Patents

Literature

462results about How to "Avoid vortex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

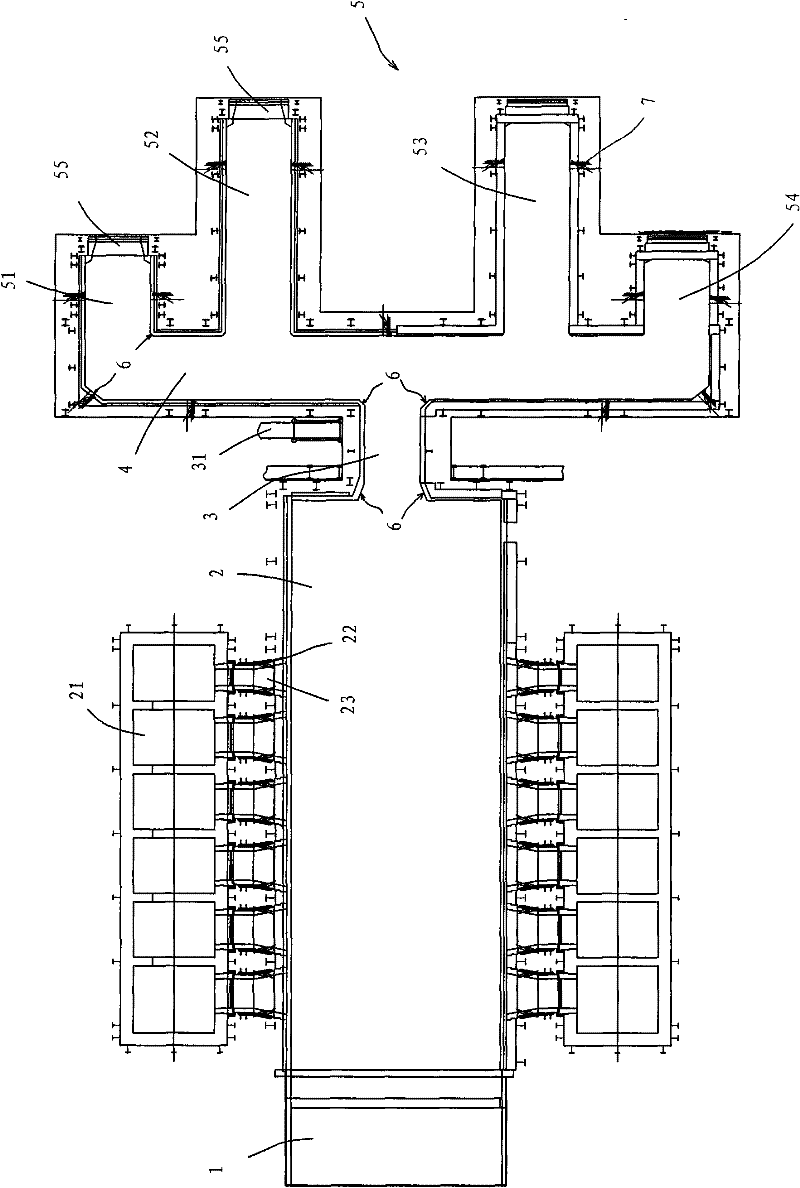

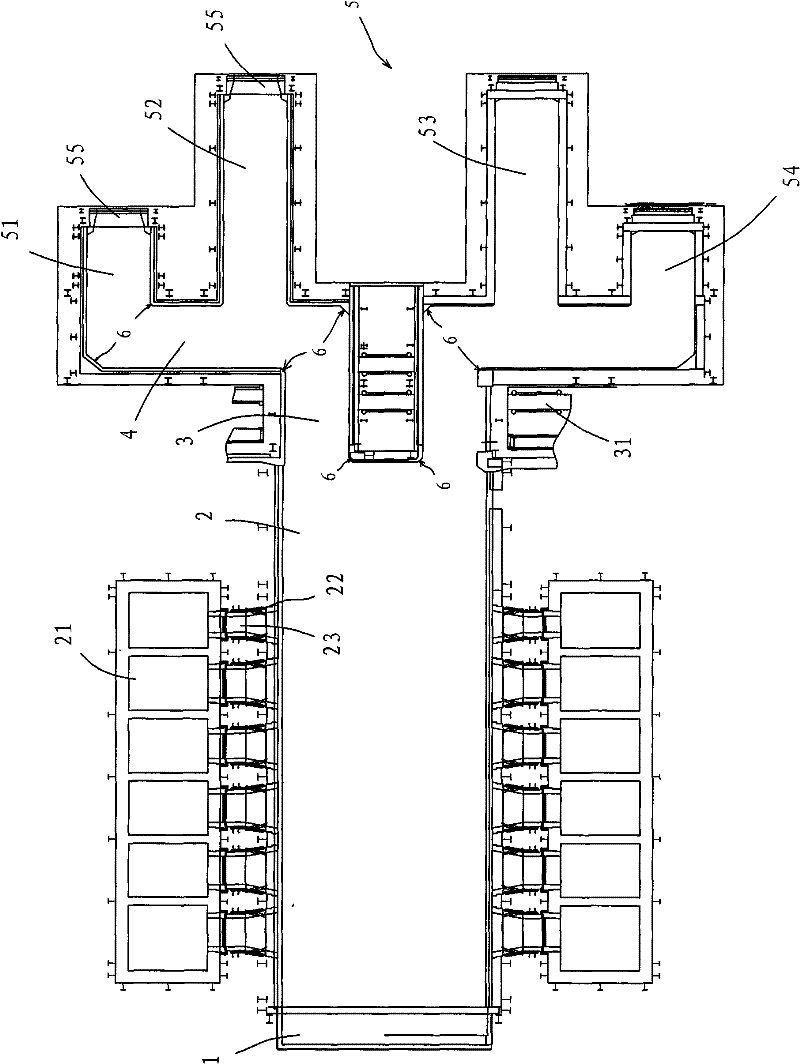

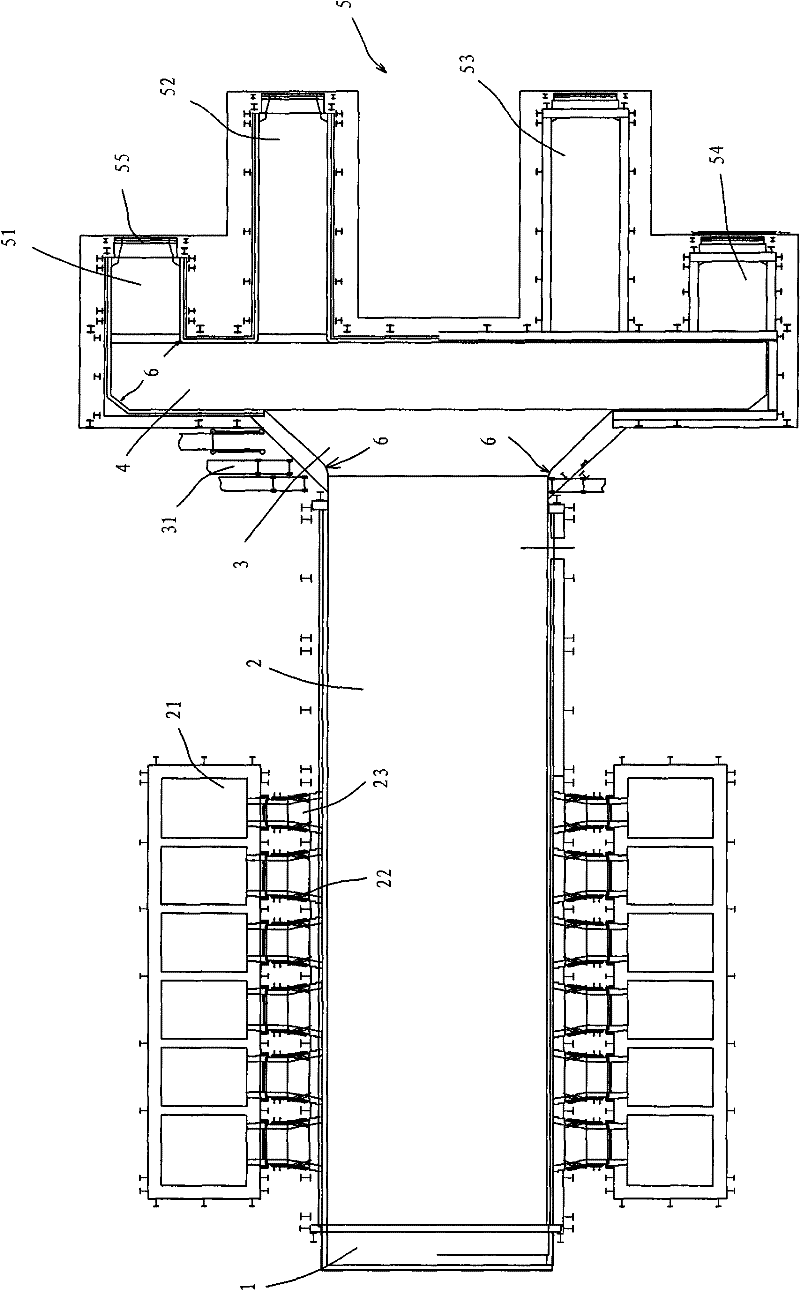

Ultrawhite calendering glass kiln

The invention provides an ultrawhite calendering glass kiln. The kiln is characterized in that: the kiln comprises a melting furnace, a main channel, a lateral channel, and a plurality of branch channels, which are sequentially communicated; and the main channel is a cylinder channel which has a round / quadrate / rectangular / trumpet-like shape, and each corner of each channel is provided with a transition surface. According to the invention, passage sections of the main channel are improved, and simultaneously the corners of all channels are provided with the transition surfaces, so a function of one kiln corresponds to multiple lines is realized, rapid changes of the velocity and the flow of a glass melt caused by a sudden change of a channel area while the glass melt enters another channel when going through the main channel are retarded or reduced, and long-time eddy and scour of the glass melt on the corner can be avoided, thereby a lateral temperature difference generated in a process that the glass melt flows from the outlet of the melting furnace to overflow ports of the branch channels can be reduced or avoided, and the production quality and the quality stability are improved.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

Method for controlling isothermal precision formed forging flow line of complicated disk cake forging

ActiveCN101716645AControl streamline distributionImprove mechanical propertiesMetal-working apparatusWheelsAxial distributionMechanical property

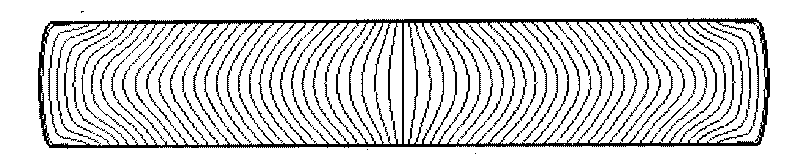

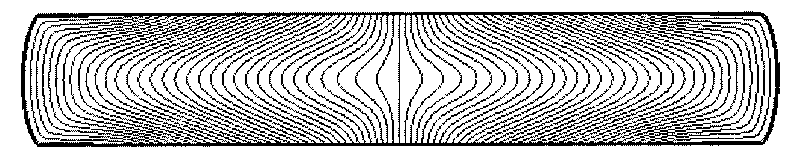

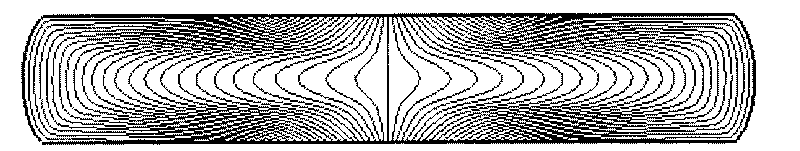

The invention discloses a method for controlling an isothermal precision formed forging flow line of a complicated disk cake forging and relates to a method for controlling a flow line of a disk cake forging. The invention aims to lead the forging flow line of the complicated disk cake forging to be distributed along the radial direction or the annular direction to improve the mechanical performance and the fatigue resistance of the complicated disk cake forging in the appointed direction. The method comprises the following main steps of: upsetting blank preparing phase: converting a flow line of an original blank material, which is distributed along the axial direction, into a flow line which is distributed along the annular direction or the radial direction; preforging formation: preparing an obtained cake blank into a preforging, leading the metal allotting amount of all parts of the preforging to be equivalent to a final forging and leading shapes of the preforging and the final forging to be similar; and final forging formation: carrying out final forging formation by two methods of a reverse extrusion deforming way and a radial resistance increase way. The method overcomes the defects of exposure, vortex, cross flowing, and the like of the flow line, which are easy to generate during isothermal precision formation of the complicated disk cake forging, has reasonable flow line distribution and improves the mechanical performance and the fatigue resistance of the disk cake forging.

Owner:HARBIN INST OF TECH

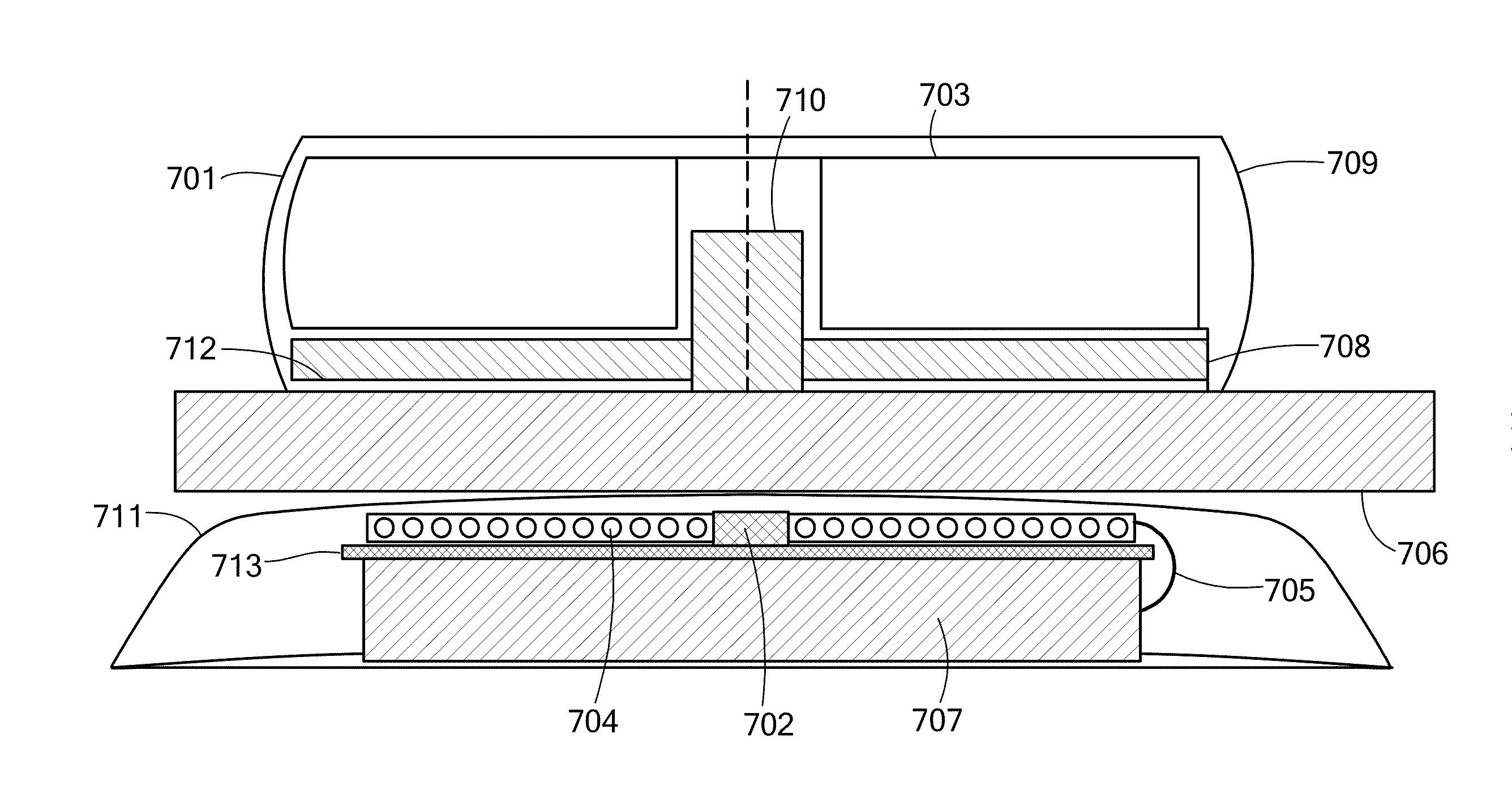

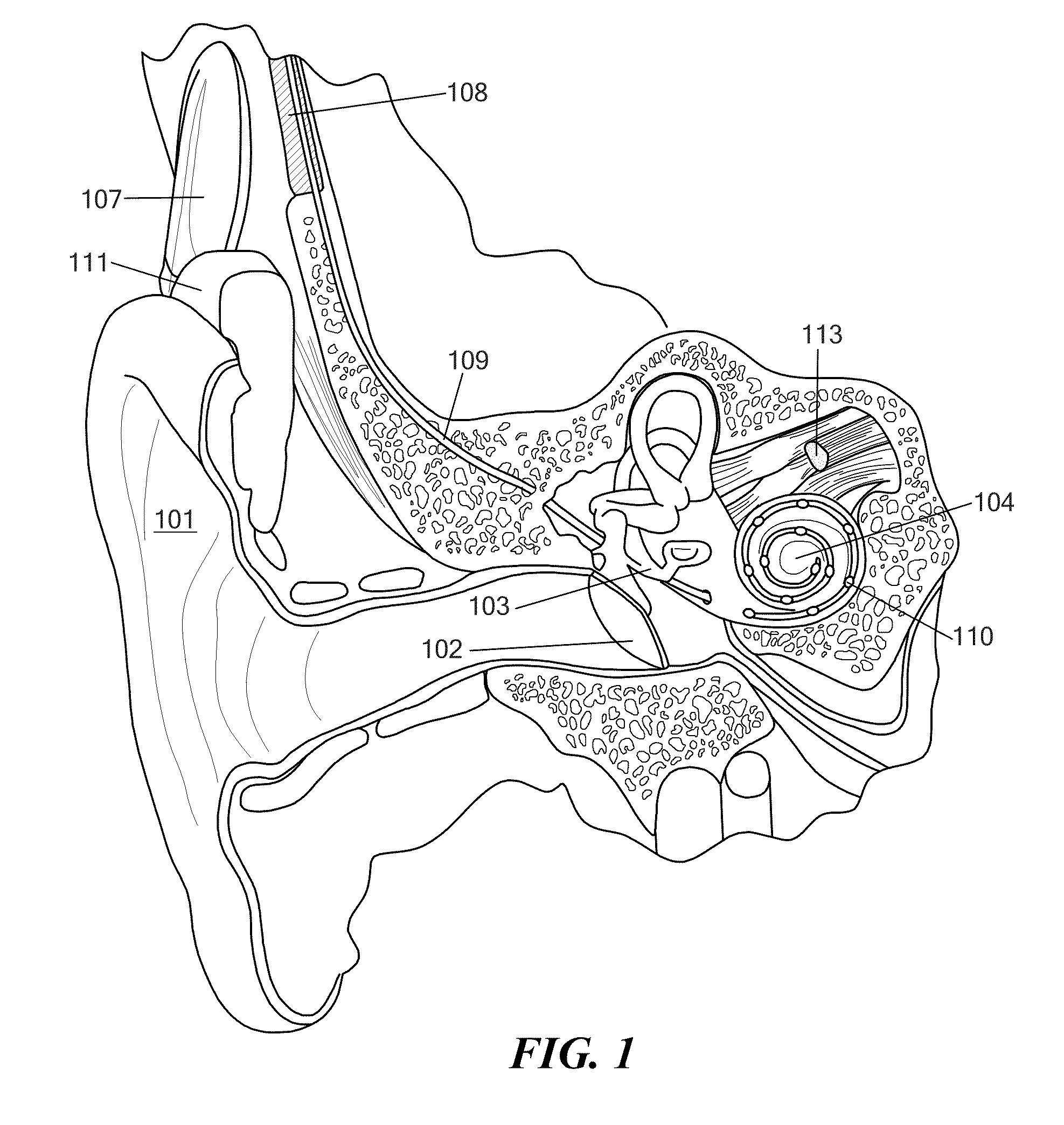

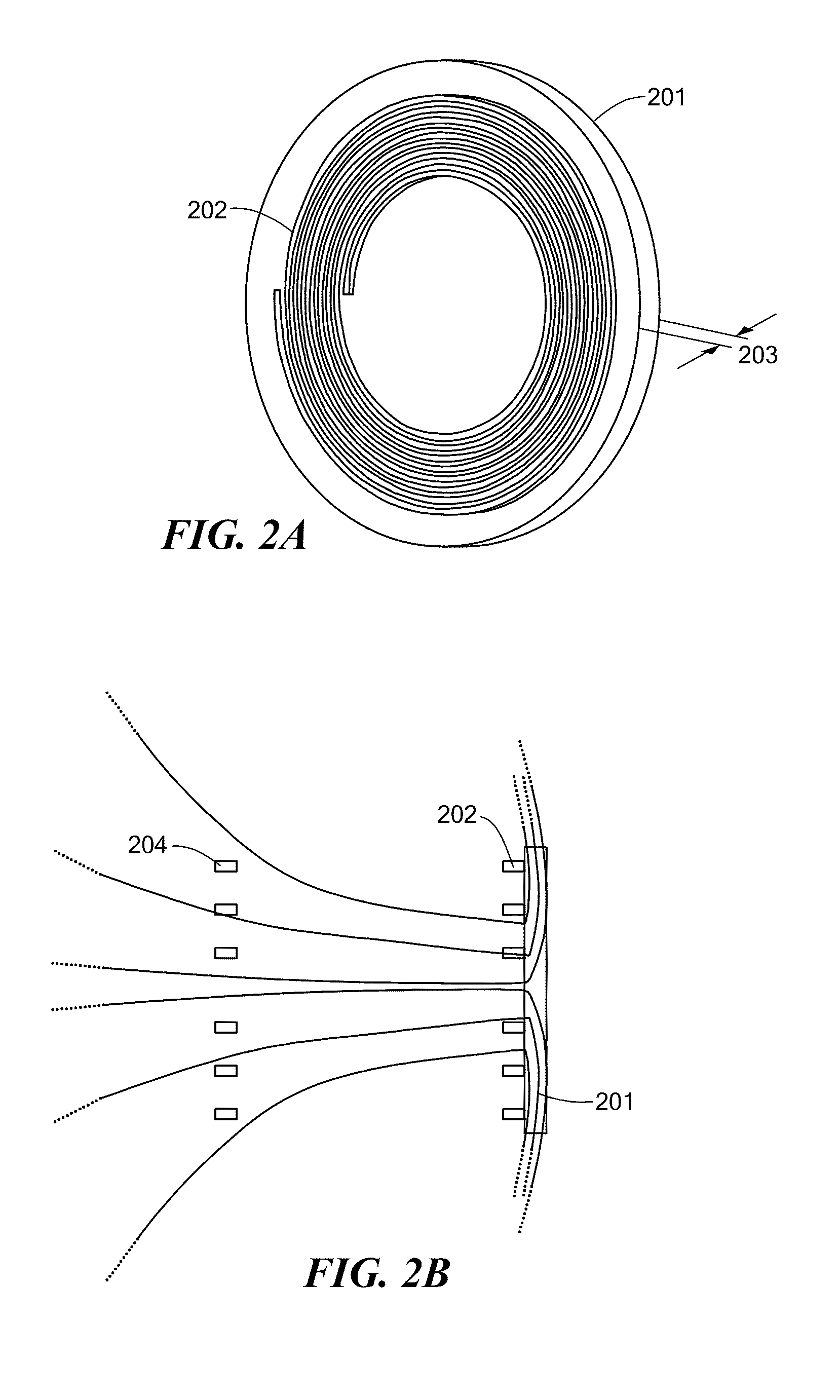

Inductive Link with Ferrite Sheets

An arrangement is described for a partially implantable medical system. A communications coil is adapted for placement parallel to a corresponding partner coil for communication of an implant communications signal having an associated magnetic field component. An implant electronics module is adjacent to the communications coil and electrically connected with it for coupling of the communications signal. And a planar coil shield lens is between the communications coil and the electronics module to promote coupling of the communications signal between the coils and to shield the electronics module from interaction with the magnetic field component.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

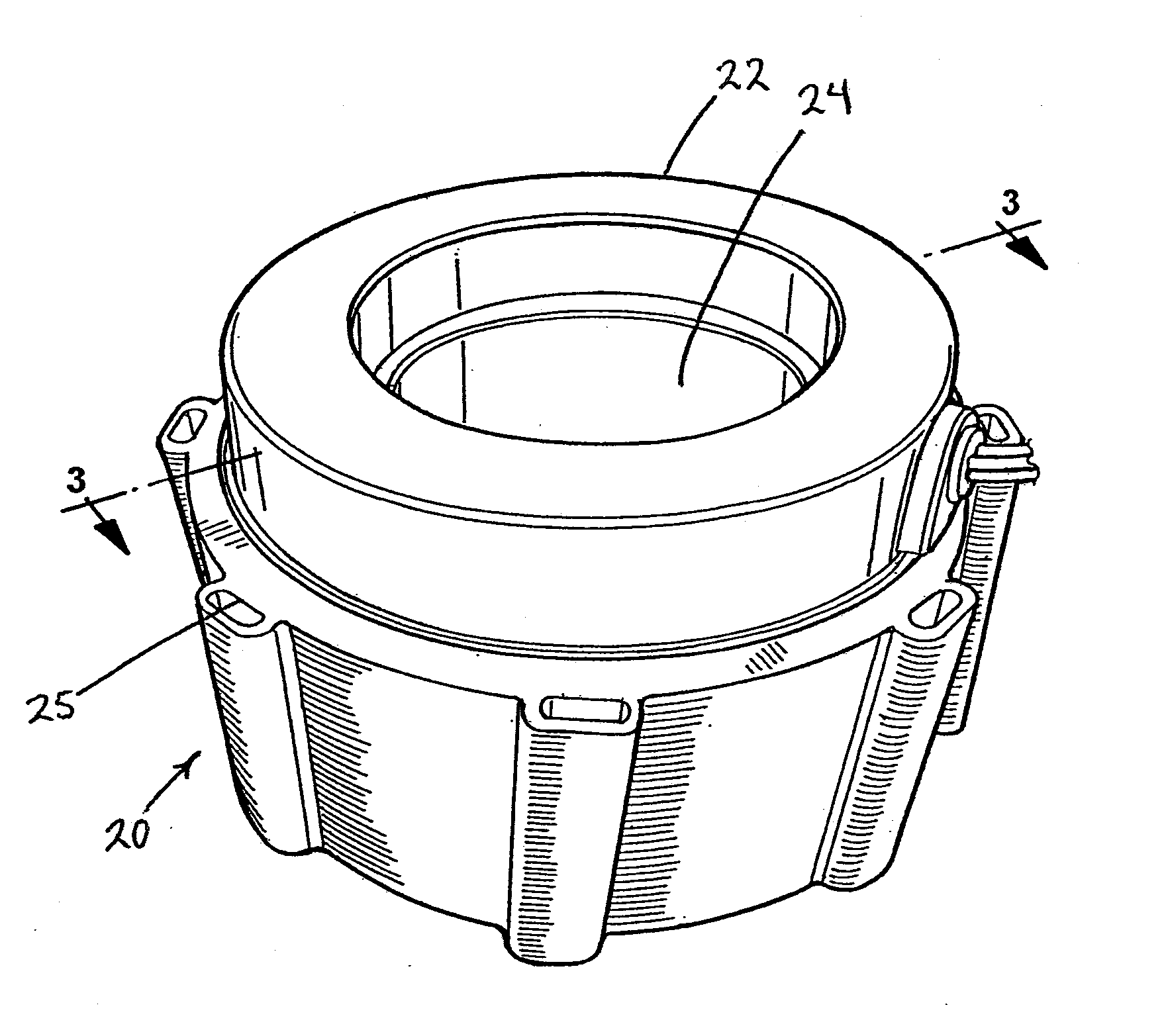

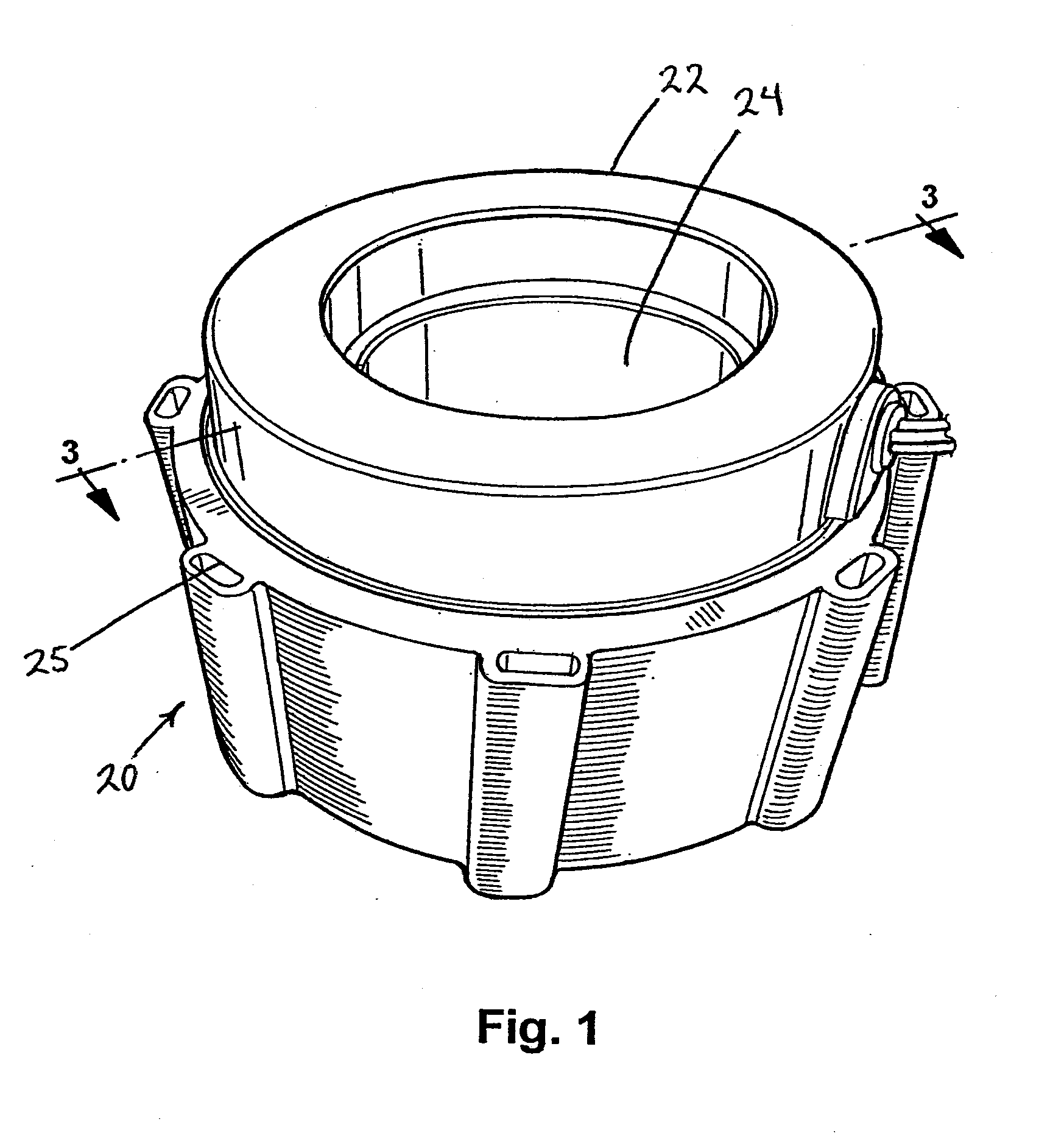

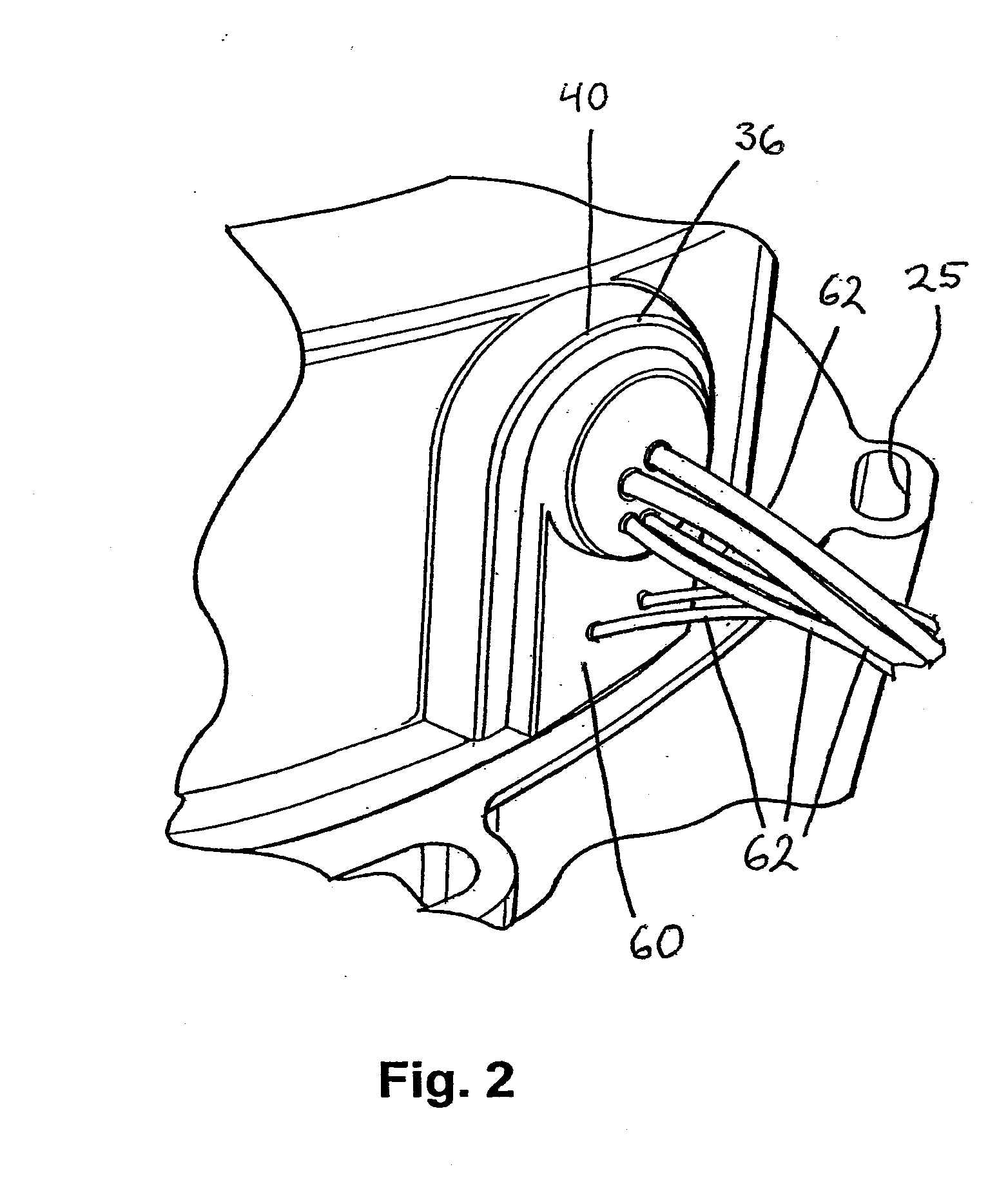

Environmentally Protected Housingless Generator/Motor

ActiveUS20120267967A1Avoid vortexImprove heat transfer performanceWindingsMagnetic circuit characterised by insulating materialsElectric machineElectric motor

A stator arrangement particularly suitable for use in an air-cooled generator or other such electric machine includes a stator with an outer stator surface, an opening therein defining an inner stator surface, and longitudinally opposed stator end surfaces. Conductive coils are supported by the stator, and include end turns overlying the longitudinally opposed stator end surfaces. In order to block out environmental contaminants and prevent conductive coil shorting, protective barriers are mounted over the end turns and secured to the stator.

Owner:KOLLMORGEN CORP

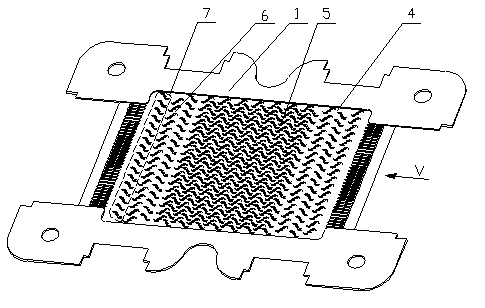

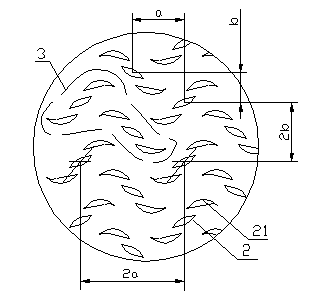

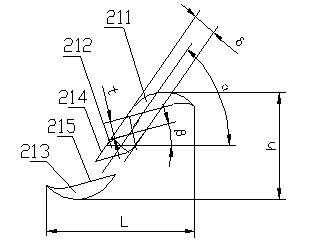

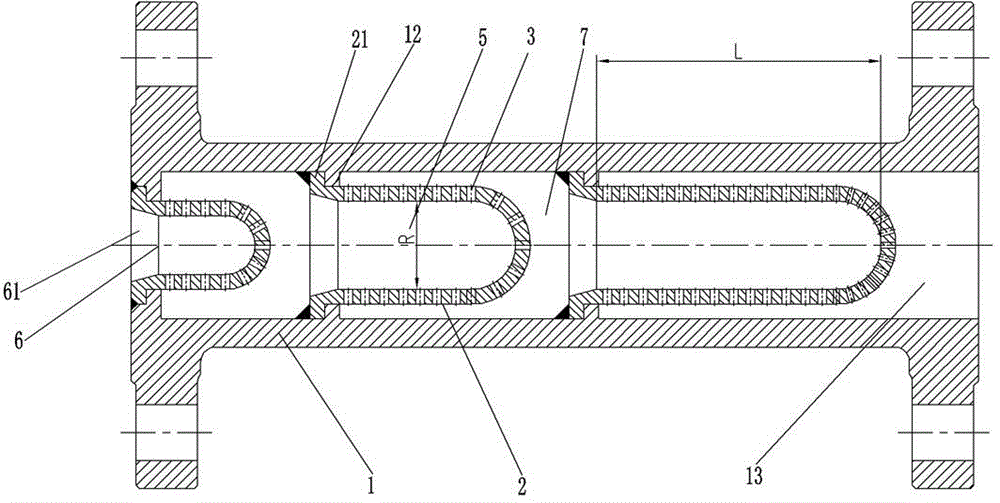

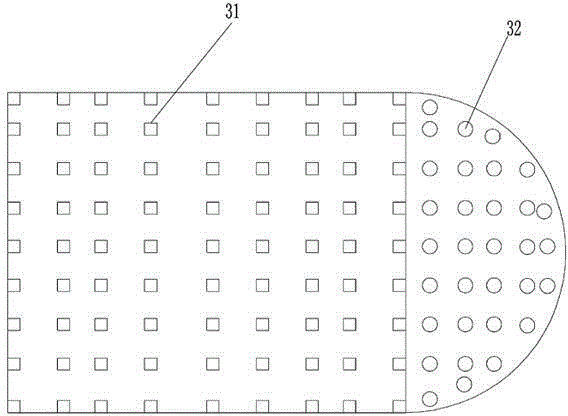

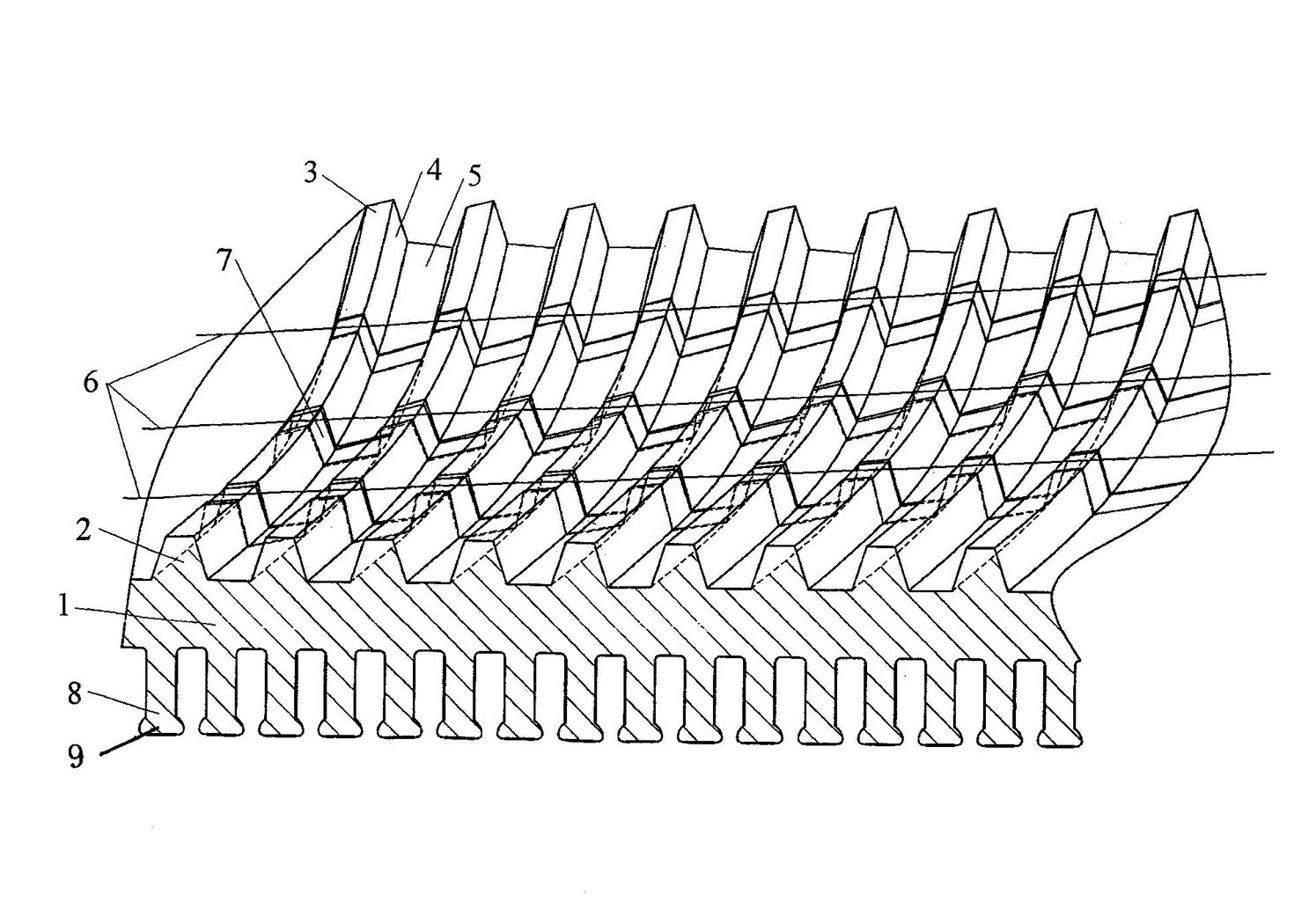

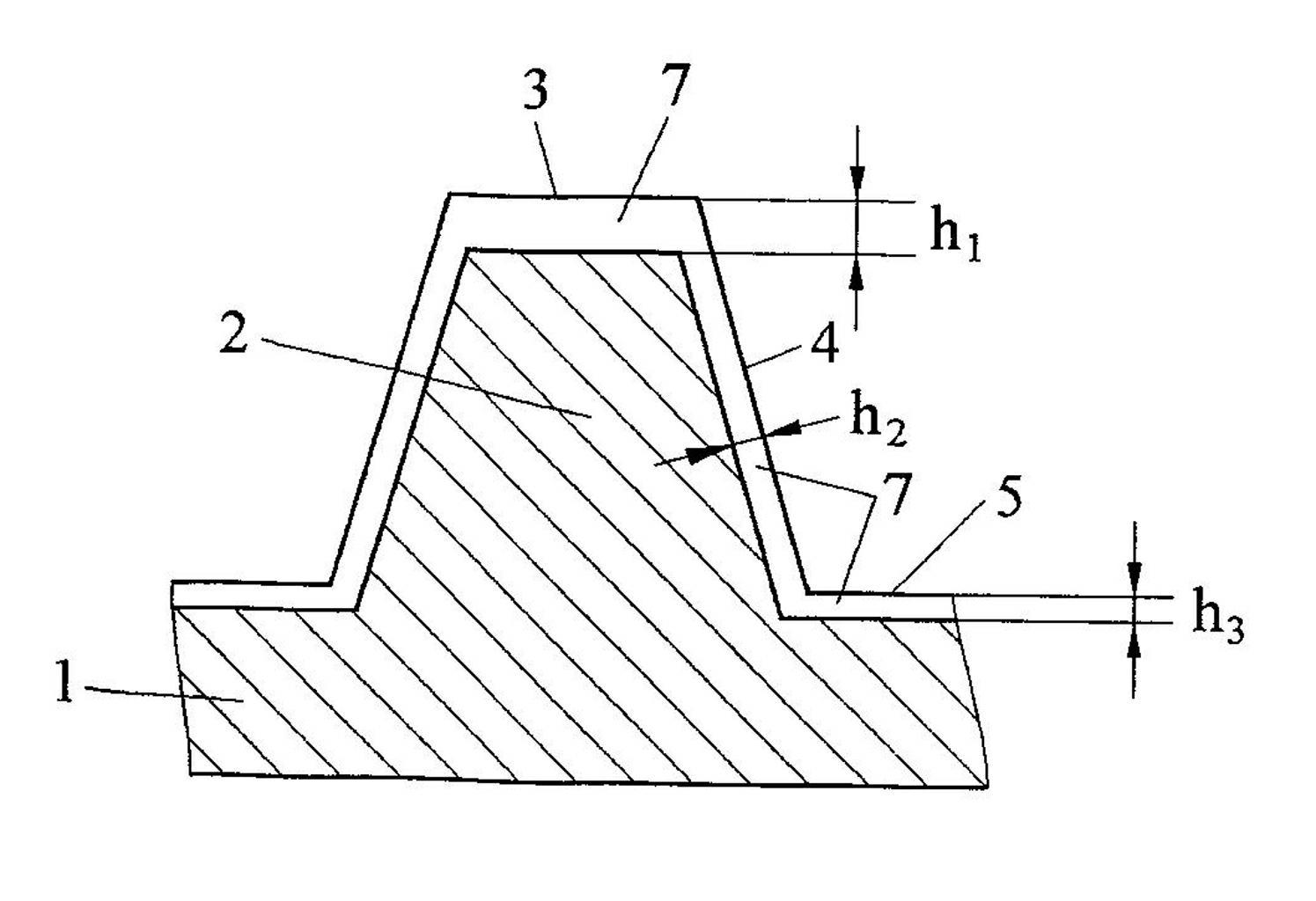

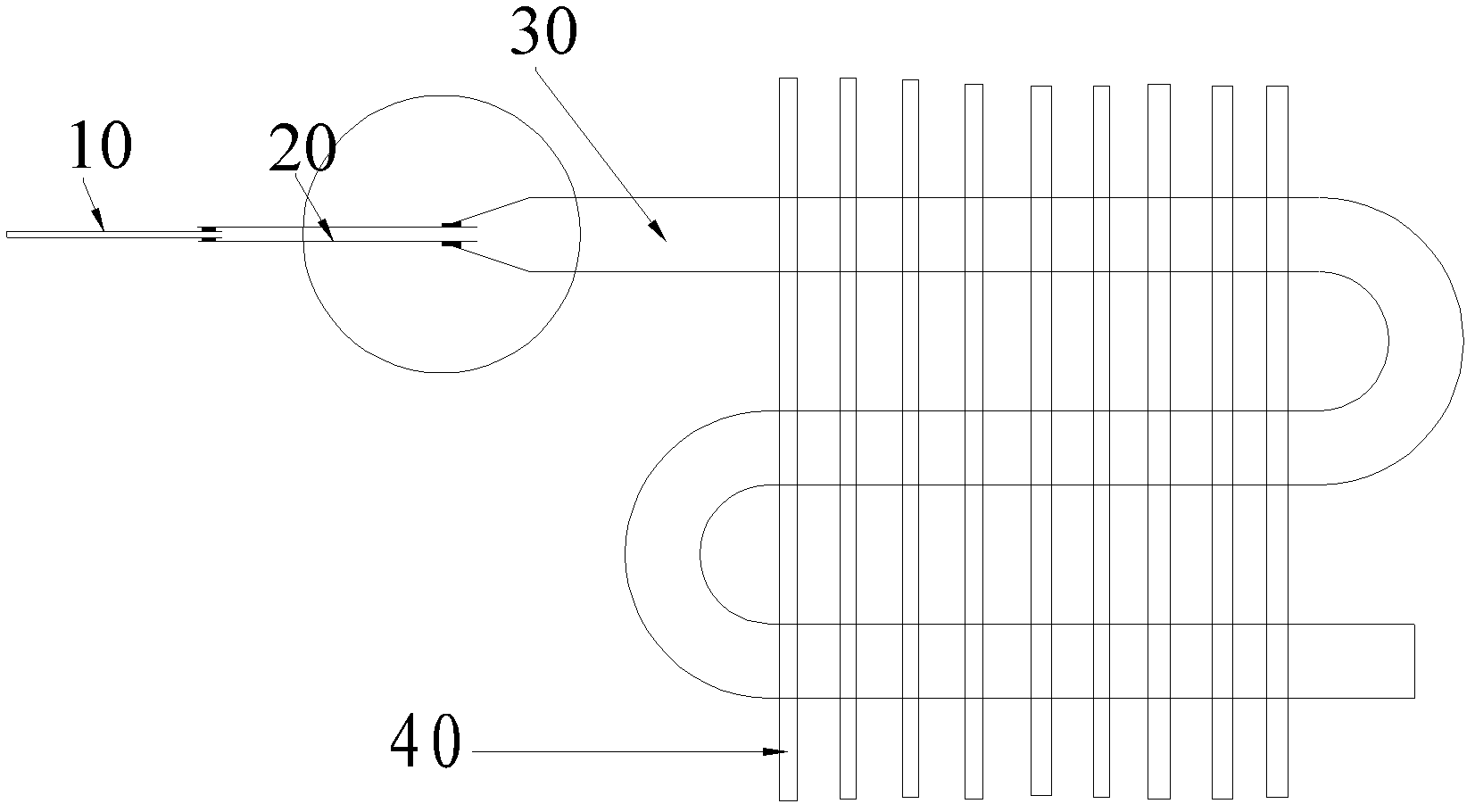

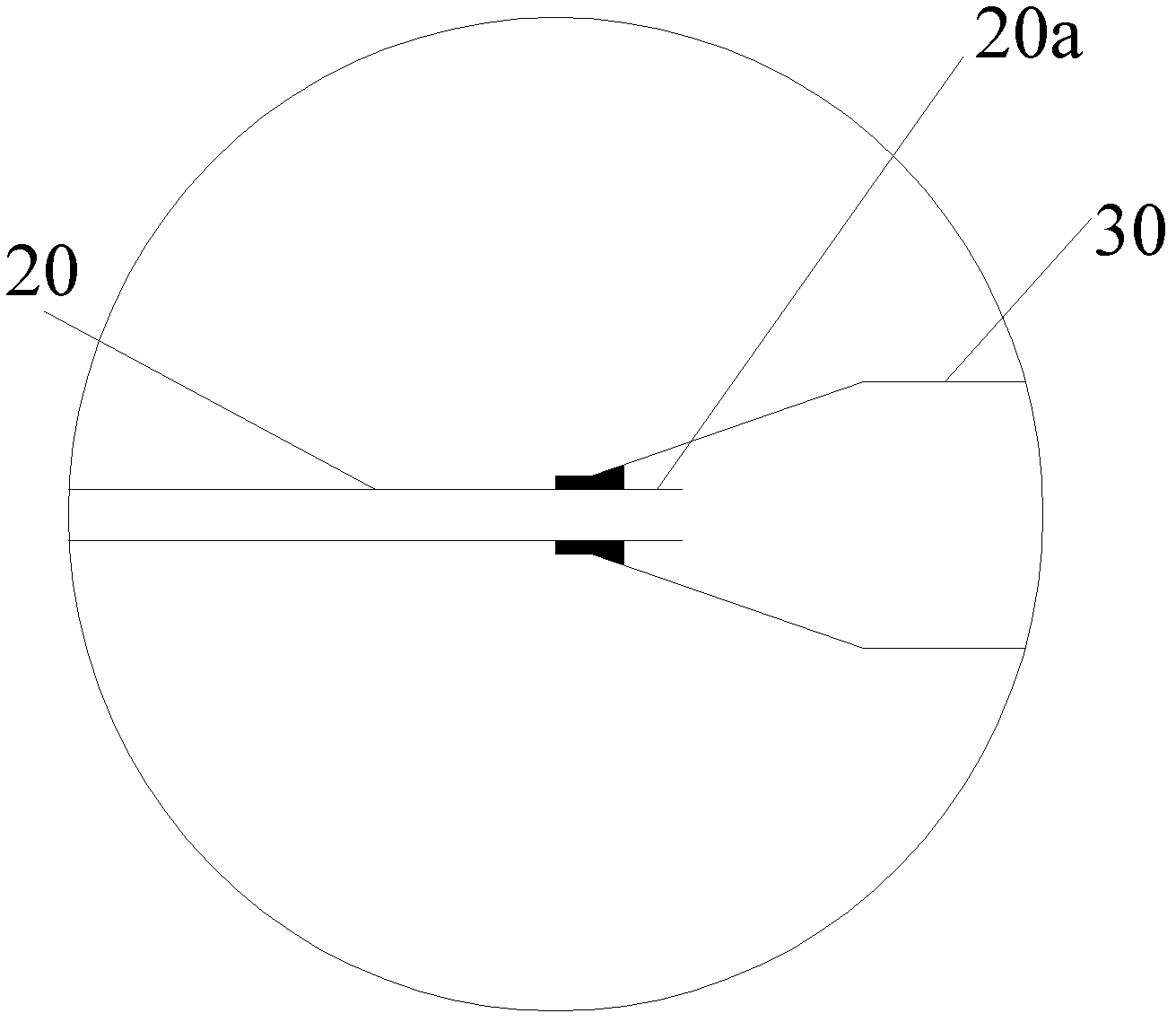

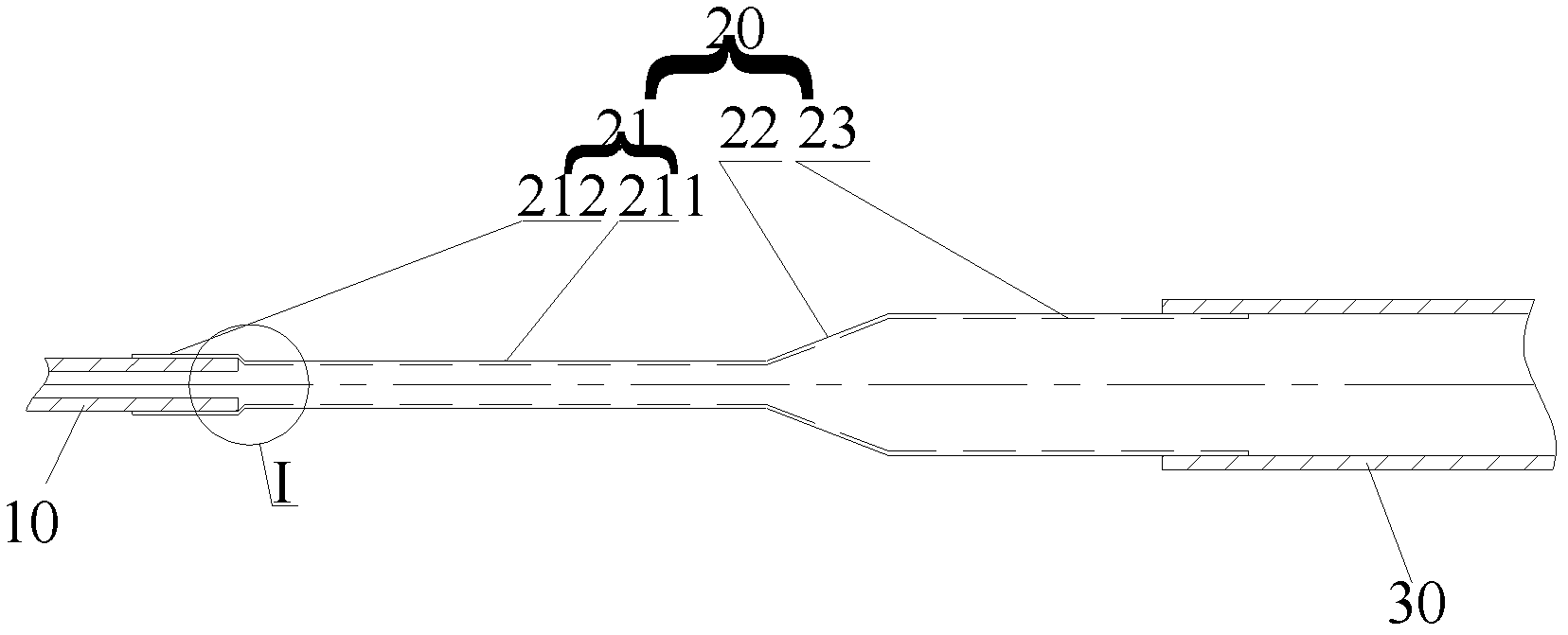

Micro-channel structure of heat exchanger

InactiveCN102706201AReduce resistanceIncrease the heat exchange areaLaminated elementsStationary plate conduit assembliesEngineeringForced convection

The invention discloses a micro-channel structure of a heat exchanger, and a micro-channel is respectively formed among multiple layers of laminated heat exchanging plates (1), each heat exchanging plate (1) is provided with a plurality of fin units (2), the fin units (2) are uniformly distributed along the direction which is vertical to the flowing direction of fluid to form a fin unit group (7), and a plurality of fin unit groups (7) are alternately arranged at intervals along the flowing direction of the fluid; the rear ends of the fin units (2) at the upstream side are arranged in the middle position of every two adjacent fin units (2) at the downstream side; each fin unit (2) consists of at least two sections of fins (21), and the two adjacent fins (21) are separated from each other for a given distance; and the micro-channel is formed by fluid channels respectively between two adjacent fin units (2) and between two adjacent fins (21). Due to the adoption of the micro-channel structure of the heat exchanger, under the situation that the small flowing resistance force is kept, the forced convection heat conduction coefficient is increased, and the heat exchanging capacity of the heat exchanger is enhanced.

Owner:浙江微智源能源技术有限公司 +1

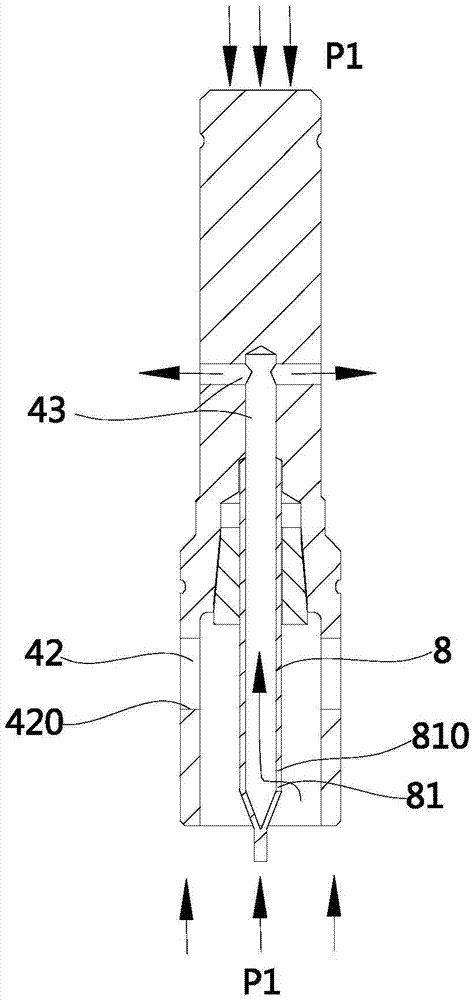

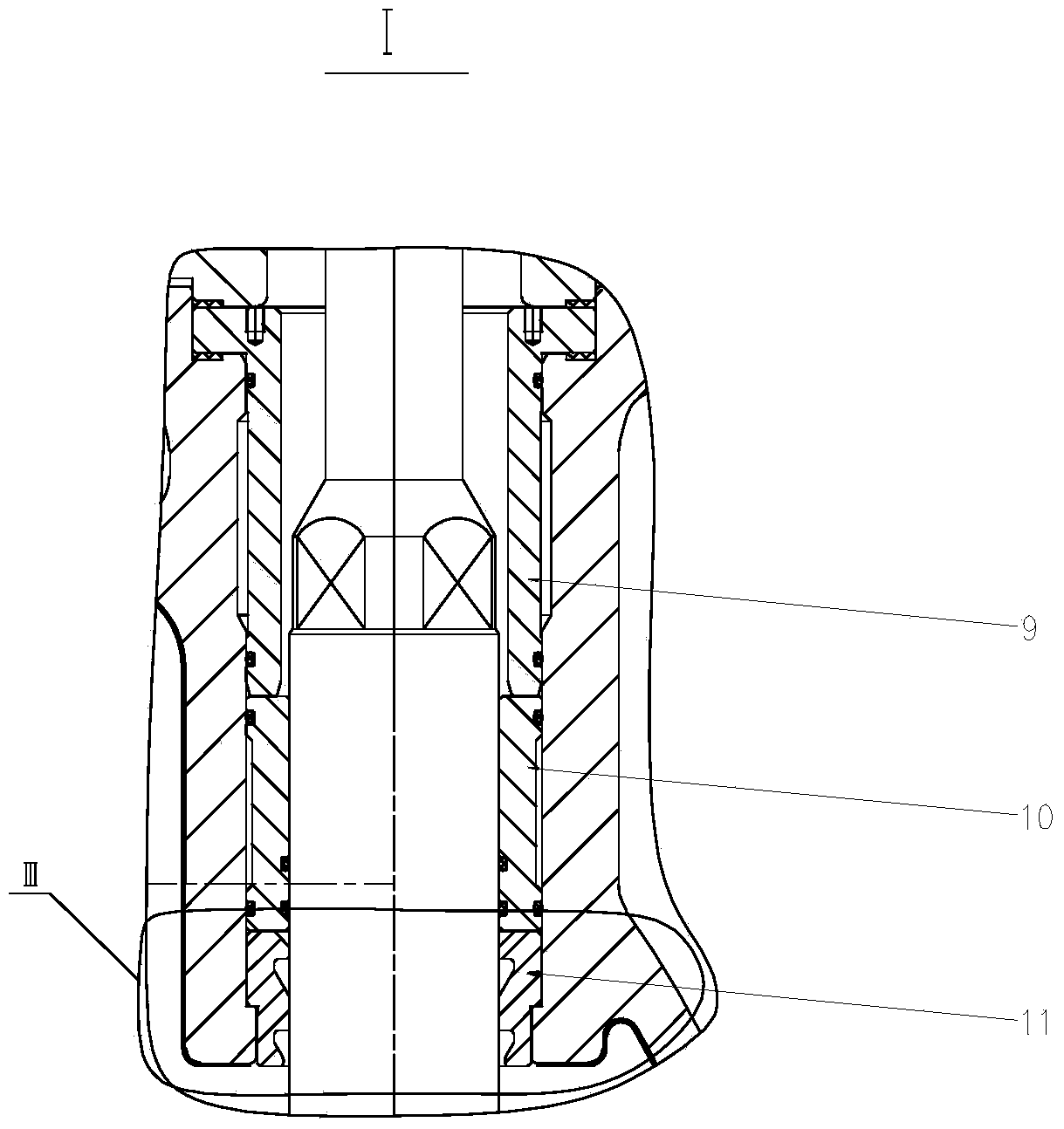

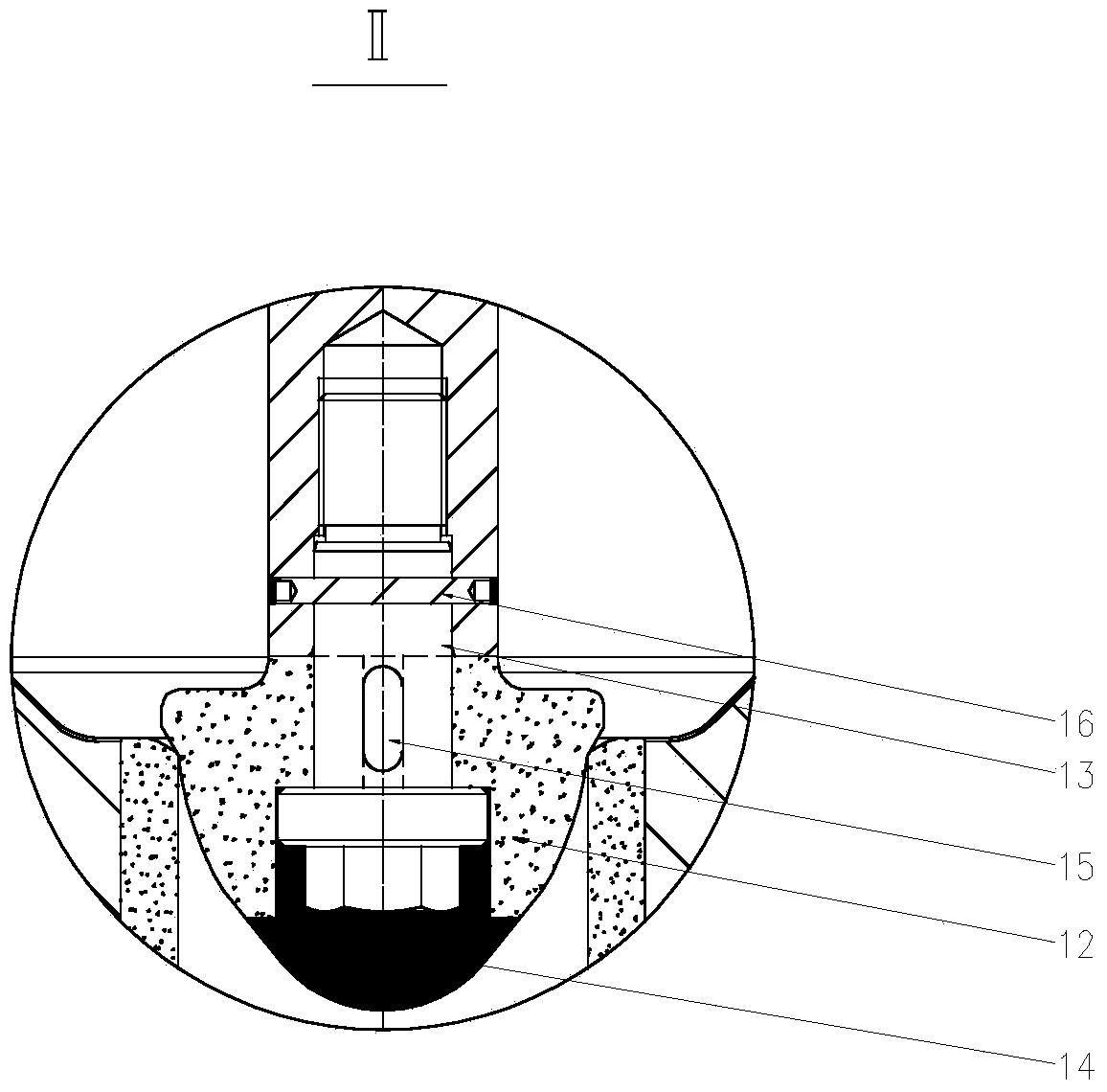

Multi-stage denoiser and valve with same

ActiveCN104913148AImprove noise reductionReduce oscillationValve members for absorbing fluid energyPipe elementsVALVE PORTSmall hole

The invention discloses a multi-stage denoiser and a valve with the same. The multi-stage denoiser comprises a hollow denoising cylinder and at least two stages of denoising covers. The denoising covers are arranged in the hollow denoising cylinder in the extension direction of the hollow denoising cylinder. Each stage of denoising cover is provided with a fluid cavity and a fluid inlet formed in the head portion of the fluid cavity. The wall of the fluid cavity of each stage of denoising cover is provided with a plurality of through holes. The fluid inlet of the fluid cavity of the rear stage of denoising cover corresponds to the tail portion of the front stage of denoising cover and forms a buffer cavity together with the tail portion of the front stage of denoising cover. The valve comprises a valve body and an outflow passageway of fluid. The outlet of the outflow passageway is fixedly connected with the denoiser in the axial direction. By arranging the multiple stages of denoising covers, the denoising efficiency is improved, the denoising effect is achieved through the frequency shift effect of small hole spraying, and the fluid flow speed is uniform through the buffer cavity. The vibration caused by fluid impact to the denoiser is reduced in the medium flowing process, and therefore the stability of the product is improved, and the overall service life of the denoiser is prolonged.

Owner:NEWAY VALVE SUZHOU

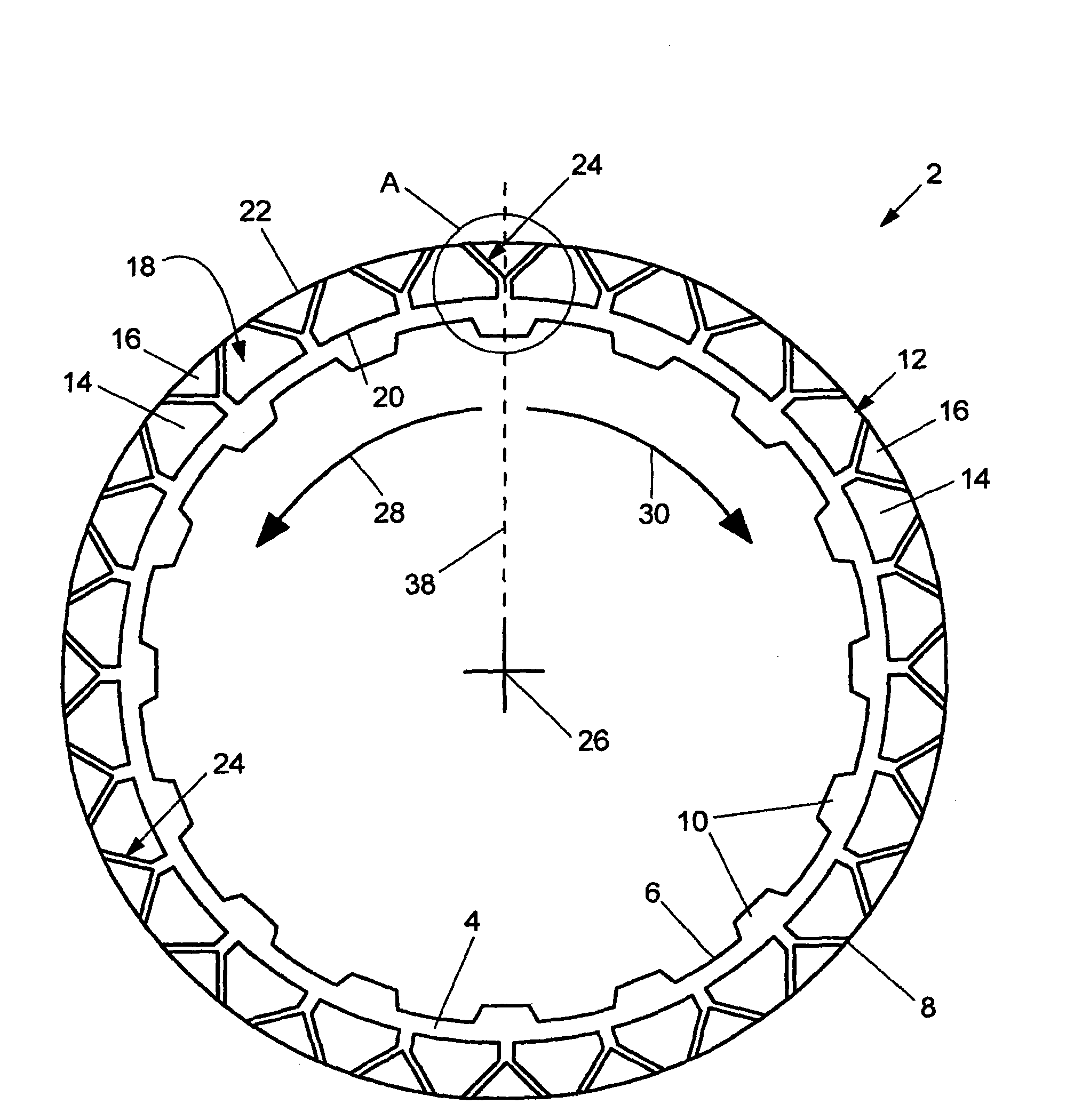

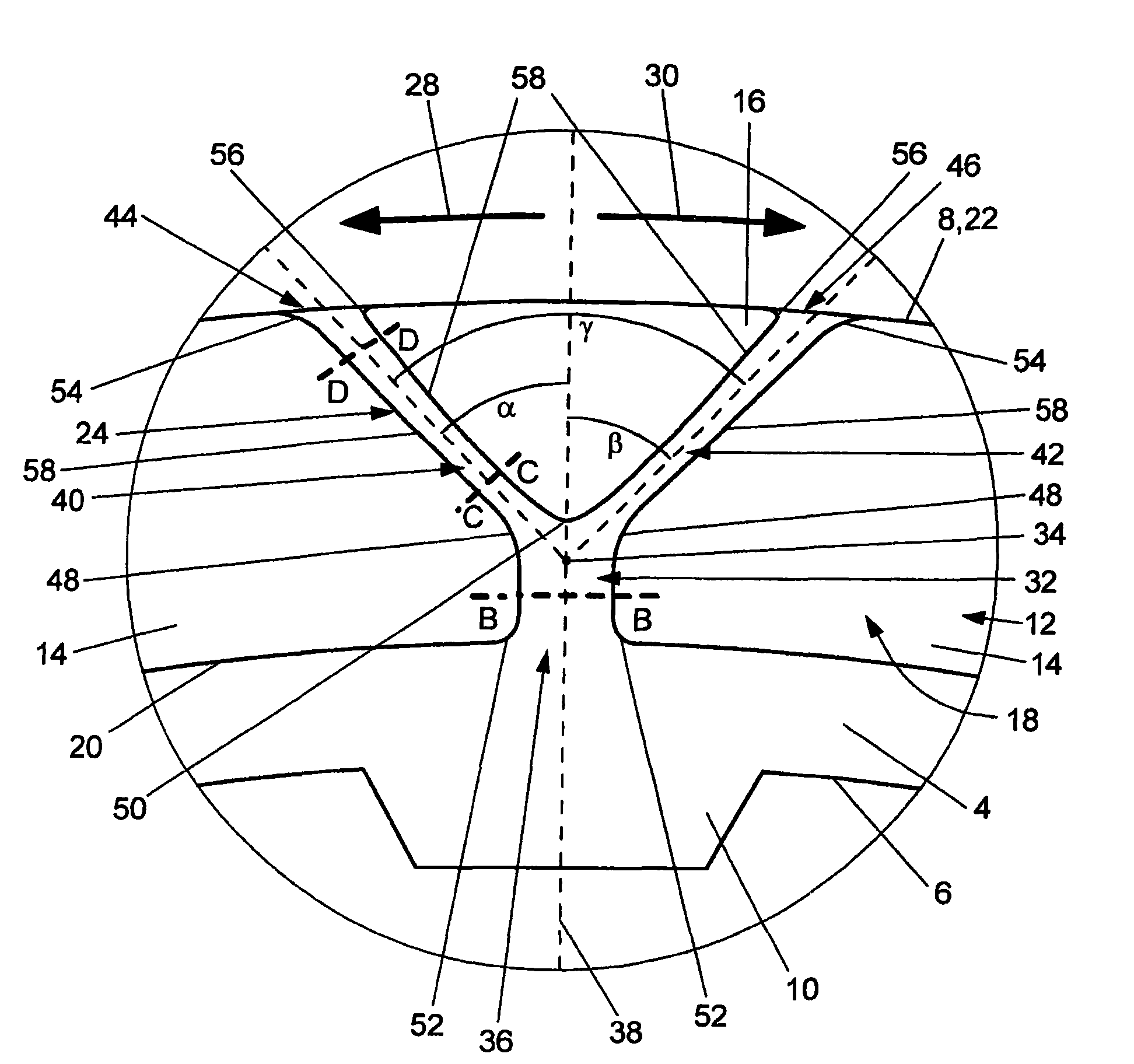

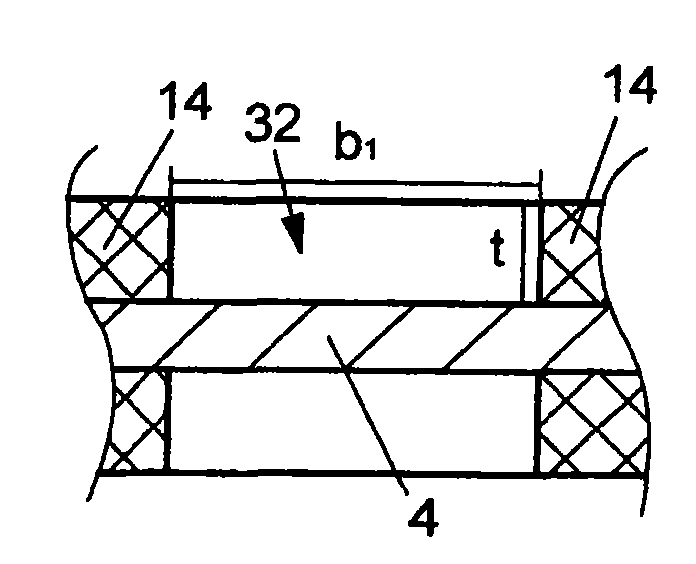

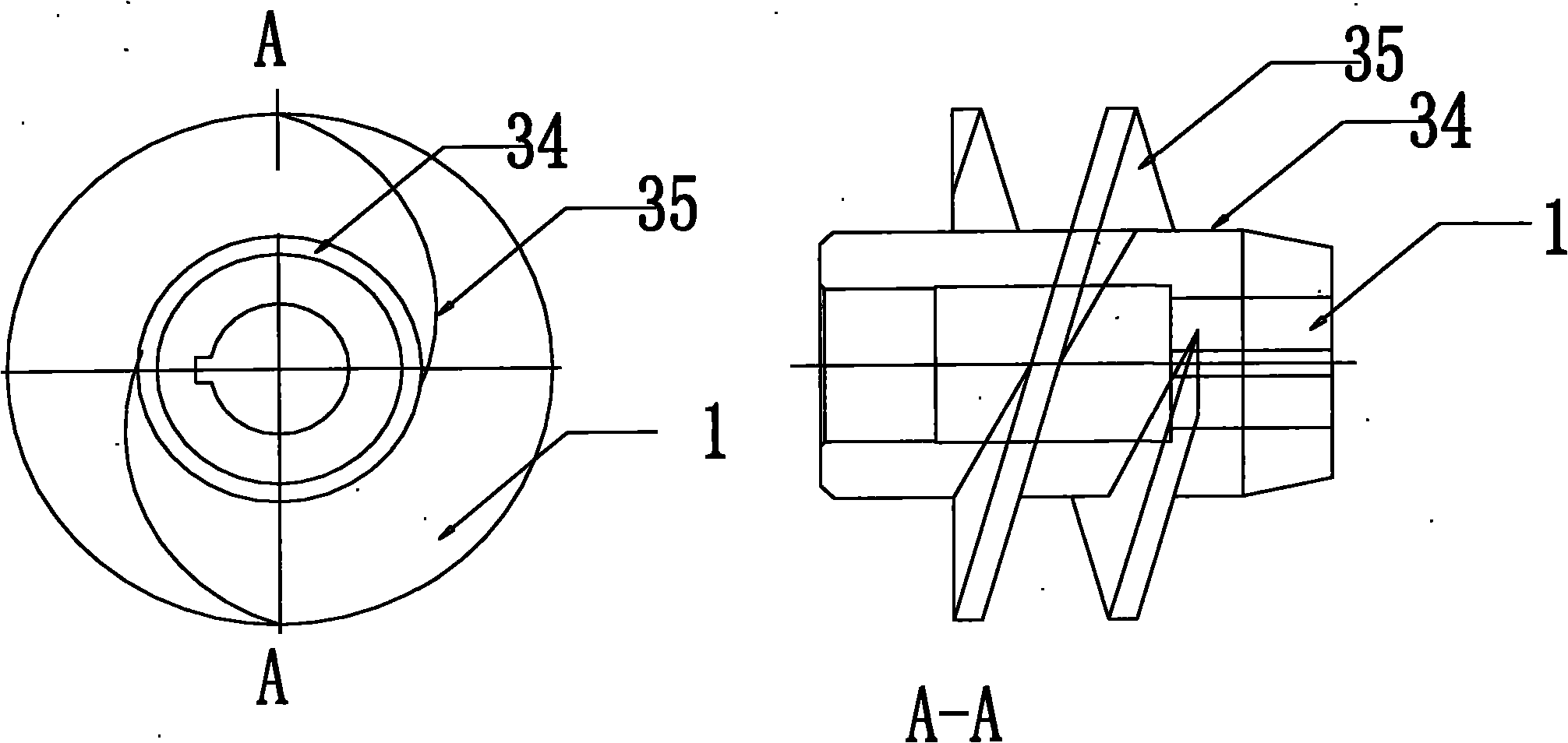

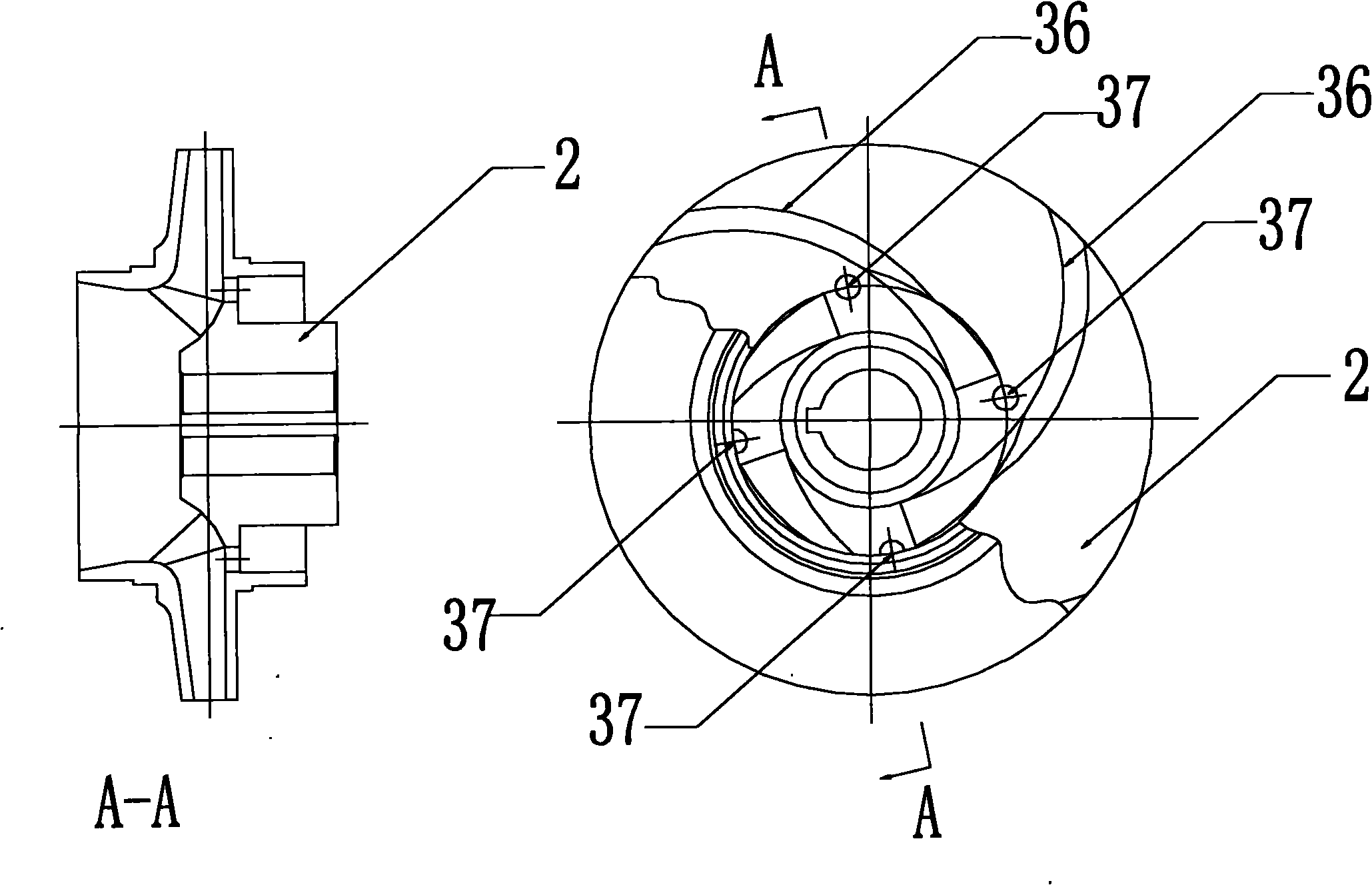

Friction part for a frictionally acting device, and frictionally acting device having a friction part of said type

InactiveCN101517256APromote absorptionAvoid vortexFriction clutchesFriction liningMechanical engineeringPhysics

The present invention relates to a friction part (2) for a frictionally acting device, having an annular friction face (18) which has an inner edge (20) and an outer edge (22), wherein at least one set of grooves (24) is provided in the friction face (18), which set of grooves (24) has a first groove (32) which extends from the inner edge (20) or the outer edge (22) to a branching point (34) between the inner edge (20) and the outer edge (22), and a second and third groove (40, 42) which extend in each case from the branching point (34) to the other edge (22, 20). According to the invention, the second groove (40) is inclined in the one peripheral direction (28) and the third groove (42) is inclined in the other peripheral direction (30) of the friction face (18) with respect to a radial line (38) through the branching point (34). The present invention also describes a frictionally acting device having a friction part (2) of said type.

Owner:BORGWARNER INC

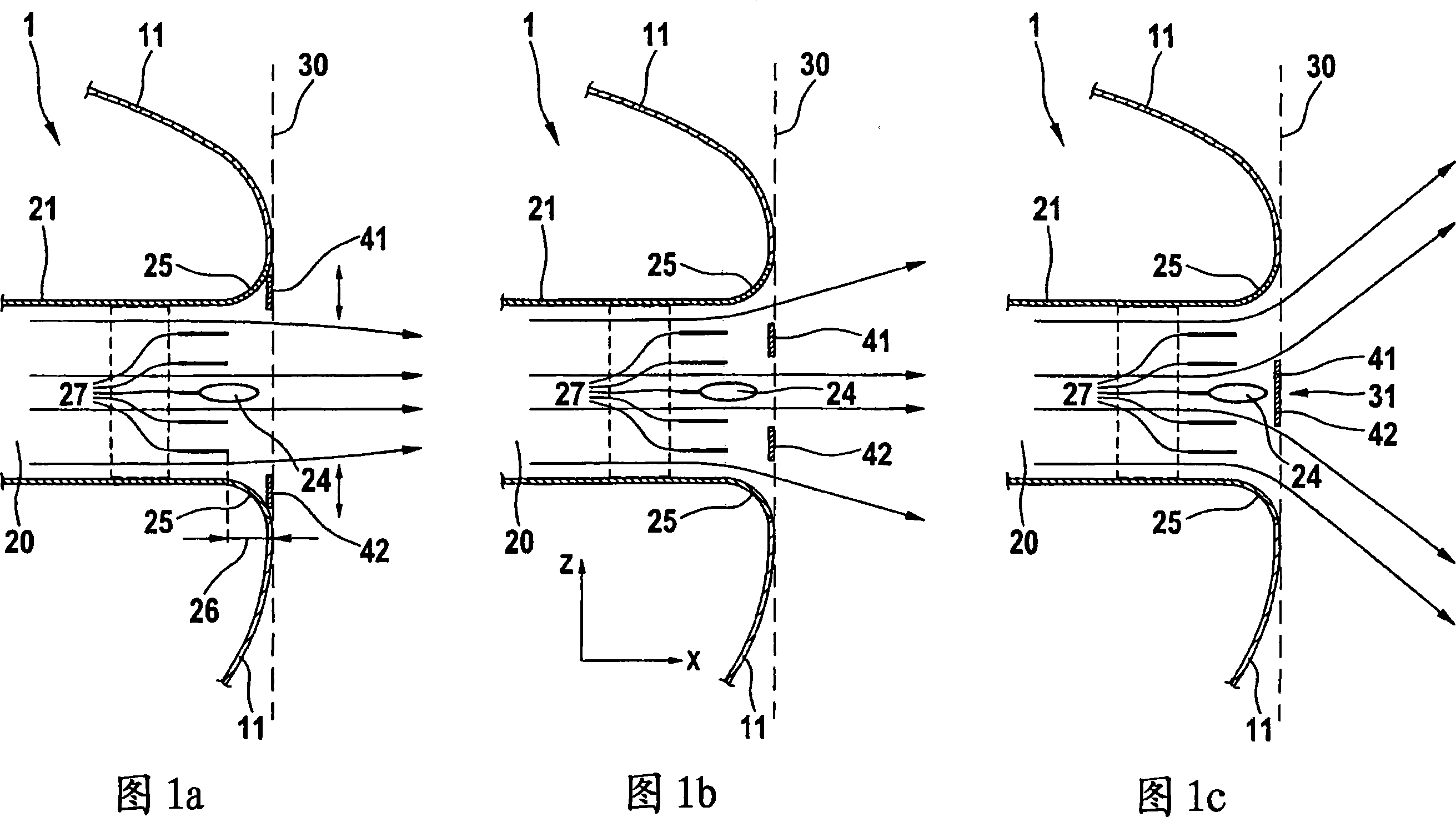

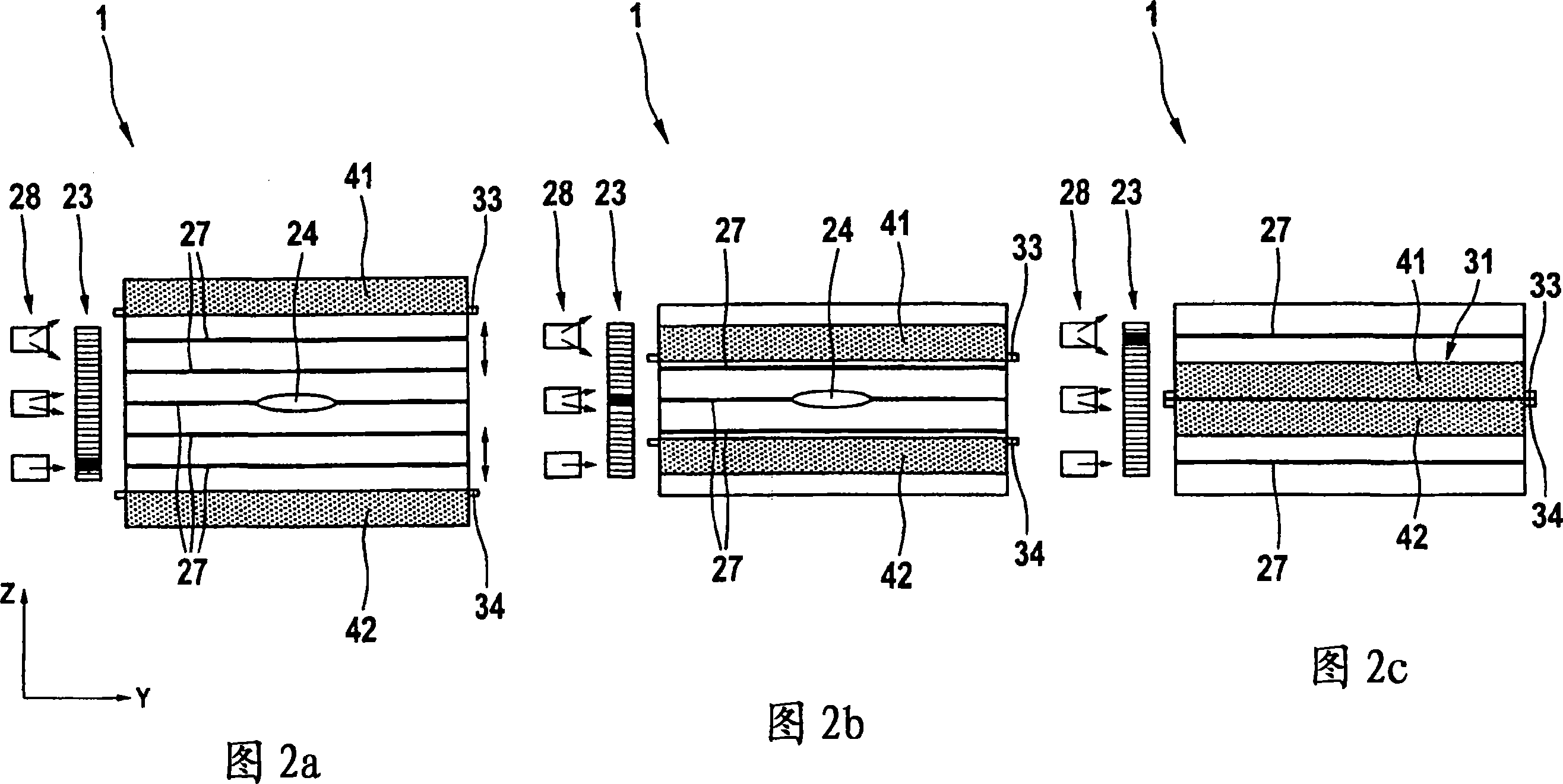

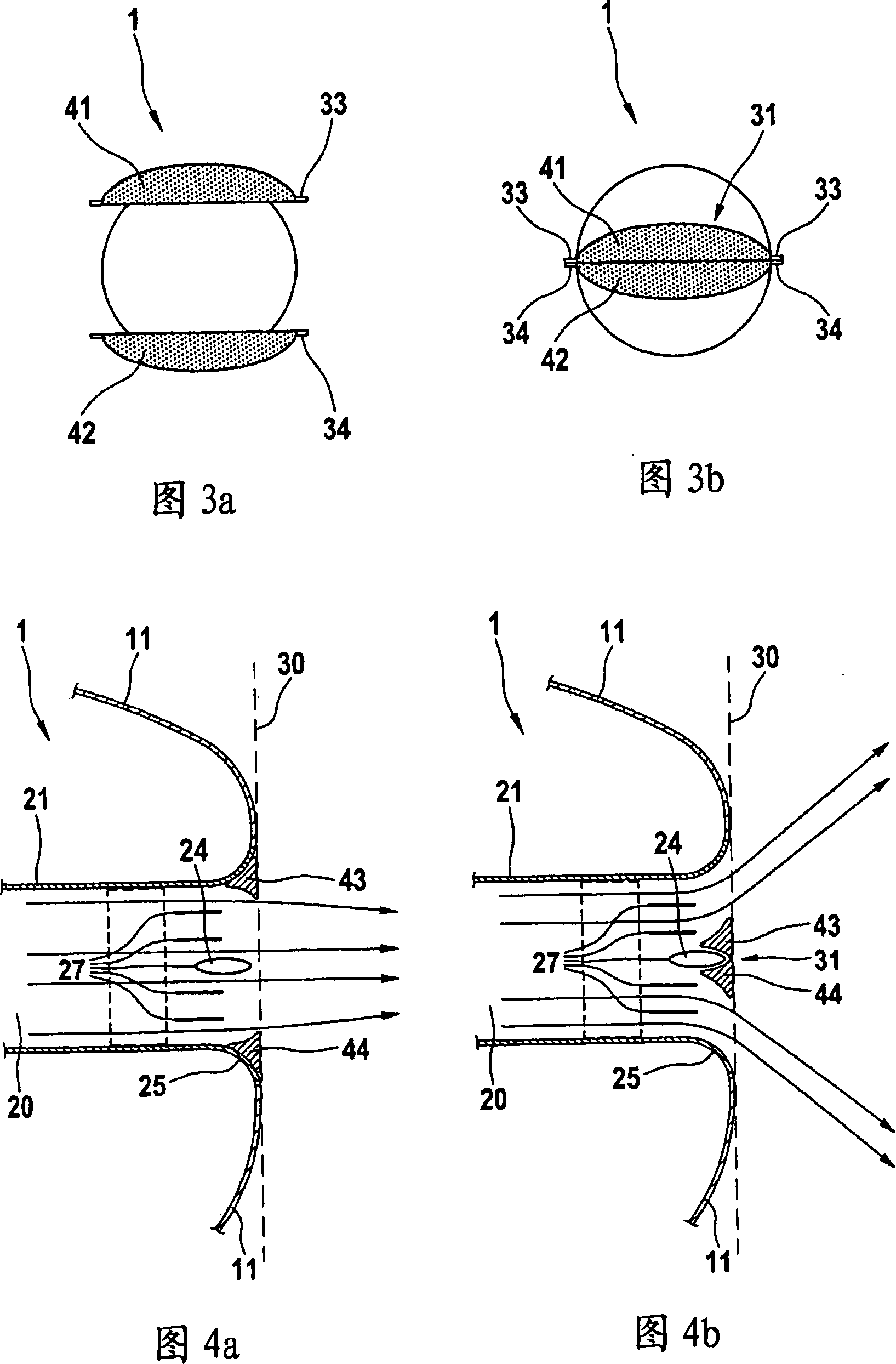

Air outlet nozzle

InactiveCN101213101ALittle flow blockageReduce flow lossAir-treating devicesVehicle heating/cooling devicesAir channelAirflow

The invention relates to an air outlet nozzle which is used to guide air in the passenger compartment of a vehicle. The air outlet nozzle comprises an air channel (20) which leads to an air outlet plane (30), and an impact plate (31) which is arranged on the air outlet plane (31) for beam expansion. The impact plate (31), which is used to adjust a diffuse position on at least two displacably mounted lamellas (29, 41-50), which are arranged in an extended manner in alignment with the air outlet plane, are provided in order to produce an economical air outlet nozzle which provides the best possible beam expansion.

Owner:DAIMLER AG

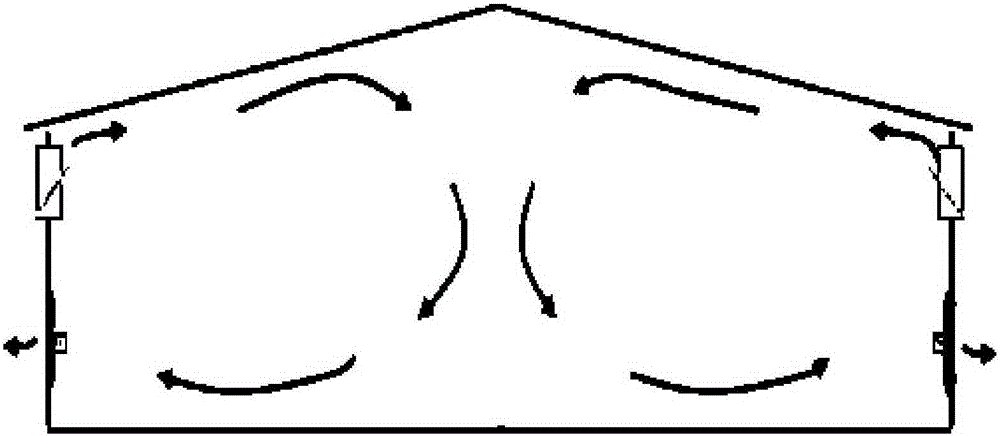

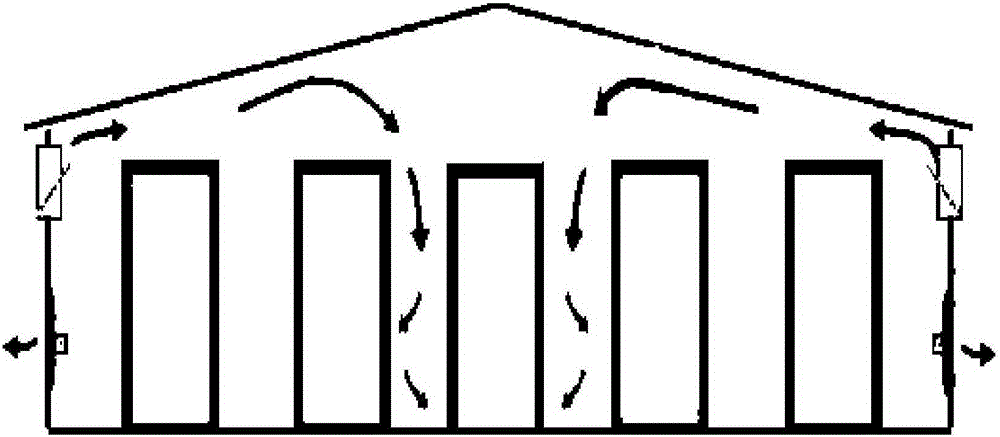

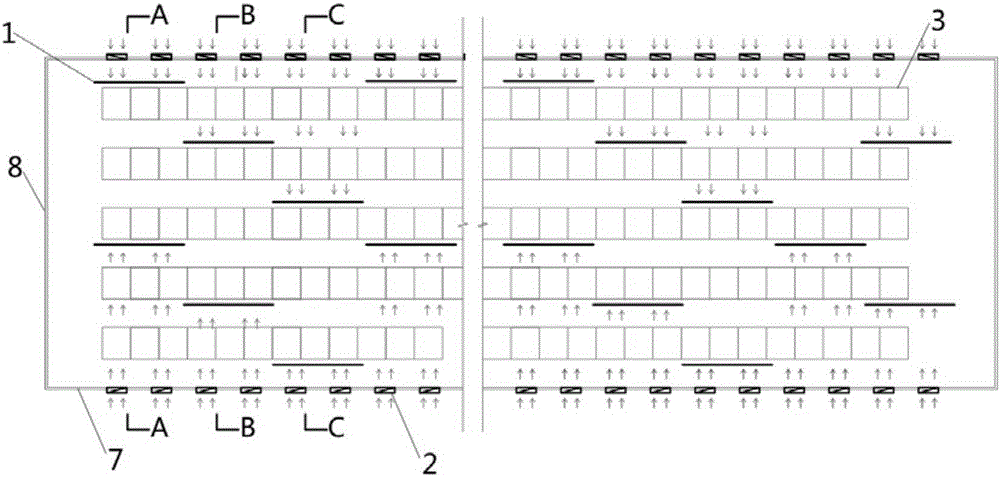

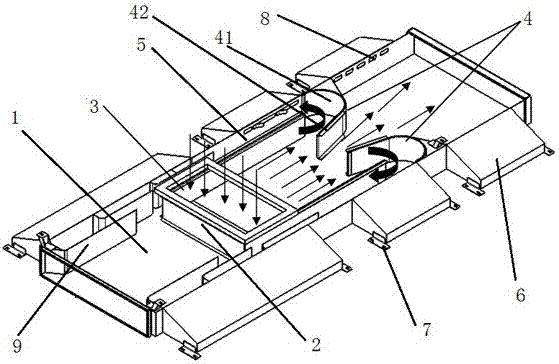

Confined poultry house winter ventilation system and air distribution method

ActiveCN105165654AIncrease the uniformity of exhaust airReduce wind speedAnimal housingBird housingsDistribution methodAgricultural engineering

The present invention belongs to the field of agricultural facilities, and relates to a confined poultry house winter ventilation system and an air distribution method. the system comprises air inlet windows (2), hencoops (3), negative-pressure air fans (6), vertical walls (7) and gable walls (8), wherein passages are formed among different hencoops (3) and between the outmost hencoops (3) and the vertical walls (7), the air inlet windows (2) are uniformly arranged on upper parts of the vertical walls (7) at two ends, a plurality of guide devices (1) are arranged in a parallel and staggered manner at a roof part corresponding to the passages, trench exhaust outlets (4) are arranged at a distance on the ground of the passages, an exhaust trench (5) is arranged lengthwise on the ground of each passage and is connected with the trench exhaust outlet (4) inside the passage, and the negative-pressure air fans (6) are installed on the gable wall (8) at one end and are communicated with the exhaust trenches (5) through pipelines. With adoption of the confined poultry house winter ventilation system and the air distribution method, differences in temperature and air qualities among different passages and different hencoop layers can be effectively reduced, and air is orderly and uniform in distribution.

Owner:CHINA AGRI UNIV

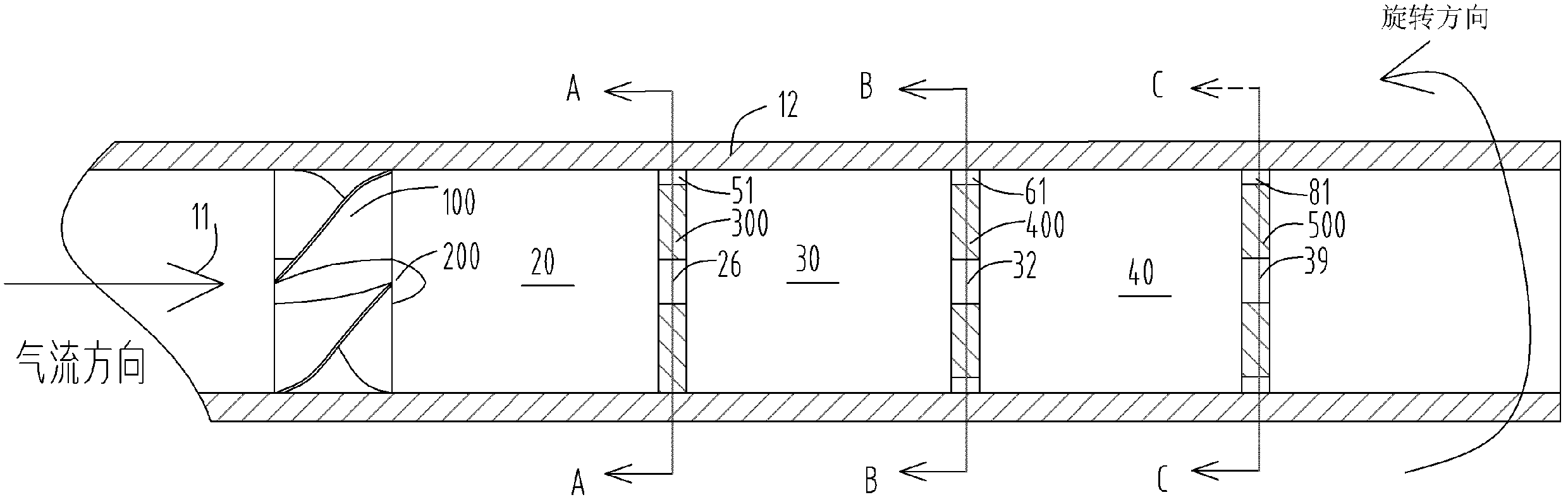

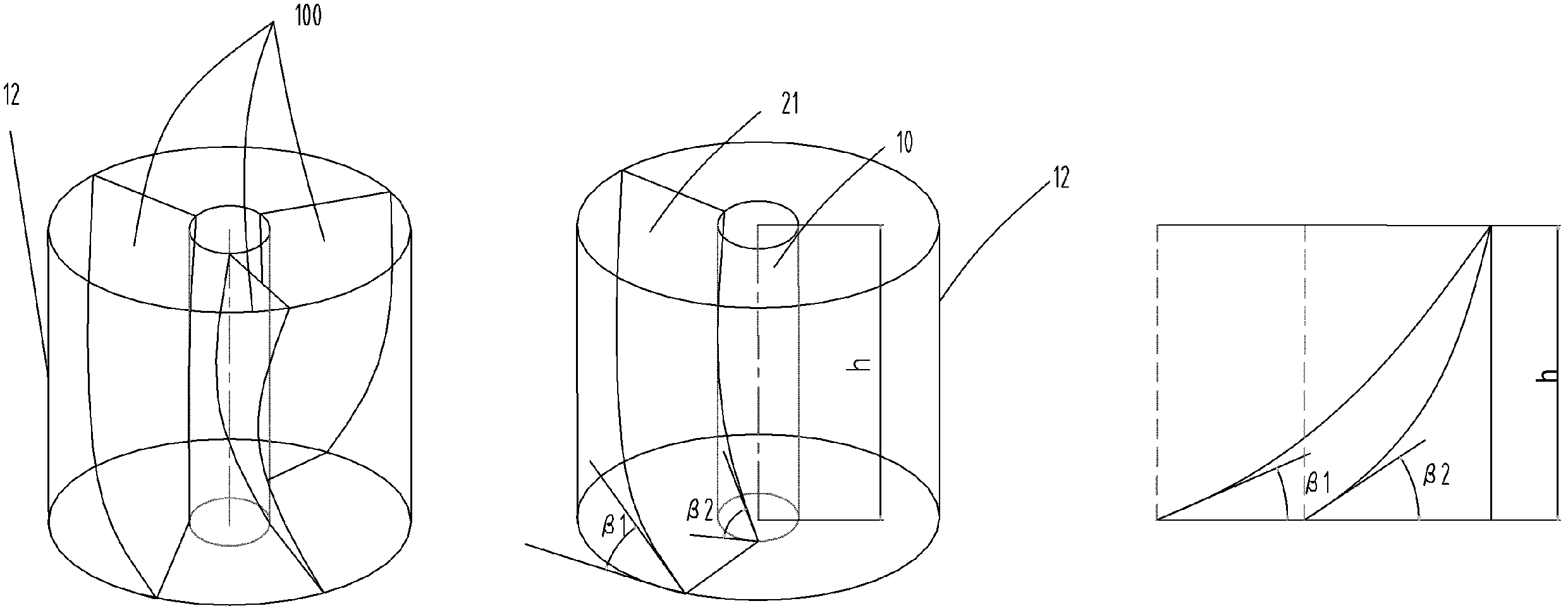

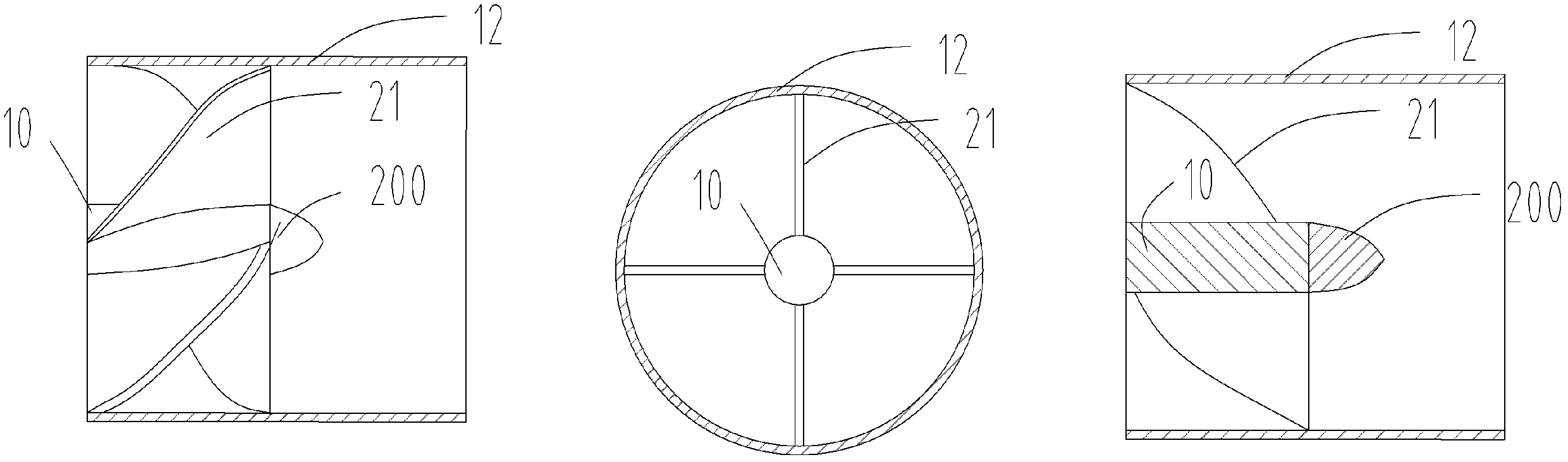

Device for controlling rotary gas-liquid mixed flow noise

InactiveCN102518498AControl drag lossAvoid secondary mixingExhaust apparatusDispersed particle separationNoise controlExhaust pipe

The invention discloses a device for controlling rotary gas-liquid mixed flow noise. The device comprises a guide vane assembly (100), a vortex control structure (200), a partition plate I (300), a partition plate II (400) and a partition plate III (500) which are sequentially arranged in a tail gas exhaust pipe (12) in an airflow direction; a resonant chamber I (20) is formed in the inner cavity of the tail gas exhaust pipe (12) between the guide vane assembly (100) and the partition plate I (300), a resonant chamber II (30) is formed in the inner cavity of the tail gas exhaust pipe (12) between the partition plate I (300) and the partition plate II (400), and a resonant chamber III (40) is formed in the inner cavity of the tail gas exhaust pipe (12) between the partition plate II (400) and the partition plate III (500); and each of the partition plate I (300), the partition plate II (400) and the partition plate III (500) is provided with a central through hole and an edge through hole. The device has the characteristic of good de-noising effect.

Owner:ZHEJIANG UNIV

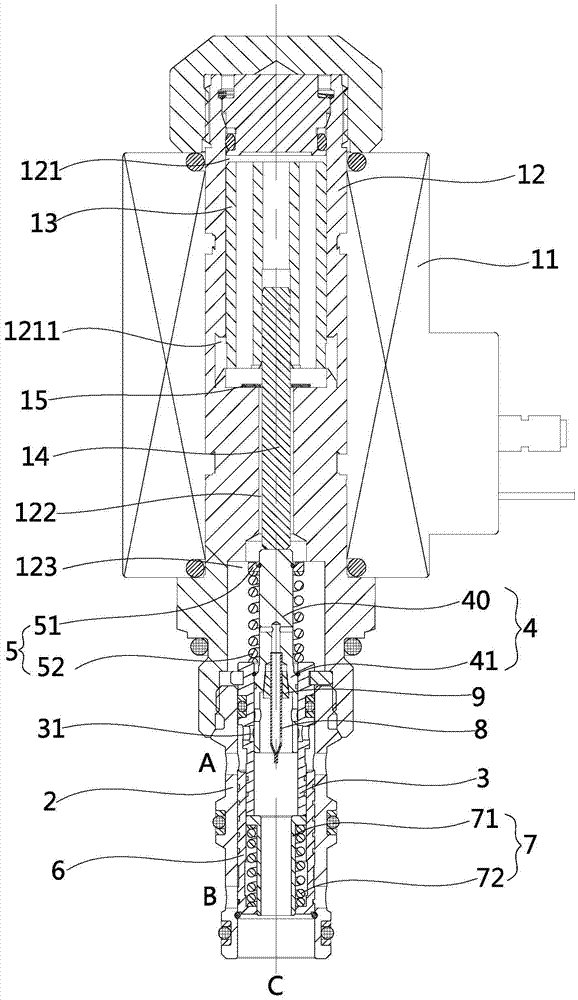

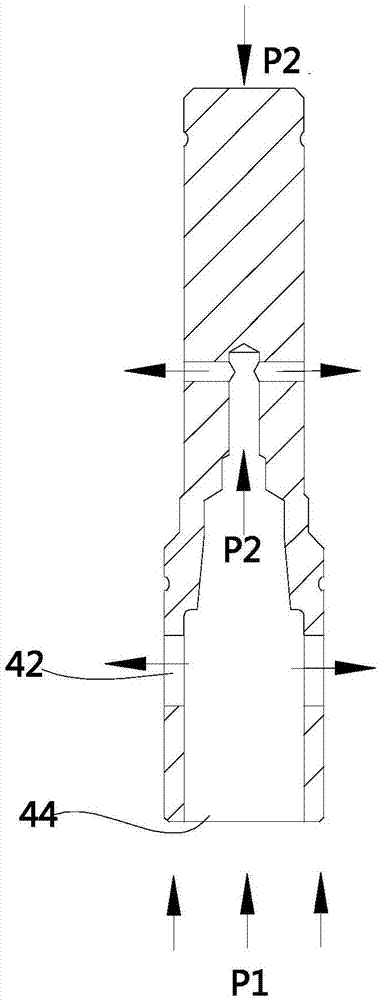

Electromagnetic proportional flow valve

ActiveCN105443837AReduced control accuracyHigh control precisionOperating means/releasing devices for valvesSlide valveControl systemEngineering

The invention discloses an electromagnetic proportional flow valve, and belongs to the technical field of hydraulic control valves. The electromagnetic proportional flow valve solves the technical problem that an existing electromagnetic proportional flow valve is poor in stability and low in control accuracy. The electromagnetic proportional flow valve comprises an electromagnetic driving mechanism, a valve sleeve, a valve base and a throttle valve element; the valve sleeve is fixedly connected between the electromagnetic driving mechanism and the valve base, and the electromagnetic driving mechanism is used for pushing the throttle valve element to downwards move in the valve base in the axial direction; a pressure release channel is arranged in the throttle valve element, and a variable throttle opening is formed in the lateral wall of the throttle valve element; and a pressure guide pipe is further arranged in the throttle valve element, the upper end of the pressure guide pipe is communicated with the pressure release channel, and a pressure guide opening is further formed in the pressure guide pipe and located below the variable throttle opening. The electromagnetic proportional flow valve is mainly applied to high-speed and low-speed switching control systems for execution mechanisms such as oil cylinders and motors.

Owner:浙江三尚智迪科技有限公司

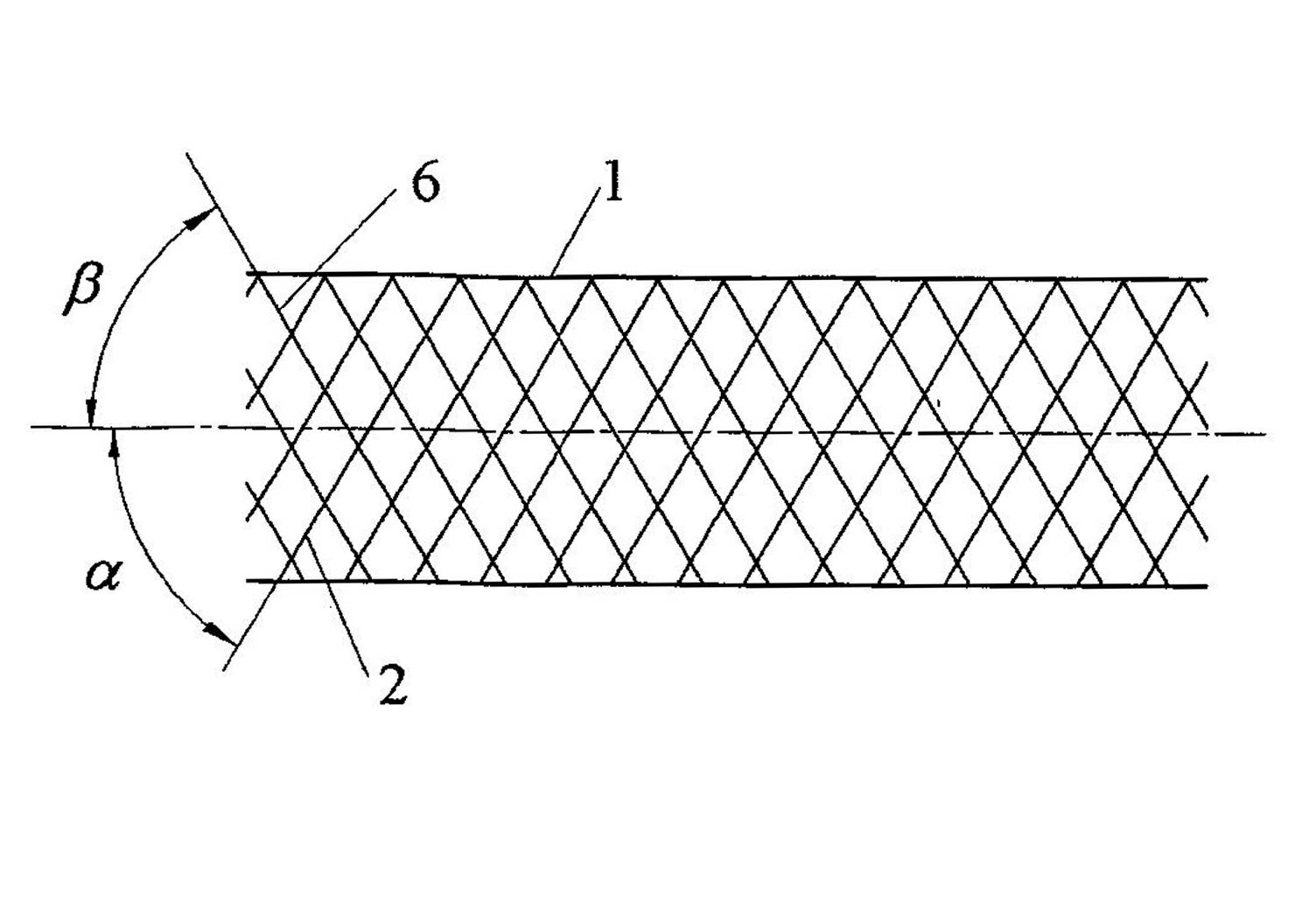

Heat-exchange tube

InactiveCN102425972AImprove heat transfer performanceIncrease the heat exchange areaTubular elementsEngineeringMechanical engineering

The invention relates to a heat-exchange tube and belongs to the technical field of enhancement of heat transfer and energy saving. The heat-exchange tube comprises a tube body, wherein the wall face of the tube body is provided with spiral fins. The heat-exchange tube is characterized in that: a group of concave passages which are spaced are formed on the spiral fins; and the concave passages extend along the direction of a spiral line, extend from the surface of a tube base at one end of the tube body to the top of a first spiral fin along one side face of the first spiral fin, extend to the other side face of the first spiral fin after passing through the top of the first spiral fin, then, extend to the surface of the tube base located between two adjacent spiral fins, and further, extend to the side face and the top of a next spiral fin till extending to the surface of the tube base at an outer side of a side face of a last spiral fin at the other end of the tube body. The heat-exchange tube has the advantages of contributing to remarkably increasing a heat-exchanging area so as to improve the heat-exchanging performance and being beneficial to avoiding increasing the flow resistance of a fluid.

Owner:JIANGSU CUILONG PRECISION COPPER TUBE CORP

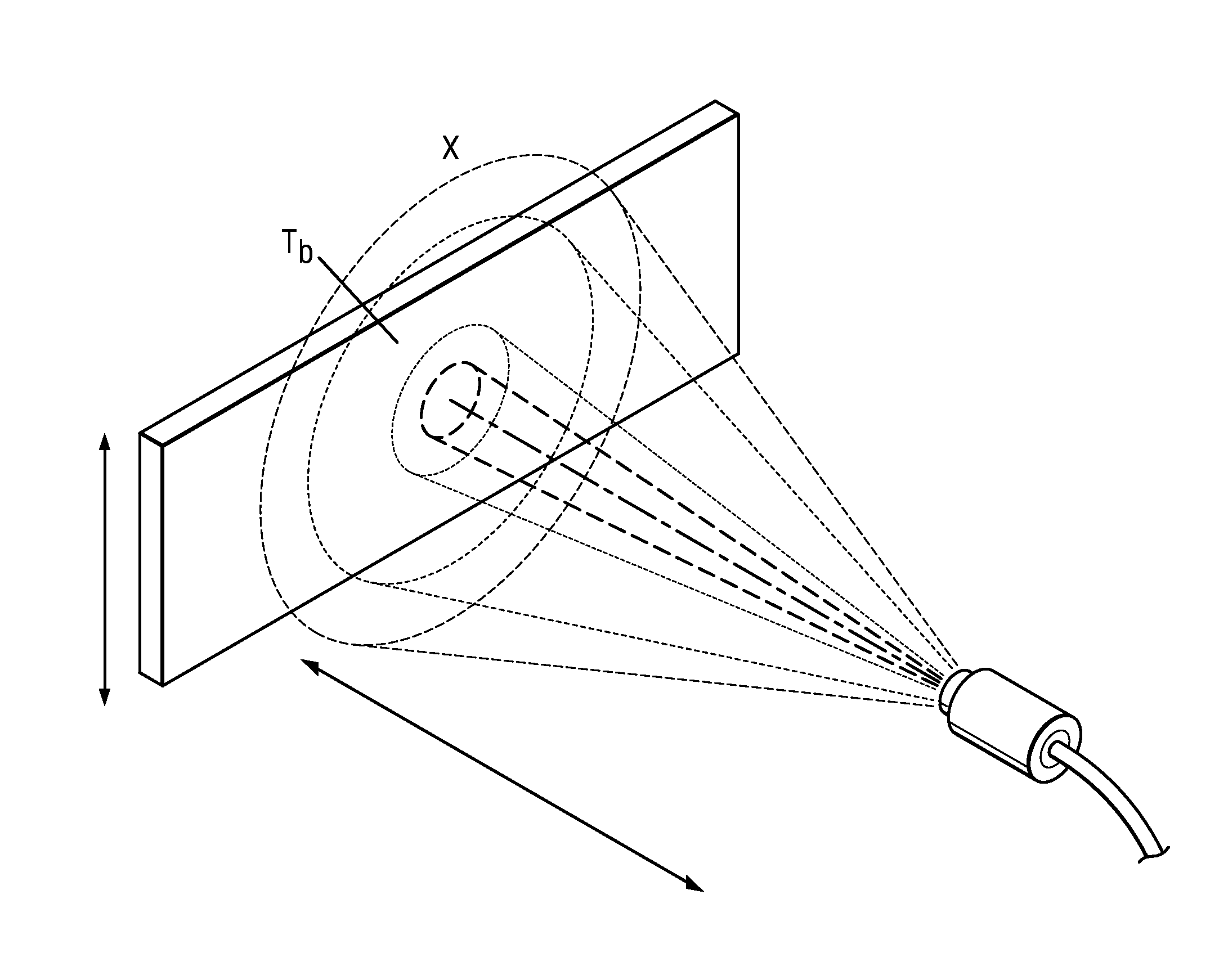

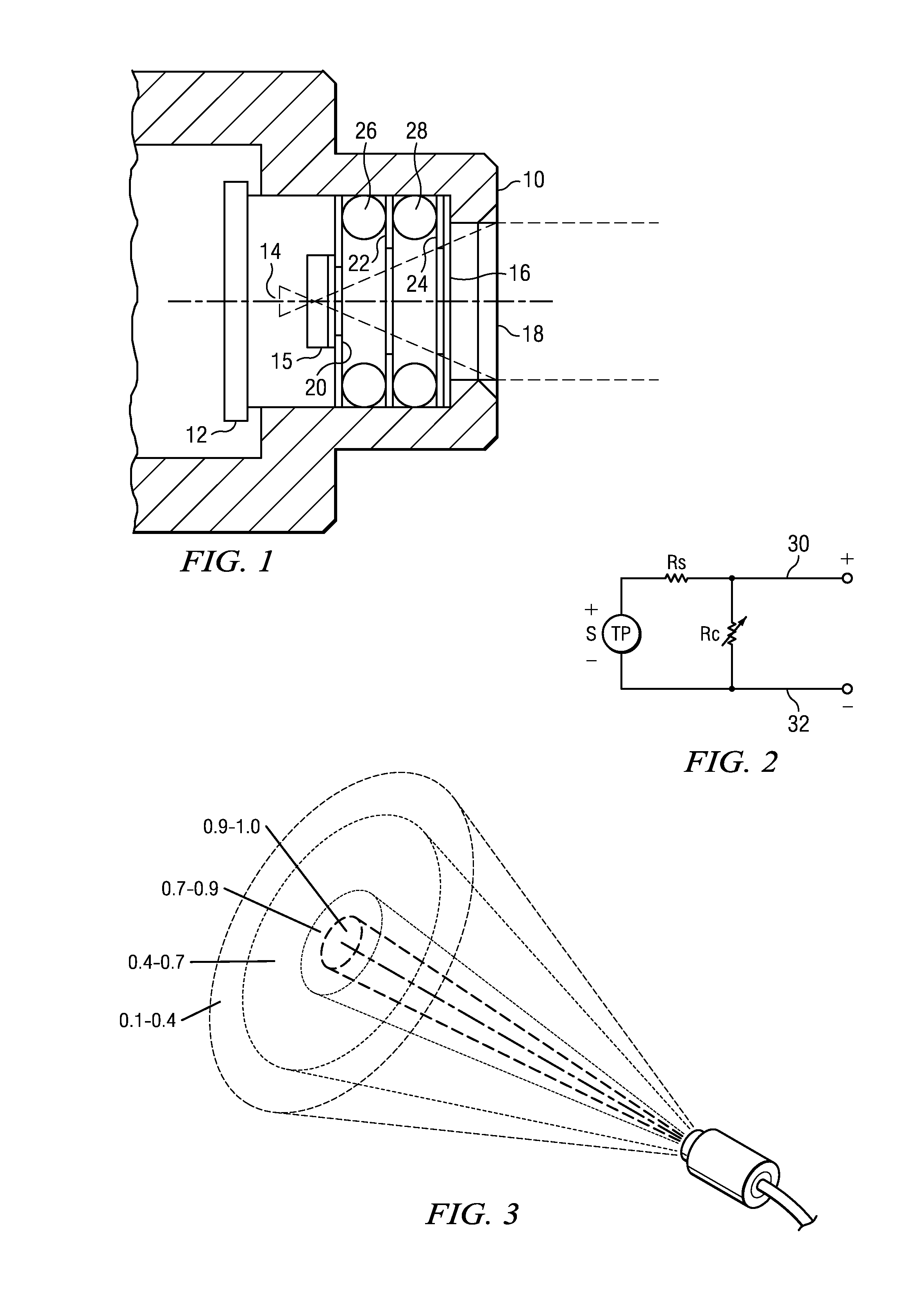

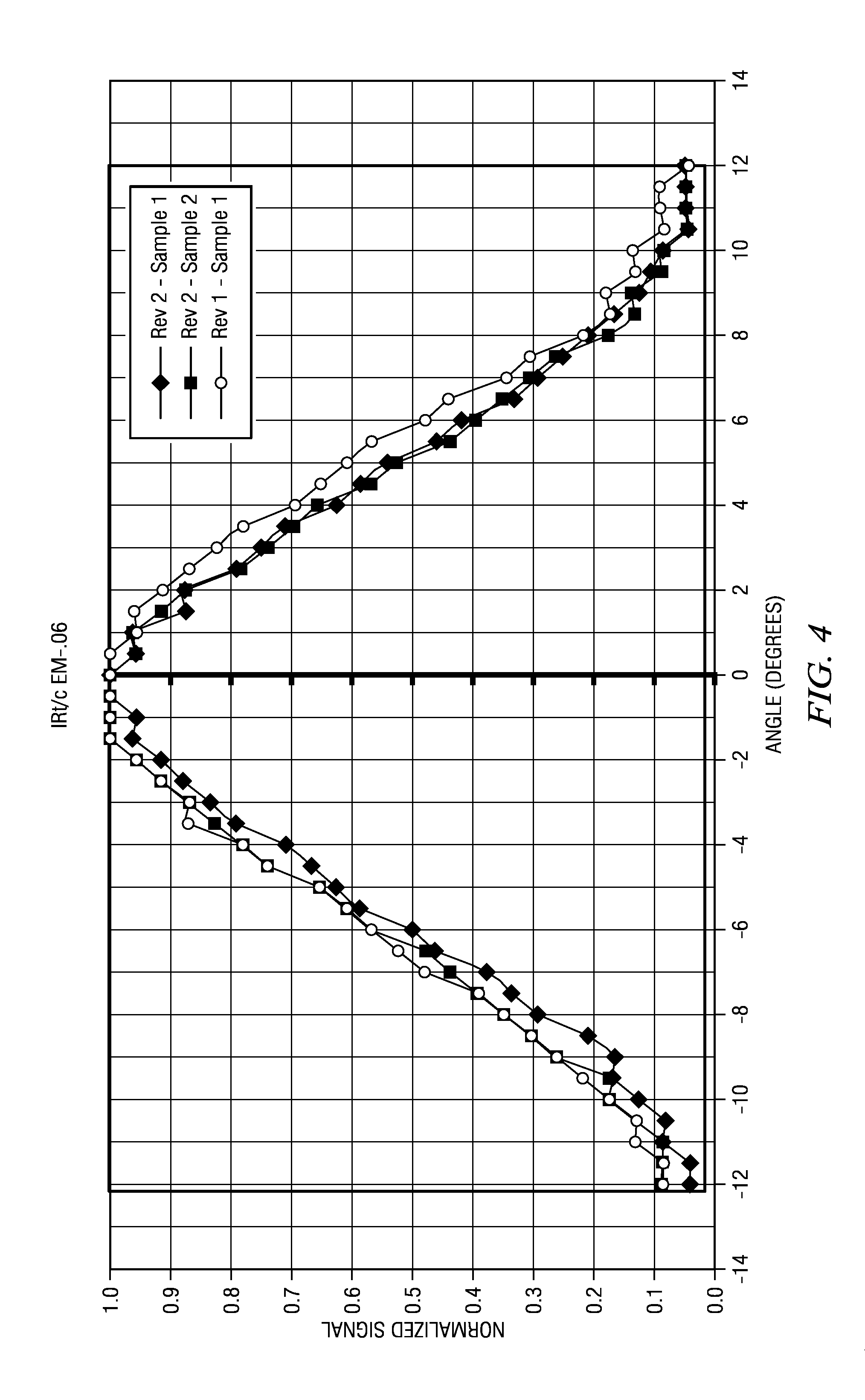

Infrared Sensor and Method for Electrical Monitoring

ActiveUS20120170612A1Low costAvoid vortexThermometers using electric/magnetic elementsUsing electrical meansFresnel lensThermopile

An inexpensive thermopile temperature detector is particularly adapted to monitoring of electrical equipment, such as a power bus bar, within an enclosed area such as a cabinet. The detector may have a plastic housing, a thermopile sensor and a plastic Fresnel lens. Each sensor also includes a calibrated element such that, but for calibration, the same sensor may be used for various applications for different target sizes and distance or, more generally, with respect to effective target percentage of field of view.

Owner:EXERGEN CORPORATION

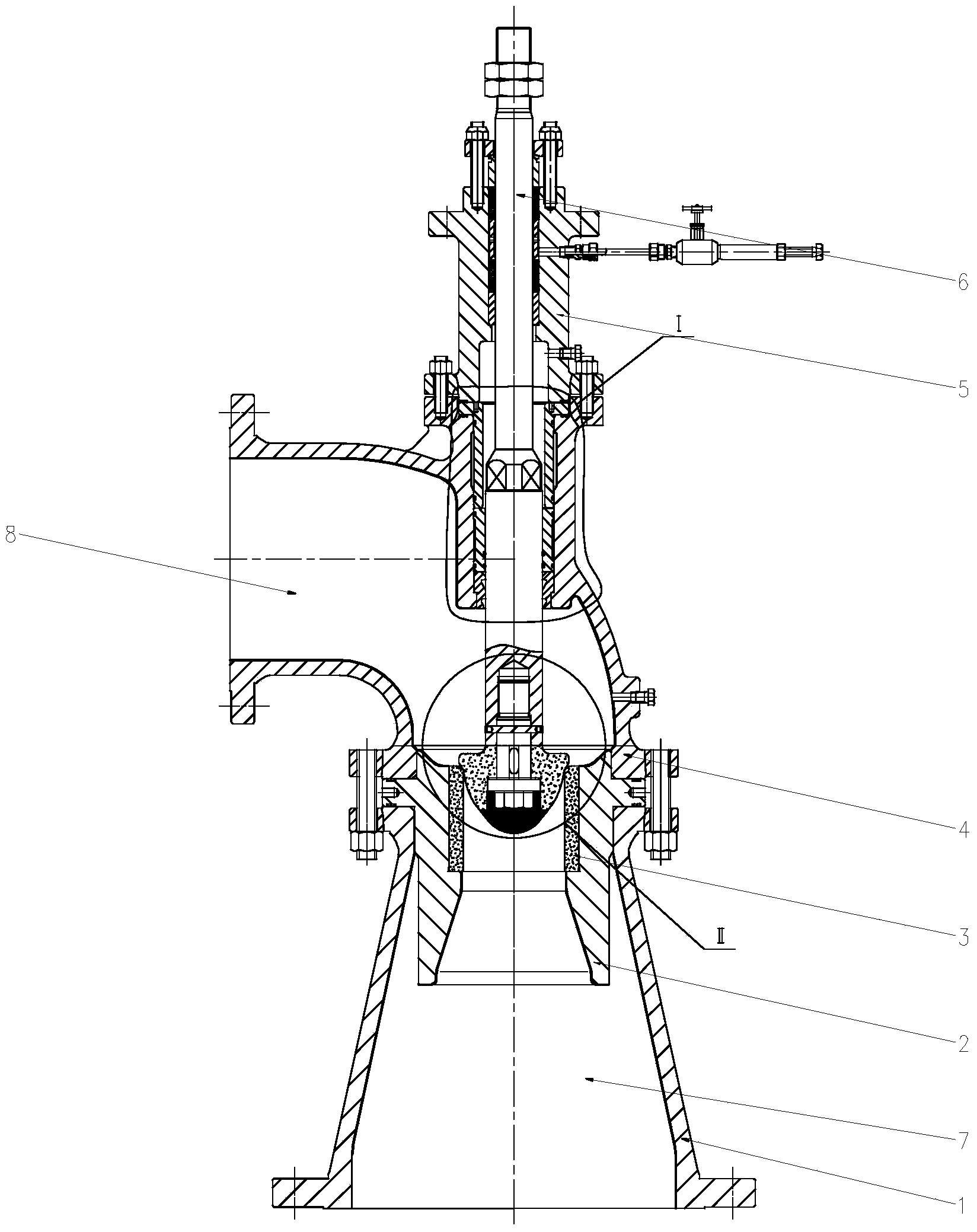

Black water coking-preventing impact-resistant shockproof regulating angle valve special for coal chemical industry

ActiveCN103591303AImprove anti-blocking performanceAvoid vortexLift valveValve housingsFluid controlControl valves

The invention relates to a regulating angle valve, in particular to a black water coking-preventing impact-resistant shockproof regulating angle valve special for the coal chemical industry, and belongs to the field of fluid control valves. The black water coking-preventing impact-resistant shockproof regulating angle valve comprises a diffusion tube and a valve body, wherein the lower end of the valve body is connected with the diffusion tube through a bolt. An inlet flowing channel is arranged in the valve body, an outlet flowing channel is arranged in the diffusion tube and is communicated with the inlet flowing channel, and the inlet flowing channel is perpendicular to the outlet flowing channel. A valve carrier base is arranged in the outlet flowing channel and is clamped through the diffusion tube and the valve body, and a valve carrier is arranged in the valve carrier base. The black water coking-preventing impact-resistant shockproof regulating angle valve is simple in structure and novel in design, can effectively solve the technical problems that a traditional black water regulating angle valve is easy to coke, poor in impact resistant performance, undesirable in shockproof effect and the like in a use process, is widely applied in sites of customers, and effectively lowers production operation cost of the customers.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

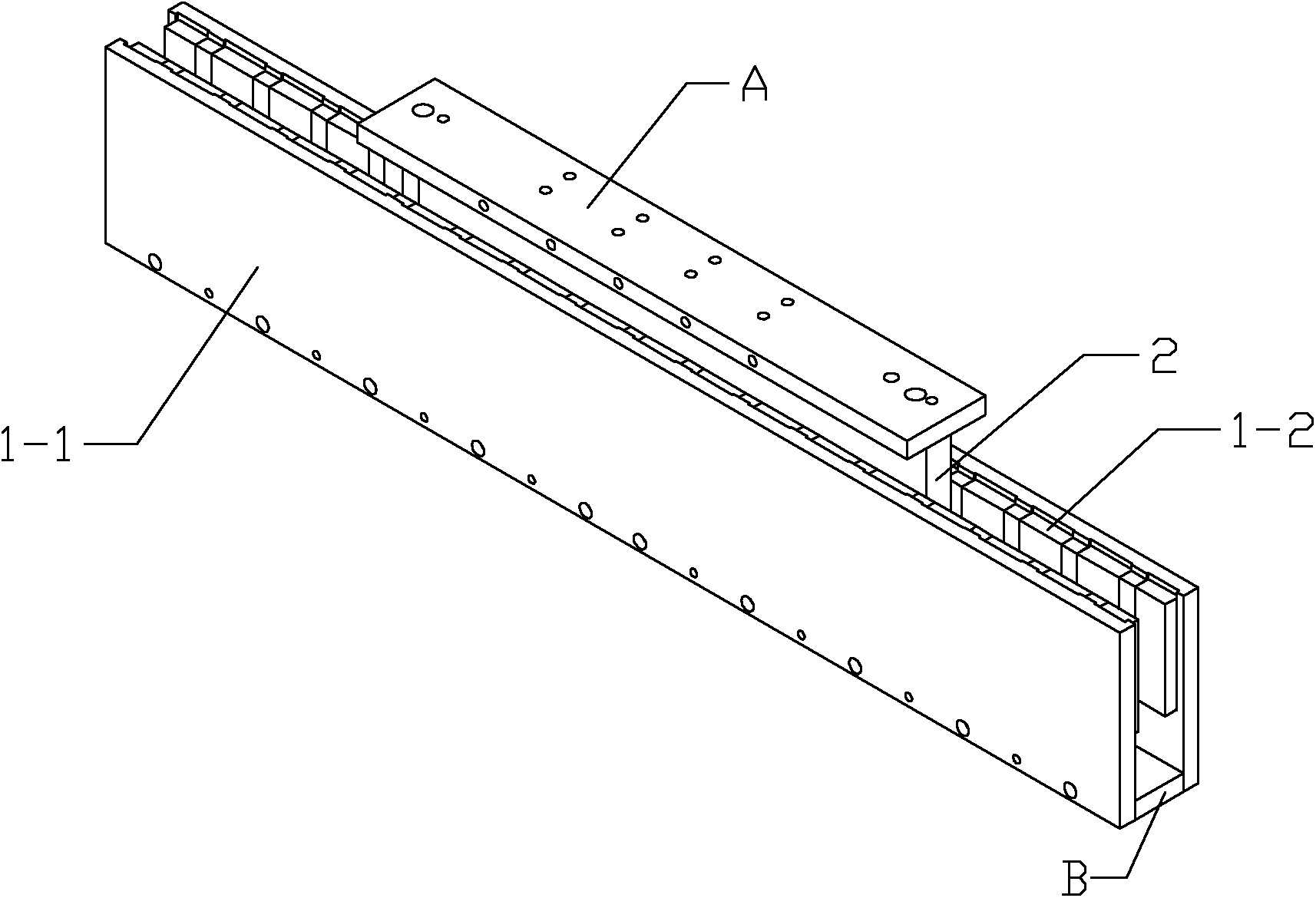

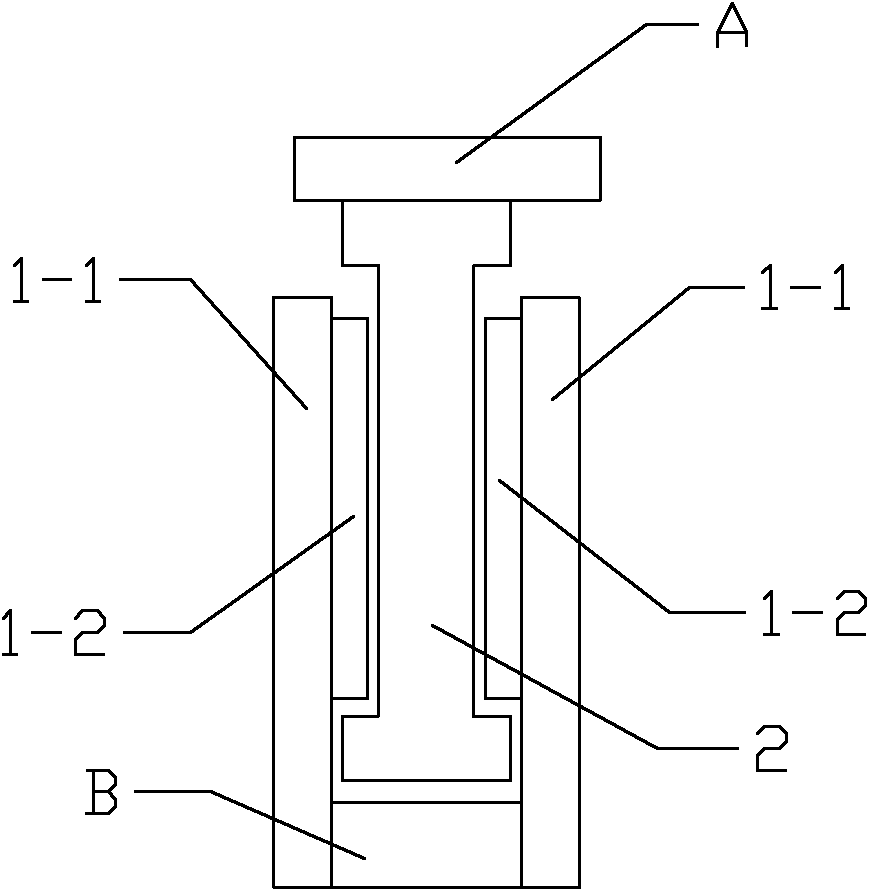

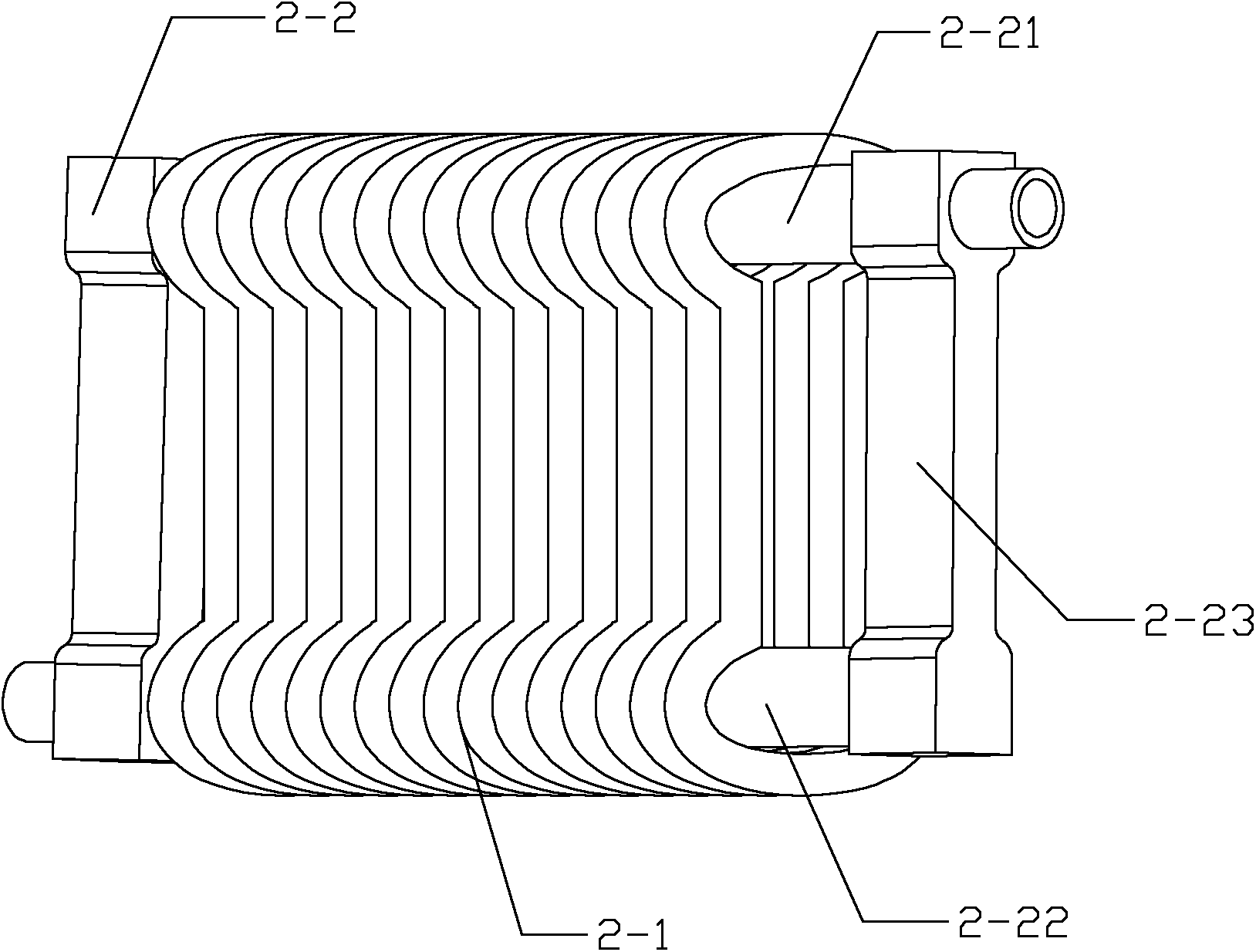

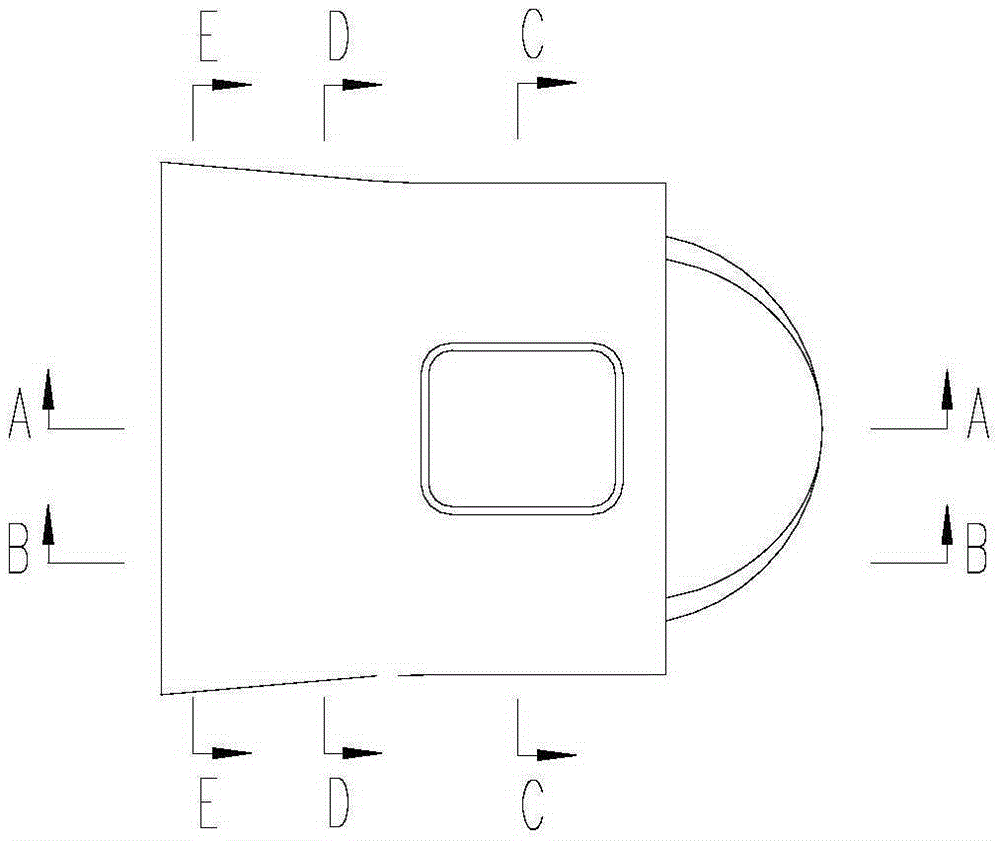

Coreless permanent magnet linear motor with cooling structure, manufacturing mould for winding coil thereof and machining process for winding coil

ActiveCN102255469ASimple structureEasy to manufactureMagnetic circuit rotating partsManufacturing dynamo-electric machinesPermanent magnet linear motorControl theory

The invention relates to a coreless permanent magnet linear motor with a cooling structure, a manufacturing mould for a winding coil thereof and a machining process for the winding coil and belongs to the technical field of linear motors. The coreless permanent magnet linear motor with the cooling structure is used for solving the radiation problem of a coreless permanent magnet linear motor. Stators of the coreless permanent magnet linear motor with the cooling structure are mirror-symmetrically arranged at the two sides of a rotor, wherein the rotor comprises an armature winding and a cooling pipeline; the cooling pipeline is composed of an upper pipeline, a lower pipeline and two connectors; the upper pipeline passes through an arc-shaped through hole which is formed on the upper end part of the armature winding; and the lower pipeline passes through an arc-shaped through hole which is formed on the lower end part of the armature winding. The manufacturing mould for the winding coil of the coreless permanent magnet linear motor with the cooling structure is composed of two winding shape-fixing components, a coil dislocation moving component and two base plates. The machining process for the winding coil by using the manufacturing mould for the winding coil is used for realizing the dislocation of upper and lower coil edges of the winding coil and preventing a winding from falling into pieces. The machining process provided by the invention is suitable for the coreless permanent magnet linear motor.

Owner:HARBIN INST OF TECH

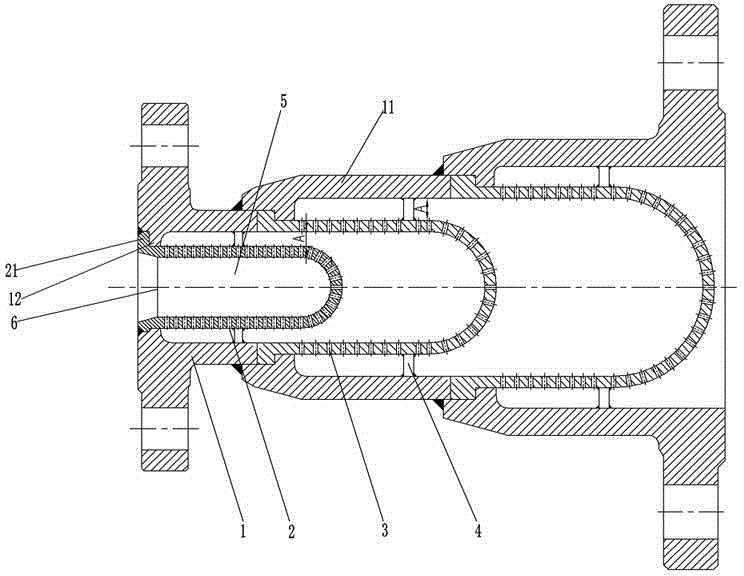

Capillary tube and evaporator connecting device and refrigerating device with same

The invention provides a capillary tube and an evaporator connecting device and a refrigerating device with same. The capillary tube and the evaporator connecting device, used for connecting the capillary tube with the evaporator, comprises a capillary tube connecting portion, an evaporator connecting portion and a transition portion between the two. The capillary tube connecting portion comprises a straight tube portion and an expansion portion, wherein the straight tube portion is connected with the transition portion, the expansion portion is connected with the straight tube portion, the inner diameter of the straight tube portion is smaller than the outer diameter of the capillary tube, a step is formed between the expansion portion and the straight tube portion, and the inner diameter of the expansion portion is equal to the outer diameter of the capillary tube. The refrigerating device comprises the capillary tube, the evaporator and the connecting device of the capillary tube and the evaporator. The refrigerating fluid can be smoothly transited from the smaller inner diameter of the capillary tube to the larger inner diameter of the evaporator tube, expansion noises caused by sudden change of the inner diameter of the tube and the fluid noises caused by block to the welding point can be avoided, thus the refrigerating device can work quietly.

Owner:HAIER GRP CORP +1

Technique method for manufacturing oriented silicon steel

ActiveCN106755843AReduce carbon contentAvoid stickingSolid state diffusion coatingFurnace typesInsulation layerNitrogen

The invention discloses a technique method for manufacturing oriented silicon steel. A full hard coil is subjected to decarburizing annealing so as to reduce the band steel carbon content; aluminum nitride is formed through nitrizing, and crystalline grains of steel are restrained from growing up; a magnesium silicate film is formed through magnesium oxide coating, and bonding between band steel is prevented; a magnesium oxide base layer and purified steel are formed through high-temperature annealing secondary recrystallization; and the band steel is subjected to insulation layer coating for eddy prevention and heat stretching leveling treatment, and the plate shape is more level. The obtained oriented silicon steel is more level in surface, stable in quality and high in percent of pass.

Owner:NINGBO YINGZHAN PRECISION SHEET

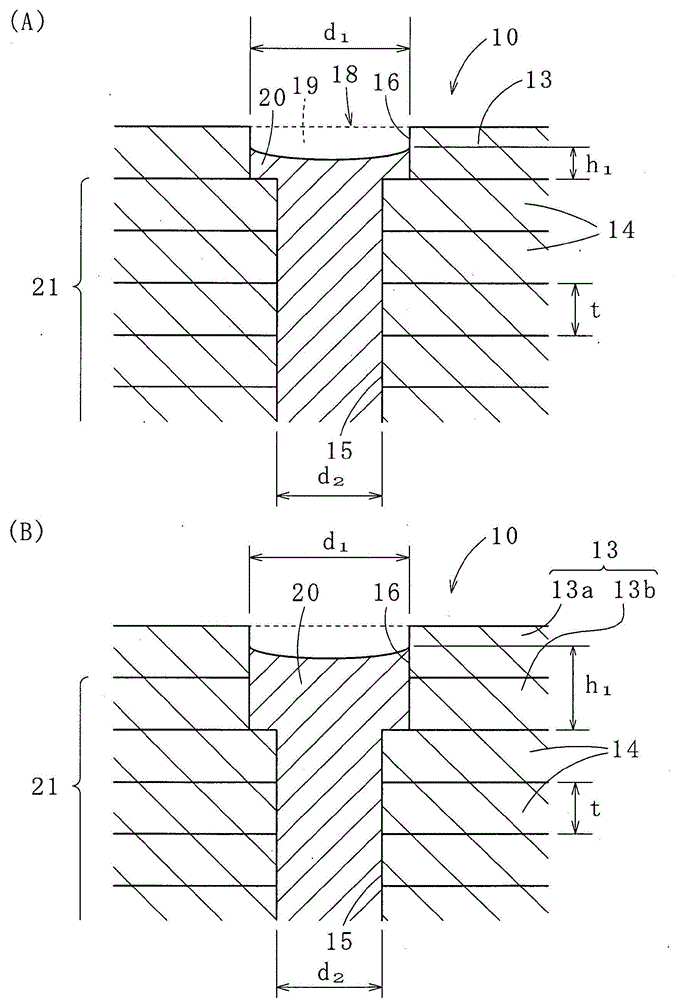

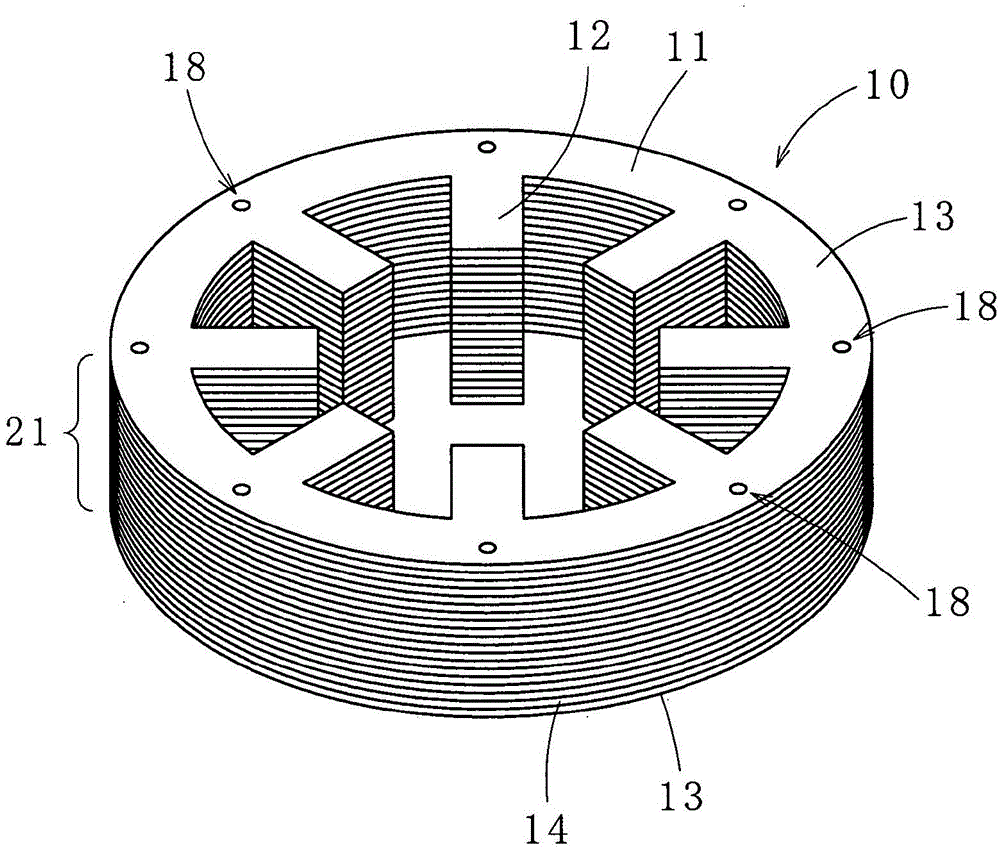

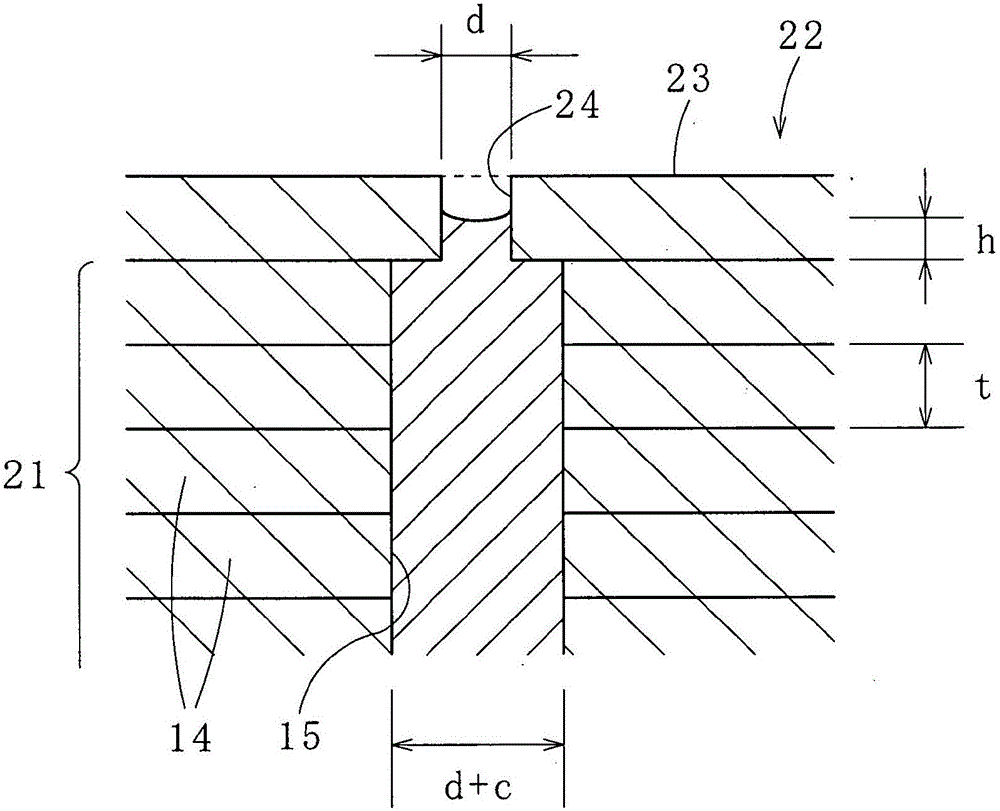

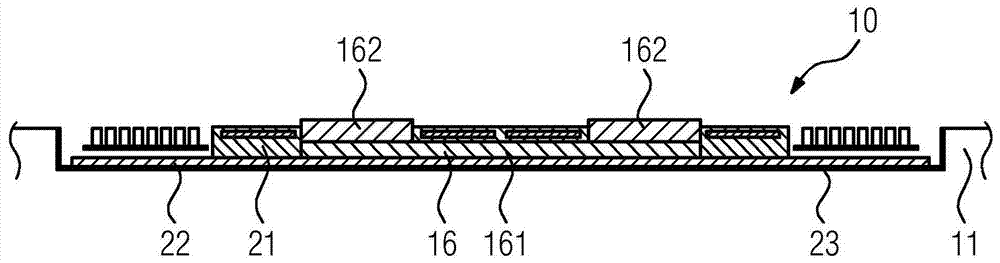

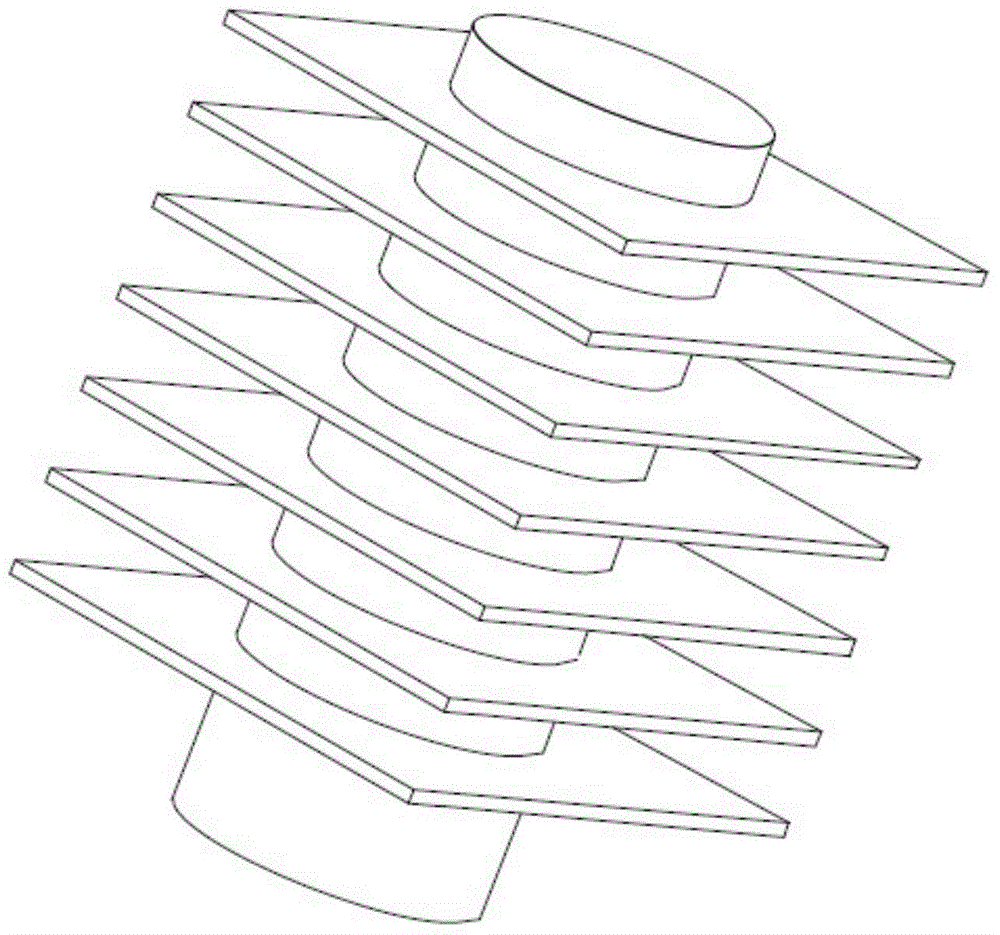

Laminated core and method for manufacturing the same

ActiveCN104578462AEnsure joint strengthPrevent peelingMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringUltimate tensile strength

A laminated core 10 including a plurality of laminated iron core pieces, each of the iron core pieces being connected in a laminating direction by filling resin in a plurality of resin holes penetrating the laminated core 10 in the laminating direction, and a method for manufacturing the laminated core 10, by making a junction area of an iron core piece (A) 13 and resin larger than a junction area of an iron core piece (U) 14 and resin, the iron core piece (A) 13 being provided on an end in an axial direction, the iron core pieces (U) 14 being arranged at positions other than the end in the axial direction, or by providing locking portions at tip portions of resin, acquired joint strength of the iron core piece (A) 13.

Owner:MITSUI HIGH TEC INC

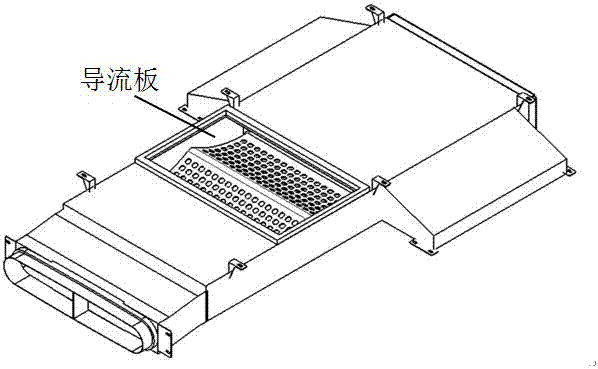

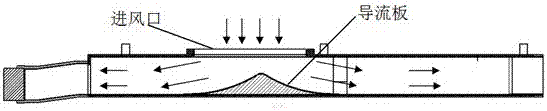

Air volume distribution structure for rail vehicle air supply passage

The invention discloses an air volume distribution structure for a rail vehicle air supply passage. The air volume distribution structure comprises a main air passage, the two sides of the main air passage are each provided with a plurality of air outlets, and a horizontally-arranged U-shaped plate is arranged in the main air passage. The upper end and the lower end of the U-shaped plate are attached to the pipe walls of the top and the bottom of the main air passage correspondingly, the opening end face of the U-shaped plate points to one end of the main air passage, each of the two sides of the U-shaped plate and the main air passage constitute a side air passage, and an air inlet is formed in the top, located at the closed end of the U-shaped plate, of the main air passage. Two symmetrically-arranged flow guiding plates are arranged on the position, located in front of the opening end of the U-shaped plate, of the main air passage and correspond to two side plates of the U-shaped plate correspondingly. A notch is formed between the two flow guiding plates, and an air flow in the U-shaped plate is distributed to flow into the side air passages of the two sides and the main air passage behind the flow guiding plates, through the two flow guiding plates and the notch between the flow guiding plates. According to the air volume distribution structure for the rail vehicle air supply passages, through the passages formed by the U-shaped plate and the main air passage, the strong air flow entering from an air inlet is buffered, and through flow distribution of the flow guiding plates, noise of the air flow is further reduced.

Owner:CRRC NANJING PUZHEN CO LTD

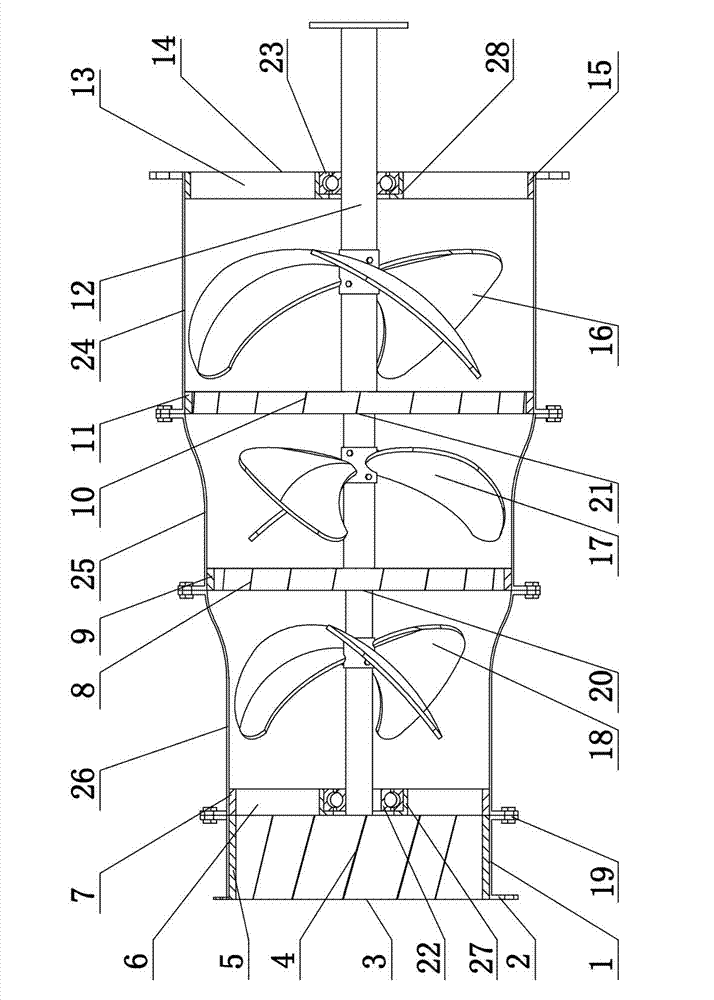

Narrow tube wind gathering power generation centrifugal wind power engine

InactiveCN102808723AImprove playbackEliminate turbulenceMachines/enginesWind energy generationPressure-gradient forceDynamic balance

The invention discloses a narrow tube wind gathering power generation centrifugal wind power engine which relates to a comprehensive discipline theory of inertial centrifugal effects, centripetal force, dynamic balance, pressure gradient force, viscous force, blade molding, spiral wind attitude causes, turbine effects and the like and a major core technology and belongs to the technical field of the narrow tube wind gathering power generation centrifugal wind power engine. The narrow tube wind gathering power generation centrifugal wind power engine comprises a butt barrel, a front flange, a fluid inlet, a regulating plate A, a fixing ring A, a strutting piece A, an annular ring A, a regulating plate B, a fixing ring B, a regulating plate C, a fixing ring C, a stepped shaft, a strutting piece B, a wind drain channel, an annular ring B, a blade C, a blade B, a blade A, a butt flange, a radial ring A, a radial ring B, a bearing A, a bearing B, a shell A, a shell B, a shell C, a shaft seat A, and a shaft seat B.

Owner:WUXI C SOLAR NEW ENERGY TECH

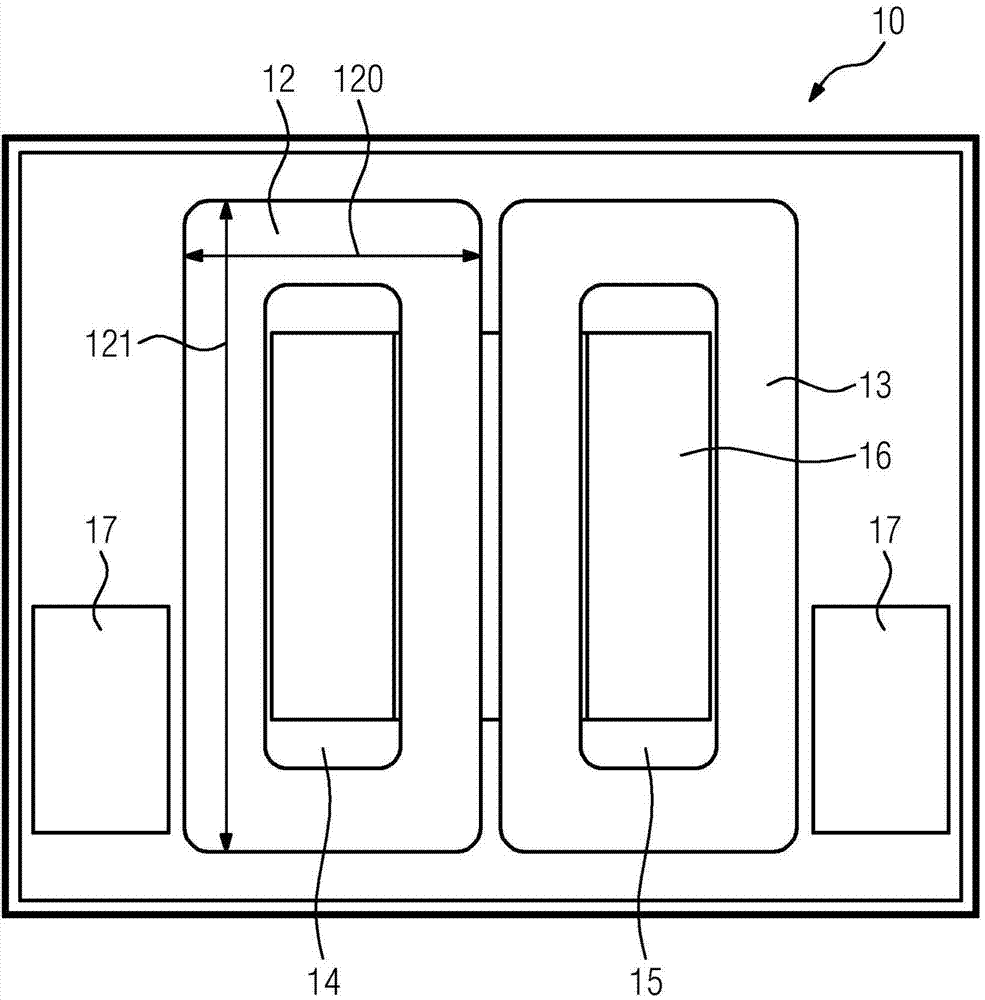

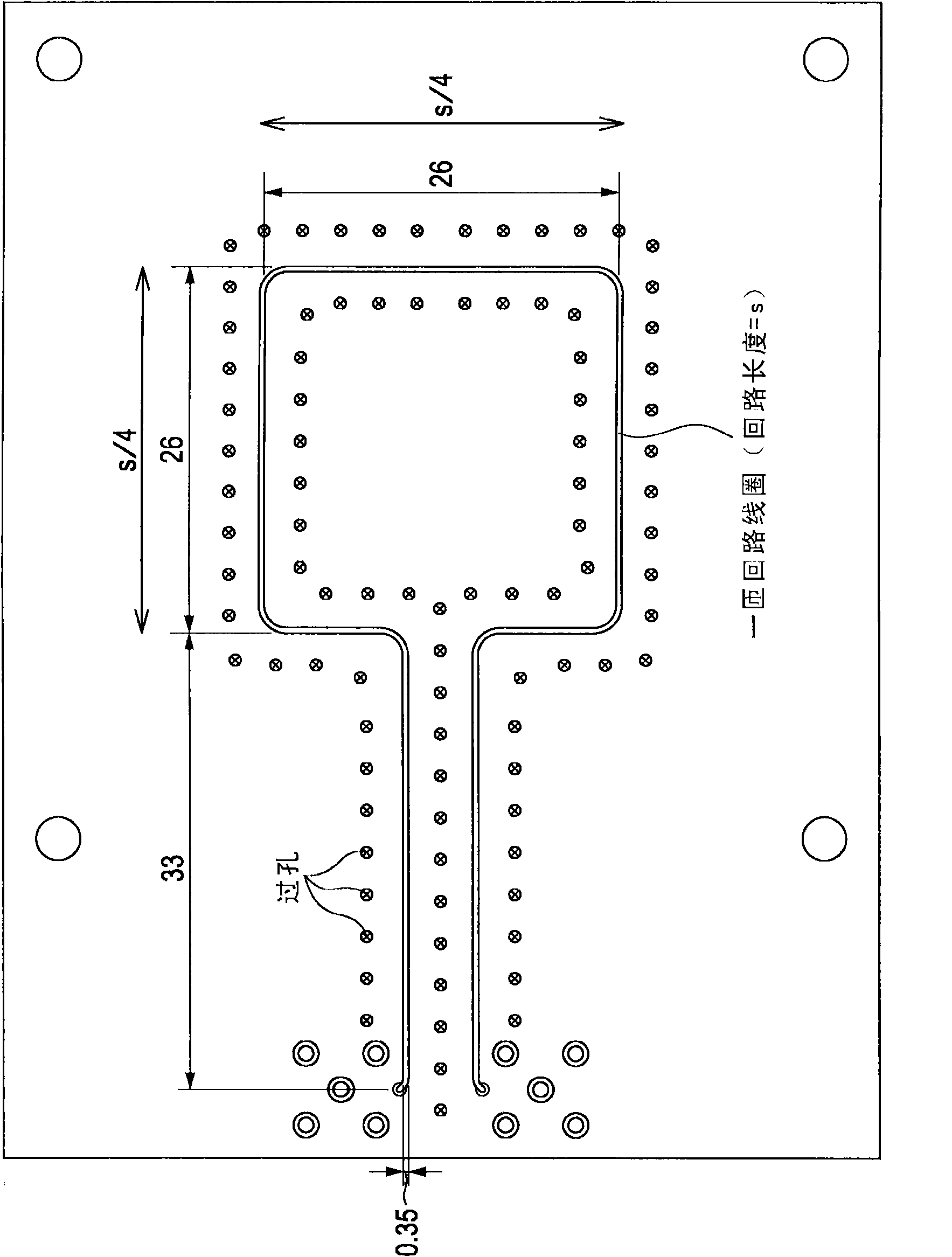

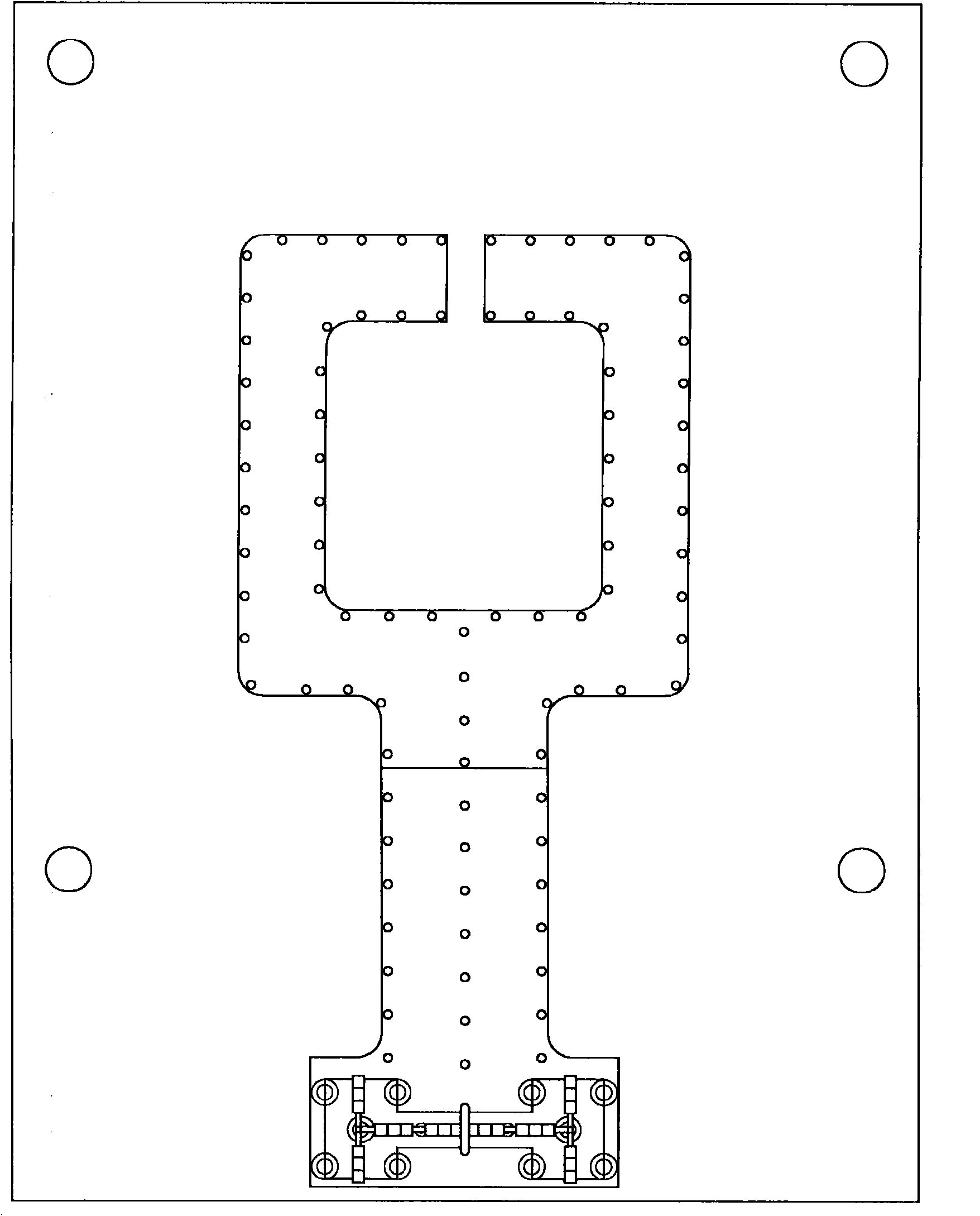

Charging configuration for the inductive wireless emission of energy

InactiveCN104518572AImprove compatibilityAvoid vortexCharging stationsElectromagnetic wave systemElectrically conductiveReceiver coil

A charging configuration for the inductive wireless transfer of energy to a receiver coil of an electrically operated vehicle. The charging configuration includes a first circularly wound electrically conductive coil extending in a plane and having a first central opening in the center of the first coil. A second circularly wound electrically conductive coil also extends in a plane and has a second central opening in its center. A U-shaped ferrite core is fashioned with a flat plate disposed below the coils and with a first and second leg portion connected to the plate. The leg portions are fashioned as rectangular panels. The first leg portion penetrates the first central opening and the second leg portion penetrates the second central opening.

Owner:SIEMENS AG

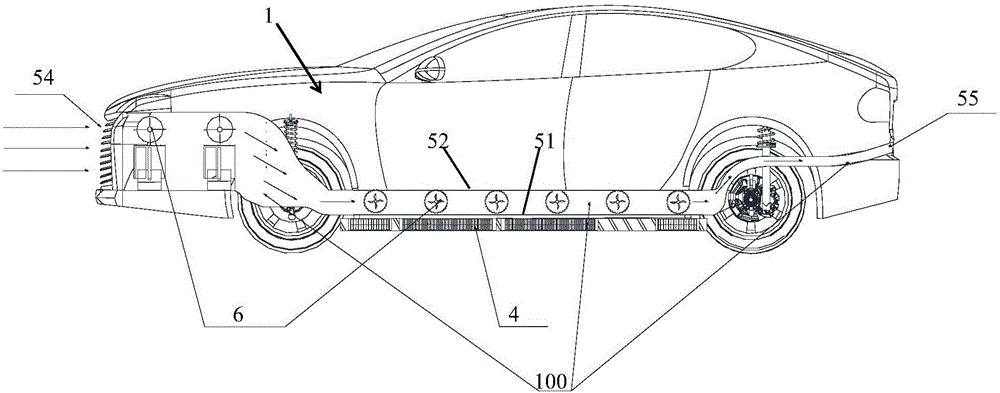

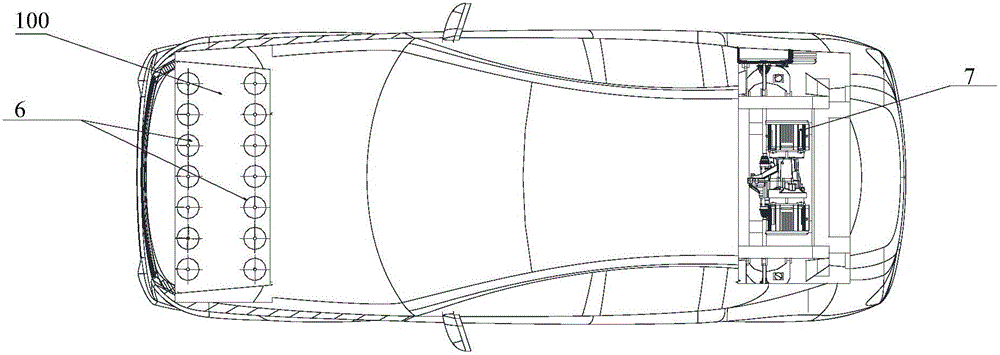

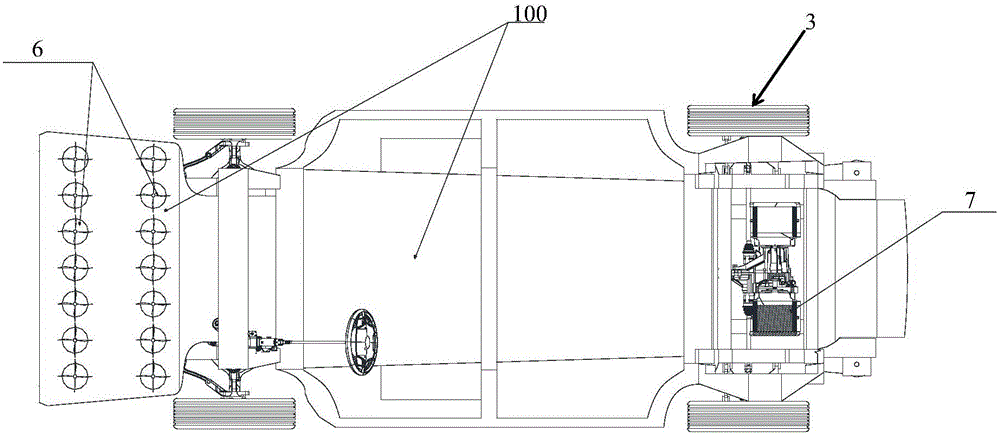

Electric automobile carrying wind power generation system

PendingCN105751889AImprove battery lifeLower center of gravityAuxillary drivesVehicular energy storageWind power systemTurbine

The invention discloses an electric automobile carrying a wind power generation system.The electric automobile comprises an automobile body, a chassis and wheels.A storage battery, a wind turbine generator system and an airway system are arranged above the chassis.The airway system comprises an airway lower plate part installed above the chassis of the electric automobile, an airway upper plate part located above the airway lower plate part, and side plate parts connected with the two ends of the airway upper plate part and the two ends of the airway lower plate parts in the width direction.A containing cavity with openings in the two ends in the length direction is formed by the airway upper plate part, the airway lower plate part and the side plate parts together.The opening in one end of the containing cavity is an air inlet, and the opening in the other end of the containing cavity is an air outlet.An airway is formed between the air inlet and the air outlet.The sectional area of at least one part, in the direction in which the air inlet extends to the air outlet, of the airway tends to decrease.Due to the adoption of the technical scheme, the inner space of the automobile body can be reasonably used, and caught wind can be efficiently used in channels.

Owner:GUIZHOU HENGJIN TECH CO LTD

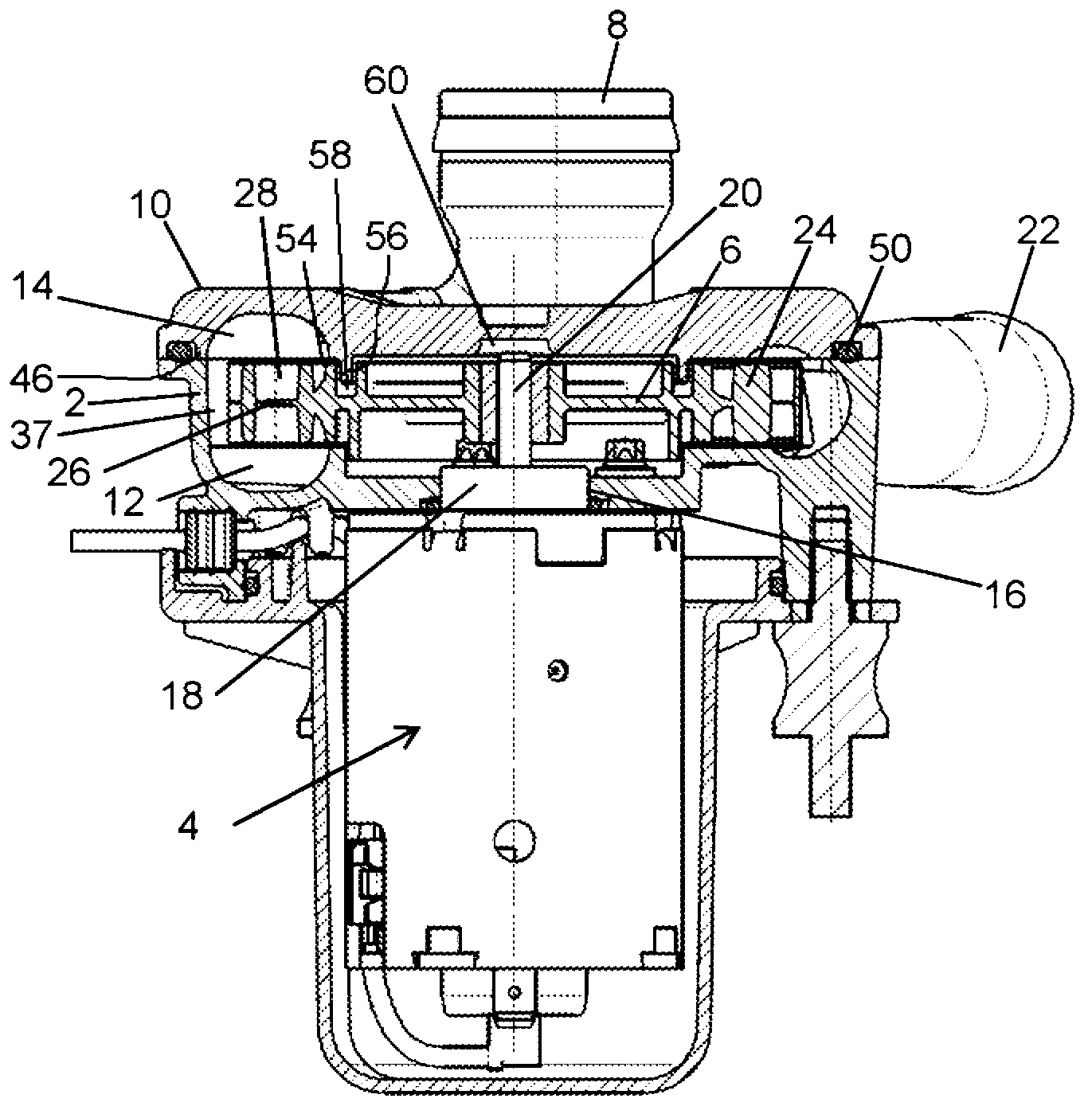

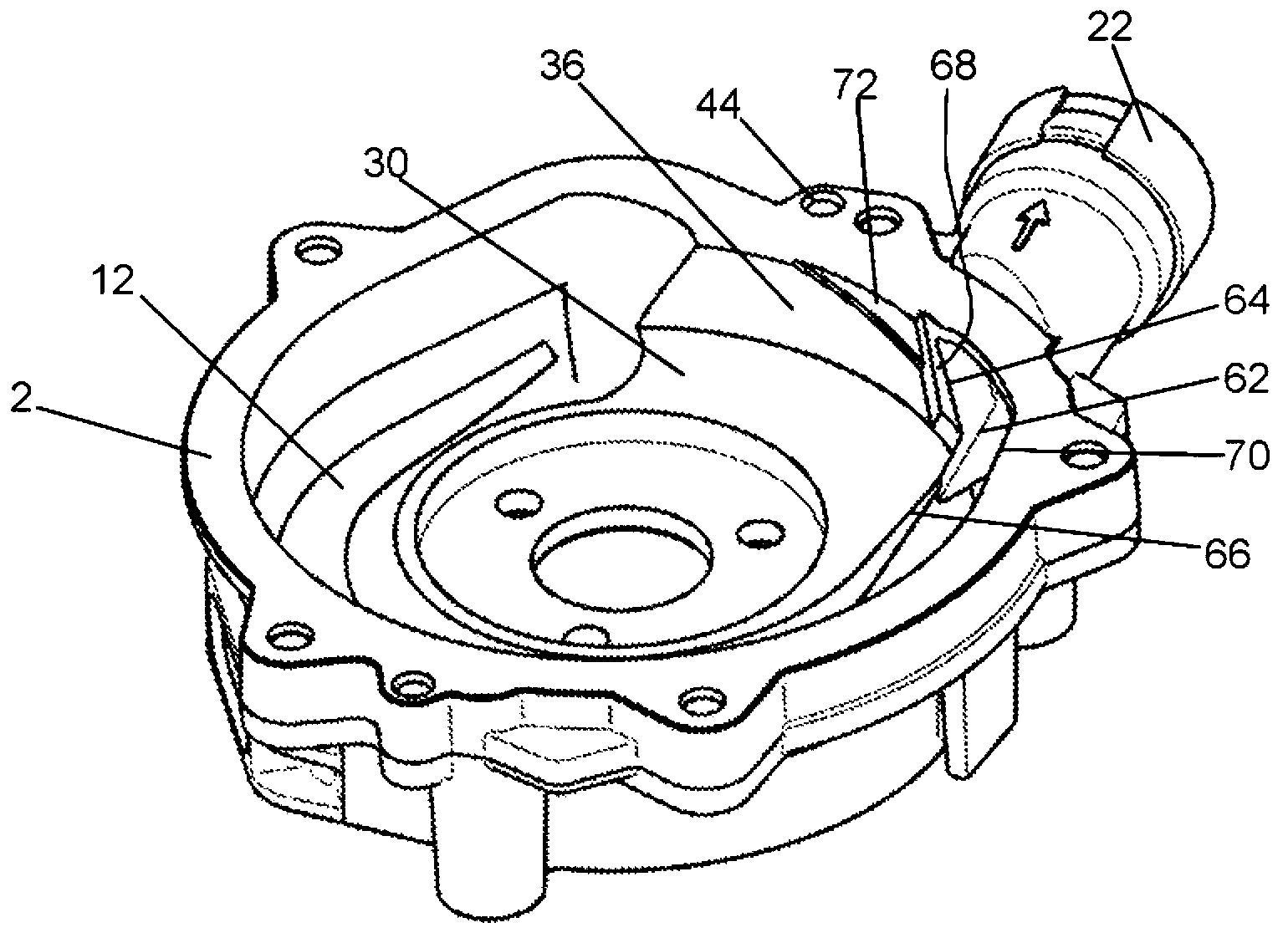

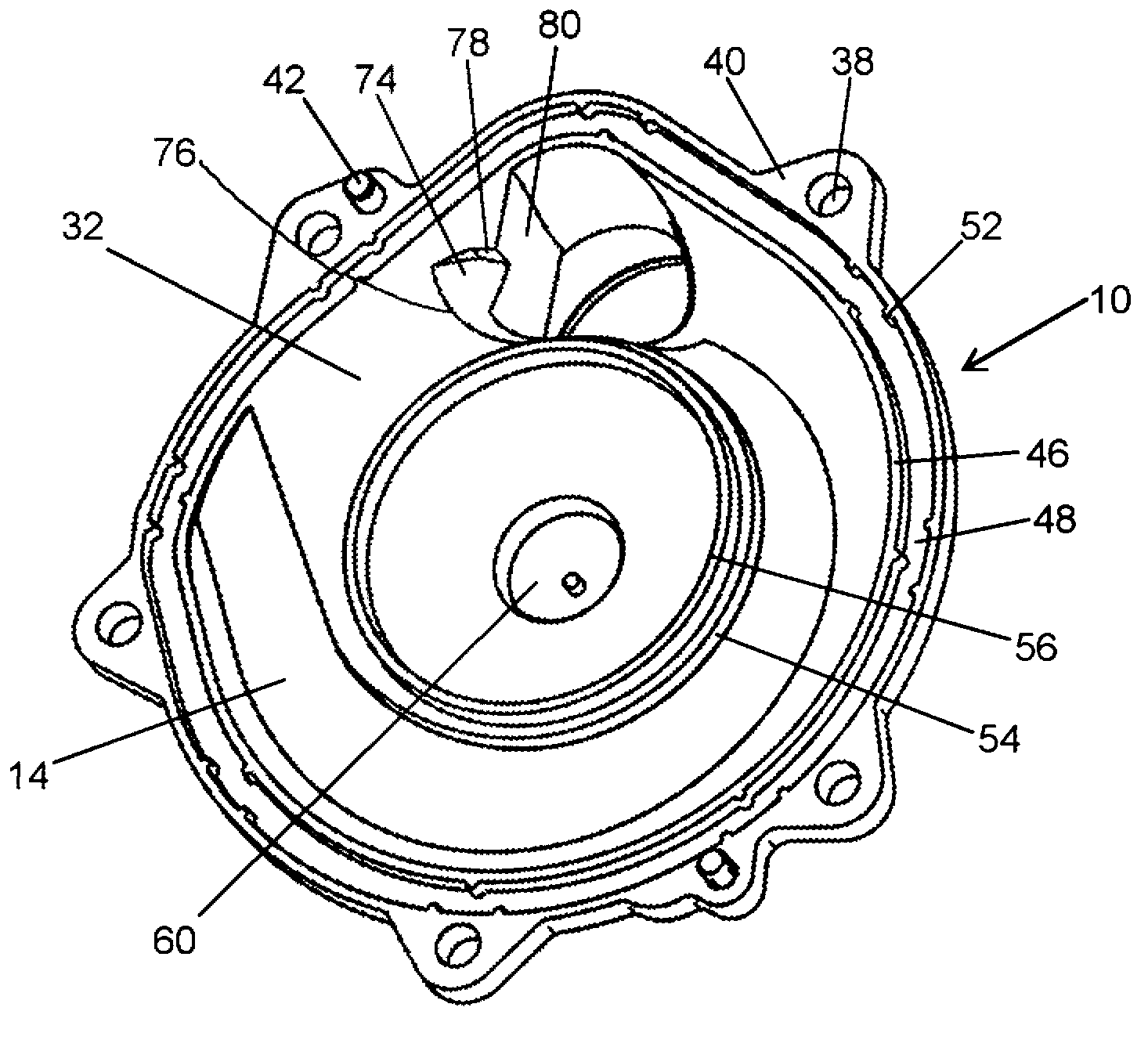

Side channel blower, in particular a secondary air blower for an internal combustion machine

ActiveCN103154523ALow emission valueReduce depthPump componentsRotary non-positive displacement pumpsCombustionEngineering

Side channel blowers having devices for minimizing noise emissions are known that do not, however, sufficiently reduce noise when the control valve is closed. The invention therefore proposes a side channel blower, in which further recesses (72, 64) are formed in the interruption region (32, 34) before the inlet (8) and after the outlet (22), the smallest distance therebetween being 0.5 to 3 times the distance between two conveying blades (26). Such an embodiment achieves further noise reduction, even when the control valve is closed, without reducing the maximum flow rate.

Owner:PIERBURG GMBH & CO KG NEUSS

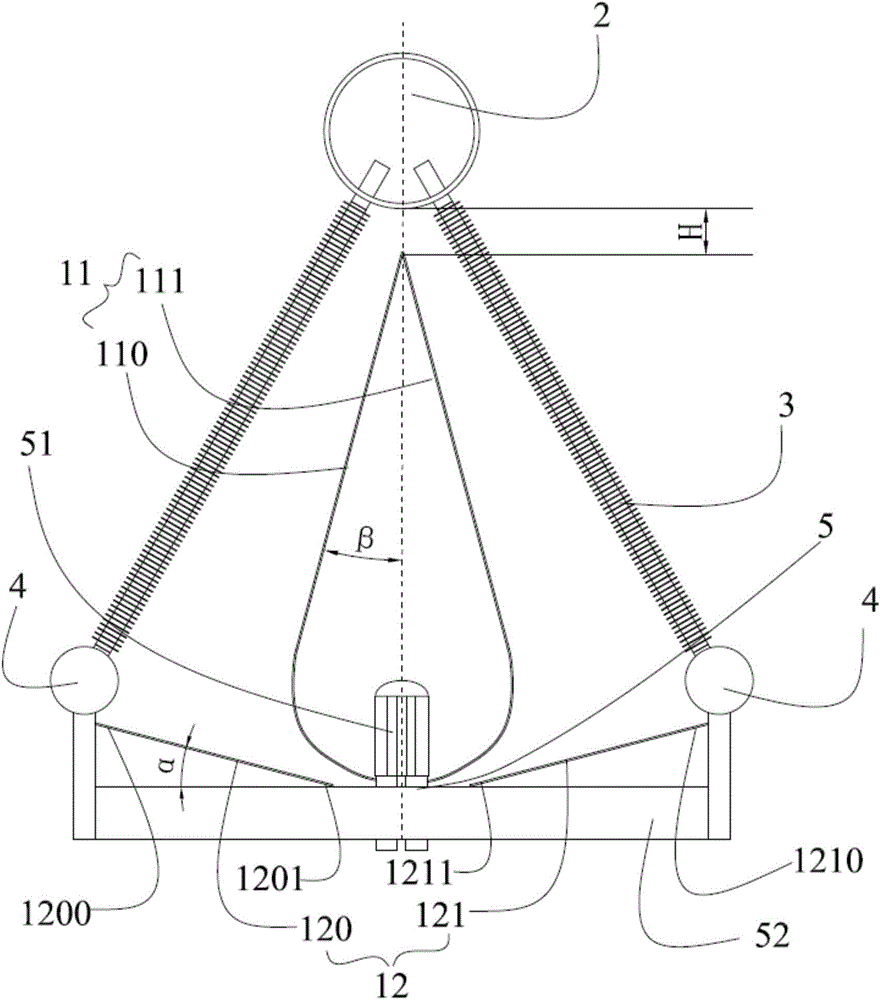

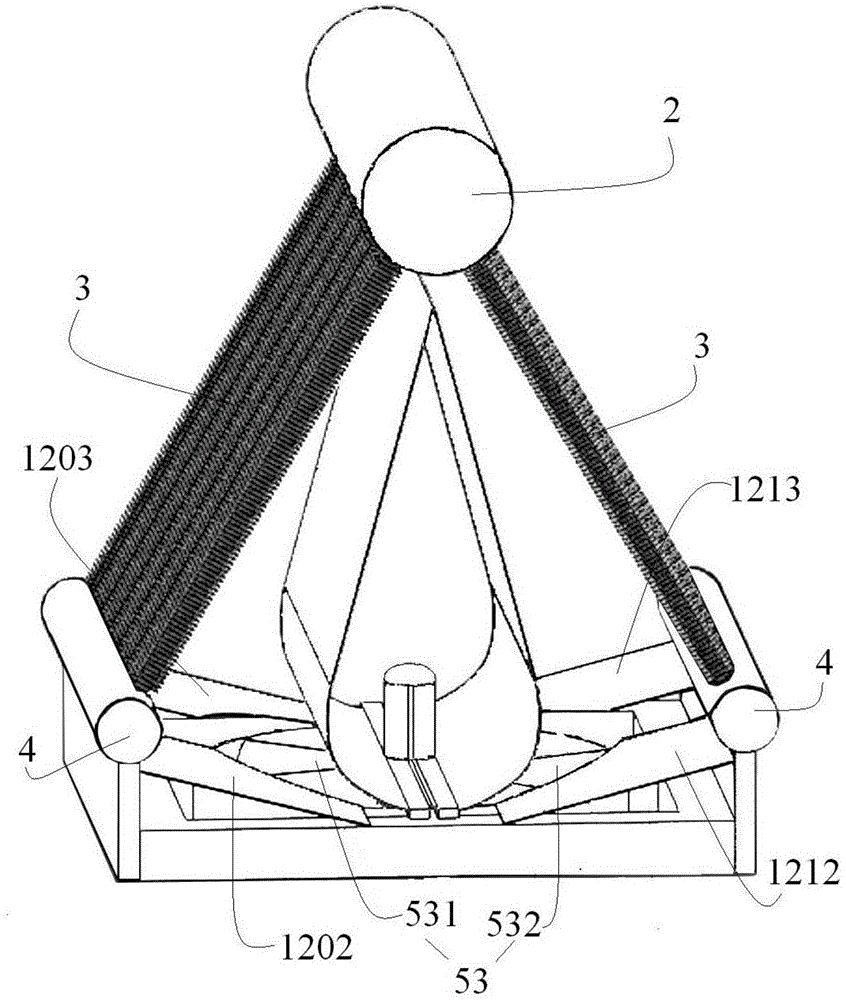

Flow guide device for air-cooled unit with Delta-shaped passage spaces

The invention discloses a flow guide device for an air-cooled unit with a Delta-shaped passage spaces. The air-cooled unit comprises a steam distribution pipe, downwards-inclined air-cooled finned tube bundles connected with the two sides of the steam distribution pipe respectively, condensate water pipes connected with the lower ends of the air-cooled finned tube bundles and an air-cooled fan arranged below the air-cooled finned tube bundles, wherein the air-cooled fan is fixedly arranged below the air-cooled finned tube bundles through an air-cooled fan frame; the steam distribution pipe, the air-cooled finned tube bundles, the condensate water pipes and the air-cooled fan enclose the Delta-shaped passage space. The flow guide device comprises a top flow guide mechanism arranged on the middle part of the Delta-shaped passage space and a bottom flow guide mechanism arranged at the bottom of the Delta-shaped passage space, wherein e top end of the top flow guide mechanism is at a certain distance far away from the bottom end of the steam distribution pipe; the bottom end of the top flow guide mechanism is connected with the air-cooled fan frame; the top flow guide mechanism and the bottom flow guide mechanism are integrated or independent. According to the scheme, cooling effects of the air-cooled unit are improved, and the cooling performance of a direct air-cooled system is improved.

Owner:GUODIAN LONGYUAN POWER TECH ENG

Low-voltage cable intermediate joint cold contraction technology

ActiveCN103337813AIncrease elasticityAvoid thermal expansion and contractionApparatus for joining/termination cablesSocial benefitsLow voltage

The invention belongs to the technical field of electric power, and especially relates to a low-voltage cable intermediate joint cold contraction technology, which can remedy defects such as coarse original material, poor insulation performance and sealing performance, weak tolerance mechanical strength, and easily getting heated and burnt of a 0.4kV low-voltage cable intermediate joint and significantly improve equipment safety running coefficients. The low-voltage cable intermediate joint cold contraction technology fundamentally helps to reduce fault probability of the 0.4kV low-voltage cable intermediate joint. The use of the new technology and the material provide effective technical support for personal safety and equipment safety, and at the same time helps electric power enterprises to save a large amount of maintenance funds, not only promotes increase of profits of the electric power enterprises but also achieves huge social benefit due to stable and continuous power supply.

Owner:STATE GRID CORP OF CHINA +1

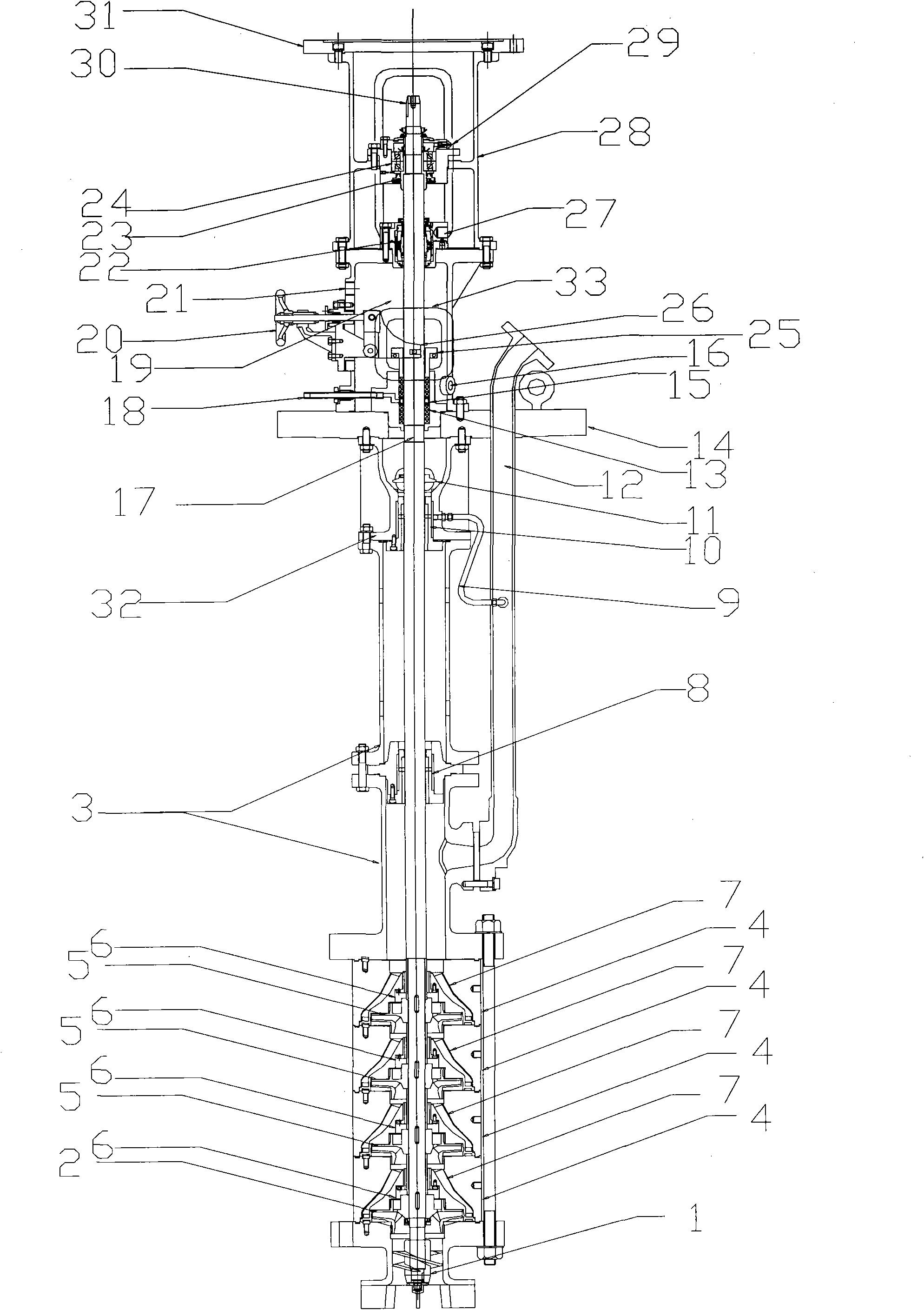

Multi-stage axial flow submerged pump with long shaft and method for conveying phosgene

InactiveCN102062107AExtended use timeExtended service lifeSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a multi-stage axial flow submerged pump with a long shaft and a method for conveying phosgene, which are mainly used for pressurizing and conveying the phosgene or chlorine gas. The submerged pump is provided with an inducer (1), a primary impeller (2), a secondary impeller (5), an auxiliary sliding bearing and shaft sleeve (6), a lower main sliding bearing and shaft sleeve (8), an upper main sliding bearing and shaft sleeve (10), a seal cavity (19) and a bearing bracket (28). The lower end of a packing box (13) is provided with an emergency seal rubber pneumatic bag (17); a double-end face mechanical seal (22) is sleeved on a pump shaft (30); a radial balancing hole (37) is arranged on the impeller; and the auxiliary sliding bearing and shaft sleeve (6) is made from silicon carbide. When both of the mechanical seal and the packing seal become invalid, high pressure nitrogen gas ensures that the emergency seal rubber pneumatic bag (17) is inflated to clasp the shaft so as to quickly block leakage of the conveyed phosgene.

Owner:甘肃银光聚银化工有限公司 +1

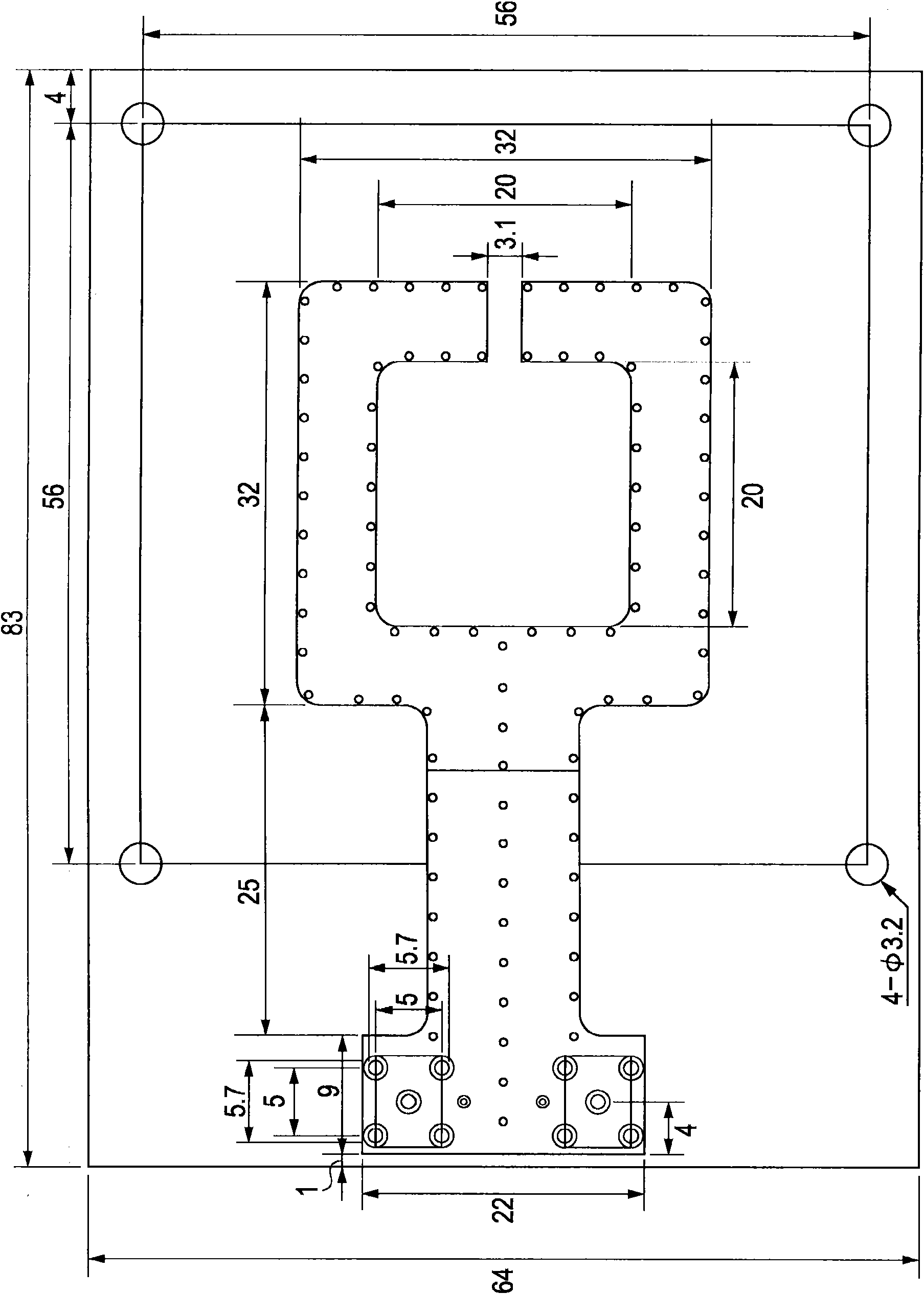

Communication device, antenna device, and communication system

ActiveCN101901369AAppropriate executionSuppresses the influence of interference wavesLoop antennas with ferromagnetic coreAntenna arraysElectrical conductorCommunications system

The invention relates to a communication device, an antenna device and a communication system. A communication device includes a conductor plane, a first loop antenna disposed on one surface of the conductor plane via a first magnetic sheet, a second loop antenna being in a loop direction opposite to a loop direction of the first loop antenna and having an opening structure approximately identical in shape to the first loop antenna, the second loop antenna being disposed on another surface of the conductor plane via a second magnetic sheet so as to be roughly superposed on the first loop antenna, and a communication circuit processing a communication signal transmitted and received by the first and second loop antennas.

Owner:SONY CORP

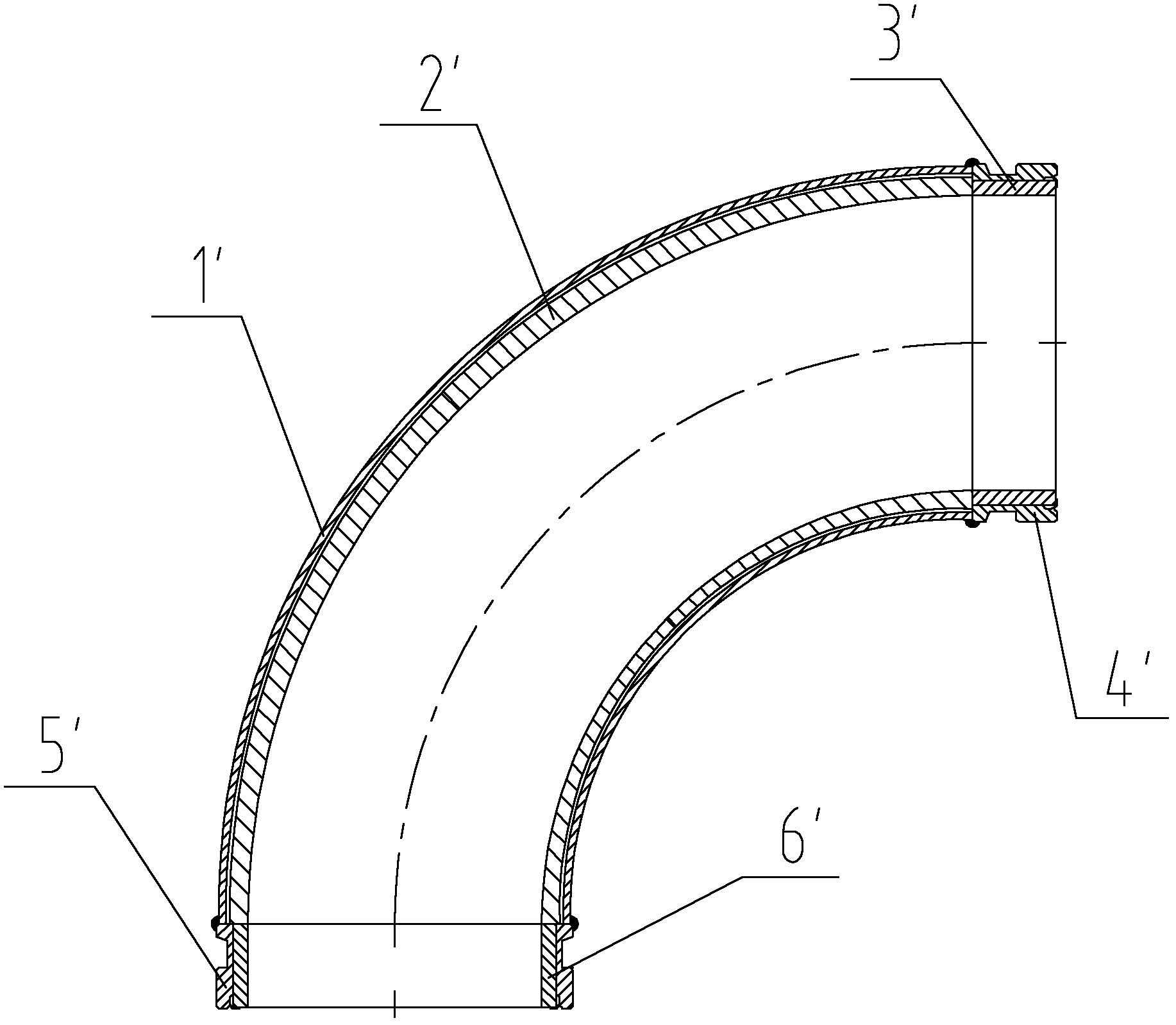

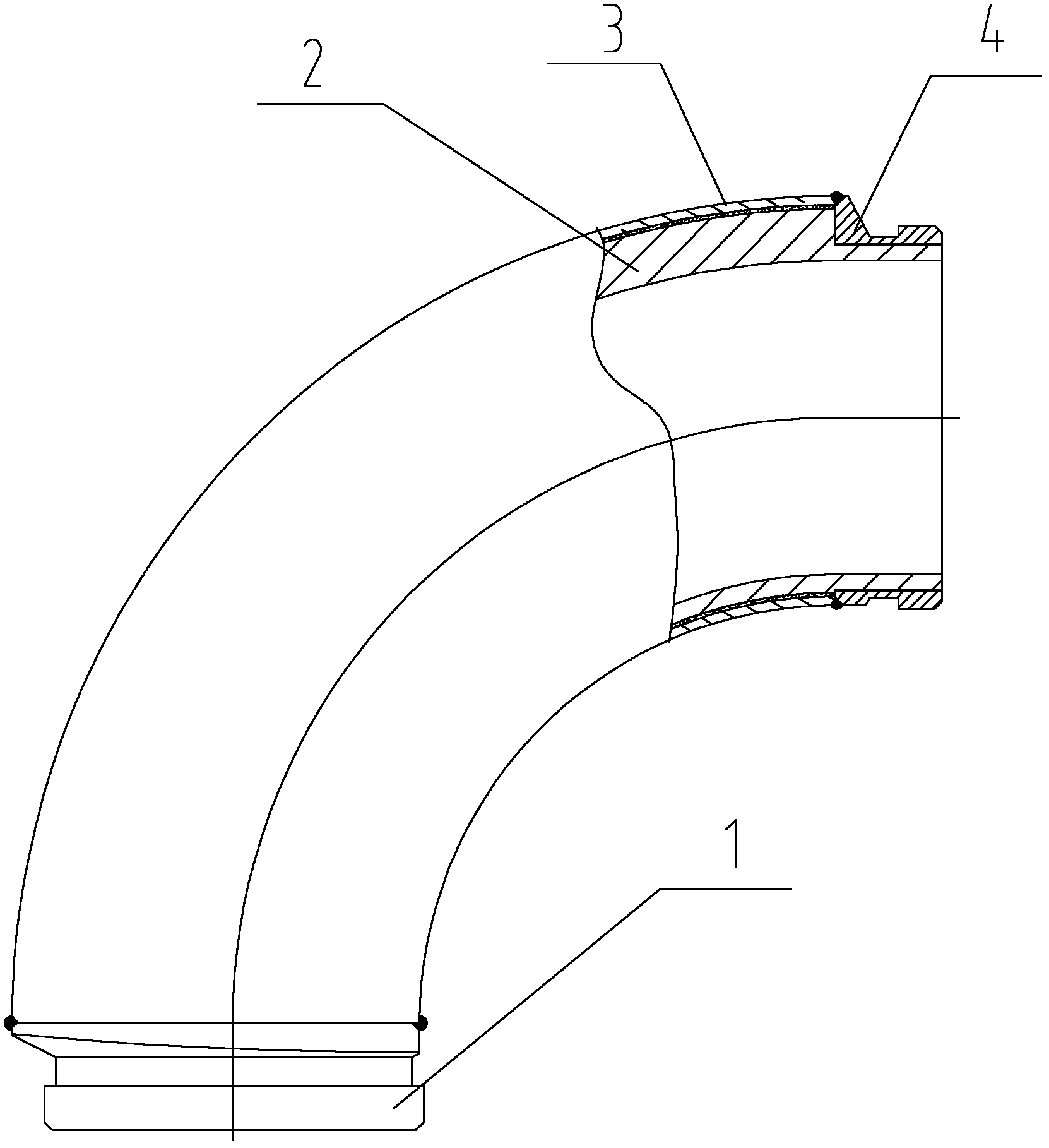

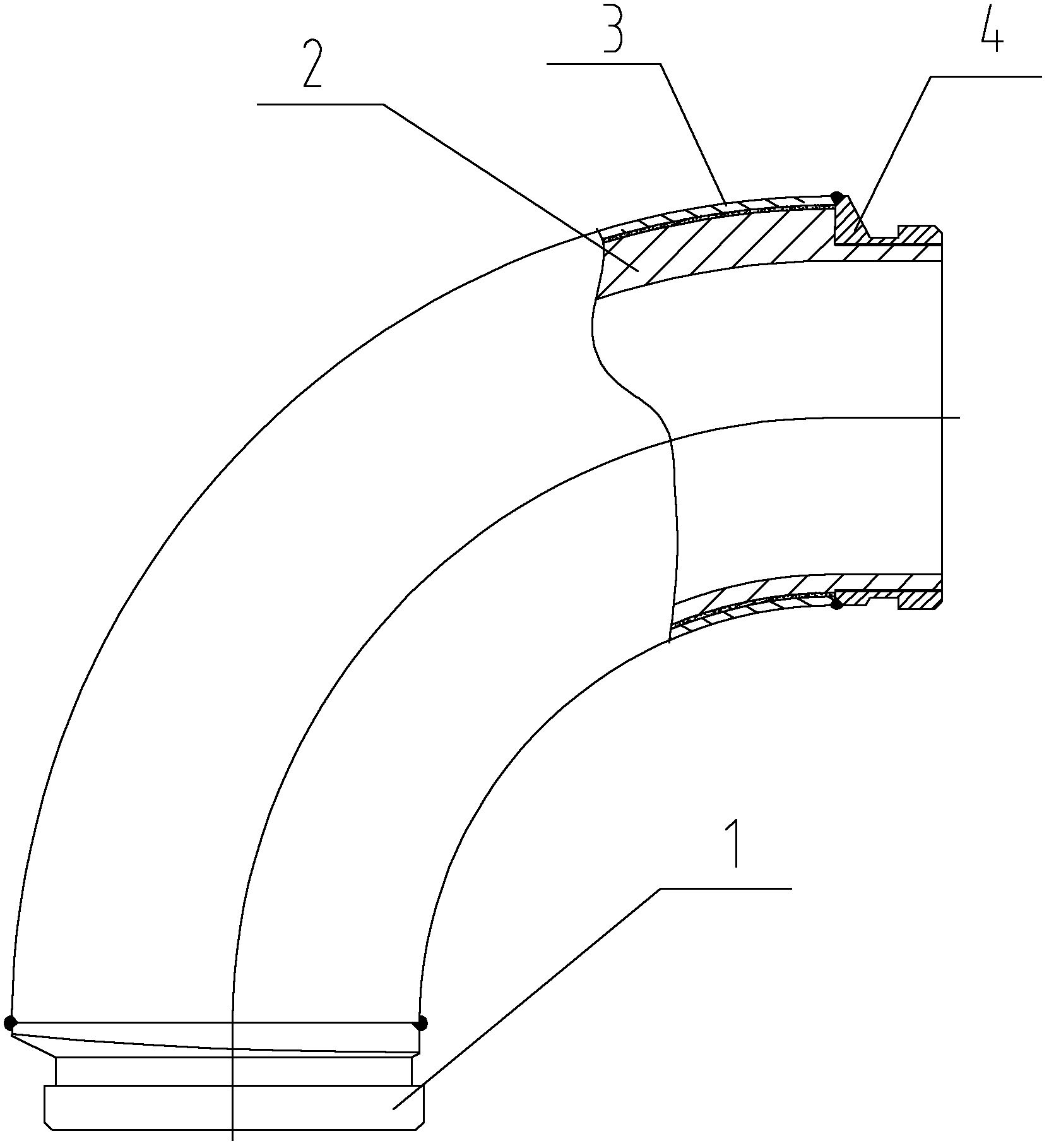

Delivery elbow pipe and production method thereof

InactiveCN102494218AReduce pressure sleeve processAvoid vortexPipe protection against damage/wearSiphonsCavitationEngineering

The invention provides a delivery elbow pipe and a production method thereof. The delivery elbow pipe comprises an outer elbow pipe (3), an inner elbow pipe (2) and a connecting flange, wherein the inner elbow pipe (2) is made of abrasion resisting materials and embedded inside the outer elbow pipe (3), at least one end of the inner elbow pipe (2) extends out of the outer elbow pipe (3) from the end portion of the outer elbow pipe (3), and the connecting flange is sleeved on the outer side of the end portion of the inner elbow pipe (2) and fixedly connected with the inner elbow pipe (2) and / or the outer elbow pipe (3). By means of the delivery elbow pipe, an abrasion resisting material layer integrally formed by the inner elbow pipe is free of seam, so that the delivery elbow pipe is capable of avoiding eddy caused in the position of the seam in the prior art and removing cavitation caused by the eddy accordingly.

Owner:ZOOMLION HEAVY IND CO LTD

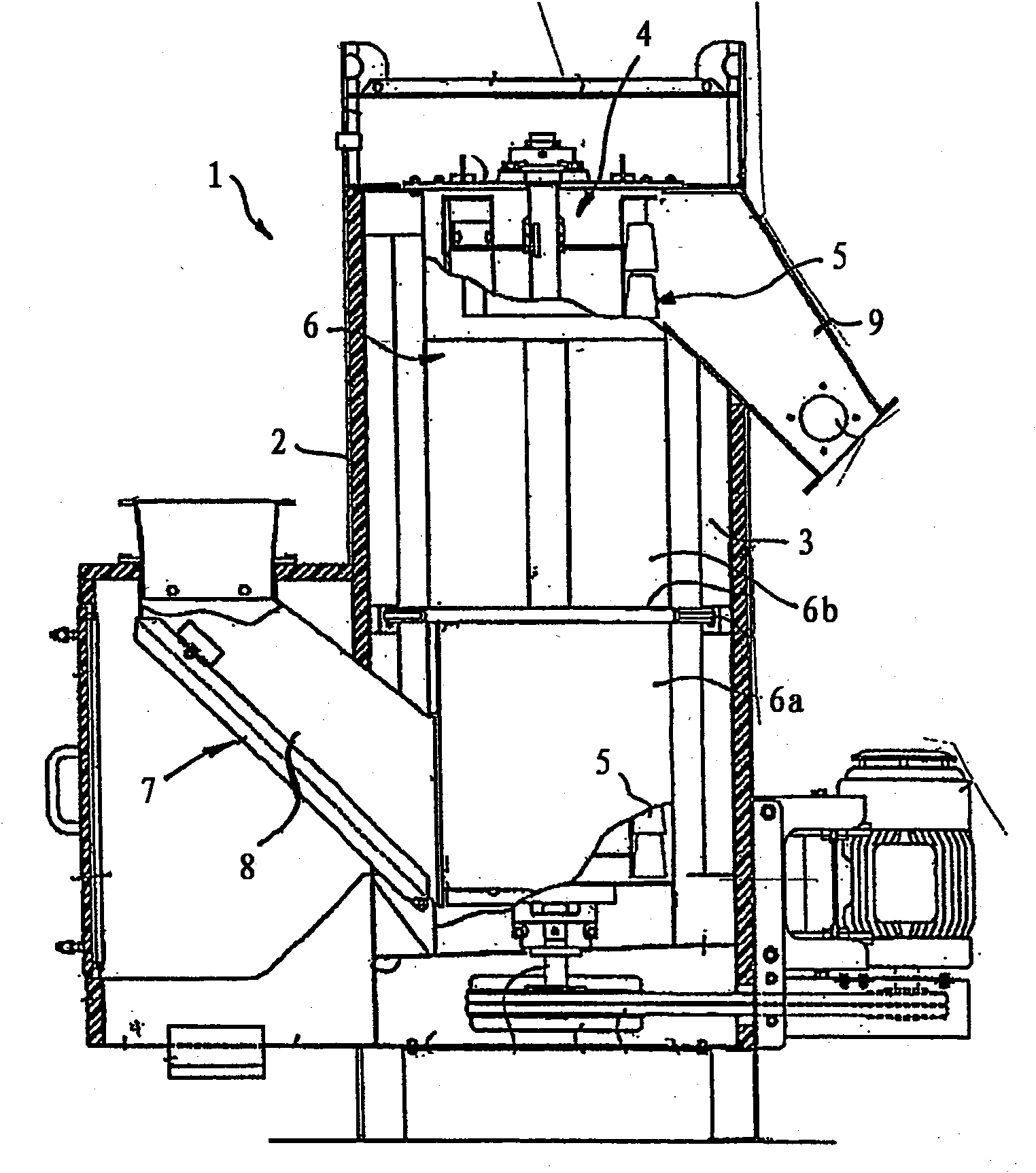

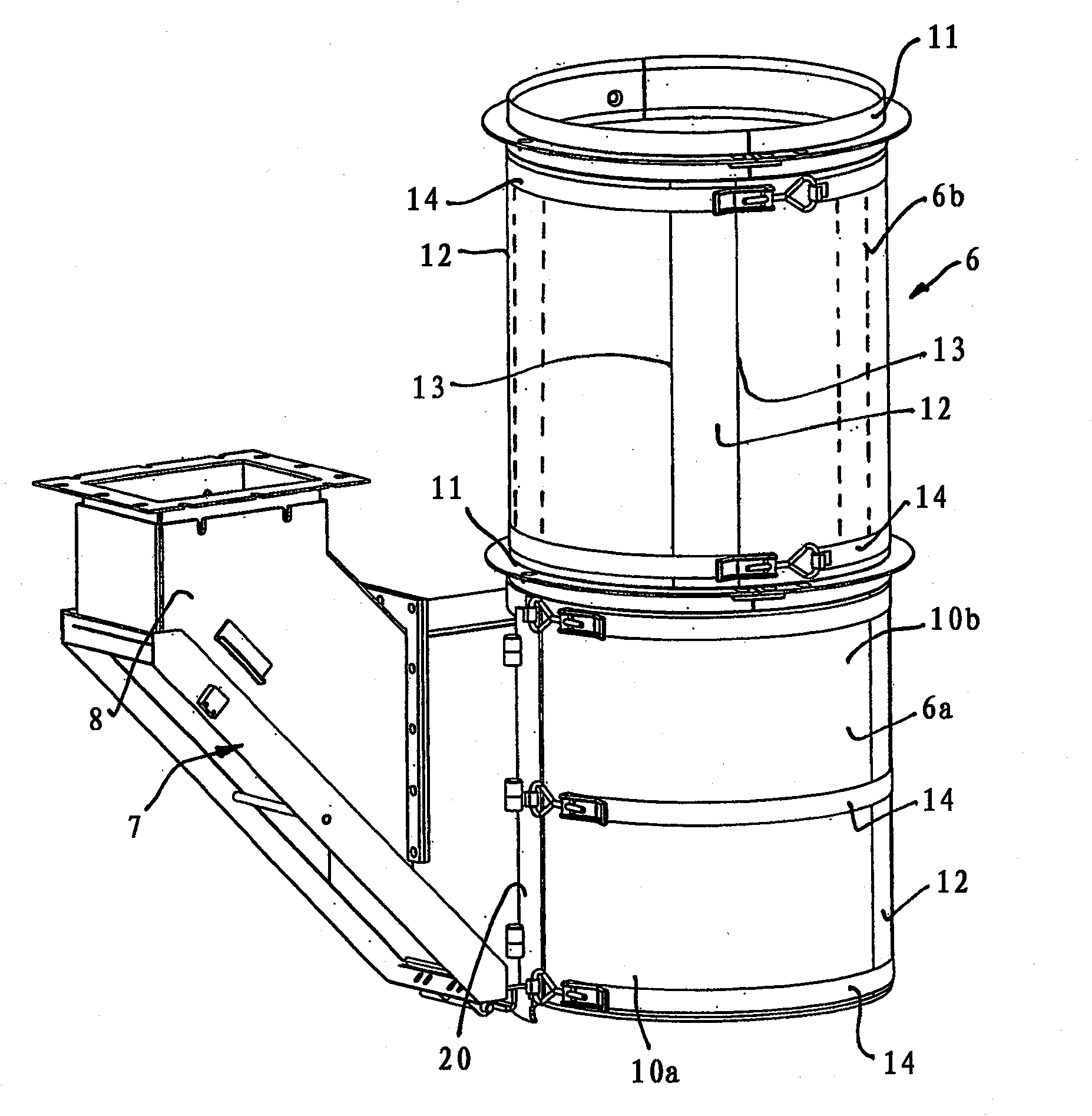

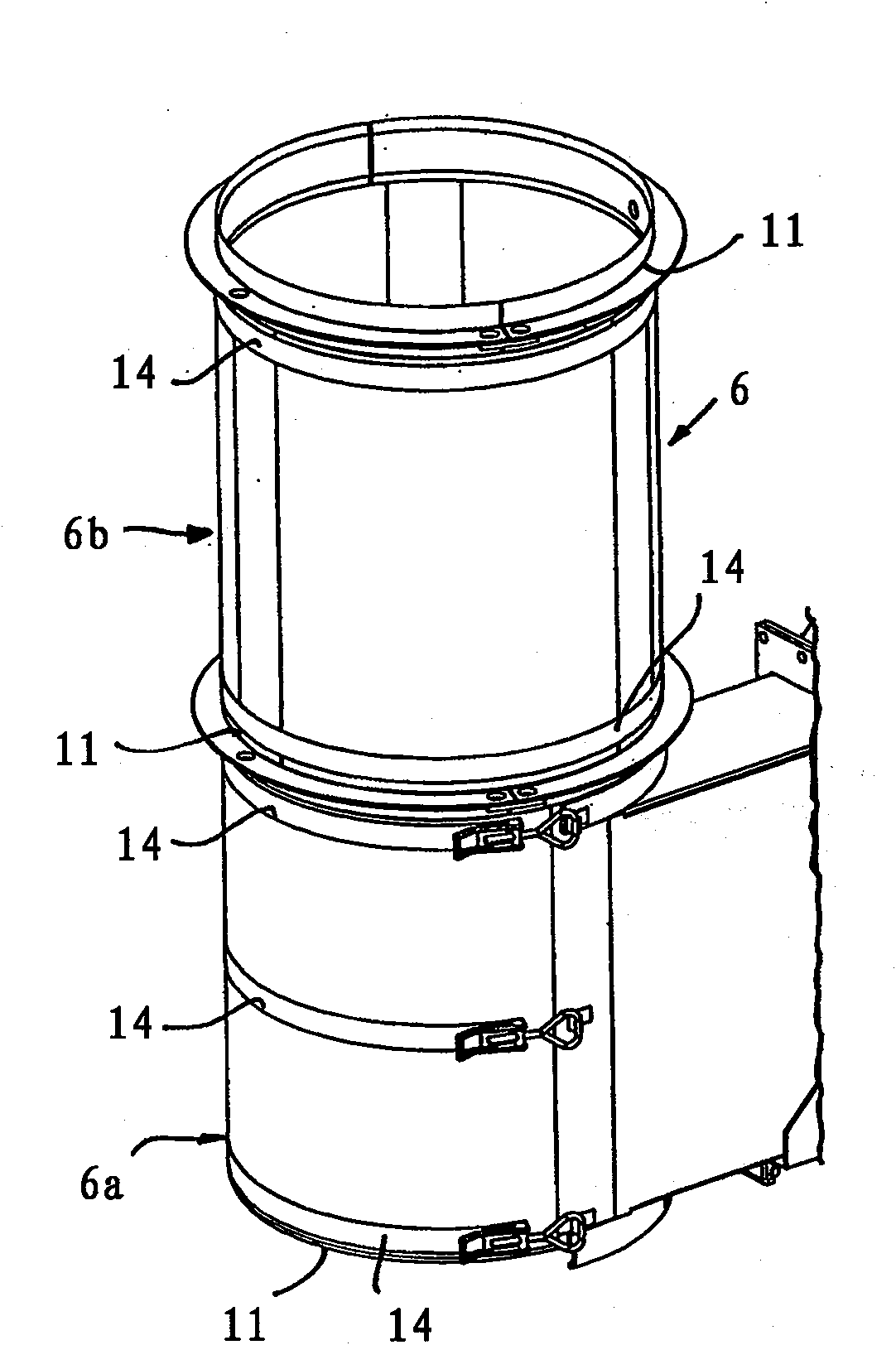

Centrifugal drier

ActiveCN101675312ANo sealing problemsPrevent slippageDrying solid materials without heatCentrifugesEngineeringMechanical engineering

Owner:GALA INDUSTRIES INC

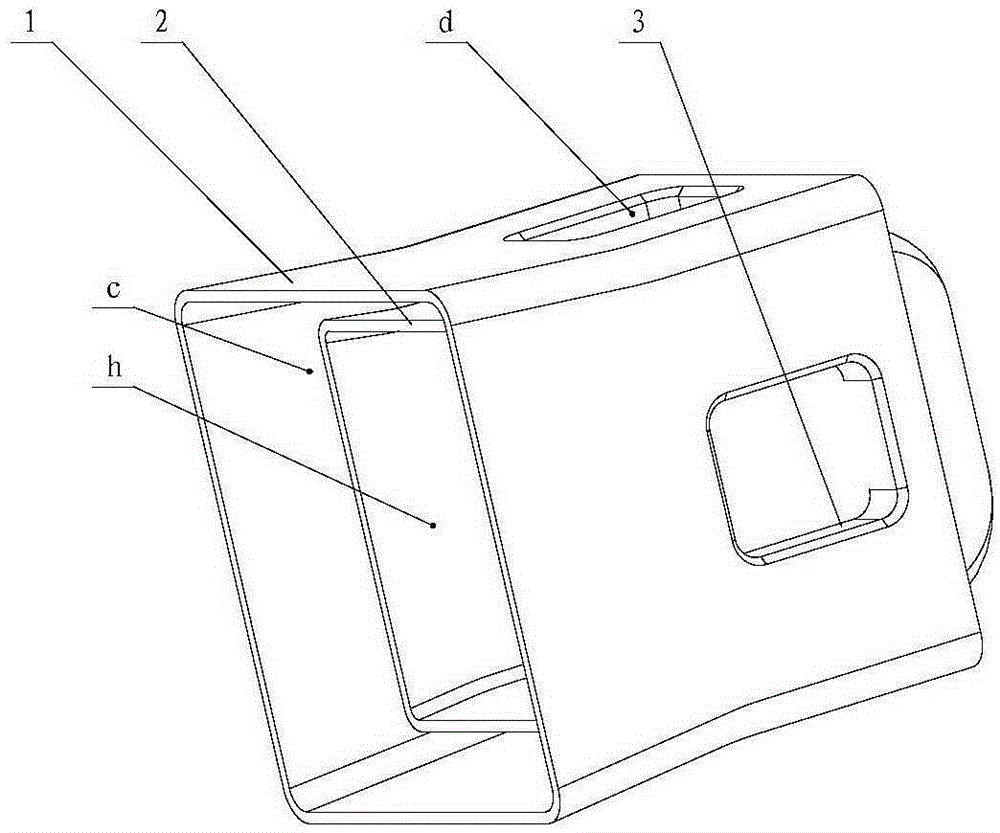

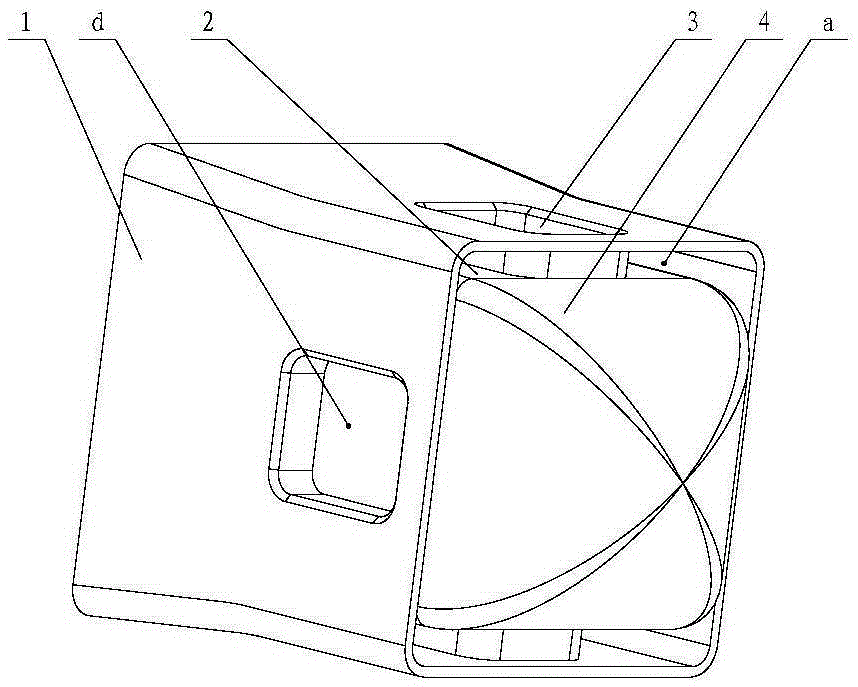

Nozzle structure, fresh air exchange device and air conditioner

InactiveCN105258312ASolve problems that are prone to uncomfortable symptomsAvoid vortexDucting arrangementsAir-flow control membersFresh airEngineering

The invention relates to the technical field of air conditioning, in particular to a nozzle structure, a fresh air exchange device and an air conditioner. The nozzle structure comprises an outer cylinder, an inner cylinder and an air guide channel; the outer cylinder sleeves the inner cylinder; since the outer cylinder sleeves the inner cylinder and the back end of the inner cylinder is sealed, high-speed air flow can pass through the space between the outer cylinder and the inner cylinder, and then blows out forwards from an outlet in the front end of the outer cylinder to form columnar jet flow, and the columnar jet flow can be entrained by active turbulent flow on the boundary and then is mixed with air flow in the inner cylinder; and since the air guide channel runs through the space between the outer cylinder and the inner cylinder, indoor air enters the inner cylinder from the air guide channel to be mixed with high-speed air flow blown out from the outlet in the front end of the outer cylinder to form jet flow, through the process, high-speed air flow generated by a driving air source is introduced, and meanwhile, through entrainment and mixing effects of the turbulent flow on the boundary of the high-speed air flow, indoor air flows and circulates in an air flow induction manner and further the problem of high possibility of unwell symptoms caused by the fact that a user stays in an air conditioning room for a long time can be solved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com