Scraping structure for rollers

A technology of scraper and scraper frame, which is applied in the field of roller scraper structure, can solve the problems of poor scraper effect and scraper wear, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

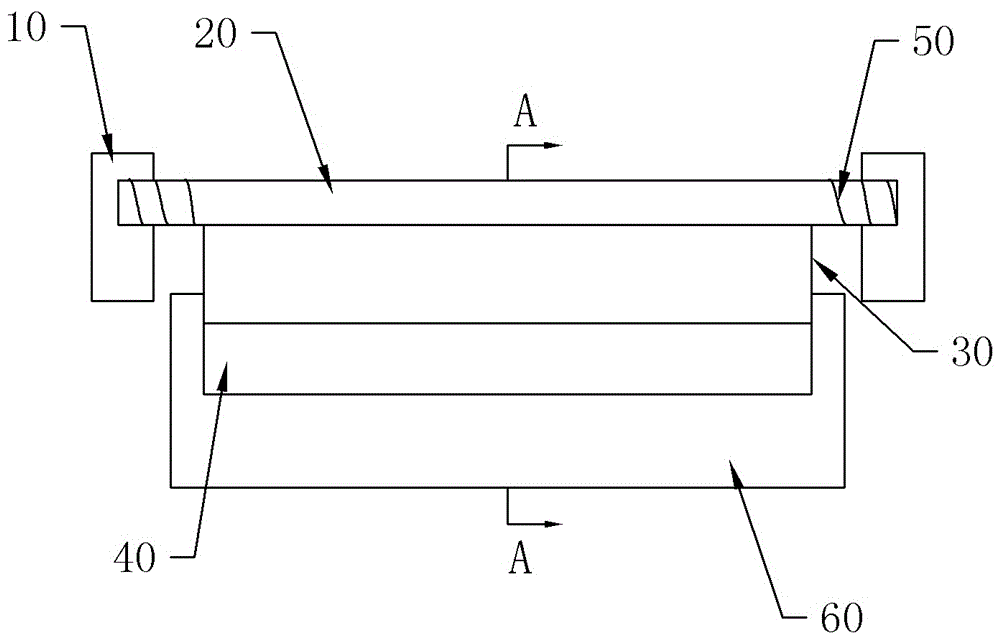

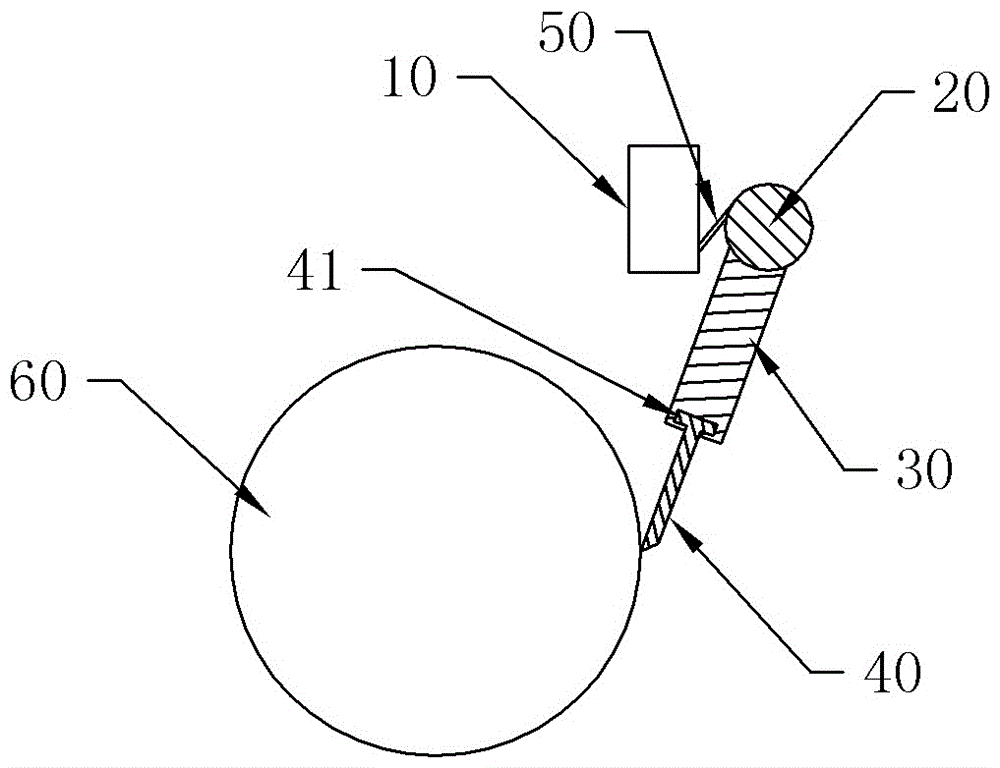

[0025] Embodiment 1 is basically as attached figure 1 and figure 2 Shown: a scraping structure for roll 60, including installation frame 10, rotating shaft 20, scraper holder 30, scraper 40 and elastic member for resetting the rotating shaft 20, in this embodiment, the elastic member used is torsion spring 50 , Two torsion springs 50 are installed on the rotating shaft 20 . The torsion spring 50 can provide the rotating force of the rotating shaft 20 , and make the rotating shaft 20 drive the scraper holder 30 and the scraper 40 , so that the scraper 40 abuts against the surface of the roll 60 . The structure that the torsion spring 50 resets as an elastic member is simple. The rotating shaft 20 is rotatably connected to the mounting frame 10 , the scraper frame 30 is mounted on the rotating shaft 20 , the scraper 40 is detachably connected to the scraper frame 30 , and under the reset action of the torsion spring 50 , the scraper 40 is offset against the surface of the rol...

Embodiment 2

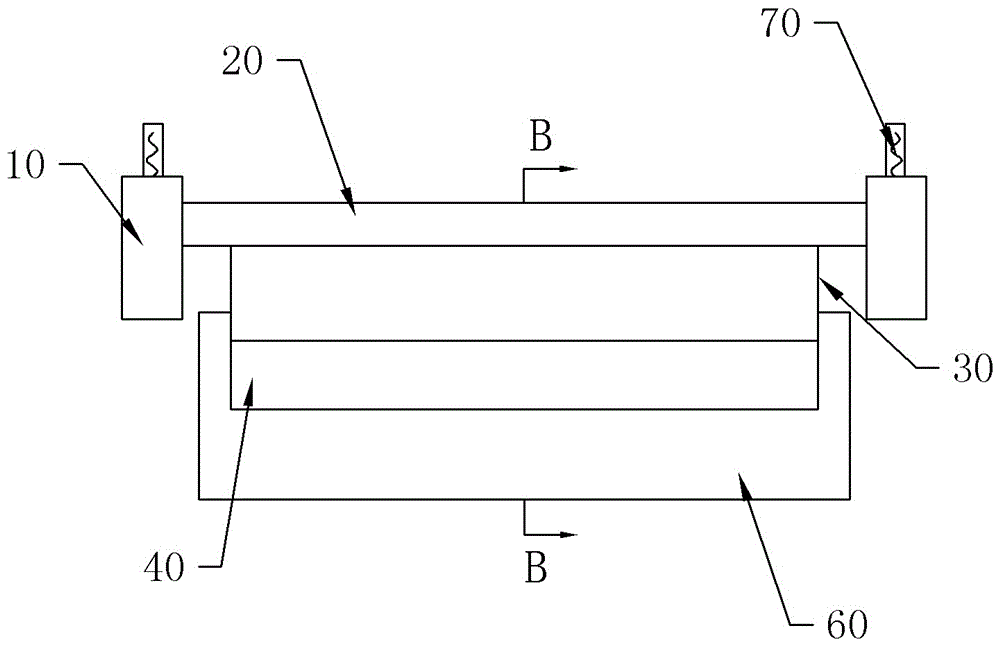

[0028] like image 3 and Figure 4 As shown, the difference with Embodiment 1 is that the elastic member in this embodiment adopts a tension spring 70, and the rotating shaft 20 is threadedly connected with a pole arranged in the radial direction, and one end of the tension spring 70 is connected with the pole, and the other end Connect with the mounting frame 10. During use, the extension spring 70 exerts force on the support rod, so that the rotating shaft 20 rotates, and the rotating shaft 20 drives the scraper holder 30 and the scraper 40 to rotate, and the scraper 40 is against the surface of the roll 60 . The extension spring 70 has a good elastic coefficient and has a long service life.

Embodiment 3

[0030] like Figure 5 As shown, the difference with Embodiment 2 is that: both sides of the scraper 40 are embedded with electromagnets 80, and the corresponding positions on the roll 60 are embedded with magnetic parts that attract each other with the two electromagnets 80. The magnetic parts are permanent magnets. During specific use, the electromagnet 80 is energized, and the electromagnet 80 on the scraper 40 is then attracted to the permanent magnet on the roll 60, so that the scraper 40 can be offset against the surface of the roll 60 to play an auxiliary role; Size is controllable, so just can control the force that scraper 40 and roll 60 surface resist, if the viscous force of dough and roll 60 is bigger, then control increases the magnetic force of electromagnet 80; If the viscous force of dough and roll 60 is less, Then the magnetic force of the electromagnet 80 is controlled to be reduced to reduce wear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com