Ball circulation screening powder sealing and discharging integrated device and method

A screening and powder technology, used in chemical instruments and methods, sieves, solid separation, etc., can solve the problems of heat can not be uniformly dispersed, peripheral fire, heat loss, etc., to ensure continuous long-term stable operation and achieve uniform dispersion. And the effect of transferring and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

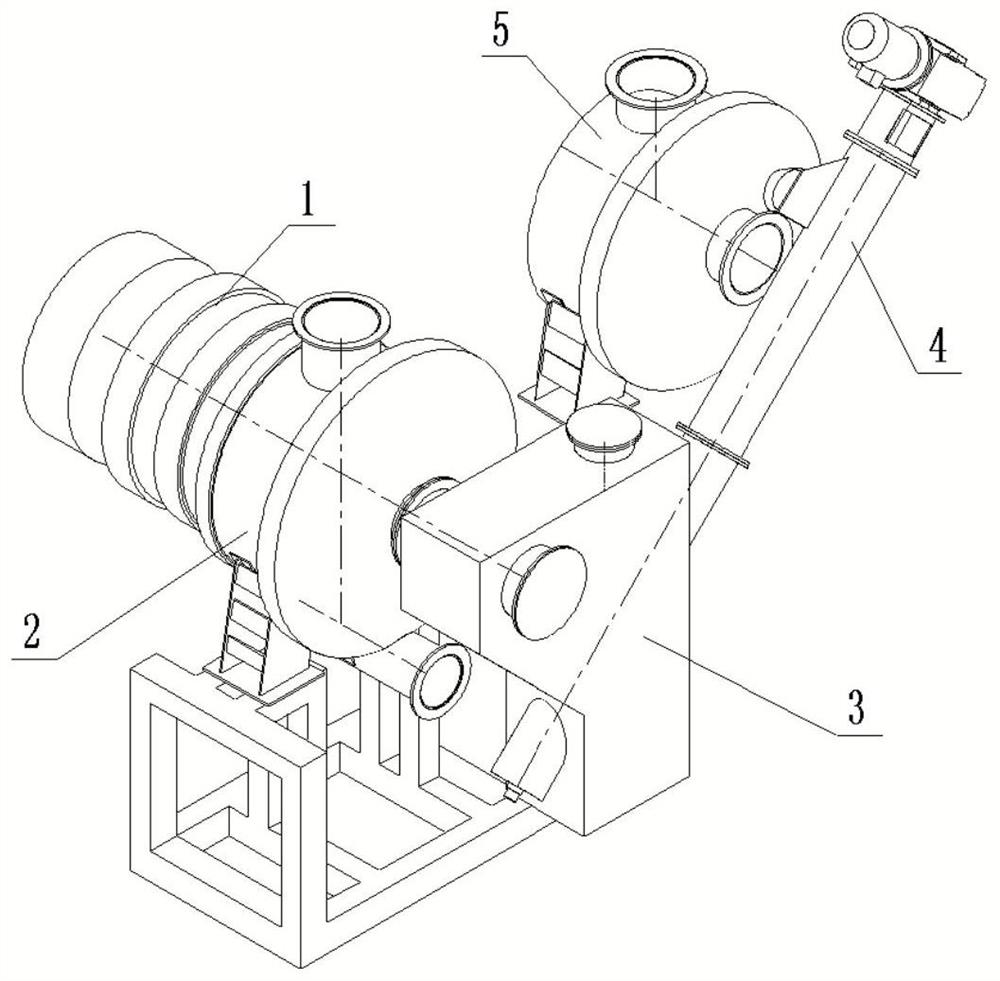

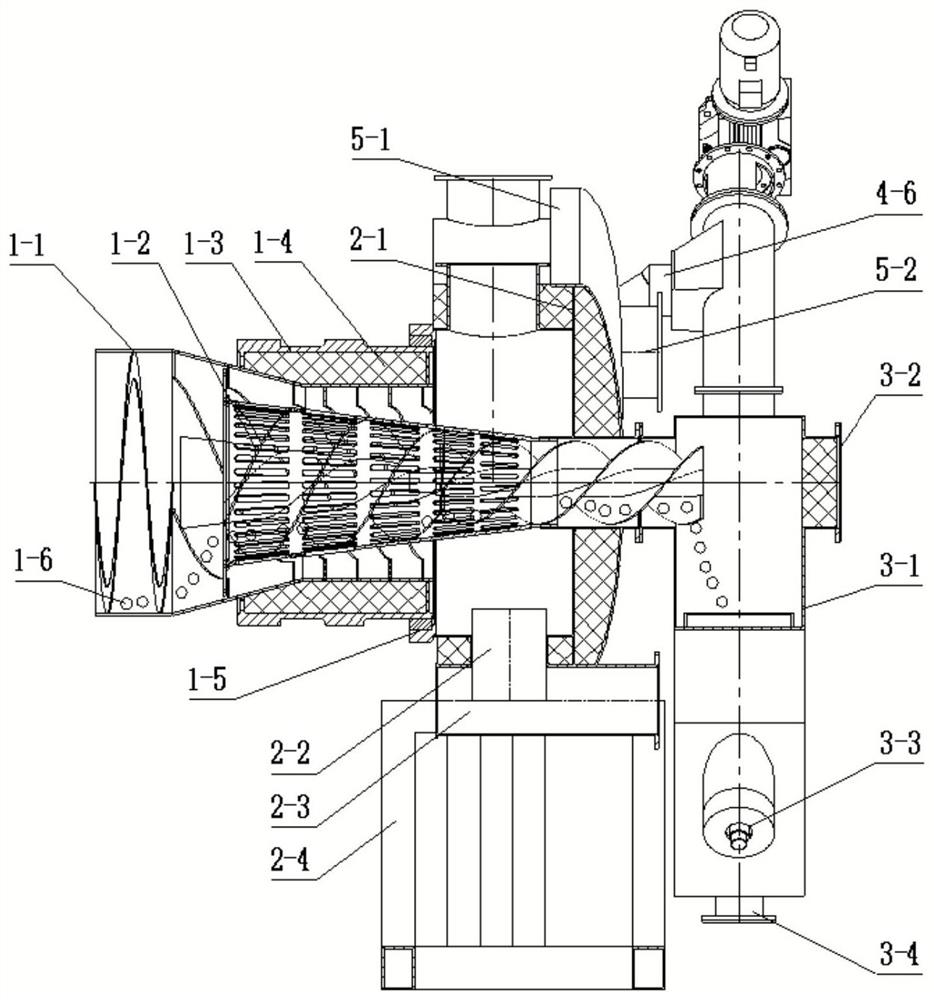

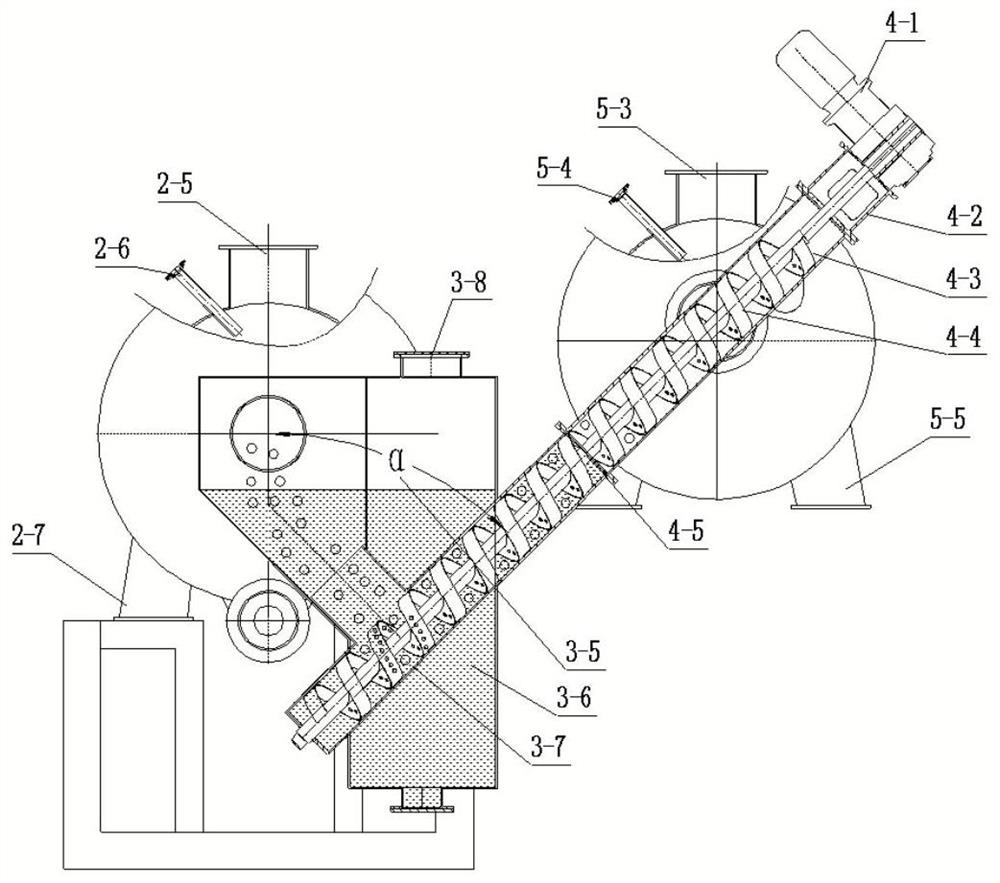

[0053] Such as Figure 1-4 As shown, a ball circulating screen dispensing powder seal isoniped, including a pyrolysis furnace rotary cylinder 1, and the thermofacco turning cylinder 1 and a pyrolytic furnace discharge end cover 2, powder sealing box 3, the ball circulation spiral hoist 4 and the drying furnace feed end cover 5 are sequentially connected; the thermofacco turning cylinder 1 includes a pyrolysis furnace rotary housing 1-1, a ball screening structure 1-2 is disposed in a pyrolysis In the furnace return housing 1-1, it is a pyrolysis of carbon powder and the separation of carbon powder and circulating ball. The thermofake rotary housing 1-1 is composed of a discharge stage and an effluent cone, and the outlet cone is connected to the ball sieve structure. The thermophilic furnace rotary cylinder 1 is provided with a ball screening structure 1-2, and the spherical screening structure 1-2 includes a ball screening fixing plate 1-2.1, the ball screening fixing plate 1-2.1 ...

Embodiment 2

[0059] The working principle of the balloon circulating sieve powder seal is:

[0060] (1) The organic material raw material is 50 mm or less by the fragmentation particle diameter, and the screw conveyor passes through the material feed port covering the feed end of the drying furnace, and the temperature of the remaining heat flue gas having a temperature of 200 ° C is directly heated to dry the material. The thermos gas temperature drops to 80 ° C, and is discharged by dry air outlet; the drying ball is completed under the rotation of the drying furnace, and the circulating ball is promoted to boost material movement in the drying section, assisting dry heat transfer .

[0061] (2) After drying the organic material with circulating balls, the feed is spirally entered into the pyrolysis furnace for indirect thermal solution. The high temperature thermal flue gas heating the thermofinder temperature is 600 ° C, and the pyrolysis carbonization temperature of the organic matter in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com