LED high-pole lamp

A technology of LED high pole lights and bottom brackets, applied in outdoor lighting, lighting and heating equipment, mechanical equipment, etc., can solve the problems of inconvenient repair, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

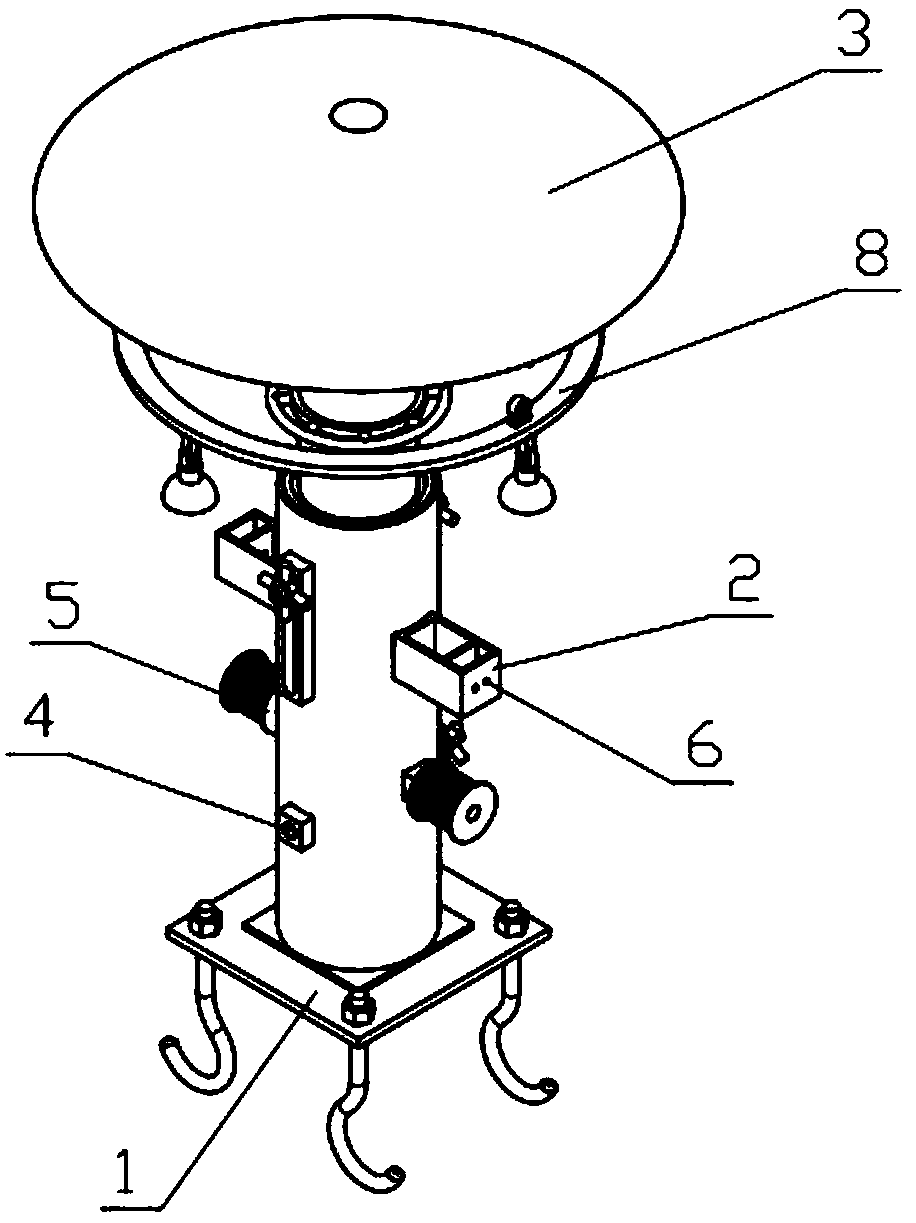

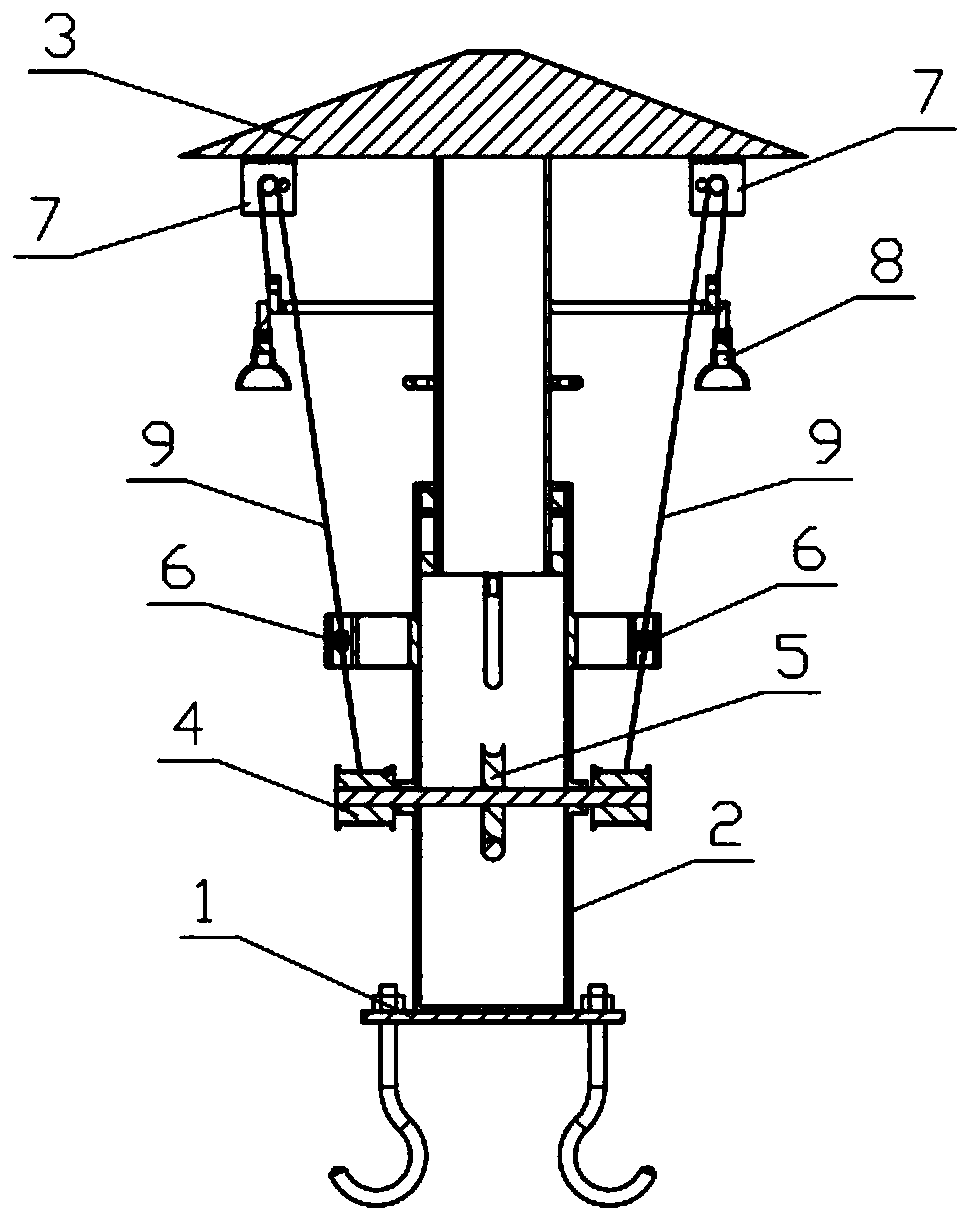

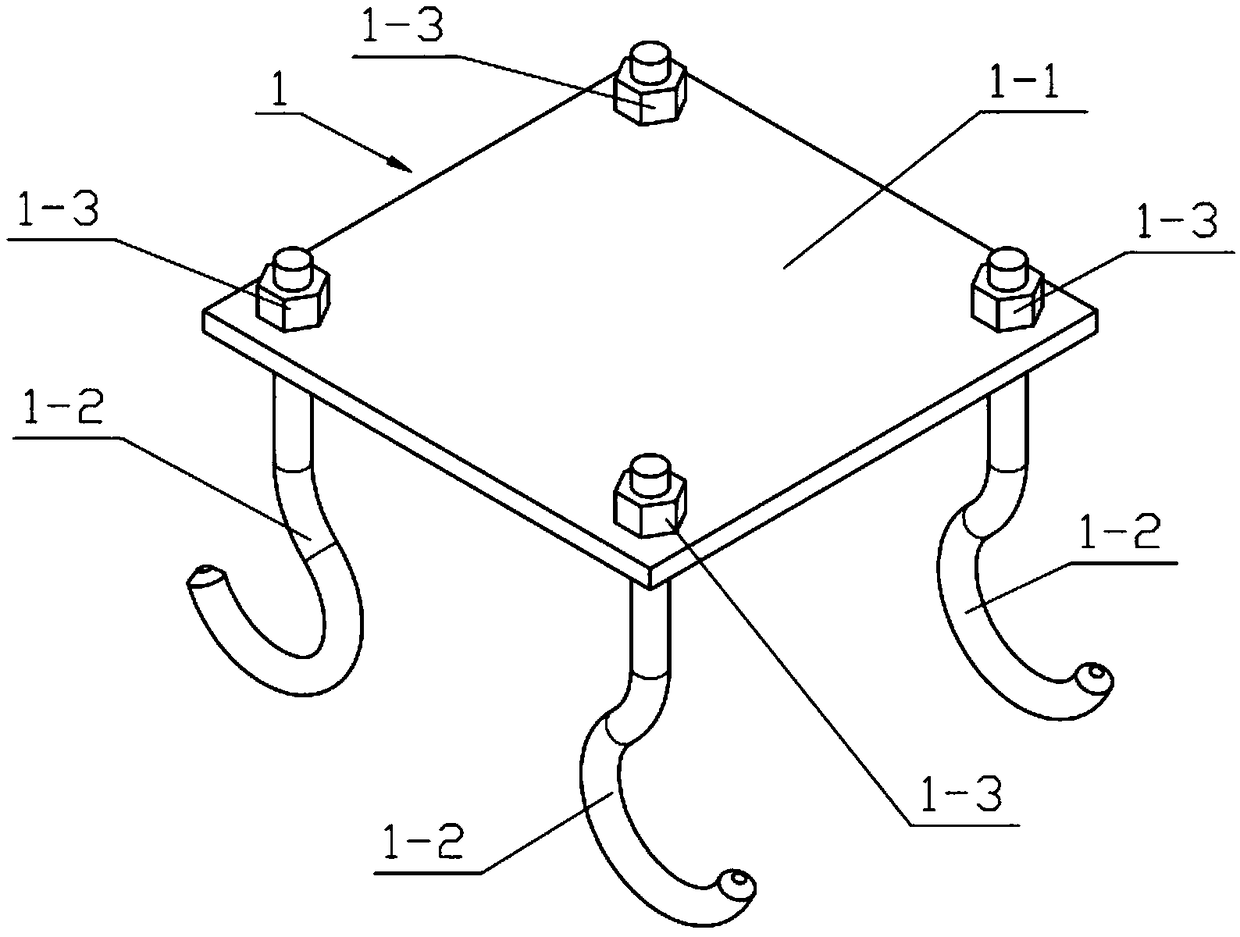

[0038] Combine below Figure 1-16 Explaining this embodiment, an LED high pole lamp includes a bottom bracket 1, an integral bracket 2, a lifting bracket 3, a power mechanism 4, a reel mechanism 5, a gear wheel I 6, a gear wheel mechanism 7, a lamp holder 8 and a wire rope 9. The reel mechanism 5 can be driven to rotate by manually turning the power mechanism 4, and the two reels 5-3 rotate in the same direction to drive the two wire ropes 9 to be wound on the two reels 5-3. The gear wheel I6 limits the wire ropes 9 on both sides to prevent the wire rope 9 from detaching. The two gear wheel mechanisms 7 on both sides limit the wire ropes 9 on both sides to prevent the wire ropes 9 on both sides from leaving the gear wheel body Ⅱ 7- 4. Ensure the movement trajectory of the wire rope 9. The wire rope 9 drives the lamp holder 8 to move up and down so that the lamp holder 8 can fall to the lower end of the device. The staff can maintain and repair the lamp holder 8 without high-alt...

specific Embodiment approach 3

[0048] Combine below Figure 1-16 To explain this embodiment, this embodiment further explains the second embodiment. The integral bracket 2 also includes a sliding mounting block 2-5 and a vertical sliding groove 2-6. The front and rear ends of the bracket cylinder 2-2 are fixedly connected. There are sliding mounting blocks 2-5, and vertical sliding grooves 2-6 are provided on the two sliding mounting blocks 2-5.

specific Embodiment approach 4

[0049] Combine below Figure 1-16 To explain this embodiment, this embodiment further explains the third embodiment. The lifting bracket 3 further includes a lifting handle 3-3, a lifting rotating plate 3-4, a lifting sliding column 3-5, and a lifting locking handle 3-6 , The lifting rotating plate 3-4 is rotatably connected to the lower end of the lifting cylinder 3-1, both sides of the lifting rotating plate 3-4 are fixedly connected with lifting sliding columns 3-5, and the two lifting sliding columns 3-5 are threaded The lifting locking handles 3-6 are connected, the two lifting sliding posts 3-5 are slidably connected in the two vertical sliding grooves 2-6, and the two lifting locking handles 3-6 are connected to the two sliding mounting blocks 2 respectively. -5 contacts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com