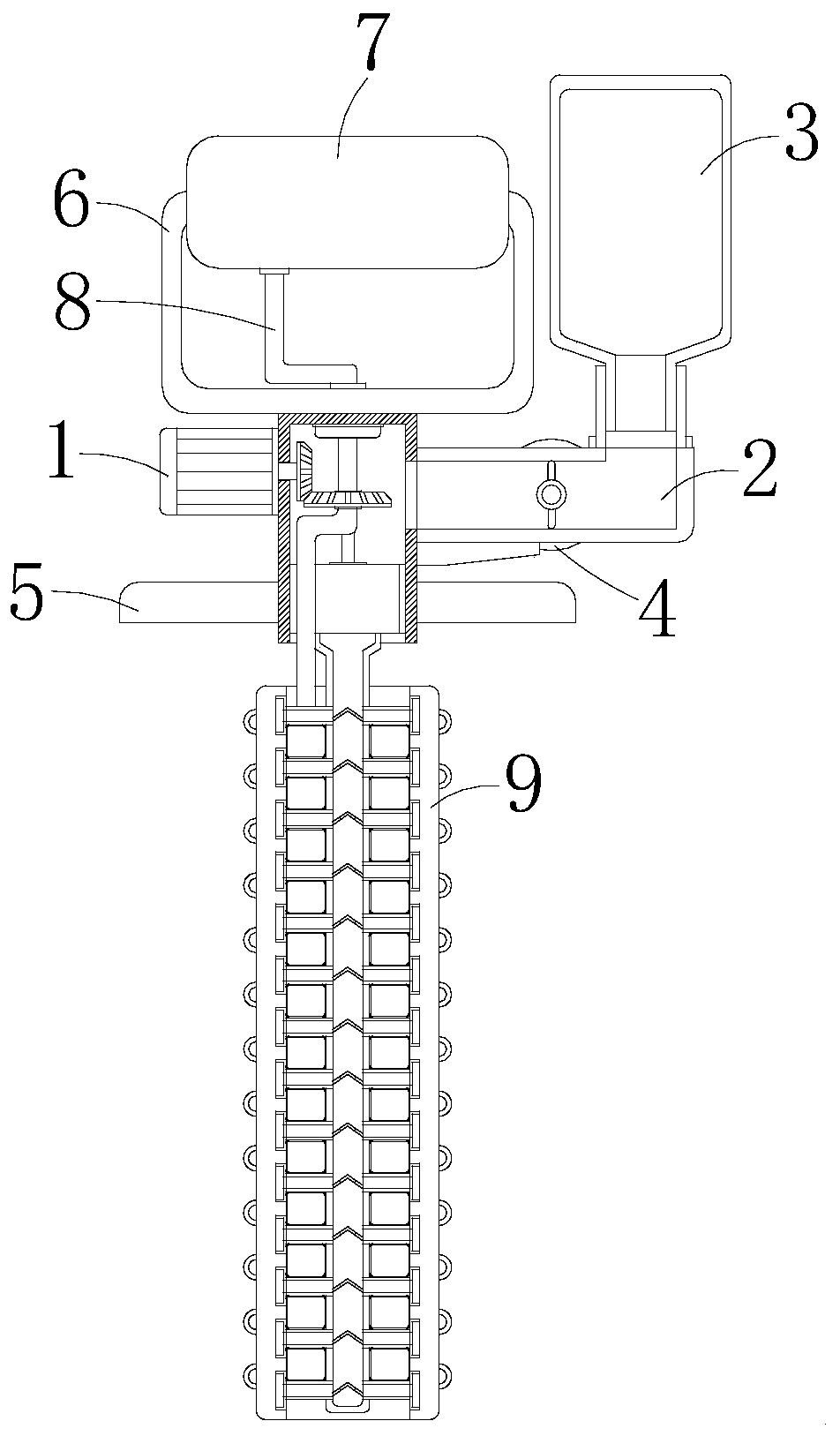

[0024] see Figure 1-4 , the present invention provides a technical solution: a fuel cylinder cleaning device, including a driving mechanism 1, a handle 6, an air bag 7, an air pipe 8 and a cleaning mechanism 9, and the middle part of the bottom of the handle 6 is fixedly connected to the driving mechanism 1 The top of the air bag 7 is fixedly installed in the middle part of the top of the handle 6, and the air outlet of the air bag 7 is connected and communicated with the top of the air delivery pipe 8, and the bottom end of the air delivery pipe 8 runs through the top of the driving mechanism 1 and extends to the driving mechanism 1, the cleaning mechanism 9 is fixedly installed below the drive mechanism 1.

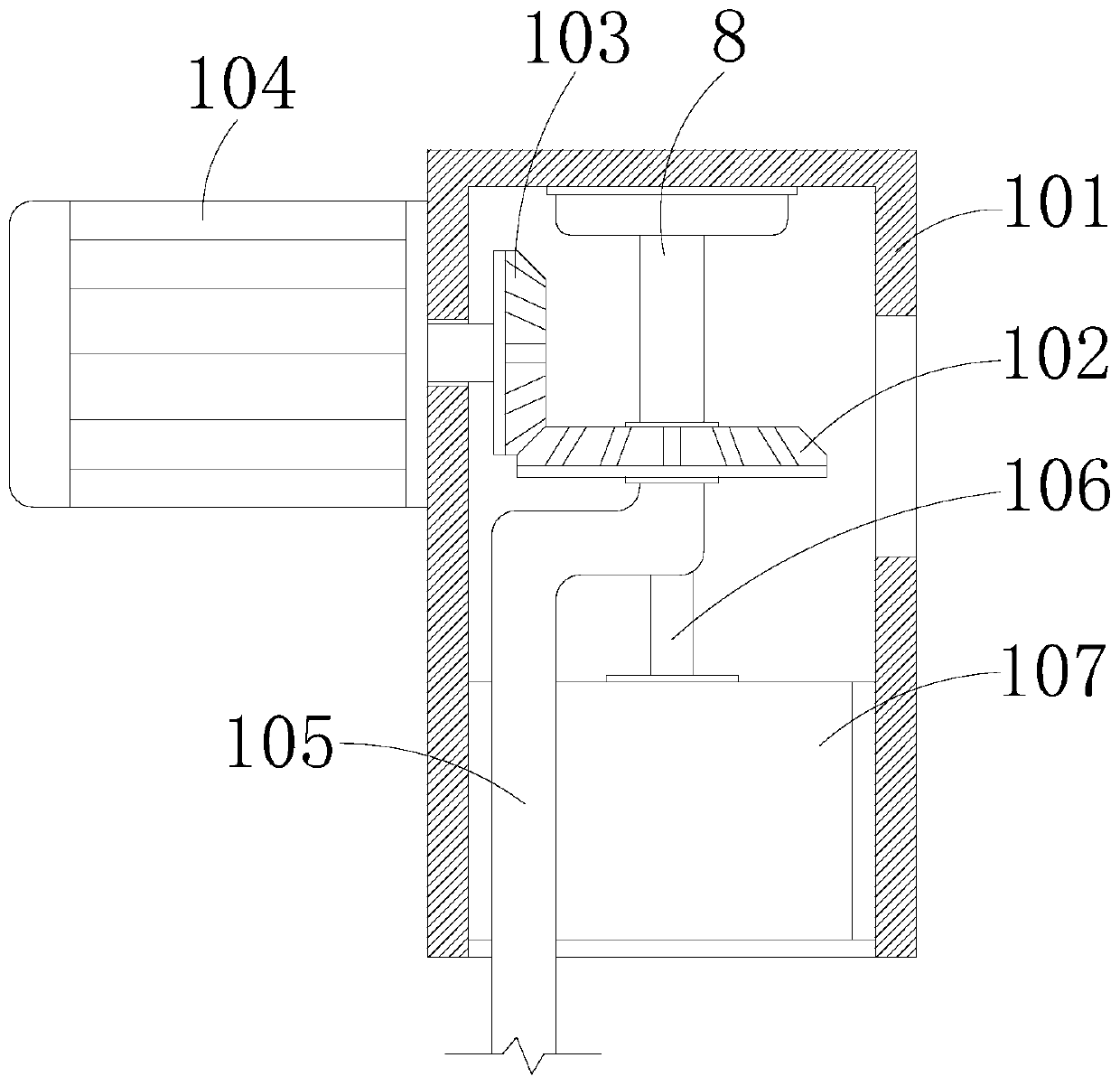

[0025] The driving mechanism 1 includes a fixed block 101, a transverse bevel gear 102, a longitudinal bevel gear 103, a drive motor 104, a bending pipe 105, a connecting rod 106 and a liquid collection pipe 107, and the gas delivery pipe 8 runs through a section in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com