Electric limit adjusting mechanism for iron pan polishing robot

A technology for adjusting mechanisms and robots, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, manipulators, etc., can solve the problems of inaccurate polishing positions, large errors, and difficult position adjustments, etc., to reduce production costs and improve production efficiency , The effect of accurate polishing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

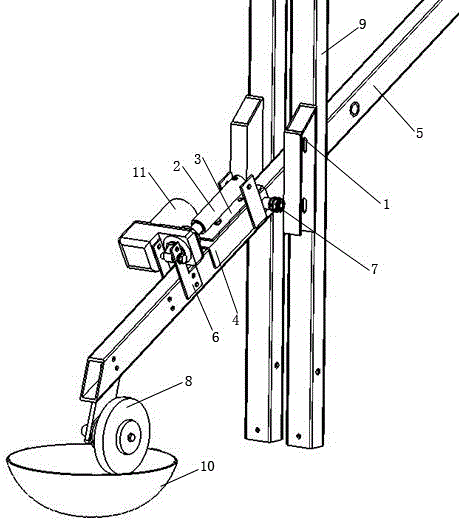

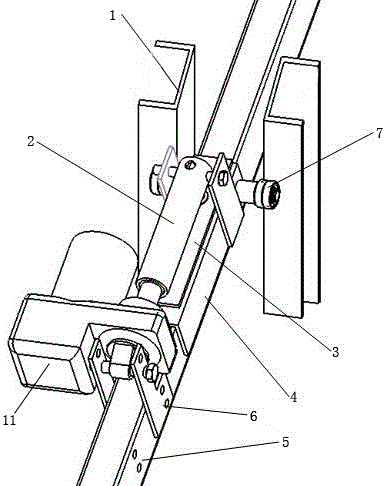

[0017] As shown in the figure, an electric limit adjustment mechanism for an iron pan polishing robot includes a swing rod 5 connected to a polishing wheel 8 at one end and used to control the movement path of the polishing wheel 8, and symmetrically arranged on both sides of the swing rod 5 to prevent The limit block 9 that the swing bar 5 moves left and right, on the swing bar 5, the slide block 4 and the electric screw rod 2 that adjusts the relative position of the slide block 4 and the swing bar 5 are slidably provided with the clip 3, and the fixing of the electric screw rod 2 The end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com