Device for controlling rotary gas-liquid mixed flow noise

A flow noise and control device technology, applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of high requirements and rare liquid phase mufflers, and achieve strong pertinence, reduce exhaust noise, and compact space structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

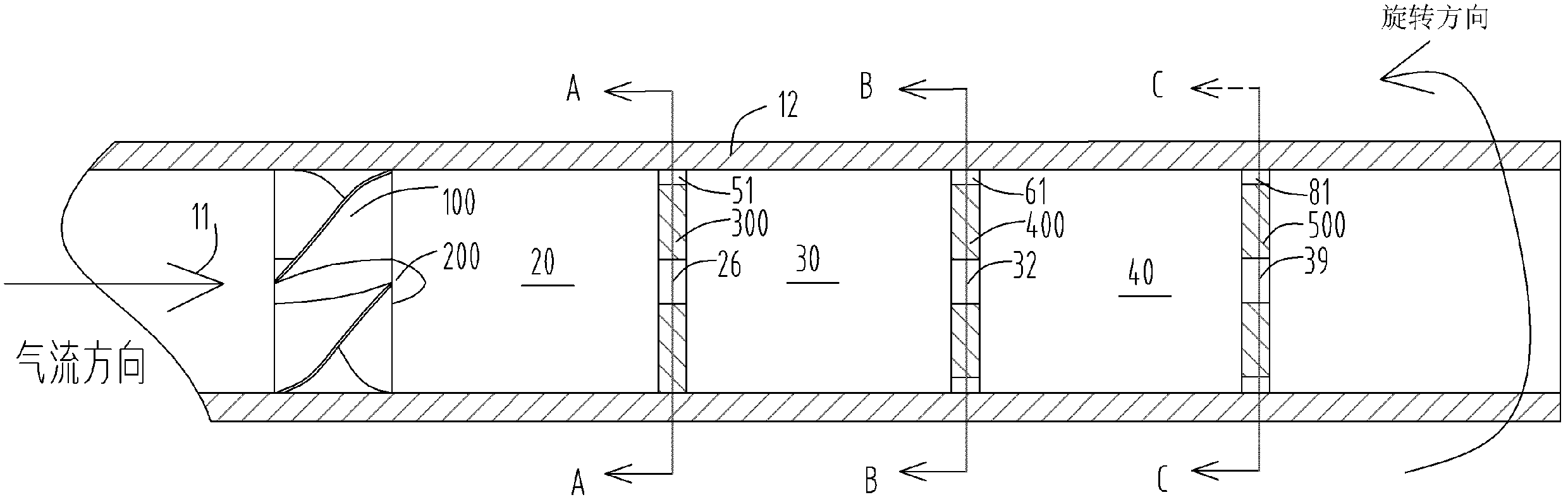

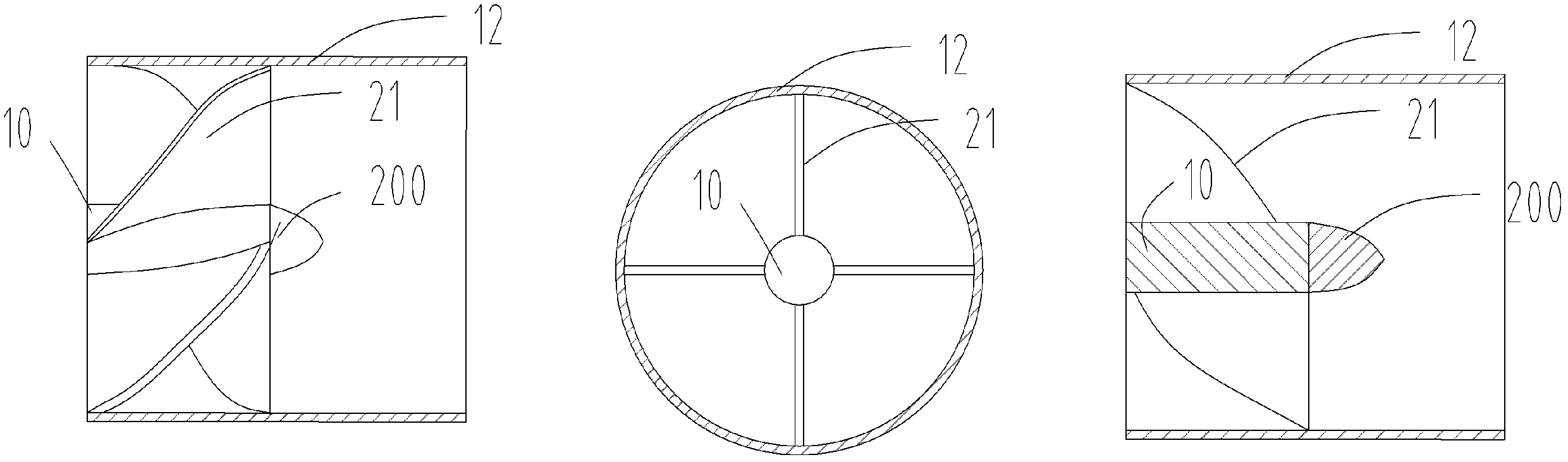

[0055] Embodiment 1, Fig. 0~ Image 6 In combination, a noise control device for rotating gas-liquid mixed flow is given, including guide vane assemblies 100, vortex control structures 200, baffles I300, baffles II400 and Partition III500;

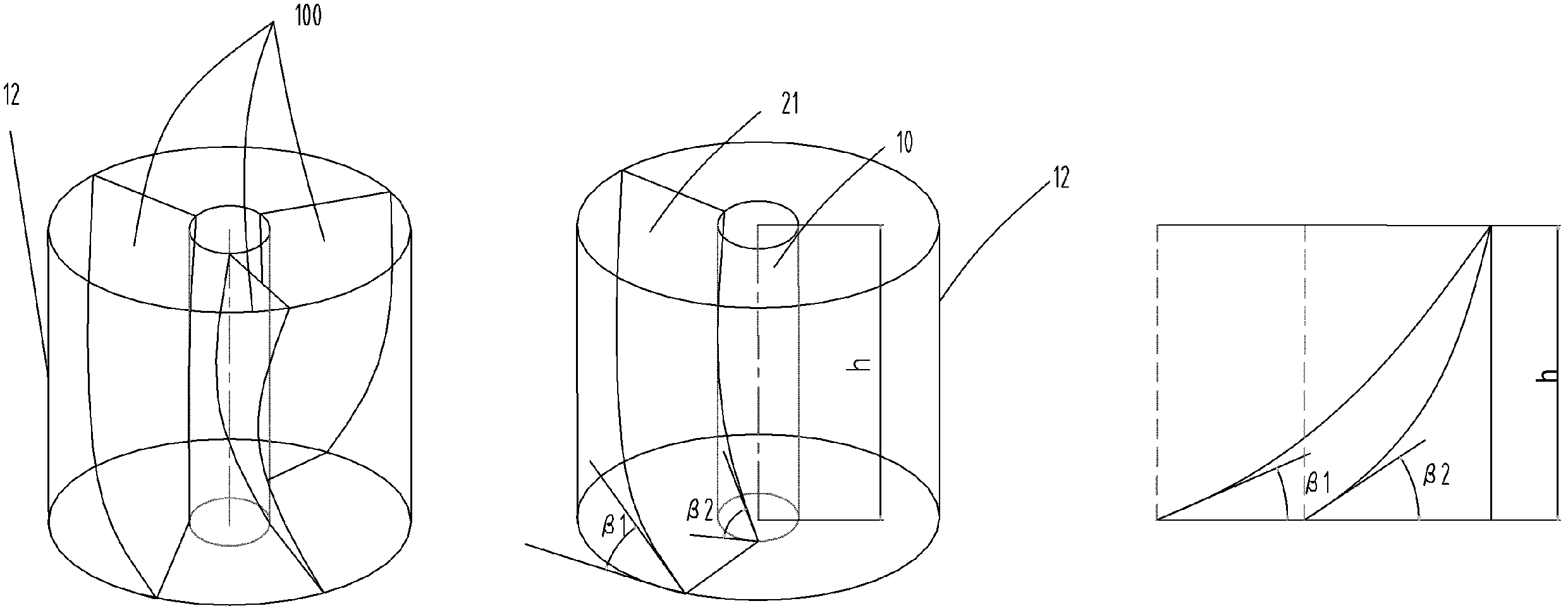

[0056] The guide vane assembly 100 is composed of a vane shaft 10 and 2 to 4 vanes 21 evenly arranged on the vane shaft 10, and the wrap angle of the vanes 21 (that is, the central angle of a fan shape of a horizontal projection of a vane) ranges from 90° ~180°. The outer outlet angle β1 of the blade 21 (that is, the angle between the intersection line between the blade 21 and the blade shaft 10 and the horizontal line in the expansion plane of the shaft cylinder of the blade 21, such as figure 1 Shown) is 30°-60°, and the inner outlet angle β2 of the blade 21 (that is, the angle between the intersection line of the blade 21 and the exhaust pipe 12 and the horizontal line in the cylinder expansion plane of the exhaust pipe 12, like f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com