Patents

Literature

140 results about "Tooth segment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

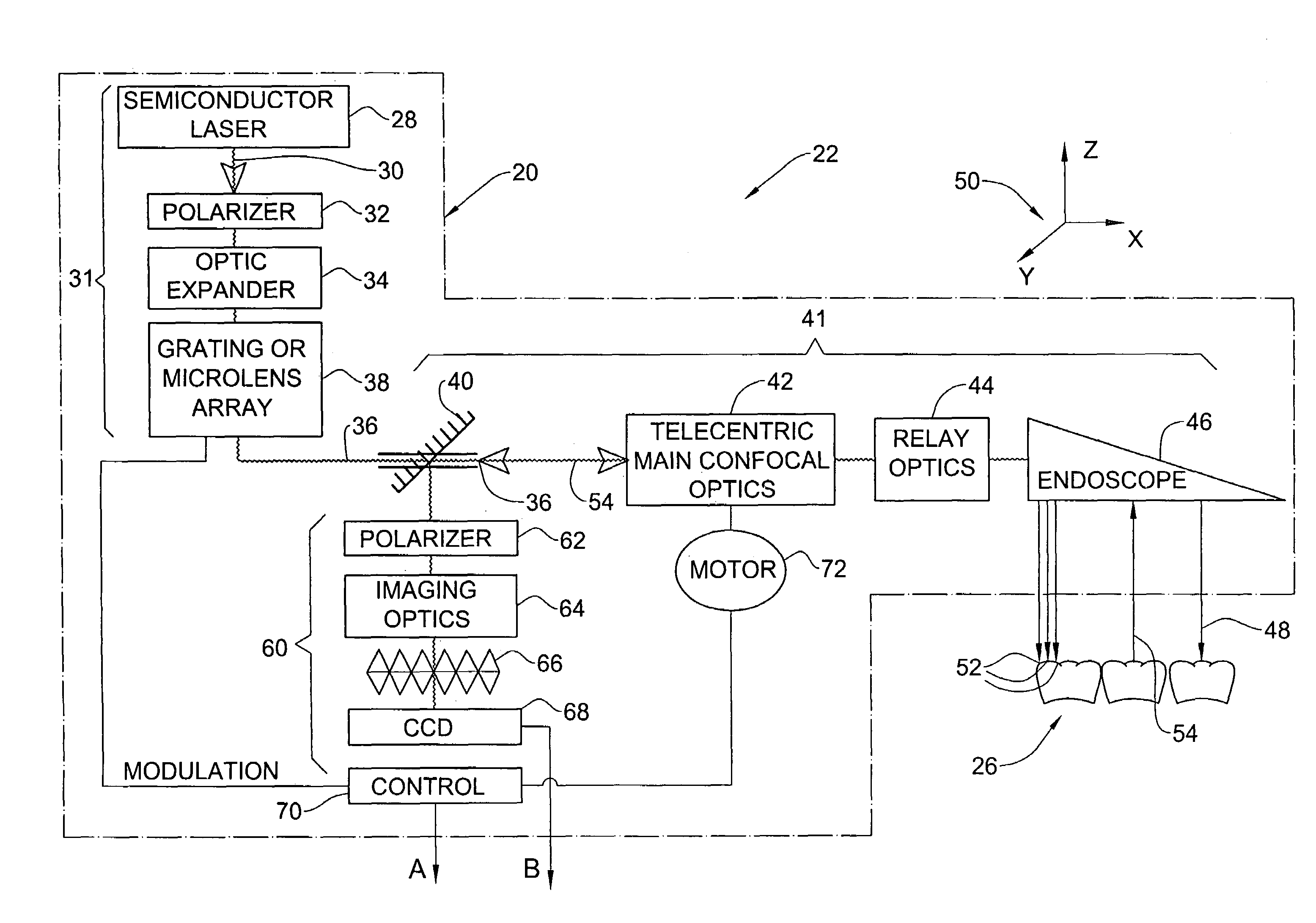

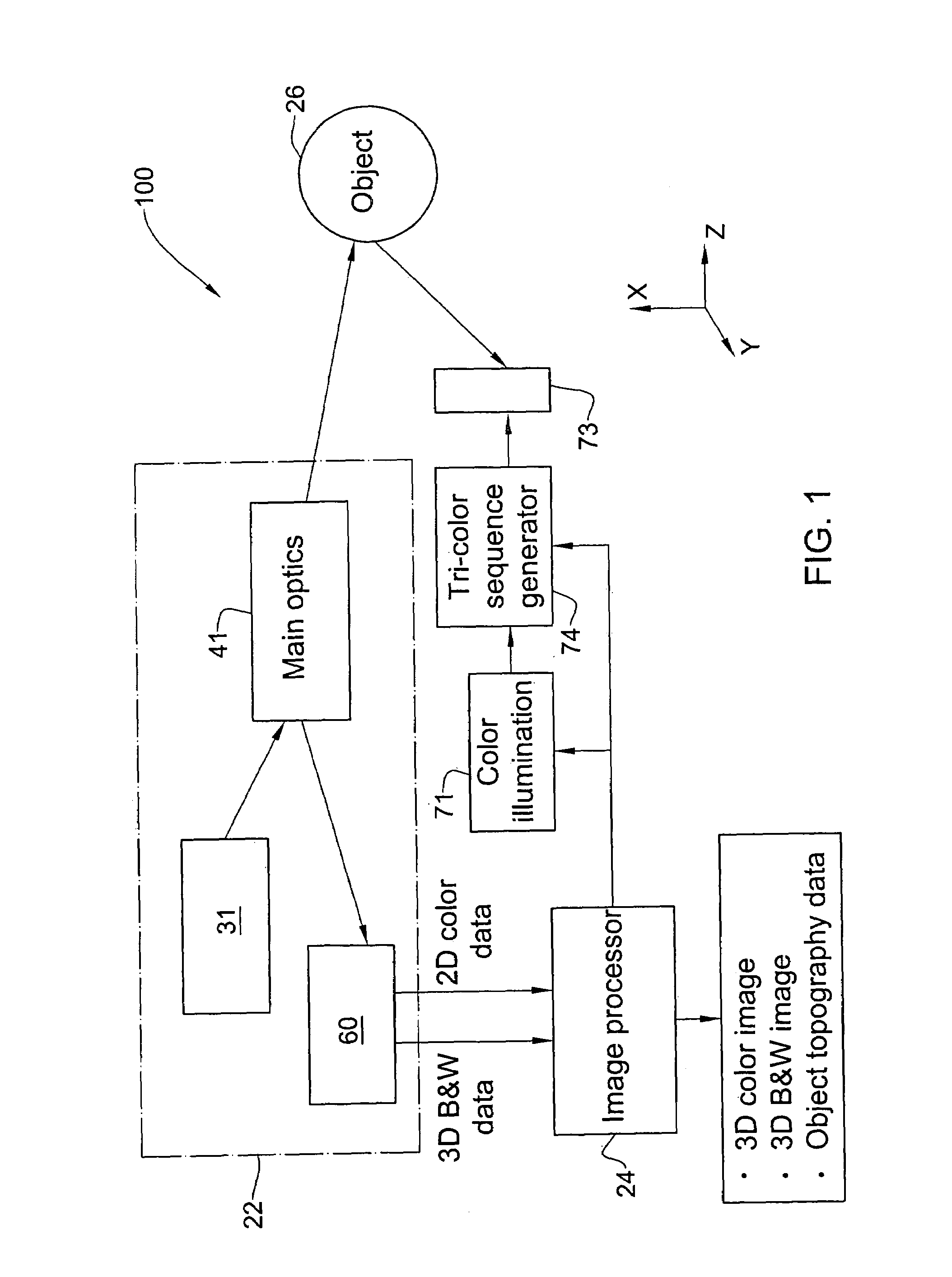

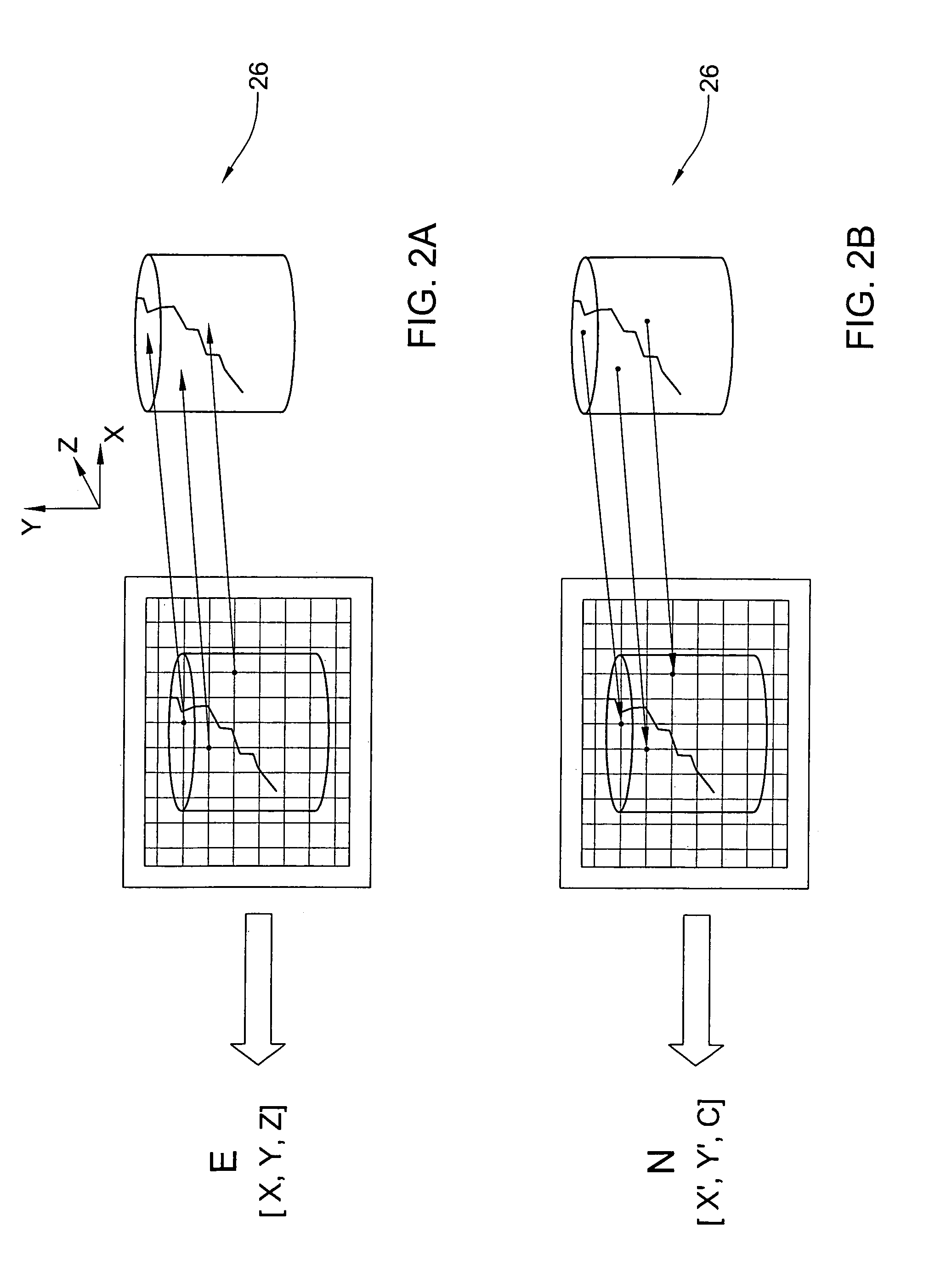

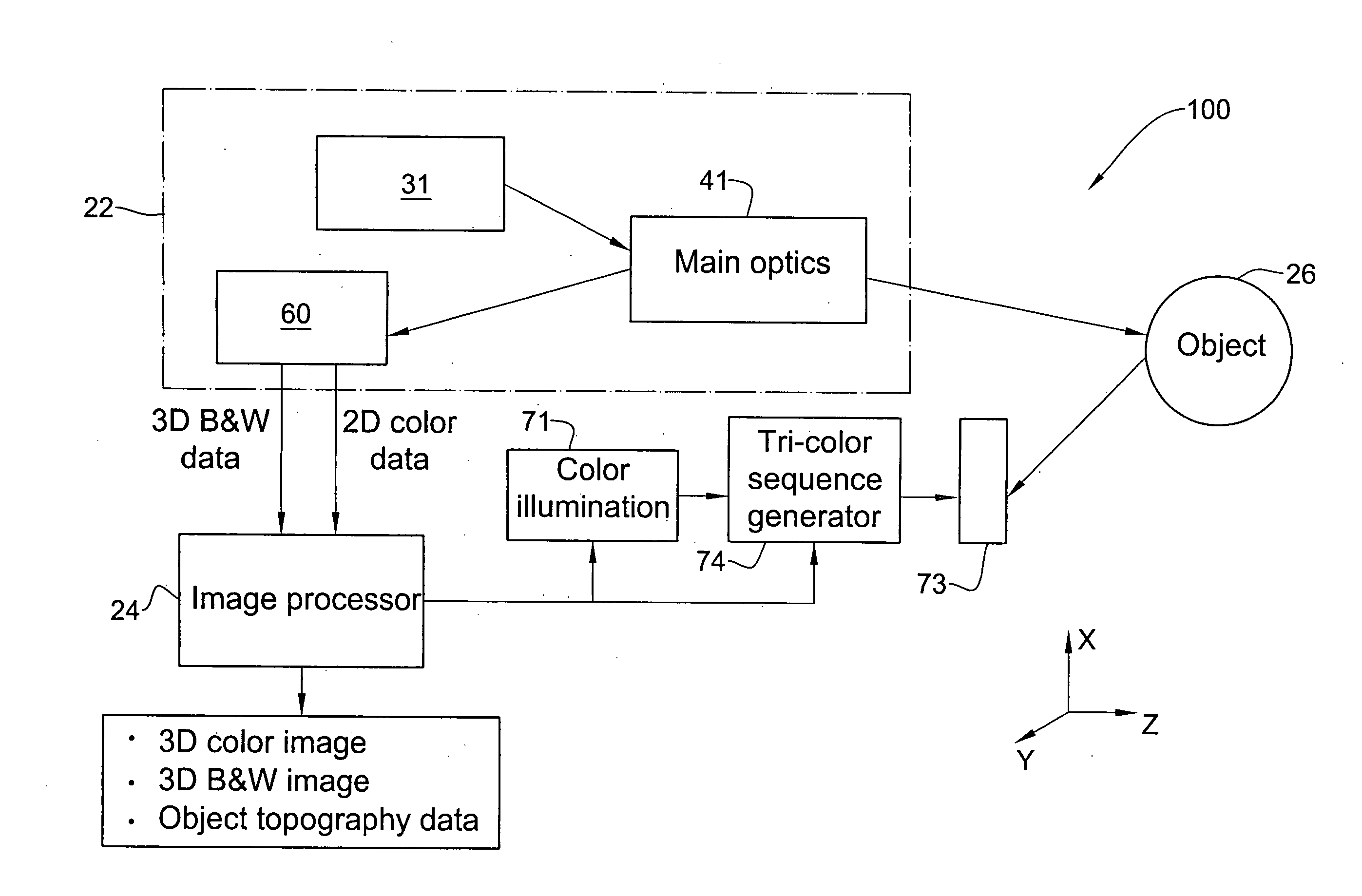

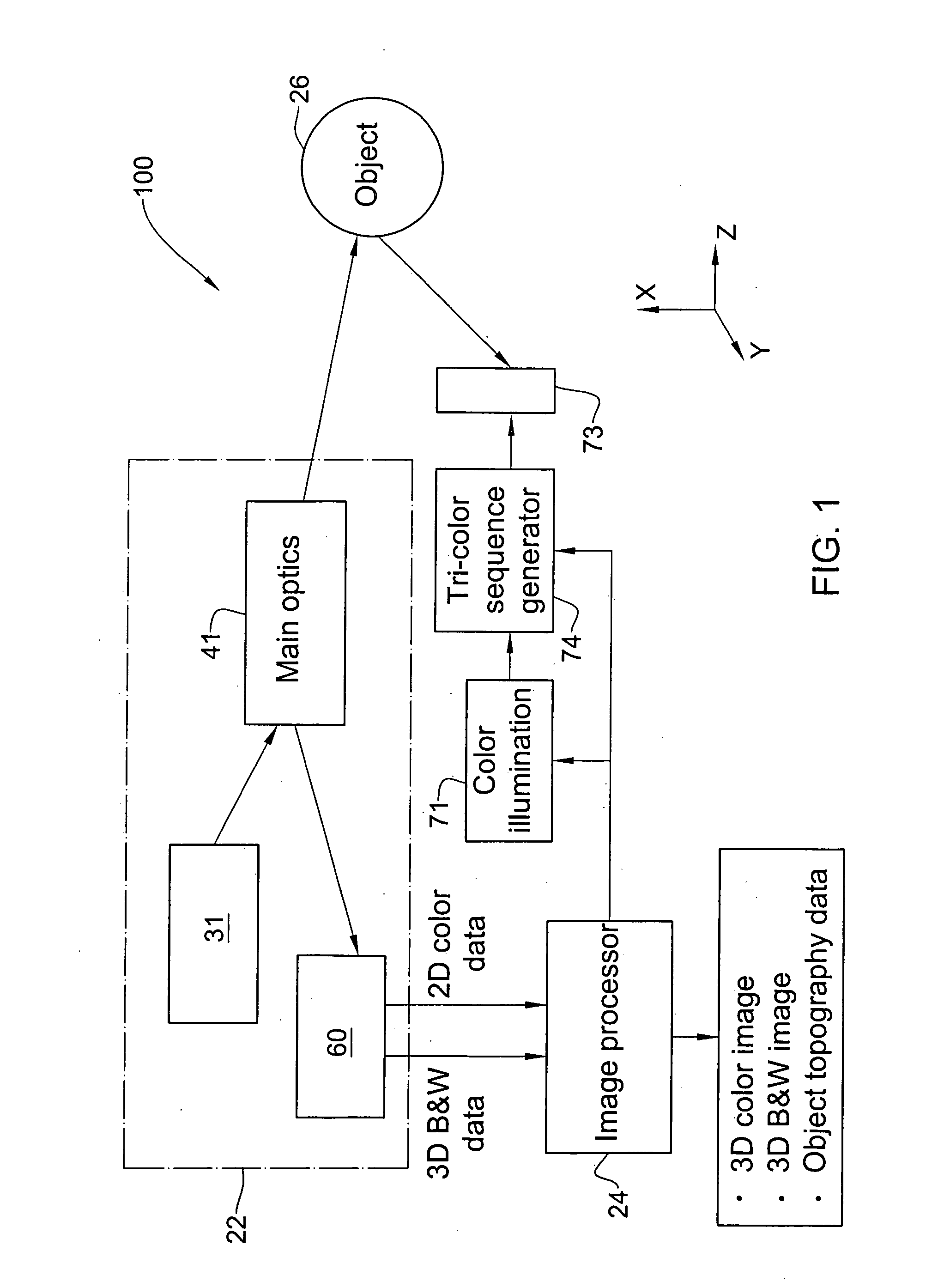

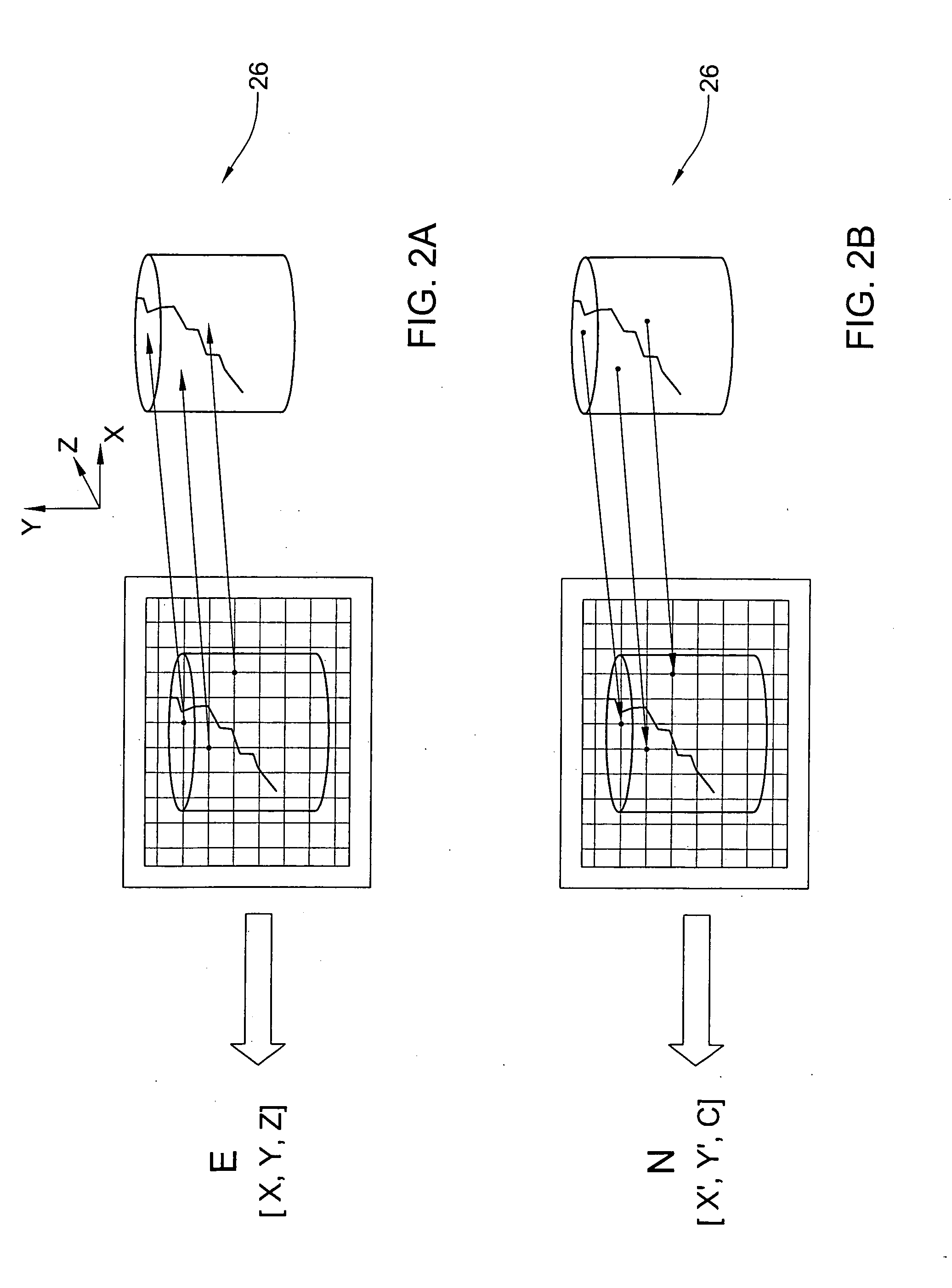

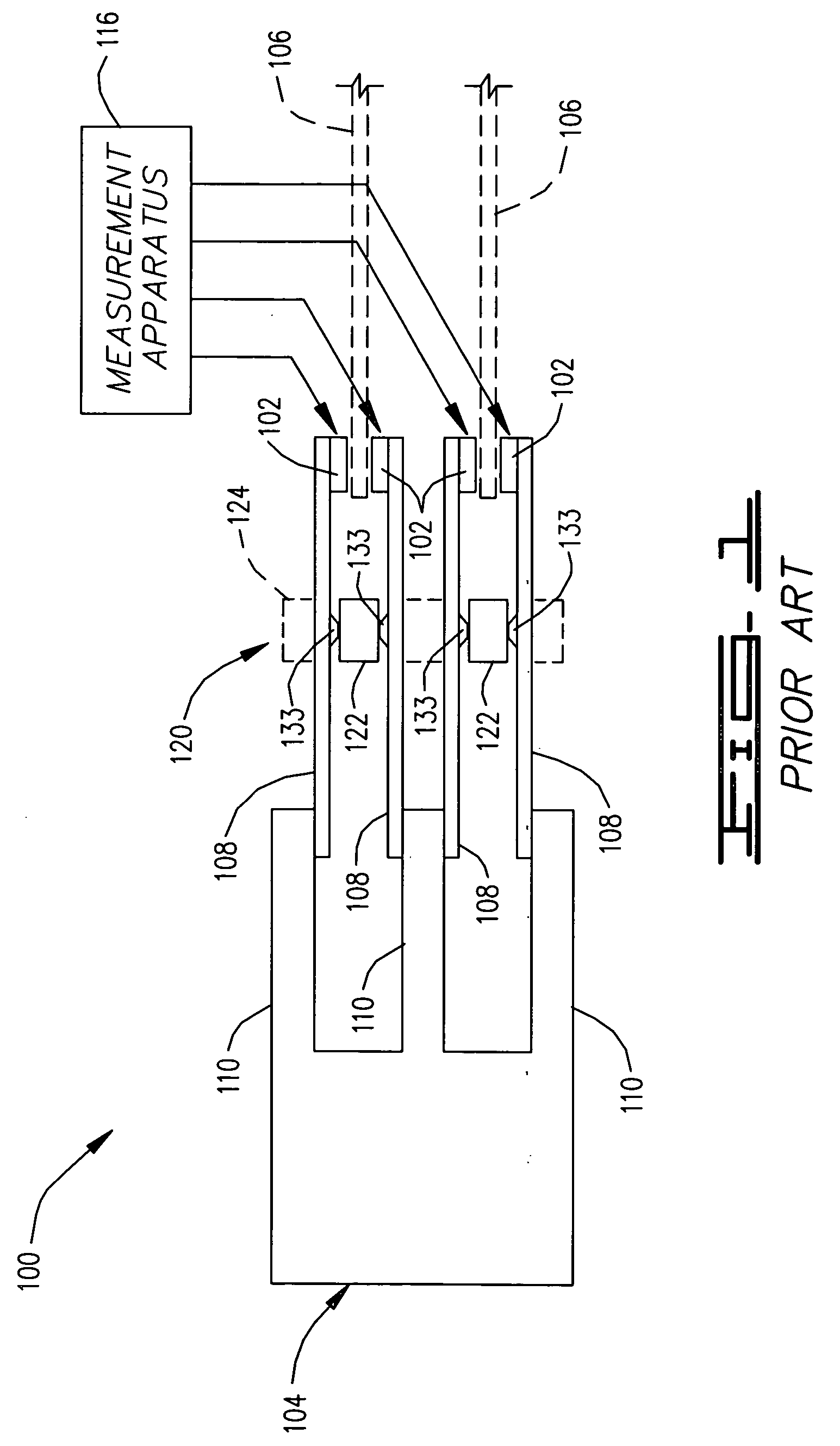

Method and apparatus for colour imaging a three-dimensional structure

A device for determining the surface topology and associated color of a structure, such as a teeth segment, includes a scanner for providing depth data for points along a two-dimensional array substantially orthogonal to the depth direction, and an image acquisition means for providing color data for each of the points of the array, while the spatial disposition of the device with respect to the structure is maintained substantially unchanged. A processor combines the color data and depth data for each point in the array, thereby providing a three-dimensional color virtual model of the surface of the structure. A corresponding method for determining the surface topology and associated color of a structure is also provided.

Owner:ALIGN TECH

Method and apparatus for colour imaging a three-dimensional structure

ActiveUS20060001739A1Accurate mappingImage enhancementImpression capsComputer graphics (images)Tooth segment

A device for determining the surface topology and associated color of a structure, such as a teeth segment, includes a scanner for providing depth data for points along a two-dimensional array substantially orthogonal to the depth direction, and an image acquisition means for providing color data for each of the points of the array, while the spatial disposition of the device with respect to the structure is maintained substantially unchanged. A processor combines the color data and depth data for each point in the array, thereby providing a three-dimensional color virtual model of the surface of the structure. A corresponding method for determining the surface topology and associated color of a structure is also provided.

Owner:ALIGN TECH

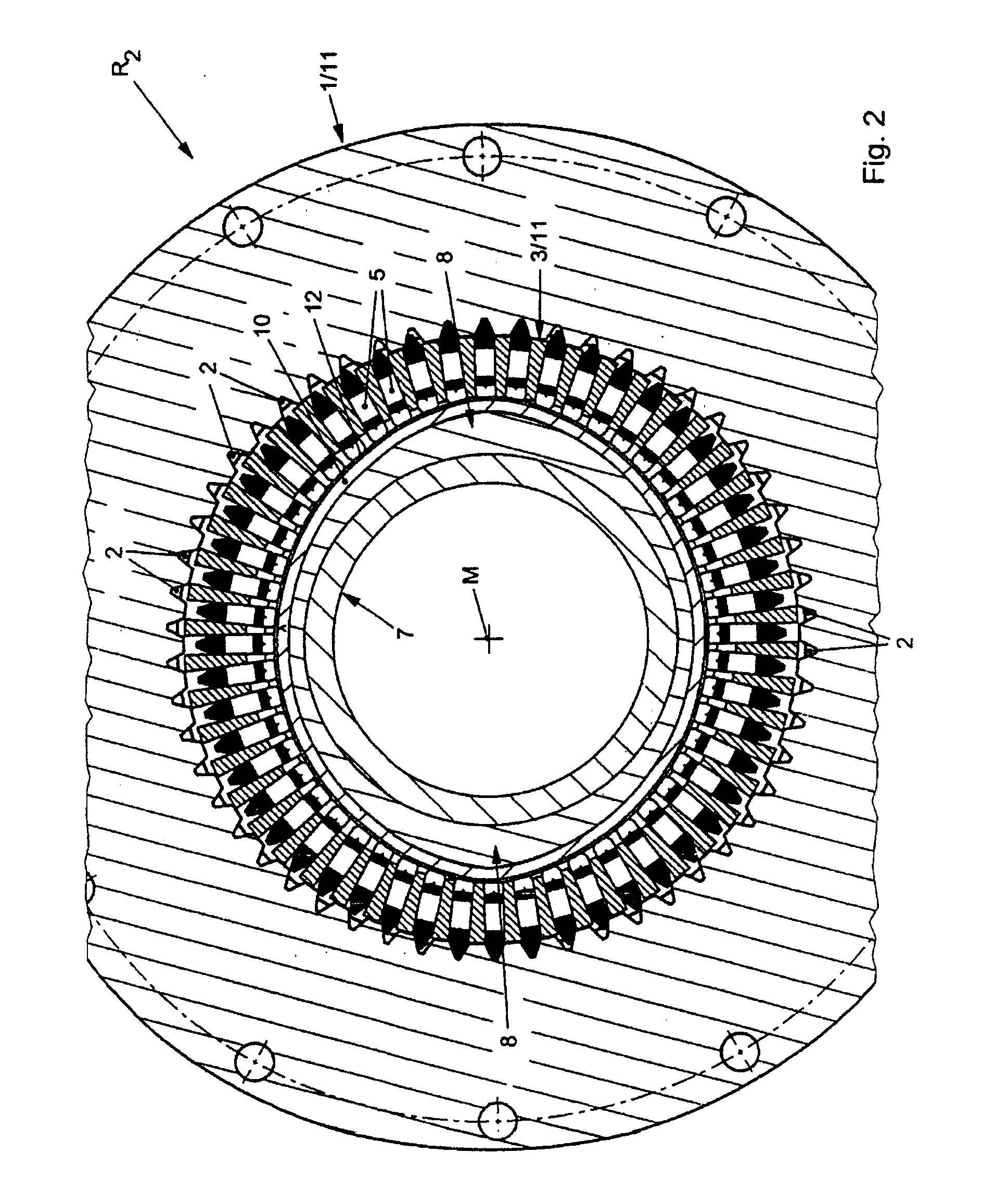

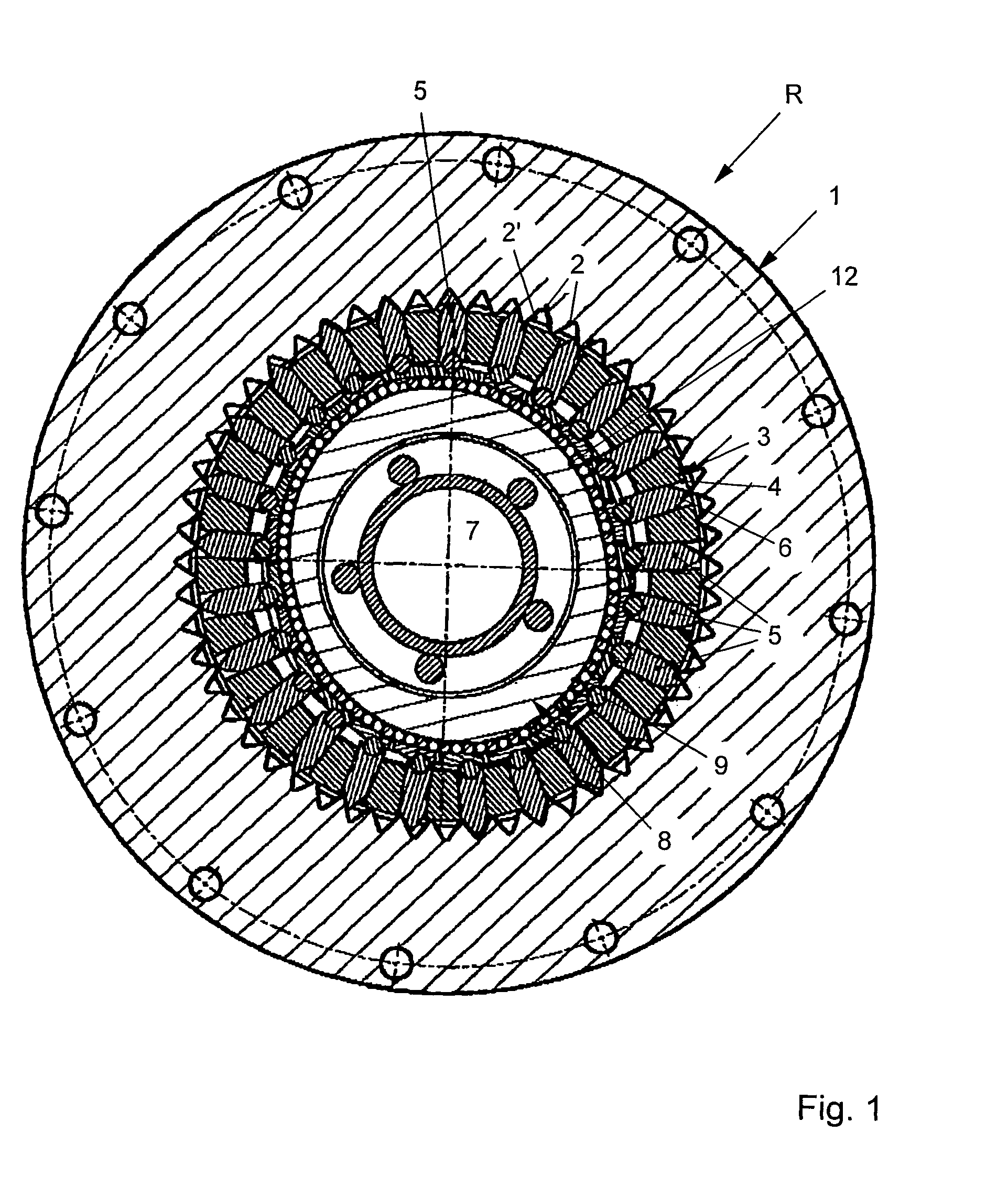

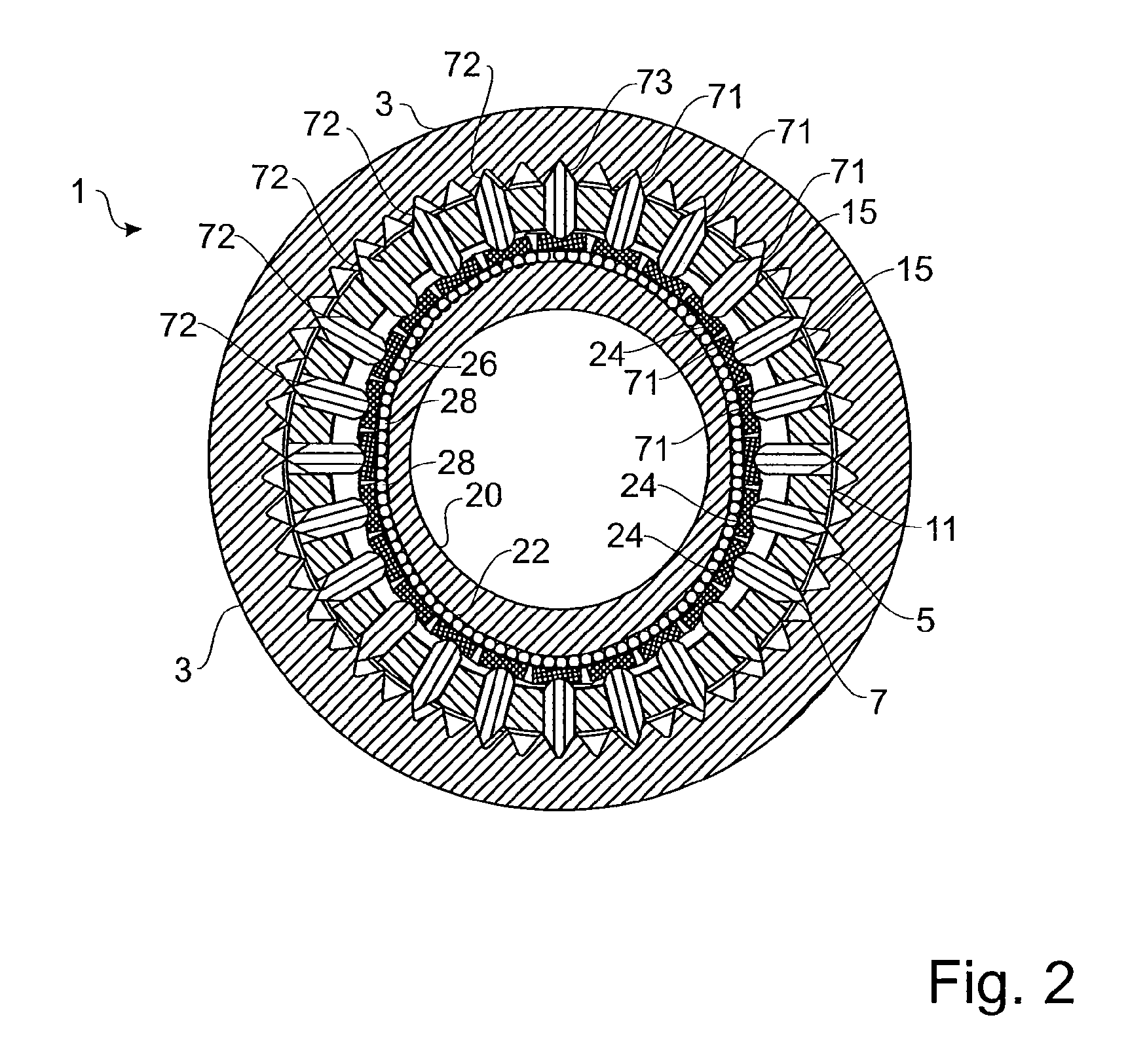

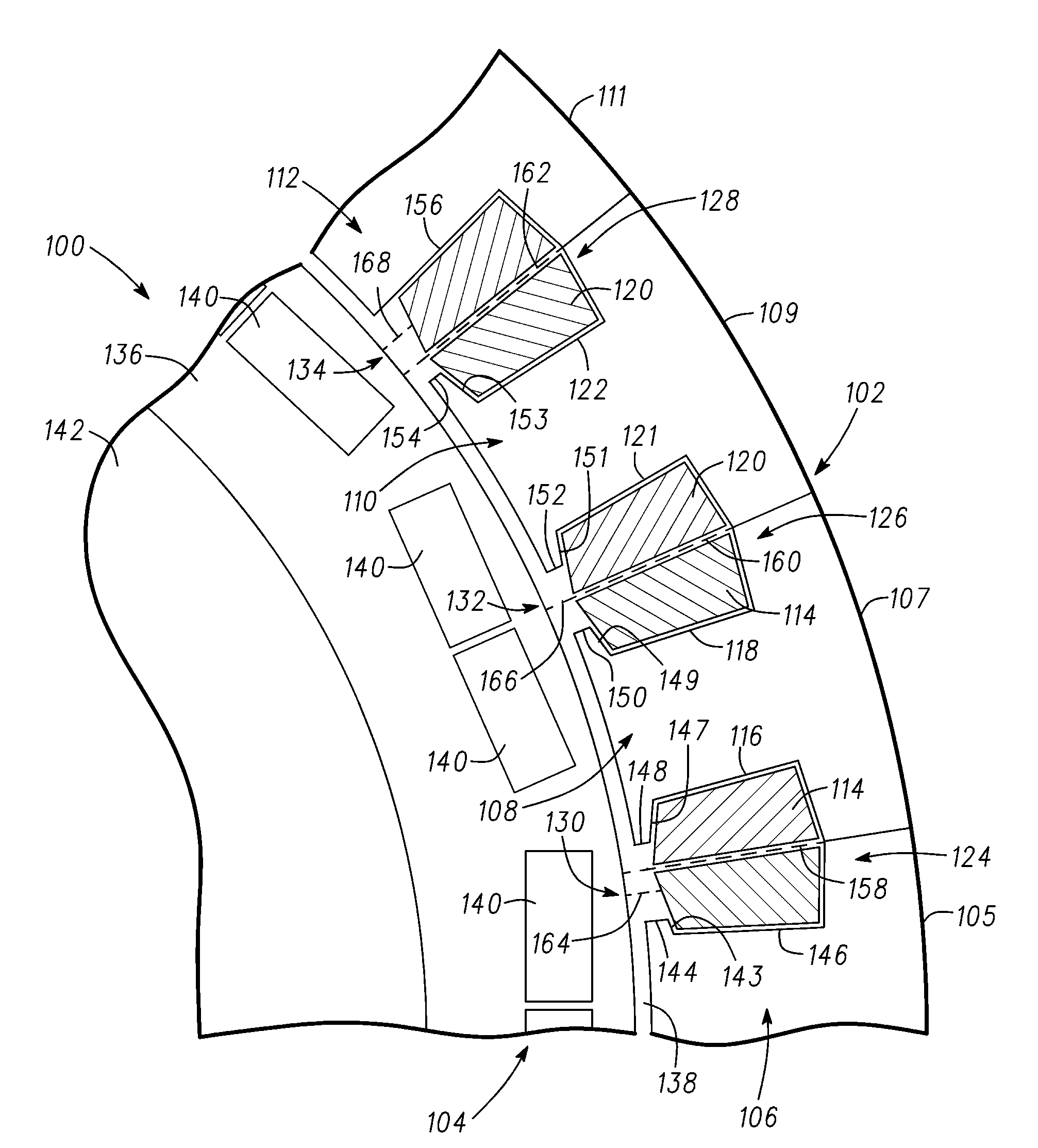

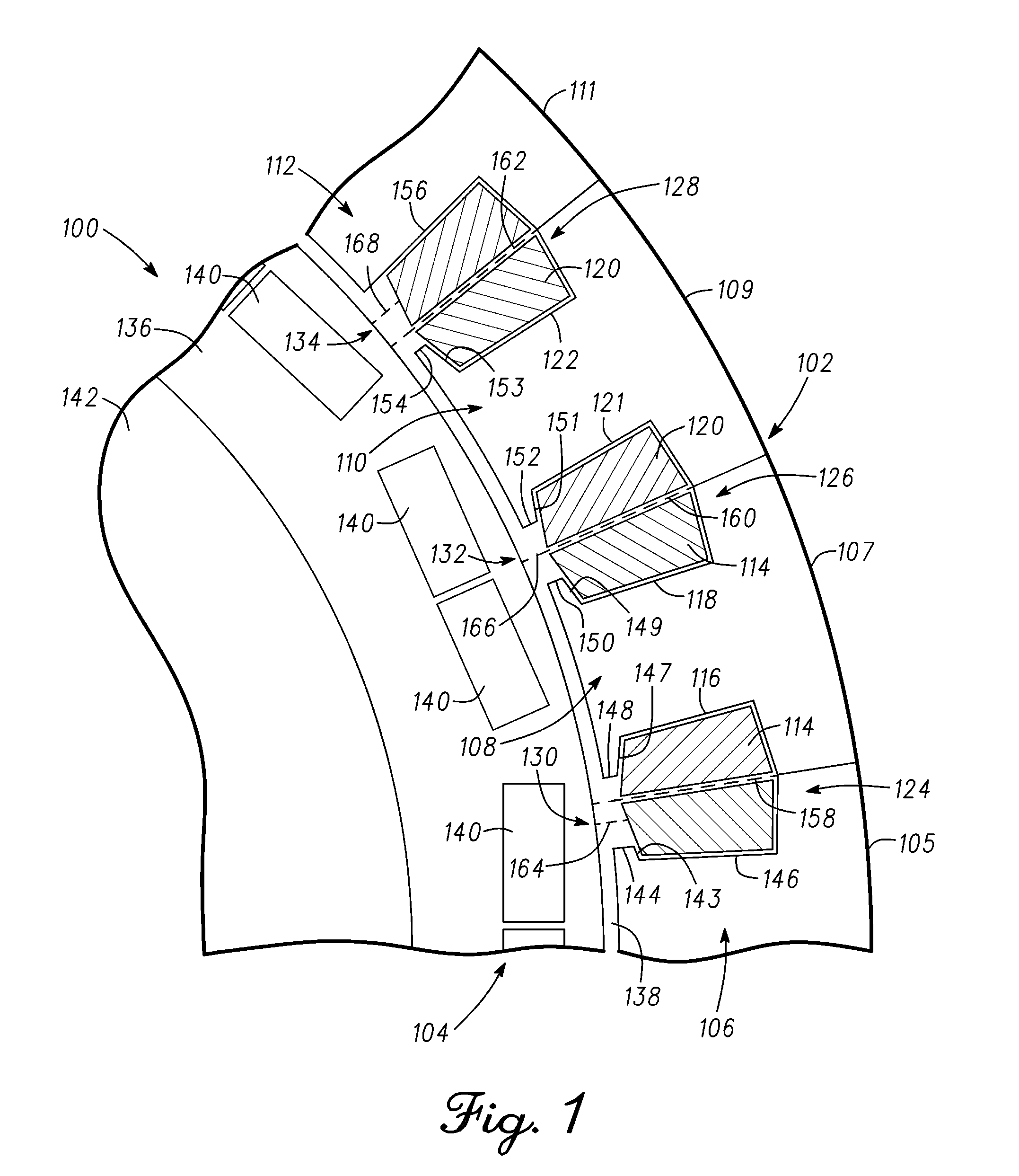

Gearing

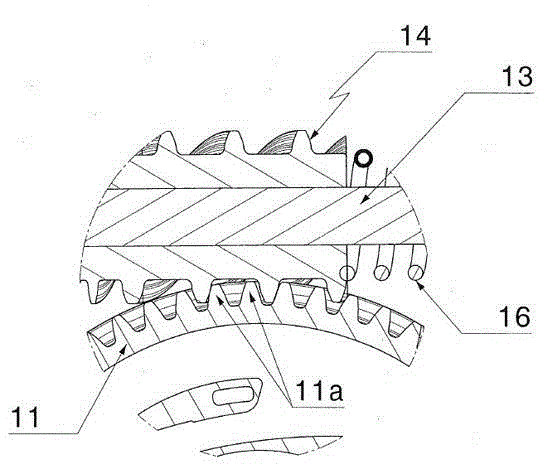

ActiveUS8656809B2High level of compactness and complexitySmall spacingToothed gearingsDifferential gearingsTooth segmentControl theory

Owner:WITTENSTEIN SE

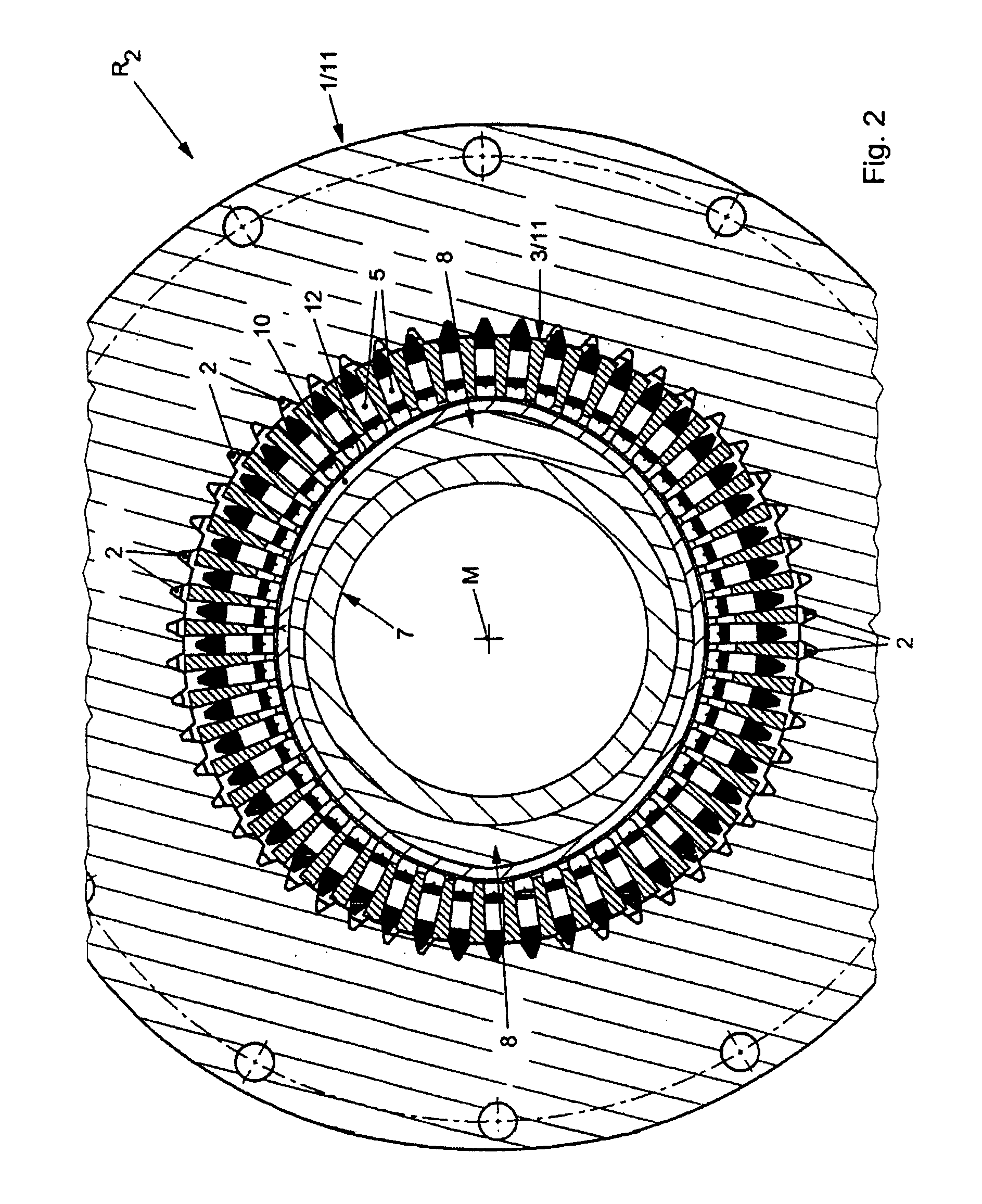

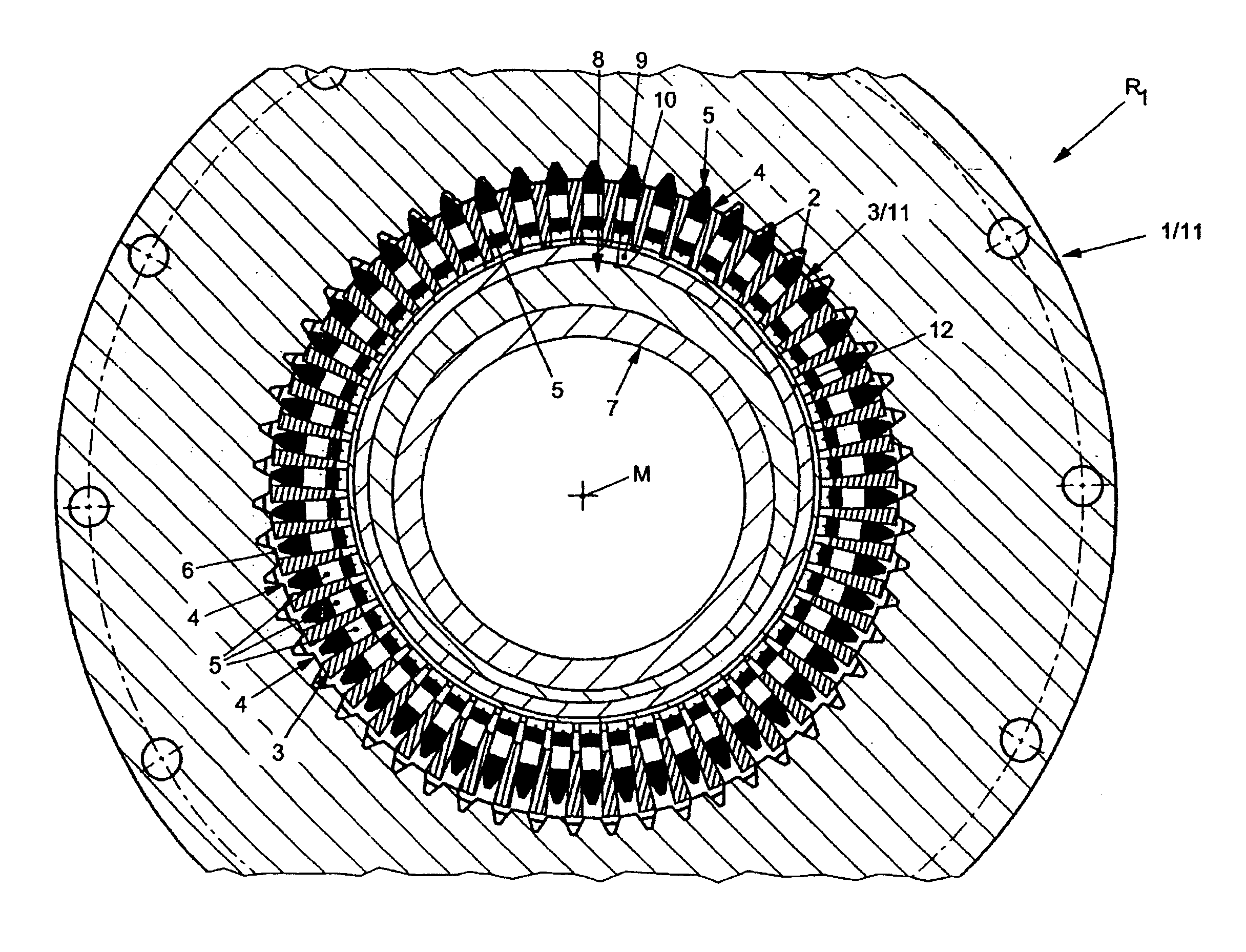

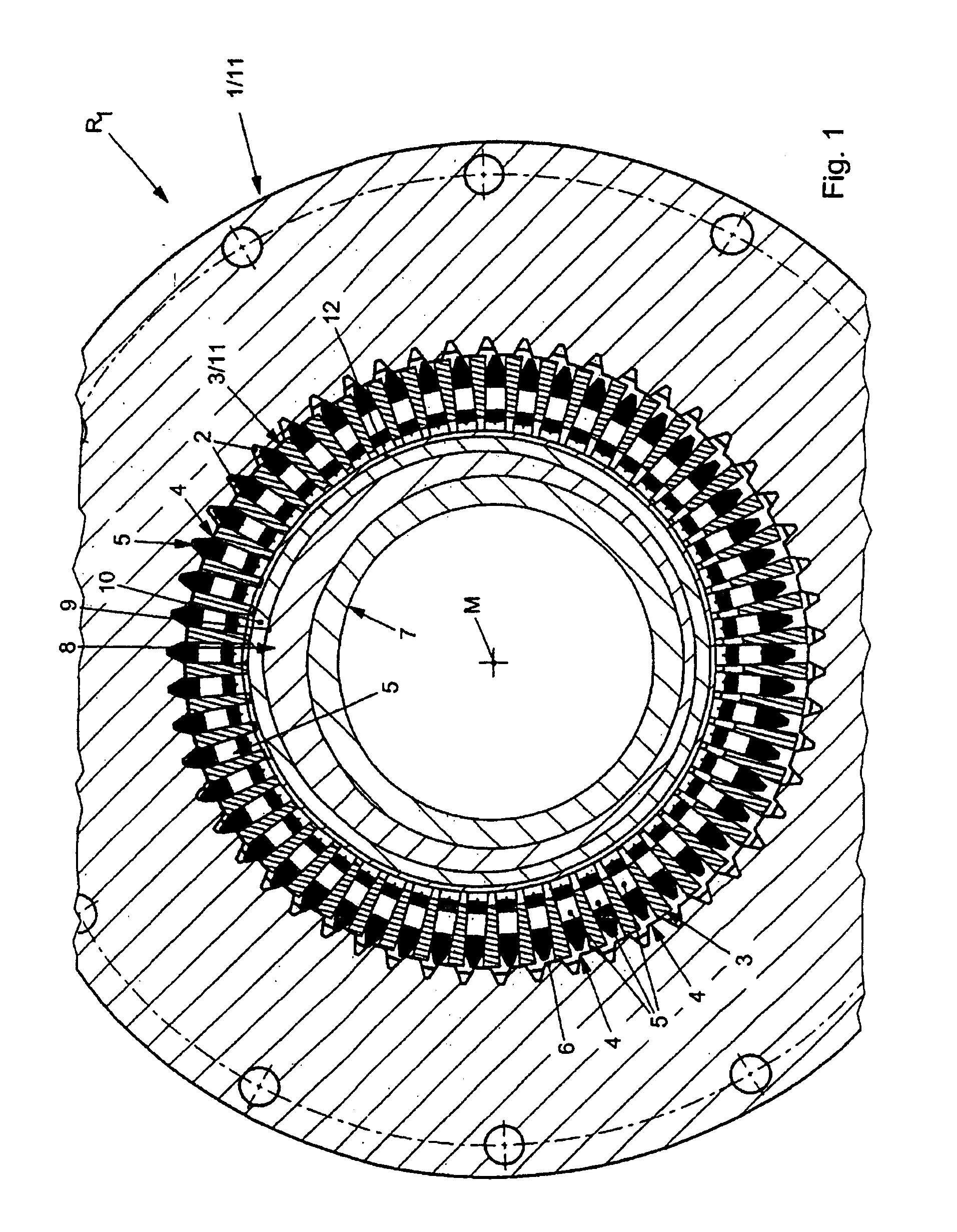

Gearing

ActiveUS20090205451A1High selectivityHigh level of compactness and complexityPortable liftingToothed gearingsTooth segmentControl theory

Owner:WITTENSTEIN SE

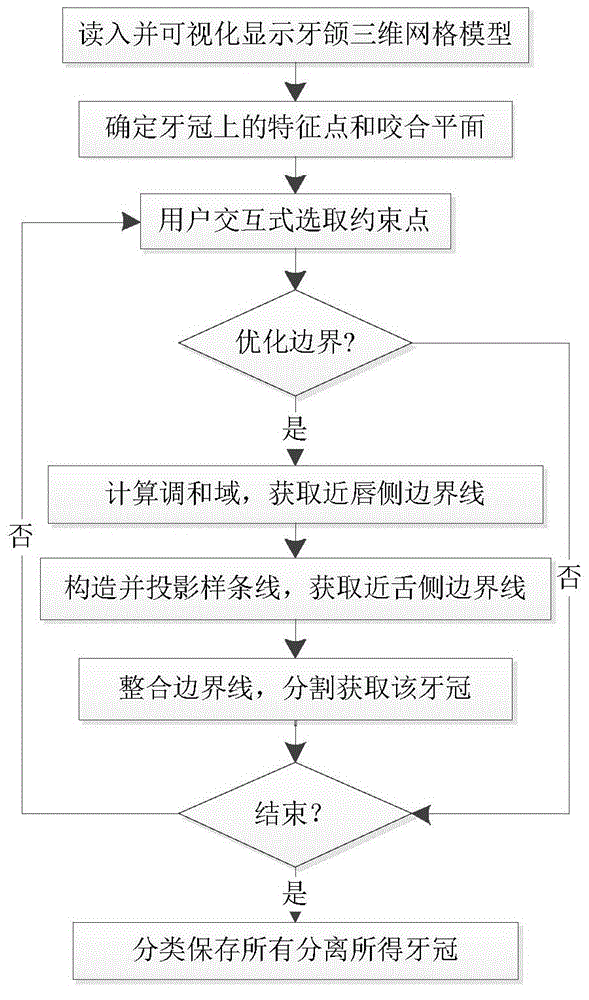

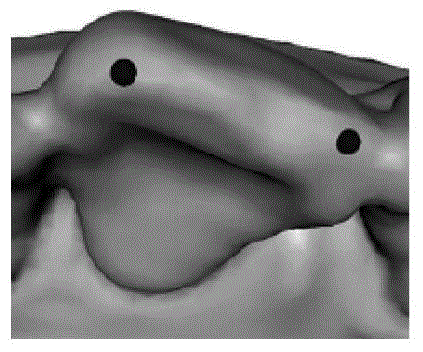

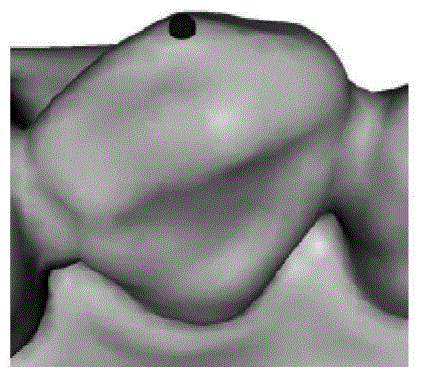

Computer interaction type method for segmenting single tooth crown from three-dimensional jaw model

InactiveCN104392492AImprove robustnessEasy to useImage data processingSpecial data processing applicationsUpper toothBorder line

The invention discloses a computer interaction type method for segmenting a single tooth crown from a three-dimensional jaw model. The method includes the steps: reading and visually displaying the three-dimensional jaw grid model; detecting anatomic characteristic points and an occlusion plane of upper teeth of a jaw in the three-dimensional jaw grid model; assigning constraint points of harmonic fields of the three-dimensional jaw grid model; calculating the harmonic fields according to constraint conditions to obtain a tooth crown segmenting border line; performing grid cutting according to the obtained tooth crown segmenting border line to obtain a tooth crown model. By the method, a tooth segmenting border can be accurately obtained, the method is simple to use, and a user interactively determines two border points on a visual view of the jaw model for a single tooth to be separated, so that the tooth crown grid model of the tooth can be accurately obtained. The method has important significance for dental orthodontics, virtual jaw surgery simulation and the like.

Owner:CENT SOUTH UNIV

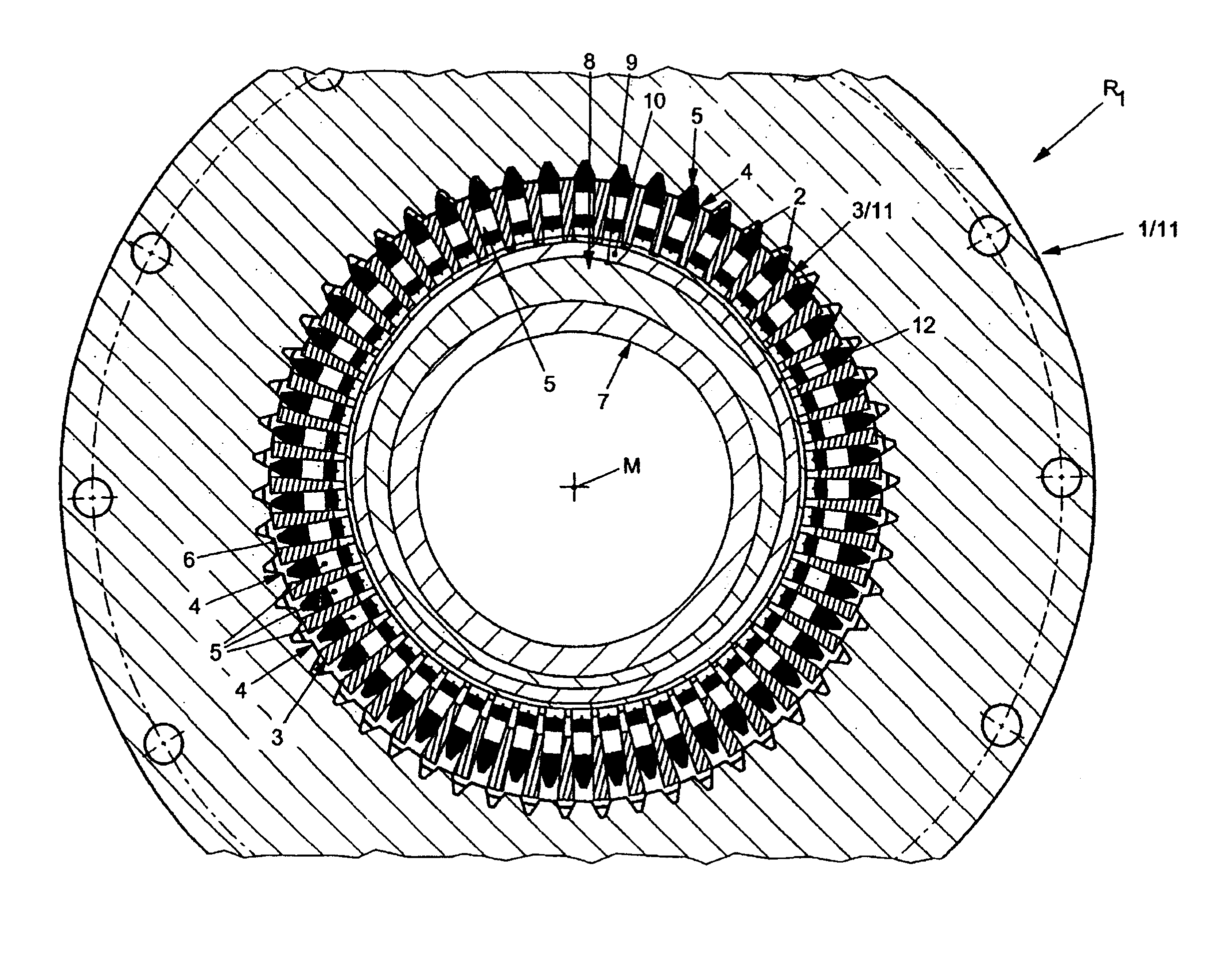

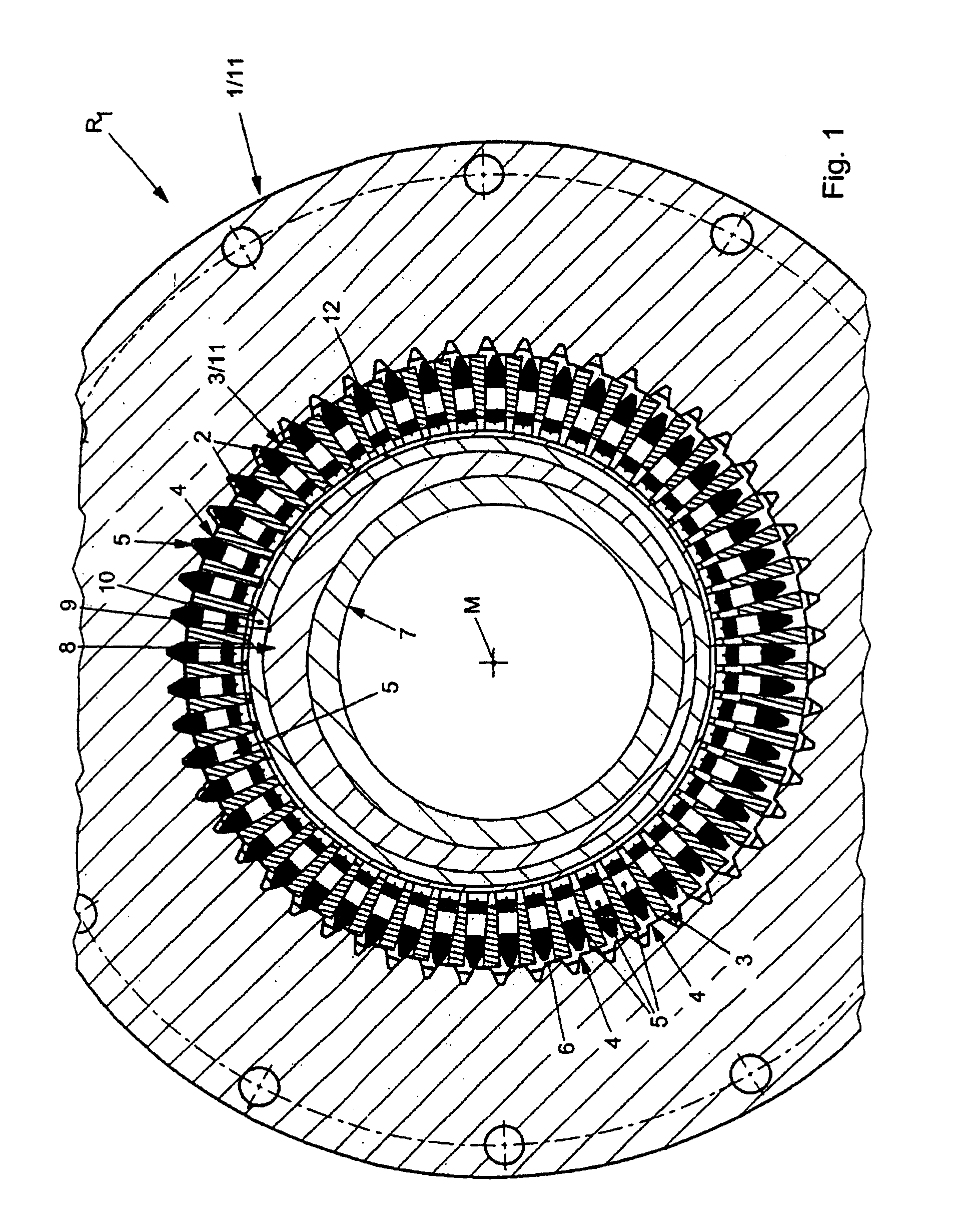

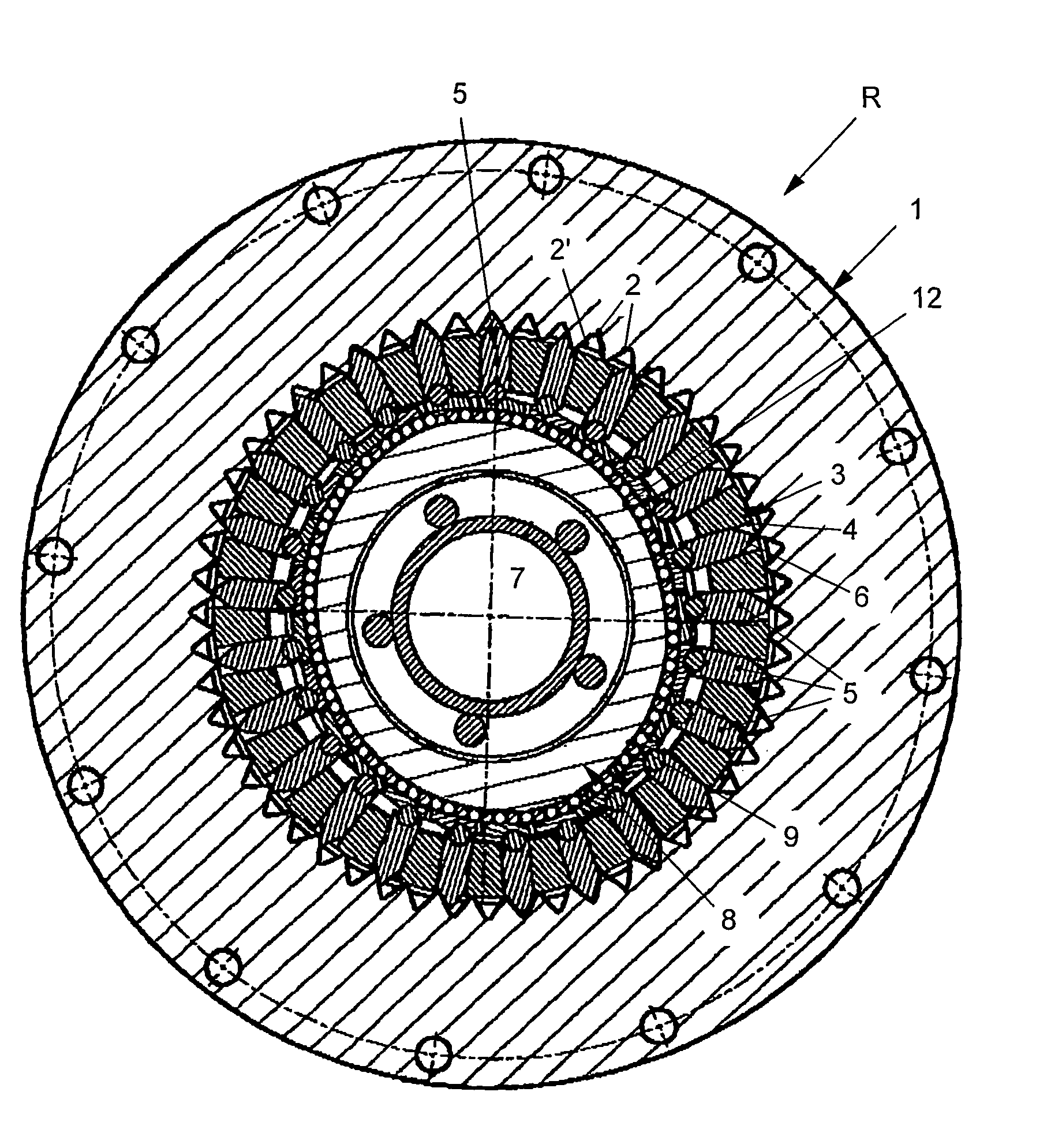

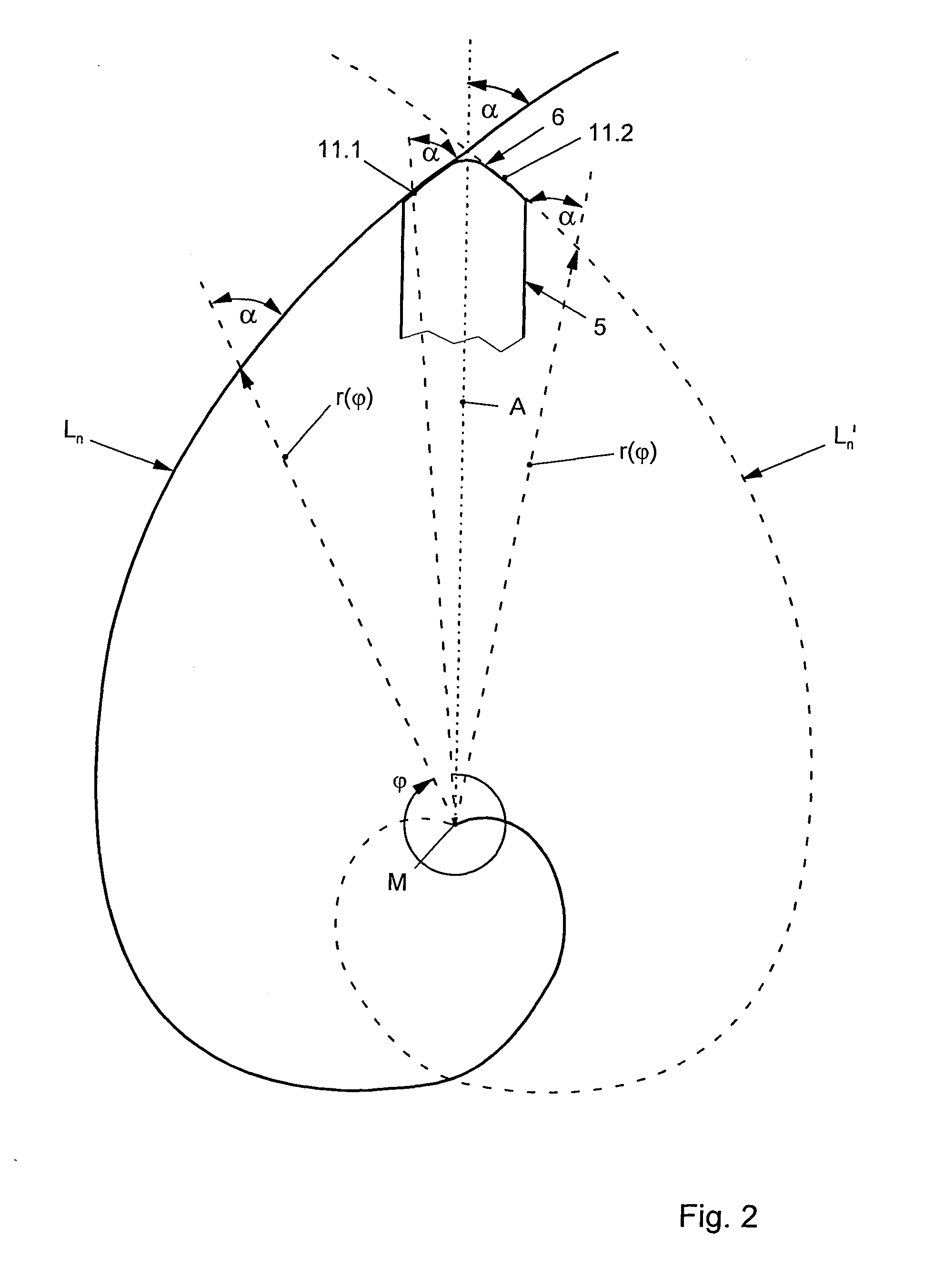

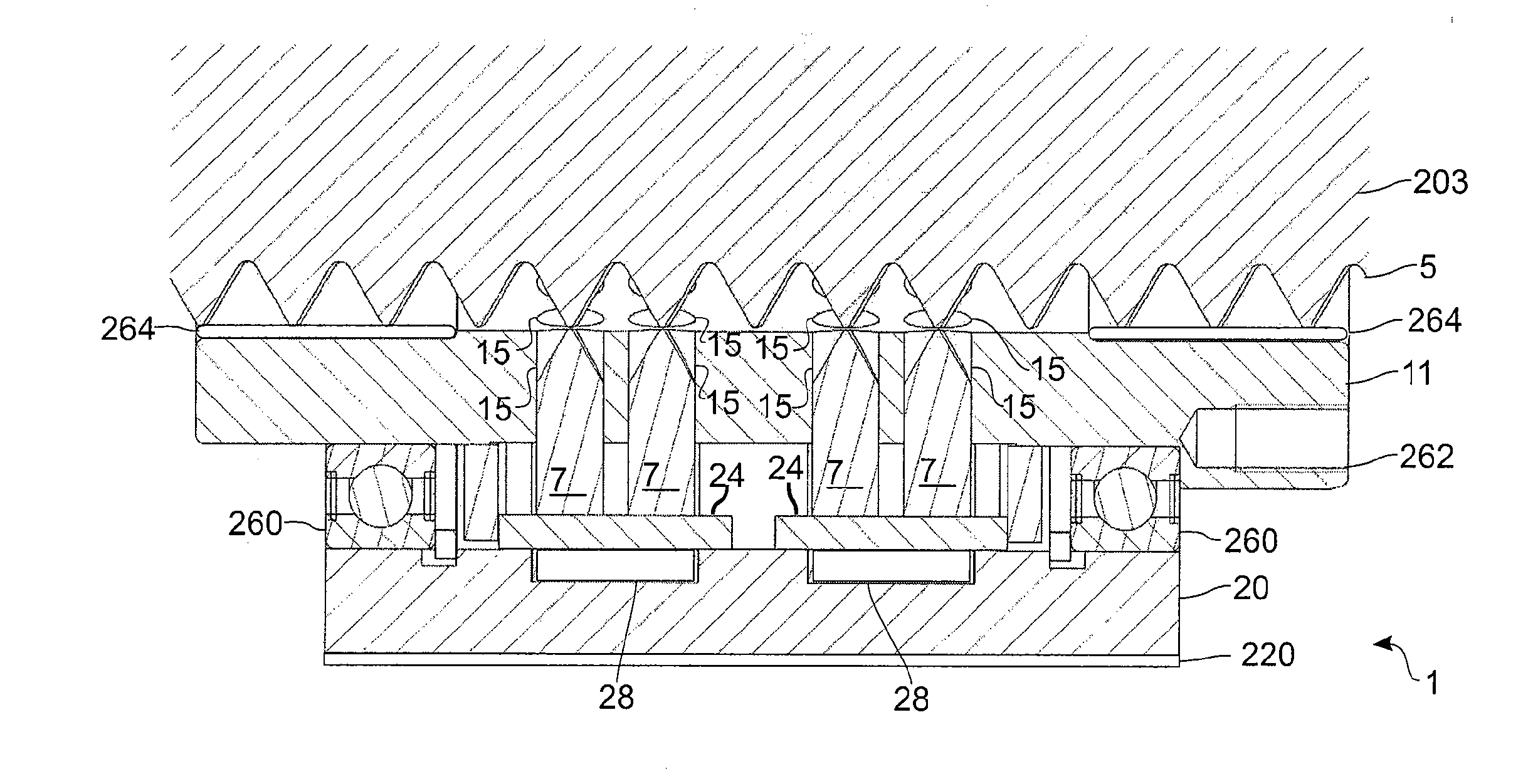

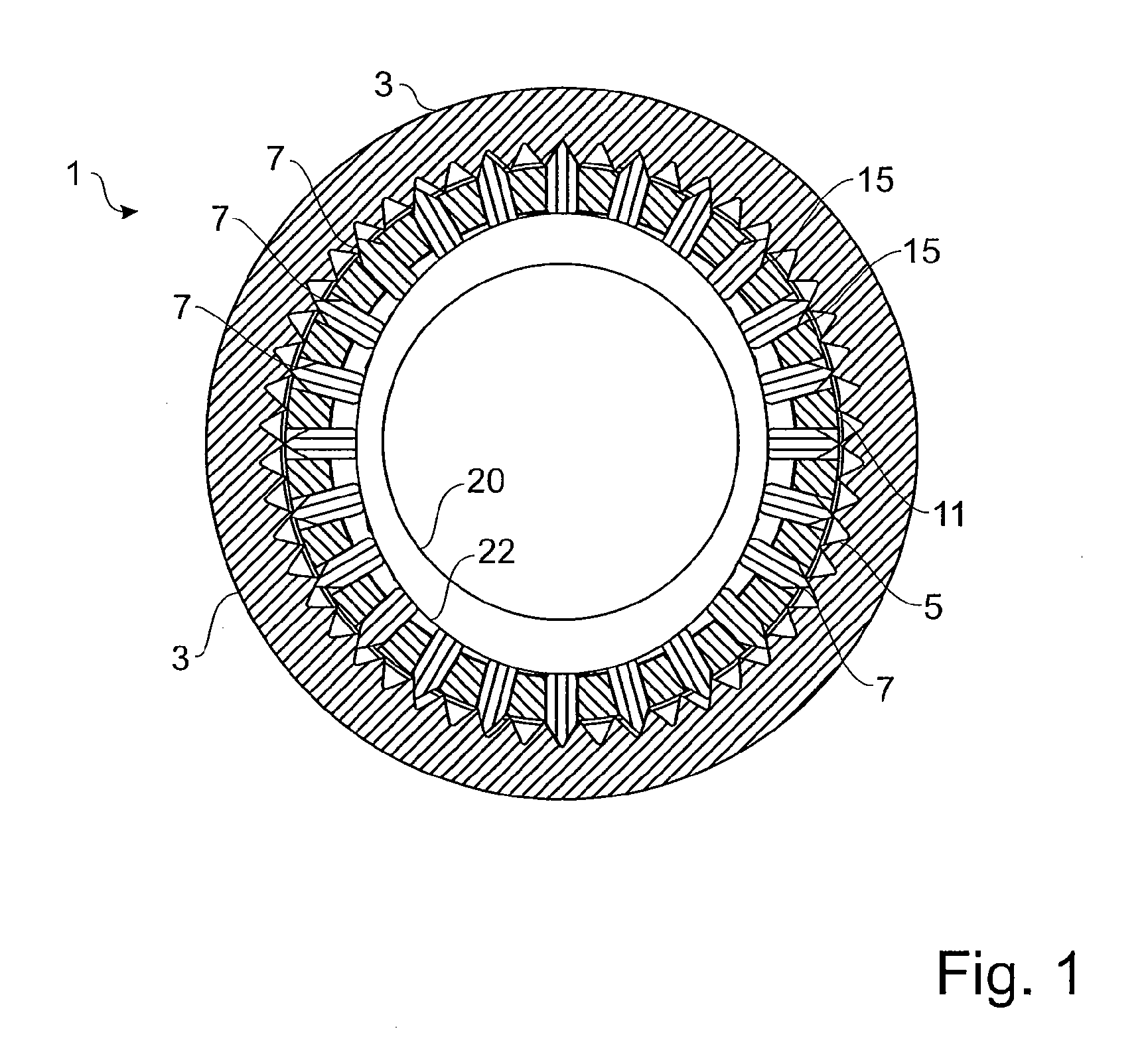

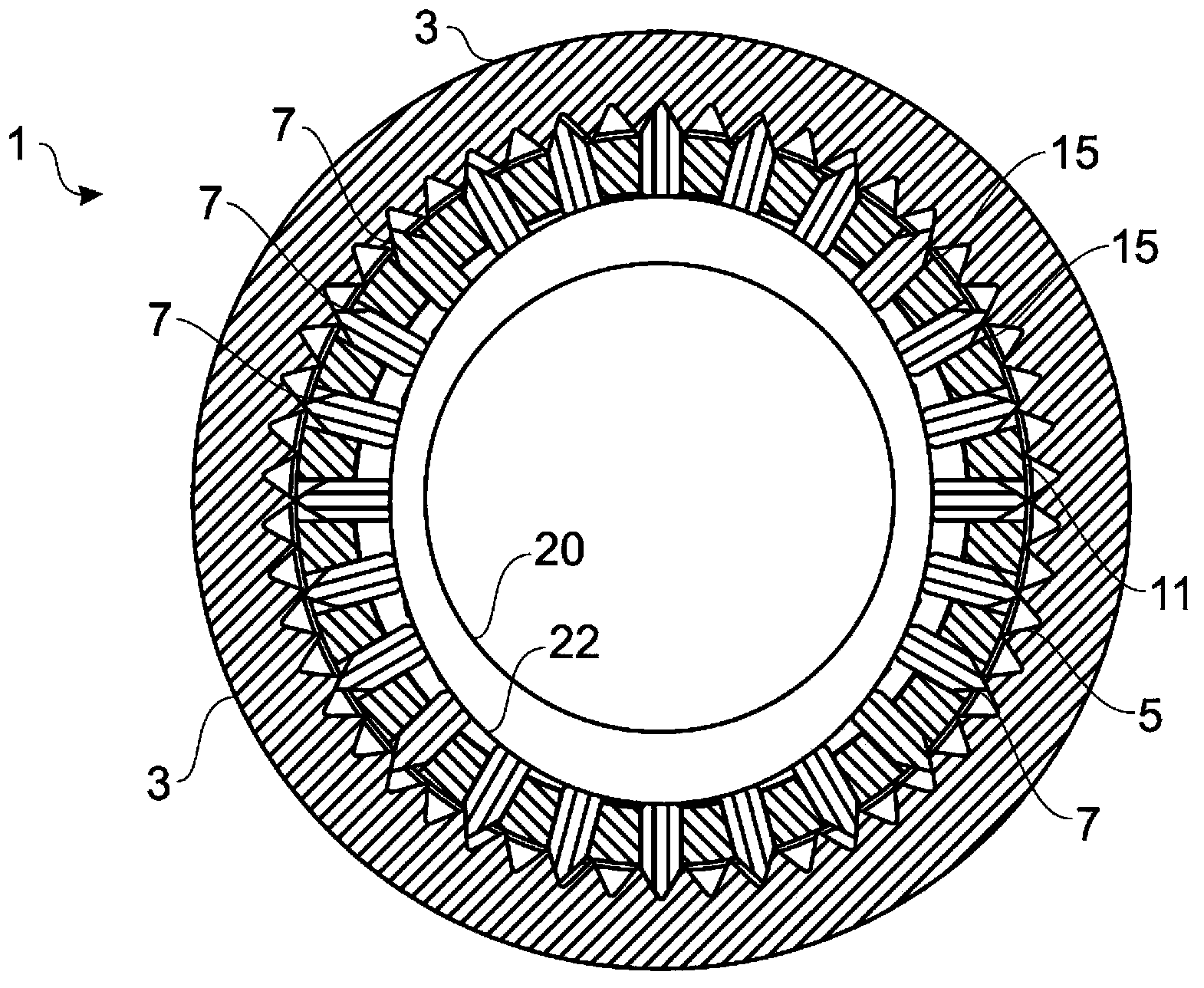

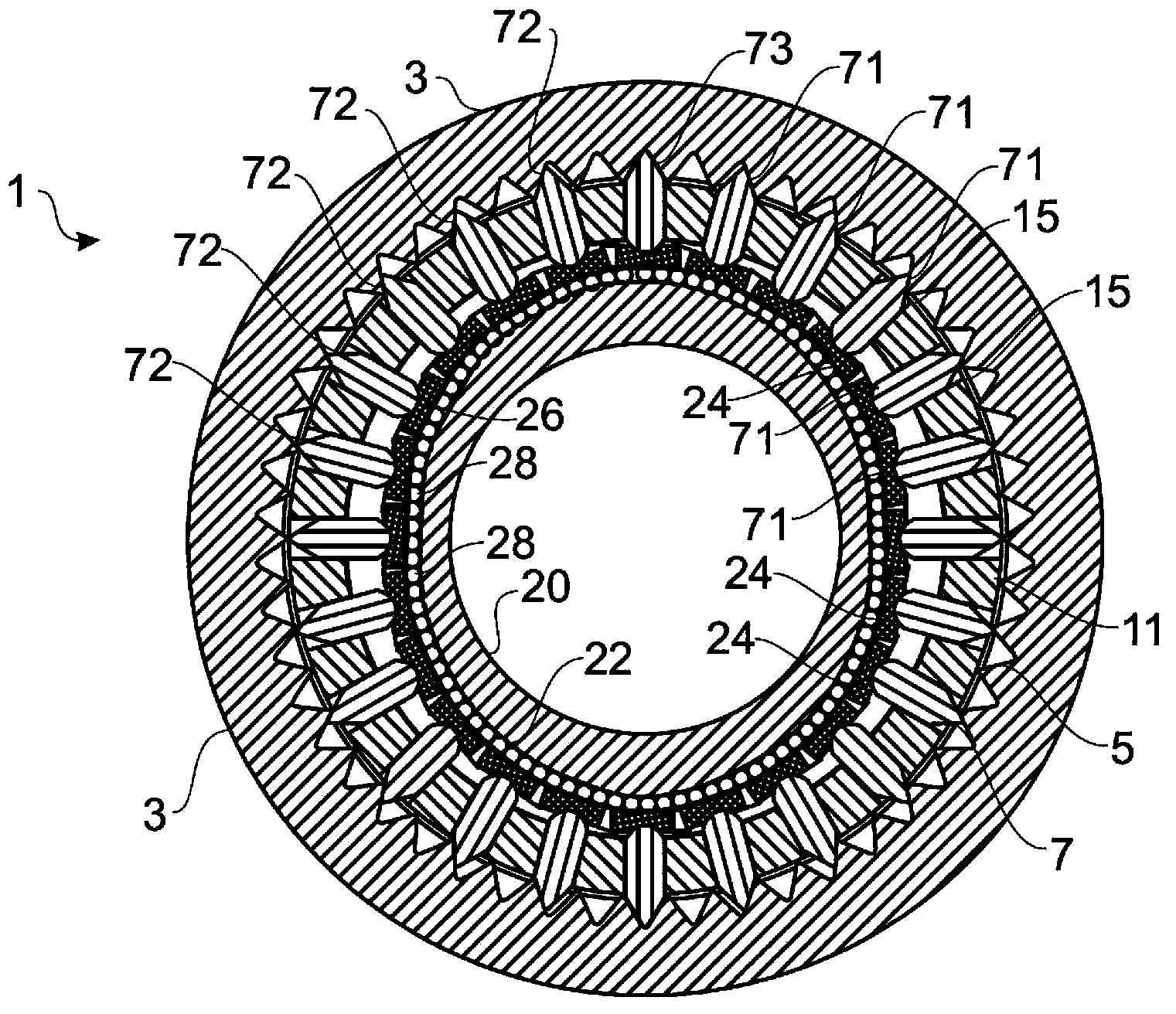

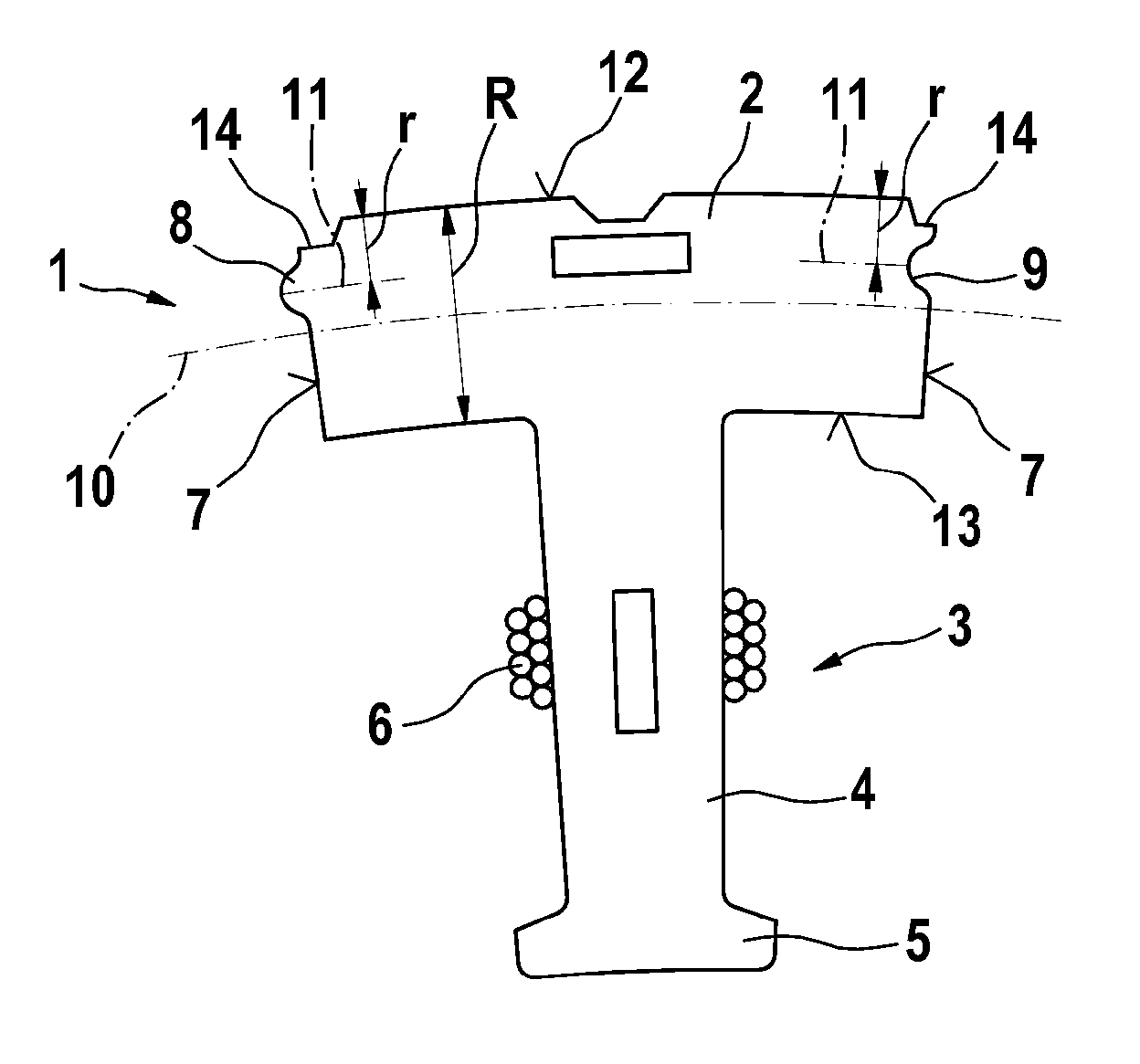

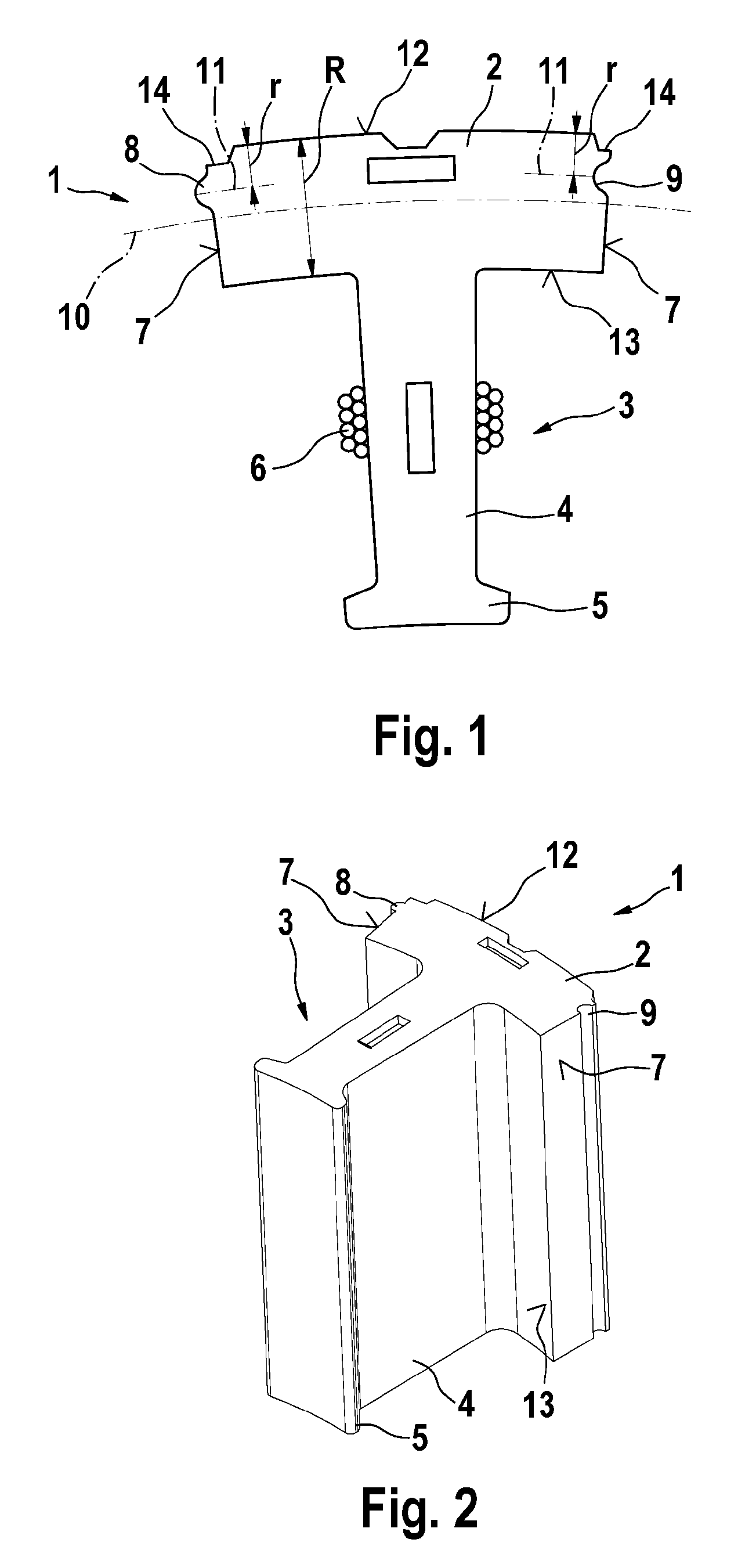

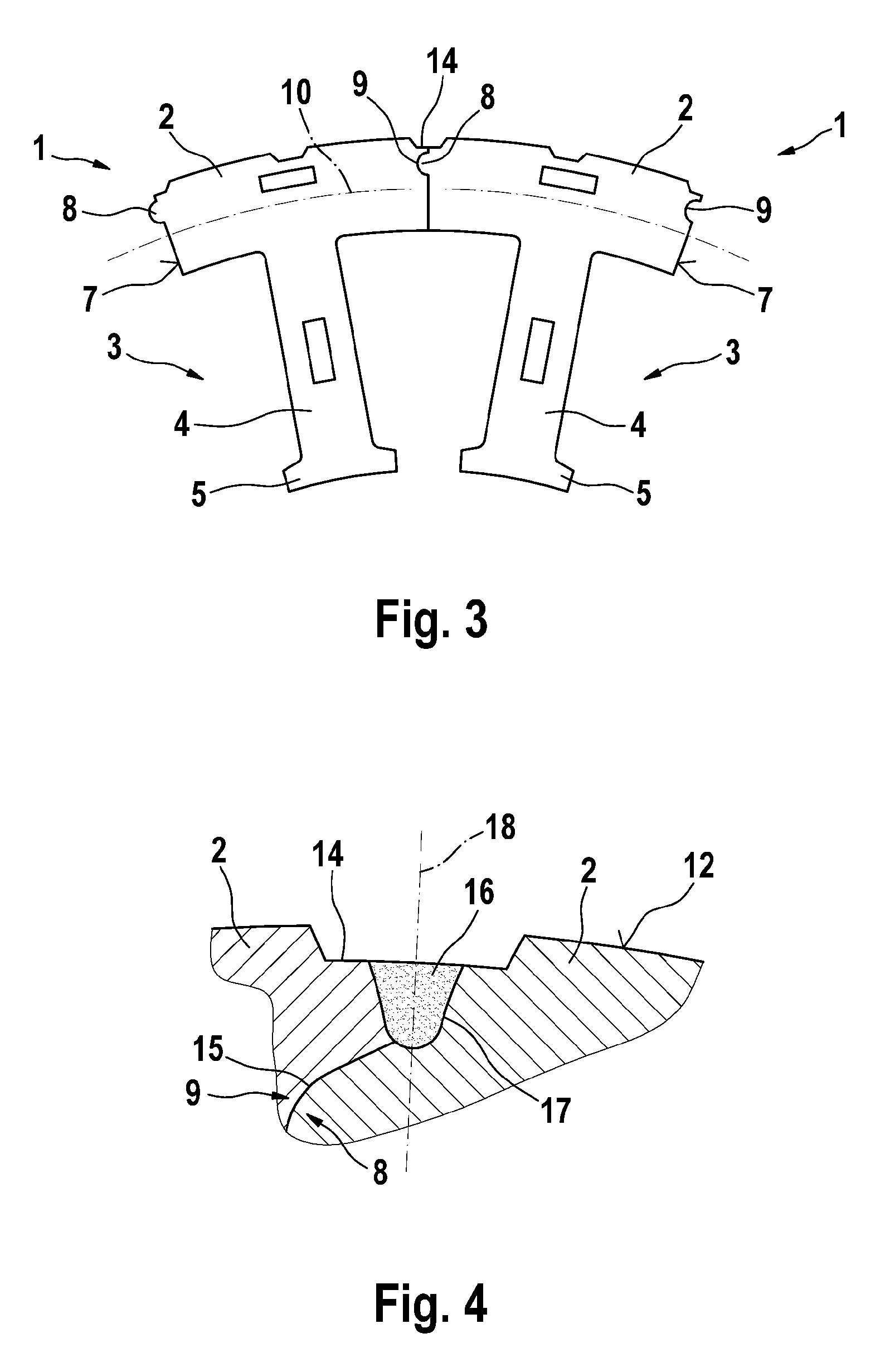

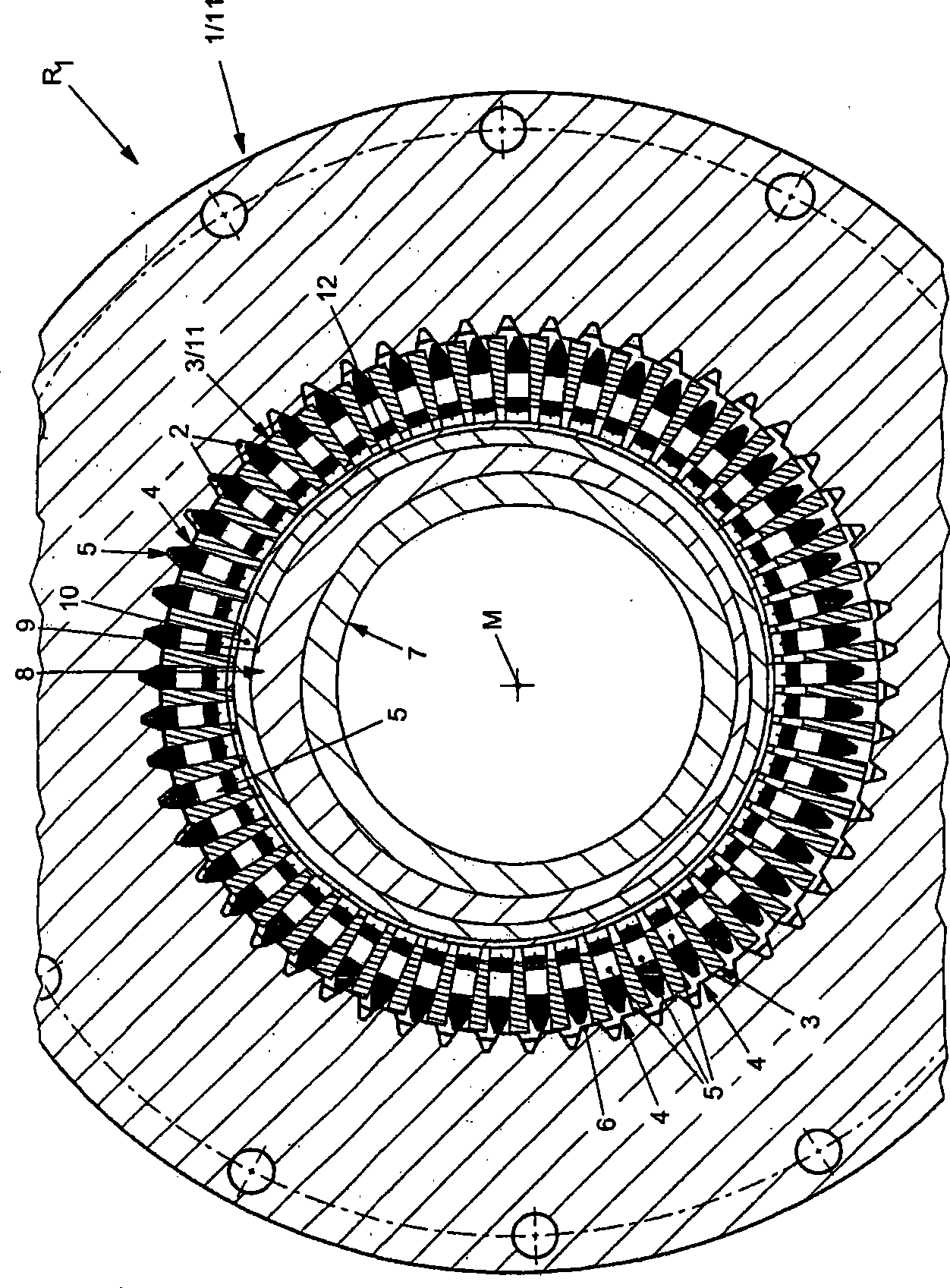

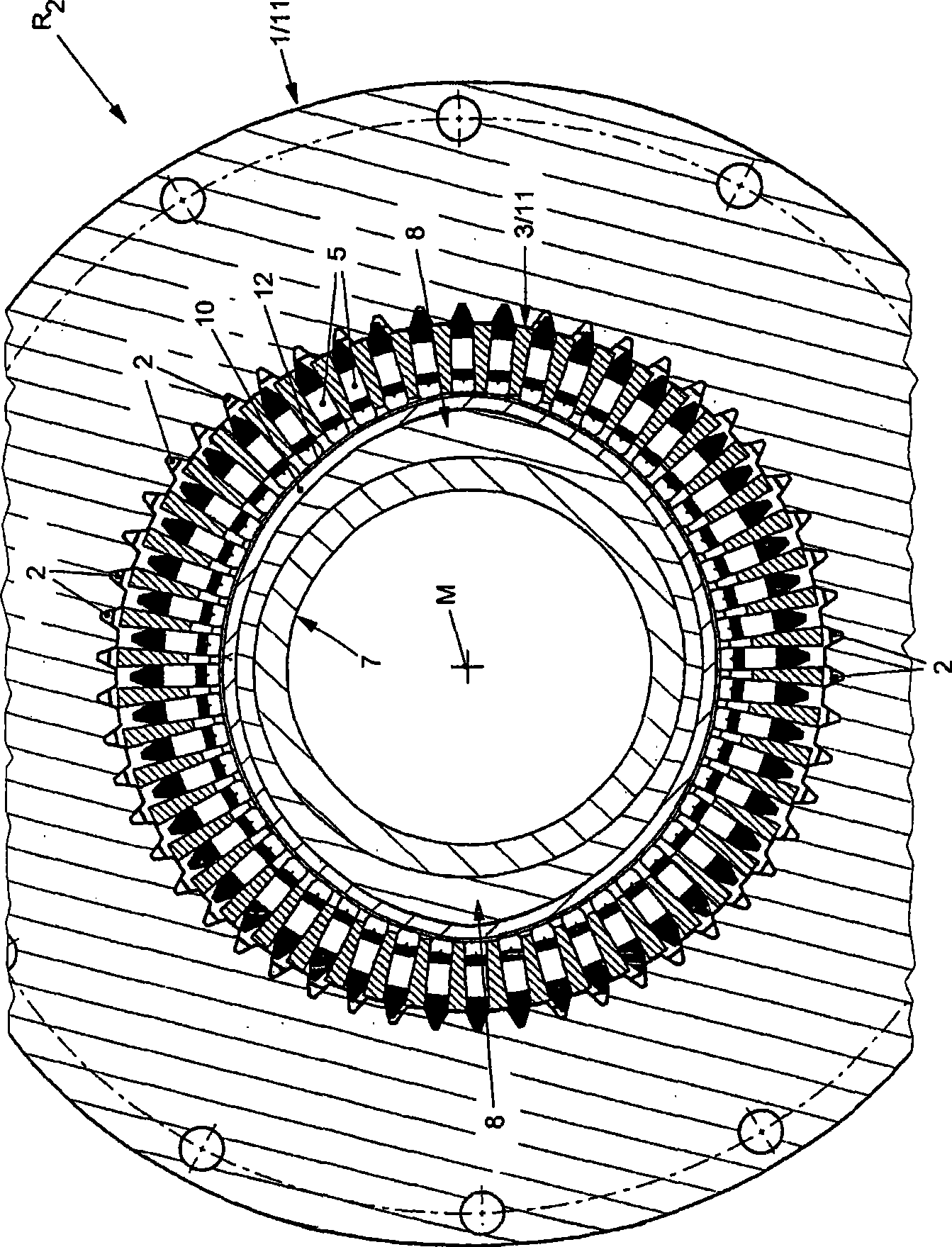

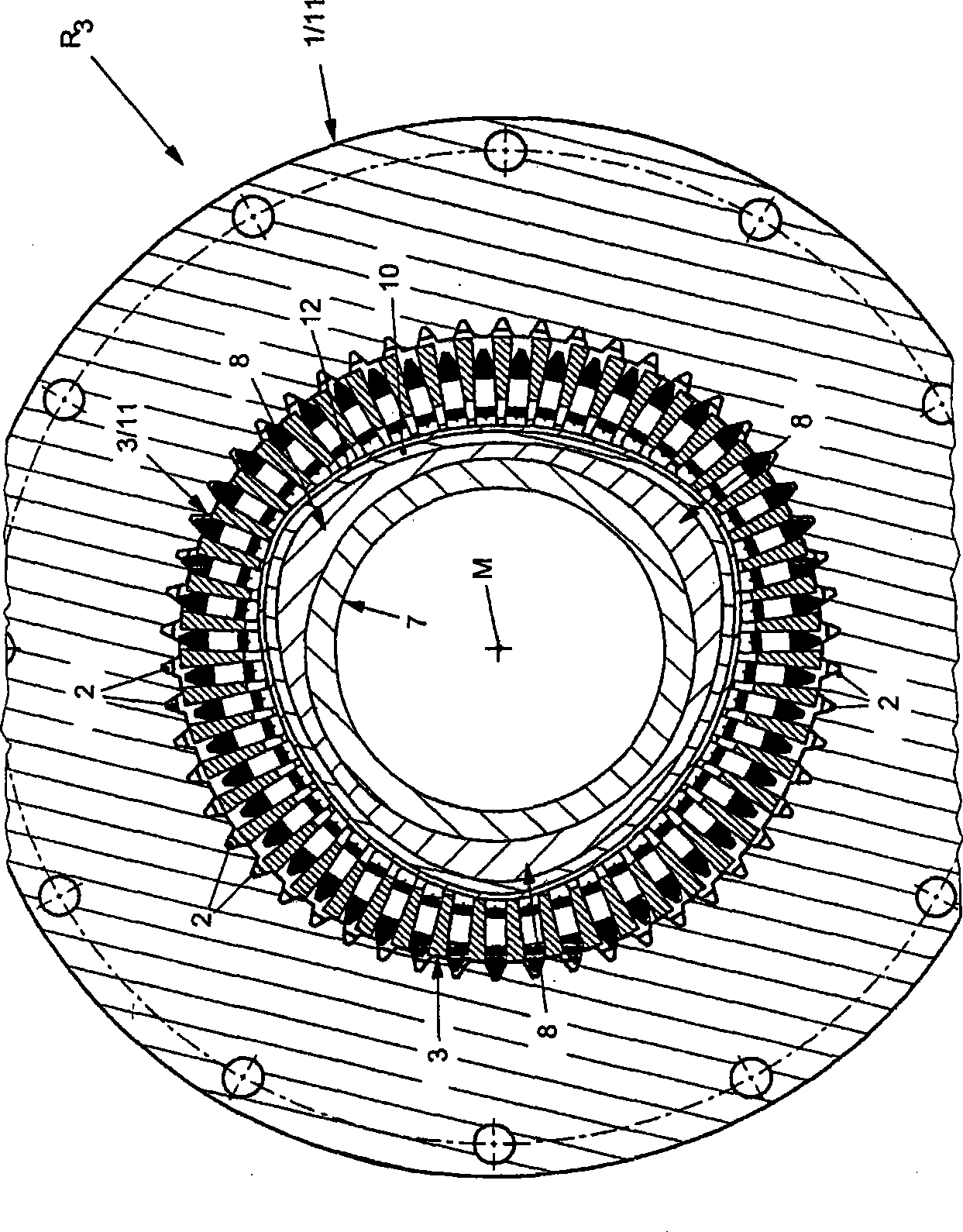

Coaxial gear set

ActiveUS8256327B2Service lifeExtended service lifePortable liftingToothed gearingsGear wheelEngineering

A coaxial gear set, in particular a hollow shaft gear set for industrial drive technology, having high power density, comprising a drive element (7), an element (3), and an output element, with a gear ratio and a transmission of a drive torque occurring between the drive element (7) and the output element via a plurality of radially movable tooth segments (5), an outer tooth flank contour (11.1, 11.2) of the tooth contour (6) of the tooth segments (5) and / or a flank contour (12.1, 12.2) of a gearing (13) of an inner gearing (15) of an internal wheel (1), relative to a gear axis (M), a tooth contour that allows surface contact in the engagement area comprising a logarithmic spiral.

Owner:WITTENSTEIN SE

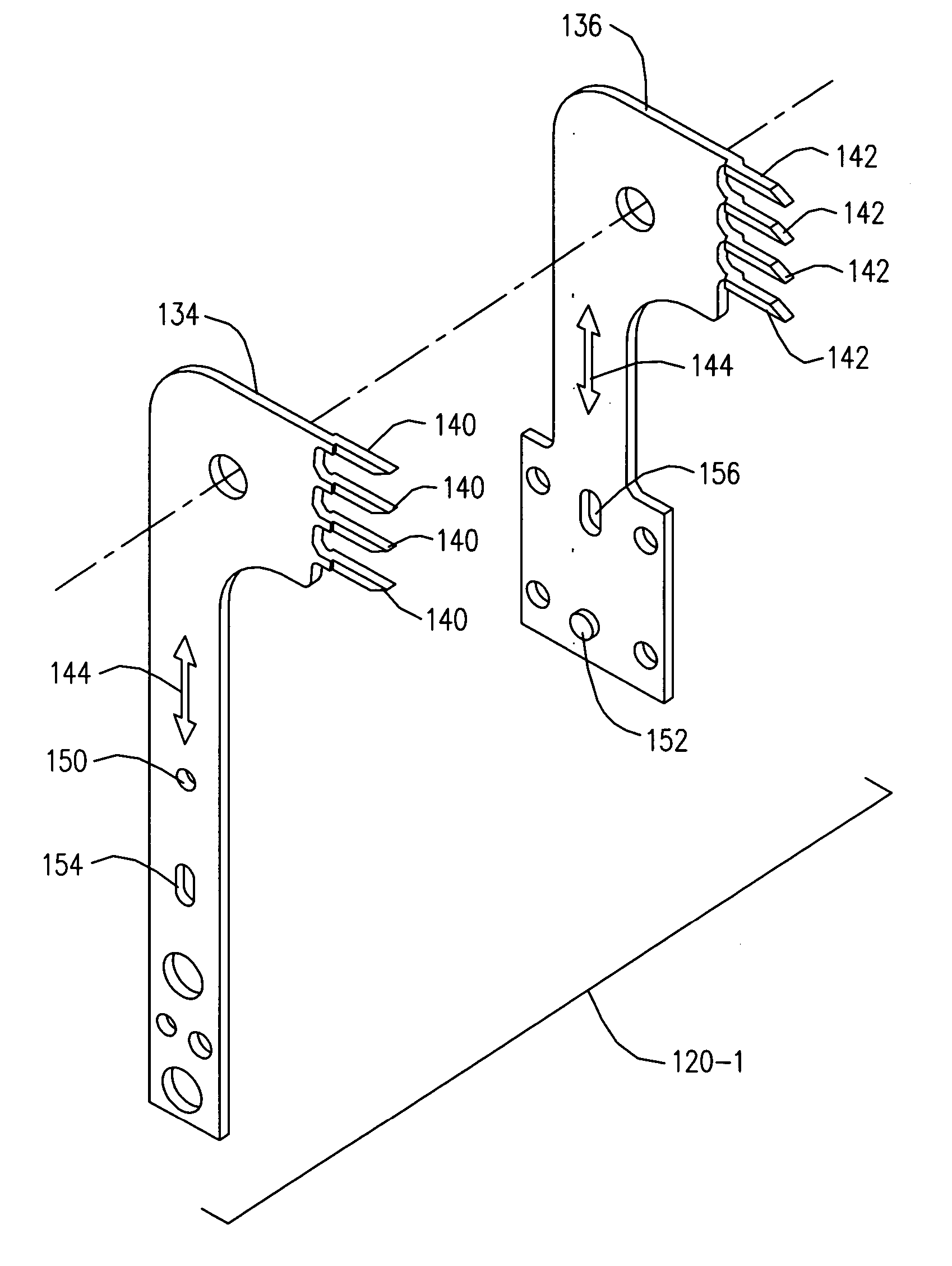

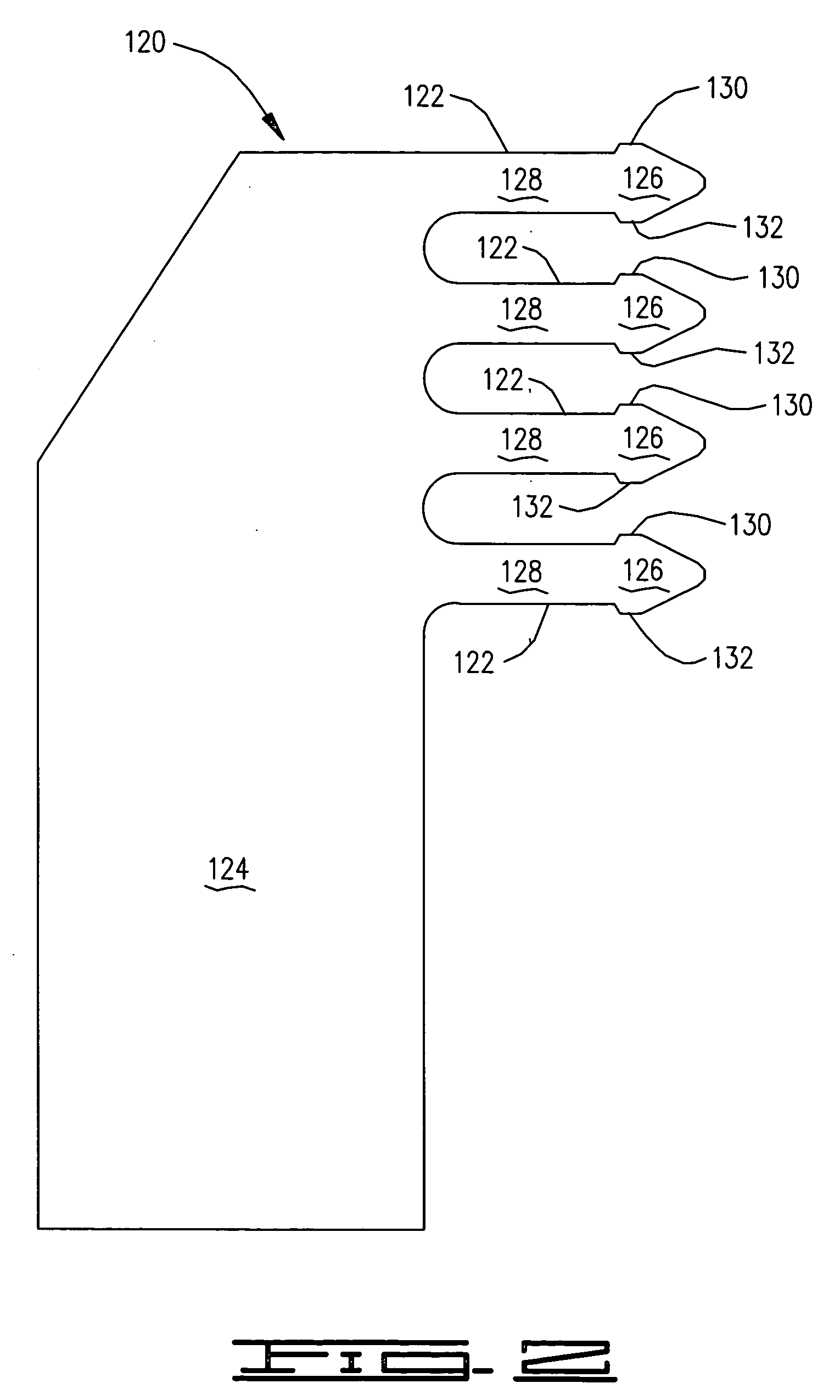

Adjustable head stack comb and method

InactiveUS20060002028A1Low profileDisposition/mounting of recording headsRecord information storageEngineeringTooth segment

An adjustable head stack comb is disclosed. The adjustable head stack comb includes first and second adjustable comb plates including at least one tooth segment which cooperatively form a comb having at least one tooth. The first and second comb plates are adjusted to adjust dimensions of the at least one tooth cooperatively formed by the tooth segments of the first and second comb plates. In the embodiments disclosed, a relative position of the first and second comb plates is adjusted to adjust a thickness dimension of the at least one tooth formed by the at least one tooth segments of the first and second comb plates. Also in illustrated embodiments, the comb plates are cooperatively adjusted to adjust an elevation or z-height of the at least one tooth of the comb.

Owner:SEAGATE TECH LLC

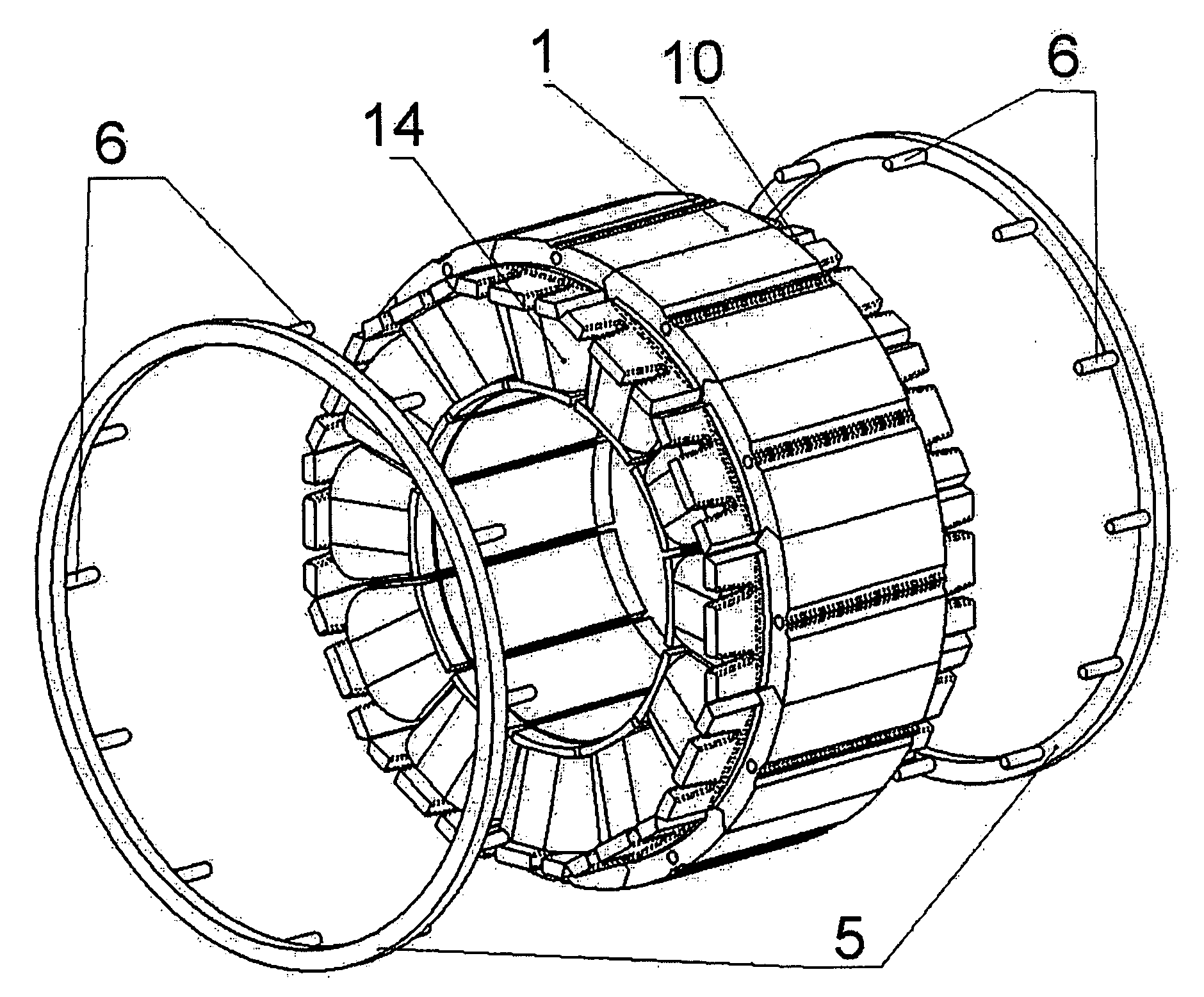

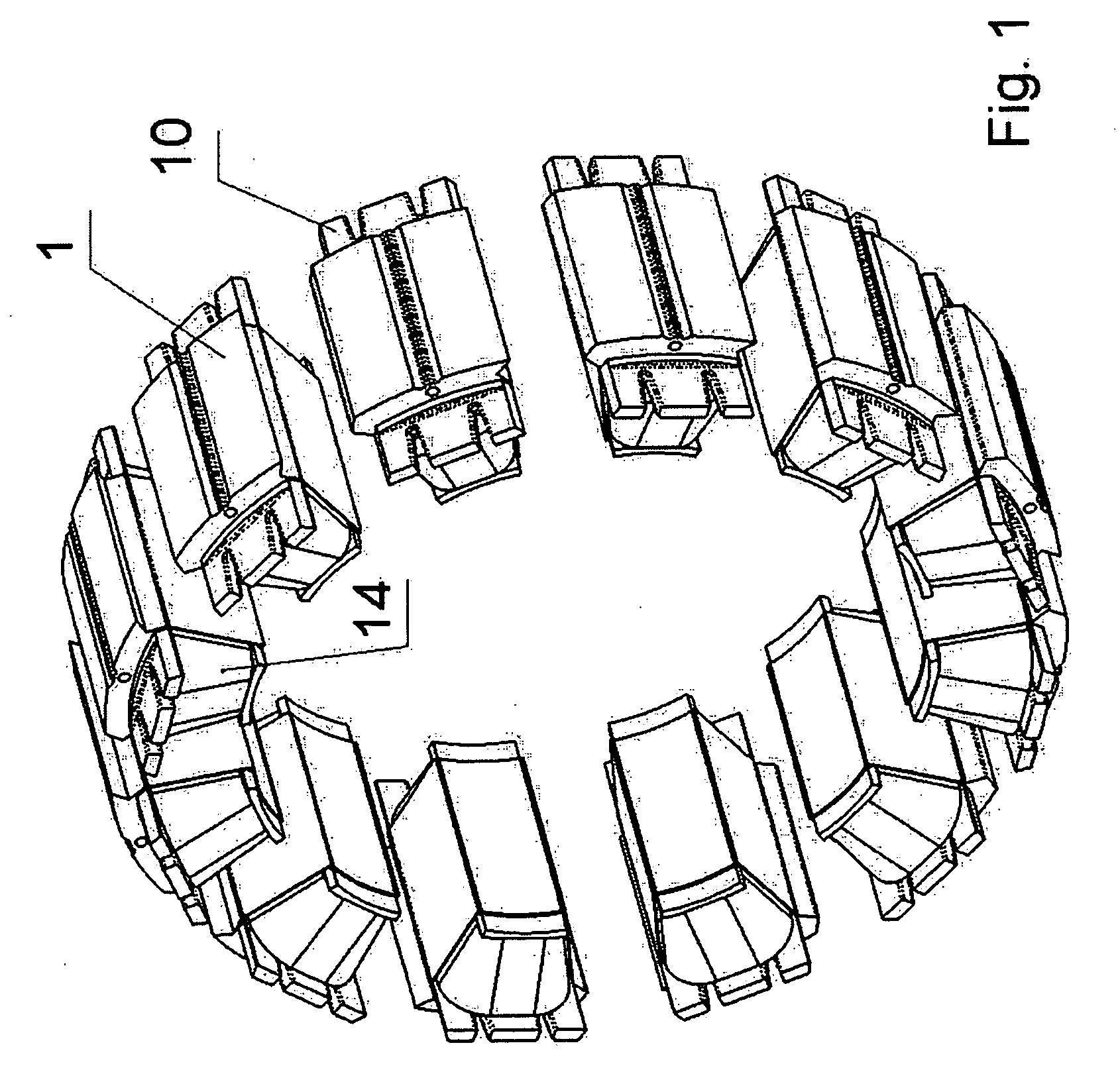

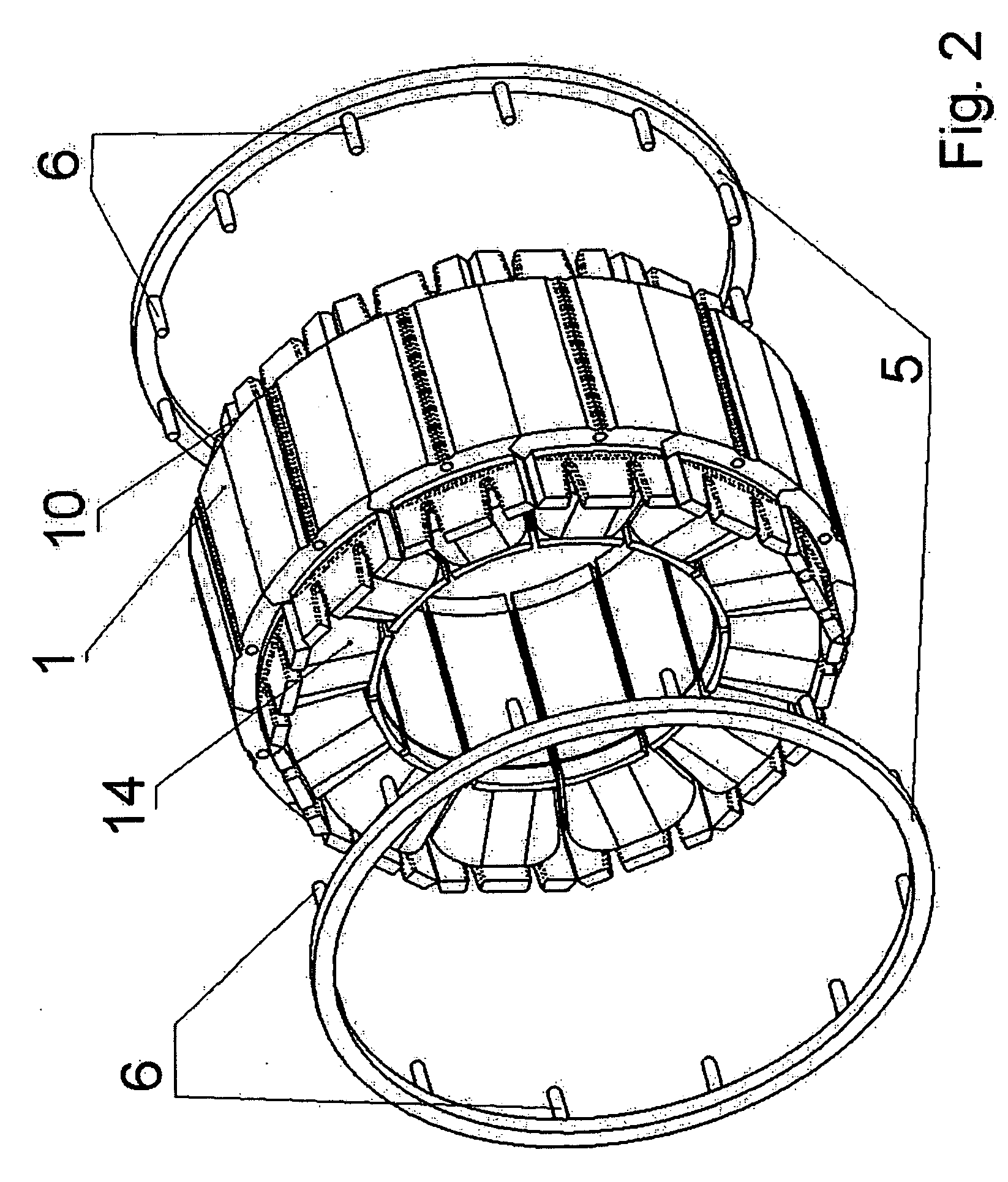

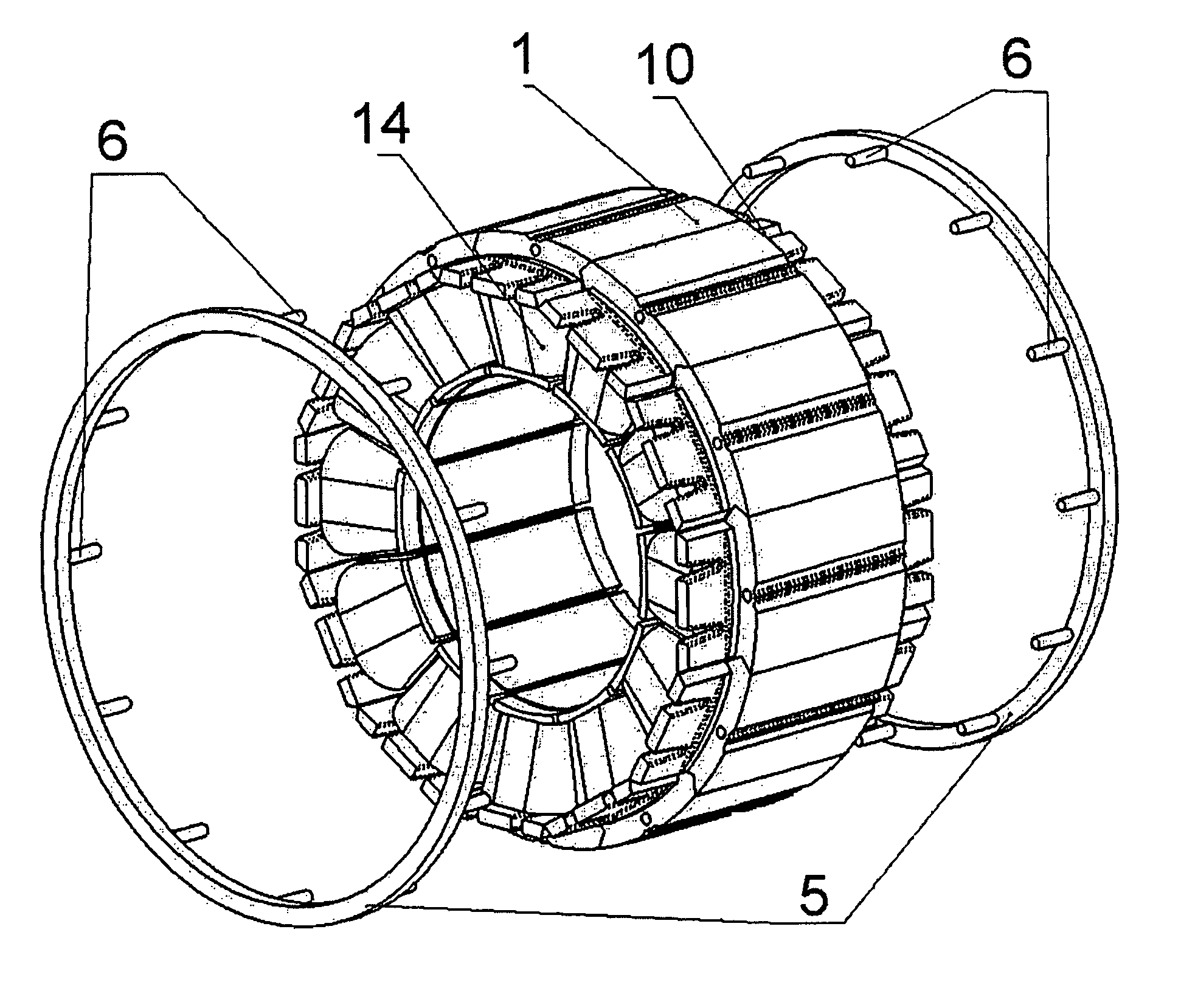

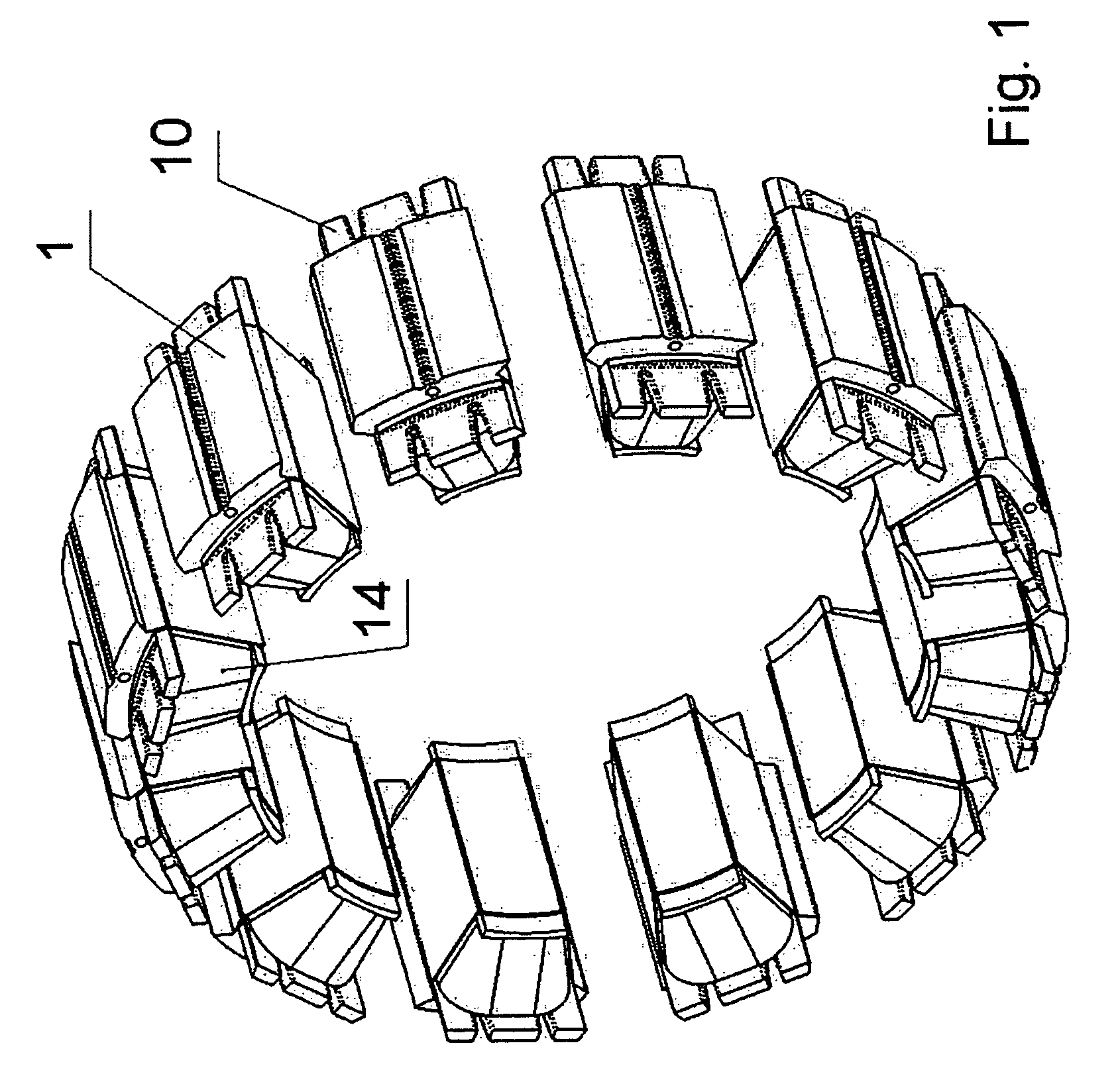

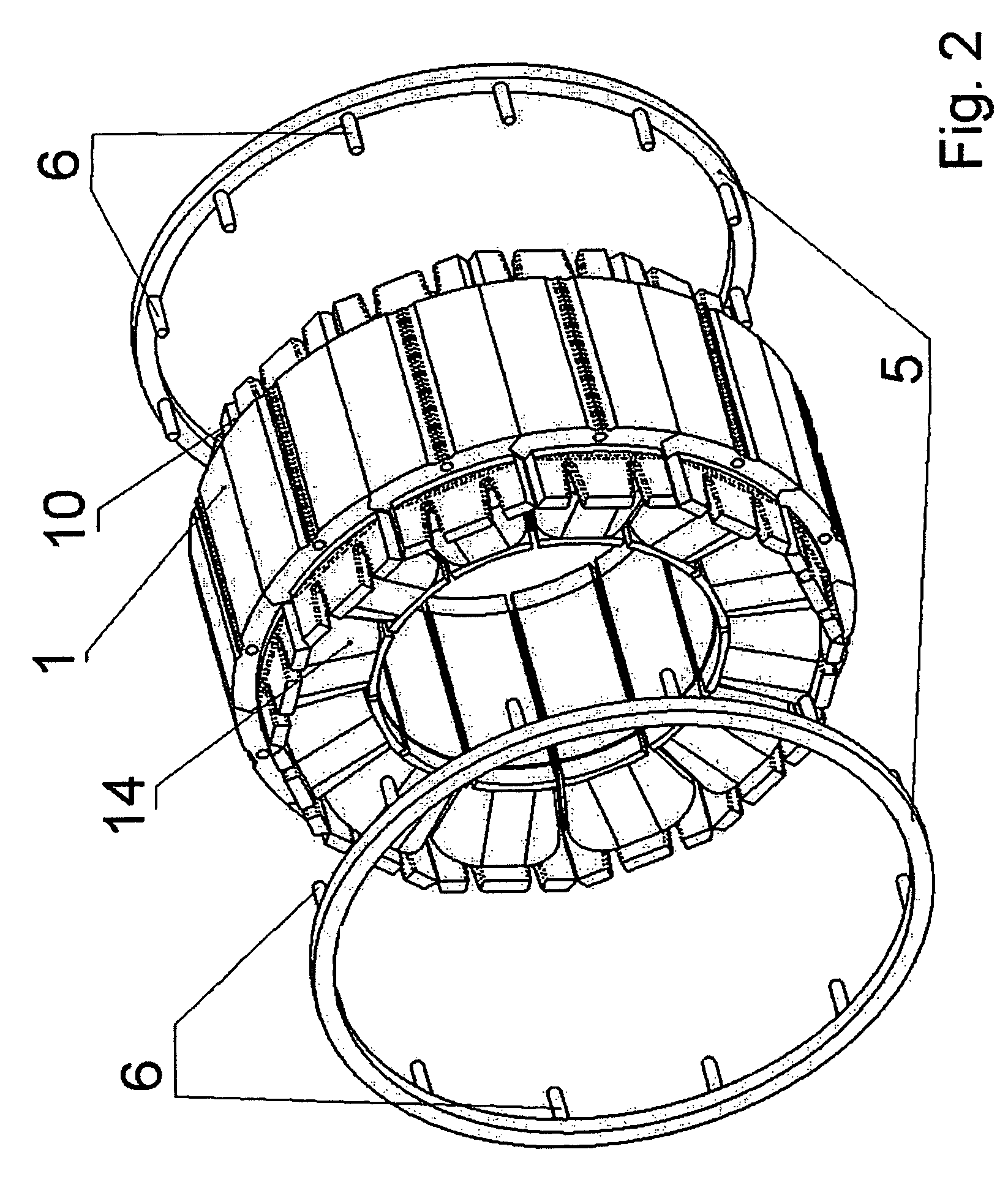

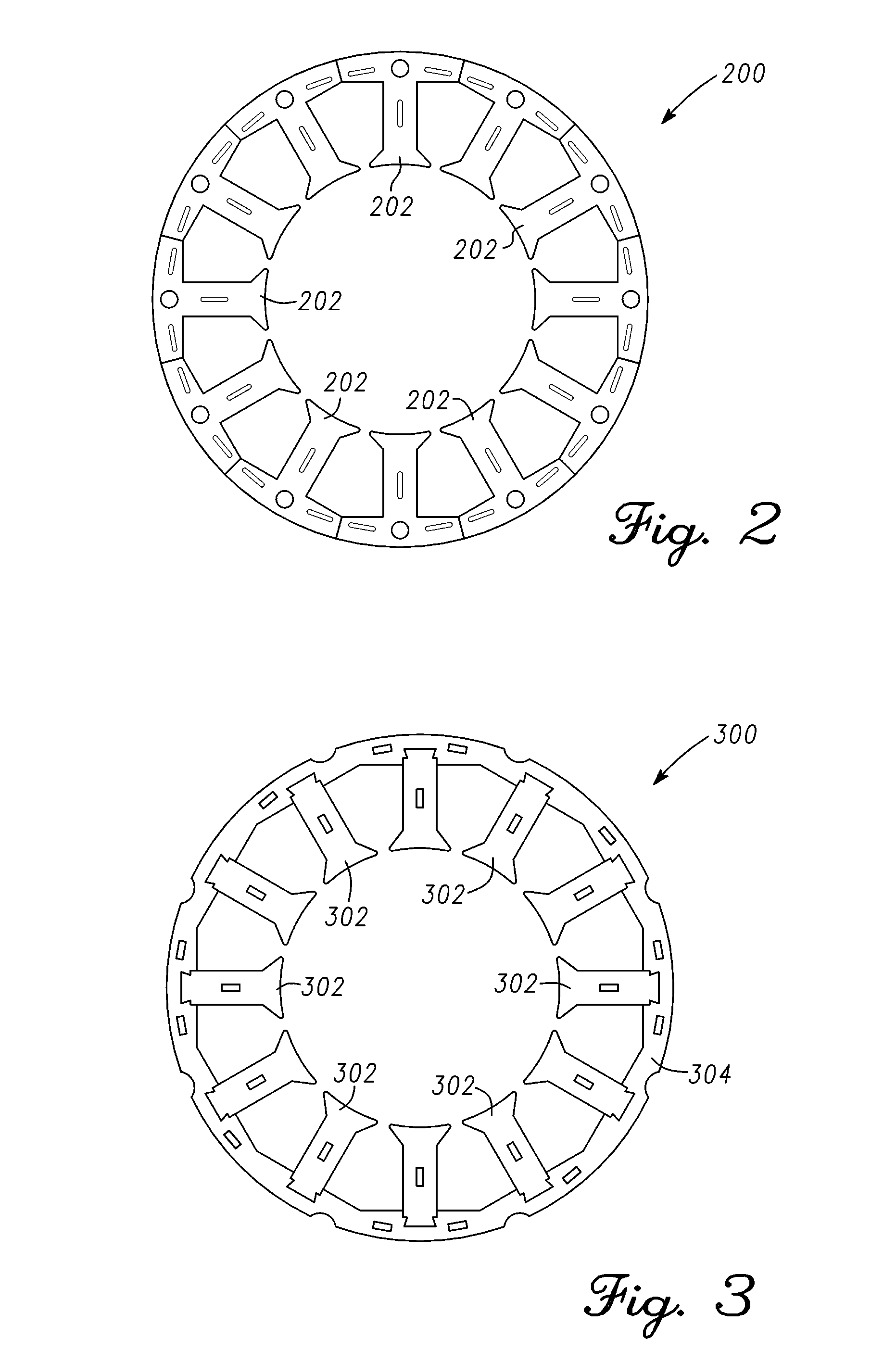

Electric Motor and Method for Manufacturing an Electric Motor

ActiveUS20090134742A1Easy to manufactureConducive to environmental protectionWindingsMagnetic circuit stationary partsStatorTooth segment

An electric motor, includes a stator, which is composed at least of stamp-packed tooth segments, the tooth segments being able to be slid together radially in the manufacture and being able to be held together by retaining elements slid on axially.

Owner:SEW-EURODRIVE GMBH & CO KG

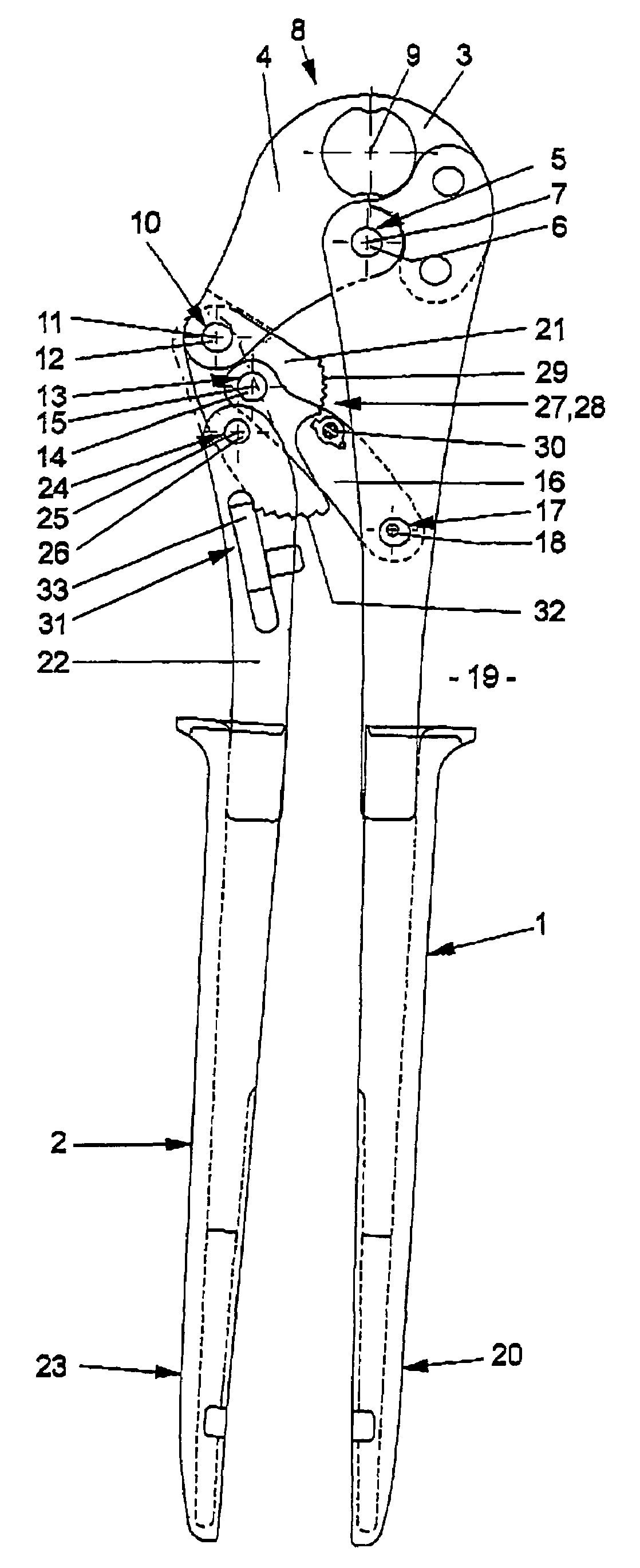

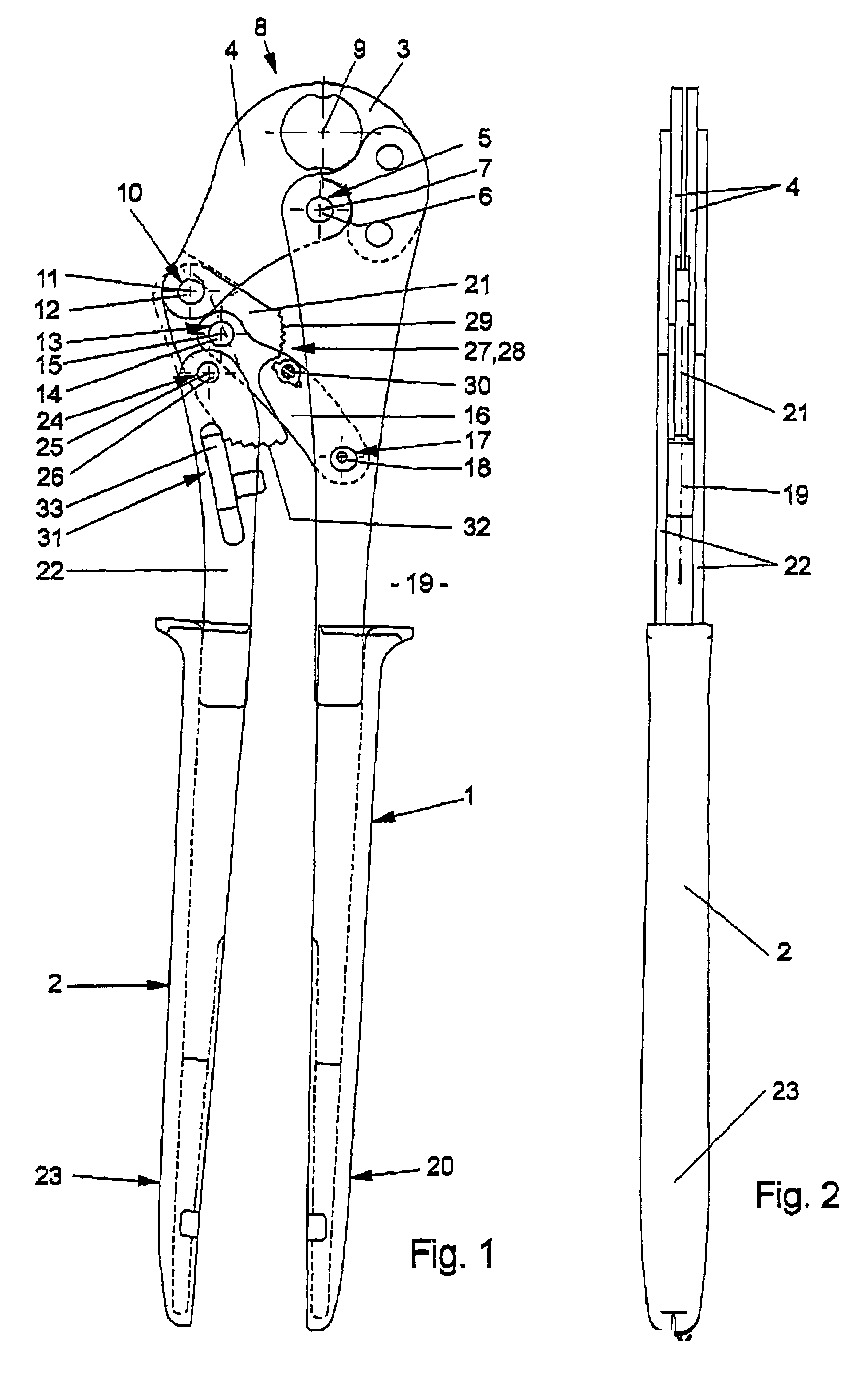

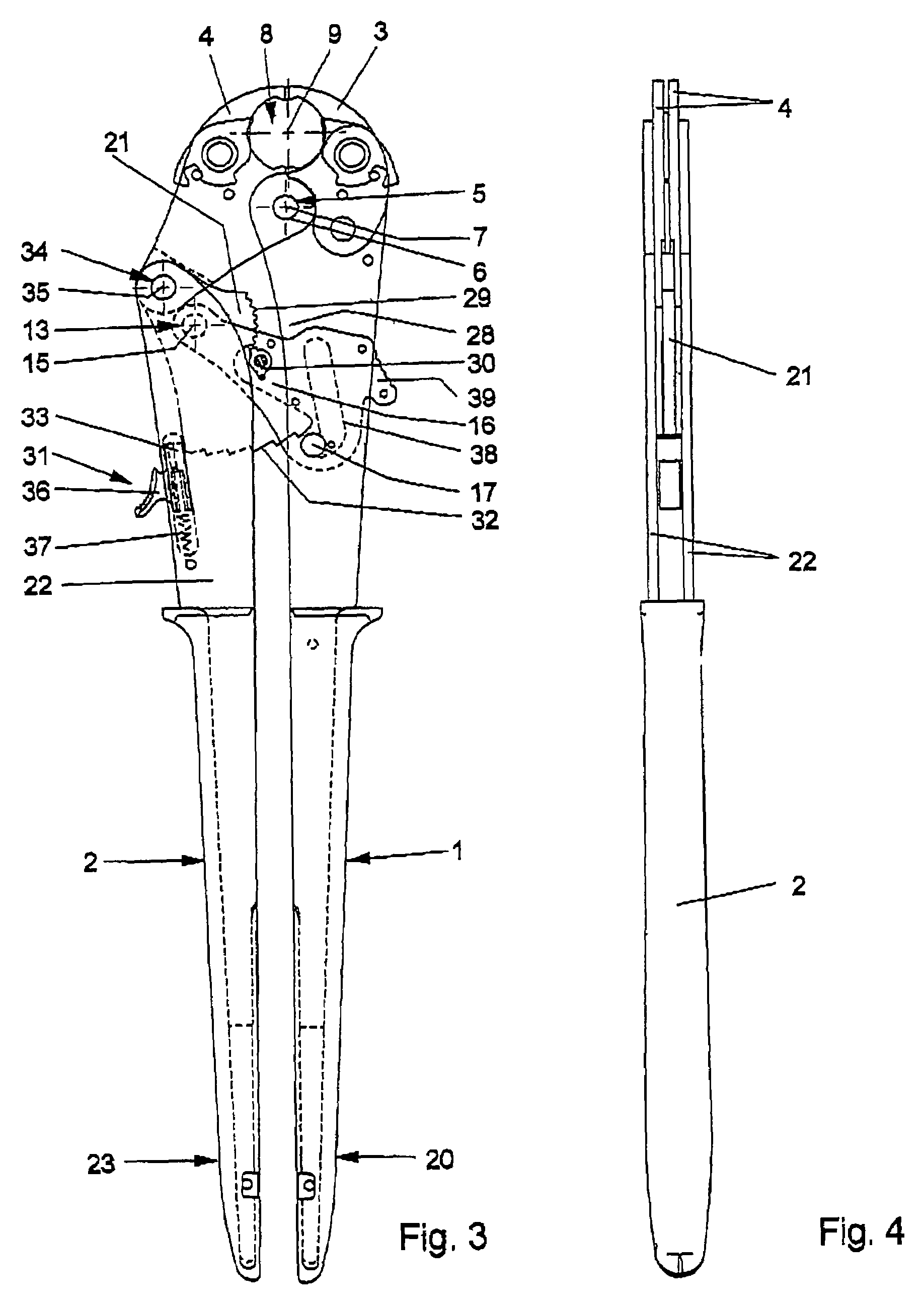

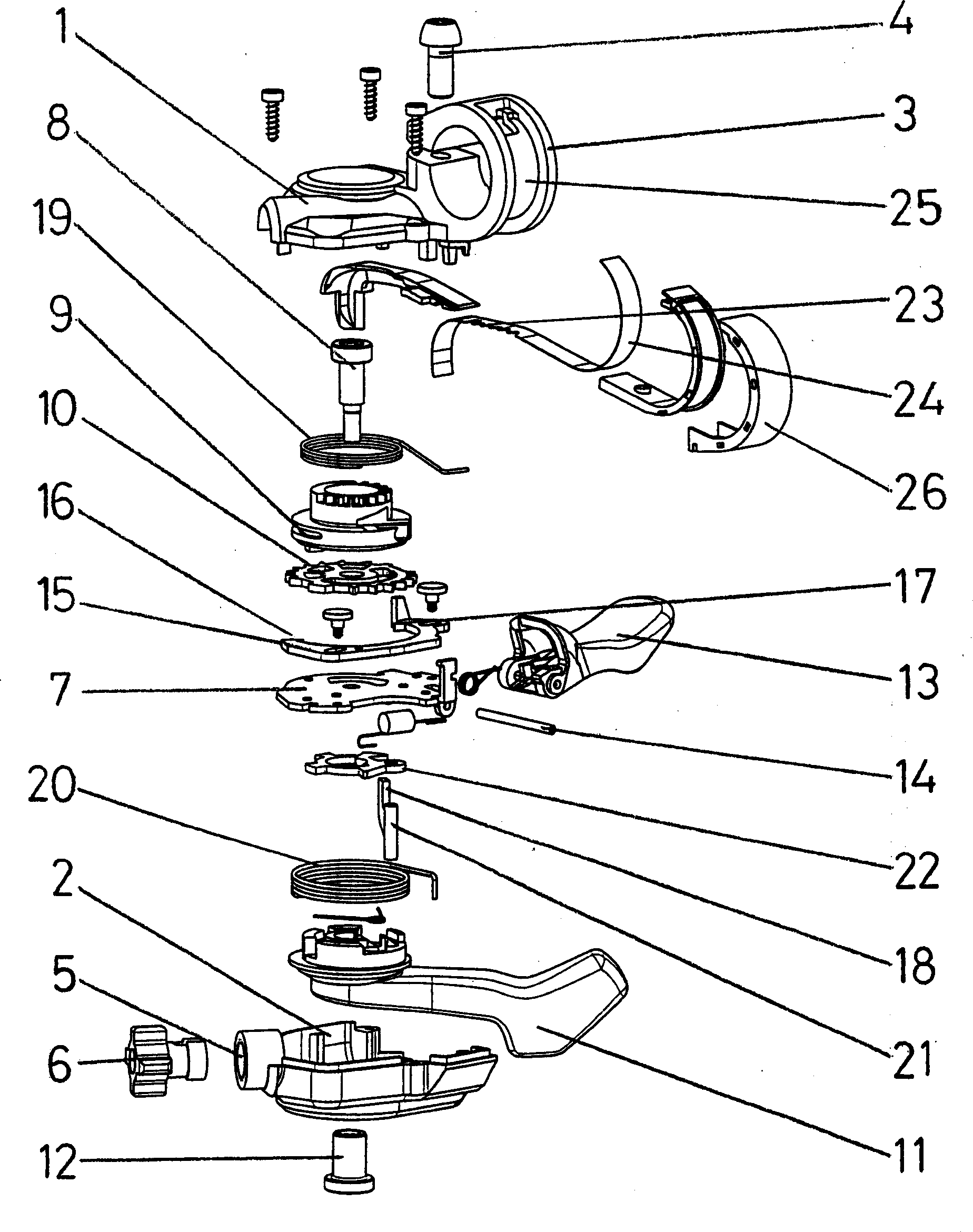

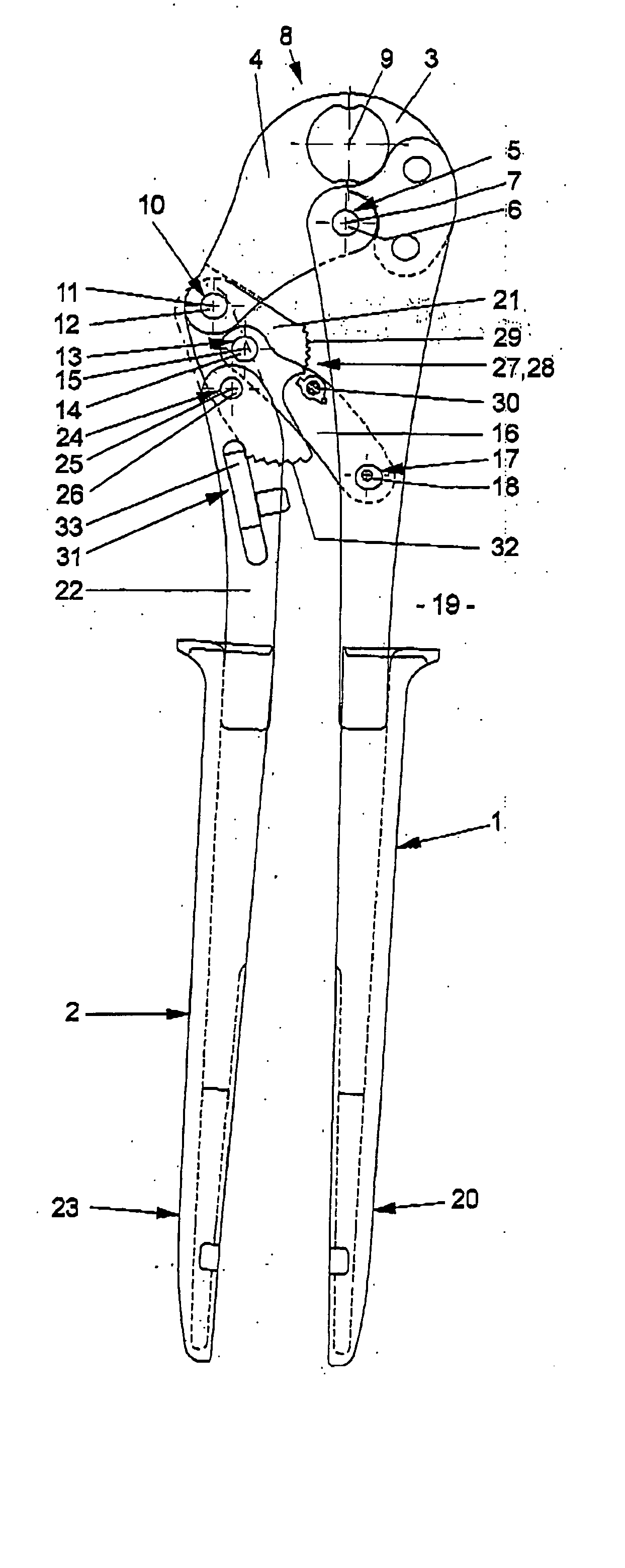

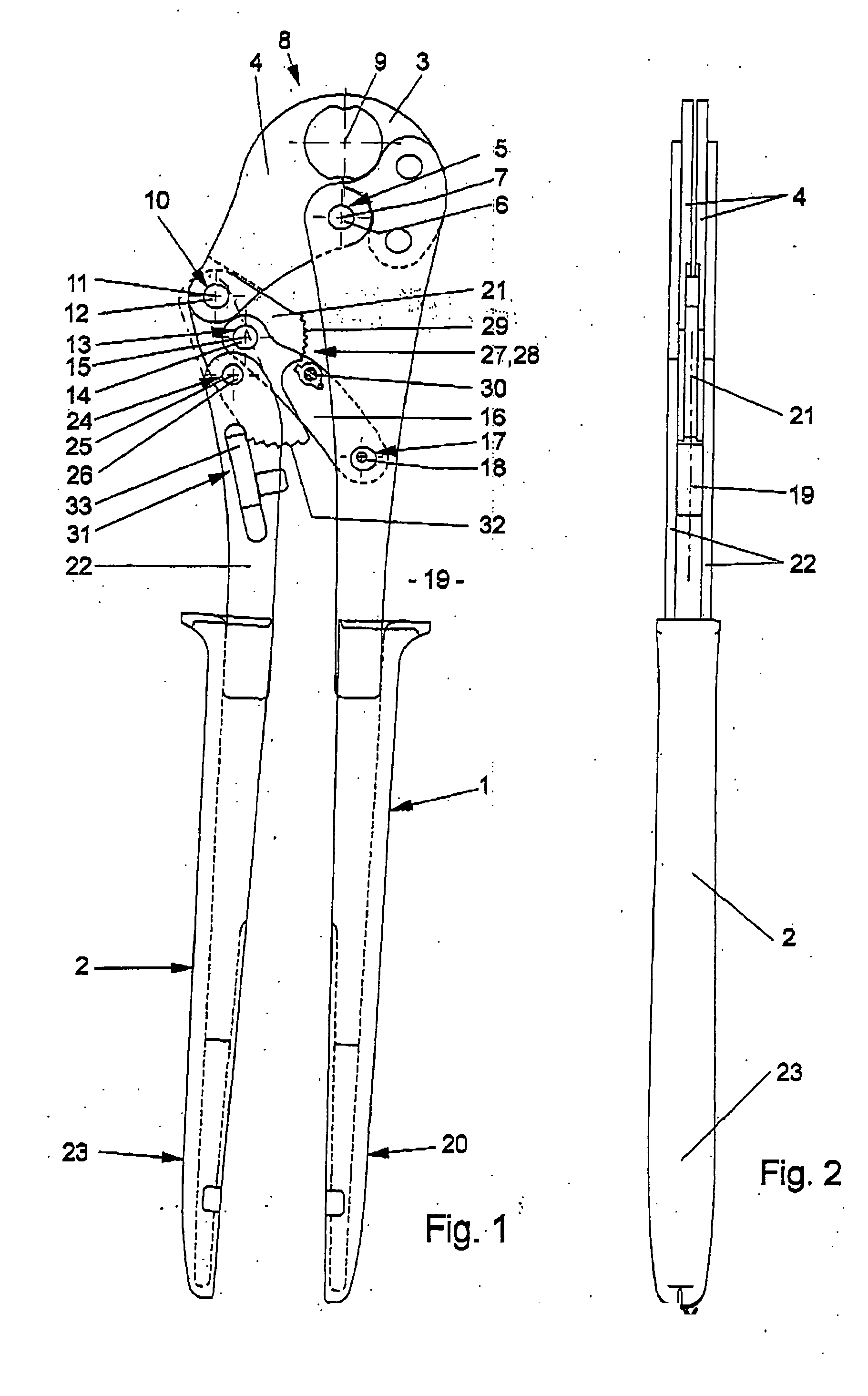

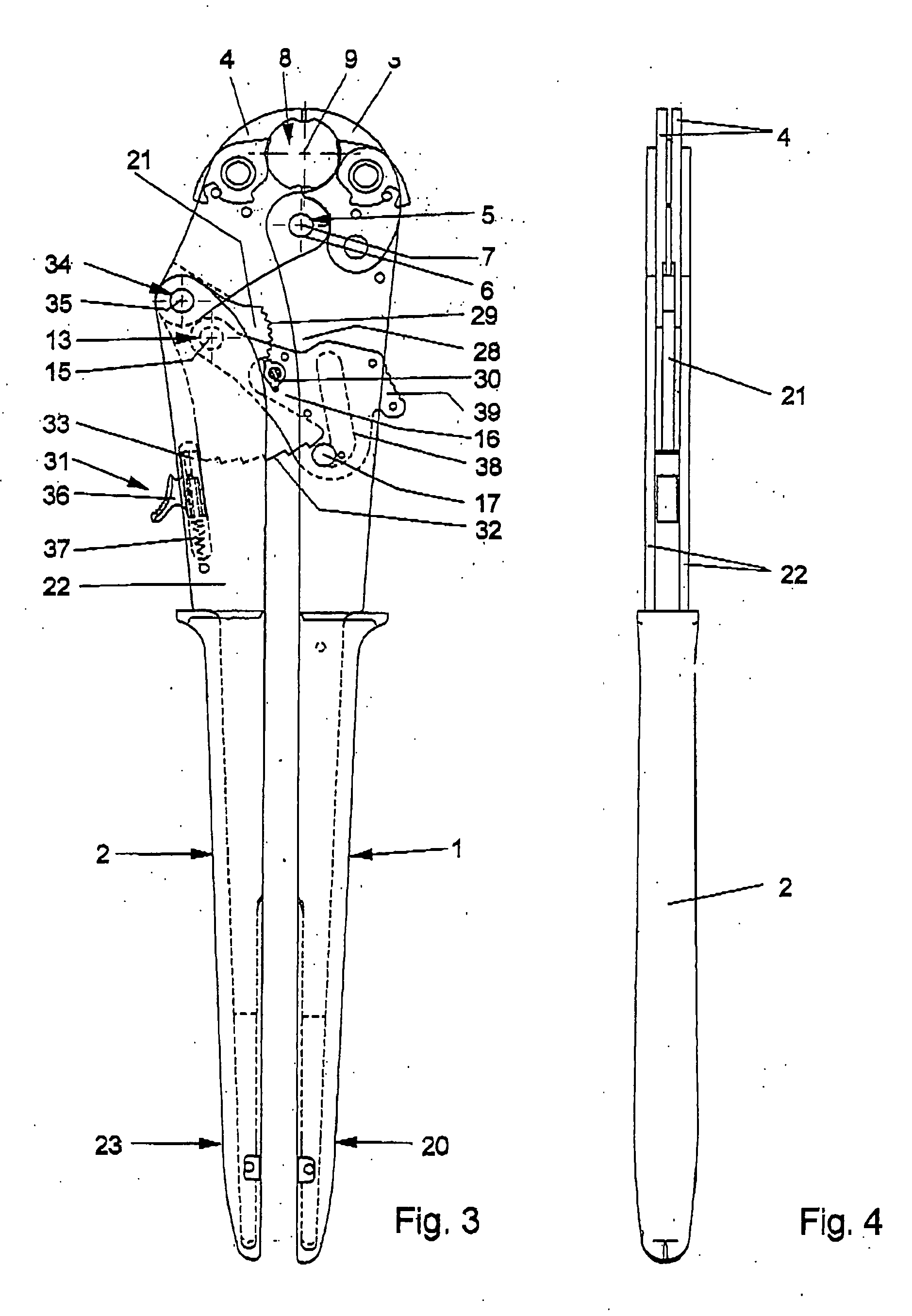

Pliers for crimping work pieces

ActiveUS7155954B2Simple designEasy to producePliersMetal-working hand toolsLocking mechanismEngineering

Owner:WEZAG GMBH & CO KG

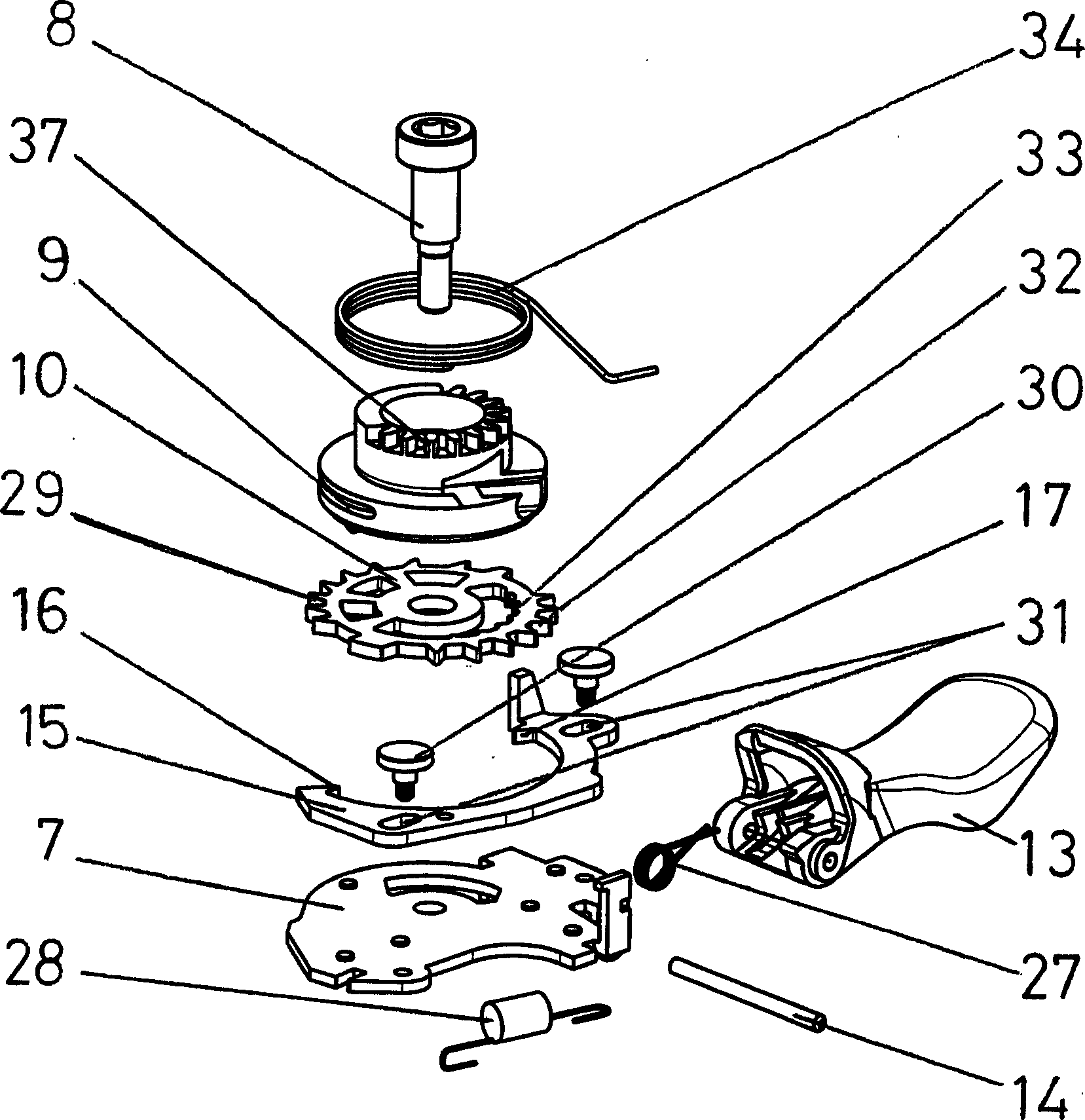

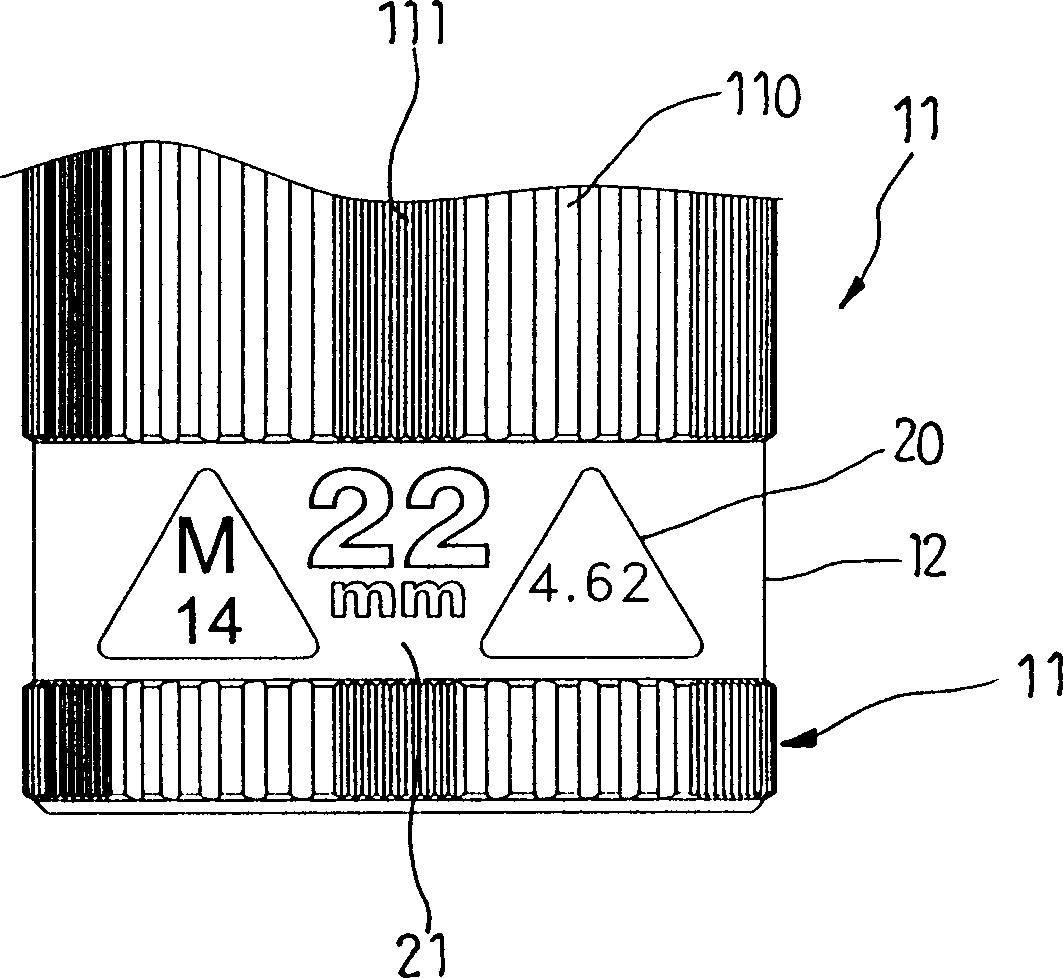

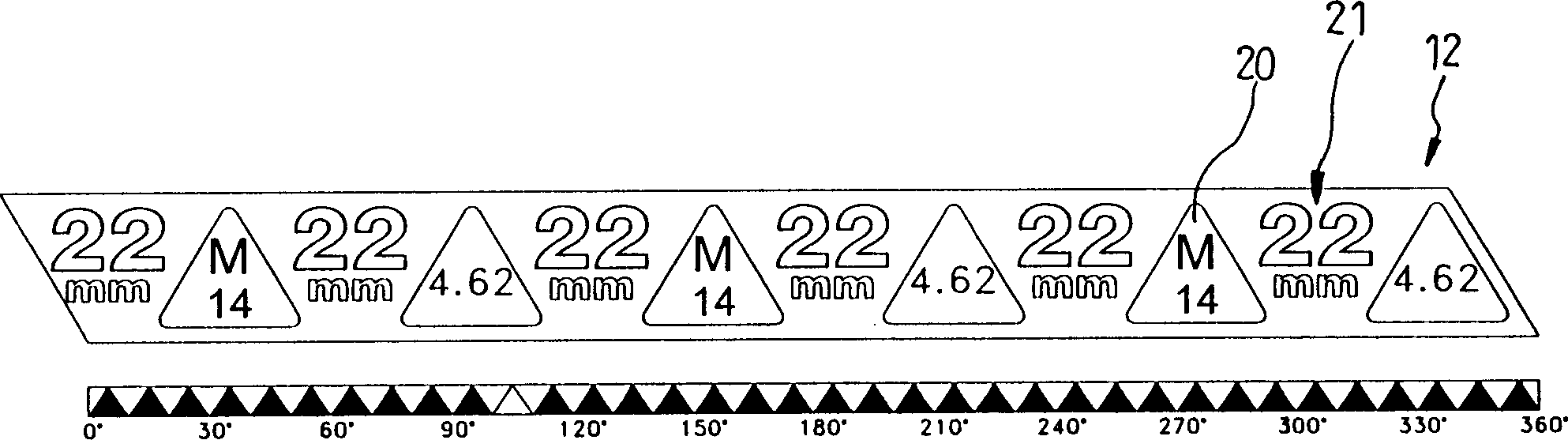

Steel cable tension mechanism for handle-type gear changer

This invention relates to a trigger-switch with a pull-up, holding and release mechanism in level or rotation-grasp-switches to operate the bicycle gear-shifter. The switch is composed of a housing with integrated handle-bar-clamp and a pull-up-, holding, release and display mechanism. The tooth-segments, in which a pull-up-, holding and stop-claw is engaged respectively, necessary for the pull-up, holding and release-process are mounted in only one dish-shaped member. Thus a tooth-segment, preferably with inner tooth, is arranged inside of the circumference in an opening of the dish-element. The pull-up-movement is transferred over a slim pull-up-claw of the operation-element through the carrier-plate to the pull-up-tooth segment located inside of the dish-element. The actual gear-state is transferred over an elastic display-band, which combs in a tooth of the rope-spool, from there out around the handle-bar, along the handle-bar-clamp into the visible region of the rider. In order to improve the display-discrimination, a transparent cover of the display-band is formed as lens or amplifying glass. The switch mechanism is surrounded by a switch-housing and a casing-element composed of plastics. The receptacle of the adjusting-bolt for the gear-traction stress exists on this casing-element.

Owner:SRAM

Transmission

ActiveUS20130255421A1Improve rigidityReduce forceGearingMetal-working apparatusEngineeringTooth segment

Owner:WITTENSTEIN SE

A transmission

ActiveCN103363027AImprove transmission stiffnessAvoid constraintsPortable liftingToothed gearingsTooth segmentEngineering

Owner:WITTENSTEIN GROUP

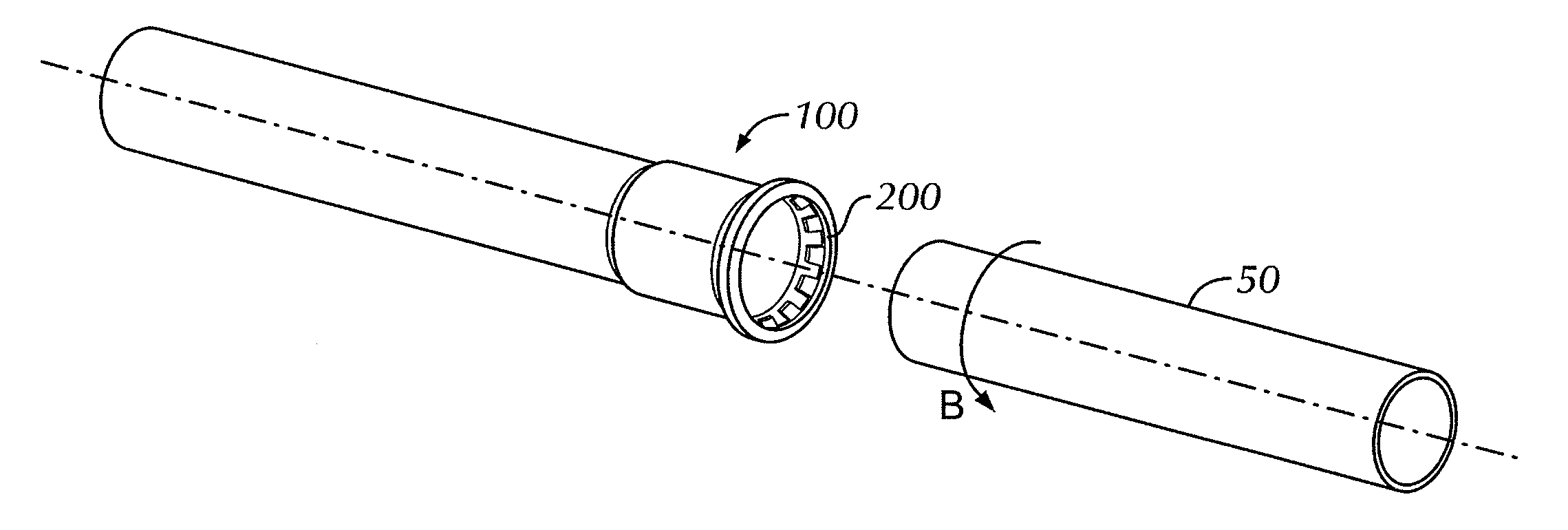

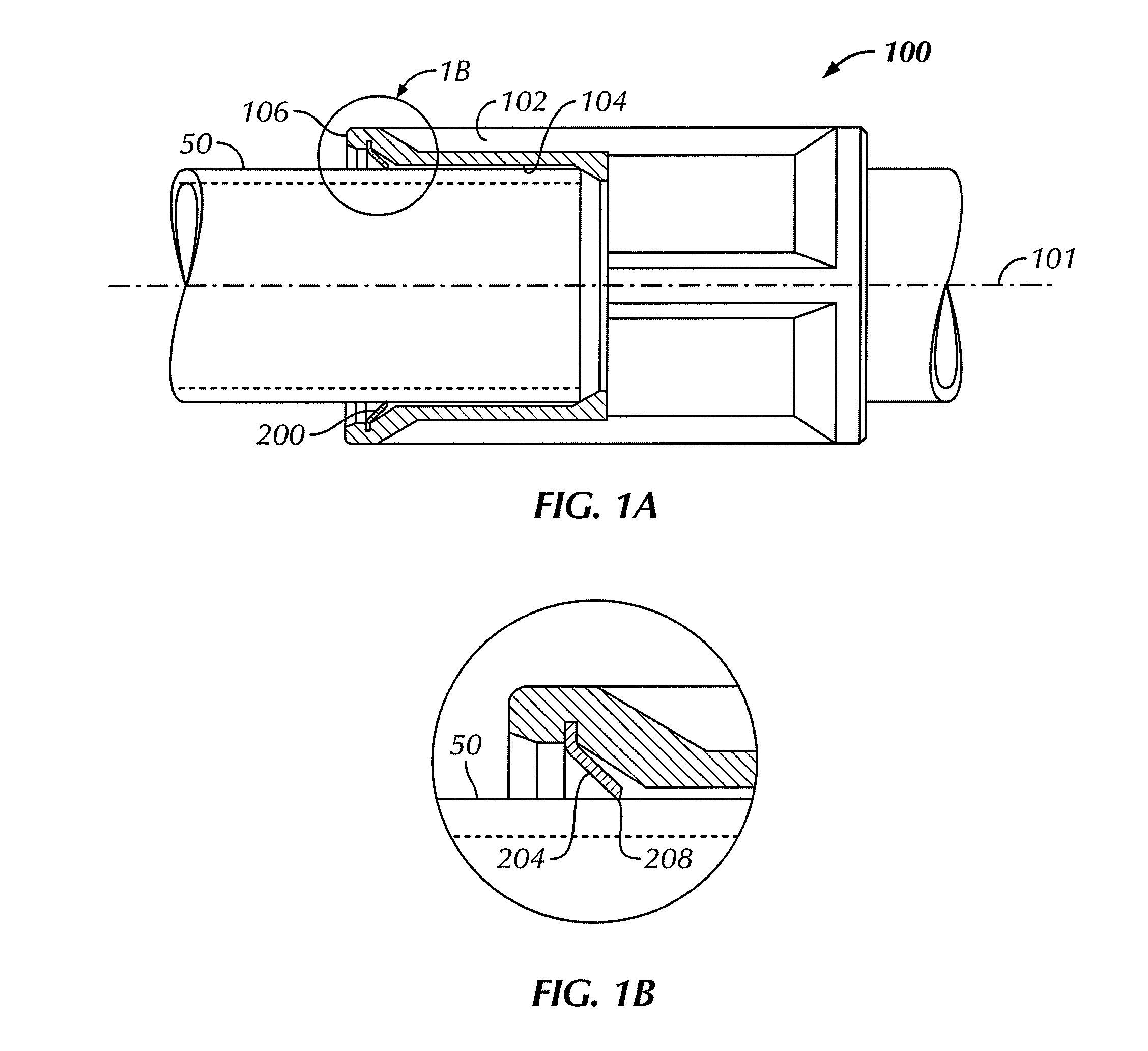

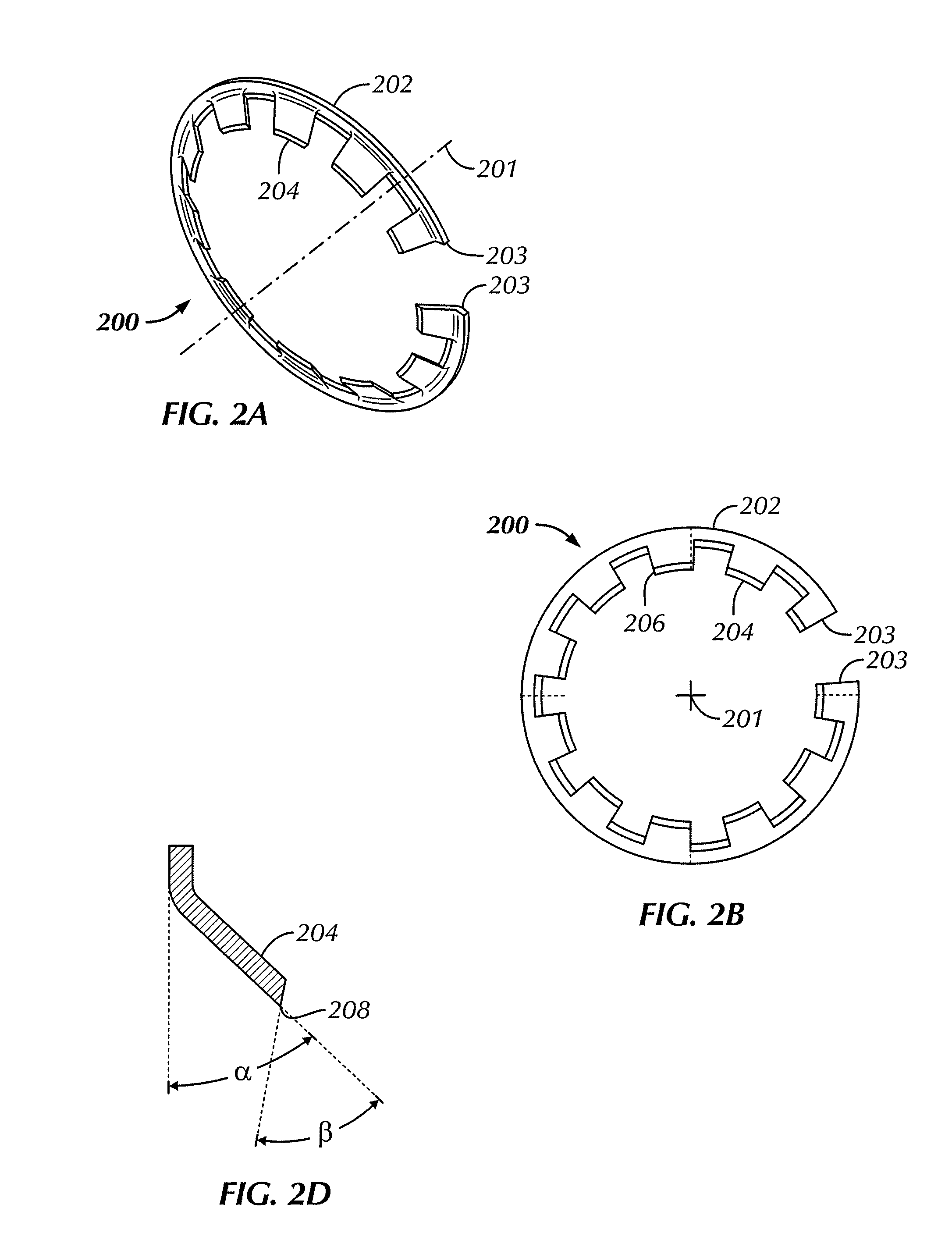

Tool-free metal conduit connector and related methods

A threadless connector includes a connector body having a central bore therethrough and a retainer ring disposed in an end of the connector body, the retainer ring comprising a plurality of teeth segments, wherein the plurality of teeth segments are configured to be inwardly angled to contact an end of a conduit inserted into the connector body.

Owner:REPUBLIC CONDUIT INC

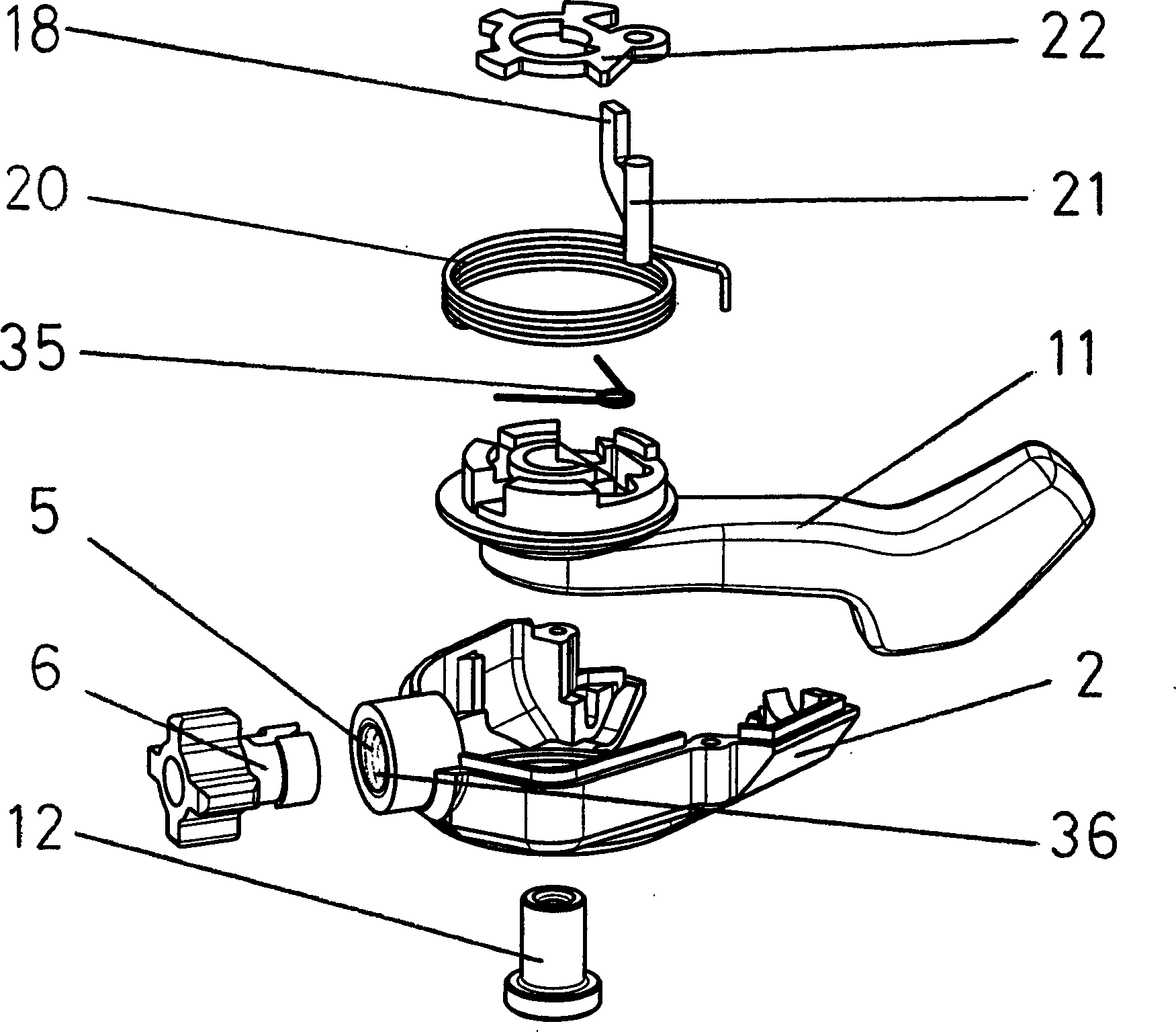

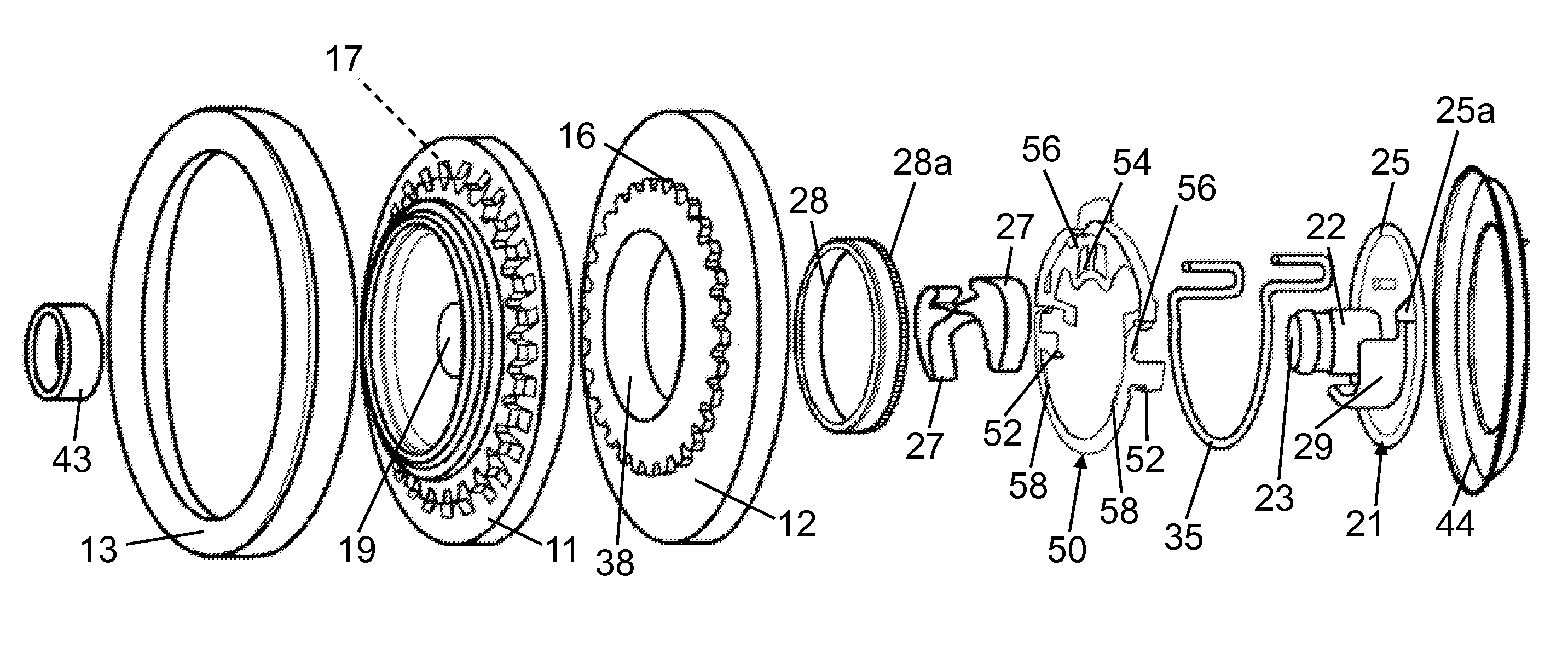

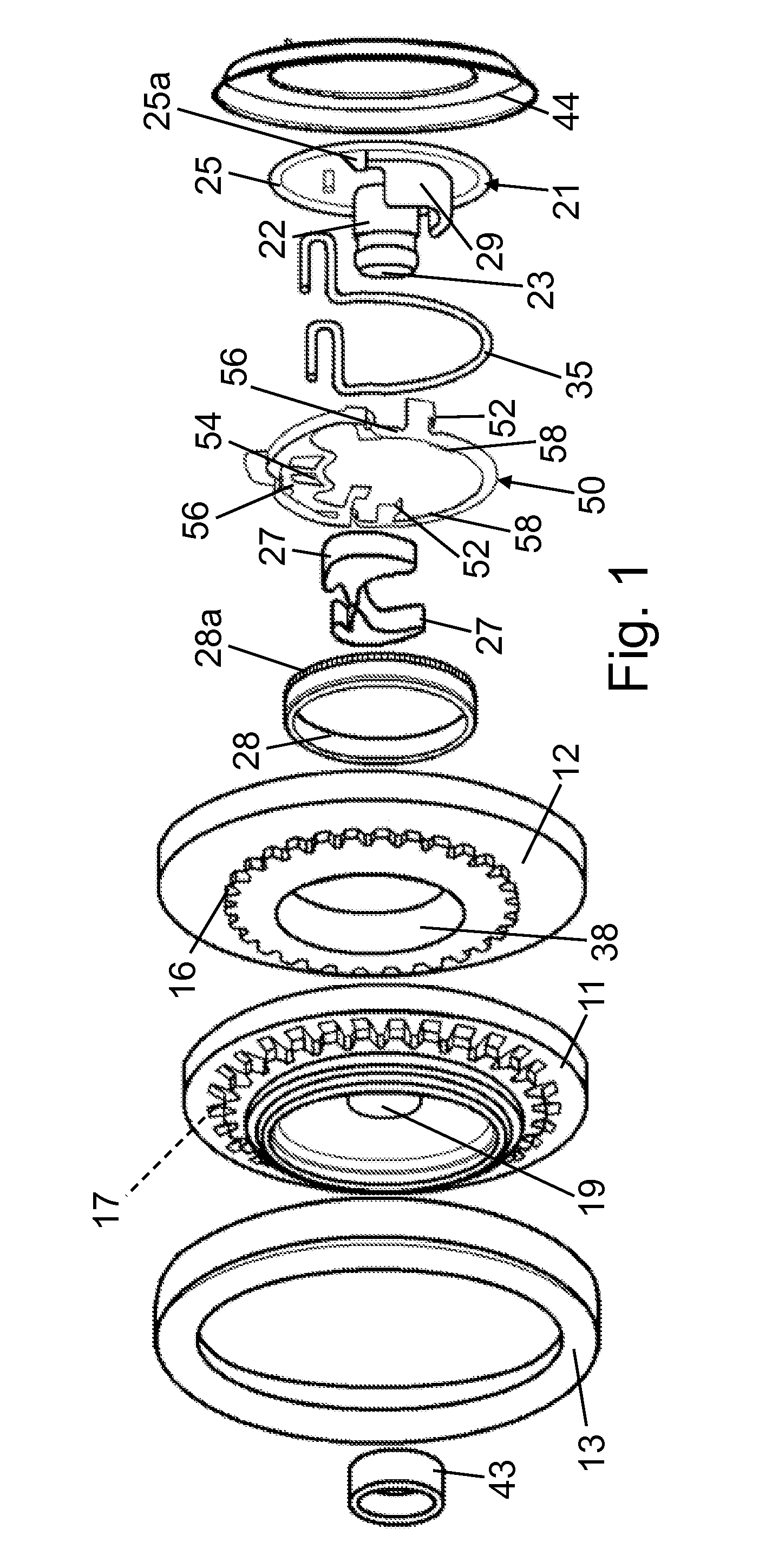

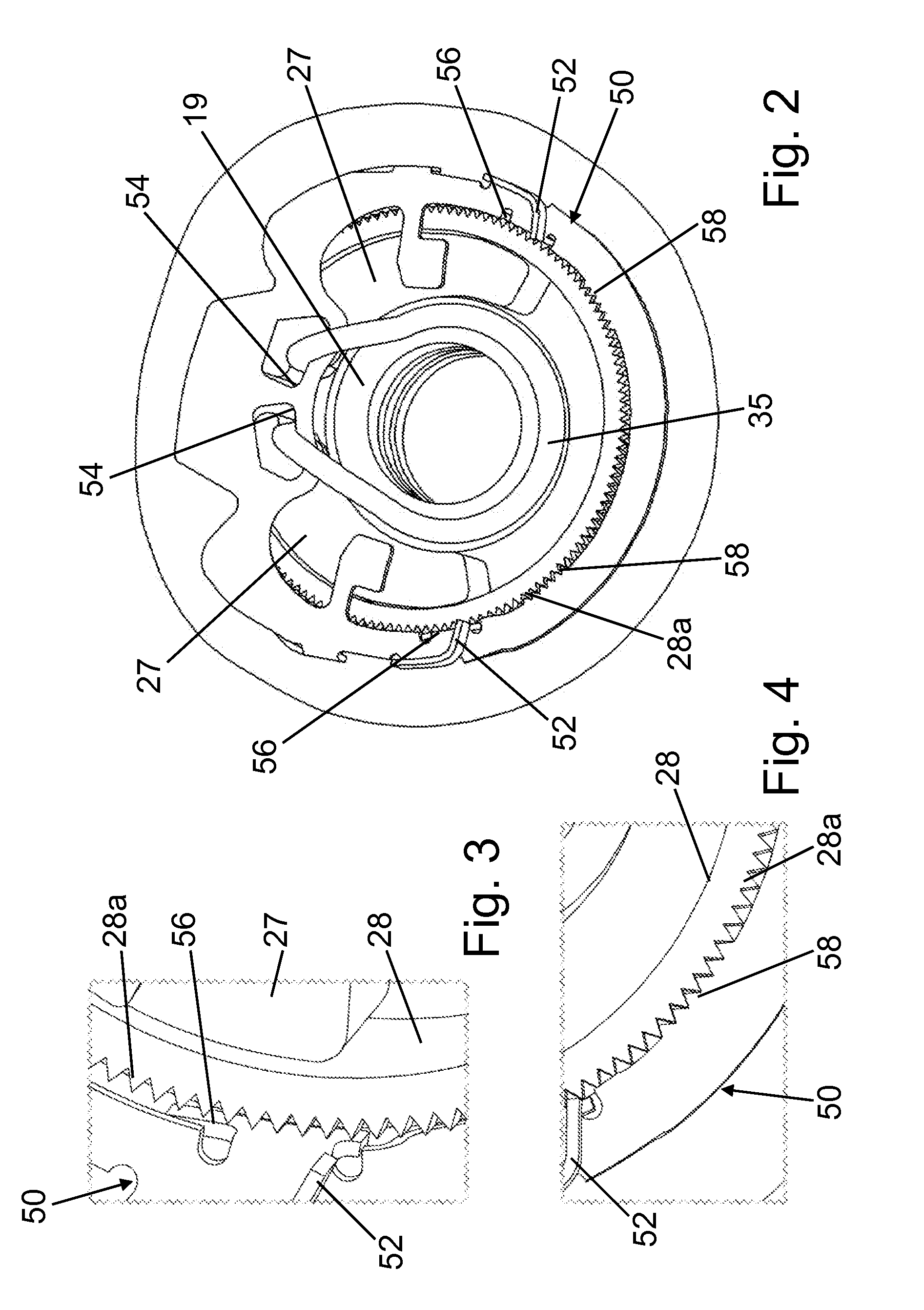

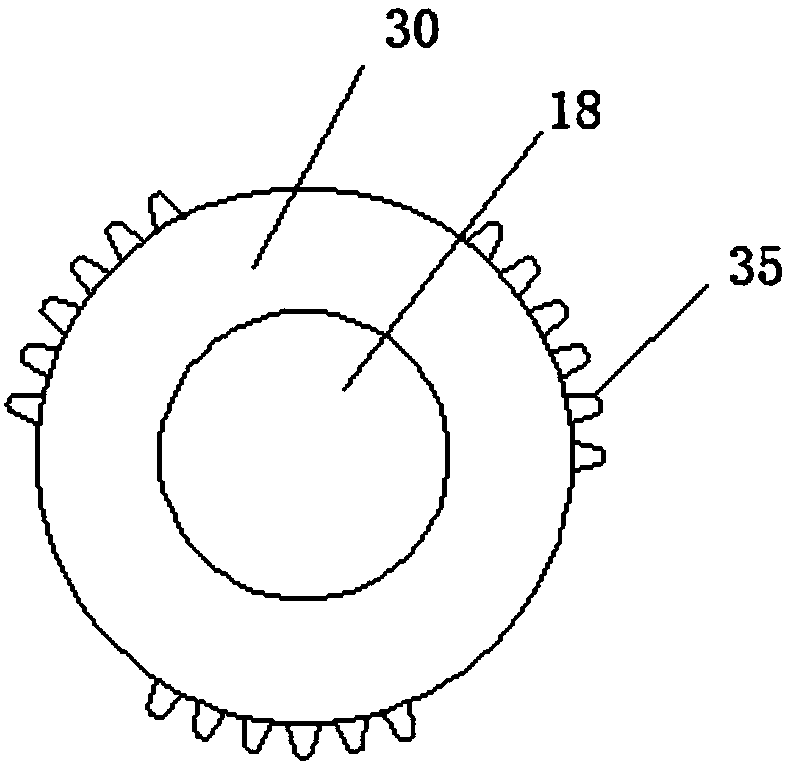

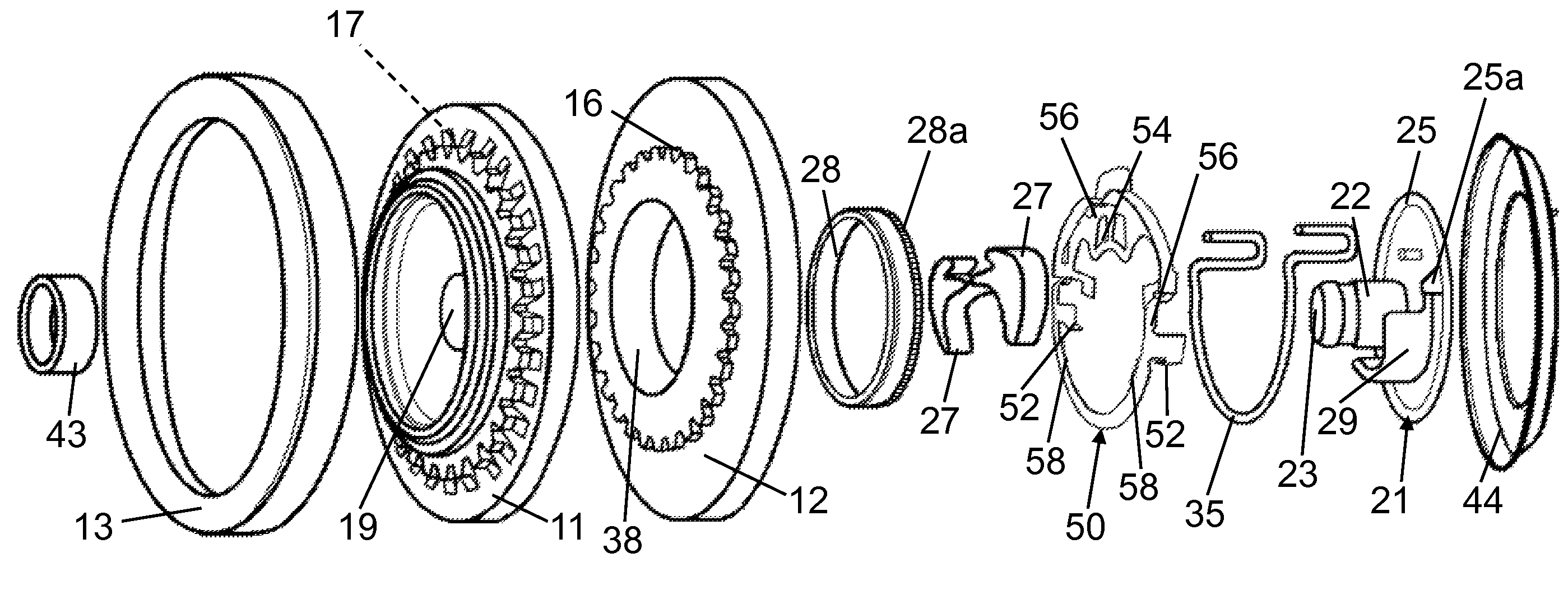

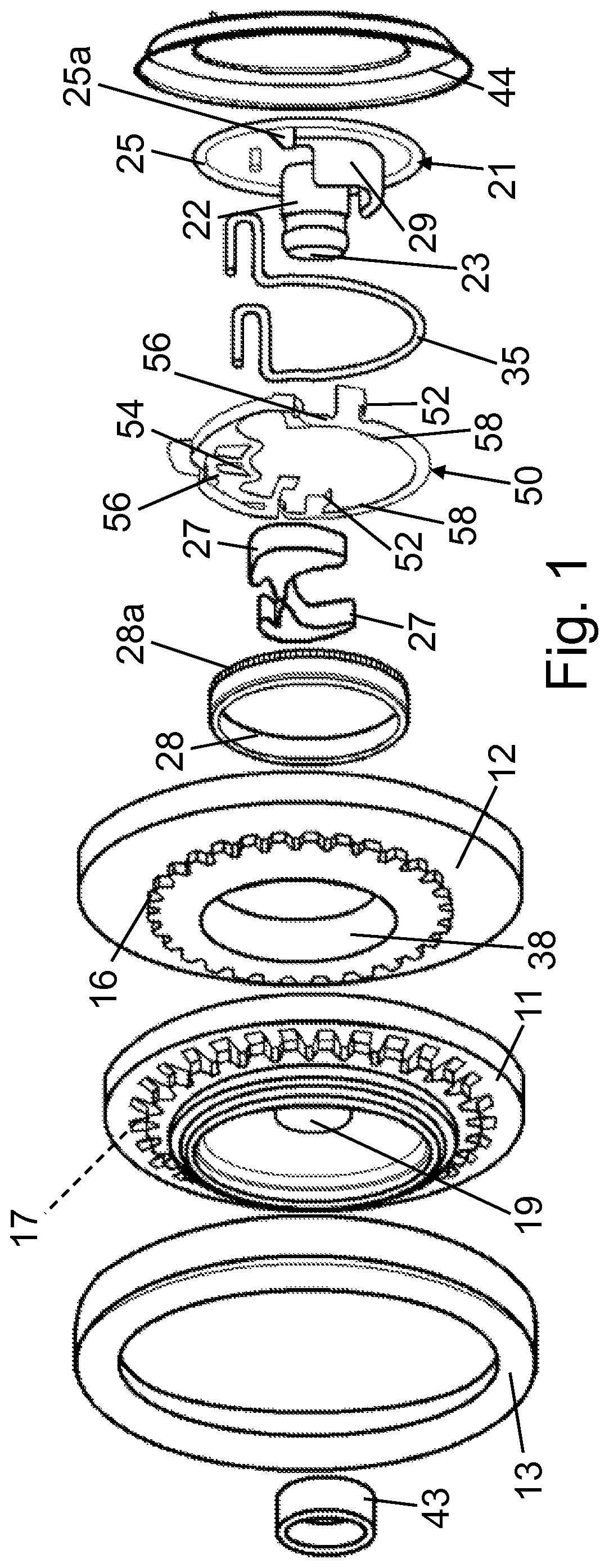

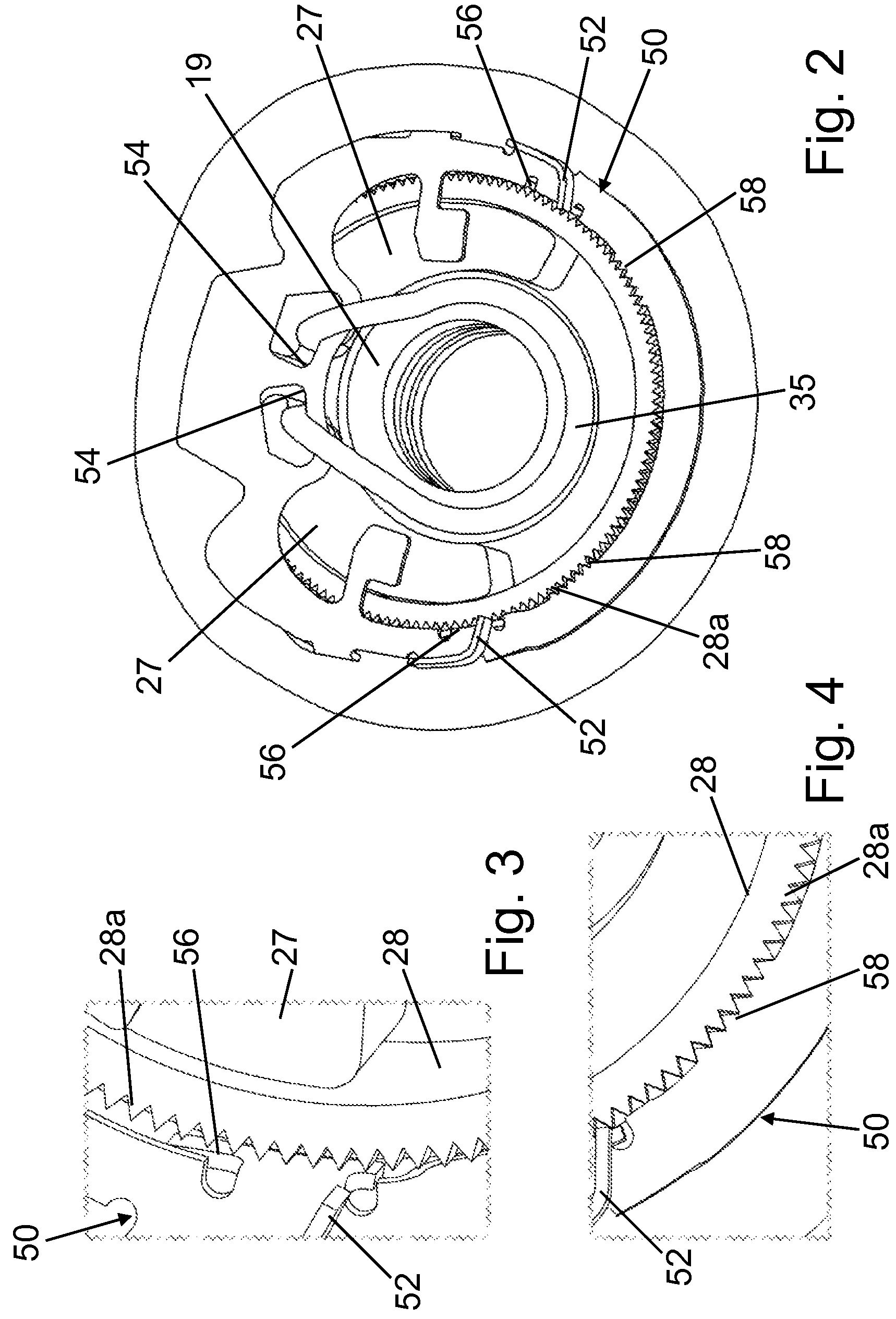

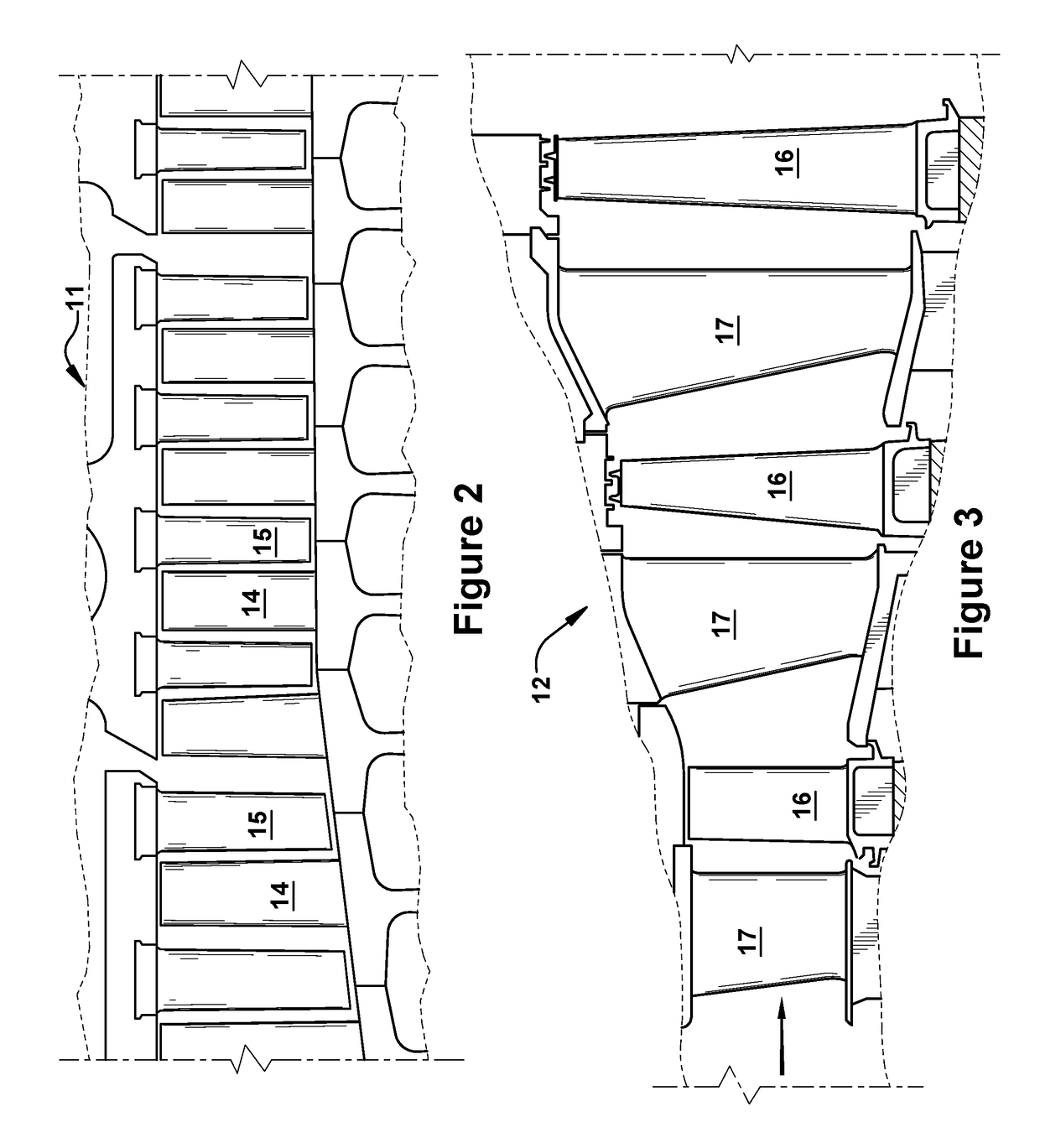

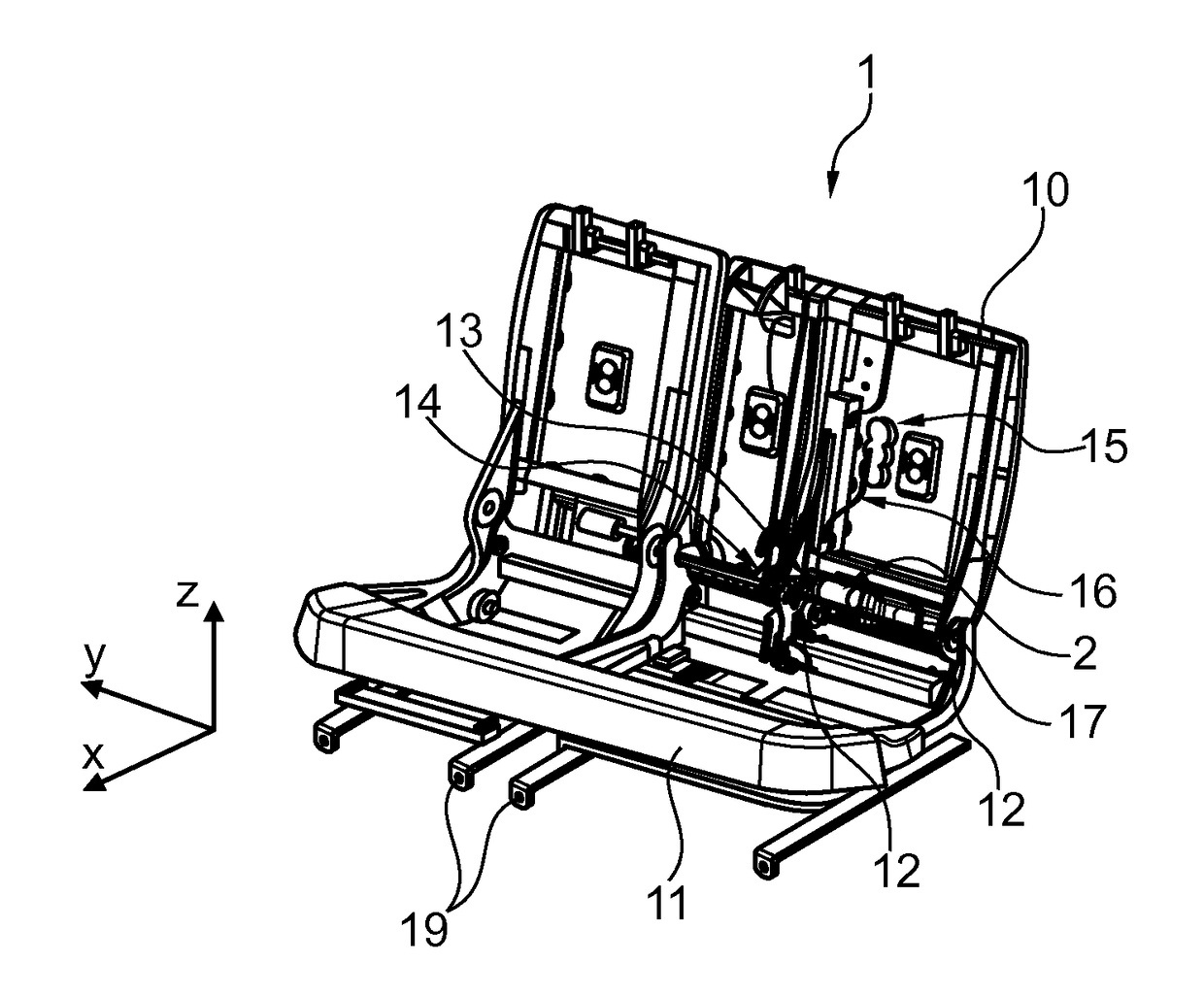

Fitting for a vehicle seat

A fitting (10) for a vehicle seat, in particular for a motor vehicle seat, includes a first fitting part (11), on which a ring gear (17) is formed, a second fitting part (12), on which a gear (16) is formed, which gear meshes with the ring gear (17), whereby the two fitting parts (11, 12) are in a transmission connection with each other, and a rotating eccentric (27, 35) for driving a relative rolling motion of the gear (16) and the ring gear (17). The eccentric is driven by a carrier (21), wherein the eccentric (27, 35) is rotatably supported in a collar (38), which is associated with one of the two fitting parts (11, 12), or in a bushing (28) sitting in said collar (38) in a rotationally fixed manner. A blocking element (50) for the eccentric (27, 35) is operative at least at times between the eccentric (27, 35) and the bushing (28). The bushing (28) has teeth (28a) pointing radially outward and the blocking element (50), which surrounds the bushing (28) annularly, has at least one, in particular two, tooth segments (58) pointing radially inward for interacting with the teeth (28a).

Owner:KEIPER SEATING MECHANISMS CO LTD

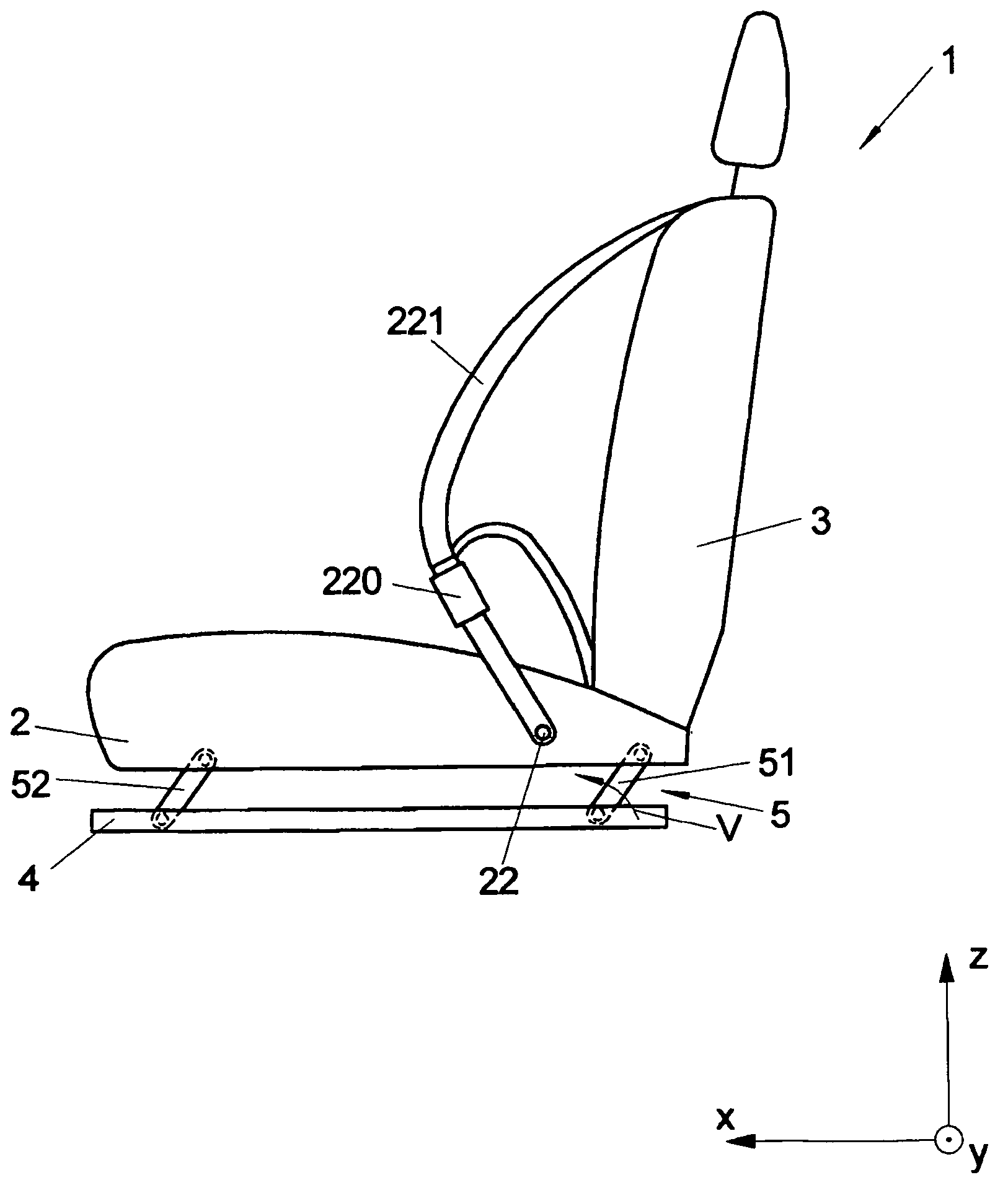

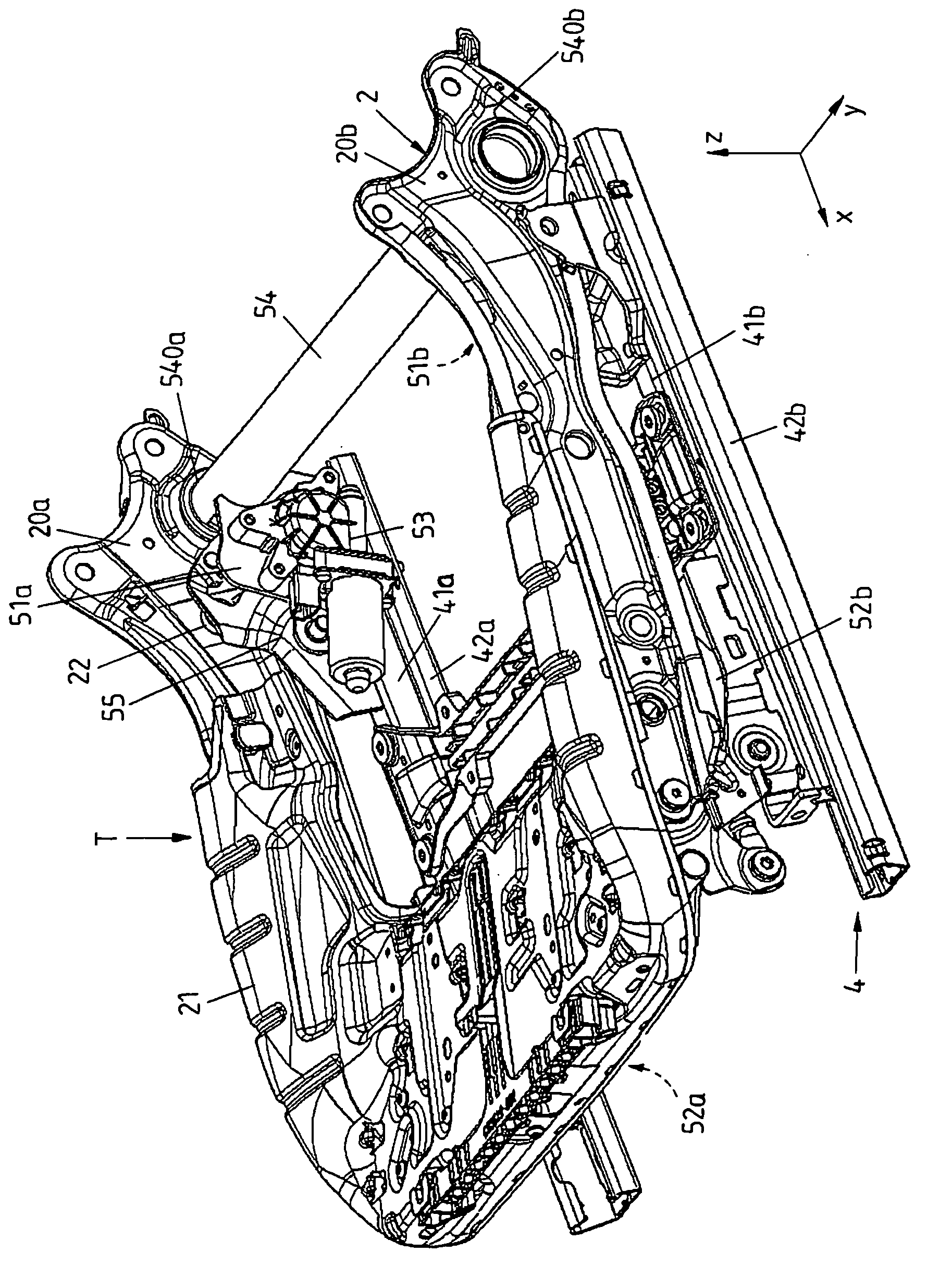

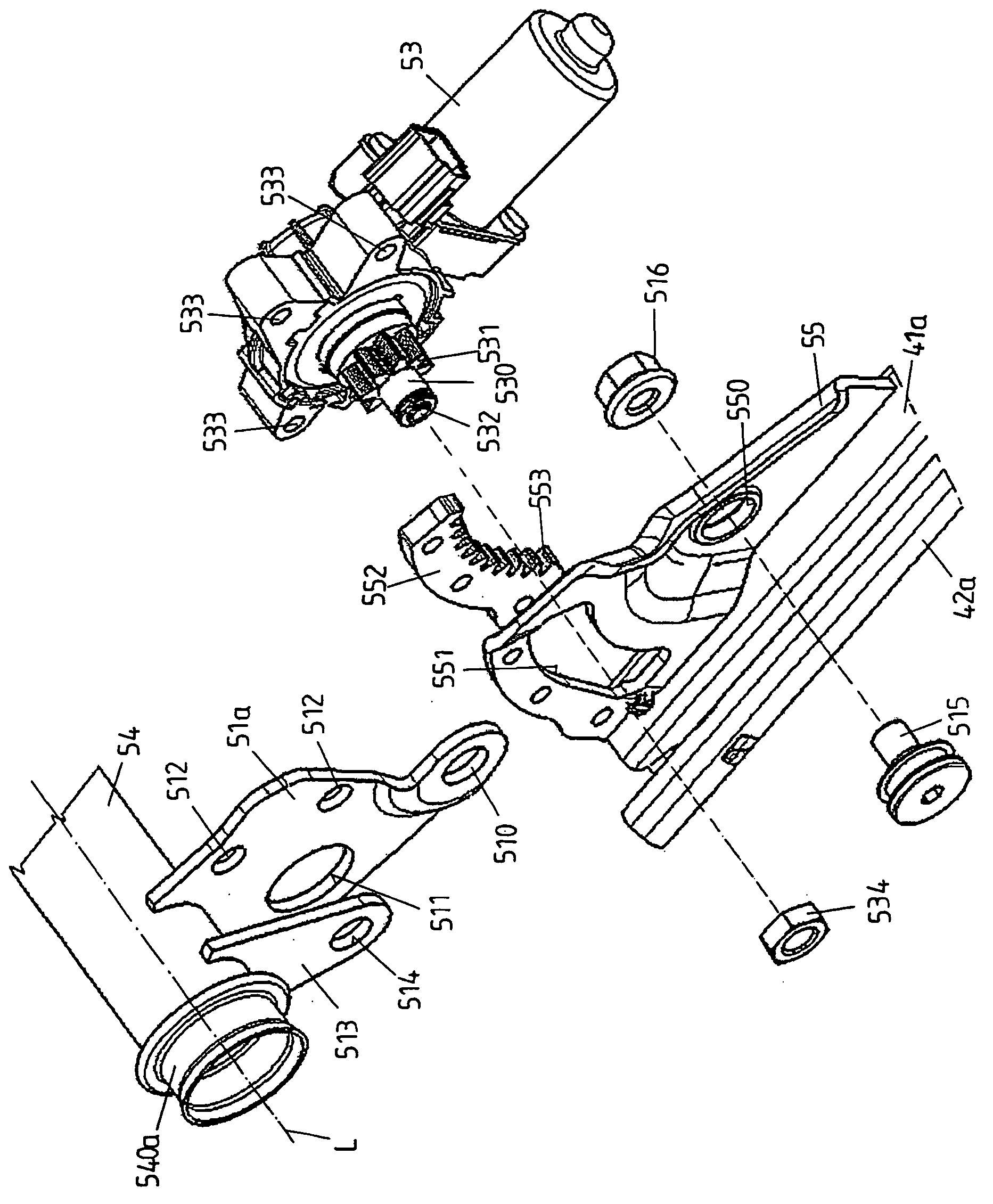

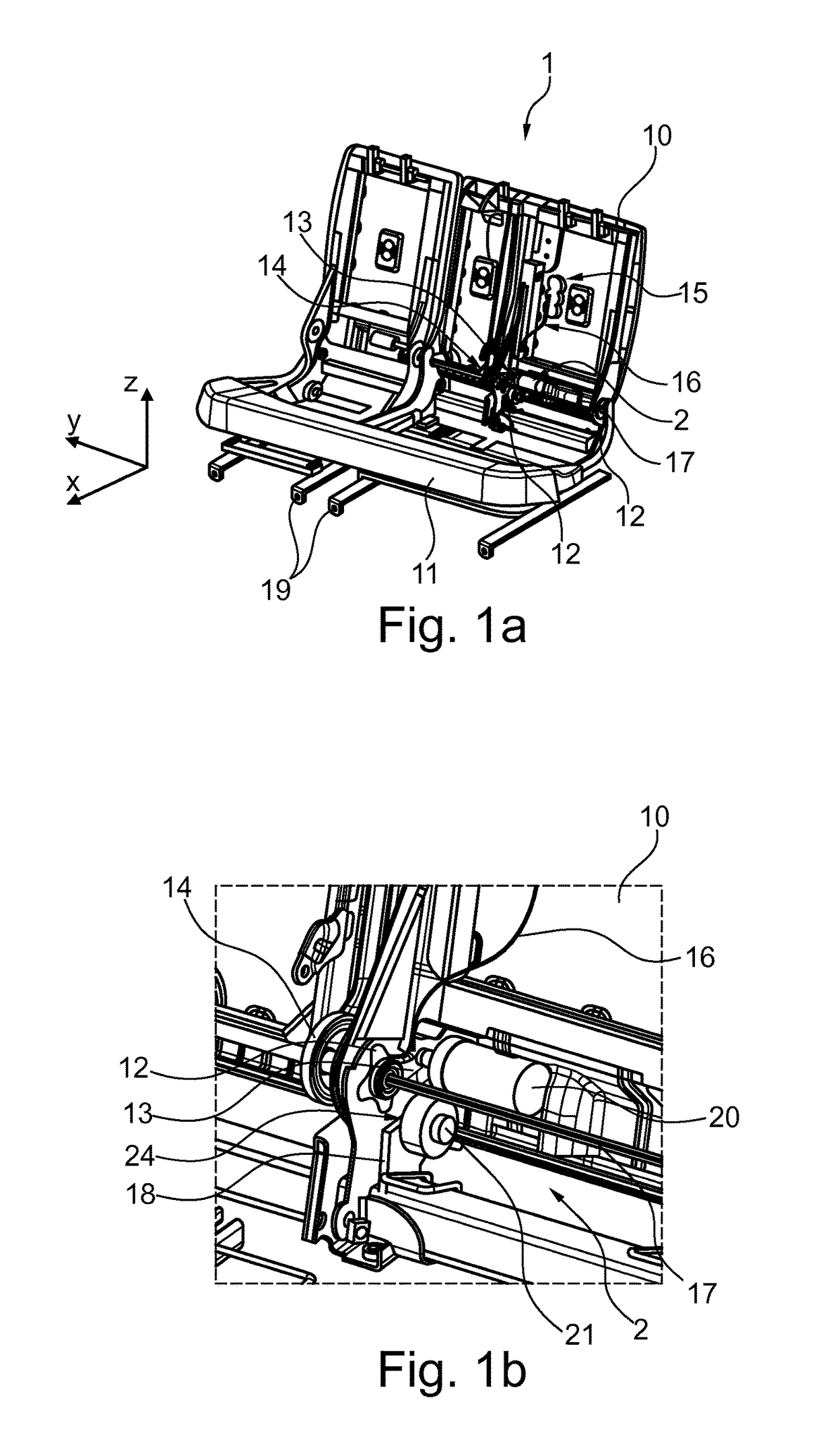

Vehicle seat having a height adjustment device

The invention relates to a vehicle seat comprising a seat part for providing a seat surface for a seat occupant, a guide track arrangement for the longitudinally adjustable arrangement of the vehicle seat in a vehicle and a height adjustment device comprising a plurality of rockers which are pivotably coupled to the seat part and the guide track arrangement and which connect the seat part to the guide track so as to be adjustable in height, and a drive unit powered by an electric motor for driving a first rocker of the plurality of rockers. The drive unit has an output pinion which engages in a toothing of a tooth segment and can be made to move in rotation with respect to the tooth segment in order to set the seat height of the seat part relative to the guide track arrangement. To this end the output pinion (531) is disposed on the first rocker (51a) and the tooth segment (552) is disposed immovably on the guide track arrangement (4) or on the seat part (2). In this way a vehicle seat is created which also enables the arrangement of a drive unit powered by an electric motor in a space-saving manner on a so-called tunnel side of a vehicle seat and at the same time can provide a reliable support for loading forces.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Electric motor and method for manufacturing an electric motor

ActiveUS8008832B2Conducive to environmental protectionEasy to manufactureWindingsManufacturing dynamo-electric machinesTooth segmentElectric motor

Owner:SEW-EURODRIVE GMBH & CO KG

Concentrated winding machines with reduced torque ripple and methods for designing the same

InactiveUS20110037339A1Well formedMagnetic circuit rotating partsAnalogue computers for electric apparatusWinding machineTooth segment

Systems and methods are provided for a motor having a concentrated winding construction with reduced torque ripple. A motor comprises a stator including a plurality of tooth segments disposed circumferentially to establish a hollow core and a rotor rotatably disposed inside the hollow core. The plurality of tooth segments define a plurality of slot openings associated with a plurality of slots. Each slot of the plurality of slots has a slot opening and at least one slot opening of the plurality of slot openings is asymmetric with respect to the plurality of slot openings.

Owner:GM GLOBAL TECH OPERATIONS LLC

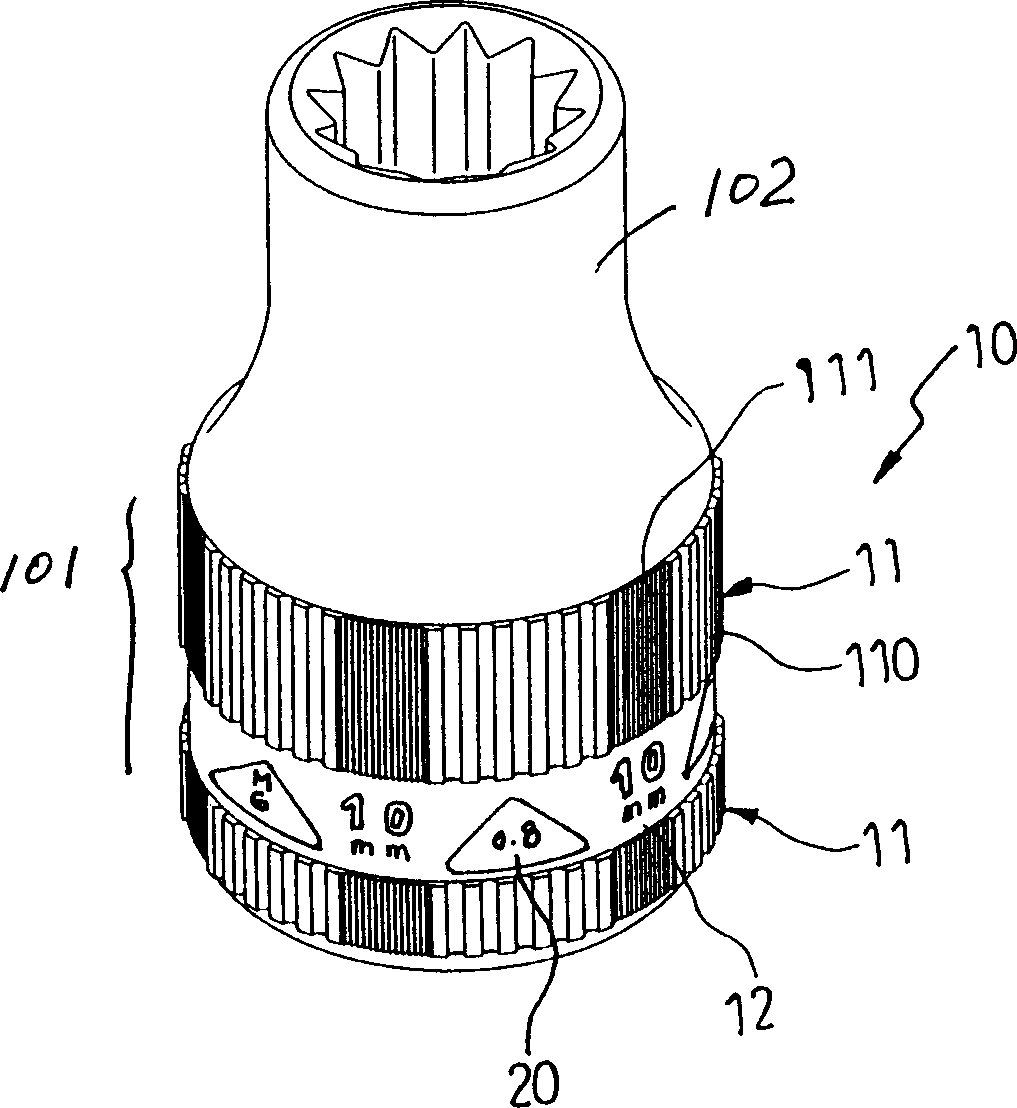

Impact wrench and method for making same

A socket wrench has an isometric body, whose cylindrical surface has a drive unit divided into two parts and a marker part between two parts of drive unit. In the drive unit the dense teeth and sparse teeth segments are alternative.

Owner:张 珍财

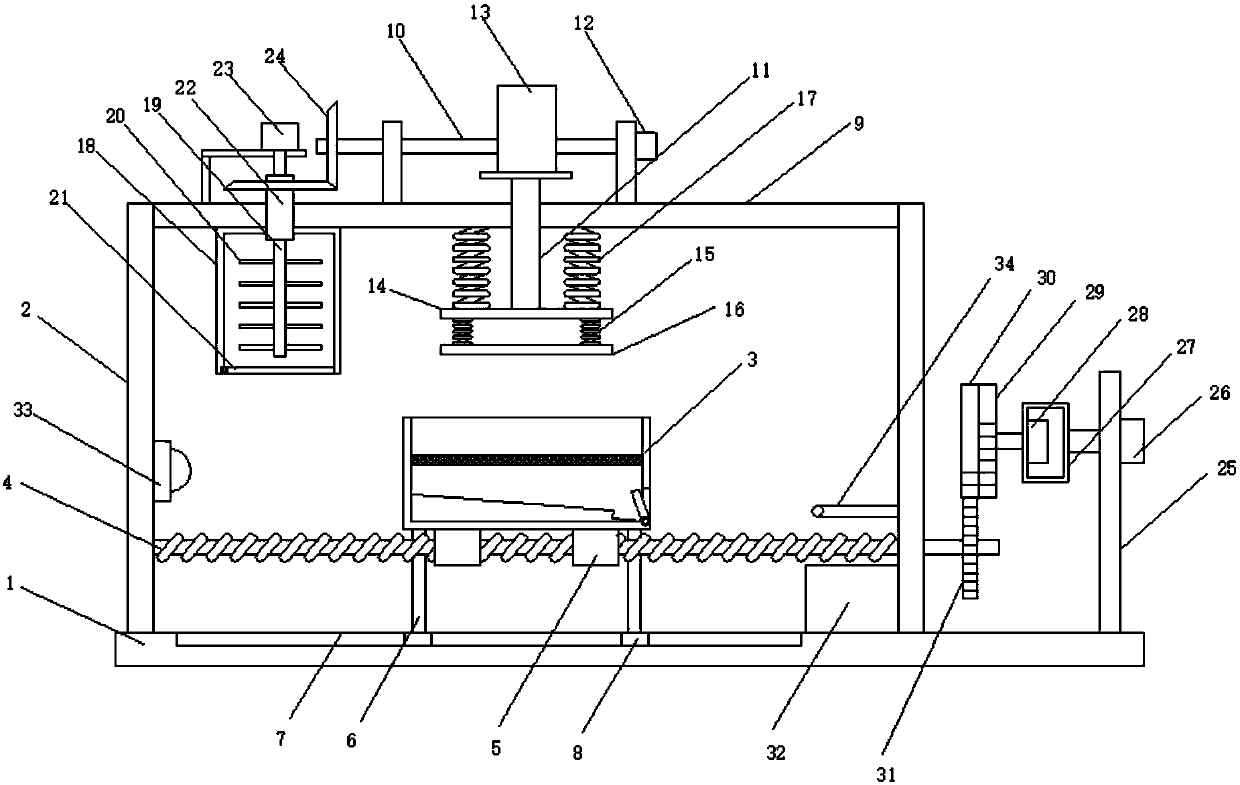

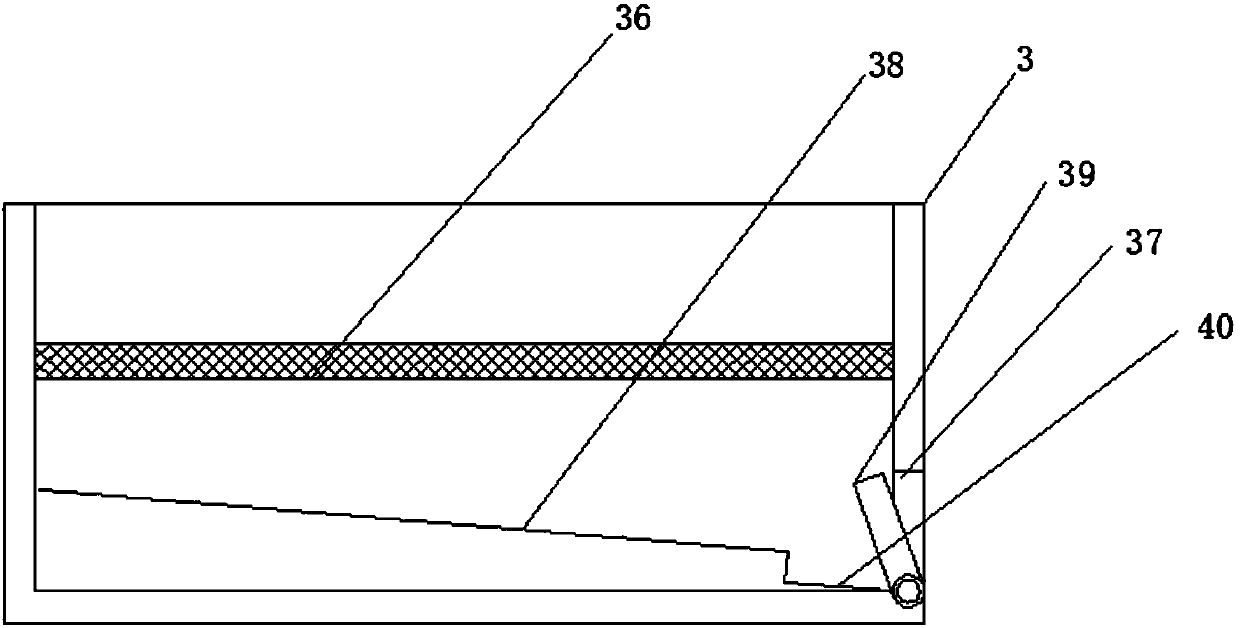

Automatic feeding and discharging dehydration device of vegetables and fruits

InactiveCN107927852ADischarge in timeNo manual operationGrain treatmentsFood treatmentTooth segmentEngineering

The invention discloses an automatic feeding and discharging dehydration device of vegetables and fruits. The automatic feeding and discharging dehydration device comprises a bottom plate, a dehydration tank and a material collecting box, wherein a screw rod shaft is arranged on the lower side of the dehydration tank, a slip sleeve connected with a screw rod section of the screw rod shaft throughscrew-thread fit is arranged on the screw rod section of the screw rod shaft, a lower closing plate is arranged at the bottom of the material collecting box, a cross shaft is arranged on a top plate,a dehydration screen plate is arranged in the dehydration tank, an oblique drainage plate is arranged at the bottom of the dehydration tank, a liquid outlet is formed at a relatively low end of the oblique drainage plate, a first incomplete gear and a second incomplete gear with same diameters are arranged on a main shaft of a positive electric motor, three meshed tooth segments are arranged on the second incomplete gear, a guide rod over against a closing plate is arranged on a side plate positioned on the right side, and a liquid collecting tank is also arranged on the right side of the upper end surface of the bottom plate. The automatic feeding and discharging dehydration device of vegetables and fruits has the advantages of simple structure, continuous operation, higher efficiency, lower labor, stable transmission, better dehydration effect and higher practicability.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

Stator in an electric motor

InactiveUS20130026878A1Easy to manufactureHigh level of stabilityMagnetic circuit stationary partsUnknown materialsEngineeringTooth segment

The invention relates to a stator in an electric motor comprising a plurality of teeth segments forming a stator ring, said teeth segments comprising outer yoke segments and radial support teeth. Connection elements are arranged on the peripheral front sides of the yoke segment and are offset in the direction of the radial outer side.

Owner:ROBERT BOSCH GMBH

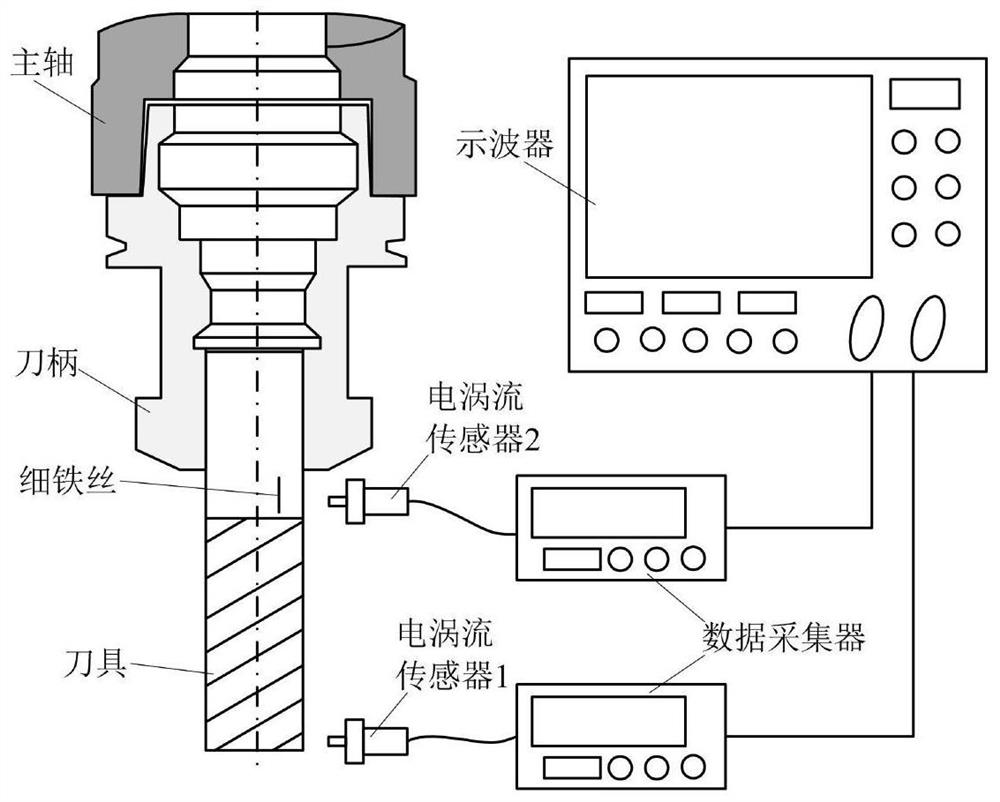

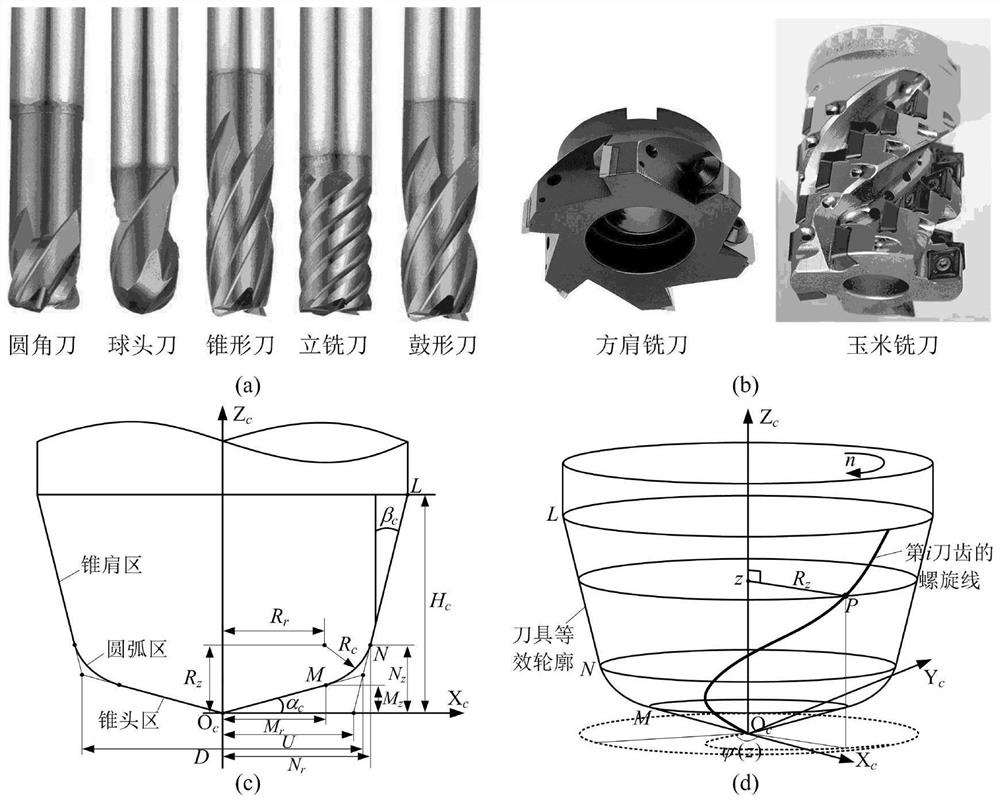

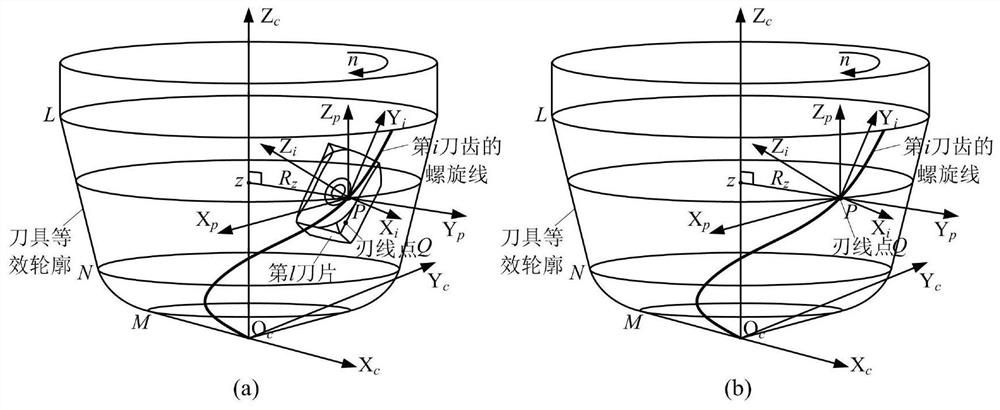

Universal on-machine non-contact calibration method for eccentric parameters of milling cutter

ActiveCN111618657AEasy to operateHigh measurement accuracyMeasurement/indication equipmentsRotational axisMilling cutter

The invention relates to a universal on-machine non-contact calibration method for eccentric parameters of a milling cutter. The method comprises the following steps of establishing a universal geometrical parameter representing mathematic model of an integral milling cutter and a machine clamped milling cutter; then carrying out quantitative description on the eccentric state of a tool by means of three states such as spin axis deflection, geometrical axis deflection and end edge eccentricity of the tool and seven independent parameters; and carrying out non-contact measurement on a target distance of a cutter tooth segment of the tool mounted on a spindle of a machine tool by using an electrical vortex sensor to obtain variable quantities of actual cutting diameters of cutting points ofdifferent blades on different cutter teeth of the tool at different axial heights so as to calibrate the eccentric parameters (including geometrical axis deflection of side edge, spin axis deflectionof the side edge and end edge eccentricity of the tool) of the tool in a rotating state of the spindle by combining a numerical optimization method. The method is better in universality and accuracy,can calibrate the eccentric state of the tool quickly and accurately on-machine, and is convenient to use in an enterprise machining site.

Owner:XI AN JIAOTONG UNIV

Fitting for a vehicle seat

A fitting (10) for a vehicle seat, in particular for a motor vehicle seat, includes a first fitting part (11), on which a ring gear (17) is formed, a second fitting part (12), on which a gear (16) is formed, which gear meshes with the ring gear (17), whereby the two fitting parts (11, 12) are in a transmission connection with each other, and a rotating eccentric (27, 35) for driving a relative rolling motion of the gear (16) and the ring gear (17). The eccentric is driven by a carrier (21), wherein the eccentric (27, 35) is rotatably supported in a collar (38), which is associated with one of the two fitting parts (11, 12), or in a bushing (28) sitting in said collar (38) in a rotationally fixed manner. A blocking element (50) for the eccentric (27, 35) is operative at least at times between the eccentric (27, 35) and the bushing (28). The bushing (28) has teeth (28a) pointing radially outward and the blocking element (50), which surrounds the bushing (28) annularly, has at least one, in particular two, tooth segments (58) pointing radially inward for interacting with the teeth (28a).

Owner:KEIPER SEATING MECHANISMS CO LTD

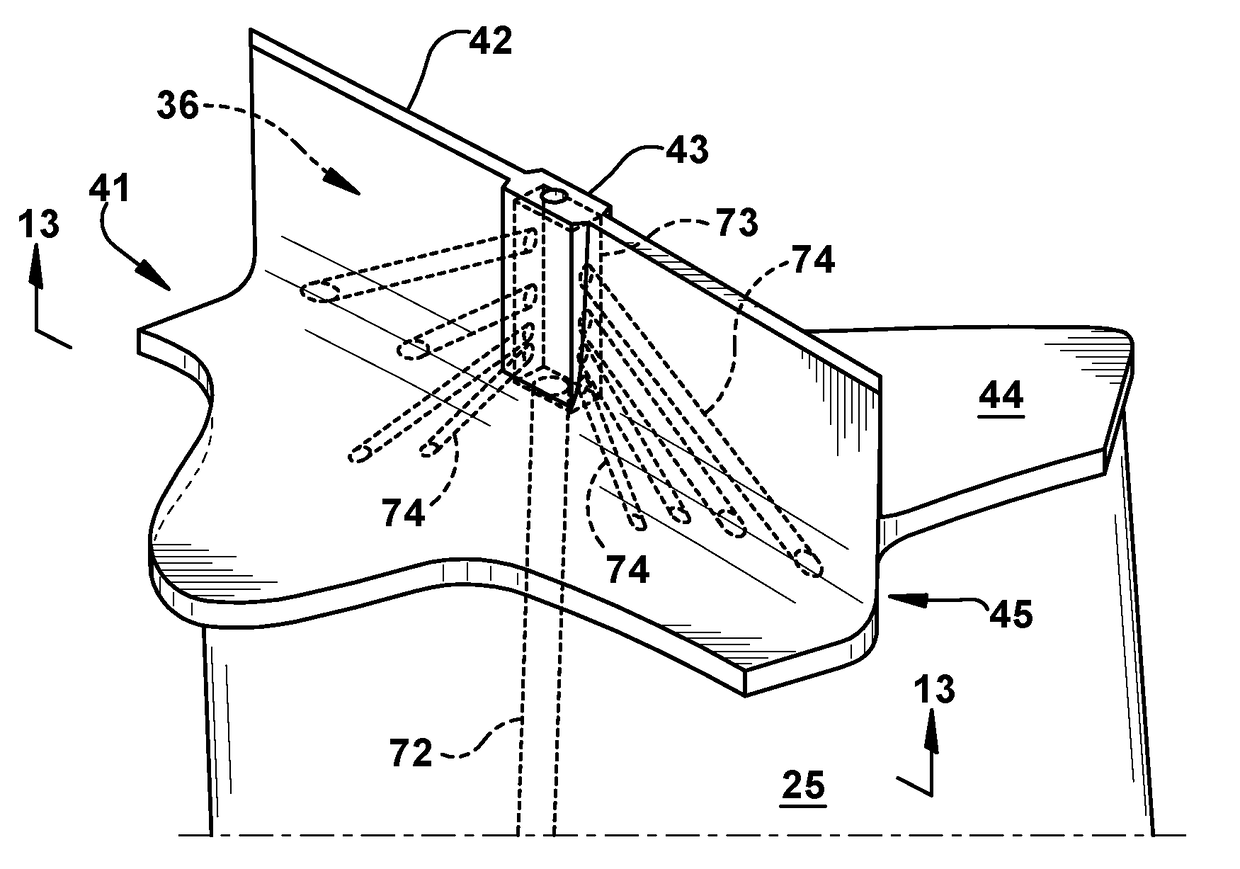

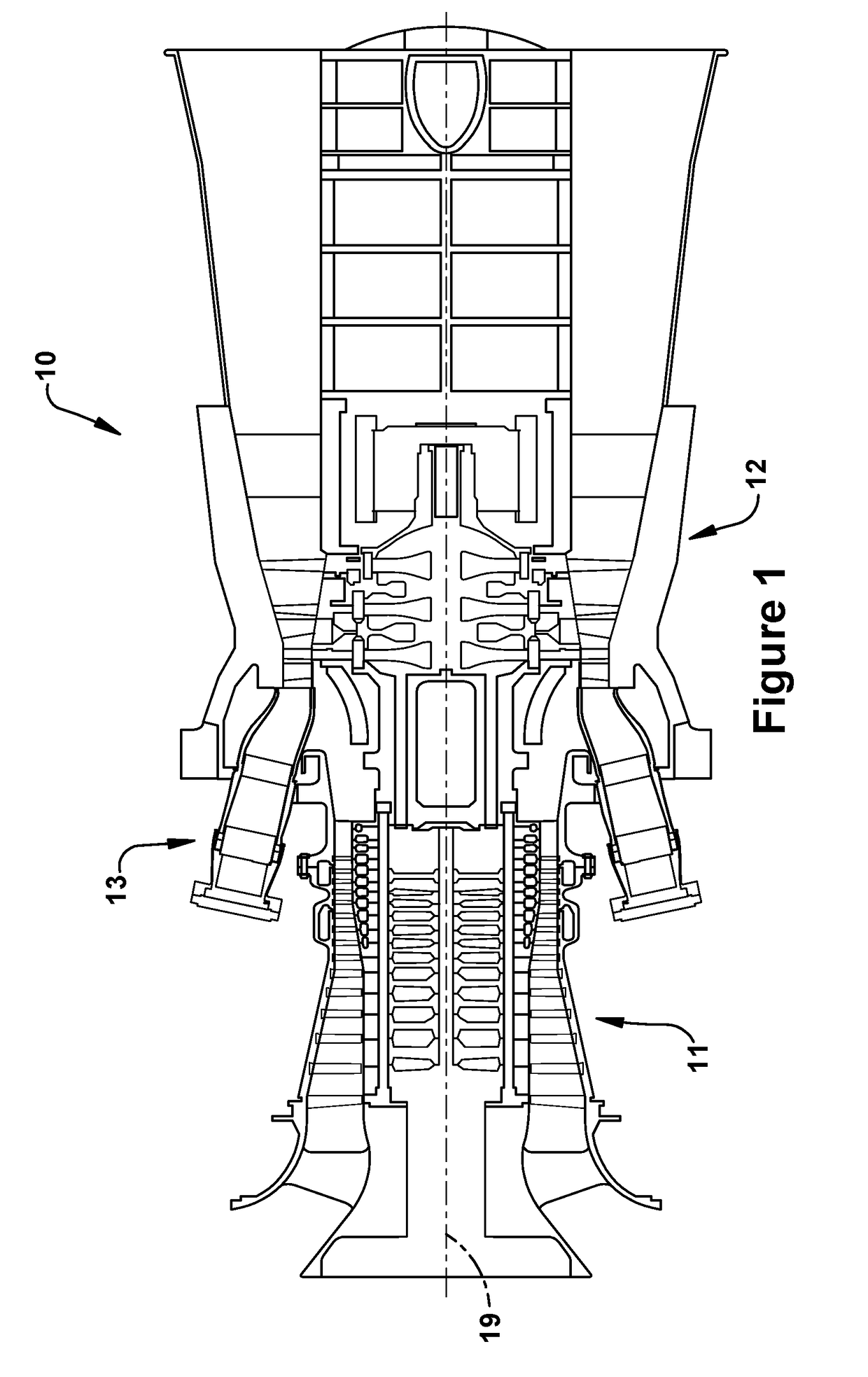

Interior cooling configurations in turbine rotor blades

A turbine rotor blade that includes: an airfoil defined between a pressure face and a suction face; a tip shroud that includes a seal rail projecting from an outboard surface and, formed thereon, a cutter tooth; and a cooling configuration that includes a cooling channel for receiving and directing a coolant through an interior of the rotor blade. The cooling channel may include fluidly connected segments, in which: a supply segment extends radially through the airfoil; a cutter tooth segment is formed within the cutter tooth of the seal rail; and branching segments formed within at least one of the tip shroud and an outboard region of the airfoil. Each of the branching segments may extend between an upstream port, which connects to the cutter tooth segment, and an outlet port, which is formed on a target surface area, so that the branching segment bisects a target interior region.

Owner:GENERAL ELECTRIC CO

Gearing

Owner:WITTENSTEIN GROUP

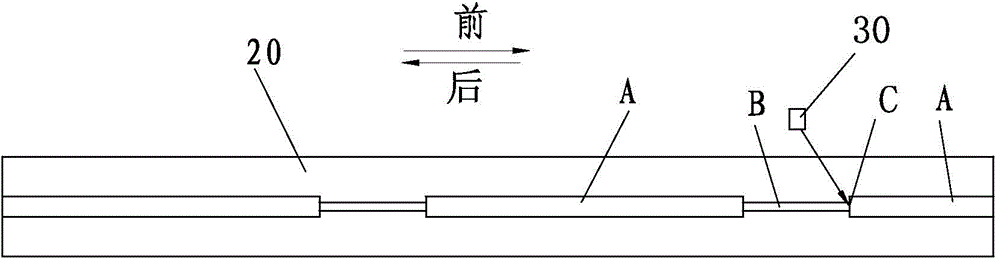

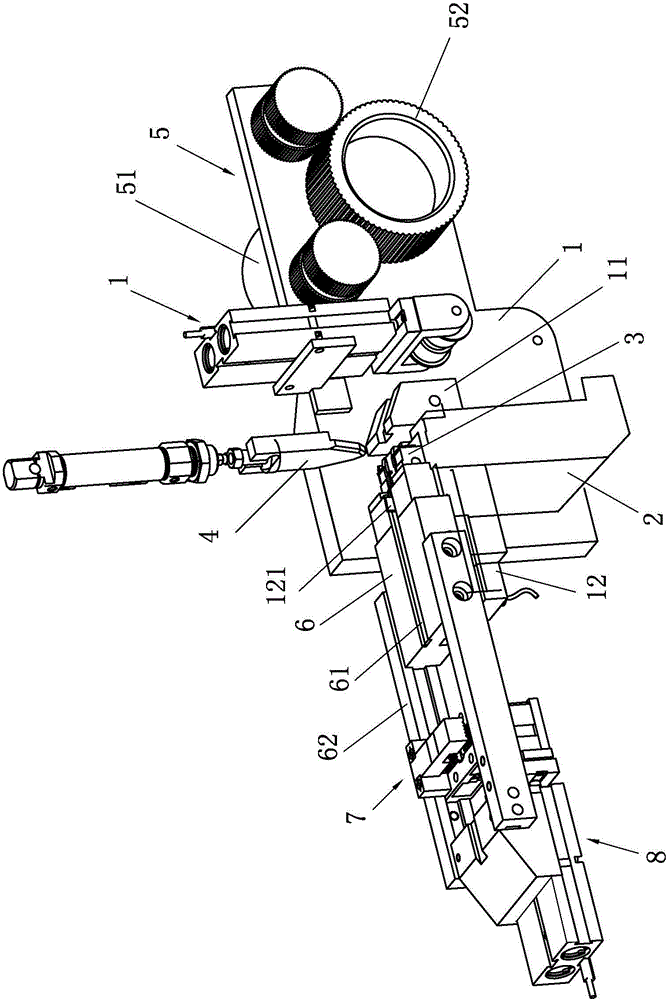

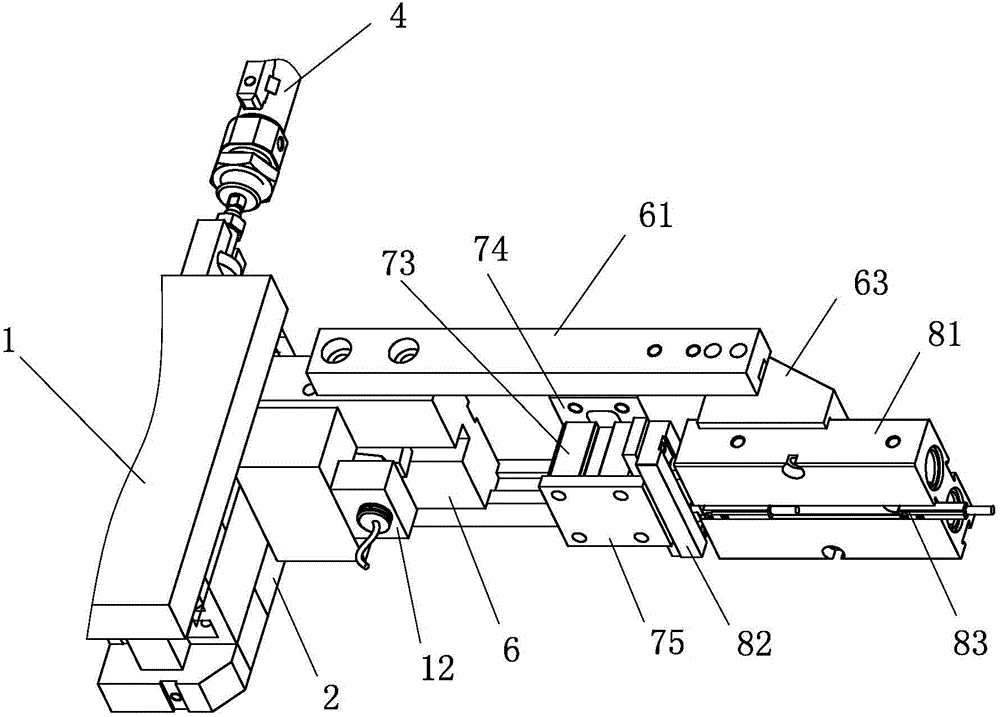

Sequential-production zipper H-shaped stopper assembling machine

The invention provides a sequential-production zipper H-shaped stopper assembling machine. The sequential-production zipper H-shaped stopper assembling machine comprises a machine frame, a zipper separation rod, a feeding and stamping seat, a belt pulling mechanism and a control unit. When a sensor on the rear side of the zipper separation rod senses a zipper tooth vacancy segment of a zipper belt, the control unit controls a motor of the belt pulling mechanism to stop rotating, and a belt clamping mechanism clamps the zipper belt; meanwhile, zipper separation is carried out through the zipper separation rod, feeding is carried out by the feeding and stamping seat, as a result, an H-shaped stopper is located at the zipper tooth vacancy segment, a belt loosening mechanism returns to loosen the originally tensioned zipper belt, the belt clamping mechanism pulls the zipper belt backward under the action of a belt pushing mechanism, and the H-shaped stopper is downwards pressed by the feeding and stamping seat after a zipper tooth at the tail end of a zipper tooth segment on the front side of the zipper tooth vacancy segment abuts against the H-shaped stopper. When a zipper is fed with the upper stopping end of the zipper facing forward, the H-shaped stopper can be stably and accurately fixed to the lower stopping end, the zipper feeding direction of the sequential-production zipper H-shaped stopper assembling machine is the same as that of a next production device, and the whole zipper production line is unified in zipper feeding mode, continuous in production process and high in production efficiency.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

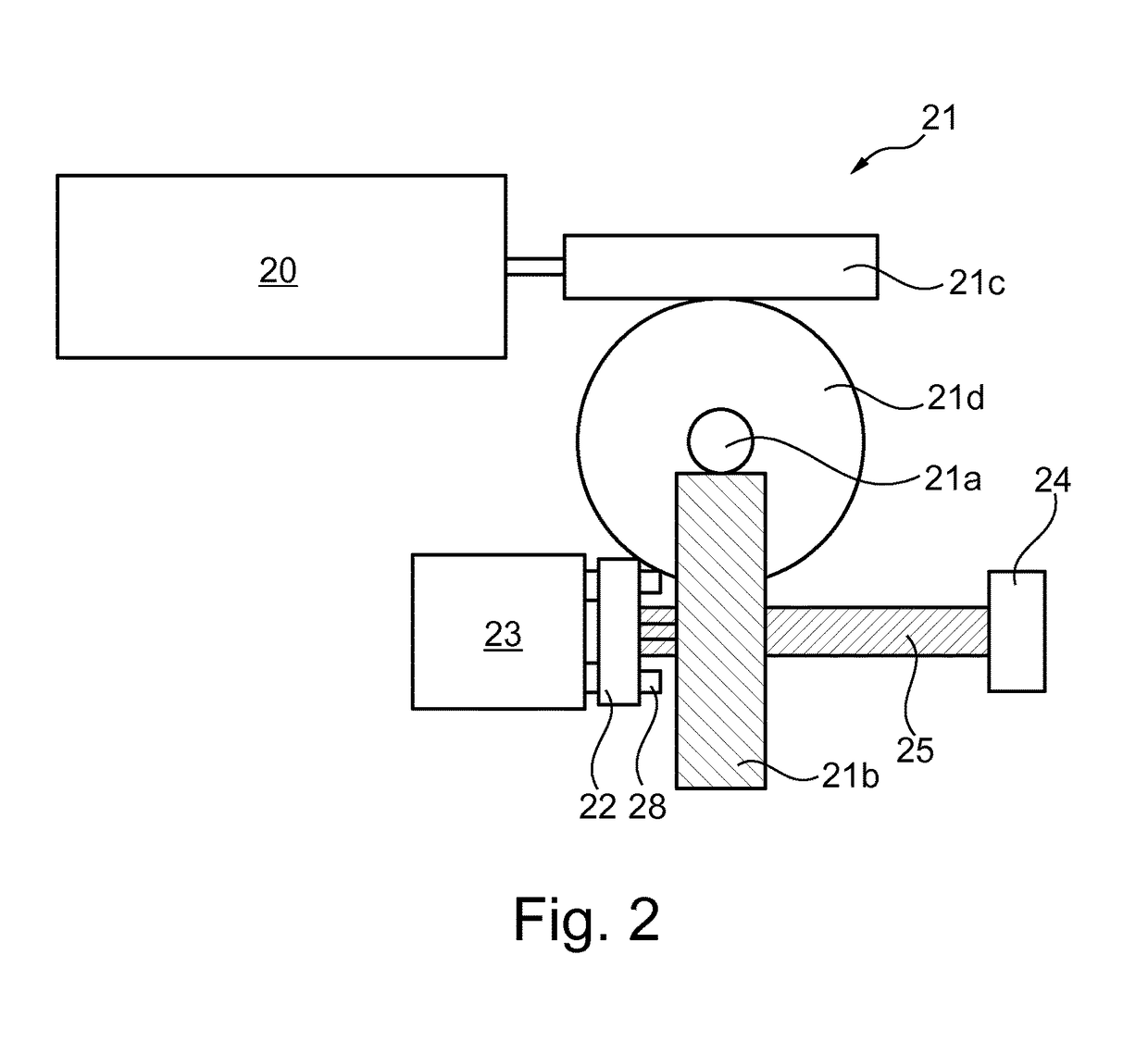

Drive system for a tilt adjustment, vehicle seat, method for operating a drive system

A drive system (2) tilt adjusts a back rest (10) of a vehicle seat (1). The back rest (10) is held on a seat base (11) by a fitting (12). An output pinion (24), drivable by a drive motor (20), is provided on the seat back side and interacts with a tooth segment (18) arranged rotationally fixed on the base (11). A pivot movement of the back rest (10) can be carried out by the drive motor (20) while the fitting (12) is unlocked. The output pinion (24) can be uncoupled from the drive motor (20) by a coupling (22). A compensation spring (14) acting between the back rest (10) and the base (11) pre-tensions the back rest (10) in the direction of the non-use position. A vehicle seat (1) with the drive system and a method for operating a drive system (2) are also provided.

Owner:ADIENT US LLC

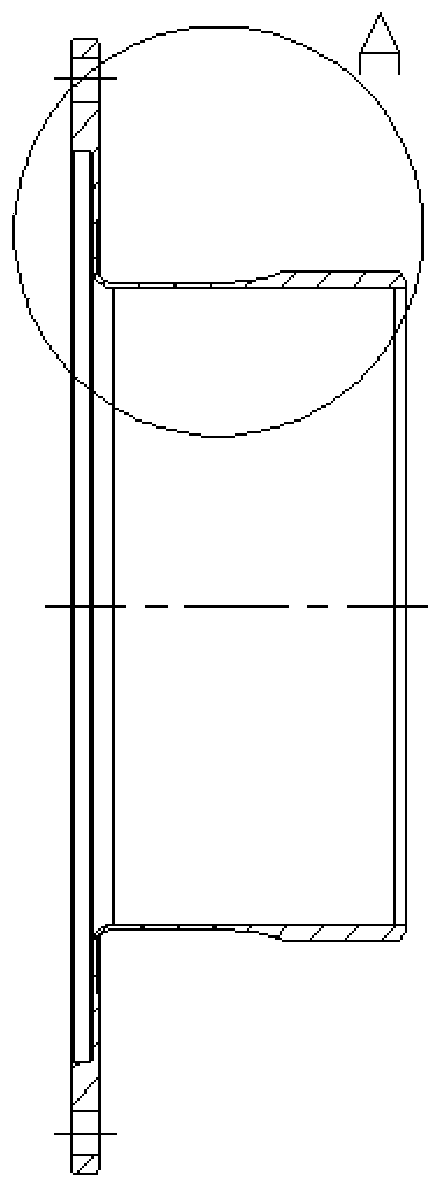

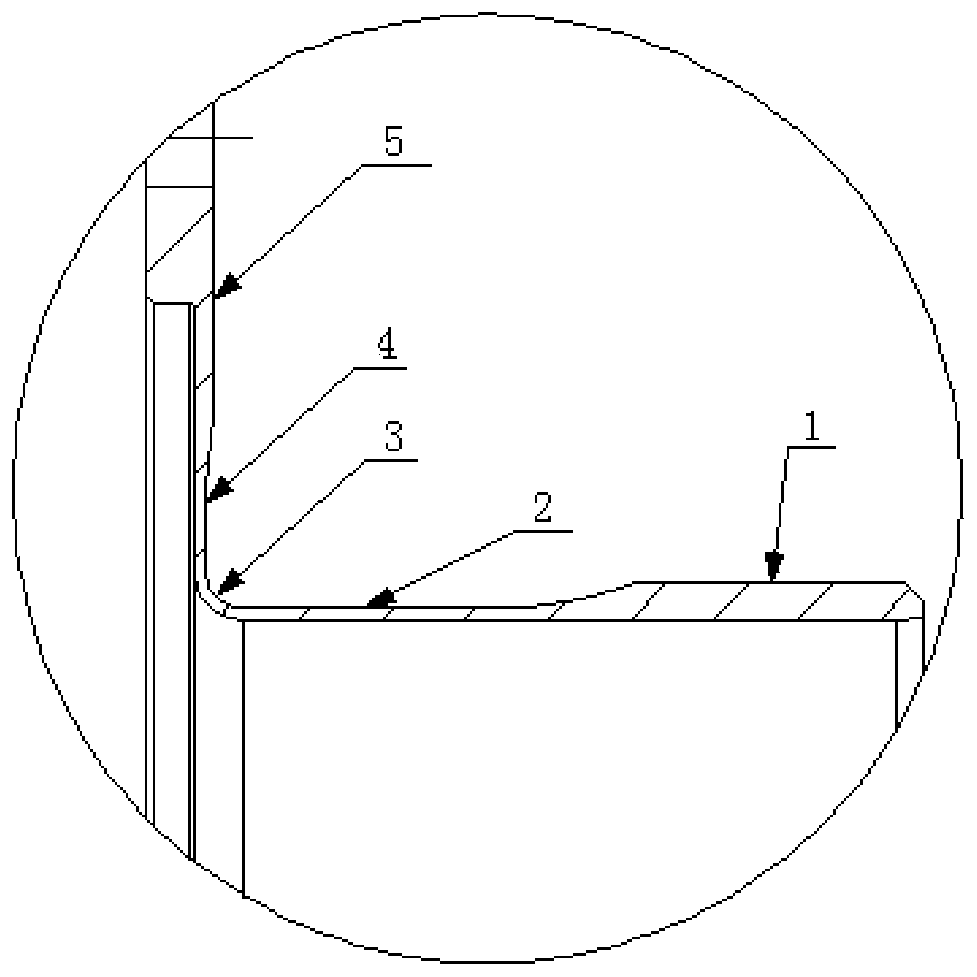

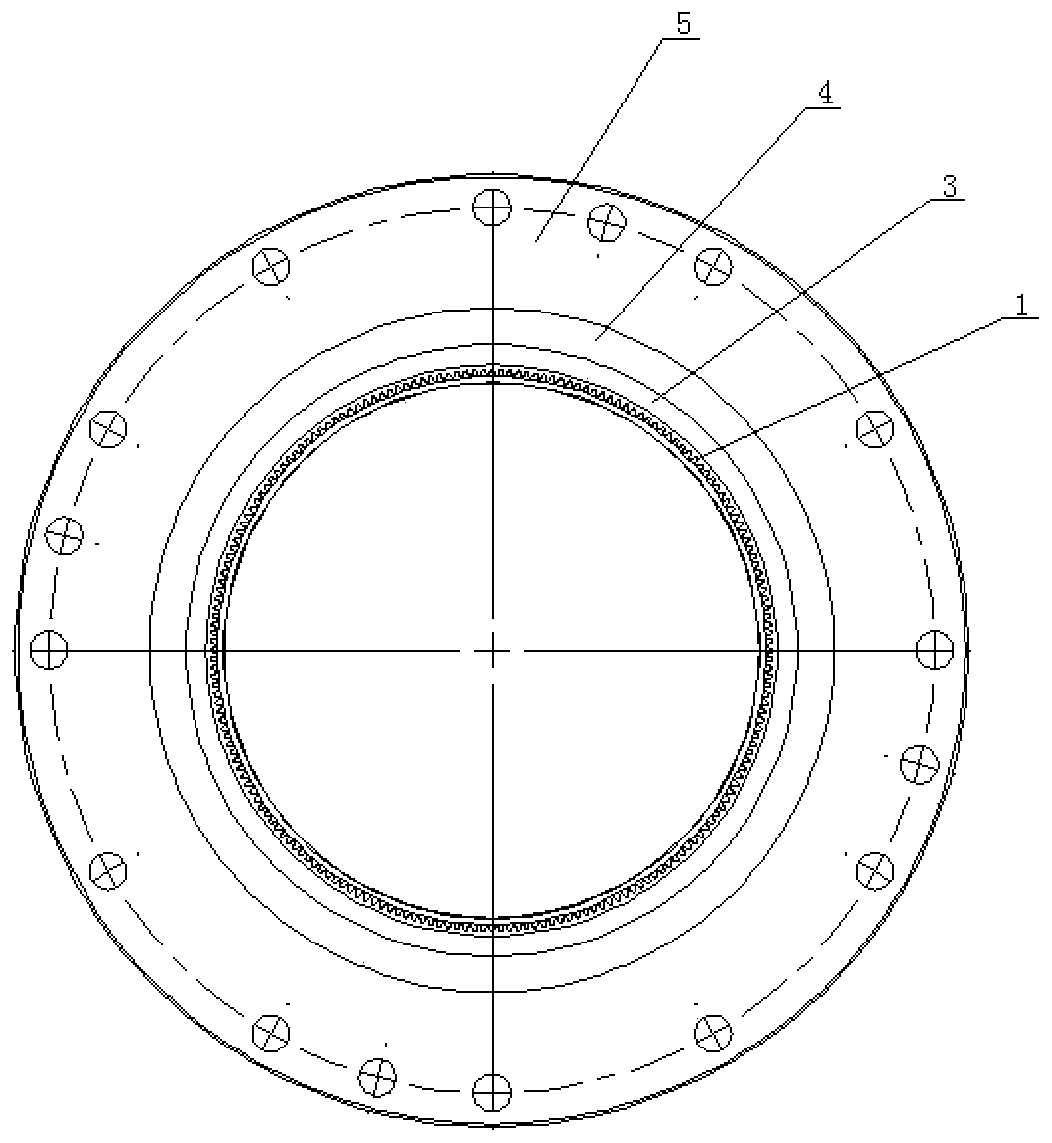

Pliers for crimping work pieces

ActiveUS20050076697A1Easy to produceMaintain designPliersMetal-working hand toolsLocking mechanismEngineering

Pliers for crimping work pieces include a pliers head, a first pivot jaw (4) and a second pivot jaw (3). A common joint (5) pivotally connects the first and second pivot jaw (4, 3). Two dies together form a crimping die (8). A first handle (2) is connected to the first pivot jaw (4). The first handle (2) is divided into at least a first portion (21) and a second portion (22). The first portion (21) is designed as a plate. A second handle (1) is connected to the second pivot jaw (3). The first handle (2) and the second handle (1) are movable with respect to one another and operable to crimp the work piece in a few crimping steps. A locking mechanism (28) includes a tooth segment (29), and it serves to attain a defined closed position of the dies. The tooth segment (29) is designed as one piece with the first portion (21). A stop mechanism (31) includes at least two stops, and it connects the first portion (21) and the second portion (22) in a plurality of different angle positions. The stops are designed as one piece with the first portion (21). A toggle lever drive (27) includes a plurality of support joints and a pressure lever (16). The pressure lever (16) connects the first portion (21) to the second handle (1). The pressure lever (16) is supported by the support joints.

Owner:WEZAG GMBH & CO KG

Variable-wall-thickness flexible gear of harmonic reducer

PendingCN110043631AReduce fatigue stressReduced risk of fatigue failureGeometric CADPortable liftingHarmonicReduction drive

The invention discloses a variable-wall-thickness flexible gear of a harmonic reducer. The variable-wall-thickness flexible gear is integrally formed by a harmonic tooth segment, a fixed-wall-thickness segment, an arc transition segment, a variable-wall-thickness segment and a flange segment. One side of the fixed-wall-thickness segment and one side of the harmonic tooth segment are fixedly connected, and the other side of the fixed-wall-thickness segment is fixedly connected with the inner circle of the variable-wall-thickness segment through the arc transition segment. The outer circle of the variable-wall-thickness segment is fixedly connected with the inner circle of the flange segment. Compared with the prior art, the fatigue stress of the flexible gear during loaded running of the harmonic reducer can be reduced, the risk that fatigue failures happen to the flexible gear can be reduced, the service life of the flexible gear can be prolonged easily, and the variable-wall-thicknessflexible gear has the value of application and popularization.

Owner:MICROPAK CNC TECH QUANZHOU

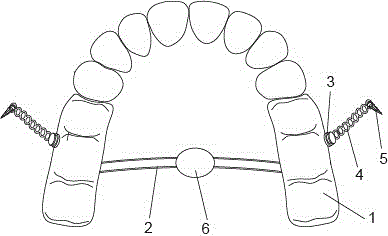

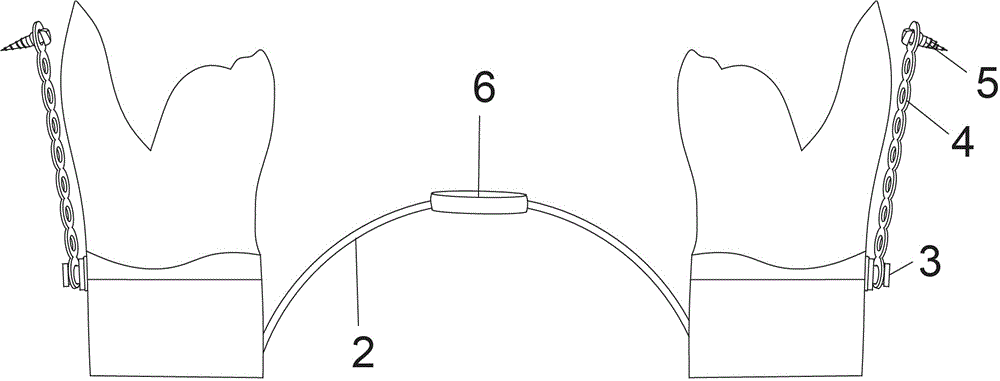

Device for integrally lowering posterior tooth segments

The invention discloses a device for integrally lowering posterior tooth segments. The device comprises two diastema pads and a casting stent, wherein the two diastema pads are fixed on left and right posterior tooth segments on two sides by adhesives; the casting stent is used for connecting the two diastema pads; a towing hook is arranged on a cheek side of each diastema pad; a rubber chain is suspended on each towing hook; the other end of each rubber chain is suspended on a mini-screw implanted into an infrazygomatic crest. The device has the advantages that the posterior tooth segments can be integrally lowered, few screws are implanted, both left and right posterior tooth segments are integrally pressed, the phenomenon that the left and right posterior tooth segments are uneven can be avoided, and the action force totally comprises three parts which are composed of tension force generated by the rubber chains, occlusal force generated by teeth on upper and lower jaws and pressure generated by the tongue.

Owner:宁波口腔医院集团有限公司

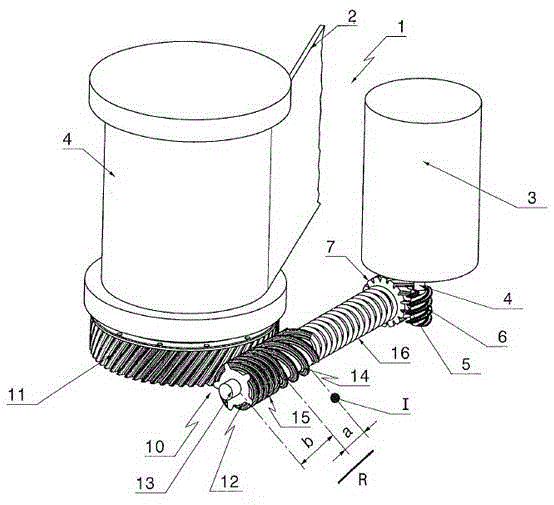

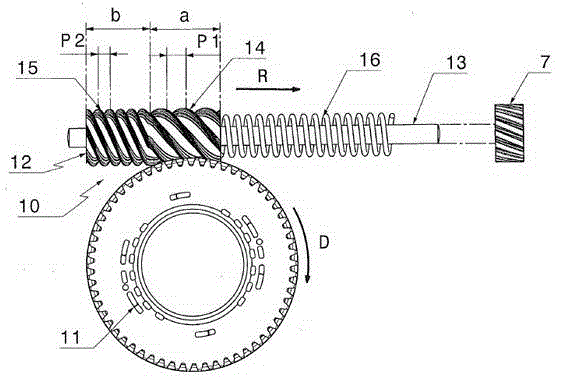

Driving device for safety belt tensioner

ActiveCN104074941AIdeal transmission coefficientHigh transmission coefficientBelt retractorsGearingAxial displacementDrive wheel

The invention relates to a safety belt tensioner driving device for tightening of a safety belt which can wind around a winding shaft. The safety belt tensioner driving device comprises a main shaft driven by a driving unit and a worm transmission device with a worm and a driven wheel. The worm is installed on the main shaft in a non-rotating mode. The driven wheel is installed on the winding shaft in a non-rotating connecting mode and is engaged with the worm. According to the invention, the worm includes a first tooth segment in the shape of a first toothed gear, and at a first position of the worm, the first tooth segment is engaged with the driven wheel. The worm includes at least one second tooth segment in the shape of a second gear. The second tooth segment is behind the first tooth segment. The shapes of the two tooth segments are designed to be identical. Axial displacement between the first position and the second position occurs to the worm when the worm is under an axial force. At the first position, the worm is engaged with the driven wheel through the first tooth segment. At the second position, the worm is engaged with the driven wheel through the second tooth segment.

Owner:IMS GEAR SE & CO KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com