Shaving board lumber drier

A particleboard and dryer technology, used in progressive dryers, drying solid materials, drying, etc., can solve problems such as affecting product quality, failing to dry the shavings, wasting energy, etc. Scattering, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

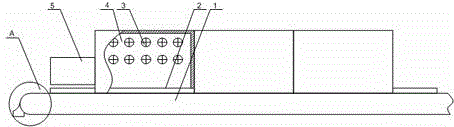

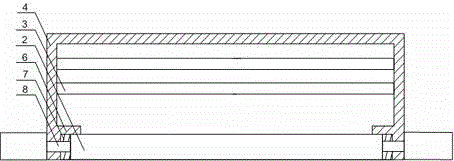

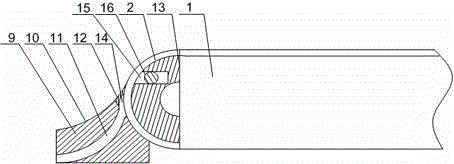

[0022] Such as Figure 1~Figure 3 As shown, this embodiment includes a bracket 1 and a conveyor belt 2 matched therewith. Above the conveyor belt 2, a plurality of drying cavities 4 arranged side by side and communicating with each other are fixed. Both sides of the drying cavities 4 are provided with At the inlet end and the outlet end, two rows of magnetrons 3 parallel to each other are fixed on the inner wall of the drying chamber 4, U-shaped grooves 7 are fixed on both sides of the conveyor belt 2, and two cylinders 8 are fixed in the bracket 1. The output ends of the two cylinders 8 are slidingly arranged in the U-shaped groove 7, and protrusions 6 are also arranged on the inner walls of both sides of the drying cavity 4, and the protrusions 6 are in contact with the upper surfaces of the two ends of the conveyor belt; It includes a roller 13 and a stopper 9 that are rotatably arranged on the bracket 1, and the conveyor belt 2 is rotatably arranged on the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com