Multi-stage denoiser and valve with same

A technology of noise reducer and noise reduction cover, applied in the field of noise reduction, can solve the problems of affecting the normal flow rate of fluid in the pipeline, low noise reduction effect of the noise reduction device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

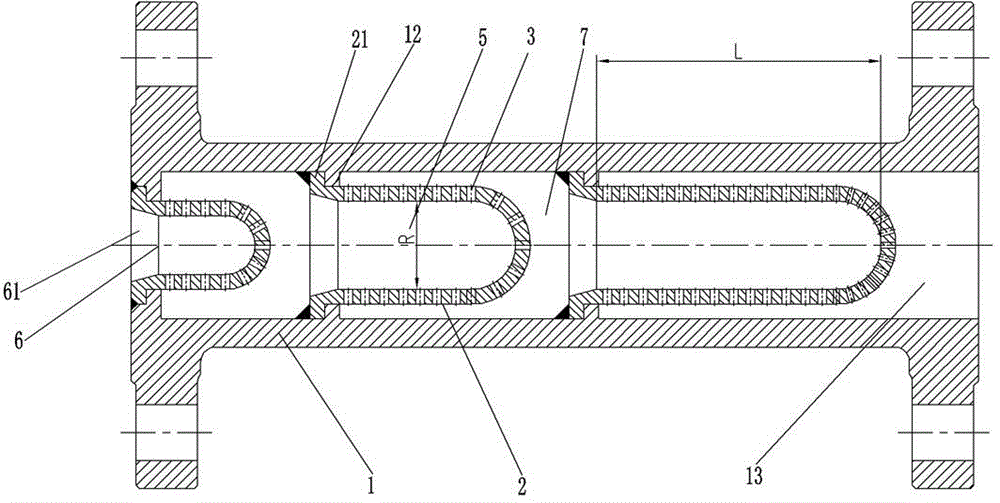

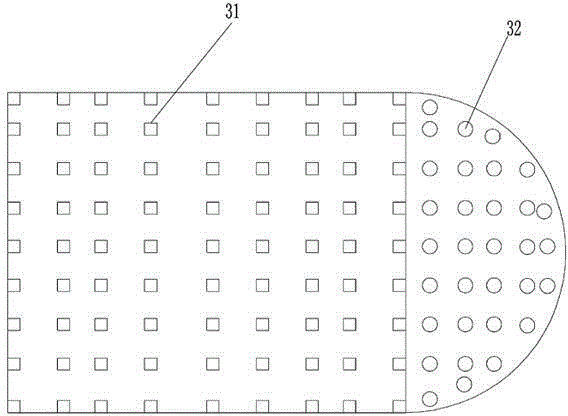

[0039] This embodiment provides a multi-stage noise reducer, such as figure 1 As shown, it includes a hollow noise reduction cylinder 1, and a three-stage noise reduction cover 2, which is arranged in the hollow noise reduction cylinder 1 along the extension direction of the hollow noise reduction cylinder 1, and each stage of the noise reduction cover 2 has The fluid cavity 5 and the fluid inlet 6 arranged at the head of the fluid cavity 5 are provided with a plurality of through holes 3 on the wall of the fluid cavity 5 of the noise reduction cover 2 of each stage, and the fluid cavity of the next stage noise reduction cover 2 The fluid inlet 6 of 5 is set corresponding to the tail of the noise reduction cover 2 of the previous stage, and forms a buffer cavity 7 with the tail of the noise reduction cover 2 of the previous stage.

[0040] For the above-mentioned three-stage noise reducer, a three-stage noise reduction cover 2 is set in the hollow noise reduction cylinder 1, a...

Embodiment 2

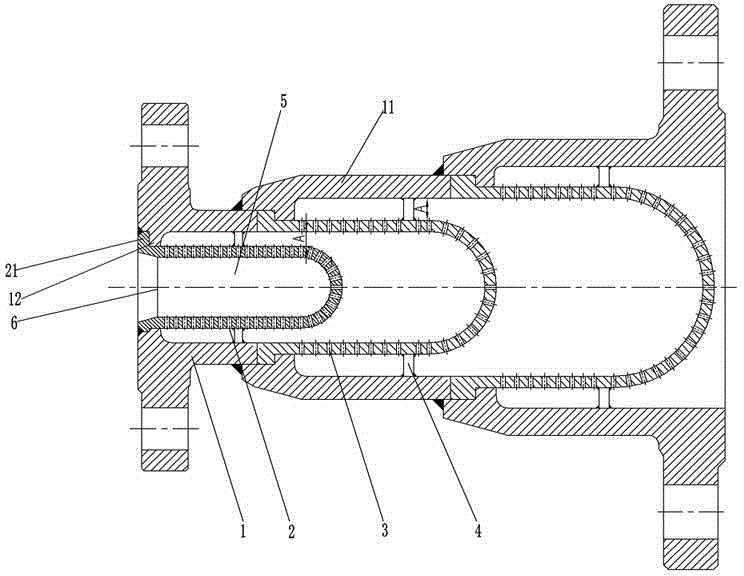

[0055] This embodiment provides a multi-stage noise reducer, such as image 3 As shown, the main difference from Embodiment 1 is that the hollow noise reduction cylinder 1 includes at least three stages of noise reduction sections 11 whose radial diameter gradually increases along the axial direction, and a noise reduction section 11 is installed in each stage of the noise reduction section 11. Among the multiple buffer cavities 7 formed by two adjacent noise reduction covers 2, the entrance width A of the buffer cavity 7 of the latter stage is larger than the entrance width A of the buffer chamber 7 of the previous stage.

[0056] By designing the hollow noise reduction cylinder 1 as three stages of noise reduction sections 11 with gradually increasing radial diameter along the axial direction, and setting a primary noise reduction cover 2 in each stage of noise reduction section 11, it is convenient to use this multiple The stage noise reducer is applied to the situation whe...

Embodiment 3

[0059] This embodiment provides a valve, including a valve body 8 and a fluid outflow channel 81, the outlet of the outflow channel (81) is fixedly connected with a noise reducer along the axial direction, and the noise reducer is the above-mentioned embodiment 1 or implementation The noise reducer in Example 2, and the valves in this embodiment can be eccentric rotary control valves, V-shaped control ball valves, butterfly valves, and other valves that require noise reduction.

[0060] For example, the three-stage noise reducer in which the hollow noise reduction cylinder 1 in Embodiment 1 is a straight cylinder is applied to a straight-stroke valve, such as a single-seat regulating valve, and the inlet end of the hollow noise reduction cylinder 1 of the noise reducer is connected to the single-seat control valve. The outflow channel 81 of the fluid behind the spool of the seat regulating valve is fixedly connected, and its assembly drawing is used, such as Figure 5 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com