Patents

Literature

106results about How to "Guaranteed movement trajectory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

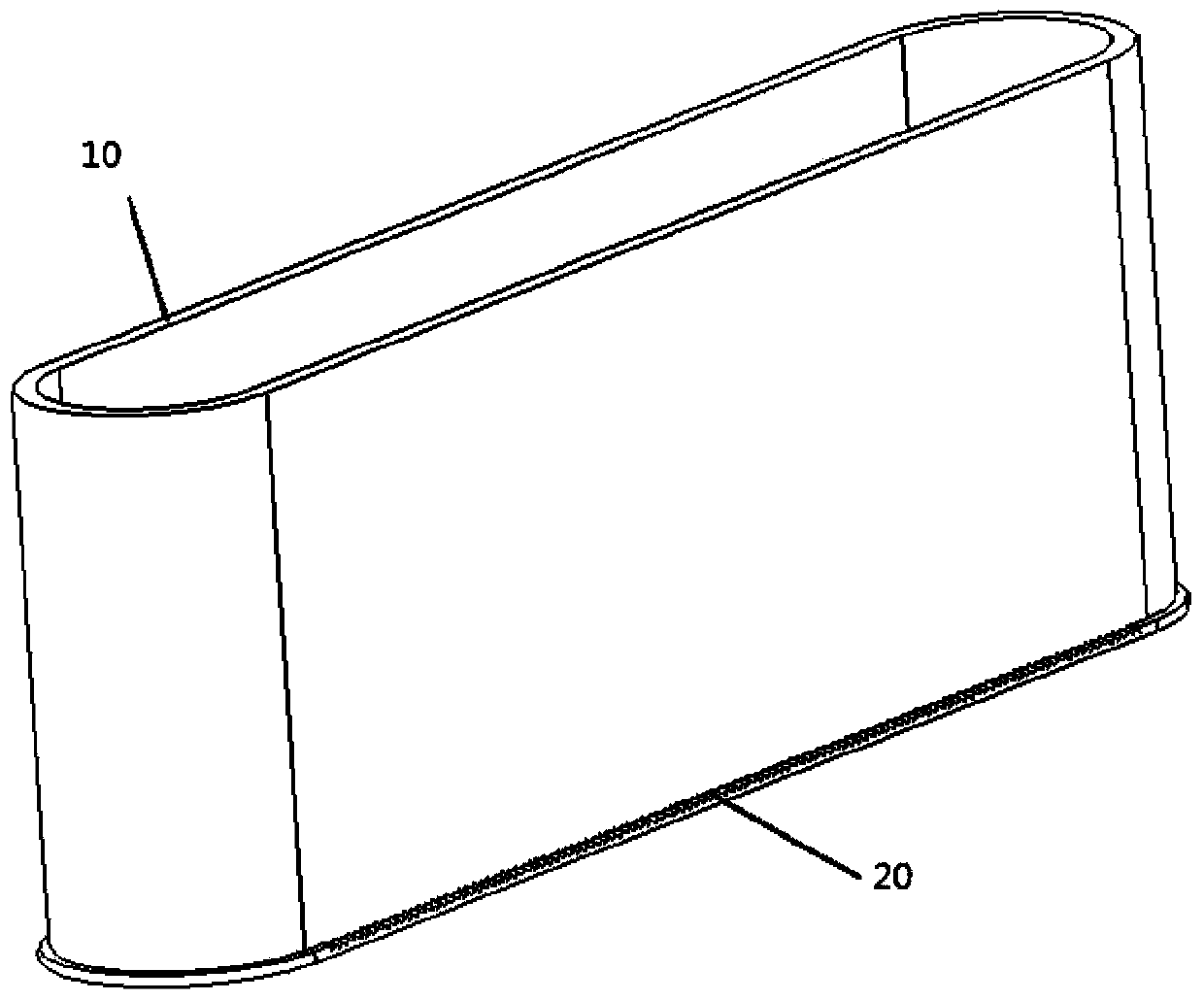

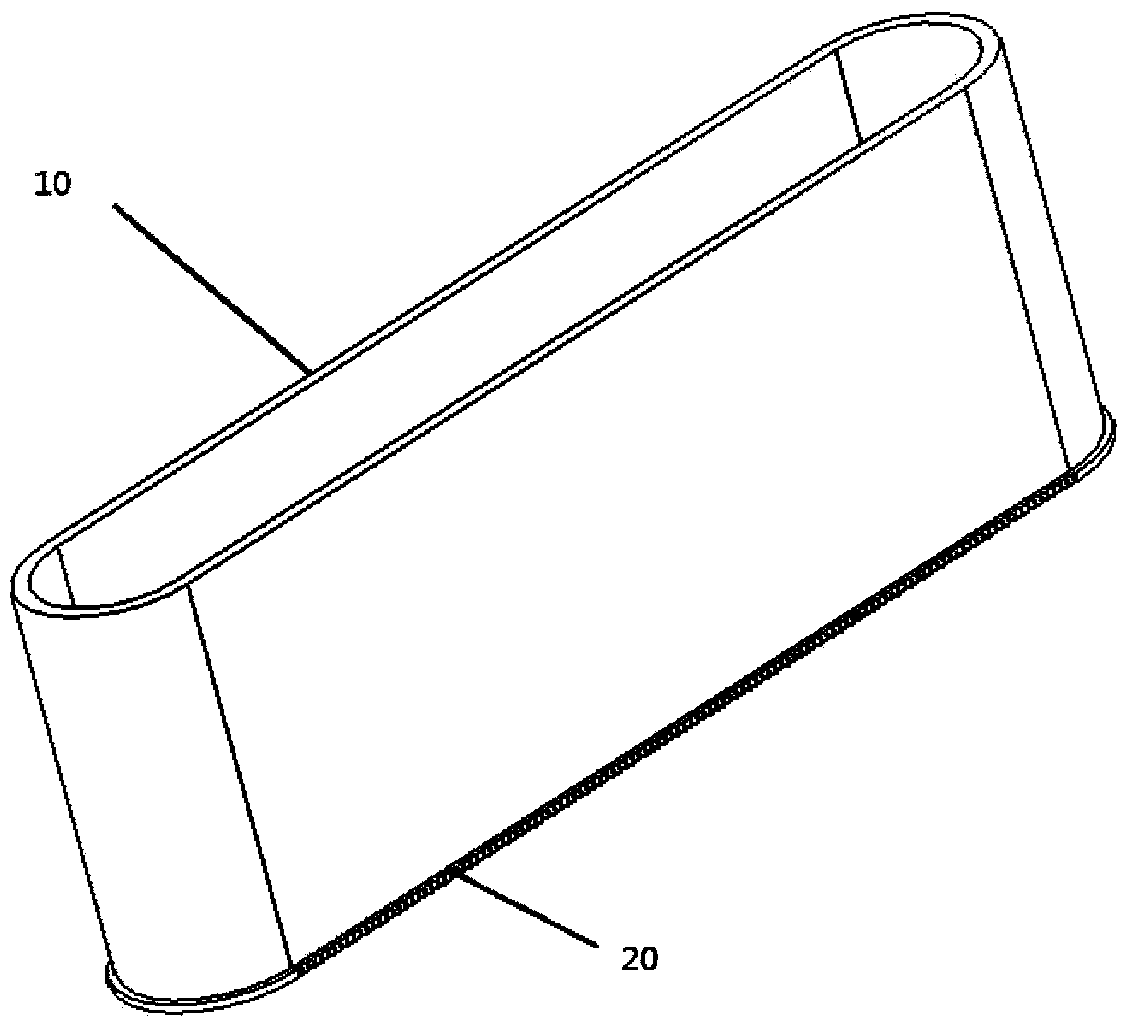

Gold and silver hollow bracelet processing technology

ActiveCN103416925AReduce processing technologyGuaranteed purity and colorJewelleryNanotechnologySheet material

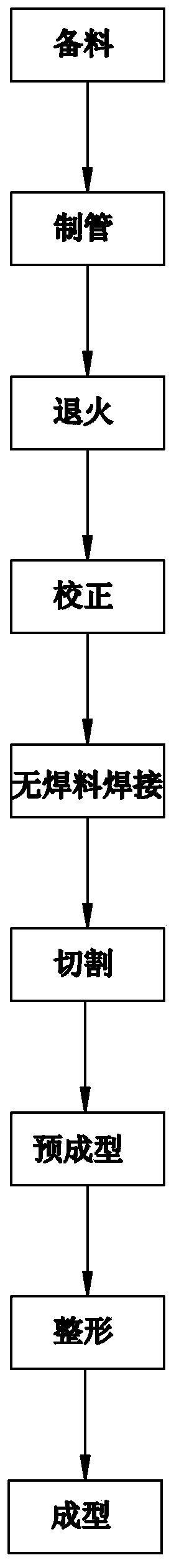

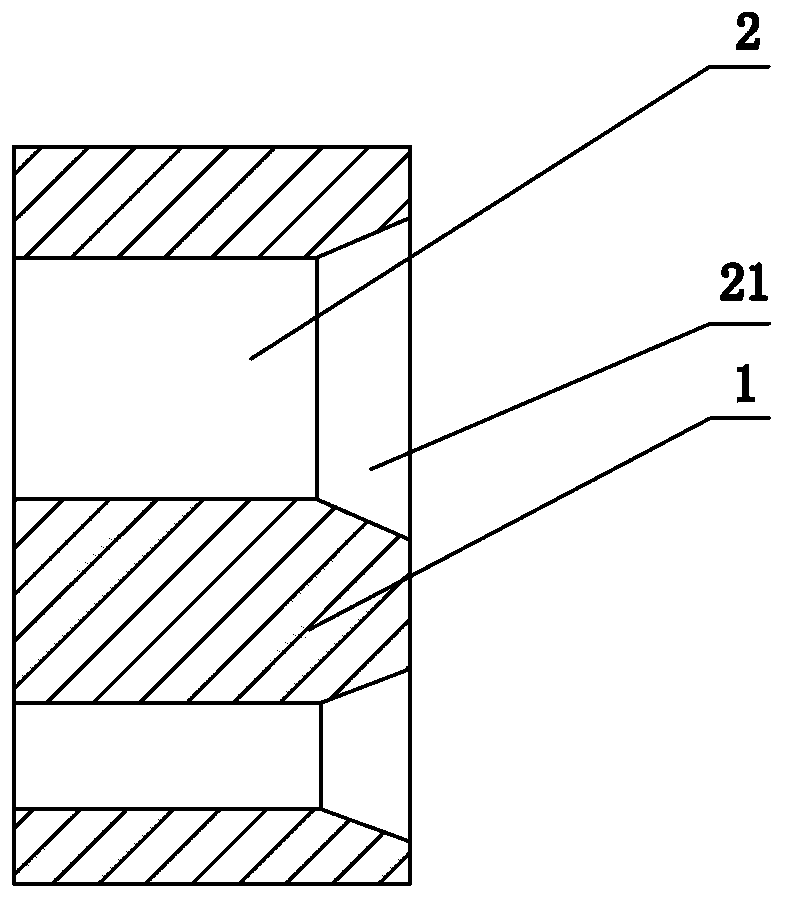

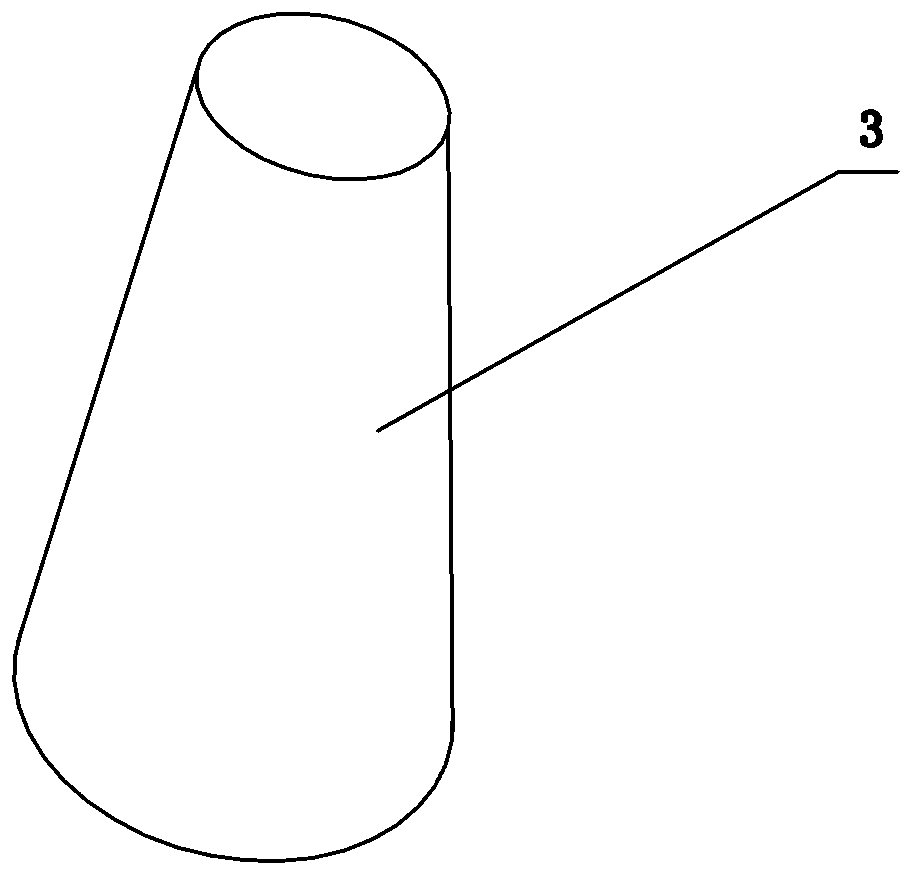

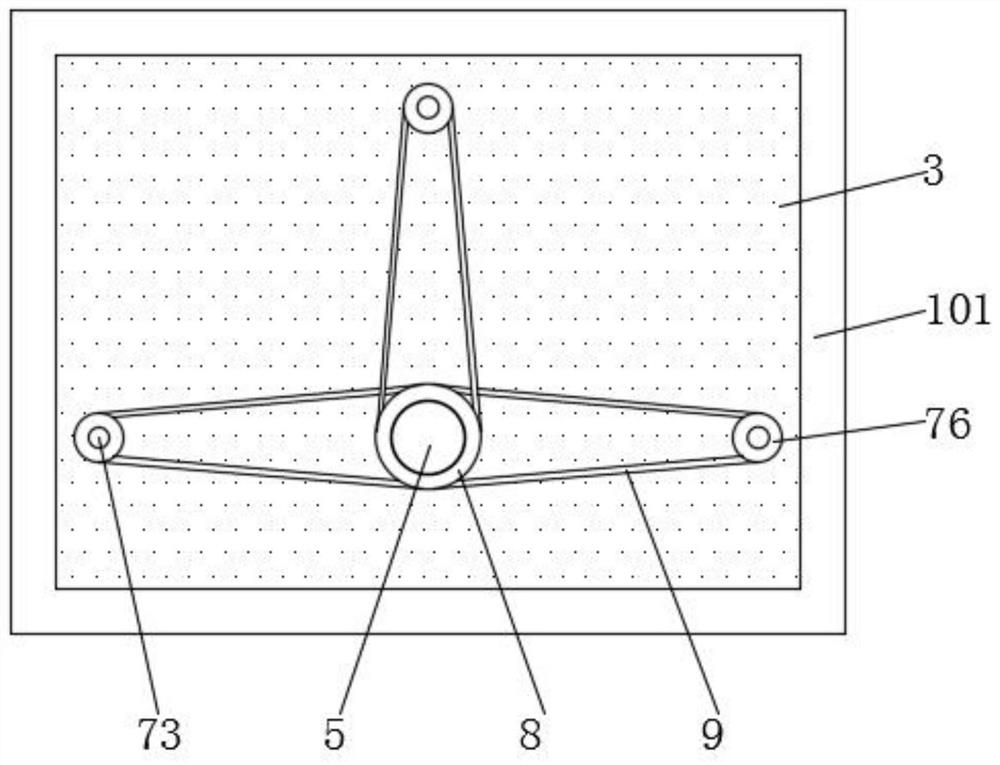

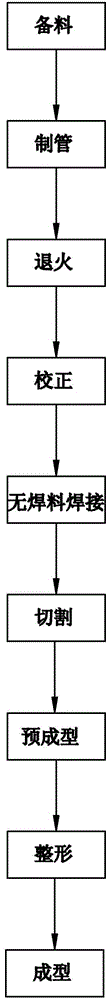

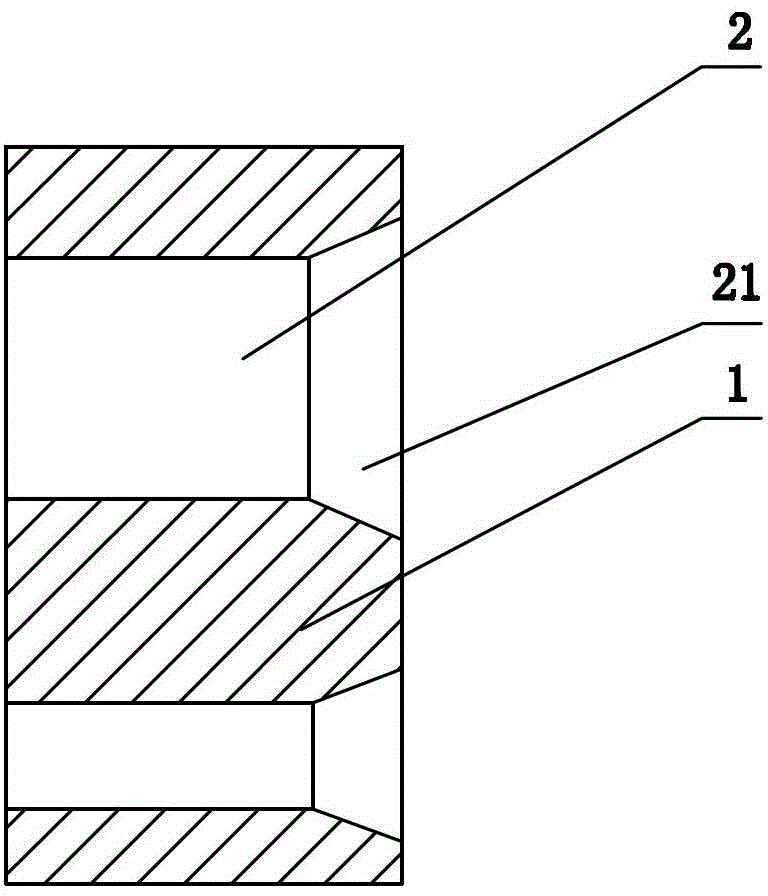

The invention discloses a gold and silver hollow bracelet processing technology and belongs to the technical field of jewelry processing technologies. The processing technology comprises the following steps: preparing material: according to the specifications for processing gold and silver hollow bracelets, preparing sheet material with corresponding specifications; manufacturing a pipe: processing the sheet material into a round pipe with a gap and straightening the round pipe; annealing; calibrating: straightening the gap; welding without welding material: eliminating gap through high-temperature heating to form a gapless round pipe; cutting: cutting the gapless round pipe according to the finished size of a gold and silver hollow bracelet, and polishing two ends of the gapless round pip; pre-forming: processing the gapless round pipe into an open type circular ring, and forming a closed circular ring by performing high-temperature heating on the open type circular ring; shaping: shaping the shape of the closed circular ring until specified requirements are met; forming: processing the closed circular ring into a hollow bracelet with elliptic sections. Through the processing steps, since a only a piece of sheet material is needed, the hollow bracelet can be manufactured, the processing technology is reduced, the processing efficiency is improved, the forming effect is good, and meanwhile, the gap is closed automatically through high temperature, so that welding without welding material is achieved, and the purity and fineness are guaranteed.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD +1

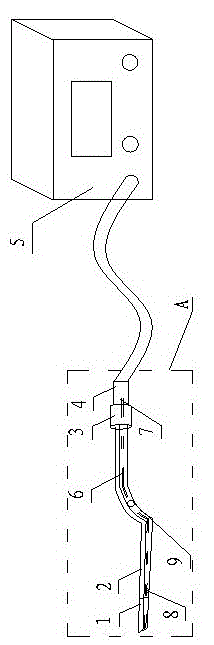

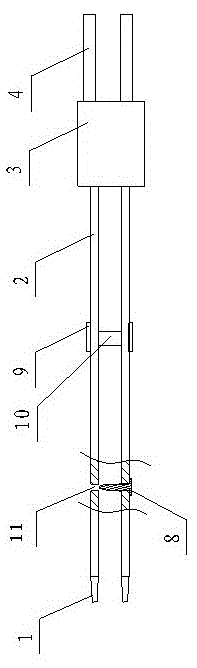

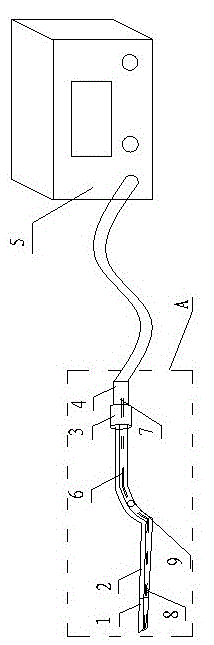

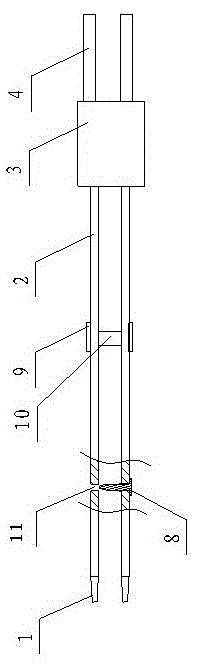

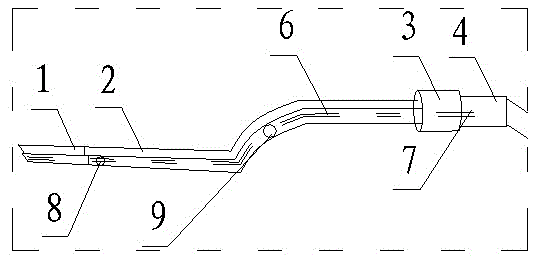

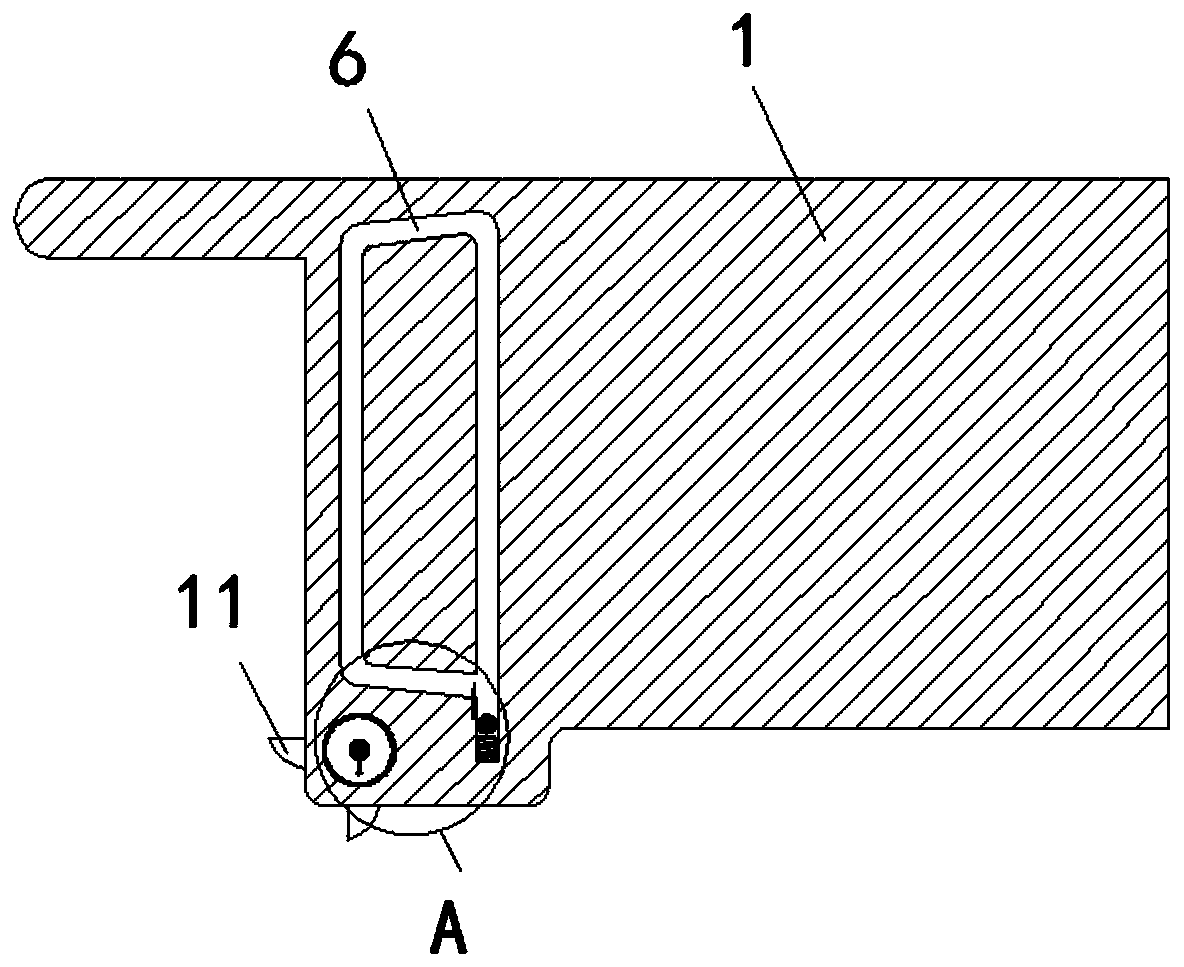

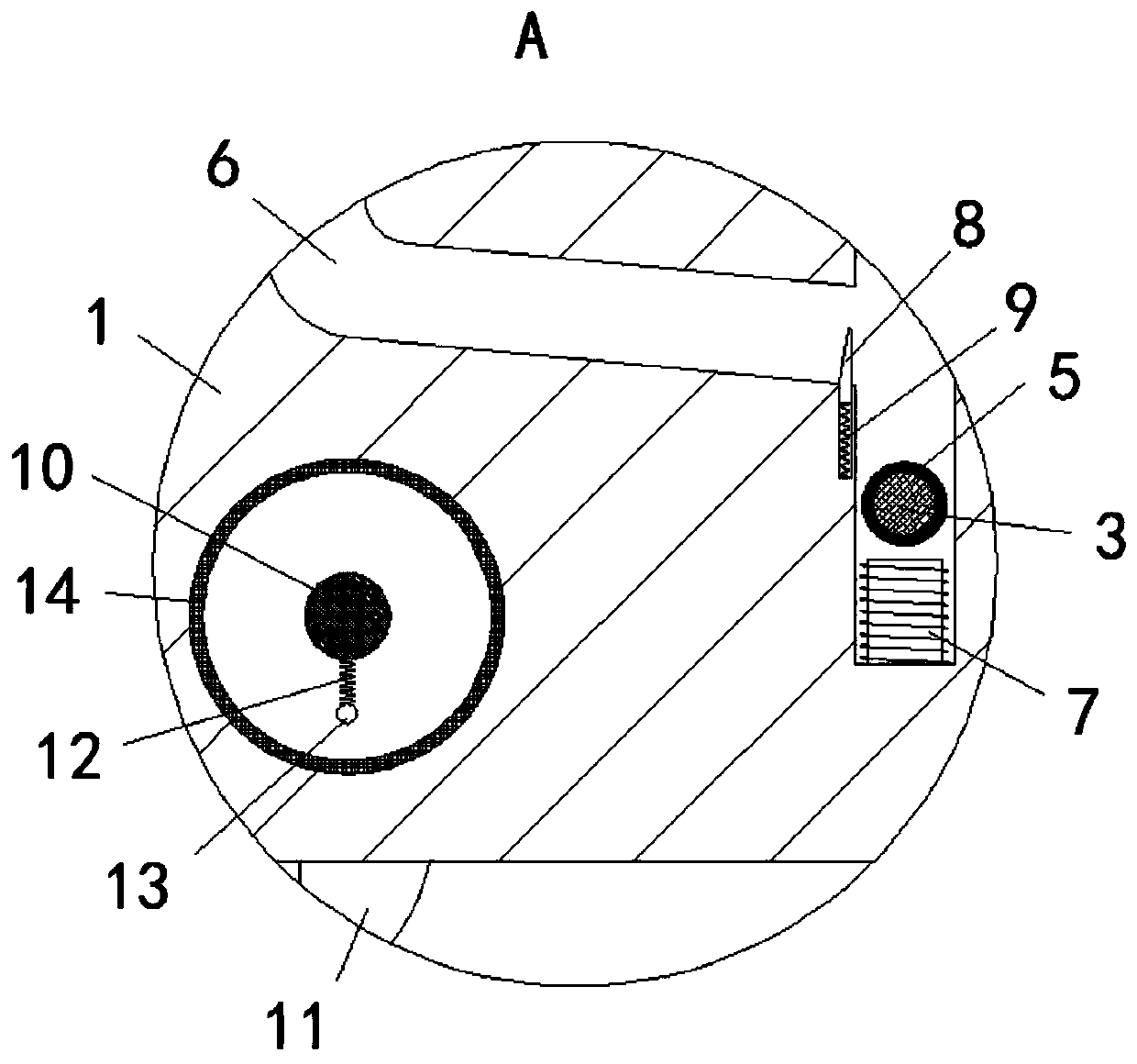

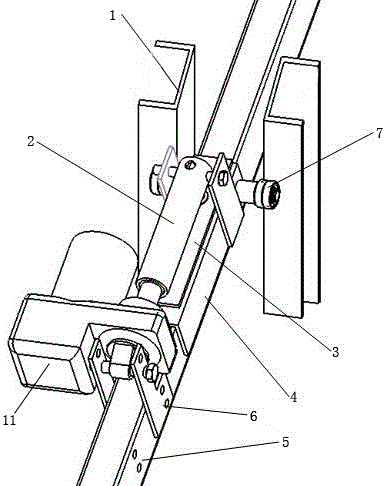

Electric coagulation forcep system with forcep point cleaning function

InactiveCN102743222AGuaranteed bonding effectEasy to operateEnemata/irrigatorsDiagnosticsMicrocontrollerMegasonic cleaning

The invention discloses an electric coagulation forcep system with a forcep point cleaning function, which comprises a forcep body and a host for providing a power source to the forcep body, wherein the forcep body comprises forcep points and forcep rods. The electric coagulation forcep system is characterized in that a temperature detecting device is arranged on the forcep points, the temperature detecting device feedbacks the detected temperature to a chip in the host; and the chip compares the temperature with the preset temperature and then adjusts the power output by the forcep points to adjust the temperature of the forcep points. The system further comprises an electric coagulation forcep supporting seat, wherein the electric coagulation forcep supporting seat comprises a base, grooves matched with two forcep rods of the electric coagulation forcep is formed in the base, the lower parts of the grooves are provided with a hollow cavity capable of holding forcep points; an ultrasound cleaner is arranged in the hollow cavity, a singlechip and a position sensing device for judging whether the forcep rods are arranged in the grooves are further arranged on the base; and a finish detecting device used for detecting the finish of the insides of the forcep points is arranged in the hollow cavity. The electric coagulation forcep system with the forcep point cleaning function is simple in structure; and by using the electric coagulation forcep system, the temperature of the forcep points are automatically detected and adjusted, and the forcep points are automatically cleaned.

Owner:CHONGQING RUNZE PHARM CO LTD

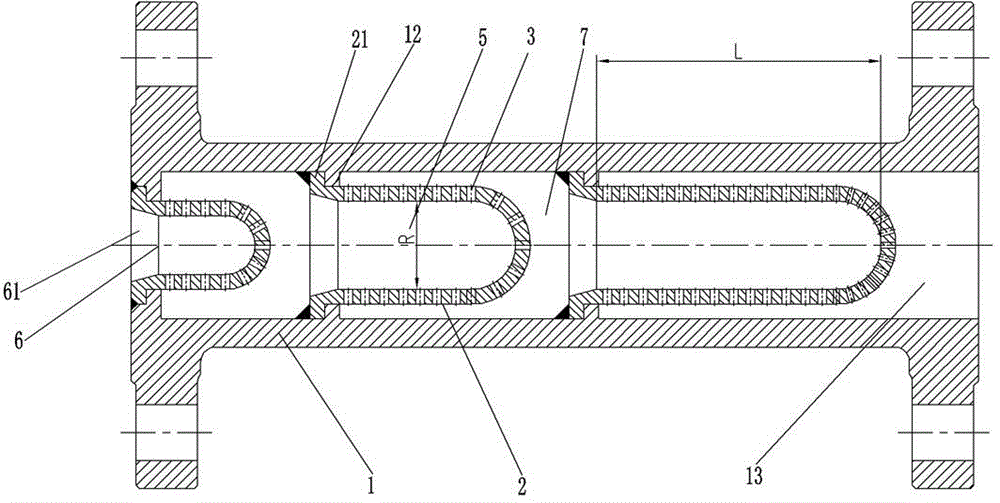

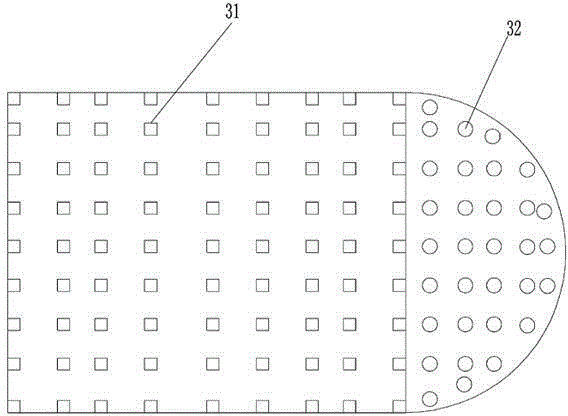

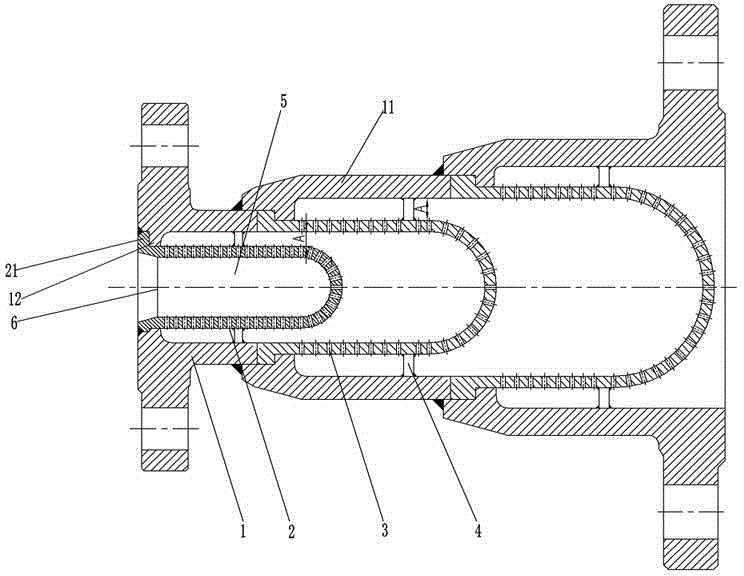

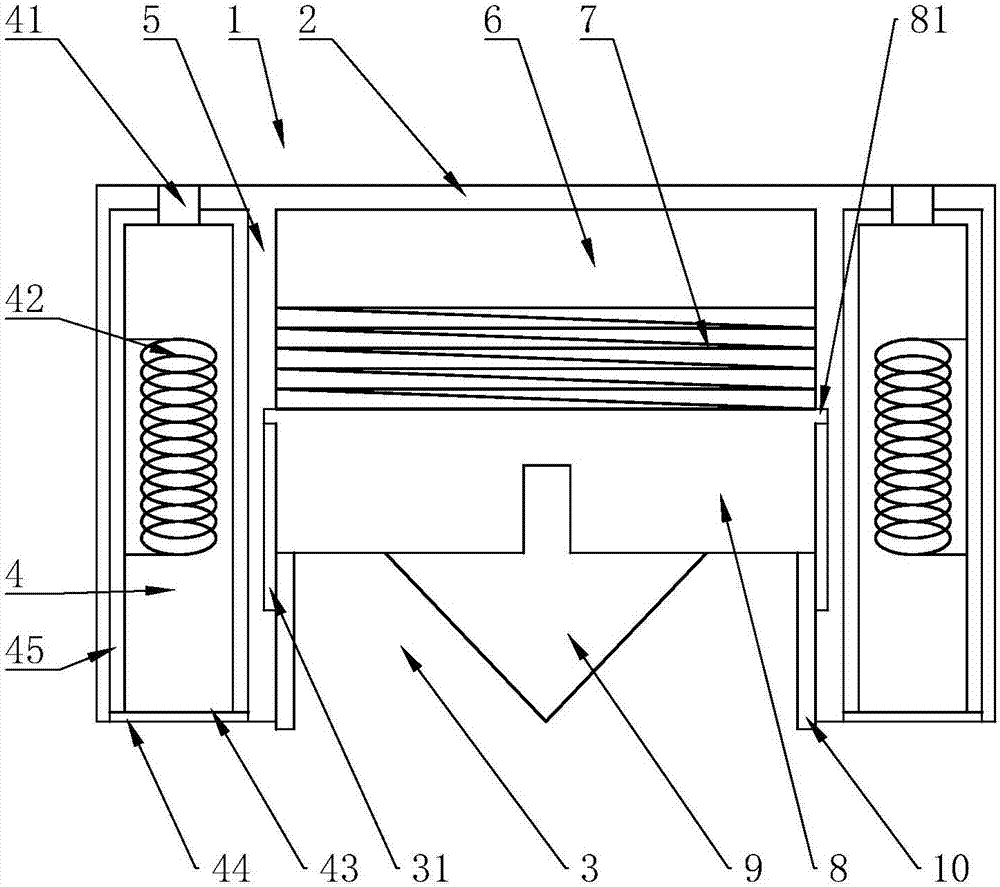

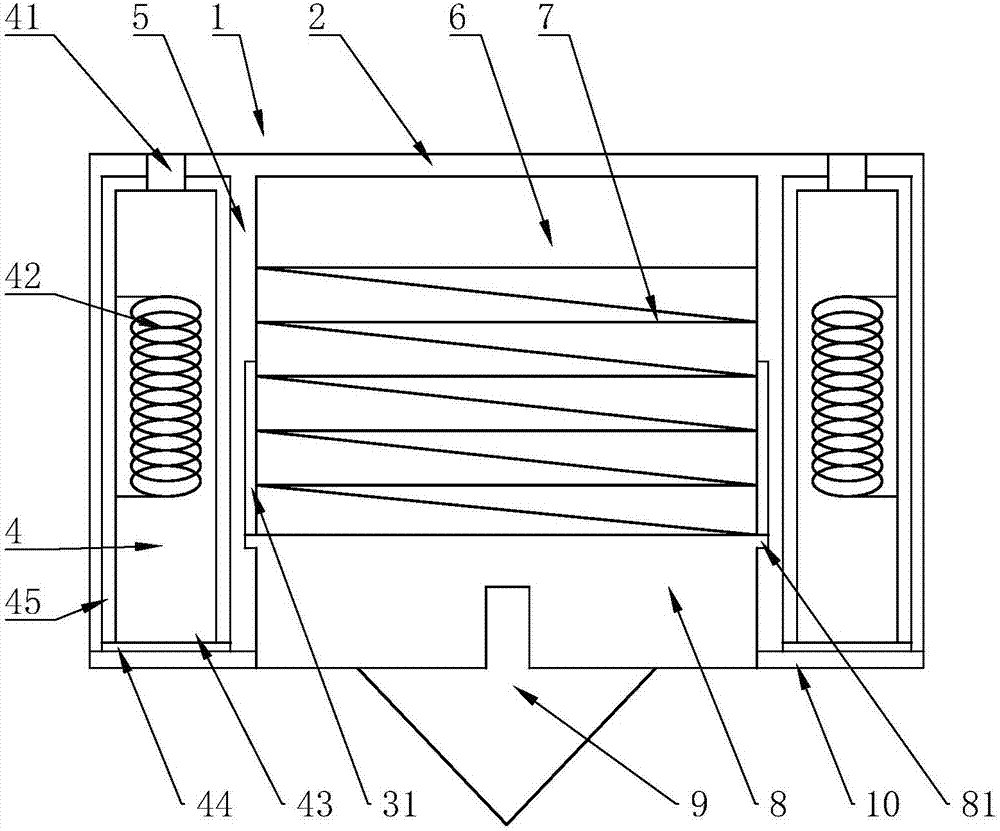

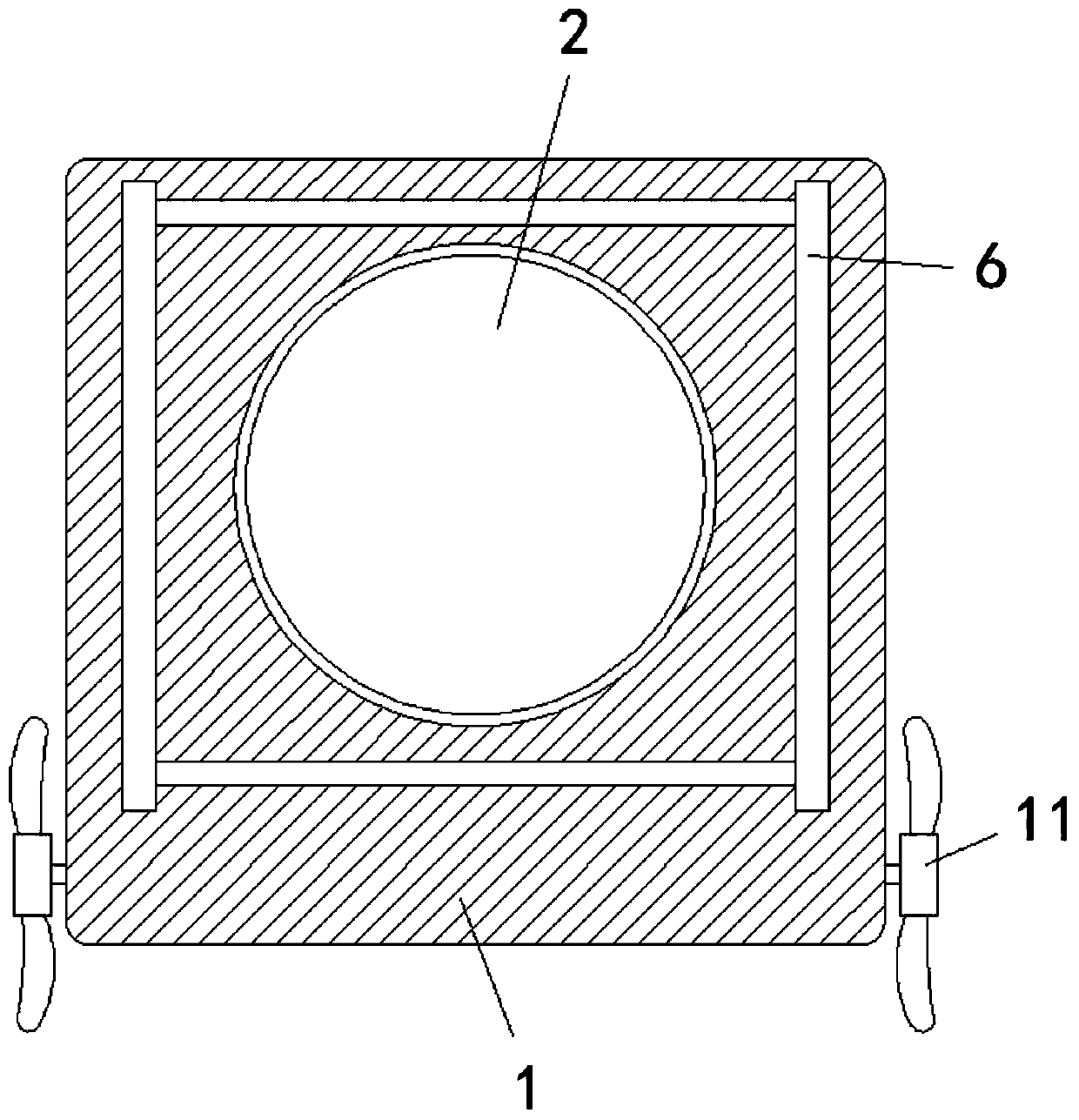

Multi-stage denoiser and valve with same

ActiveCN104913148AImprove noise reductionReduce oscillationValve members for absorbing fluid energyPipe elementsVALVE PORTSmall hole

The invention discloses a multi-stage denoiser and a valve with the same. The multi-stage denoiser comprises a hollow denoising cylinder and at least two stages of denoising covers. The denoising covers are arranged in the hollow denoising cylinder in the extension direction of the hollow denoising cylinder. Each stage of denoising cover is provided with a fluid cavity and a fluid inlet formed in the head portion of the fluid cavity. The wall of the fluid cavity of each stage of denoising cover is provided with a plurality of through holes. The fluid inlet of the fluid cavity of the rear stage of denoising cover corresponds to the tail portion of the front stage of denoising cover and forms a buffer cavity together with the tail portion of the front stage of denoising cover. The valve comprises a valve body and an outflow passageway of fluid. The outlet of the outflow passageway is fixedly connected with the denoiser in the axial direction. By arranging the multiple stages of denoising covers, the denoising efficiency is improved, the denoising effect is achieved through the frequency shift effect of small hole spraying, and the fluid flow speed is uniform through the buffer cavity. The vibration caused by fluid impact to the denoiser is reduced in the medium flowing process, and therefore the stability of the product is improved, and the overall service life of the denoiser is prolonged.

Owner:NEWAY VALVE SUZHOU

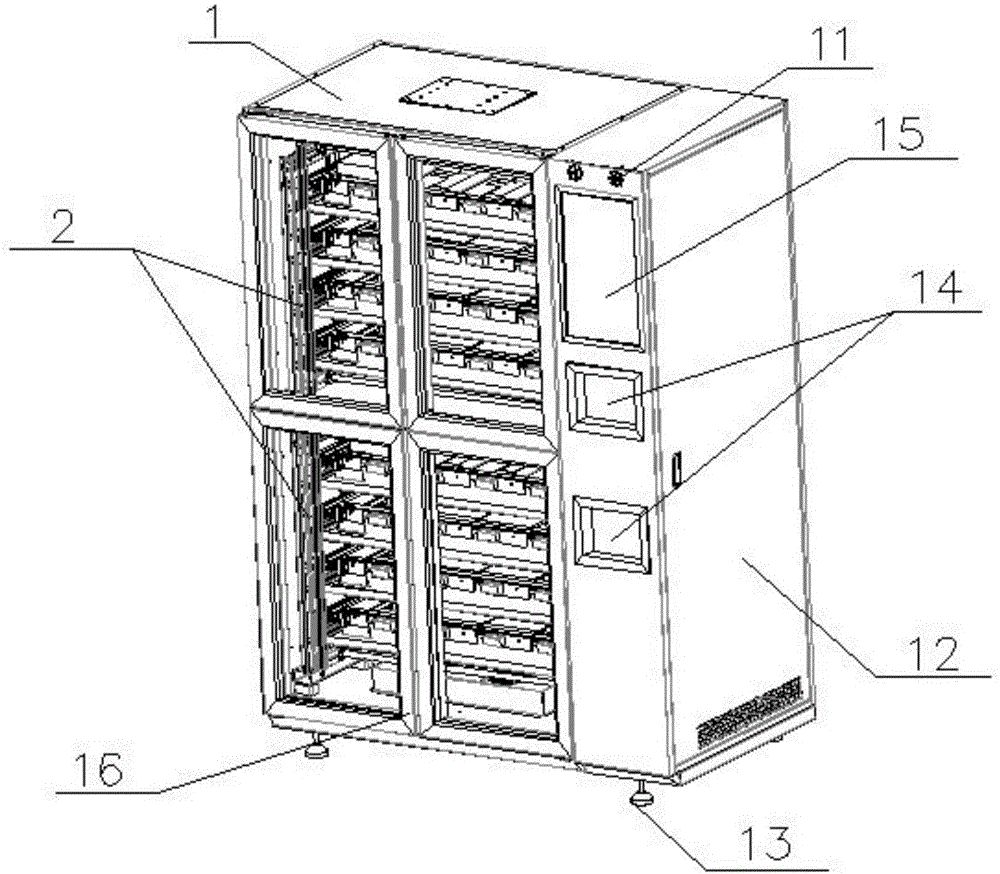

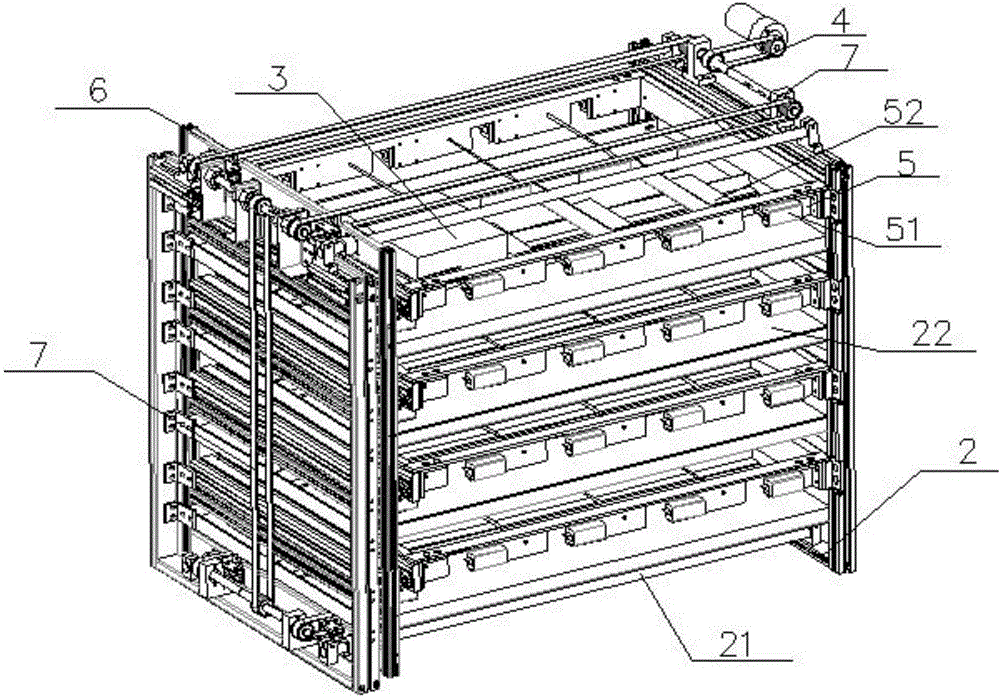

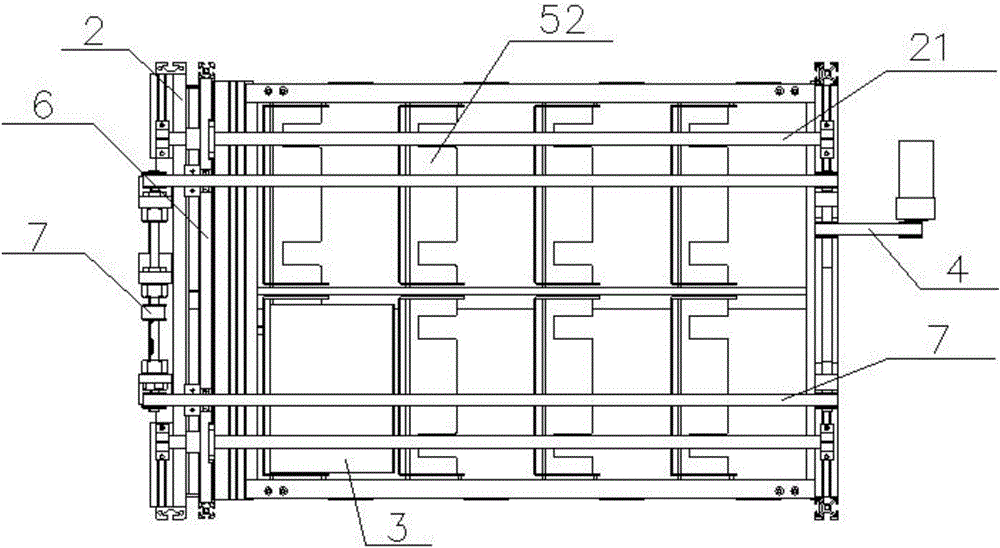

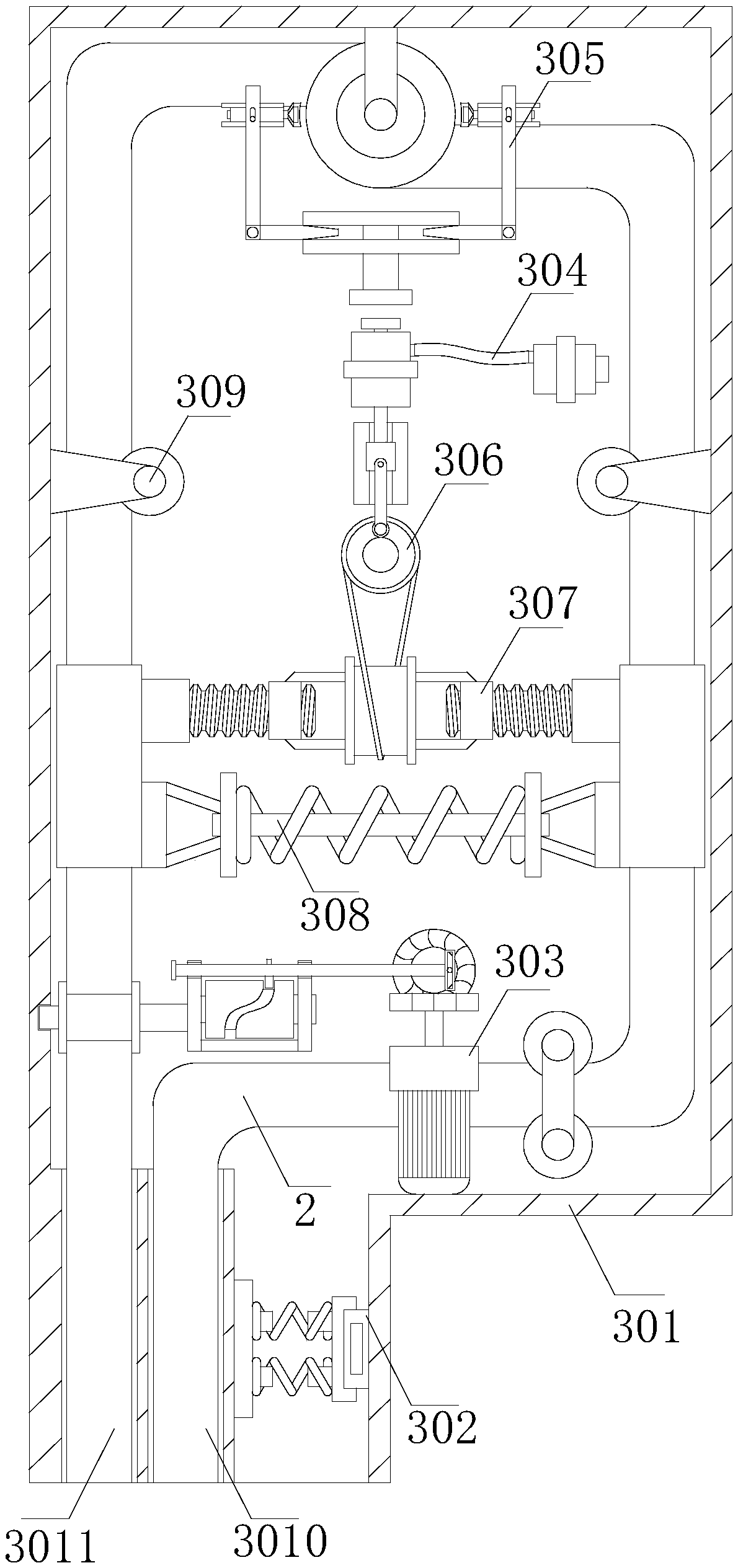

Vending machine with reservation function

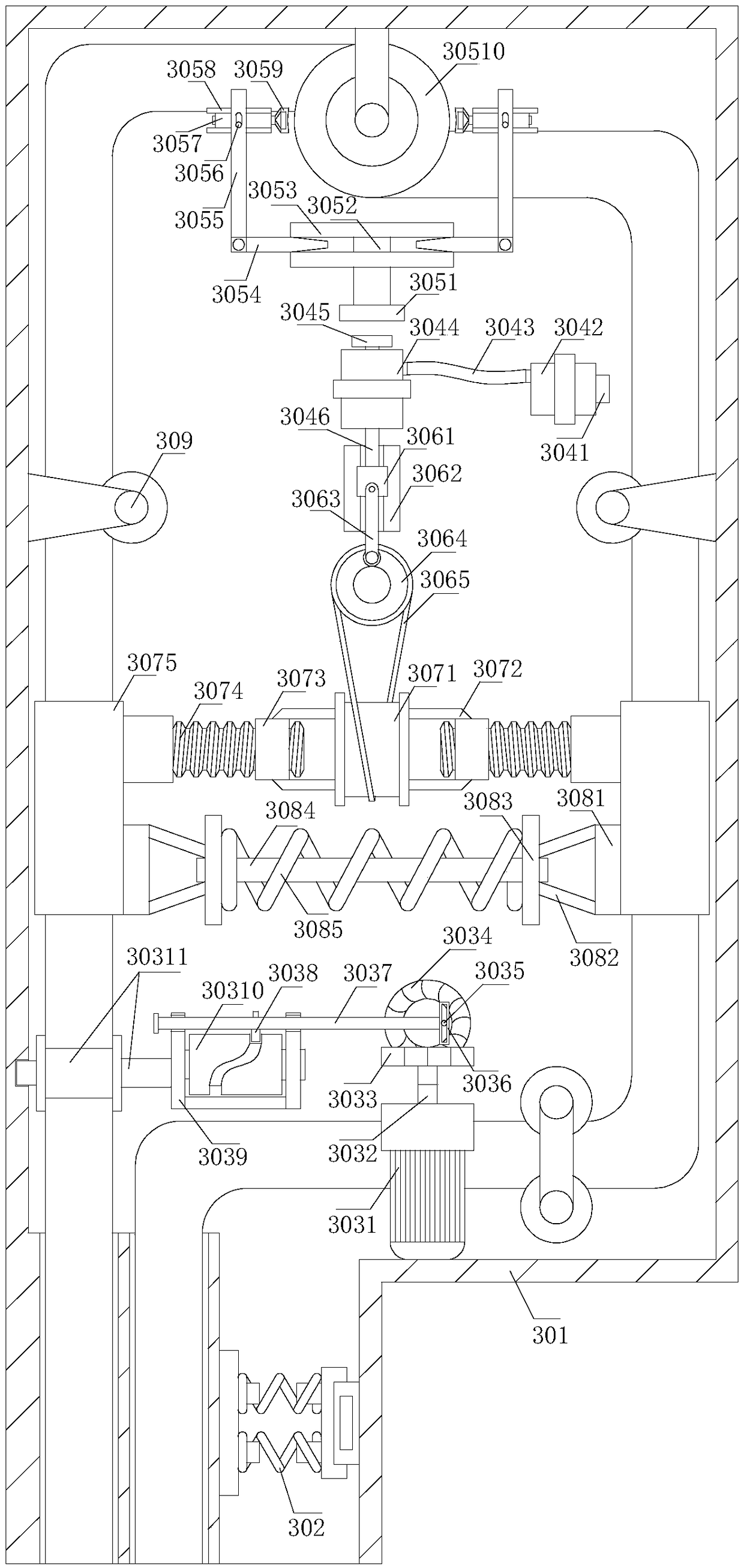

ActiveCN106781018AEffective temperature controlQuality assuranceCoin-freed apparatus detailsApparatus for dispensing discrete articlesDrive shaftDisplay device

The invention discloses a vending machine with a reservation function. The vending machine comprises a main cabinet, brackets, storage grids, push frames, lifting push platforms and article containing plates, wherein the main cabinet is internally divided into an upper layer and a lower layer by a detachable heat preservation spacer plate; the main cabinet is provided with a plurality of glass doors; the right side of the main cabinet is communicated with an auxiliary cabinet; the auxiliary cabinet is provided with a loudspeaker and an article taking mouth; the auxiliary cabinet is provided with a display device and is internally provided with the plurality of lifting push platforms; the slideable push frames and the plurality of storage grids are installed on the brackets; the push frames are provided with a plurality of sliding rail mounting sleeves and push racks; the lifting push platforms are provided with a plurality of tracks and transmission shafts; the article containing plates are installed on the lifting push platforms in a sliding way; the peripheries of the article containing plates are fixedly connected with auxiliary conveyor belts by screw fixing pieces; each article containing plate is provided with a front push handle and a side push handle in a matching way. The vending machine is beneficial to storage of a great deal of articles and different types of articles, effectively controls the temperature of the articles, and enables people to clearly know the information of the reserved articles.

Owner:严福英

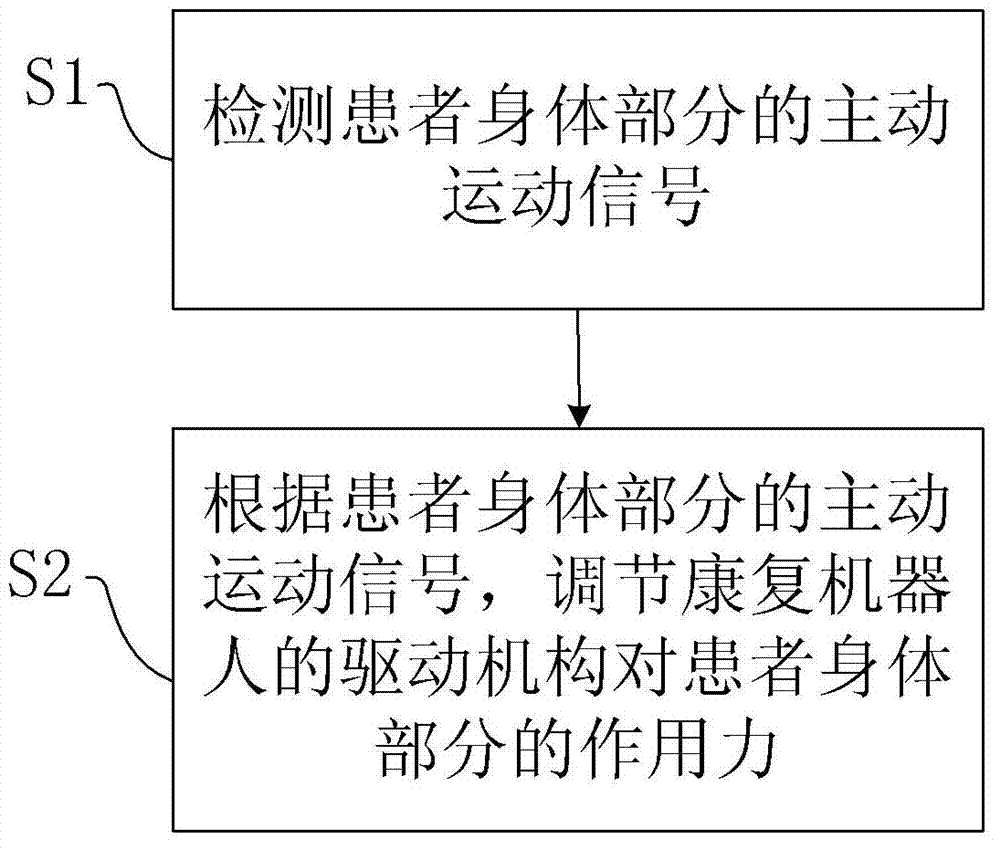

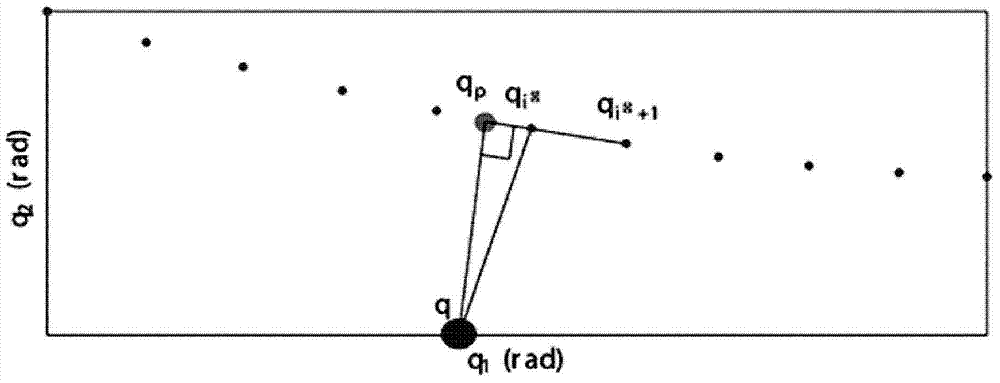

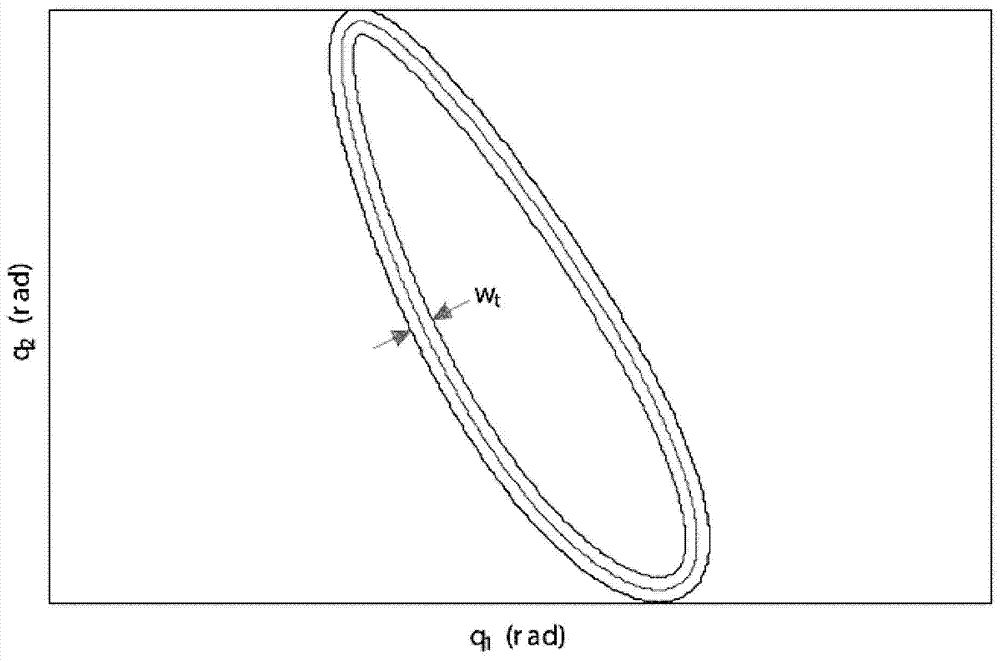

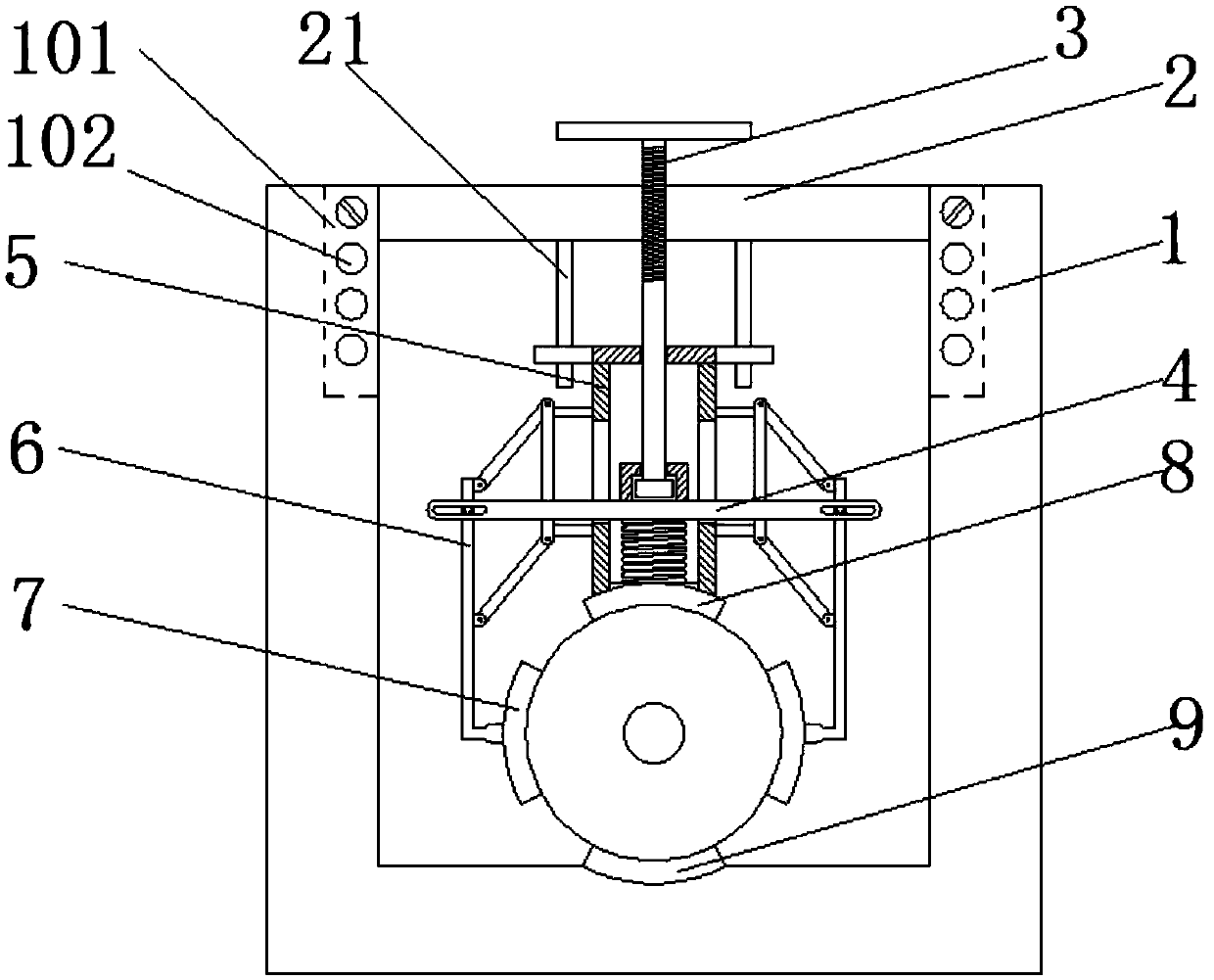

Task-oriented active training control method and corresponding rehabilitation robot

ActiveCN104492066AGuaranteed movement trajectoryImprove consistencyGymnastic exercisingControl systemEngineering

The invention discloses a task-oriented active training control method applied to a rehabilitation robot. The rehabilitation robot is provided with a sensor, a control system and a driving mechanism, the control system is used for receiving a signal generation control command collected by the sensor and sending the control command to the driving mechanism, and the driving mechanism can be worn on the body part of a patient and is used for receiving the control command and applying and regulating acting force on the body part of the patient according to the control command so as to control rehabilitation training of the patient. The control method includes the steps: S1, detecting an active movement signal of the body part of the patient; S2, regulating the acting force applied by the driving mechanism of the rehabilitation robot on the body part of the patient according to the active movement signal of the body part of the patient.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

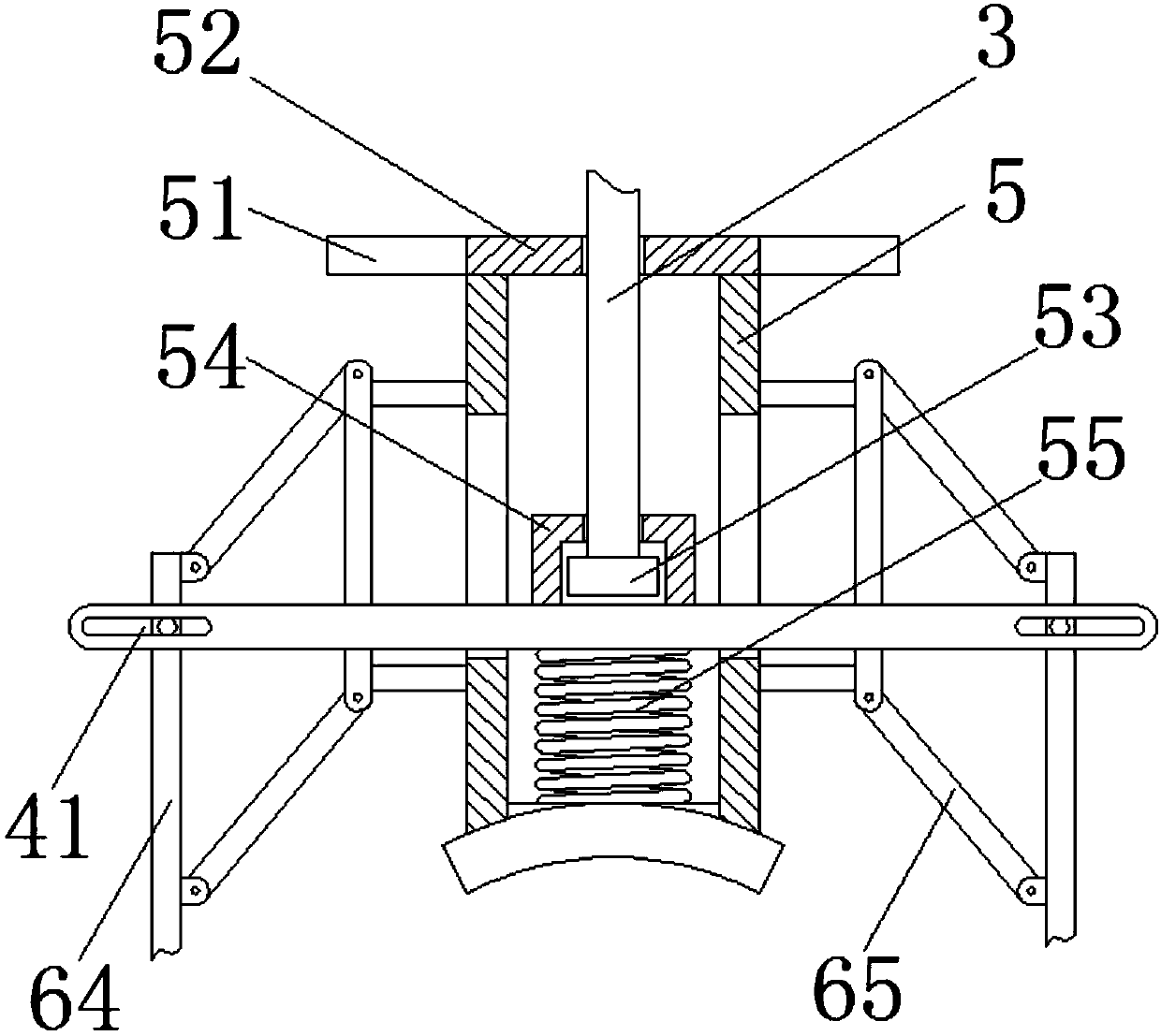

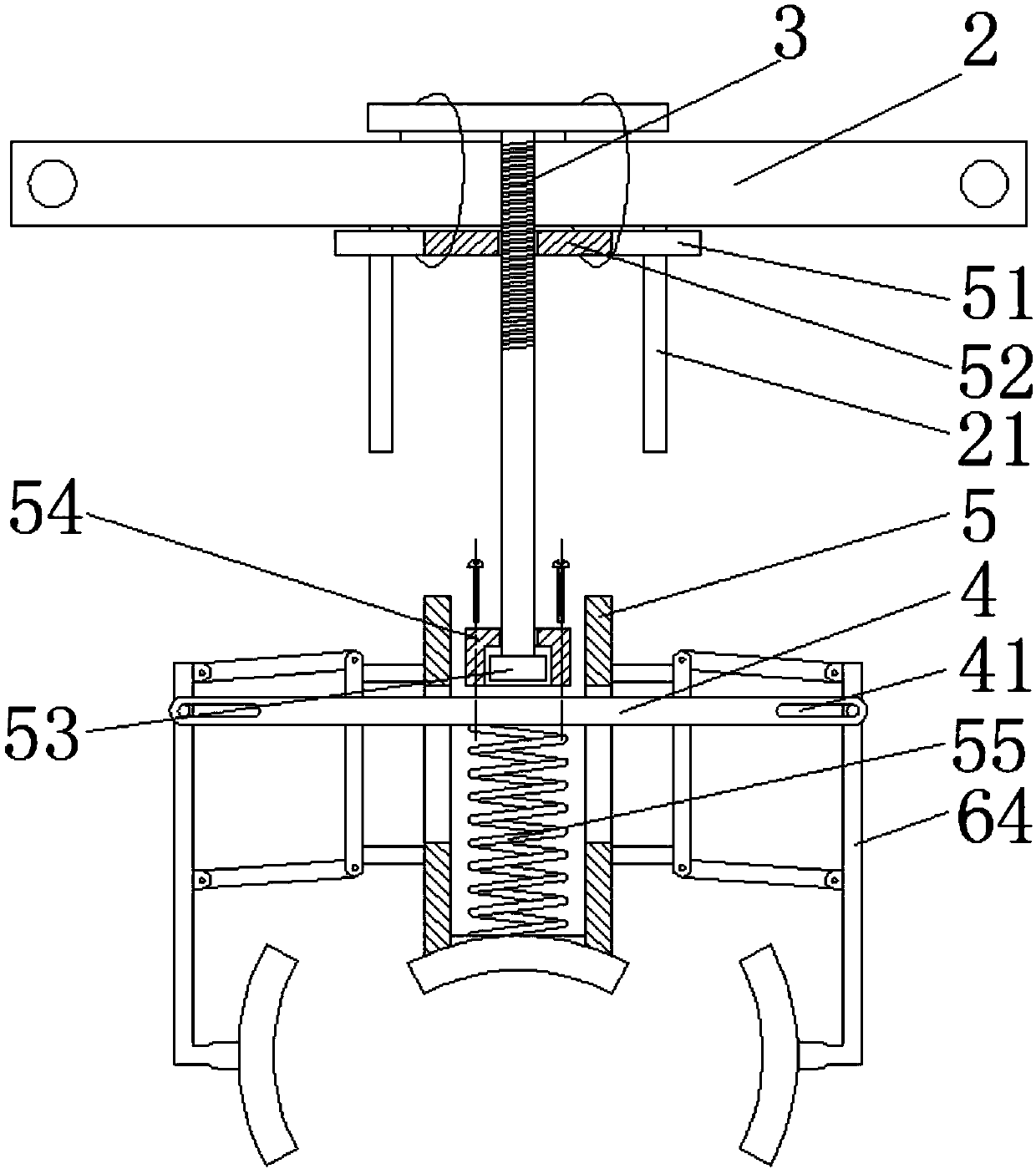

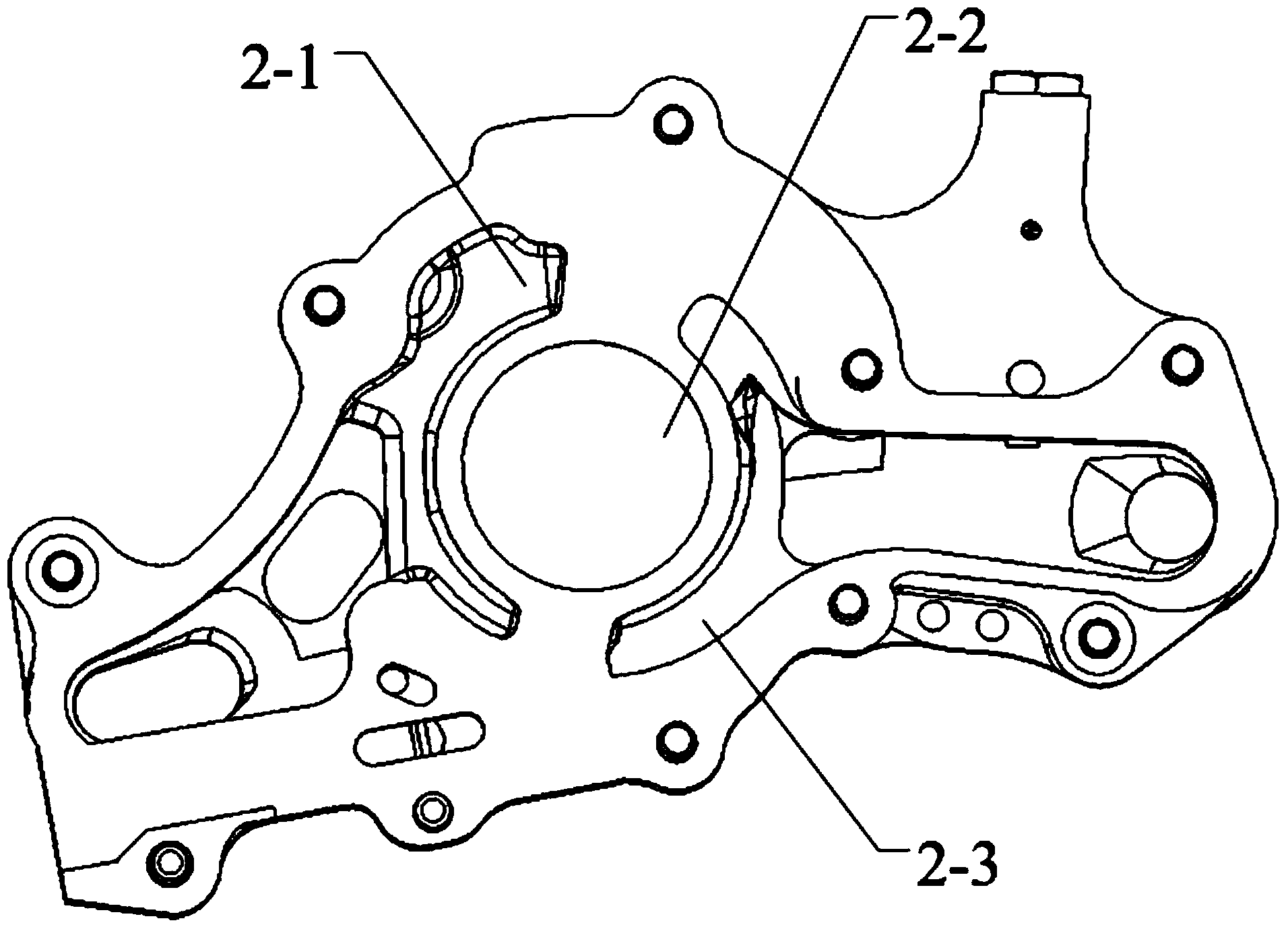

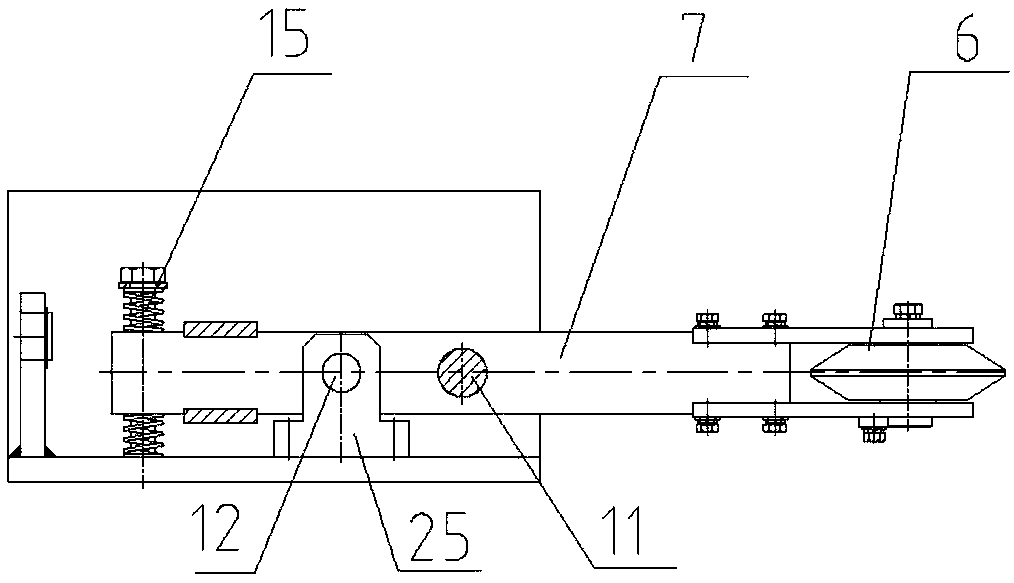

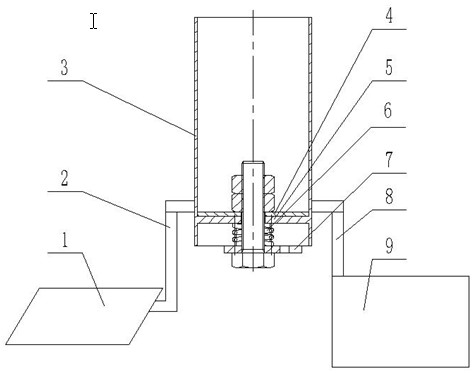

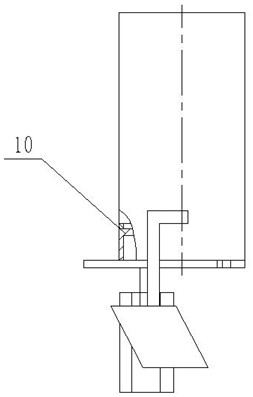

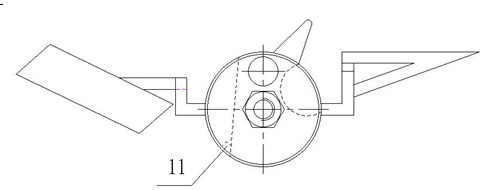

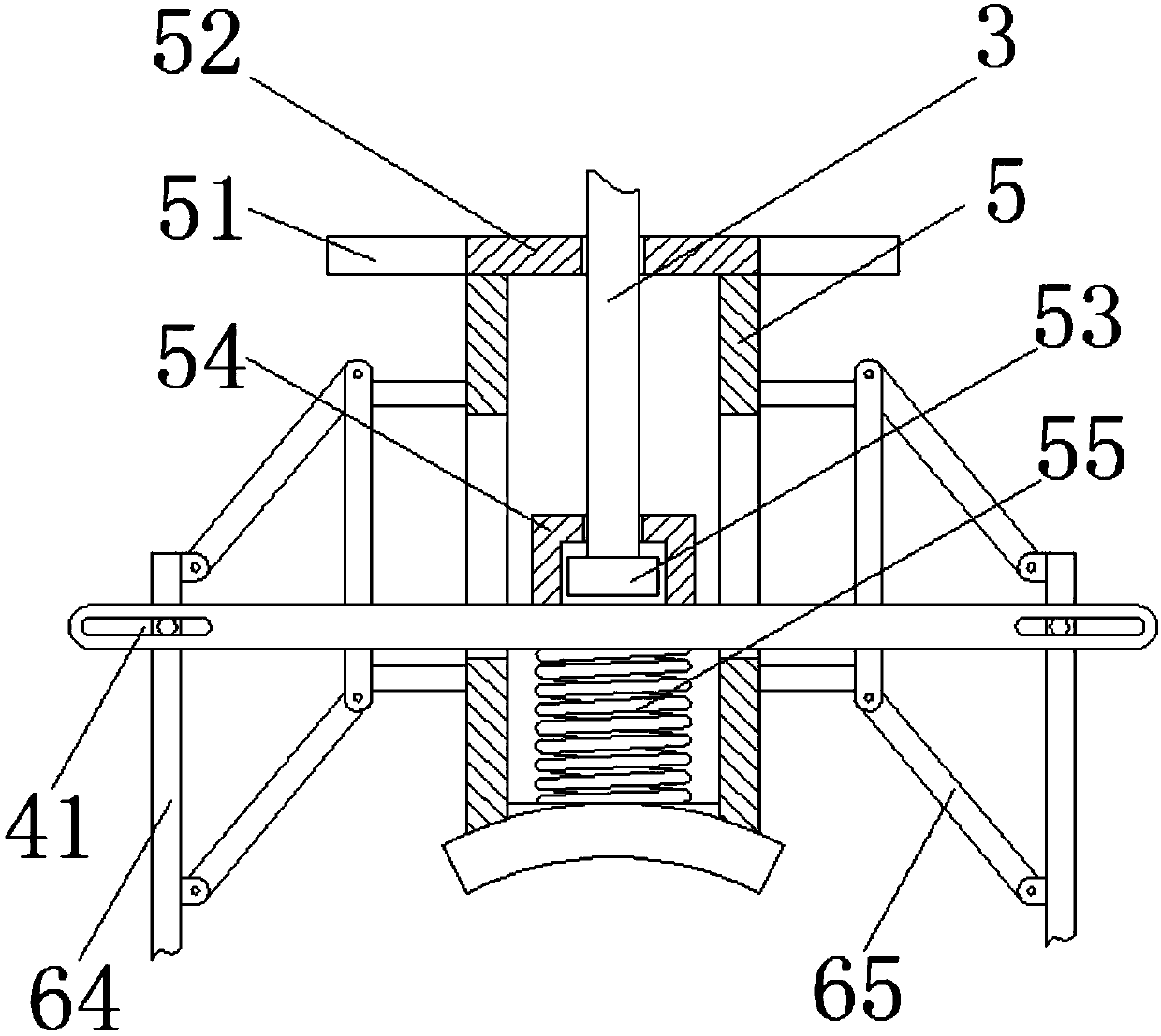

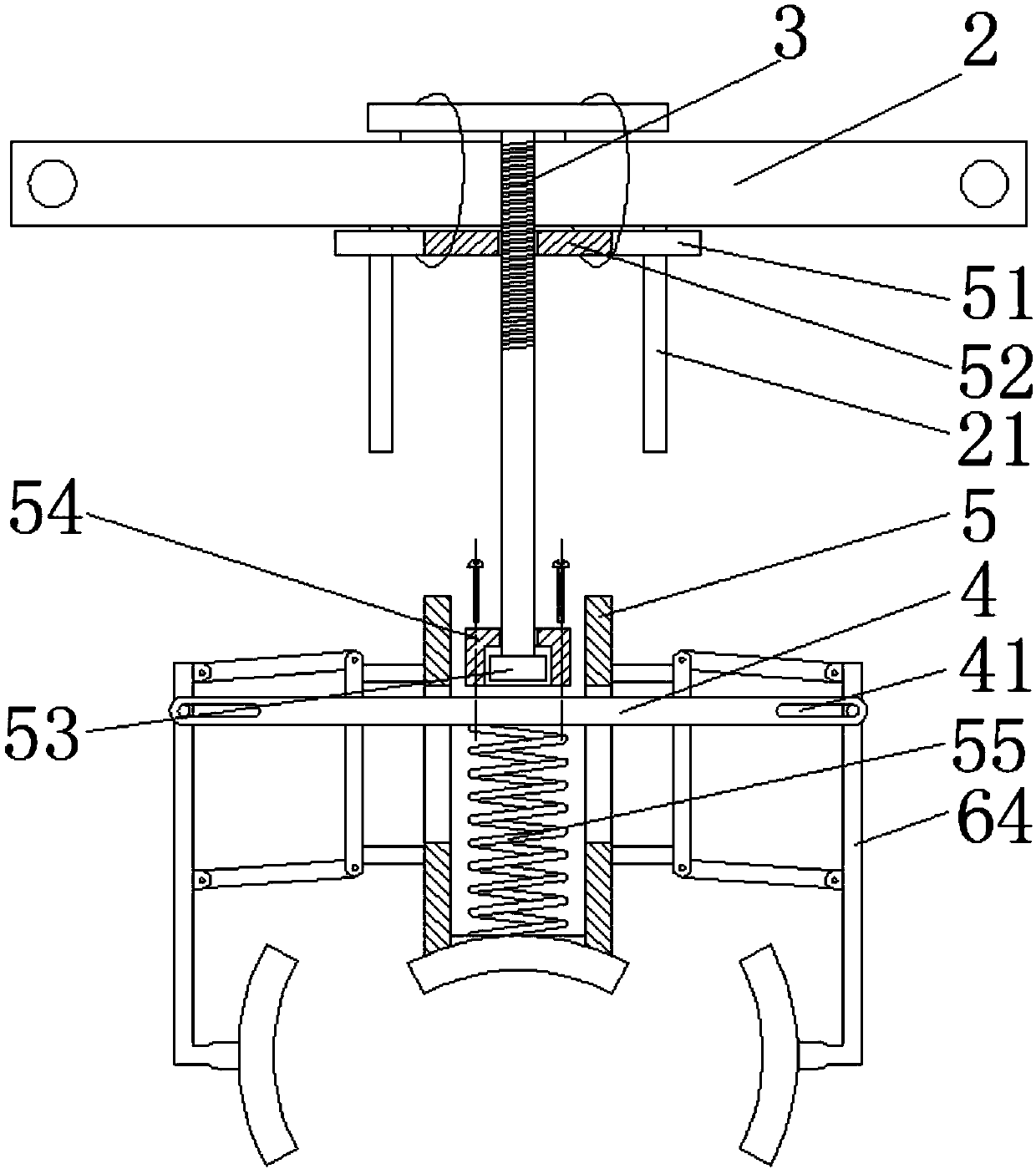

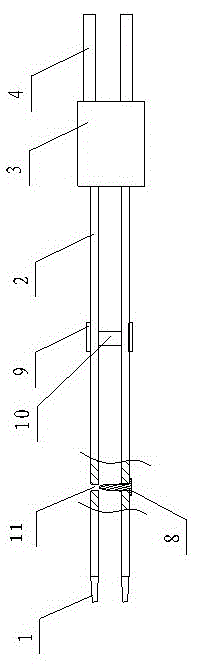

Assembling method of device for clamping insulator

The invention belongs to the technical field of insulator clamping equipment, and particularly relates to an assembling method of a device for clamping an insulator. The device for clamping the insulator comprises a U-shaped frame and an opening cross rod, and the two ends of the opening cross rod are inserted into sliding grooves formed in the two sides of the U-shaped frame and fixed through bolts; a screwing rod is arranged in the middle of the opening cross rod, the lower end of the screwing rod penetrates through a sleeve flange disc to enter a fixing sleeve, a fixing block is connected to the lower end of the screwing rod and arranged in a fixing cavity, the lower end of the fixing cavity is connected with a horizontal cross rod, and a spring is arranged between the horizontal crossrod and the bottom of the fixing sleeve; and quadrangular connecting rod frames are connected to the two ends of the horizontal cross rod separately, side face clamping blocks are hinged to the lowerends of movable rods, an upper end clamping block is arranged at the lower end of the fixing sleeve, and a lower end clamping block is arranged at the bottom of the U-shaped frame. The insulator doesnot need to be disassembled in the clamping process, the clamping position is automatically positioned, and a clamping mode with both fixed clamping force and variable clamping force is formed.

Owner:温州炘都工业设计有限公司

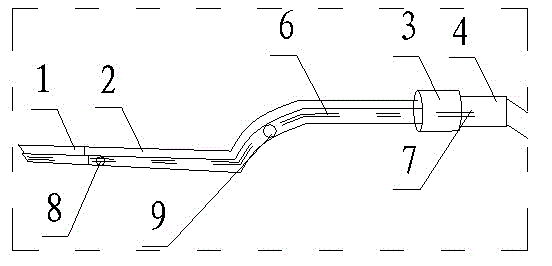

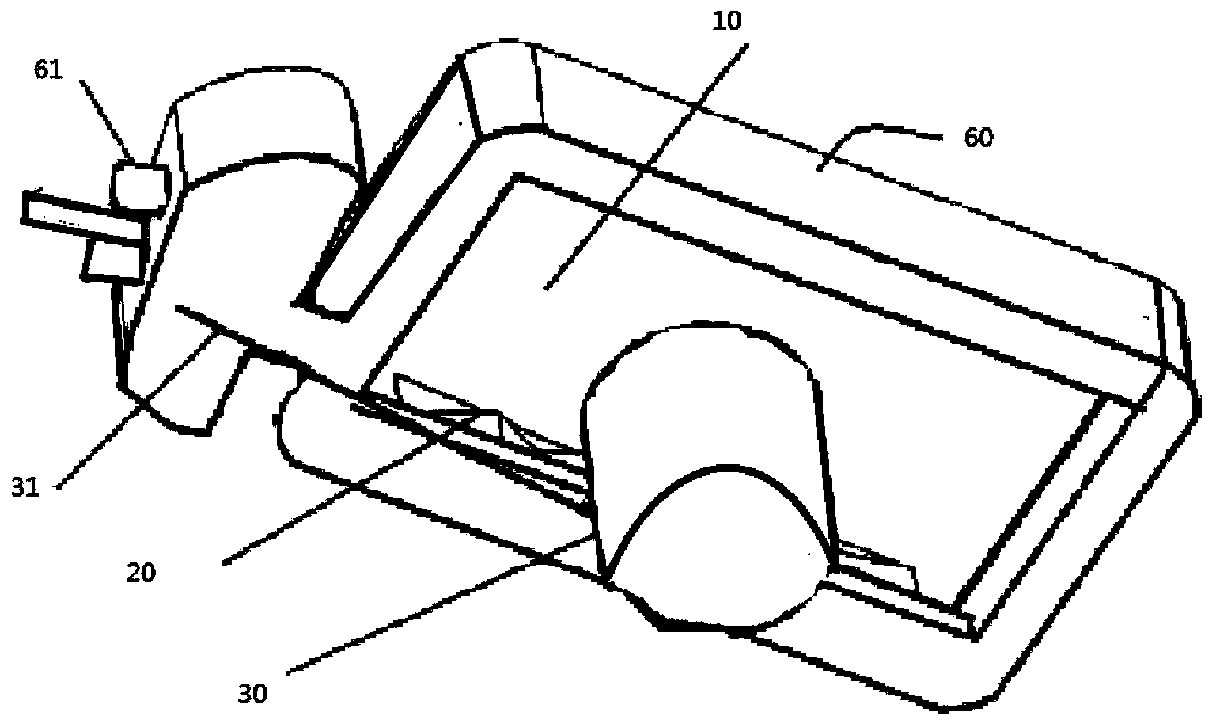

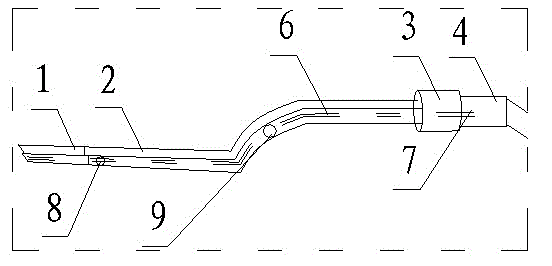

Outside rear-view mirror

ActiveCN103434450APreventing problems caused by wipingGuaranteed movement trajectoryVehicle cleaningOptical viewingMotor driveGear wheel

The invention discloses an outside rear-view mirror which comprises a mirror frame, a flexible lens, a scraping blade and rolling shafts, wherein the outside rear-view mirror further comprises a gear and a motor driving the gear to rotate; the rolling shafts comprise a first rolling shaft and a second rolling shaft; the flexible lens is of a sleeve shape and is arranged on the first rolling shaft and the second rolling shaft in a sleeved mode, the flexible lens is provided with racks connected end to end, and the racks are meshed with the gear; the gear is used for driving the flexible lens to rotate around the rolling shafts through the racks, and the scraping blade is used for scraping objects on the outer surface of the flexible lens. According to the outside rear-view mirror, the sleeve-shaped flexible lens is adopted, the motor drives the flexible lens to rotate, therefore, water or other impurities on the flexible lens fixed on the mirror frame are scraped, the problem brought by water scraping carried out by a traditional rocker arm type scraping blade is solved, and the problems that a small part of the surface of a traditional lens cannot be cleaned, and the scraping blade shields a part of the visual field in the operating process are resolved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Novel intelligent electric coagulation forceps system

InactiveCN102743221AGuaranteed bonding effectAvoid overheatingSurgical instruments for heatingGradual increaseForceps

The invention discloses a novel intelligent electric coagulation forceps system which comprises a forceps body and a main machine for supplying power to the forceps body, wherein the forceps body comprises forceps tips and forceps rods. The novel intelligent electric coagulation forceps system is characterized by further comprising a current detection device and a voltage detection device which are used for respectively detecting current and voltage between the forceps tips. Impedance of an object between the forceps tips is calculated according to the ratio of the voltage to the current, and the main machine gradually decreases output power of the forceps tips along with gradual increase of the impedance. A water inlet channel is arranged on the forceps body, an outlet of the water inlet channel is located at the positions of the forceps tips, a first positioning rod is fixed in front of the forceps rod on one side, and a corresponding positioning hole is arranged on the forceps rod on the other side. The temperature of the forceps tips is controlled within a certain range by detecting the temperature of the forceps tips in real time, so that adhesion effect of the electric coagulation forceps is ensured, and a superheat phenomenon is avoided.

Owner:CHONGQING RUNZE PHARM CO LTD

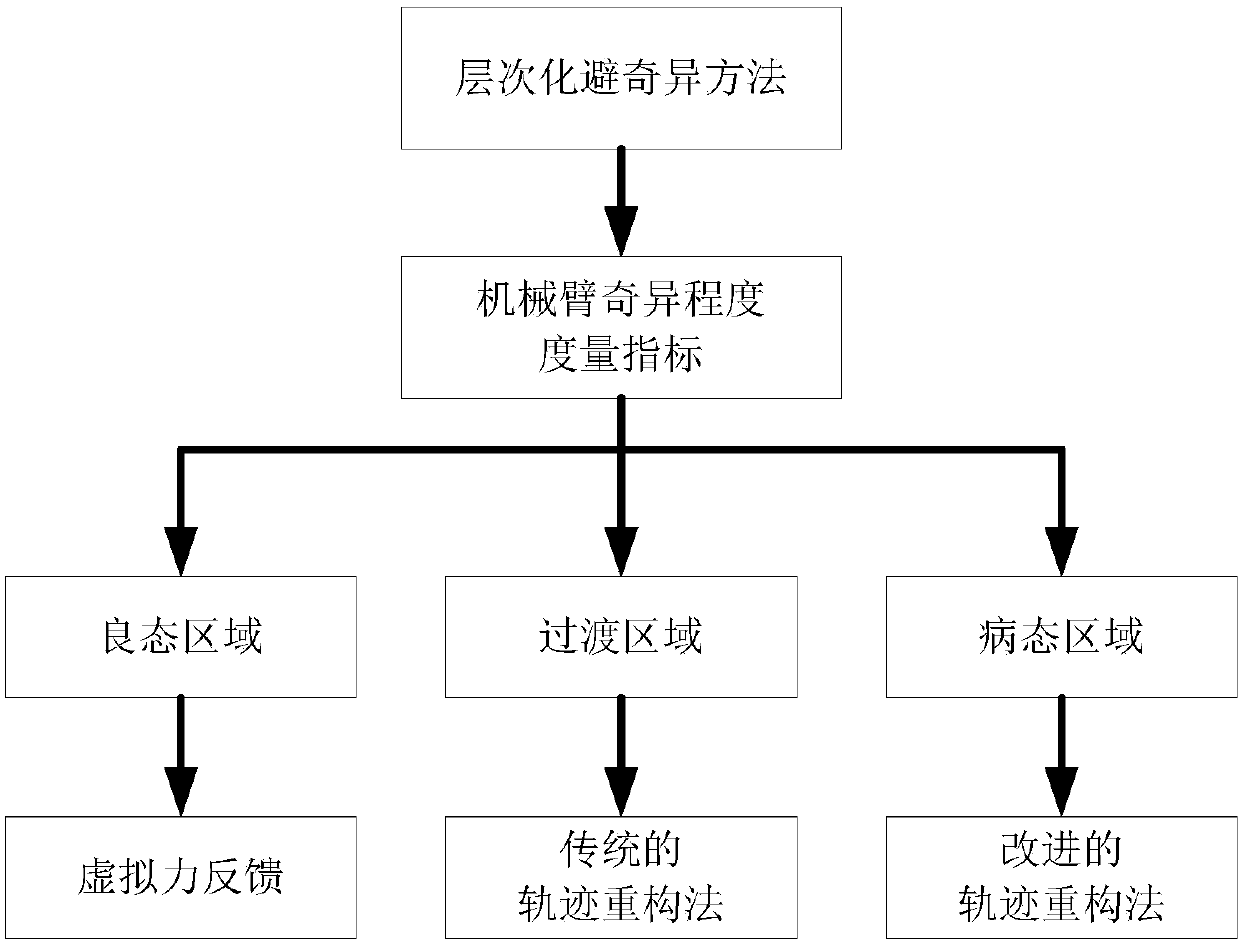

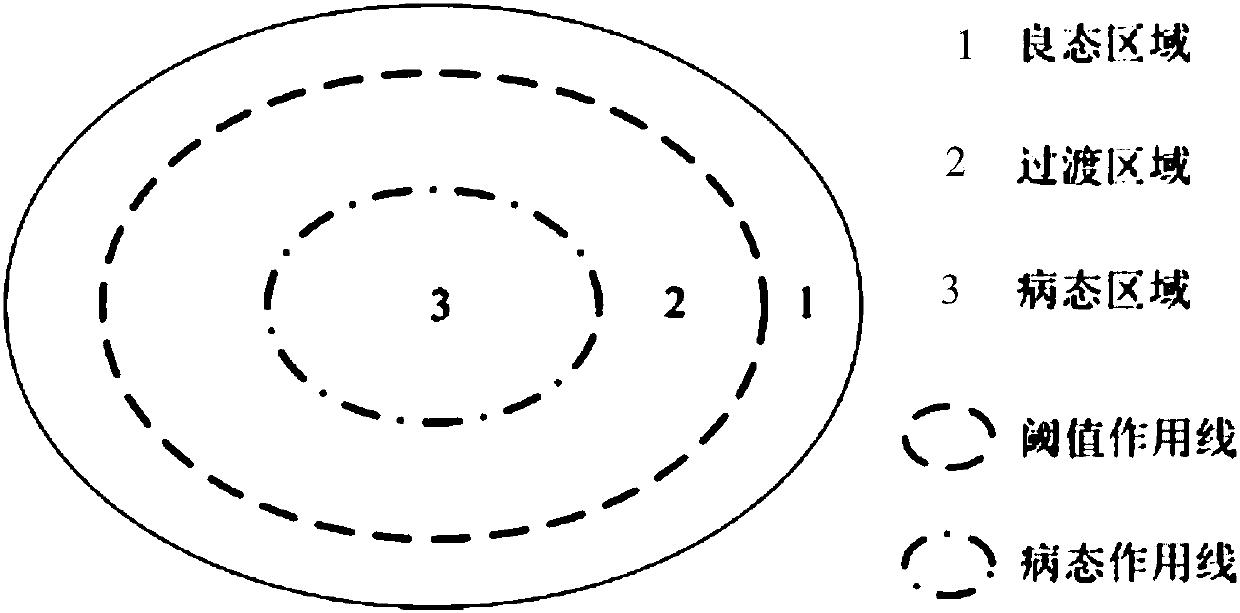

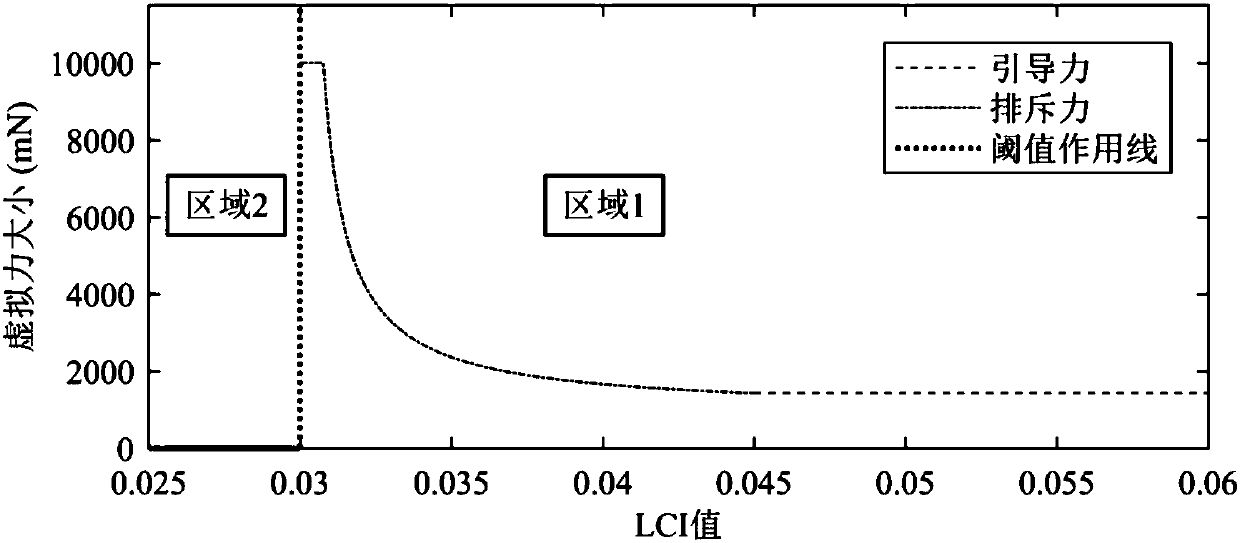

Layering singularity avoidance method of remotely operating mechanical arm

ActiveCN107831680AGuaranteed movement trajectoryProgramme control in sequence/logic controllersSingularity avoidanceReconstruction method

A layering singularity avoidance method of a remotely operating mechanical arm belongs to the field of robot remote operation. The invention aims to solve the problem that in the existing mechanical arm movement process, a single method is adopted to avoid singularity, and the normal motion trail of the mechanical arm cannot be effectively ensured. The singularity avoidance layer of operation state of the mechanical arm is divided into a good region, a transition area and a sick area according to the local condition sequence of a mechanical arm singularity degree measurement index. When the mechanical arm operates in a good area, the movement of an operator of a main end is guided in a virtual force feedback mode; when the mechanical arm operates in the transition area, a traditional trackreconstruction method is adopted to reconstruct the tail end track of the mechanical arm; and when the mechanical arm operates in a sick area, the tail end track of the mechanical arm is reconstructed by adopting an improved track reconstruction method. The method is used for avoiding singularity of a mechanical arm.

Owner:HARBIN INST OF TECH

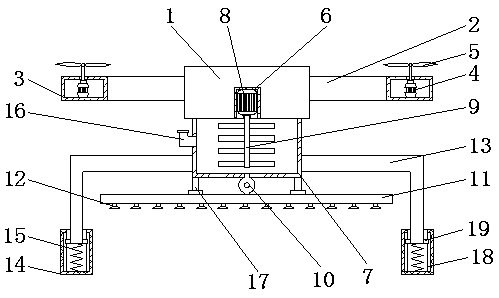

Agricultural unmanned aerial vehicle

InactiveCN109334987APlay a mixed effectPlay a buffering effectAircraft componentsRotary stirring mixersPropellerAgricultural engineering

The invention discloses an agricultural unmanned aerial vehicle, which comprises an unmanned aerial vehicle body. Horizontal plates are fixedly connected to two sides of the unmanned aerial vehicle body, mounting grooves are formed in the sides, away from the unmanned aerial vehicle body, of the horizontal plates, a first motor is fixedly mounted at the bottom of an inner cavity of each mounting groove, an output shaft of each first motor is sleeved with a propeller, and the propellers extend out of the mounting grooves. A groove is formed in the bottom of the unmanned aerial vehicle body, a pesticide box is fixedly connected to the bottom of the unmanned aerial vehicle body, and a second motor is fixedly connected to the top of an inner cavity of the groove. A pesticide mixing effect is achieved by arranging the groove, the second motor and a stirring blade, a buffer effect during landing of the unmanned aerial vehicle is achieved by arranging sleeves and springs, and the problems that pesticides carried by existing agricultural unmanned aerial vehicles are prone to being settled in the spraying process, consequently pesticide liquid is blocked during spraying, the spraying effectis lowered and spraying is not uniform are solved.

Owner:河南中恒网络科技有限公司

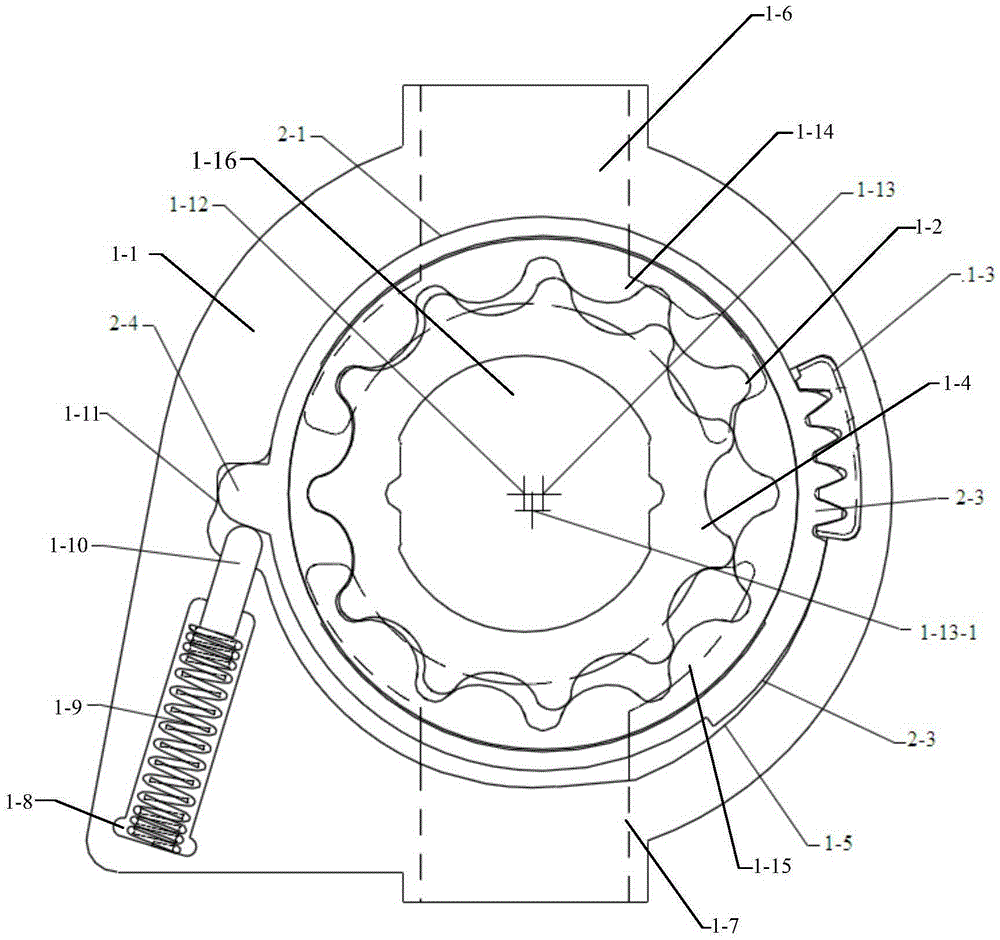

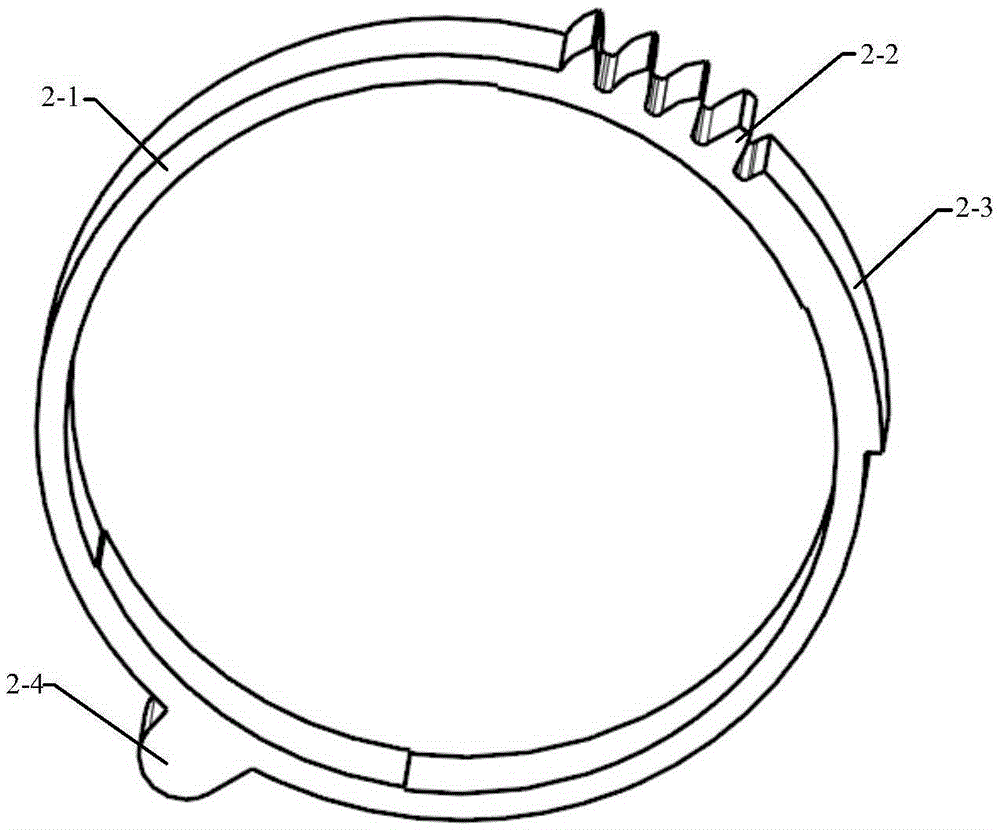

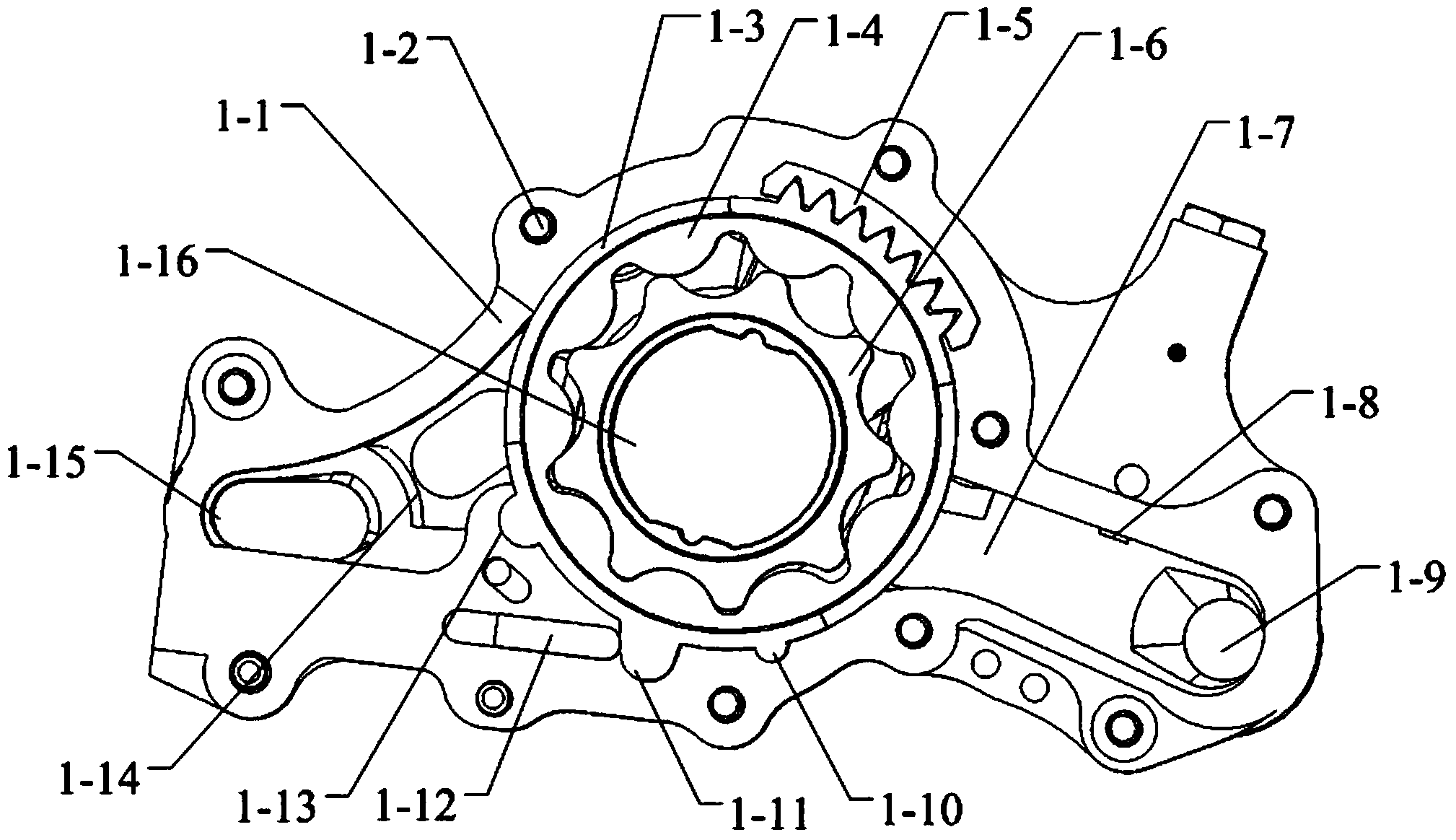

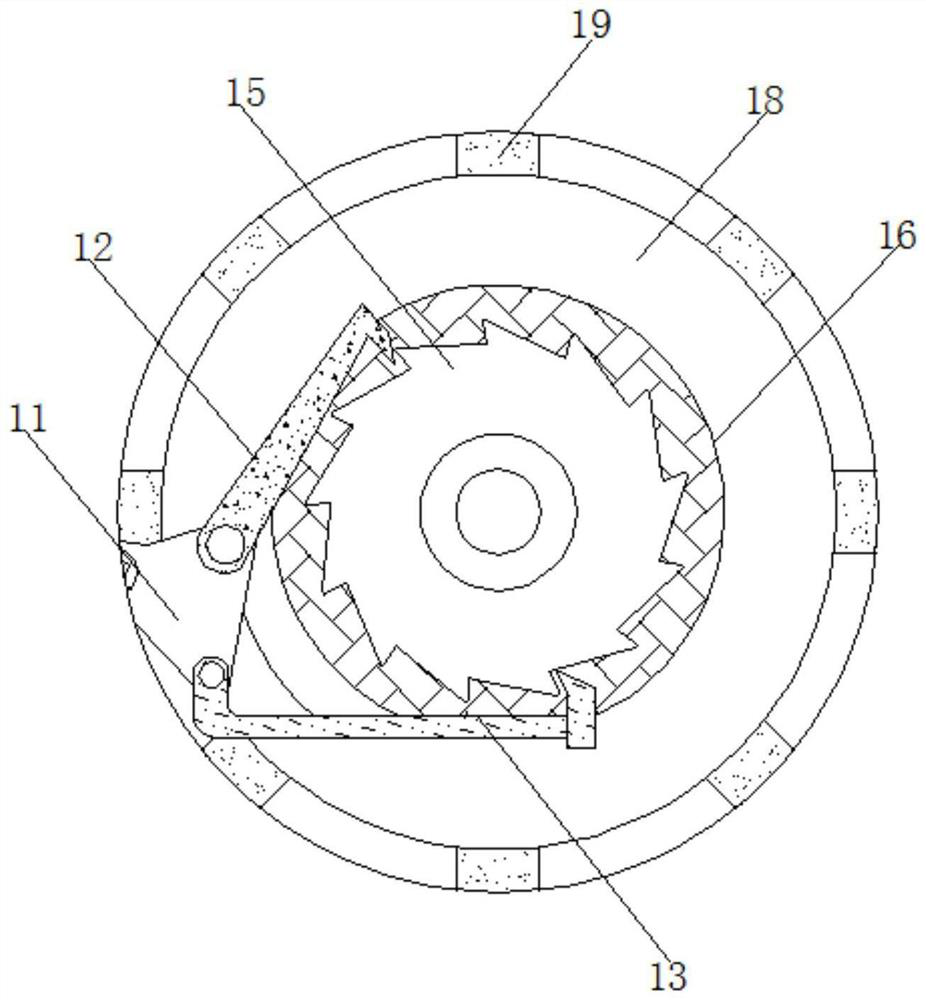

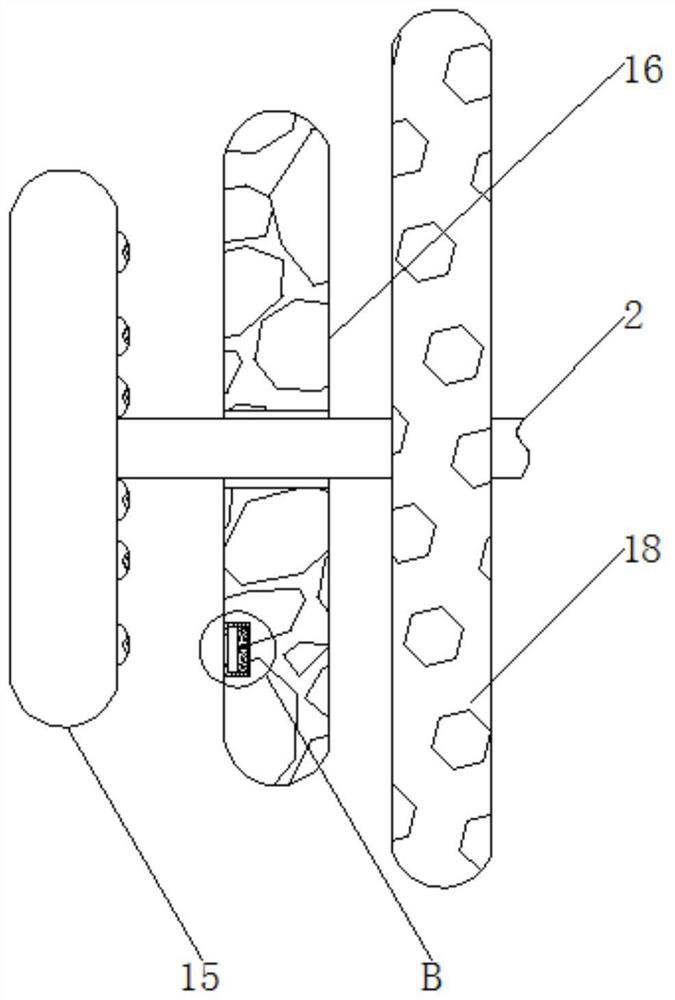

Rotor variable pump

The invention provides a rotor variable pump. The rotor variable pump comprises a pump body, a pump cover, an inner rotor, an outer rotor, an adjusting ring and a force application device; the adjusting ring is provided with pitch circle arc segments; matching arc segments corresponding to the pitch circle arc segments are arranged on the pump body; when the pressure in the pump body is increased, the adjusting ring rolls on the matching arc segments under the limit of the engagement relation between adjusting teeth segments and fixed teeth segments and the limit of the pitch circle arc segments and the matching arc segments of the pump body, and the adjusting ring is made to move towards an oil inlet area; when the pressure in the pump body is deceased, under the action force of the force application device, the adjusting ring rolls on the matching arc segments of the pump body under the limit of the engagement relation between the adjusting teeth segments and the fixed teeth segments and the limit of the pitch circle arc segments and the matching arc segments of the pump body, the adjusting ring is made to move towards an oil outlet area, and therefore the moving track of the adjusting ring is limited; accordingly, under the condition of certain eccentric distance of the inner and outer rotors, the eccentric position of rotation by the outer rotor around the center of the inner rotor can be changed, and the purpose of adjusting displacement of a fuel pump is achieved.

Owner:富奥泵业(湖北)有限公司

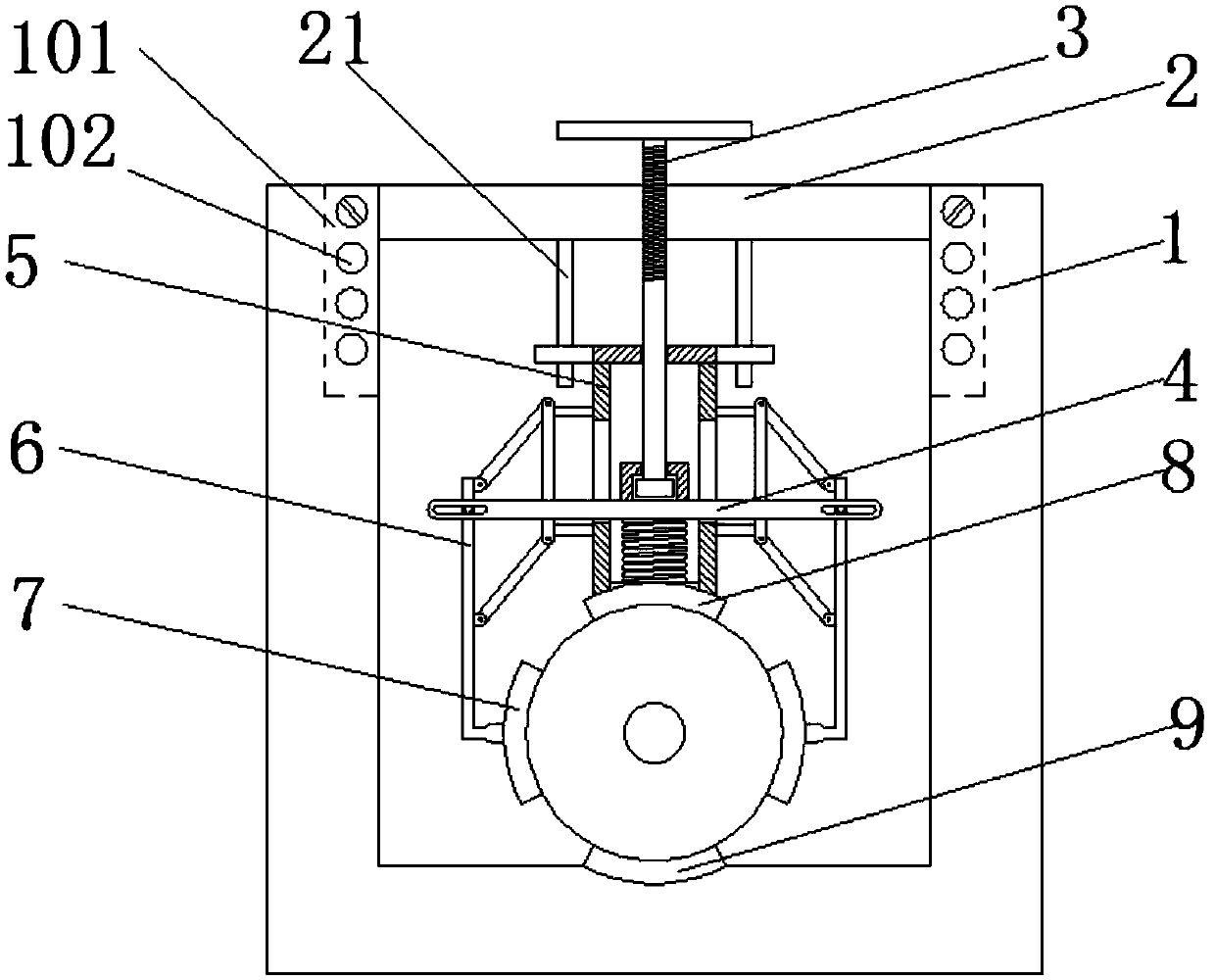

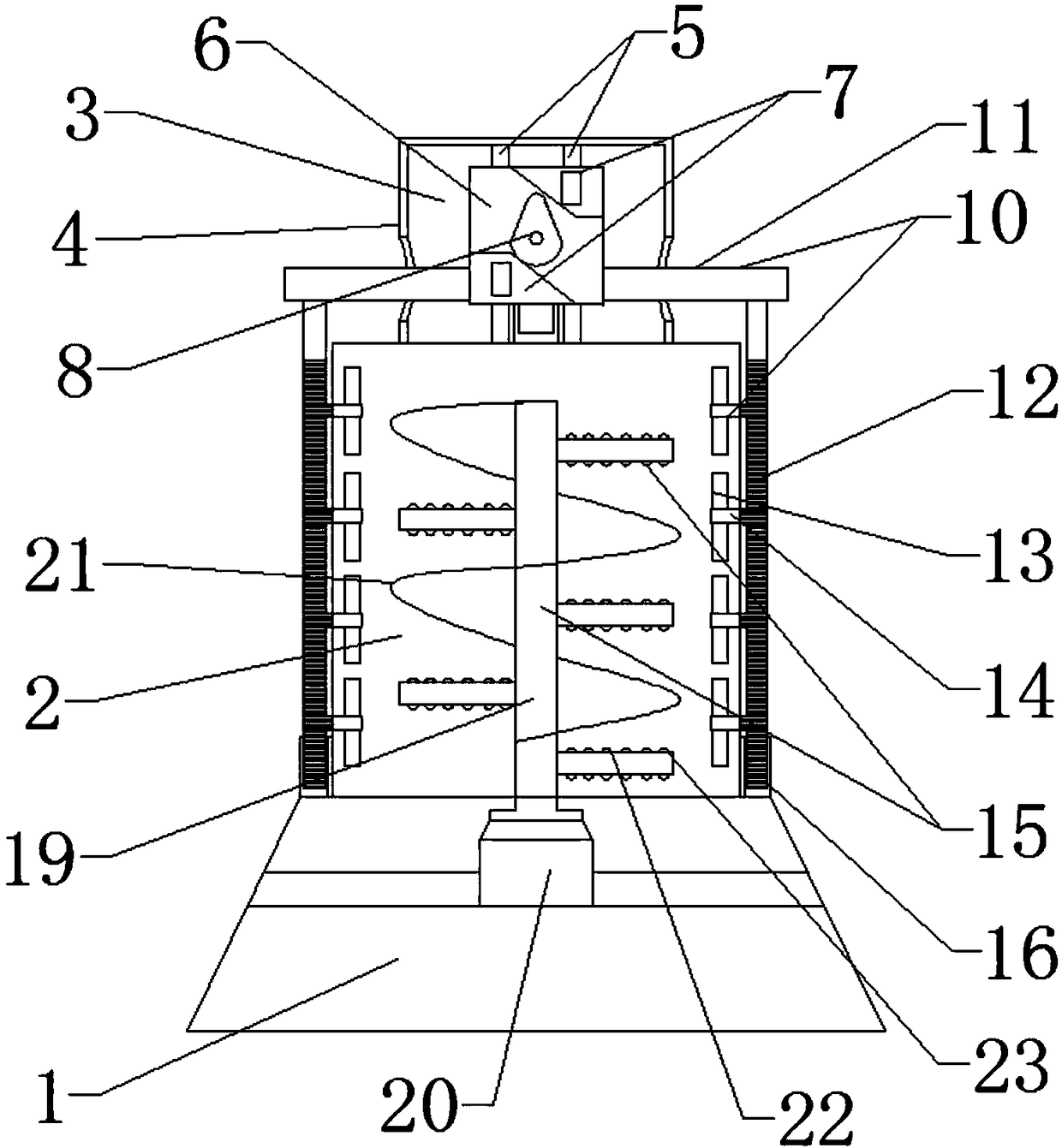

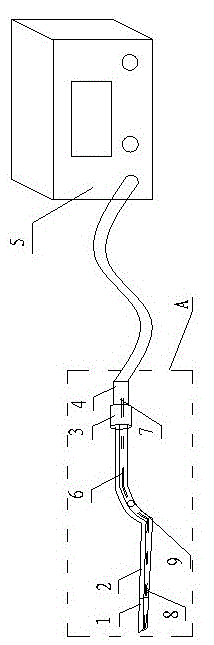

Escape device for slowly descending

The invention discloses an escape device for slowly descending. The structure of the device comprises a rope holder, a rope, a controller, a lifting lug and a base, wherein the rope is mounted insidethe controller and is movably connected, the descending speed of rope can be regulated by adjusting the speed of a speed regulating motor, moreover, the vibration generated in the operation of the rope is reduced by the action of a vibration reduction mechanism, so that an evacuee descends slowly and the safety of the evacuee is ensured. A plurality of anti-pulleys are arranged in the controller,the rope is straightened, and the rope is prevented from winding during the running process; a knob at the upper end of an offset rod causes a slide block to slide inside a fixed sliding plate to ensure the movement track of the slide block, the slide block pushes a brake pad, the brake pad is tightly pressed against the brake by a connecting turntable, the connecting turntable is decelerated to make the rope decelerate, and a clamping pipe is driven to run in the middle; the clamping pipe at both ends pull the two ends of the rope so as to slow the running speed of the rope, thereby slowing down the descent speed of the evacuee and achieving the effect of slowing down.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

Rotor-type variable pump

ActiveCN103759121AImprove sealingMature processing technologyLubricating pumpsDrive shaftEngineering

The invention provides a rotor-type variable pump which comprises a pump body, a pump cover, an inner rotor and an outer rotor. The pump body and the pump cover enclose to form a rotor cavity and a pipeline structure. The pipeline structure comprises an inlet area and an outlet area which are located on two sides of the rotor cavity and not communicated with each other; at least one operation area provided with a sealed outline and alternatively communicated with the inlet area and the outlet area is arranged between the inner rotor and the outer rotor; a drive device drives the inner rotor to rotate around a central axis of the inner rotor through a drive shaft; the rotor-type variable pump further comprises an adjusting ring, a fixed-tooth section and an applying device; an adjusting-tooth section is arranged on the adjusting ring which deflects under the limitation of the fixed-tooth section and under the action of external force. Rotation of the adjusting ring is completed through a gear cooperation mode, a gear cooperation part of the adjusting ring only accounts for a small proportion of the periphery of the adjusting ring, while other positions are in simple circular surface contact, so that airtightness at the position of the adjusting ring can be easily guaranteed.

Owner:富奥泵业(湖北)有限公司

Vehicle windscreen wiper

The invention discloses a vehicle windscreen wiper which comprises a wiper body. The wiper body comprises a concave shell. A cavity is formed in the concave shell. Heating cavities are symmetrically formed in the two sides of the cavity. Isolation walls are arranged between the cavity and the heating cavities. An air inlet and a heating piece are arranged in each heating cavity. An air outlet is formed in one end of each heating cavity. The heating pieces are located between the air inlets and the air outlets. Air outlet nets are arranged at the air outlets. An electromagnet is arranged in thecavity and connected with a steel body through a compression spring. The steel body is connected into the cavity in a sliding mode and provided with positioning blocks. Rails matched with the positioning blocks are arranged on the isolation walls. The steel body is connected with a rubber strip, and connected with baffles matched with the two air outlets. The baffles are hinged to the steel bodythrough torsional springs. The technical problems that a windscreen wiper can not remove ice layers and the wiping efficiency of the windscreen wiper is reduced when rubber strips make contact with awindscreen are solved, the vehicle windscreen wiper is reasonable in structural arrangement, the use convenience is improved, and the vehicle windscreen wiper is suitable for large-scale use and popularization.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

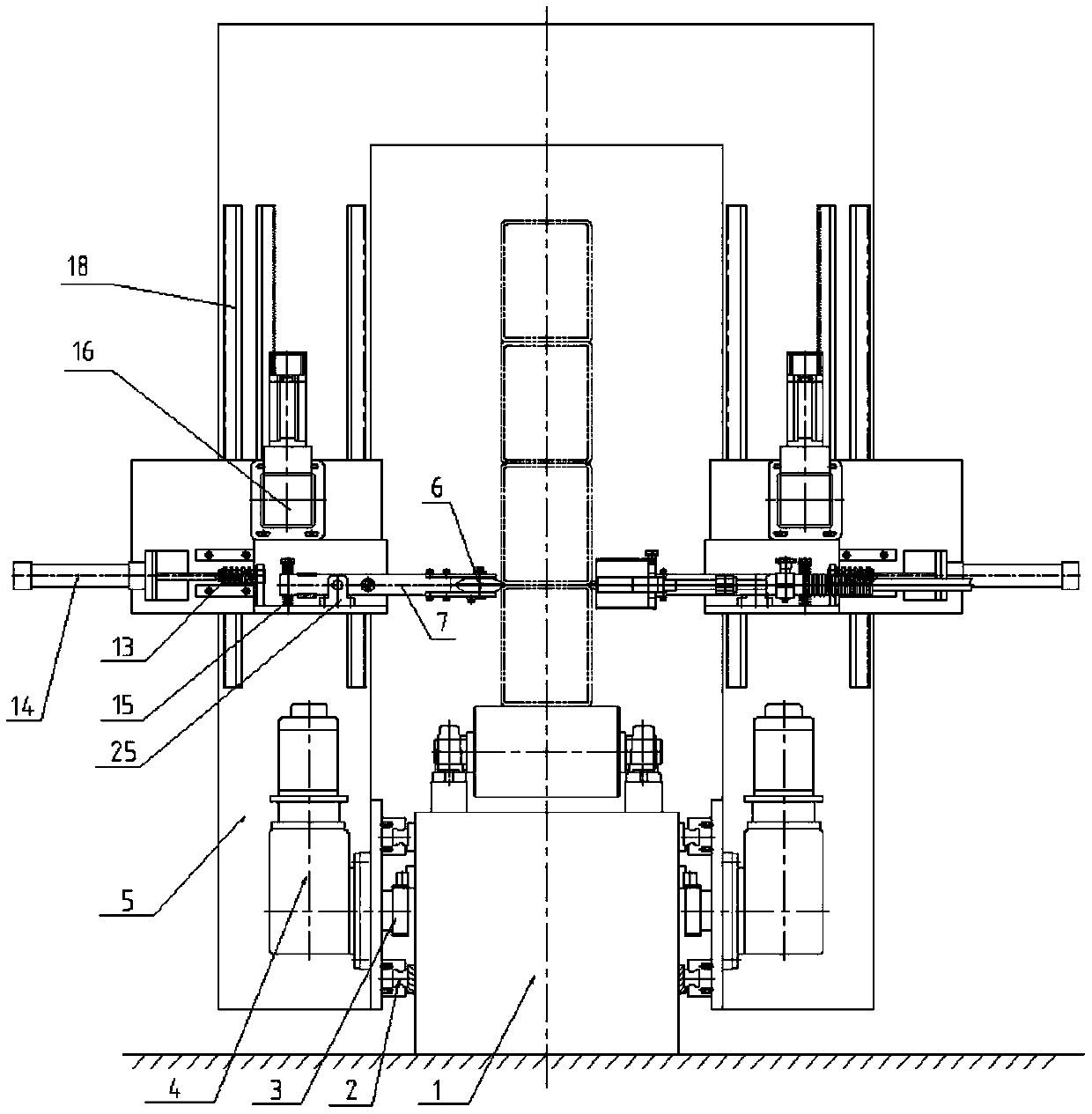

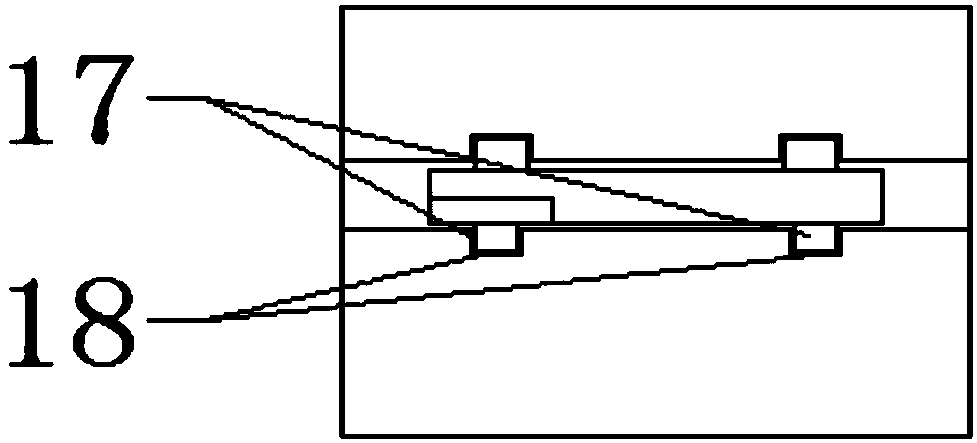

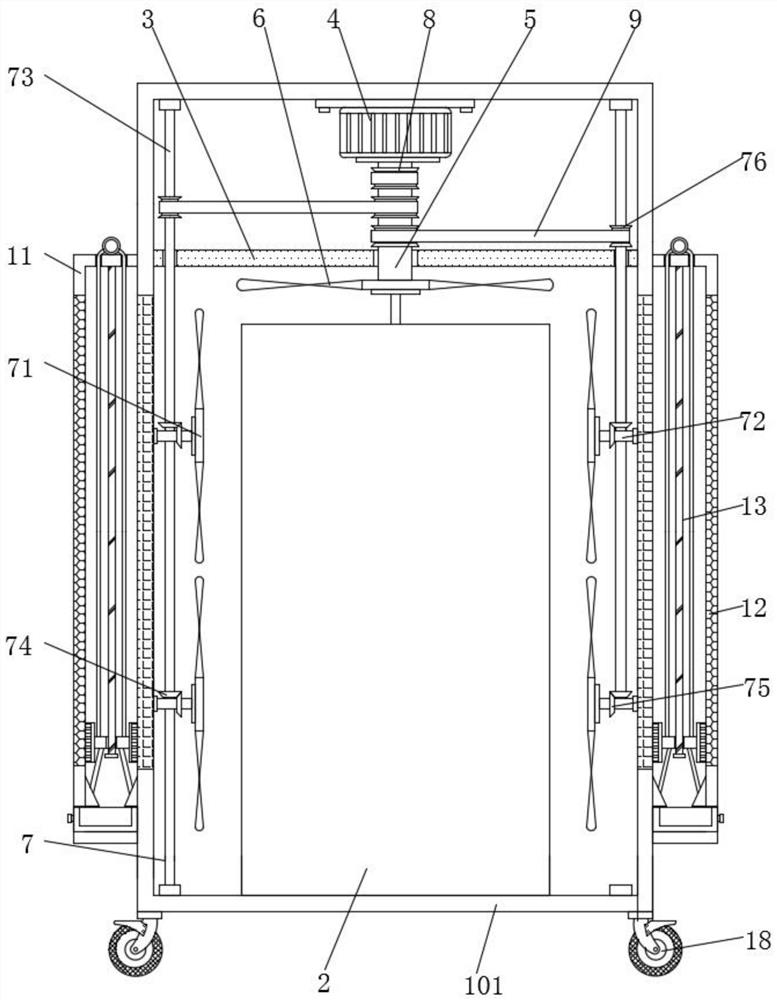

Weld joint deviation correcting device

PendingCN109623228AImprove welding precisionGuaranteed movement trajectoryWelding/cutting auxillary devicesAuxillary welding devicesThermal deformationWeld seam

The invention relates to the technical field of welding, and provides a welding joint deviation correcting device. The device comprises a workpiece fixing table, a door-shaped rack is arranged on thetwo sides of the workpiece fixing table in a sliding mode, the two sides of the door-shaped rack are respectively provided with a liftable welding machine head, a sliding plate which is perpendicularto the front and back sliding of the workpiece fixing table is arranged on the welding machine head, a deviation correcting knife wheel and a welding gun are sequentially arranged on the sliding platein the welding advancing direction, the deviation correcting knife wheel is arranged on the guide adjusting mechanism, and the welding gun is connected with the deviation correcting knife wheel. Thewelding seam deviation correcting device is used for connecting a welding gun with a deviation correcting knife wheel installed on the adjusting mechanism, the deviation correcting knife wheel moves forwards along the gap and changes along with the gap, and meanwhile, the deviation correcting knife wheel is enabled to be tightly attached to the workpiece gap to move, so that the movement track ofthe deviation correcting knife wheel and the gap needing to be welded are overlapped, and the welding quality of the welding joint is improved, so that the bending of the welding seam of the workpieceduring the welding of the straight welding line is realized, or due to thermal deformation in the welding process, and a good welding effect is achieved.

Owner:HEBEI FLEXTRONICS ELECTRICAL TECH

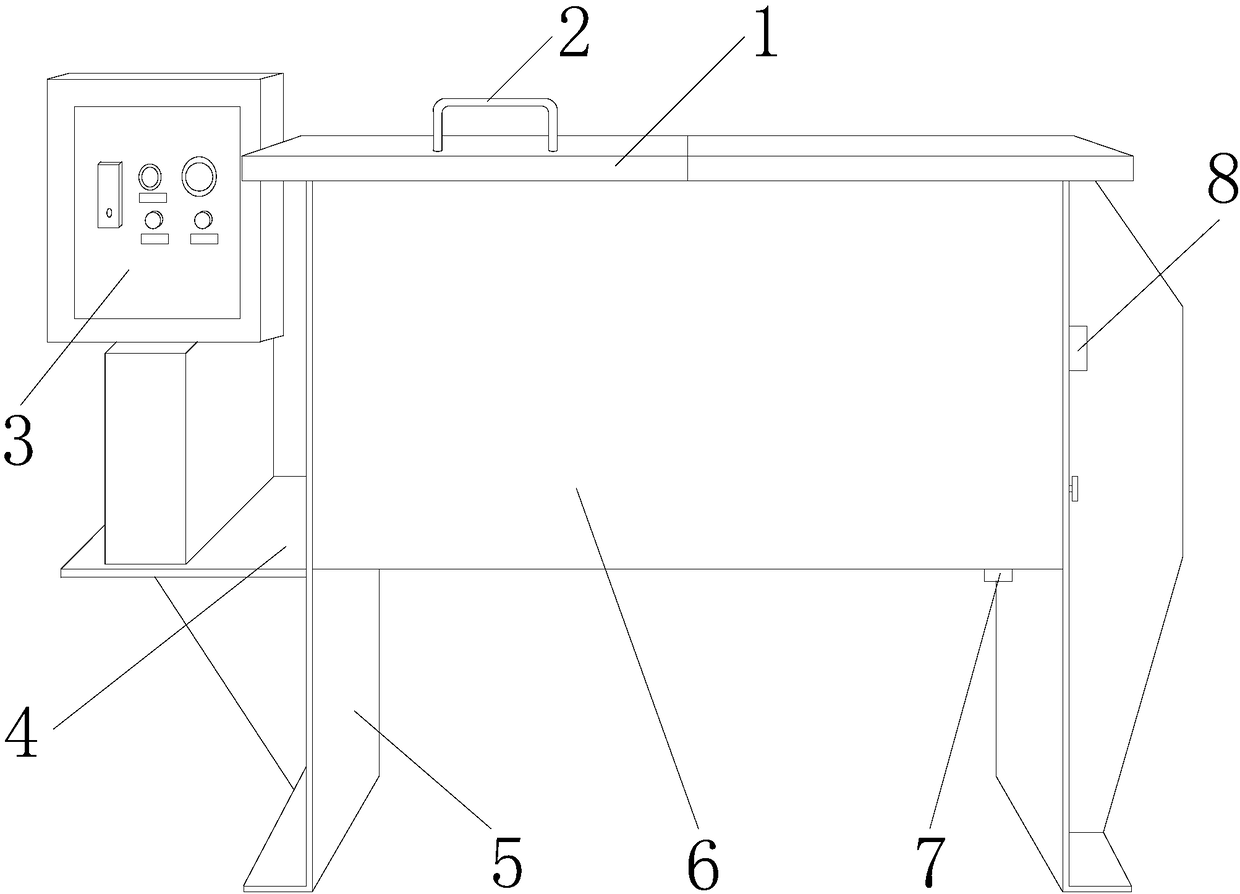

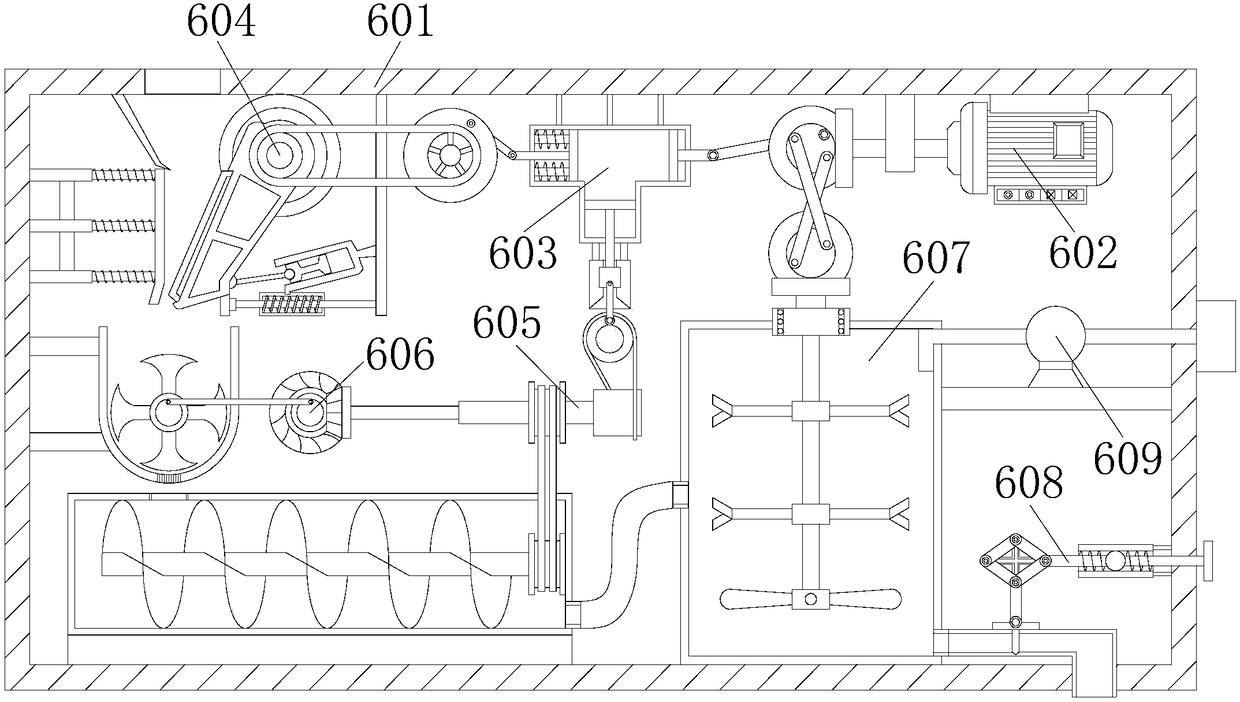

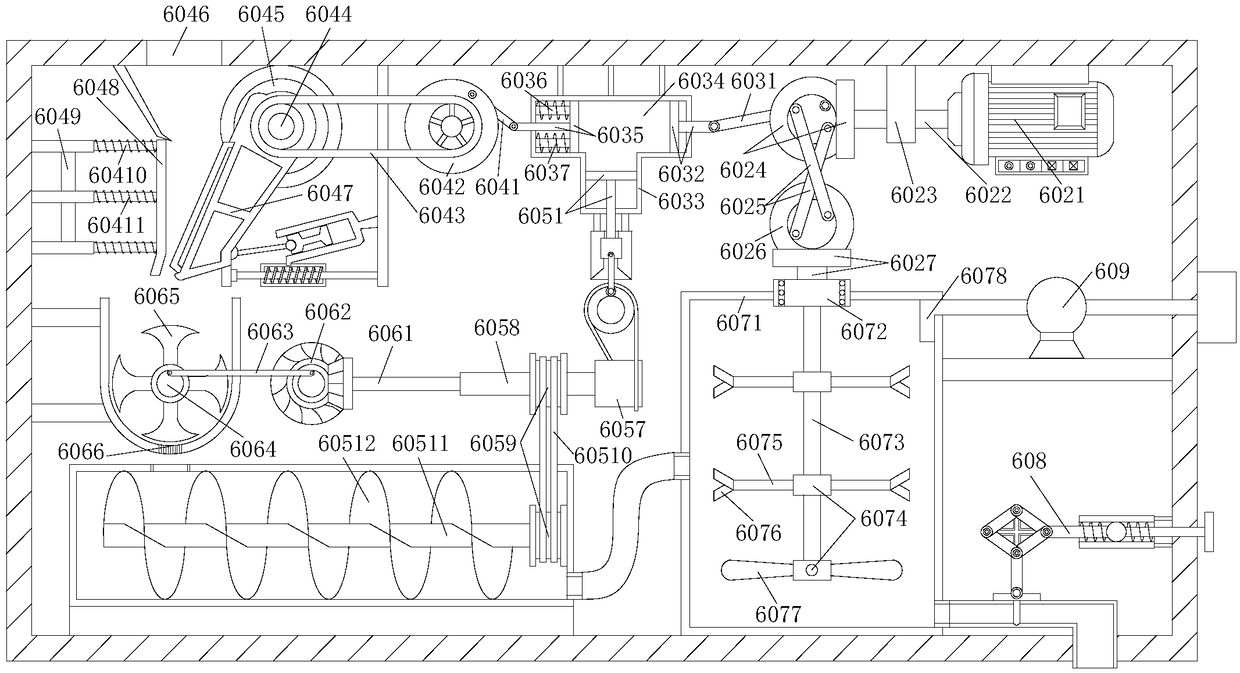

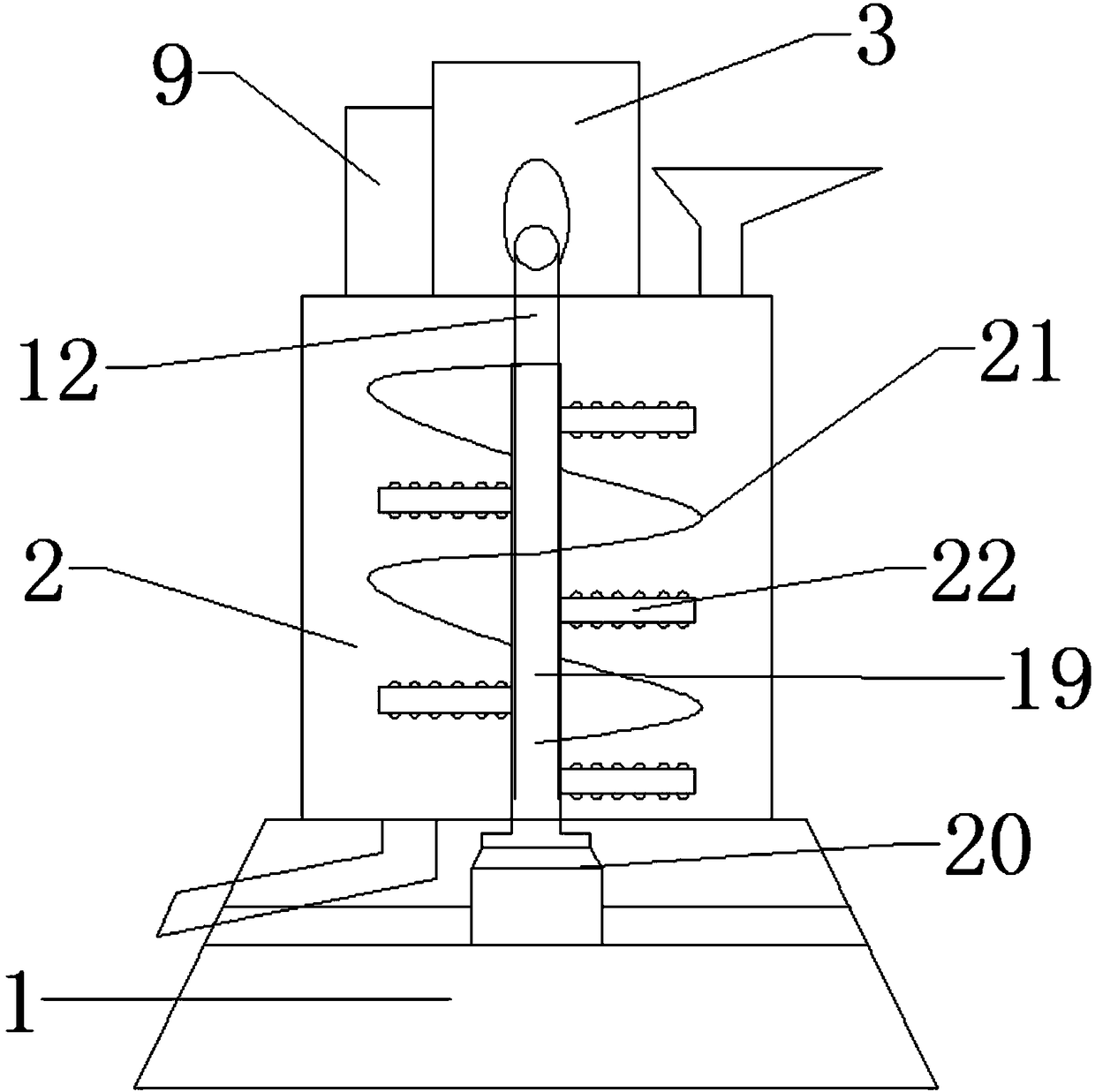

Efficient mixing device for paint production

InactiveCN108452724AImprove the mixing effectGuaranteed movement trajectoryRotary stirring mixersTransportation and packagingCircular discScreening effect

The invention discloses an efficient mixing device for paint production. The structure of the device comprises a top cover, a handle, an operation box, a supporting foot, a mixing mainframe, a paint outlet pipe and a water inlet pipe, wherein an eccentric shaft drives a connecting frame to swing, so that a moving jaw plate to swing laterally; vibration damping effect is achieved through a supporting rod and a damping spring, so that a fixed jaw plate keeps still; a material is crushed through the matching of the moving jaw plate and the fixed jaw plate, so that preparatory work is performed for production; a rotating rod drives a screw rod to rotate; a sawtooth disc meshed with the screw rod rotates; a rotating shaft rotates through the linkage effect of a linkage rod; a screening blade begins rotating to screen the material; the screened material is discharged from a screening outlet, so that the material is finer, and the screening effect is better; the operating efficiency is improved through the effect of reducing friction through a bearing; a stirring rotating rod drives a stirring rod and a stirring blade to perform stirring and mixing on the material, so that more sufficientstirring and mixing operation is realized.

Owner:郑长泉

Nano-pesticide fine grinding equipment

ActiveCN112742551ASmall particle sizeLarge specific surface areaGrain treatmentsAgricultural engineeringElectric machinery

The invention discloses nano-pesticide fine grinding equipment. A main shaft fixing cavity is fixedly formed in the top surface of a rack; a grinding cylinder is fixedly arranged on the top surface of the rack and located on the left side of the main shaft fixing cavity; a driving cavity is fixedly arranged on the top surface of the rack and located on the right side of the main shaft fixing cavity; a main shaft is arranged inside the grinding cylinder; the right end of the main shaft penetrates through the main shaft fixing cavity and is arranged in the driving cavity; an auxiliary belt wheel is fixedly arranged at the end, in the driving cavity, of the main shaft; a motor is arranged in the rack through a motor mounting base; and a main belt wheel is fixedly arranged at the output end of the motor. In the circulating process of materials in the grinding cylinder, the main shaft drives a dispersion turbine, a grinding turbine and a diffusion turbine to stir a grinding medium, and the materials are continuously crushed and shaped under the comprehensive action of various forces such as impact, shearing and friction of the grinding medium, so that the particle size is continuously reduced, and the specific surface area is continuously increased.

Owner:安徽儒特实业有限公司

Encrypted file extraction device for e-commerce based on photoresistor

The invention relates to the technical field of e-commerce, and discloses an encrypted file extraction device for the e-commerce based on photoresistor. The encrypted file extraction device comprisesa shell and a rotating shaft, wherein a motor is movably connected to the outside of the shell, a gear I is movably connected to the outside of the motor, a gear II is engaged to the outside of the gear I, a rotating rod is fixedly connected to the outside of the gear II, and a rotating cylinder is movably connected to the outside of the rotating rod. Through the interaction among the shell, the motor, the gear I, the gear II, the rotating rod, the rotating cylinder, an inclined plate, a sliding rod, a push rod and a movable rod, a user can start the device to operate only through an externalfingerprint coded lock, so that the protection performance of the device is ensured, the safety of a file hard disk is enhanced, and the push rod can do reciprocating motion through transmission amongthe structures, so that a foundation is provided for a user to extract corresponding files later, the file extraction convenience is guaranteed, and the more time and the more labor are saved.

Owner:聊城八月瓜大数据服务有限公司

Closed-circuit television monitoring device based on centrifugal force automatic sharpening

InactiveCN111556297AGuaranteed clarityMagneticTelevision system detailsColor television detailsCCTV - Closed circuit televisionEngineering

The invention provides a closed-circuit television monitoring device based on centrifugal force automatic sharpening. The device comprises a monitoring main body. Cleaning rollers are movably mountedon the left sides of the lenses through rollers. The outer side of the roller is fixedly sleeved with a magnetic ring. An electromagnet is fixedly installed at the bottom of the sliding groove, a windwheel is fixedly connected to the outer side of the rotating shaft and located on the outer side of the monitoring body in a sleeving mode, a ball is connected to the outer side of the rotating shaftand located in the monitoring body through a tension spring, and a contact switch corresponding to the electromagnet is fixedly installed in the monitoring body and located on the outer side of the ball. When wind power is too large, the wind wheel drives the rotating shaft to rotate, the ball body drives the tension spring to deform and stretch under the action of centrifugal force, the ball body makes contact with the contact type switch, the electromagnet is powered on and has magnetism, the idler wheel is pushed to move upwards, and in the upward moving process of the idler wheel, the cleaning roller scrapes and cleans the surface of the lens. And then the roller slides down along the closed groove to extrude the baffle plate down and fall back into the vertical groove.

Owner:广西南宁导思电子科技有限公司

Medical glass slide assembling device

The invention, which belongs to the field of medical instrument equipment, discloses a medical glass slide assembling device comprising a base, a feeding device, a loading device, a box covering device, a feeding conveyor belt, a box cover conveyor belt, a glass slide conveyor belt and motor chutes. Motor chutes are formed in the upper surface in the rear of the base symmetrically. The feeding device is installed on the upper surface of the base symmetrically; the feeding conveyor belt is arranged in front of the feeding device; the box covering device is installed at the side of the feeding device; the box cover conveyor belt is arranged in front of the box covering device; the loading device is arranged above the feeding device; and the glass slide conveyor belt is arranged in the rear of the loading device. The feeding device is responsible for clamping and positioning of a bottom box; the loading device places a glass slide in the bottom box; and the box covering device places a cover on the bottom box. The whole assembly process is complete and the adaptability is high.

Owner:李亚琼

Quantitative topdressing mechanism in corn intertillage period

InactiveCN113228905AAvoid breakingEasy to cause wastePlantingFertiliser distributersSoil scienceAgricultural engineering

The invention discloses a quantitative fertilization mechanism in a corn intertillage period, and aims to solve the problems that manual and mechanical topdressing operation in the intertillage period of corn planting is not easy to perform in a field, the working space is small, crops are easy to damage, fertilizer is wasted, the topdressing effect cannot be achieved and the like. The quantitative fertilization mechanism is characterized in that when the quantitative fertilization mechanism performs field operation, a furrow opener on the front side of the mechanism divides soil to two sides, and after quantitative topdressing operation is completed, a soil covering device on the rear side of a charging barrel covers the surface of the fertilizer with the soil, so that the fertilizer is in full contact with the soil, and the quantitative topdressing effect is achieved; the mechanism does not have working dead angles, so that fertilizer accumulation is avoided; no topdressing is omitted; the furrow opener, the charging barrel and the soil covering device work separately, so that the interference phenomenon does not exist; the arc-shaped design of a rotating plate ensures that the fertilizer in a fertilizer limiting sleeve completely falls into furrows; and bolts enable a fertilizer baffle and the rotating plate to coaxially move, so that the movement track of the fertilizer in the charging barrel is ensured, the smooth operation of quantitative topdressing is ensured, the manual topdressing cost can be reduced, and the topdressing effect in the corn intertillage period can be ensured.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

Device for clamping insulator

The invention belongs to the technical field of insulator clamping equipment, and particularly relates to a device for clamping an insulator. The device for clamping the insulator comprise an U-shapedframework and an opening cross rod, wherein two ends of the opening cross rod are respectively inserted into sliding grooves in two sides of the U-shaped framework and are fixed by bolts, a screwingrod is arranged at a middle part of the opening cross rod, a lower end of the screwing rod enters a fixed sleeve through a sleeve flange disc and is connected with a fixed block, the fixed block is arranged in a fixed cavity, a lower end of the fixed cavity is connected with a horizontal cross rod, a spring is arranged between the horizontal cross rod and the bottom of the fixed sleeve, a quadrangle connection rod rack is connected with each of two ends of the horizontal cross rod, a side-surface clamping block is hinged with a lower end of the horizontal cross rod, an upper-end clamping blockis arranged at a lower end of the fixed sleeve, a lower-end clamping block is arranged at the bottom of the U-shaped framework, the insulator is not needed to be disassembled during the clamping process, a clamping position is automatically positioned, and a clamping mode having a fixed clamping force and also having a variable clamping force is formed.

Owner:ZHUZHOU SUNSHINE ELECTRIC PORCELAIN

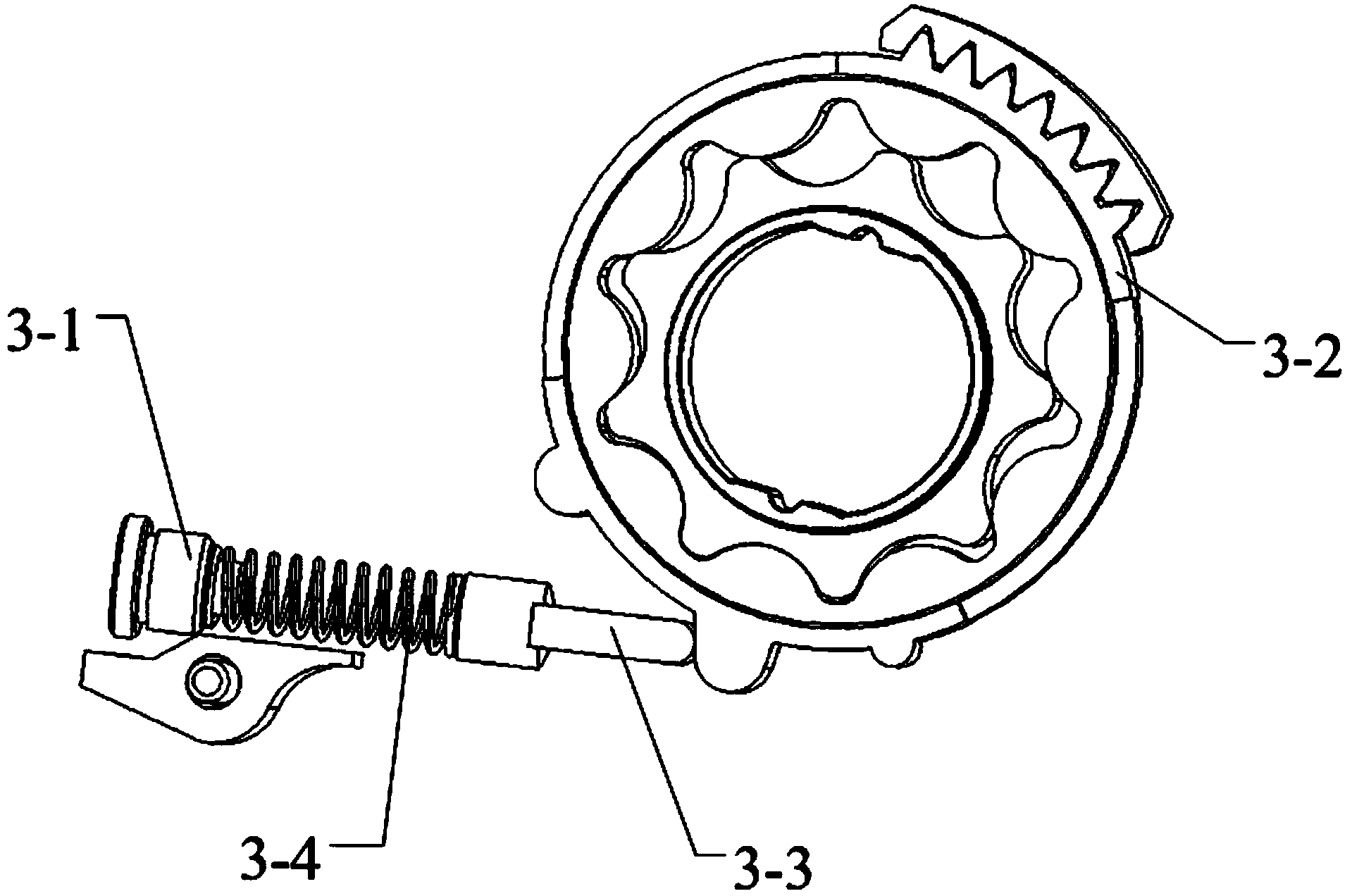

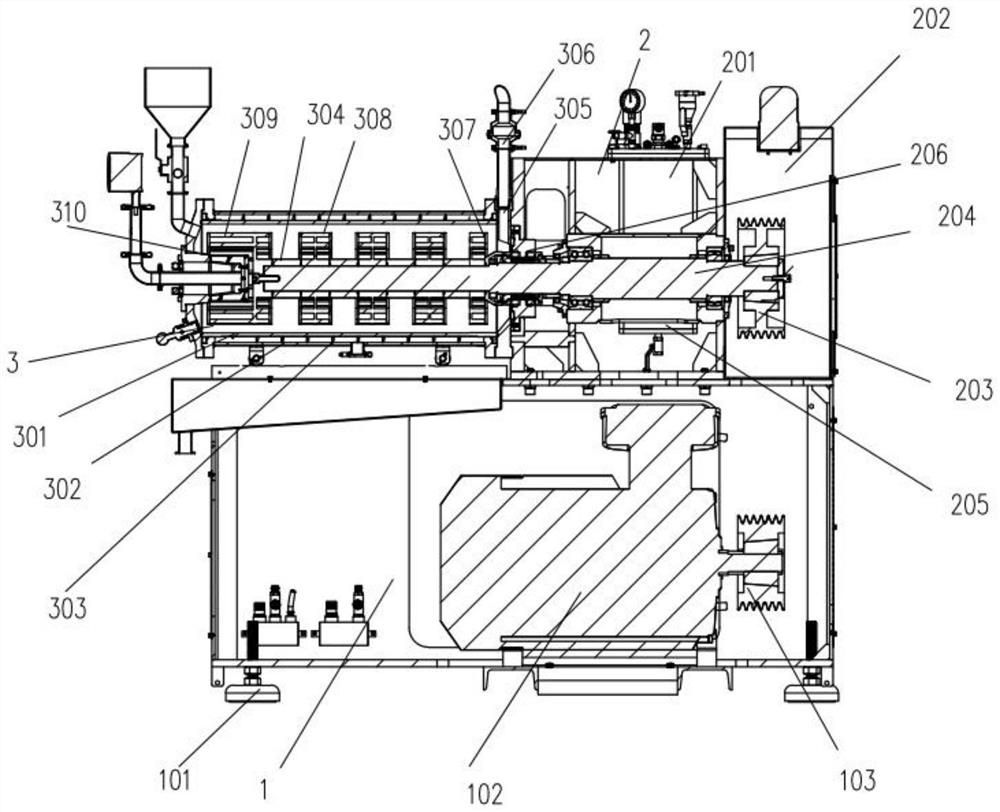

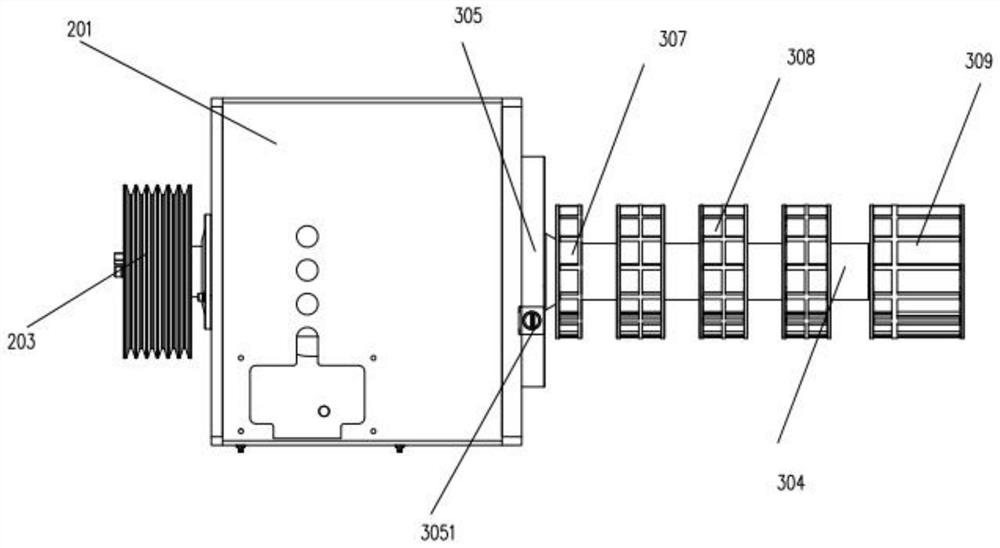

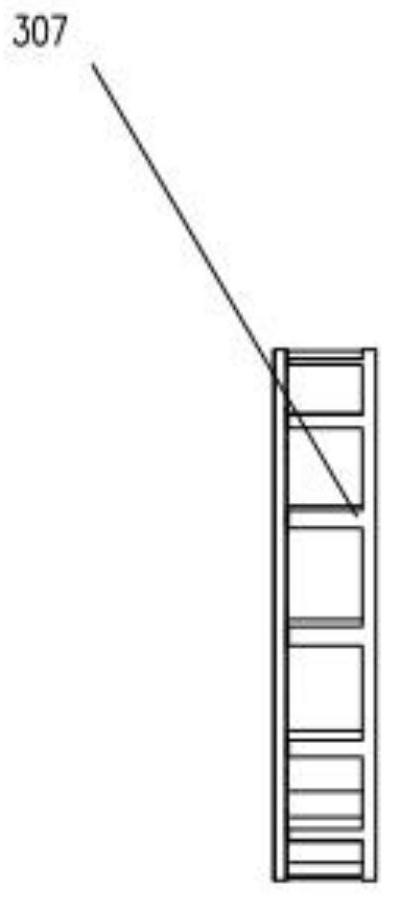

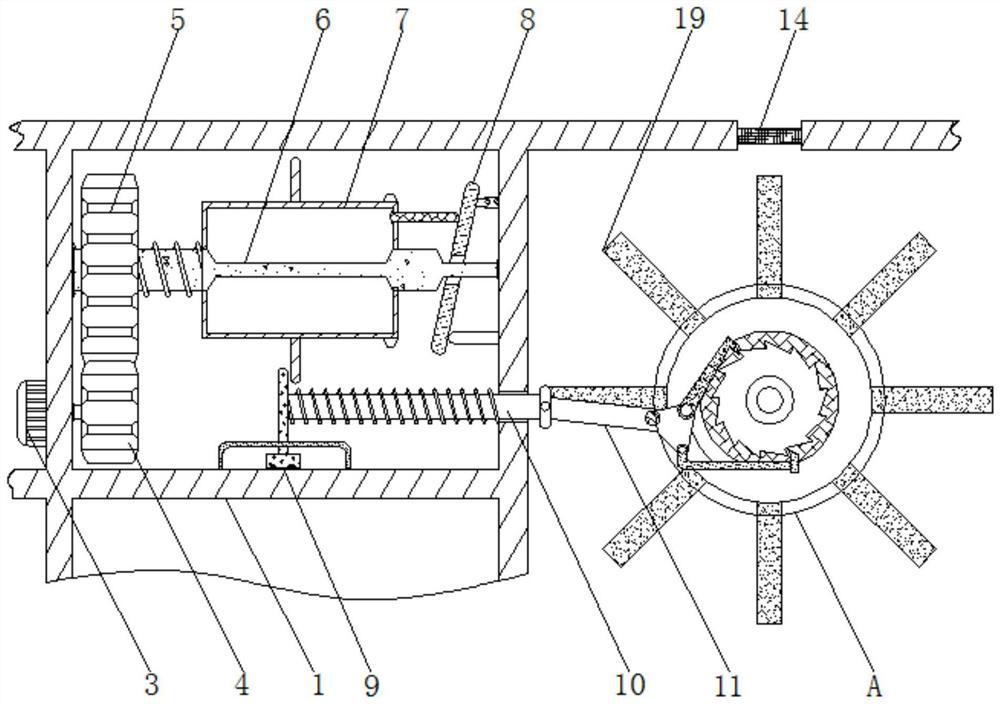

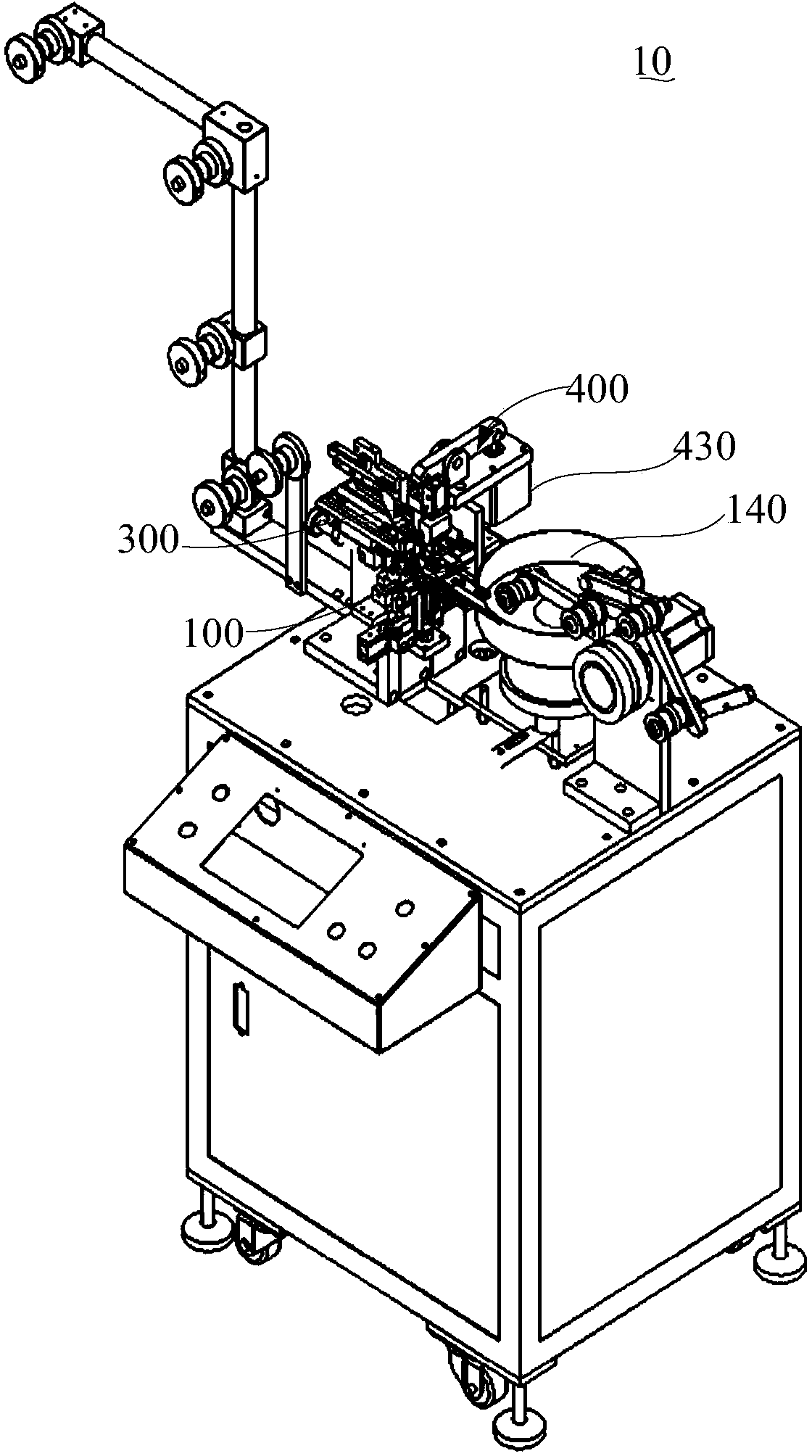

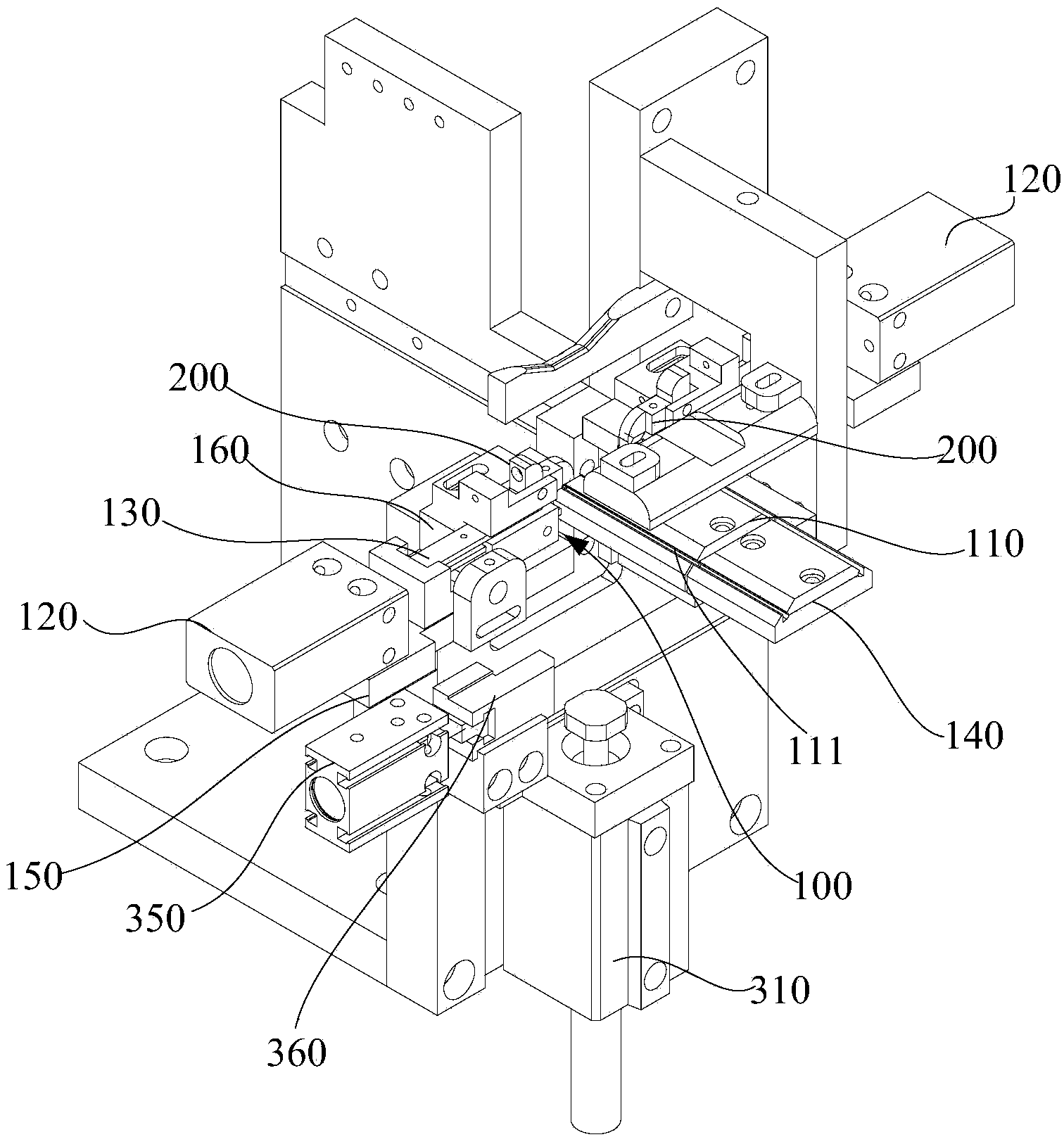

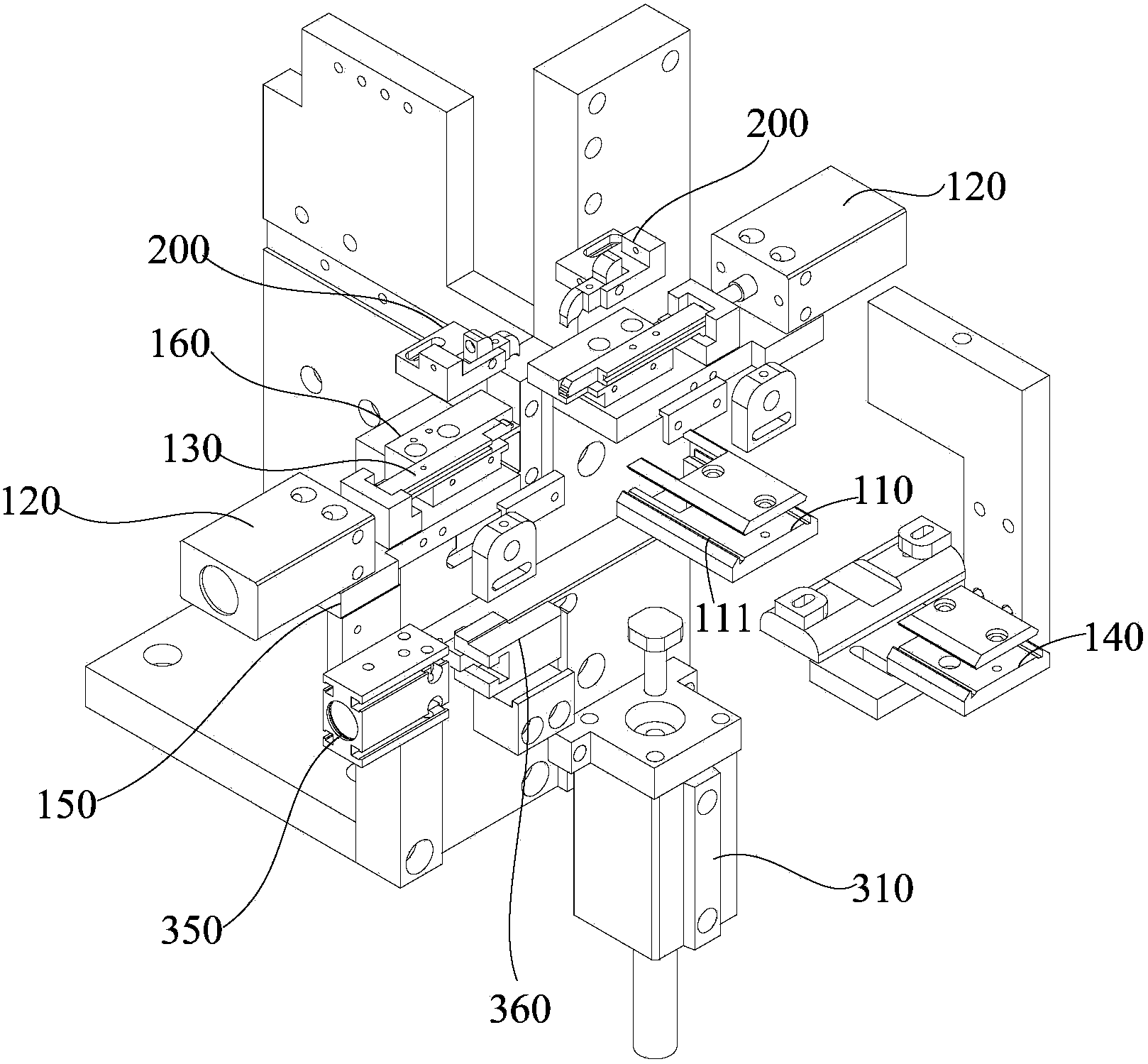

Metal zipper granulator

ActiveCN104273806AGuaranteed movement trajectoryArrive accuratelySlide fastenersEngineeringMachining

A metal zipper granulator comprises a feed component. The feed component comprises a feed plate, two push air cylinders and two push rods. The feed plate is used for supplying particles for manufacturing metal zippers, the push air cylinders are arranged on two sides of the feed plate relatively, the telescopic directions of the push air cylinders are perpendicular to the moving direction of the feed plate, one ends of the push rods are connected with the push air cylinders, the push air cylinders drive the push rods to be telescopic, and the push rods are used for being combined with the particles on the feed plate and driving the particles to move to a preset machining position. In the metal zipper granulator, the push rods push the particles to the preset position, motion tracks of the particles can be guaranteed, the problem that the particles cannot reach the preset position is avoided, and high production yield is achieved.

Owner:SHENZHEN LANCER M&E TECH

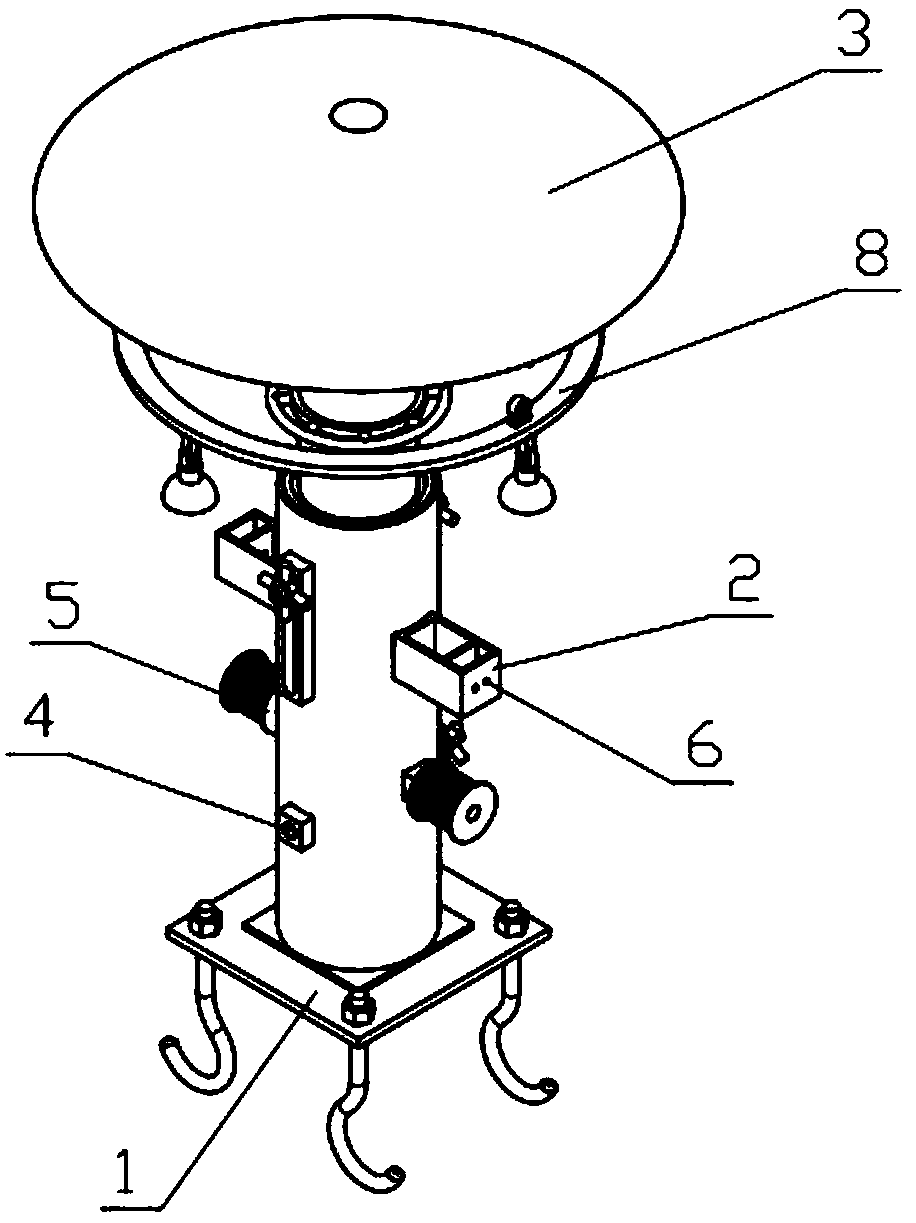

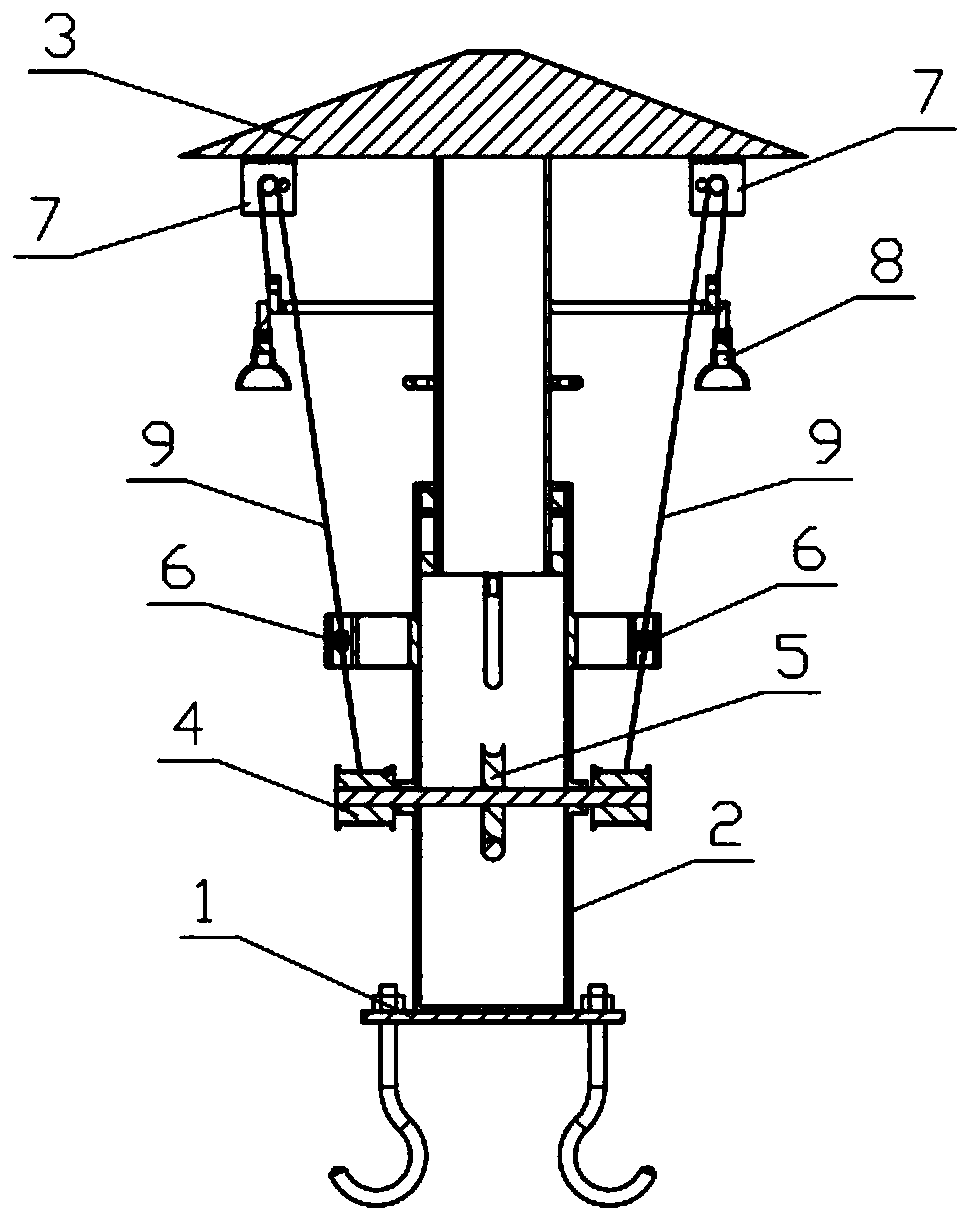

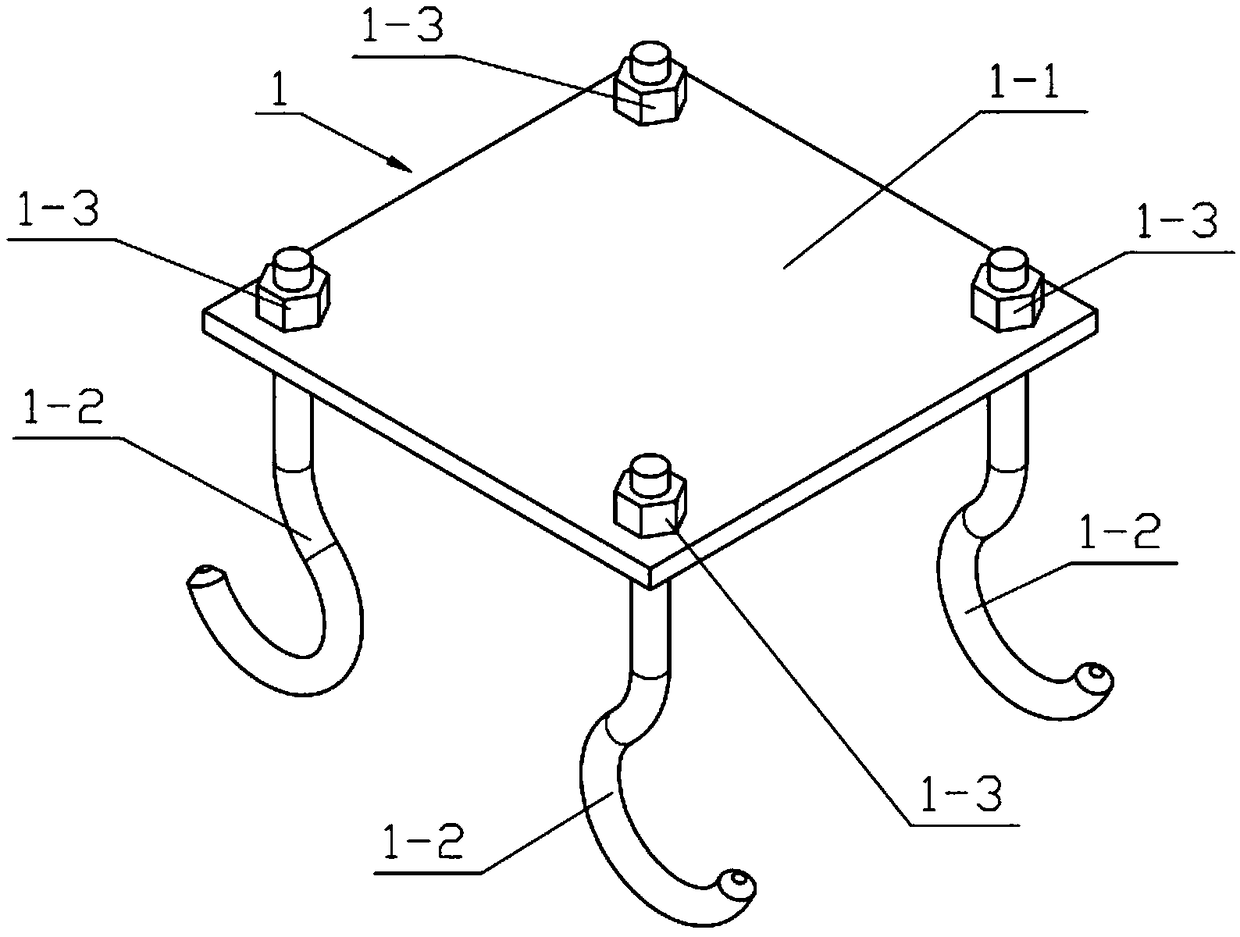

LED high-pole lamp

ActiveCN109140331APrevent disengagementGuaranteed movement trajectoryMechanical apparatusLighting support devicesGear wheelEngineering

The invention relates to a high-pole lamp, in particular to an LED high-pole lamp. The LED high-pole lamp comprises a bottom support, an overall support, a lifting support, a power mechanism, a reel mechanism, gear wheels II, gear wheel mechanisms, lamp brackets and steel wire ropes. The power mechanism can be rotated manually to drive the reel mechanism to rotate, and the rotating directions of two reels are the same, so that the two steel wire ropes are driven to wind around the two reels; the steel wire ropes on the two sides are limited by the two gear wheels I on the two sides and prevented from being separated, the steel wire ropes on the two sides are limited by the two gear wheel mechanisms on the two sides and prevented from being separated from gear wheels II, the motion track ofthe steel wire ropes is guaranteed, the lamp brackets are driven by the steel wire ropes to move up and down and can drop to the lower end of the lamp, and the lamp brackets can be maintained and repaired by a worker without working aloft.

Owner:YANGZHOU DIANDI LIGHTING CO LTD

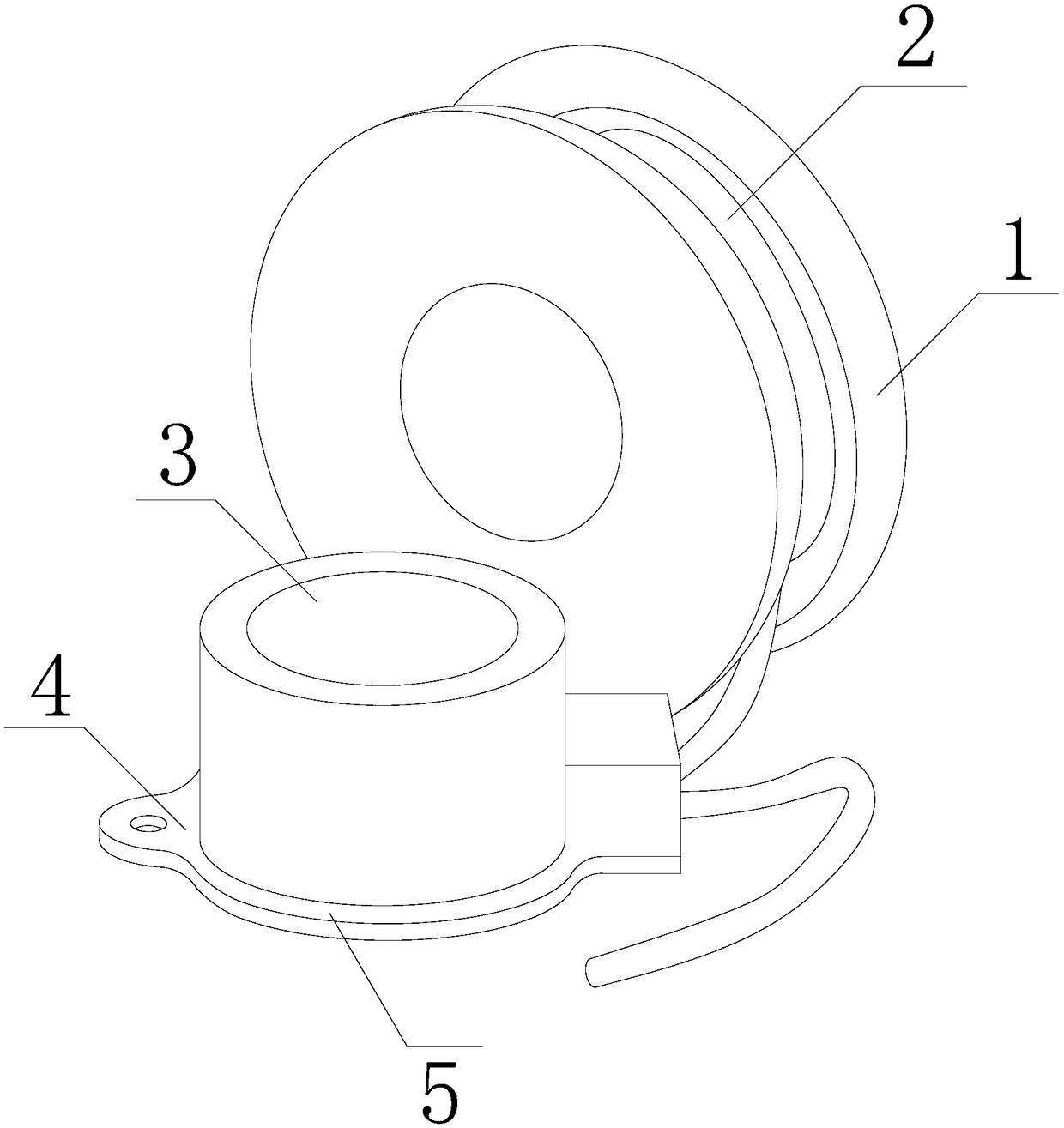

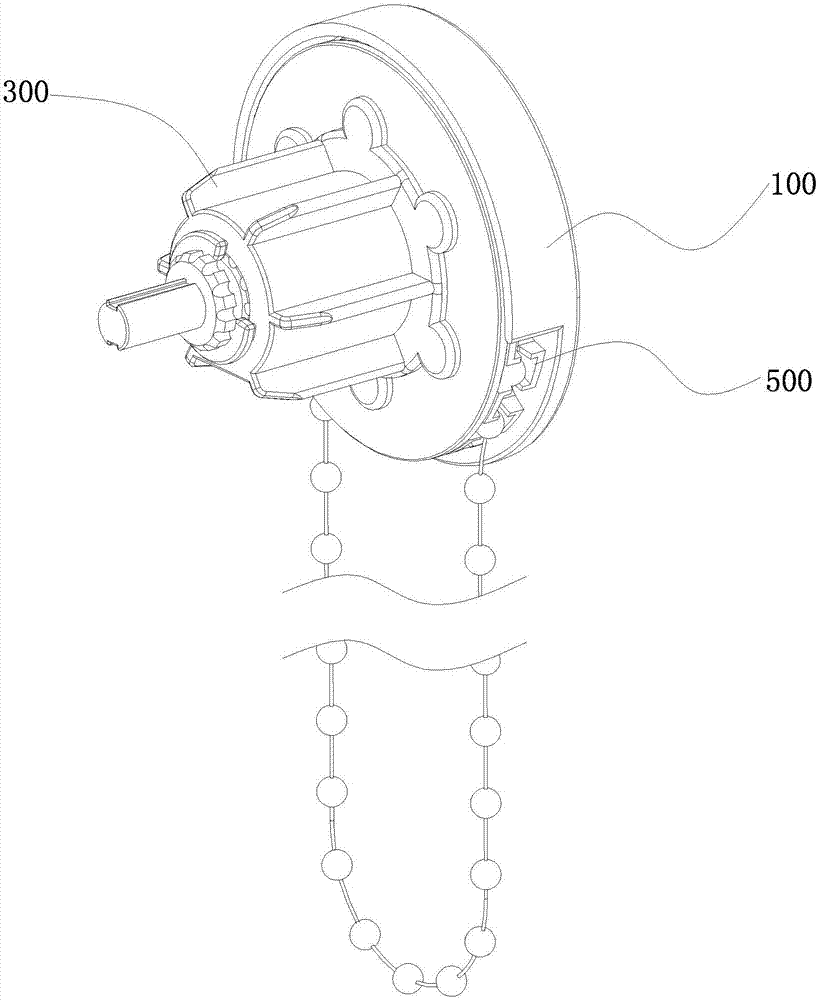

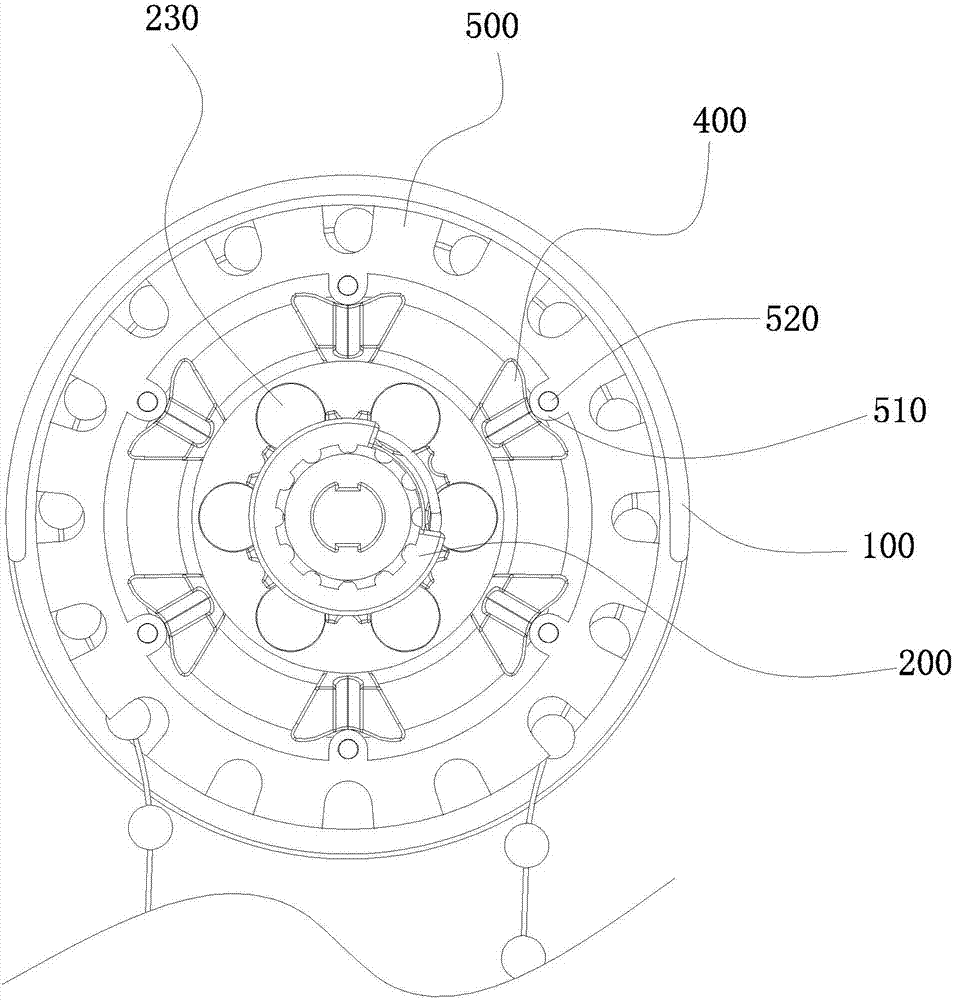

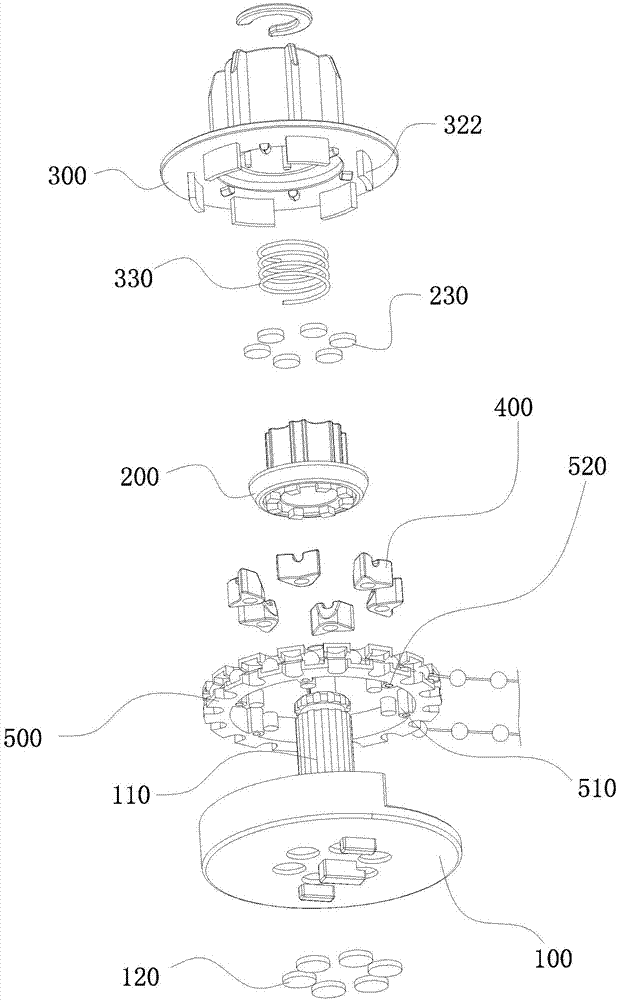

Curtain bead-pull driving device

ActiveCN107191126AStable opening and closingPull effortDoor/window protective devicesEngineeringSelf locking

The invention provides a curtain bead-pull driving device. The curtain bead-pull driving device comprises a base, a brake disc, a pipe stopper, movable wedges, and a bead disc, wherein the base is fixedly arranged, and a mandrel is arranged on the base; an umbrella-shaped oblique plane is arranged at the rear end of the brake disc, the brake disc is arranged on the mandrel in a penetrated mode, and the base limits rotating of the brake disc when the brake disc is in abut connection with the base; the pipe stopper is used for driving a curtain reel pipe to rotate, and the pipe stopper is connected with the brake disc in a linked mode; the movable wedges are movably arranged on the umbrella-shaped oblique plane of the brake disc, and located between the pipe stopper and the base; and the bead disc is arranged on the outer portion of the brake disc in a sleeving mode, and connected with the movable wedges in a linked mode, and when the bead disc rotates, the bead disc compresses the movable wedges, so that the movable wedges drive the brake disc to be separated from the base. The curtain bead-pull driving device has the beneficial effects that the bead-pull driving device can achieve the self-locking function with a torsion-spring-free structure, thus a curtain is stable when being opened or closed, moreover, large friction force cannot be generated, labor is also saved when a user pulls the curtain, and the curtain bead-pull driving device is stable and reliable when being used.

Owner:NINGBO XIANFENG NEW MATERIAL

Beating machine for paper production

PendingCN108252146AImprove crushing effectConsistent crushing densityPulp beating methodsPaper recyclingElectric machineryPaper production

The invention discloses a beating machine for paper production, belongs to the field of paper production equipment, and aims at providing the beating machine with a uniform pulverizing effect. The machine is characterized in that a sliding groove is formed in a lifting housing, a sliding block which moves in the length direction of the sliding groove is arranged in the lifting housing, a cam is arranged between power transmission blocks, the main shaft of the cam is connected with a motor, and two other side faces of the sliding block are connected with bucket wall beating assemblies; the bucket wall beating assemblies comprise moving rods which are slidably connected with the sliding block, the other ends of the moving blocks are connected with racks, the racks are arranged on the outer side of a beating bucket, a plurality of beating blades are arranged on the inner wall of the beating bucket, the main shafts of the beating blades penetrate through the beating bucket, and the other ends of the main shafts of the beating blades mesh with the racks. The invention provides a beating machine with a targeted pulverizing effect on pulp on the wall of a pulverizing bucket and capable ofachieving uniform pulverizing density of the pulp in the whole pulverizing bucket.

Owner:郑州华美彩印纸品有限公司

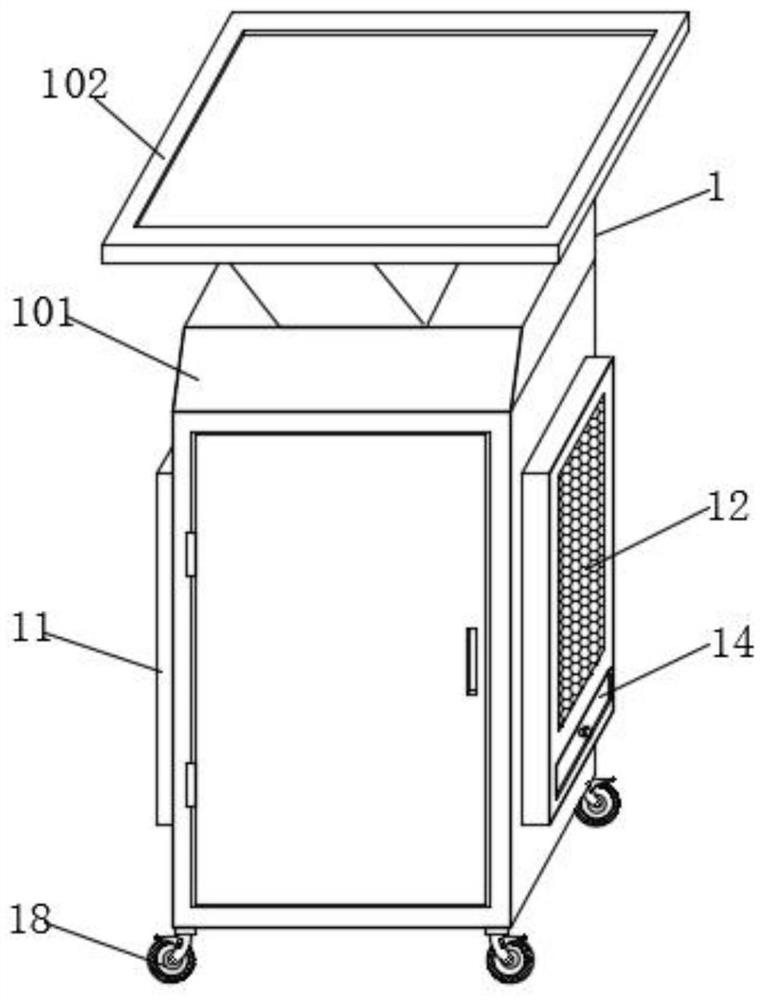

Information processing device of electronic equipment

InactiveCN113885677AEfficient removalAvoid cloggingCleaning using toolsDigital processing power distributionElectric machineryDust control

The invention belongs to the technical field of information processing equipment, and discloses an information processing device of electronic equipment, and the information processing device comprises an information processor body, the information processor body comprises a case and a touch screen, and an electric appliance element is arranged in the case. According to the scheme, during use, a driving motor is powered on to operate to drive a rotating shaft to rotate, then a first cooling fan is driven to rotate, the electric appliance element in the case is cooled, meanwhile, along with rotation of the rotating shaft, three first belt wheels are driven to rotate, and through mutual cooperation of three belts, auxiliary heat dissipation pieces on the left side, the right side and the rear side of the electric appliance element are driven to work at the same time, so that the heat dissipation effect is improved, dust on a first heat dissipation net and a second heat dissipation net can be effectively removed through a dust removal assembly in the using process, the first heat dissipation net and the second heat dissipation net are prevented from being blocked, the heat dissipation effect is improved, and the dust is collected in a dust collection box, therefore, centralized processing is facilitated.

Owner:苏州一八零信息科技有限公司

Gold and silver hollow bracelet processing technology

ActiveCN103416925BGuaranteed purityReduce processing technologyJewelleryNanotechnologySheet material

The invention discloses a gold and silver hollow bracelet processing technology and belongs to the technical field of jewelry processing technologies. The processing technology comprises the following steps: preparing material: according to the specifications for processing gold and silver hollow bracelets, preparing sheet material with corresponding specifications; manufacturing a pipe: processing the sheet material into a round pipe with a gap and straightening the round pipe; annealing; calibrating: straightening the gap; welding without welding material: eliminating gap through high-temperature heating to form a gapless round pipe; cutting: cutting the gapless round pipe according to the finished size of a gold and silver hollow bracelet, and polishing two ends of the gapless round pip; pre-forming: processing the gapless round pipe into an open type circular ring, and forming a closed circular ring by performing high-temperature heating on the open type circular ring; shaping: shaping the shape of the closed circular ring until specified requirements are met; forming: processing the closed circular ring into a hollow bracelet with elliptic sections. Through the processing steps, since a only a piece of sheet material is needed, the hollow bracelet can be manufactured, the processing technology is reduced, the processing efficiency is improved, the forming effect is good, and meanwhile, the gap is closed automatically through high temperature, so that welding without welding material is achieved, and the purity and fineness are guaranteed.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD +1

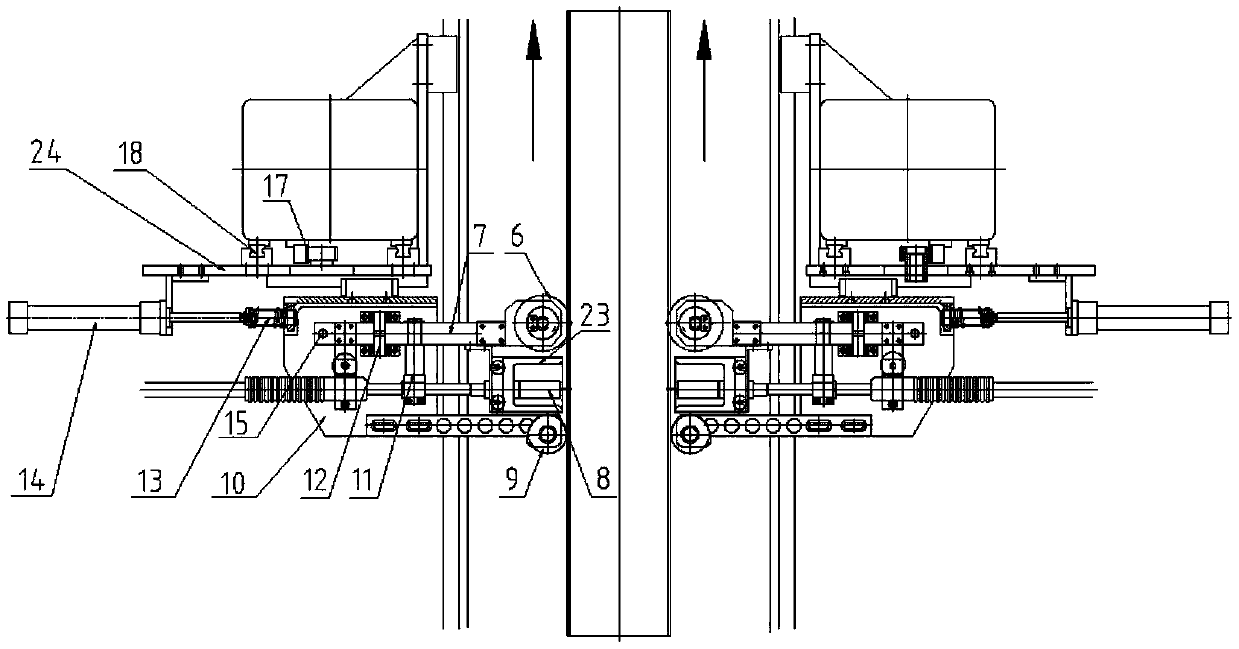

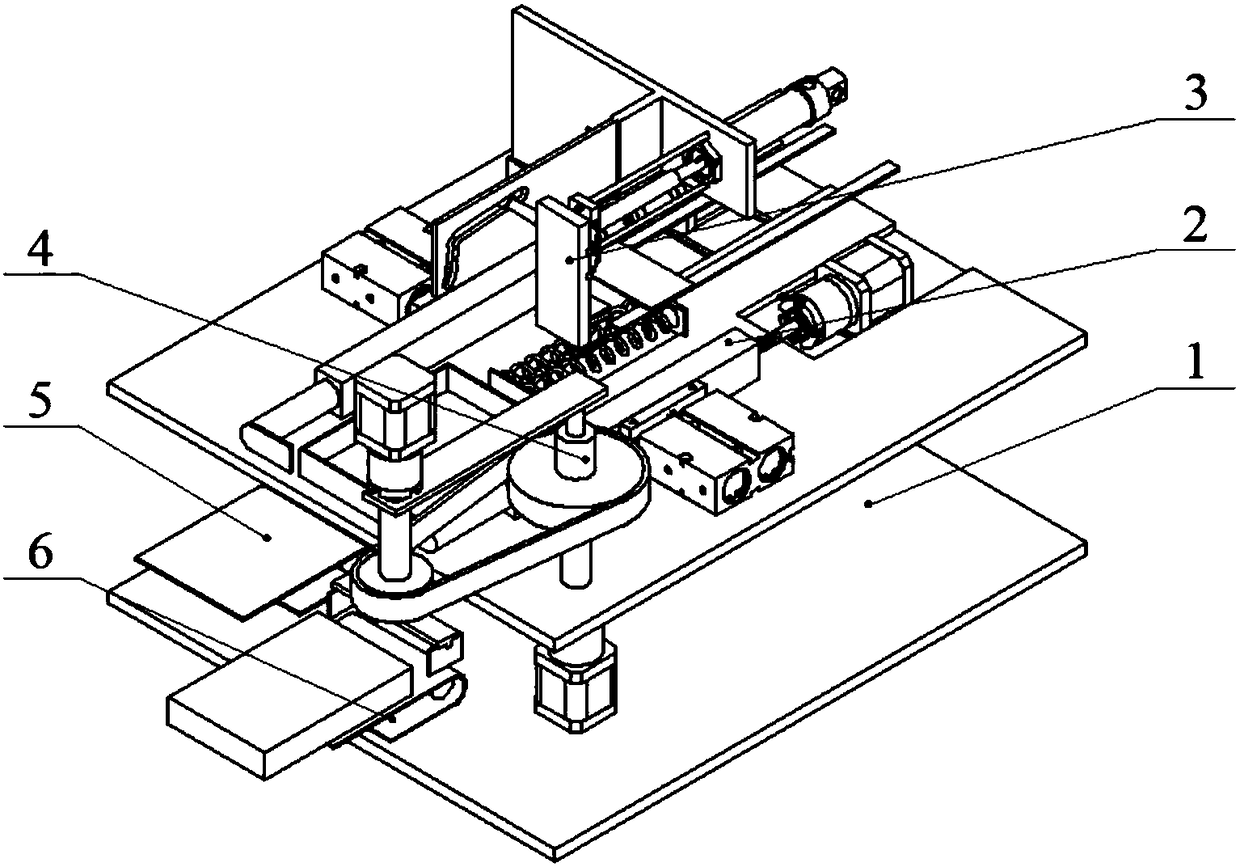

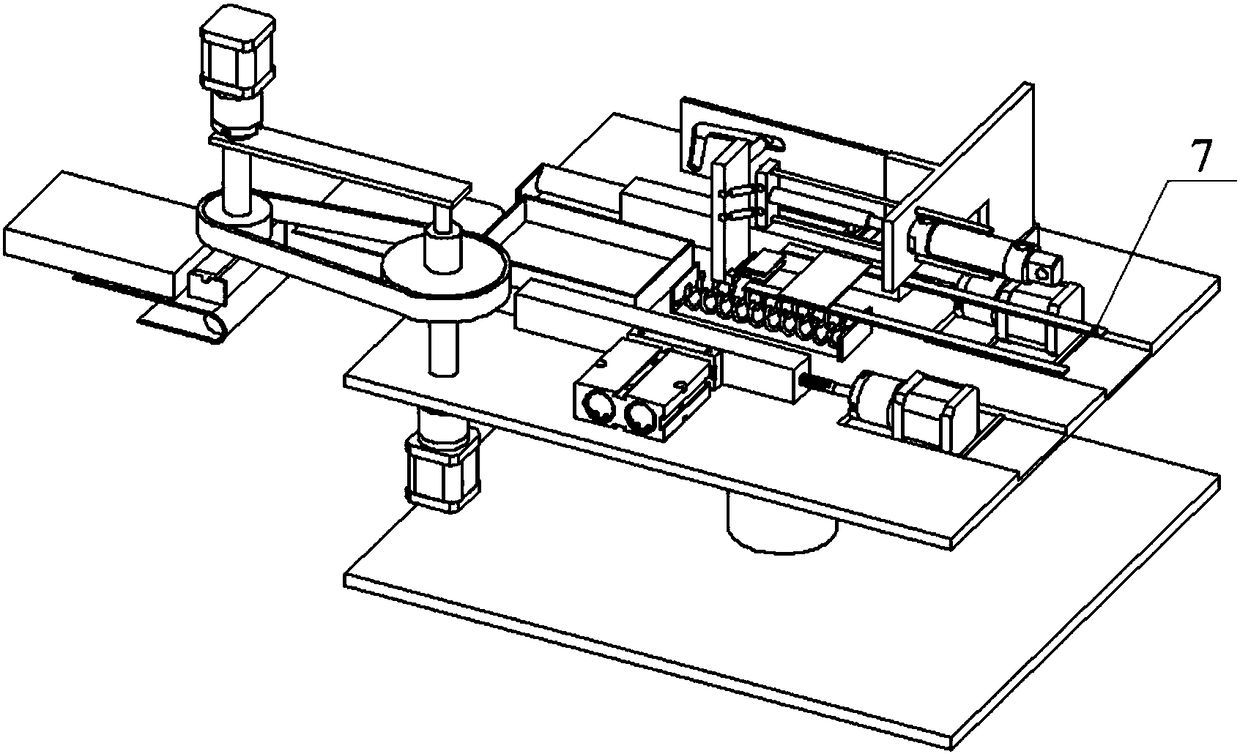

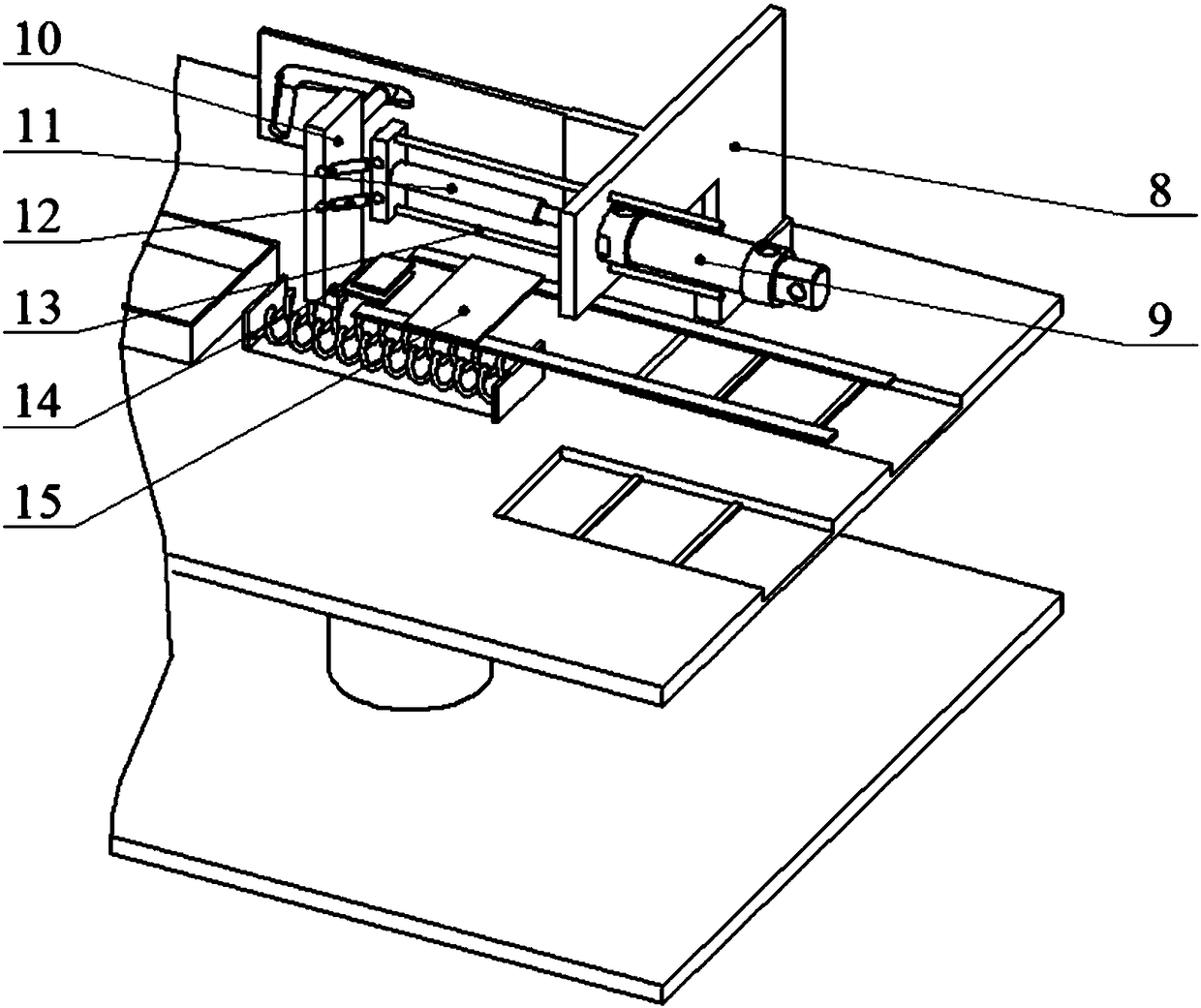

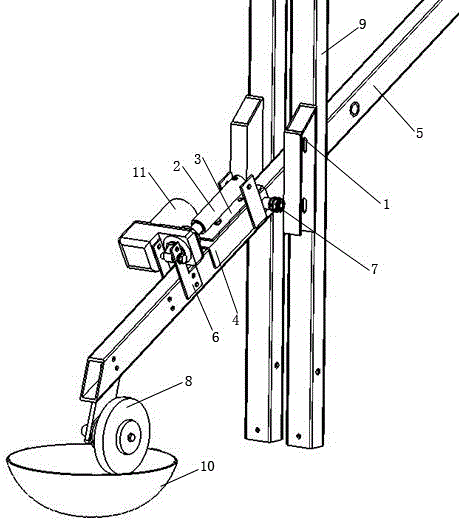

Electric limit adjusting mechanism for iron pan polishing robot

ActiveCN106826923AGuaranteed movement trajectoryPrevent side to side movementPolishing machinesManipulatorEngineeringGrinding wheel

The invention discloses an electric limit adjusting mechanism for an iron pan polishing robot. The electric limit adjusting mechanism for the iron pan polishing robot comprises an oscillating rod of which one end is connected with a polishing grinding wheel and which is used for controlling the movement path of the polishing grinding wheel. Two sides of the oscillating rod are symmetrically provided with a limiting stopper for preventing the leftward and rightward movement of the oscillating rod. The oscillating rod is slidably provided with a slider through a clamping sheet and an electric screw for adjusting the relative position of the slider and the oscillating rod. The fixed end of the electric screw is fixedly connected with two fixing blocks symmetrically installed on the oscillating rod. The telescopic end of the electric screw is fixedly connected with the slider. The limiting stopper is symmetrically provided with two limit blocking columns for limiting the sliding range of the slider, and the slider is symmetrically provided with two rollers which are upwards and downwards rolled along the limit blocking columns. The electric limit adjusting mechanism for the iron pan polishing robot has the characteristics of accurate polishing position, easy position adjustment, and small error, so the production quality of the iron pan is improved.

Owner:HENAN MOXI MACHINE MFG

Intelligent type electric coagulation forcep system

InactiveCN102743224AGuaranteed bonding effectEasy to operateSurgical instruments for heatingTemperature controlPower flow

The invention discloses an intelligent type electric coagulation forcep system, which comprises a forcep body and a host used for providing a power source to the forcep body, wherein the forcep body comprises forcep points and forcep rods. The key is that the system comprises the forcep body and the host used for providing the power source to the forcep body, wherein the forcep body comprises the forcep points and the forcep rods. The intelligent type electric coagulation forcep system is characterized by further comprising a current detecting device a voltage detecting device for detecting the current and voltage between the forcep points; an impedance of a matter between the forcep points is calculated according to the ratio of the voltage and the current; with the gradually increasing of the impedance, the host gradually decreases the output power of the forcep points; and a water inlet channel is arranged on the forcep body, an outlet of the water inlet channel is located at the forcep points, the front part of the forcep rod at one side is fixed with a first positioning rod, and the forcep rod at the other side is provided with a corresponding positioning hole. By detecting the temperature of the forcep points in real time, the temperature of the forcep points is controlled within a certain scale, therefore, the sticking effect of the electric coagulation forceps is guaranteed, and the overheat phenomenon is avoided.

Owner:CHONGQING RUNZE PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com