Low-flow-resistant near-wall small-space annular shock wave focusing direct priming device

A shock wave focusing and detonation device technology, which is applied to intermittent injection devices, jet propulsion devices, rocket engine devices, etc., can solve the problems of low ignition energy, long transition distance from deflagration to detonation, and large flow resistance loss. Achieve the effects of controlling resistance loss, simple structure, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

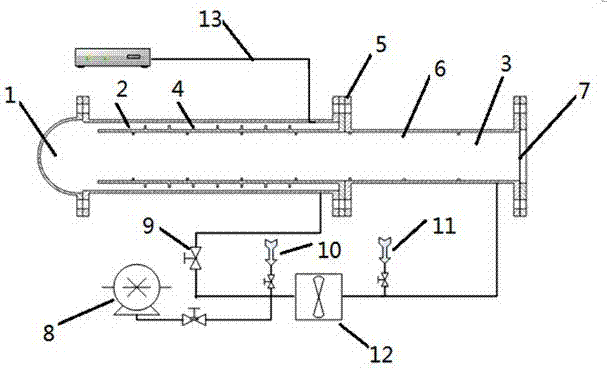

[0026] In the following, a direct detonation device with low flow resistance near the wall and small space annular shock wave focusing and direct detonation device proposed by the present invention will be described in detail in combination with the accompanying drawings.

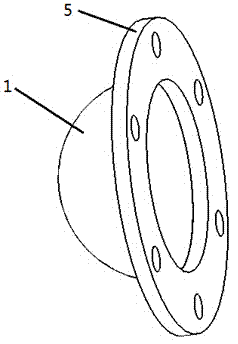

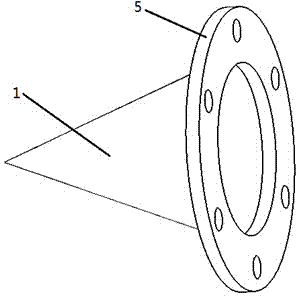

[0027] Such as figure 1 As shown, a ring-shaped shock wave focusing direct detonation device in a small space near the wall with low flow resistance includes a pulse detonation engine, an ignition system 13 and a feed system. Such as Figure 5 and 6 As shown, the pulse detonation engine is connected in parallel with the main detonation chamber using a near-wall space structure, including the main detonation chamber 3 and an enclosure, the enclosure is at one end of the main detonation chamber 3 and extends to the main detonation chamber Outside the wall of chamber 3, the port of the closed cover located outside the wall of chamber 3 of the main detonation chamber is connected with the outer surface of cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com