Air outlet nozzle

An air outlet, nozzle technology, used in air handling equipment, heating/cooling equipment, transportation and packaging, etc., can solve problems such as loss, high pressure, etc., and achieve the effect of reducing flow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

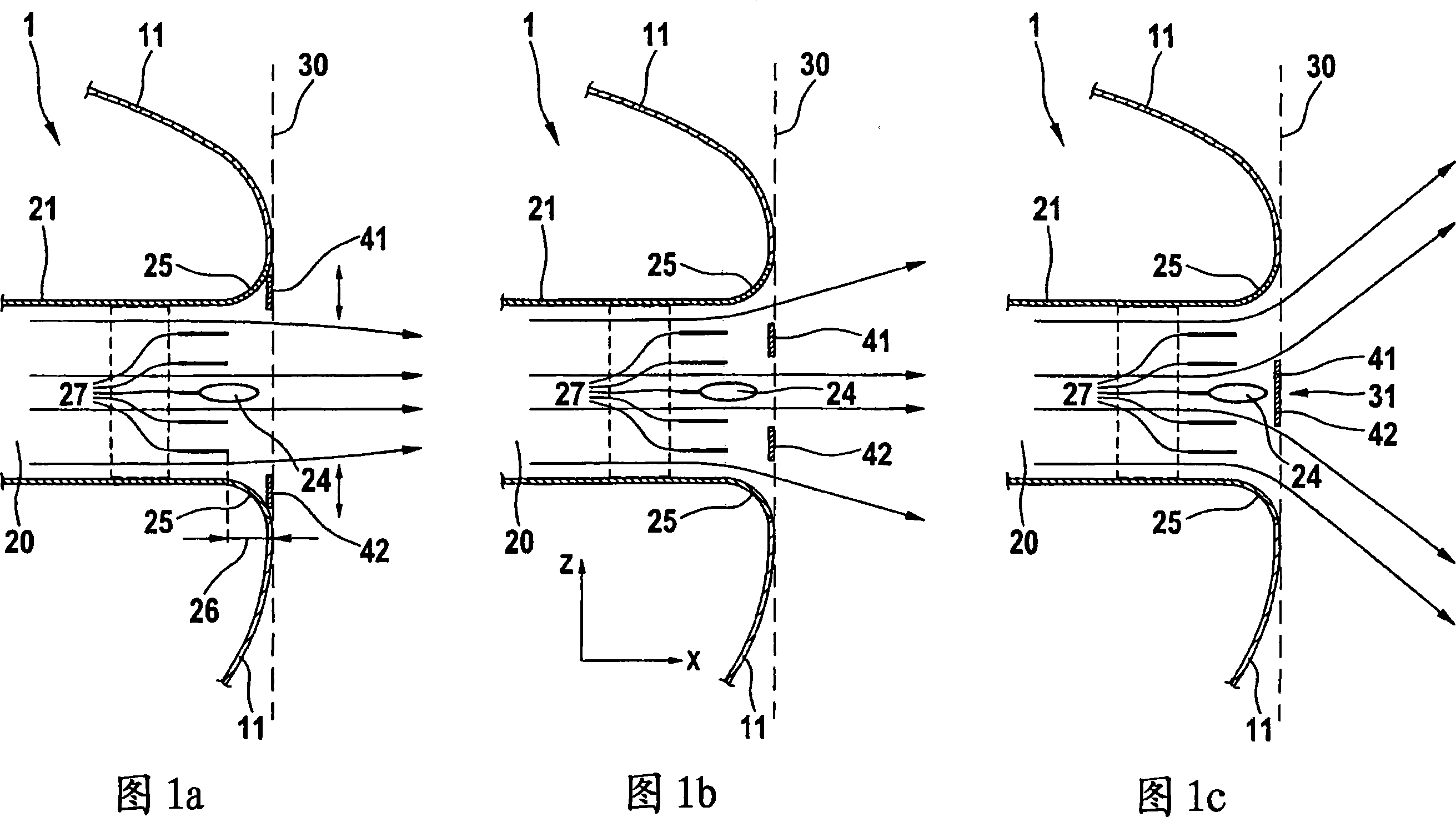

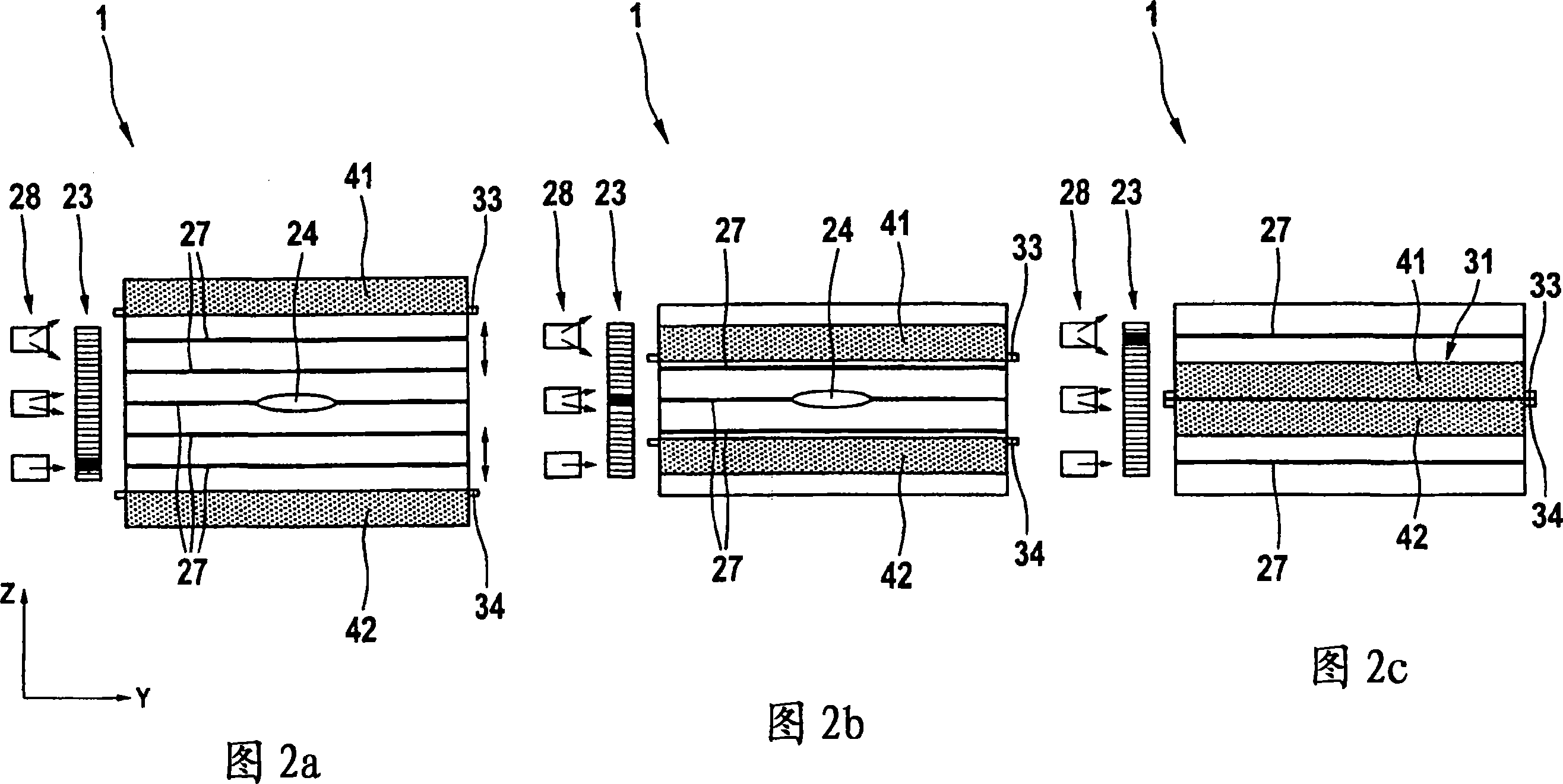

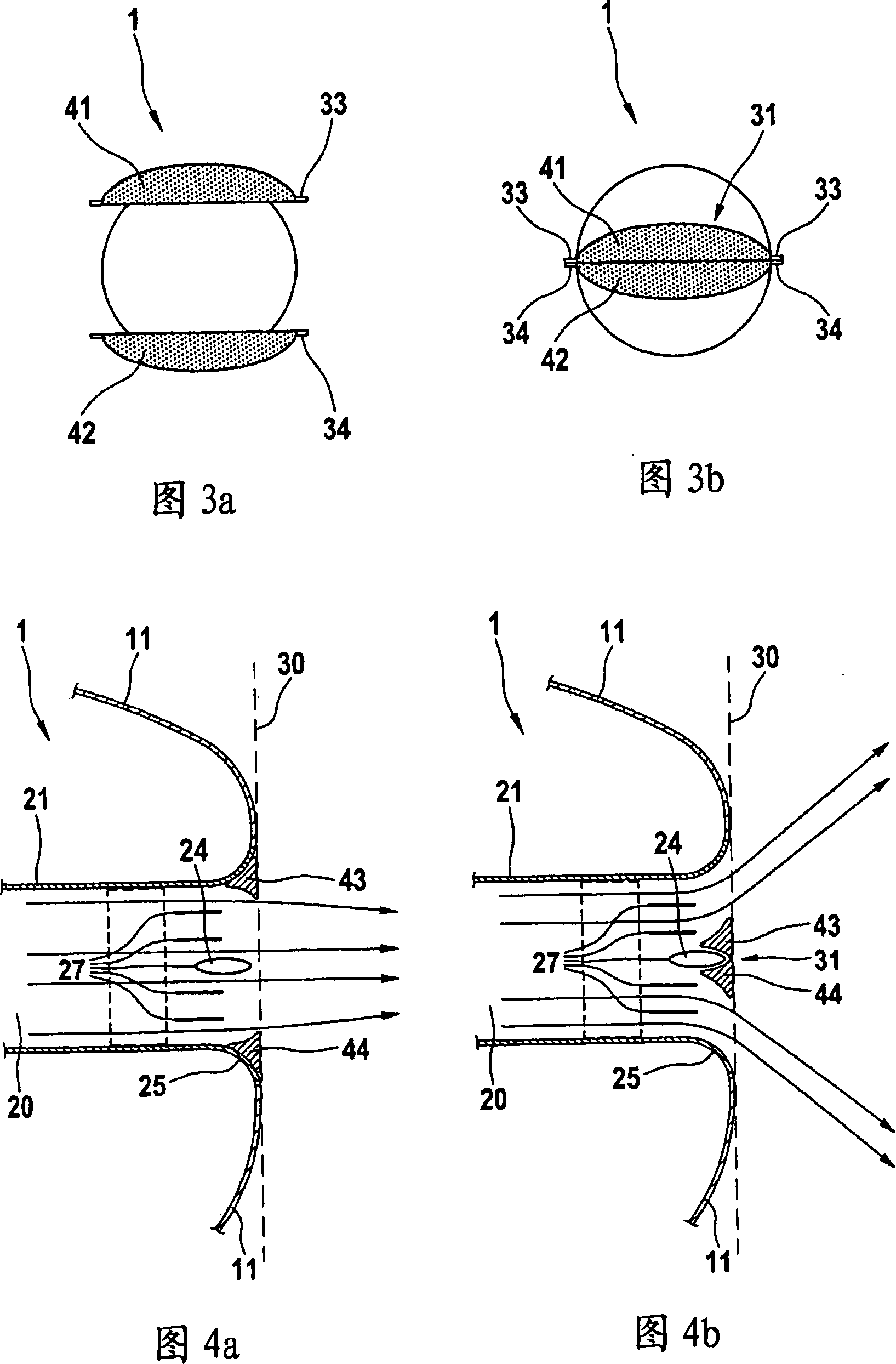

[0033] 1A, 1B and 1C show a schematic sectional view of an air outlet nozzle 1 arranged in a dashboard 11 of a motor vehicle. The air outlet nozzle 1 has an air duct 20 which extends from an air supply device arranged in the center of the vehicle to an air outlet plane 30 distributed on the instrument panel 11 . The air duct 20 conveys air from a central air supply device, preferably a fan of the heating and / or air conditioning system, to one or more air outlet nozzles 1 leading to the vehicle interior.

[0034] In the air channel 20 , in the upstream region adjacent to the air outlet plane 30 , a plurality of parallel H-shaped lamellae 27 are arranged, which can pass together through an adjusting element 24 according to their inclination relative to the air channel 20 adjustment in order thereby to control the direction of the air flow coming out of the air outlet nozzle 1 in the horizontal plane. Of course, V-shaped slices can also be used to control the outlet direction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com