Micro-channel structure of heat exchanger

A micro-channel structure, heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of reduced fluid flow resistance, lack of induced condensation or evaporation phase change, etc. Enhanced thermal capacity, beneficial to phase change heat transfer, and enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

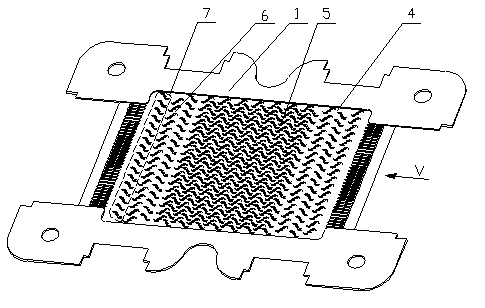

[0032] figure 1 It is a new type of microchannel structure patented by the present invention, wherein the microchannel is formed between multi-layer stacked heat exchange plates 1, and a plurality of fin units 2 are formed on the heat exchange plate 1, and the fin units 2 Fin unit groups 7 are evenly arranged in the direction perpendicular to the fluid flow, and a plurality of fin unit groups 7 are arranged alternately at intervals along the fluid flow direction; the rear end of the fin unit 2 on the upstream side It is arranged in the middle of two adjacent fin units 2 on the downstream side. The intermediate position in the present invention refers to any position between two adjacent fin units 2 on the downstream side, which not only includes the rear end of the fin unit 2 on the upstream side protruding into the adjacent fin unit 2 on the downstream side. The interior between the fin units 2 also includes the exterior between the adjacent fin units 2 on the downstream si...

Embodiment 2

[0041] Figure 4 and Figure 5 It is another microchannel structure of the present invention, which is basically the same as the microchannel structure in Example 1, the difference lies in the shape of the fin unit.

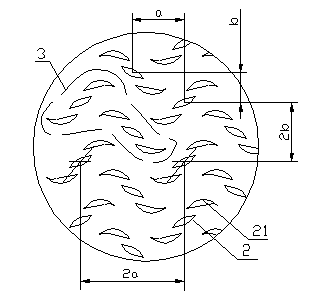

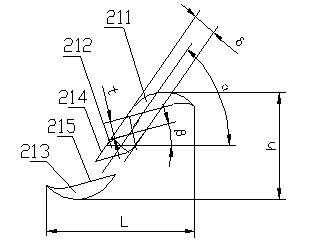

[0042] The outer contour of the fin unit 2 is linear. Specifically, in this embodiment, the fin unit 2 is composed of three parallelogram fins 21, and the obtuse angle sides of the parallelogram 21 are Arc transition. The microchannel with such a structure avoids the eddy current formed by continuous curves, thereby reducing the resistance loss of flow. The angle α between the fin unit 2 and the fluid flow direction is 45 0 .

[0043] Among them, such as Figure 4 As shown, the distance a between the two fin units 2 in the fluid flow direction is 1 mm, and the distance b perpendicular to the fluid flow direction is 2 mm; the fluid flow between adjacent pairs of fin units 3 The spacing in the direction is 3 mm, and the spacing between adjacent pairs of fin u...

Embodiment 3

[0047] The microchannel structure of this embodiment is basically the same as that of Embodiment 2, the difference lies in the arrangement position and size parameters of the fins.

[0048] Wherein, the angle α between the fin unit 2 and the fluid flow direction is 55° 0 . The distance a between the two fin units 2 in the direction of fluid flow is 1.5 mm, and the distance b perpendicular to the direction of fluid flow is 1.5 mm; between adjacent pairs of fin units 3 in the direction of fluid flow The spacing above is 3 mm, and the spacing between adjacent pairs of fin units 3 perpendicular to the fluid flow direction is 4 mm.

[0049] Such as Figure 5 As shown, the length L of the fin unit 2 along the direction of fluid flow is 2 mm, the width h perpendicular to the direction of fluid flow is 1 mm, and the thickness δ of the fin is 0.25 mm.

[0050] The distance t between the splitter edges 214 adjacent to the fins 21 is 0.05 mm; the included angle β between the splitter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com