Heat-exchange tube

A heat exchange tube and tube body technology, which is applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problem of increased heat exchange area, achieve increased heat exchange area, improved heat transfer performance, and enhanced heat transfer The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

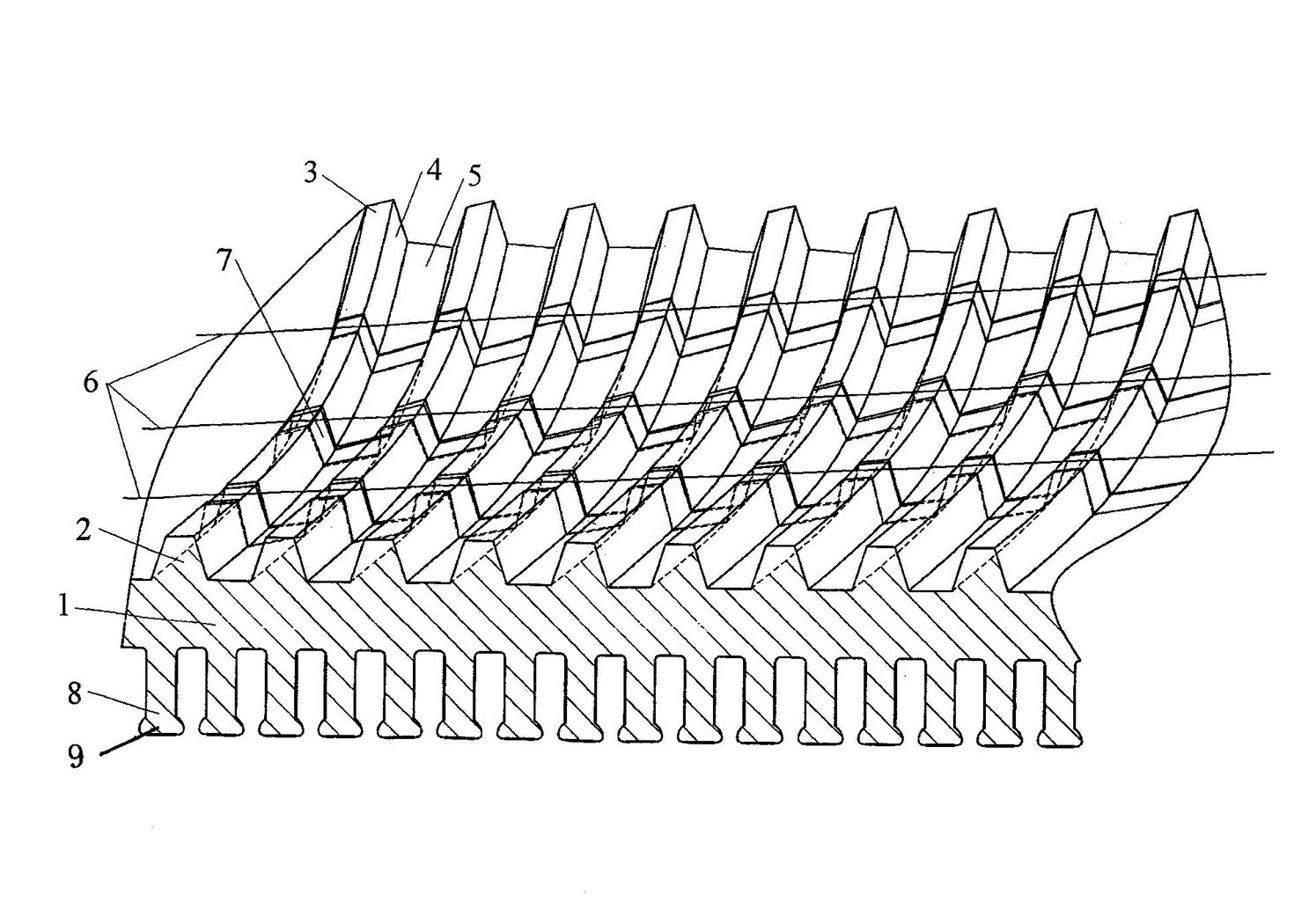

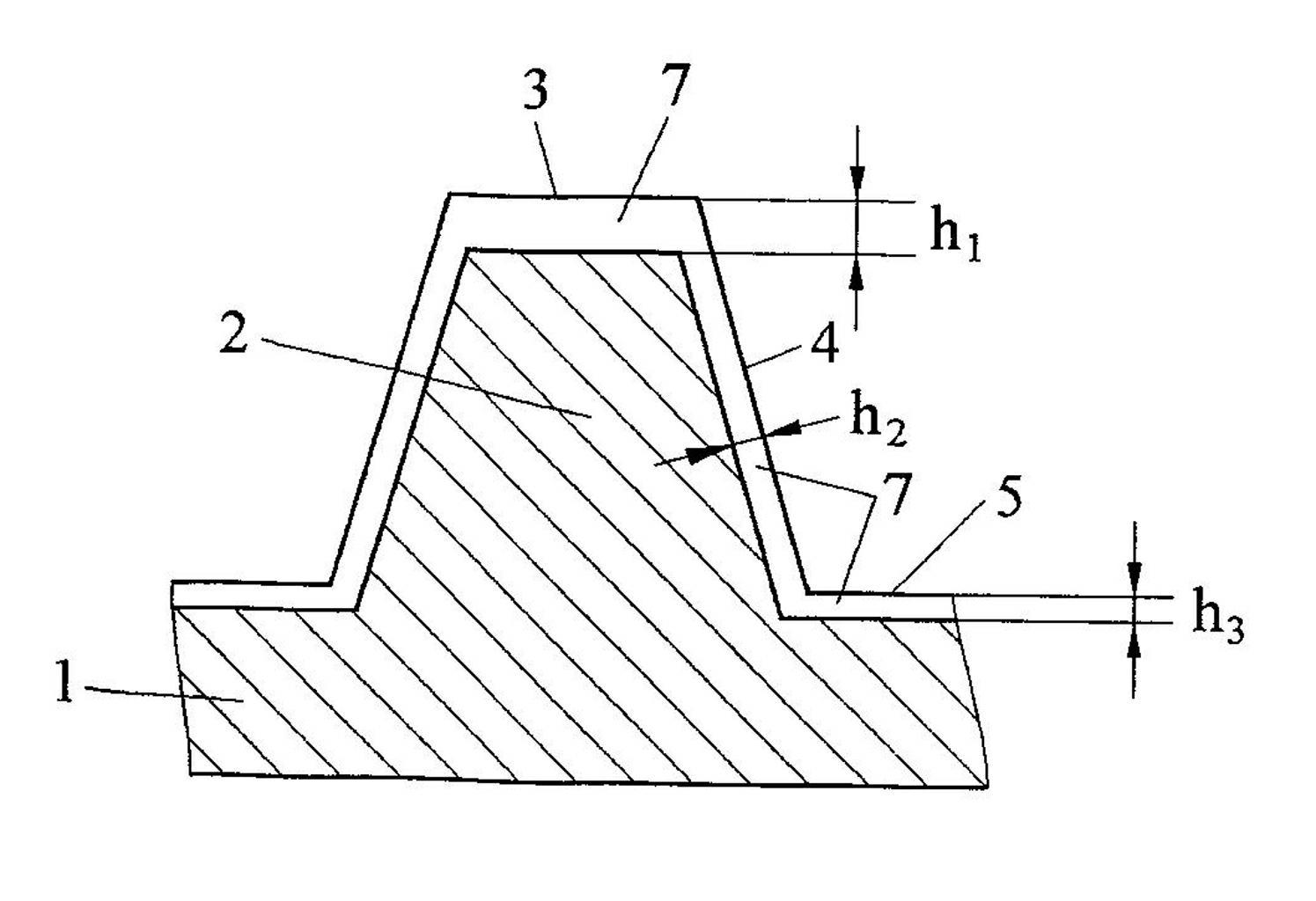

[0016] Example 1: See figure 1 , figure 2 and image 3 , the pipe body 1 is given, the length of the pipe body 1 is not limited, that is to say, there is no need to limit the length of the pipe body 1 in the present invention. Outer fins 8 are formed on the outer wall of the tube body 1. Preferably, fin top bosses 9 can be formed at the top of the outer fins 8, and the width between the fin top bosses 9 on adjacent outer fins 8 is smaller than the corresponding width. Width between adjacent outer fins 8 .

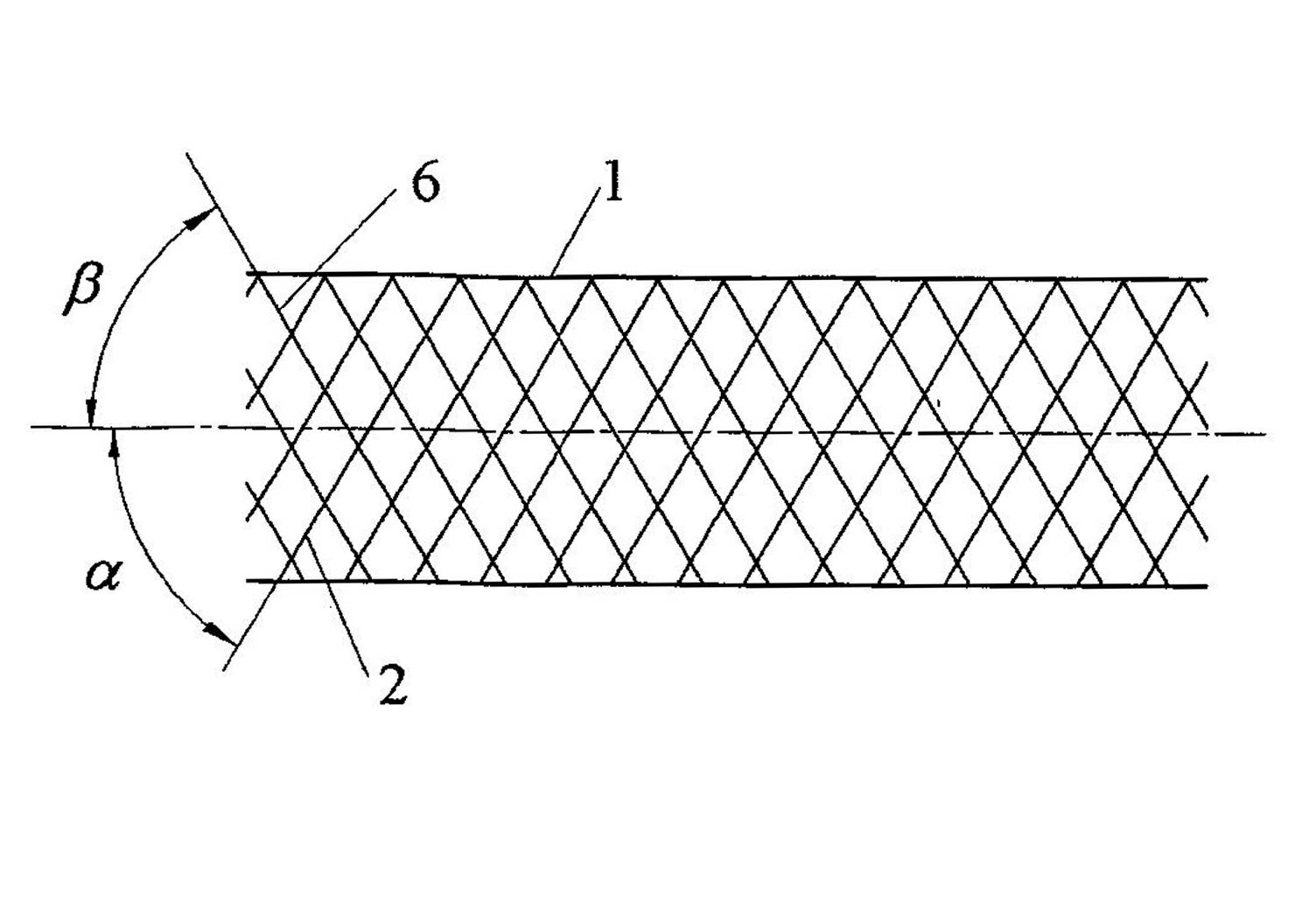

[0017] Spiral fins 2 are formed on the inner wall of the pipe body 1, and a set of grooves 7 are formed on the spiral fins 2 at intervals, that is to say, a group of grooves 7 spaced apart from each other are cut out on the spiral fins 2 by a cutter. , each groove 7 extends along the direction of the helix 6 from one end of the inner wall of the tubular body 1 toward the other end of the inner wall of the tubular body 1, more specifically along the helical fin on...

Embodiment 2

[0020] Figure omitted, only the first depth h 1 Change to 1.0㎜, the second depth h 2 Change to 0.5㎜, the third depth h 3 Changed to 0.1㎜, the cross-sectional shape of the groove 7 is arc-shaped, the width of the groove 7 is 2.5㎜, the angle of the first included angle α is 90°, and the angle of the second included angle β is 55°. The distance between the grooves 7 is 3.5mm. All the other are the same as the description to embodiment 1.

Embodiment 3

[0022] Figure omitted, only the first depth h 1 Change to 0.2㎜, the second depth h 2 Change to 0.03㎜, the third depth h 3 Changed to 0.08㎜, the cross-sectional shape of the groove 7 is triangular, the width (average width) of the groove 7 is changed to 1.5㎜, the angle of the first included angle α is changed to 65°, and the angle of the second included angle β is 0 °, the distance between adjacent grooves 7 is changed to 1.0mm. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com