Crushed lithium battery screening and recycling device

A recovery device and crushed material technology, applied in battery recovery, recycling technology, waste collector recovery, etc., can solve the problems of failure to pass through the screen, poor effect, low screening efficiency, etc., and achieve a simple and compact overall structure, avoid Effect of re-agglomeration, improving screening efficiency and screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

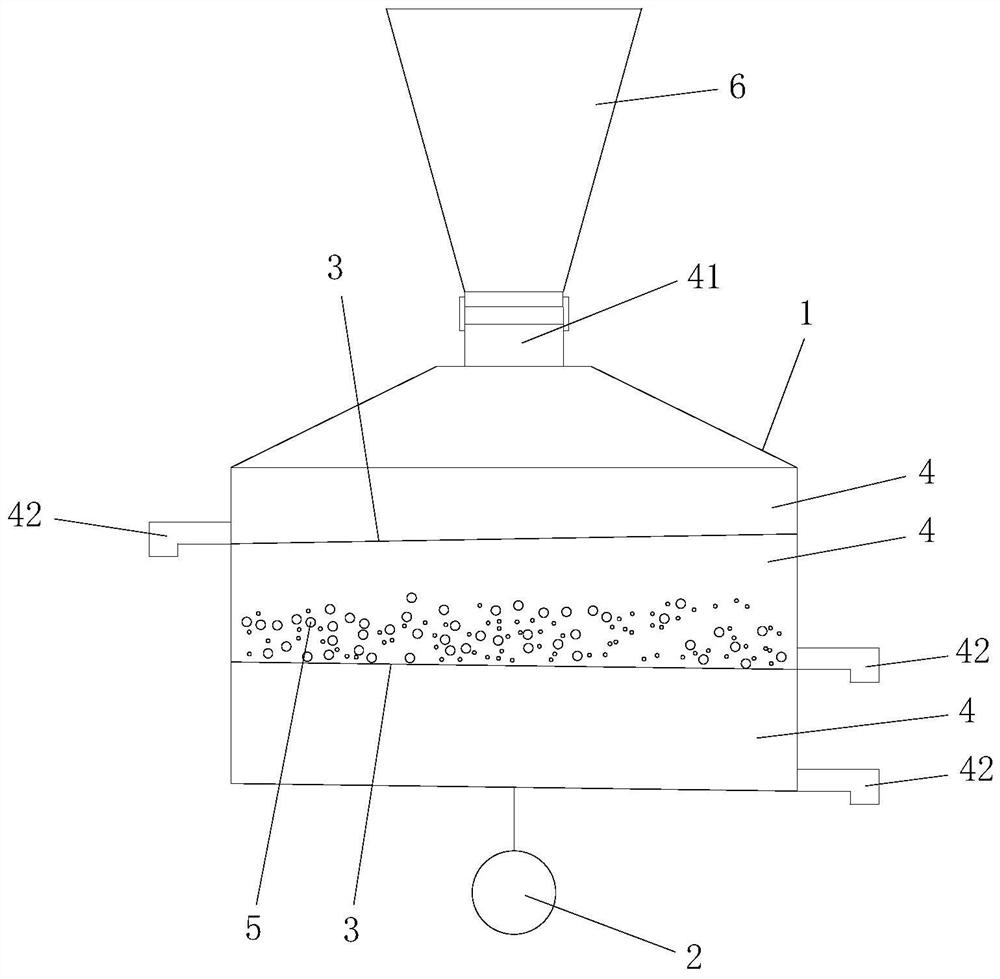

[0020] Such as figure 1 As shown, the screening and recovery device for crushed lithium battery materials in this embodiment includes a housing 1 and a vibration drive assembly 2 for driving the vibration of the housing 1. The housing 1 has a screening chamber, and multiple screens are installed in the screening chamber. Layers of screens 3 are arranged at intervals from top to bottom, and the sieve apertures of the multi-layer screens 3 decrease layer by layer along the direction from top to bottom. The multi-layer screens 3 separate the screening chamber into A plurality of cavities 4 arranged, the upper cavity 4 is provided with a feed port 41, each cavity 4 is provided with a discharge port 42, at least one cavity 4 between adjacent two layers of screens 3 There are a plurality of scrap pieces 5 that can dance in the cavity 4 und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com