Beating machine for paper production

A beating machine and beating barrel technology, applied in the field of papermaking equipment, can solve the problems of low crushing degree, inconsistent density, inconvenient production, etc., and achieve the effects of improving stability, consistent crushing density, and improving crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

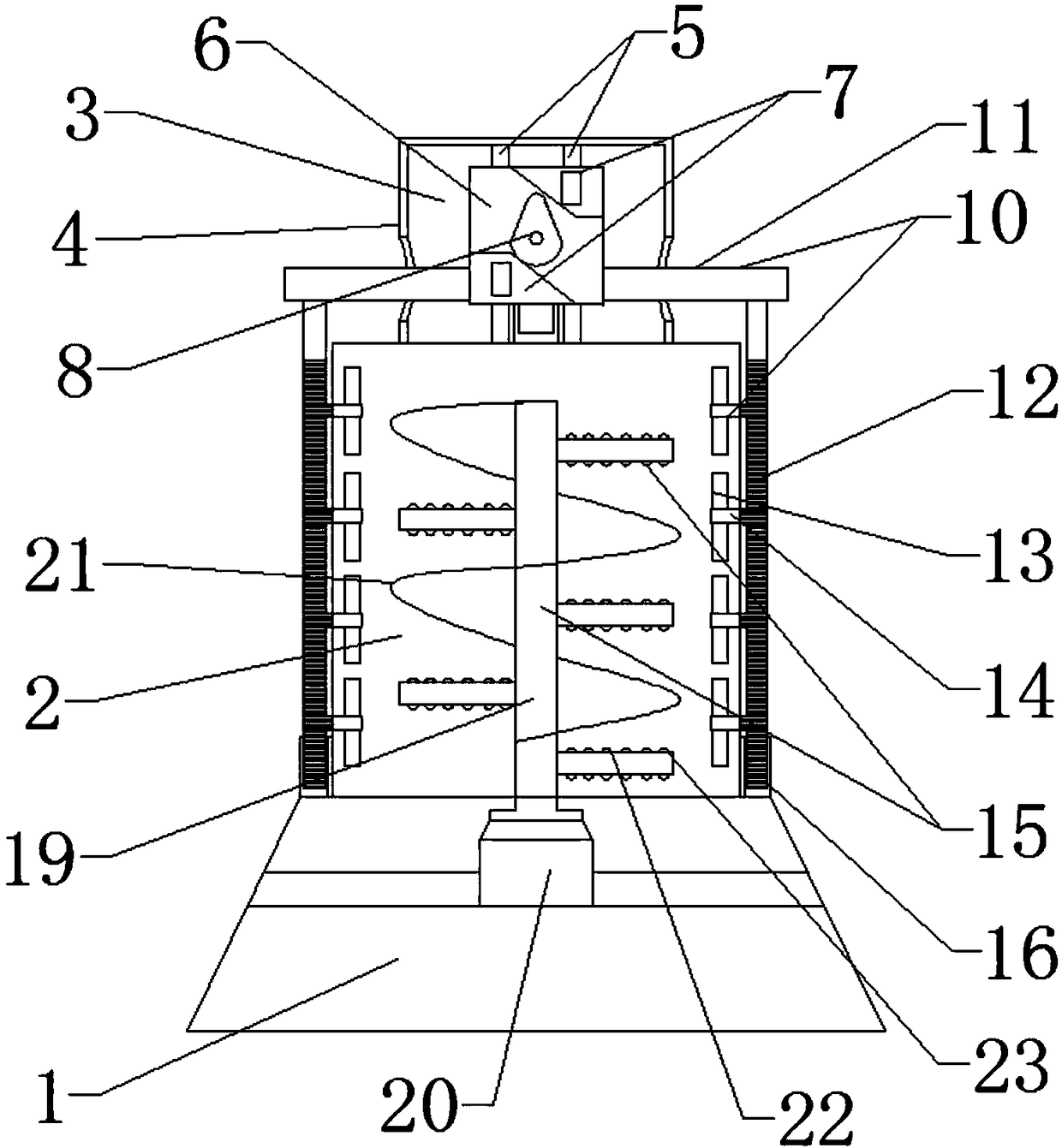

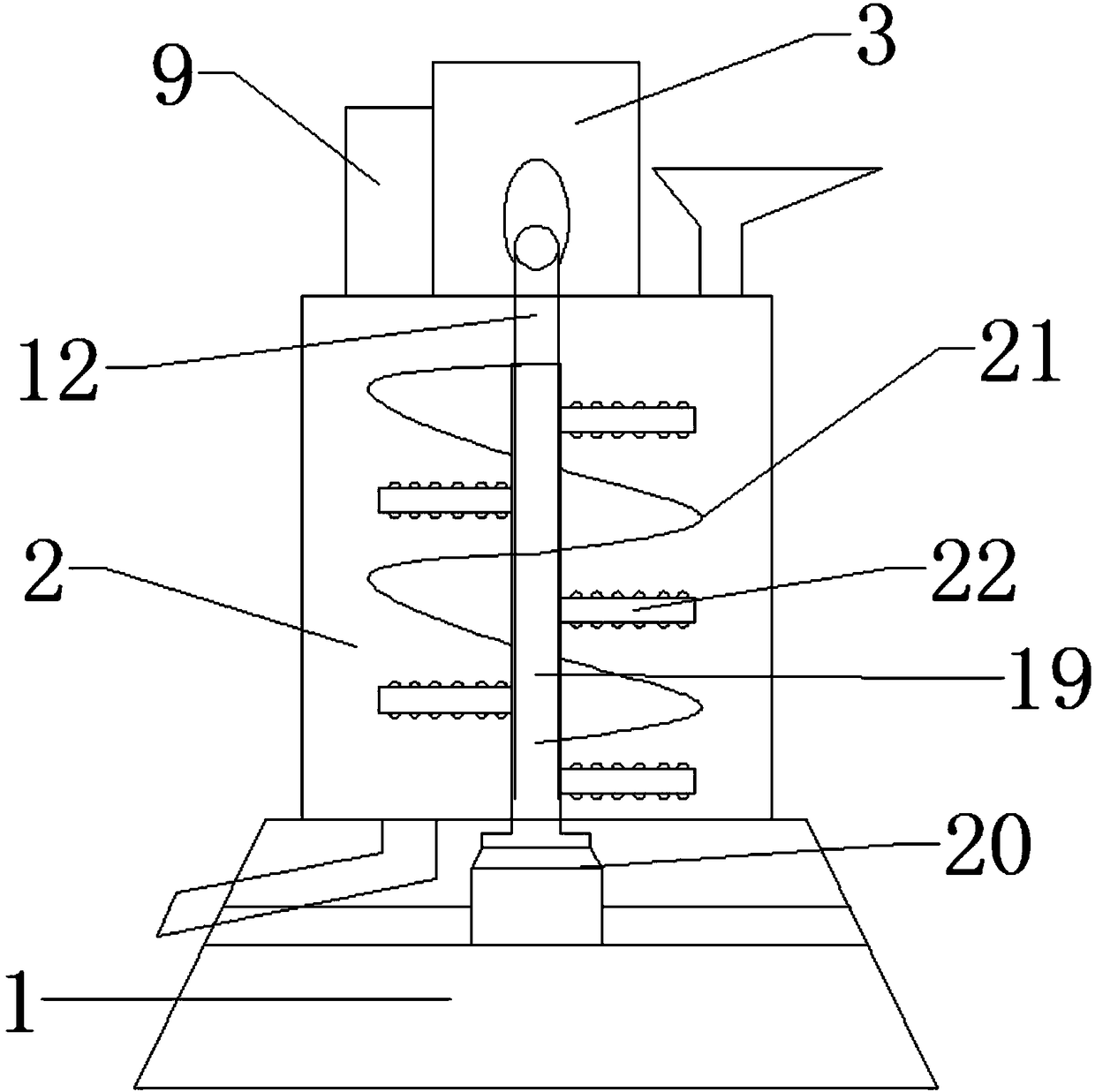

Embodiment 1

[0031]A beating machine for papermaking, comprising a base 1, a beating bucket 2 arranged on the upper end of the base 1, the upper end of the beating bucket 2 is provided with a lifting device 3, the lifting device 3 includes a lifting shell 4, the lifting shell 4 is provided with a chute 5 and a slider 6 moving along the length direction of the chute 5. A pair of power transmission blocks 7 are arranged on one side of the slider 6, and a cam 8 is arranged between the power transmission blocks 7. The main shaft of the cam 8 is connected with a motor 9, and the motor 9 is placed on one side of the lifting shell 4; the other two sides of the slider 6 are connected with a bucket wall beating assembly 10; Connected moving rod 11, the moving rod 11 passes through the lifting shell 4, the other end of the moving rod 11 is connected with a rack 12, the rack 12 is placed on the outside of the beating barrel 2, the rack 12, the central axis is parallel to the central axis of the beati...

Embodiment 2

[0033] On the basis of Embodiment 1, the lower end of the rack 12 is provided with a sliding sleeve 16, the sliding sleeve 16 is sleeved on the lower end of the rack 12, and the other end of the sliding sleeve 16 is fixed on the base 1 , the lower end of the rack 12 slides up and down along the path of the sliding sleeve 16 length.

Embodiment 3

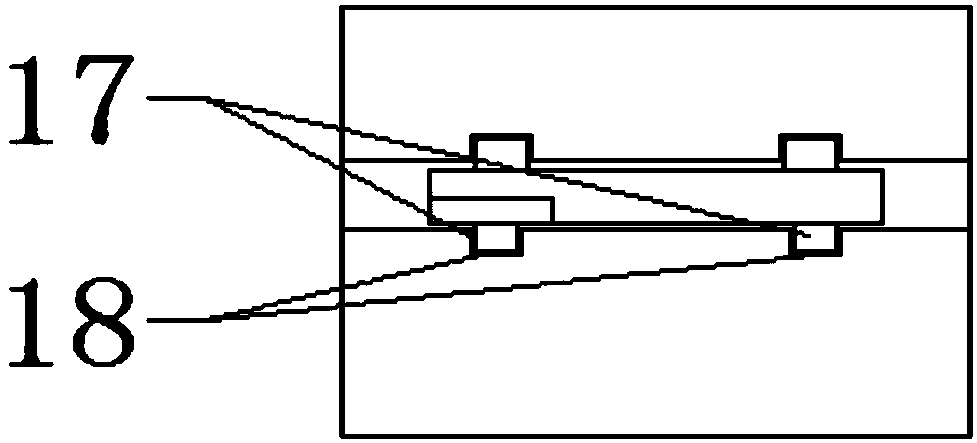

[0035] On the basis of Embodiment 2, the other end surface of the power transmission block 7 is provided with a slider B17, and the side of the lifting housing 4 adjacent to the slider B17 is provided with a chute matching the slider B17 B18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com