In-situ remediation method for petroleum-contaminated soil

An in-situ remediation and oil pollution technology, applied in the field of contaminated soil treatment, can solve the problems of great influence on soil physical and chemical properties, high energy consumption of incineration technology, etc., and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

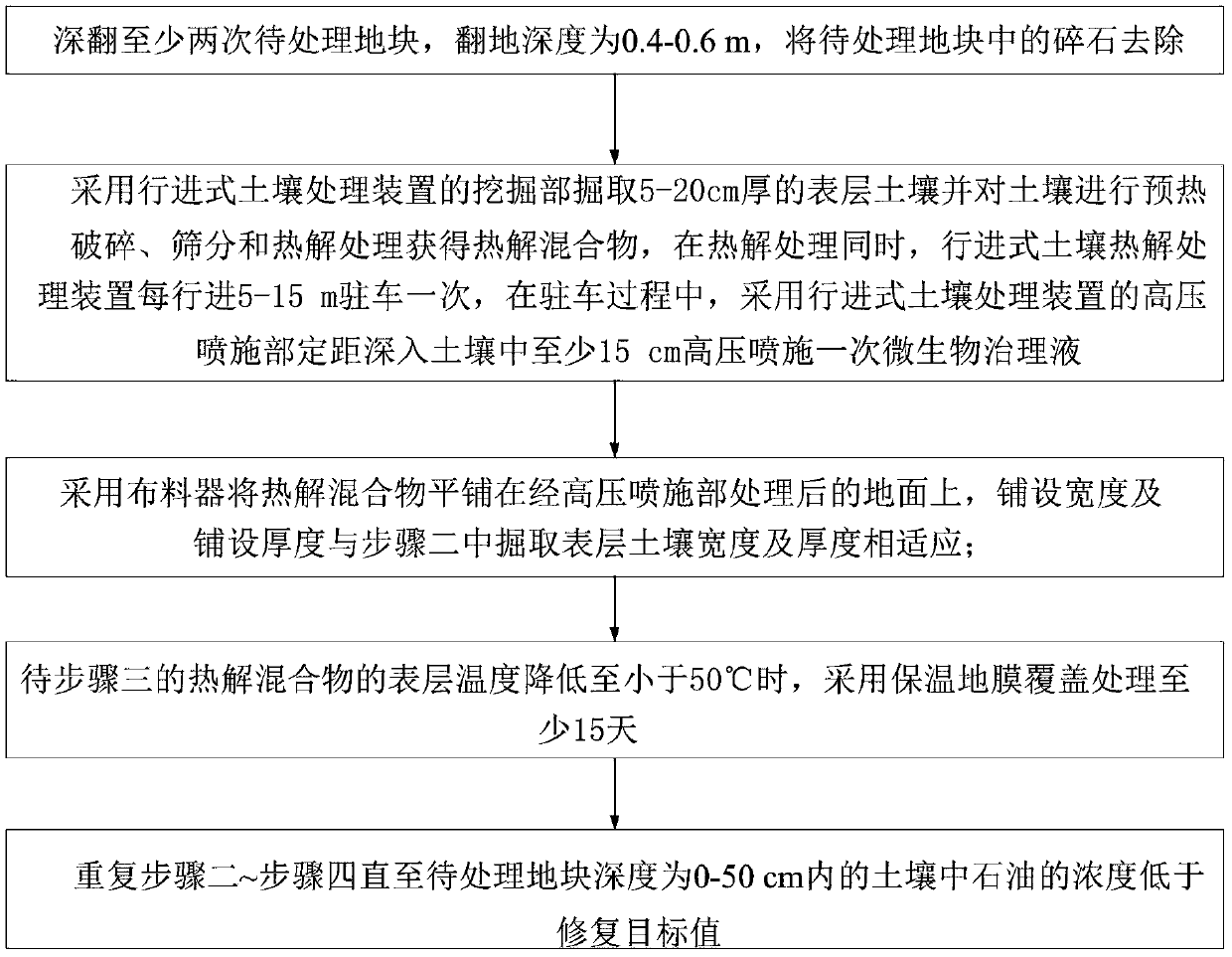

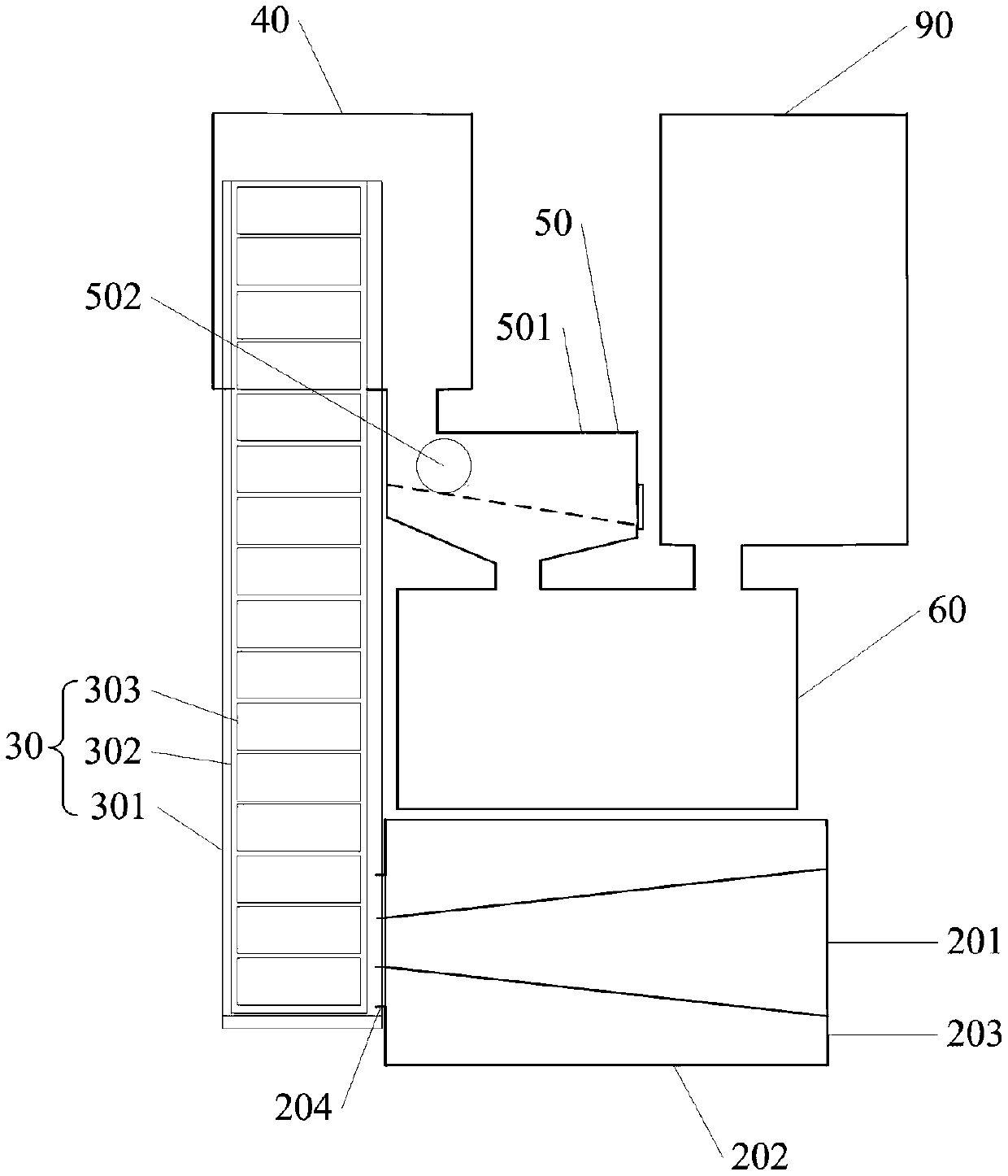

[0039] Such as Figure 1~4Shown, a kind of oil-contaminated soil in-situ remediation method in the method of the present invention comprises the following steps:

[0040] Step 1, deep excavate the land to be processed at least twice, the depth of digging is 0.4-0.6m, and remove the gravel in the land to be processed;

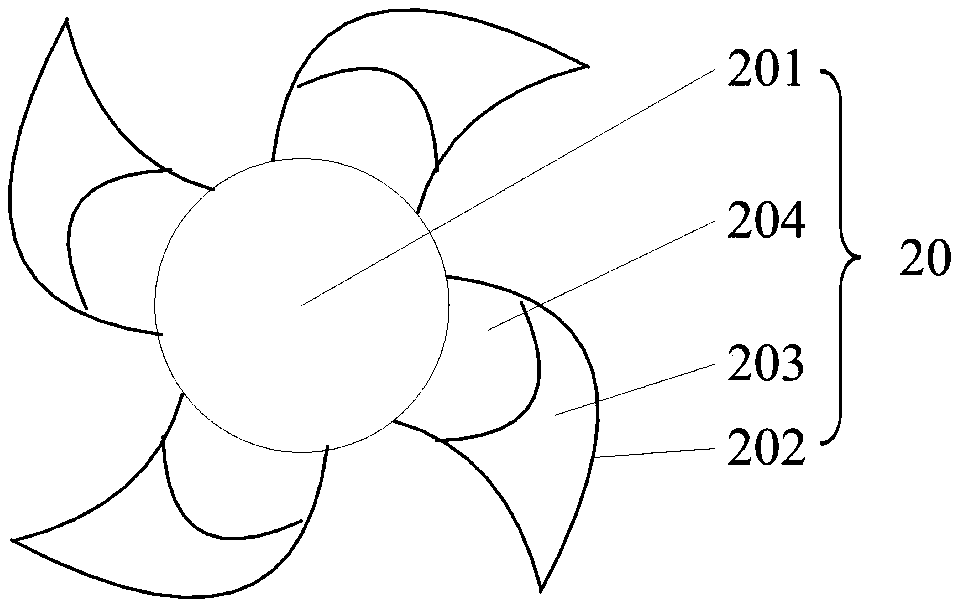

[0041] Step 2, use the excavation part of the traveling soil treatment device to dig out 5-20cm thick surface soil and preheat the soil to crush, sieve and pyrolyze to obtain the pyrolysis mixture. The solution treatment device is parked once every 5-15m. During the parking process, the high-pressure spraying part of the traveling soil treatment device is used to spray the microbial treatment solution at least 15cm deep into the soil at a fixed distance;

[0042] Step 3, using a spreader to spread the pyrolysis mixture on the ground treated by the high-pressure spraying part, the laying width and laying thickness are suitable for the width and thickness of the ...

Embodiment 2

[0063] Step 1, deep excavate the land to be processed at least twice, the depth of digging is 0.4m, and remove the gravel in the land to be processed;

[0064] Step 2, use the excavation part of the traveling soil treatment device to dig out 5-10cm thick surface soil and preheat the soil for crushing, screening and pyrolysis to obtain the pyrolysis mixture. The solution treatment device is parked once every 5-6m, and during the parking process, the high-pressure spraying part of the traveling soil treatment device is used to spray the microbial treatment solution once in the soil at a fixed distance of 15-20cm;

[0065] Step 3, using a spreader to spread the pyrolysis mixture on the ground treated by the high-pressure spraying part, the laying width and laying thickness are suitable for the width and thickness of the excavated surface soil in step 2;

[0066] Step 4, when the surface temperature of the pyrolysis mixture in step 3 is reduced to 45-48°C, cover it with thermal in...

Embodiment 3

[0073] Step 1, deep excavate the land to be processed at least twice, the depth of digging is 0.5m, and remove the gravel in the land to be processed;

[0074]Step 2: Excavate 10-13cm thick surface soil by using the excavation part of the traveling soil treatment device, and perform preheating, crushing, screening and pyrolysis treatment on the soil to obtain a pyrolysis mixture. The solution treatment device is parked once every 8-10-13m, and during the parking process, the high-pressure spraying part of the traveling soil treatment device is used to spray the microbial treatment solution once in the soil at a fixed distance of 20-25cm;

[0075] Step 3, using a spreader to spread the pyrolysis mixture on the ground treated by the high-pressure spraying part, the laying width and laying thickness are suitable for the width and thickness of the excavated surface soil in step 2;

[0076] Step 4, when the surface temperature of the pyrolysis mixture in step 3 is reduced to 40-45°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com