Edge sealing machine flat edge scraping mechanism with flat scraping tool assembly

一种刀具组件、平刮边的技术,应用在家用元件、木材加工器具等方向,能够解决平刮边机构外形大、占据空间多等问题,达到保证刮边效果、加强结构稳定性、结构精细化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

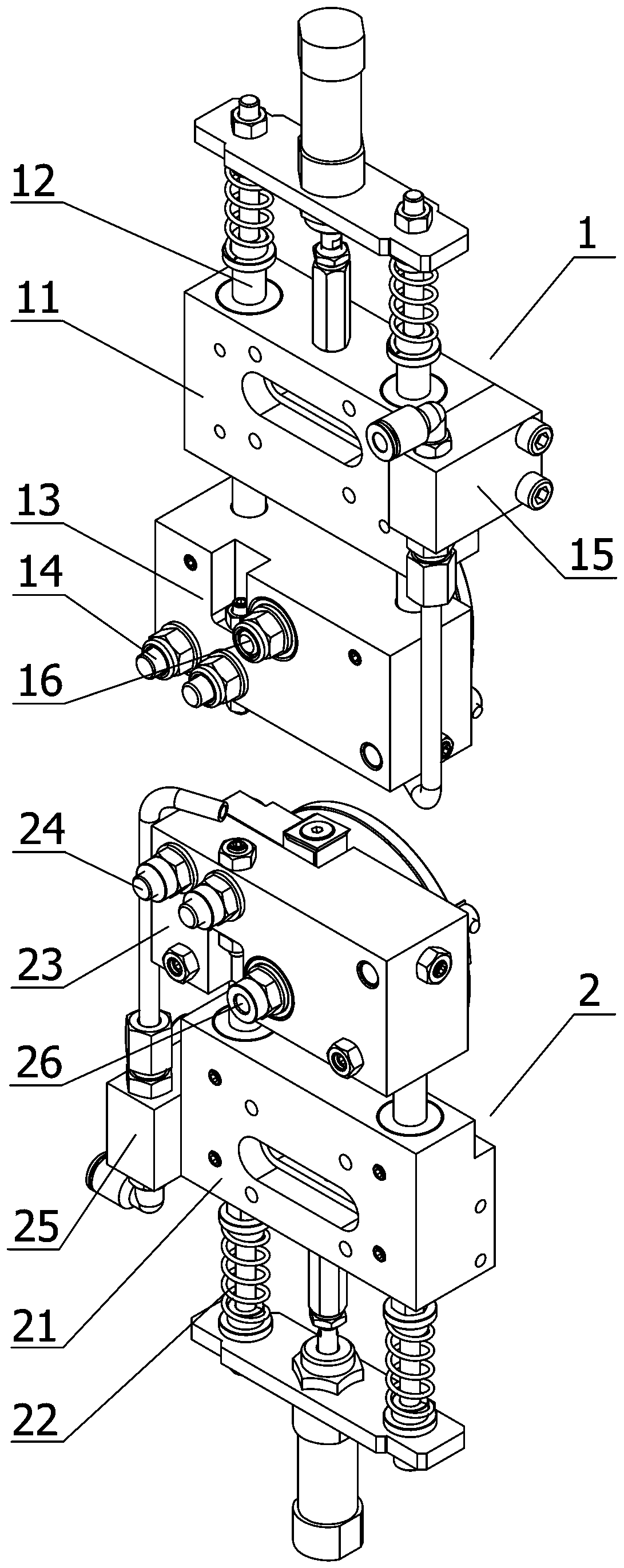

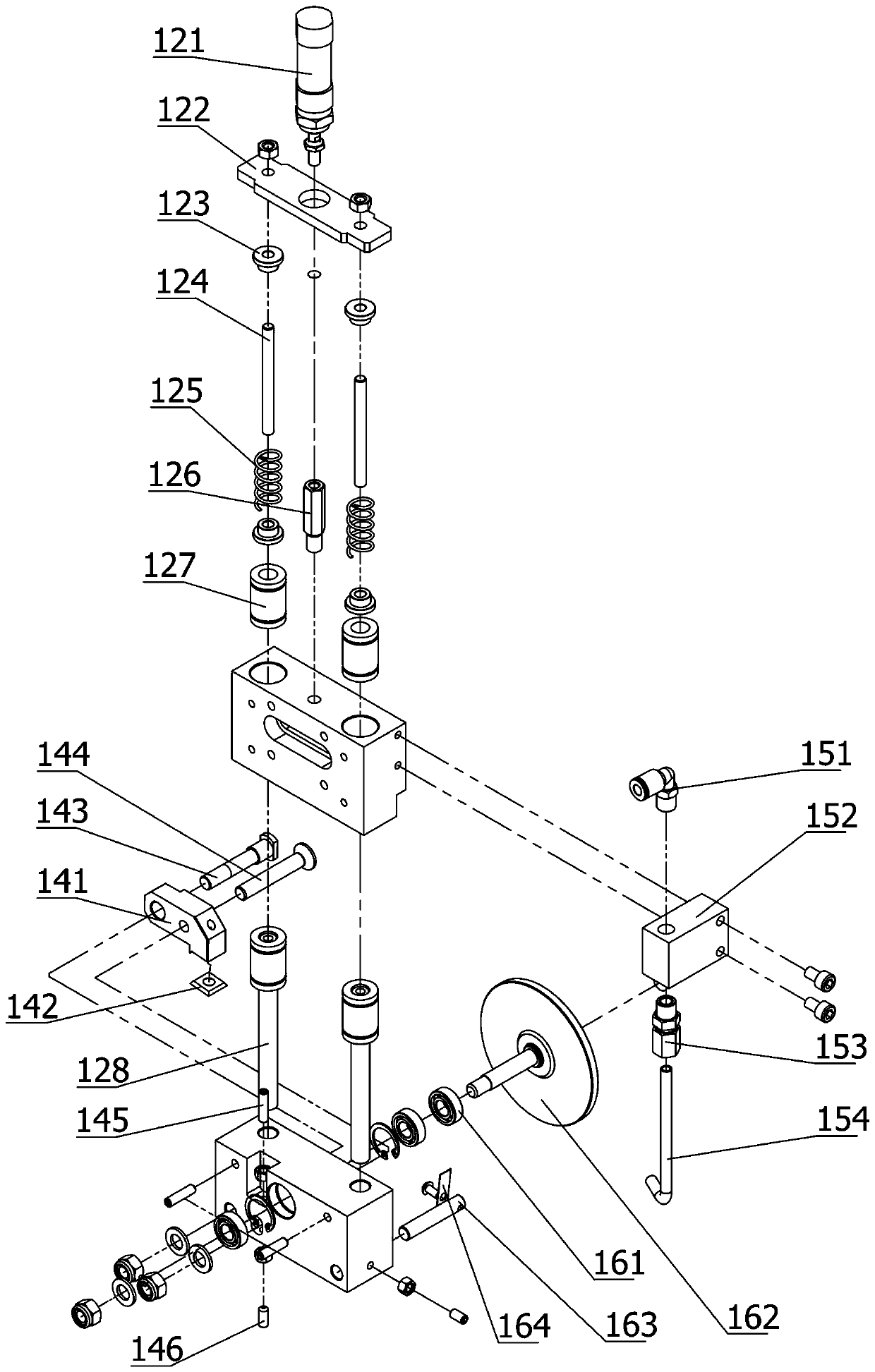

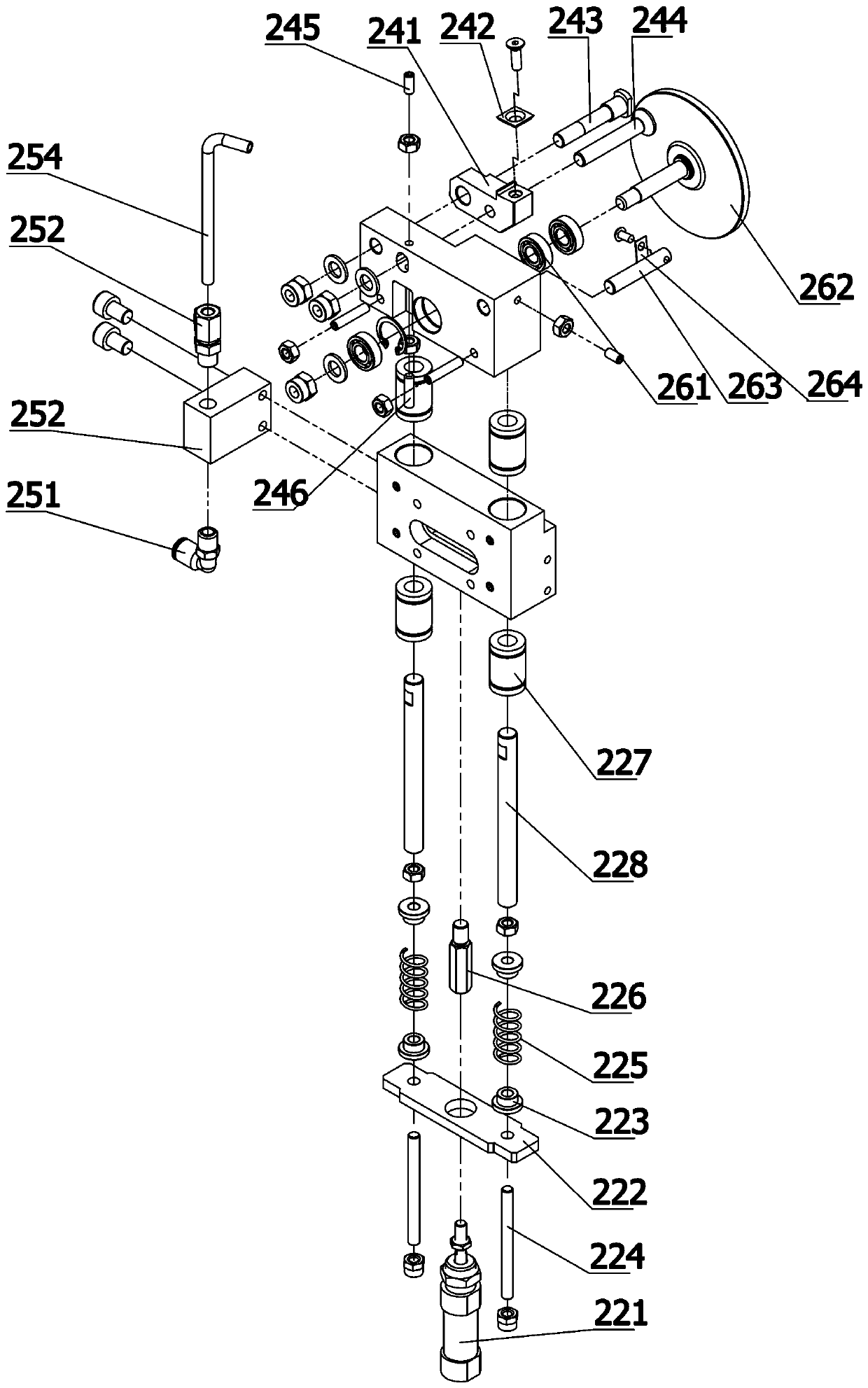

[0020] According to attached Figure 1 to Figure 3 As shown, the flat edge scraping mechanism of the edge banding machine with the flat scraper assembly of the present invention includes an upper flat edge scraping device 1 and a lower flat edge scraping device 2 installed separately. The upper flat edge scraping device 1 includes an upper fixed seat 11, an upper connection buffer assembly 12, an upper knife seat 13, an upper flat scraping tool assembly 14 and an upper blowing assembly 15, and the lower flat edge scraping device 2 includes a lower fixed seat 21 , The lower connection buffer assembly 22, the lower knife seat 23, the lower flat scraper assembly 24 and the lower blowing assembly 25. Wherein, the upper fixing base 11 is installed on a beam, and the lower fixing base 21 is installed on a guide rail. The upper fixing seat 11 is connected with the upper kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com