Gearing

A technology of transmission device and transmission ratio, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc. It can solve the problems of poor efficiency of harmonic drive transmission device, low torsional stability, and no flexible spline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

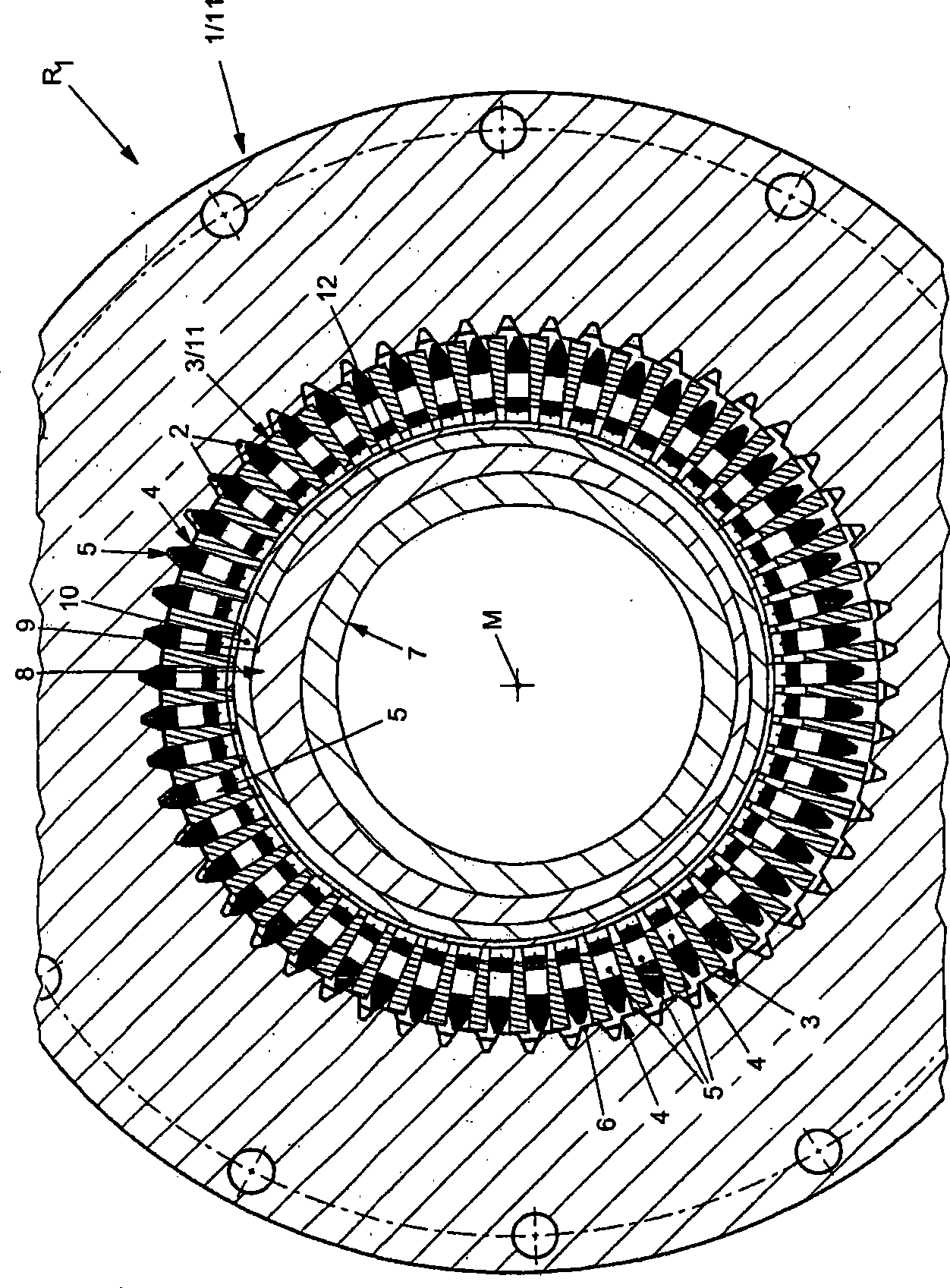

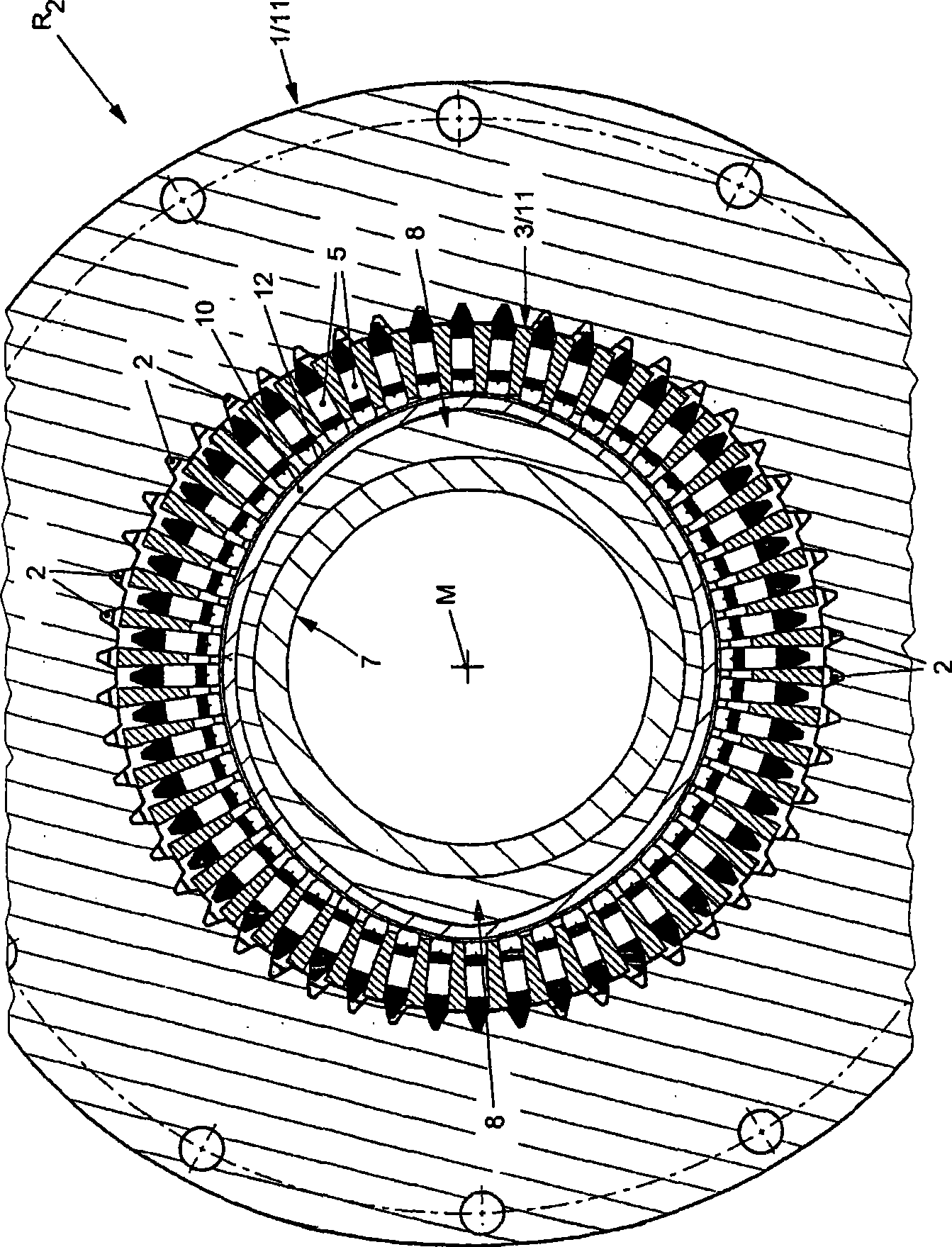

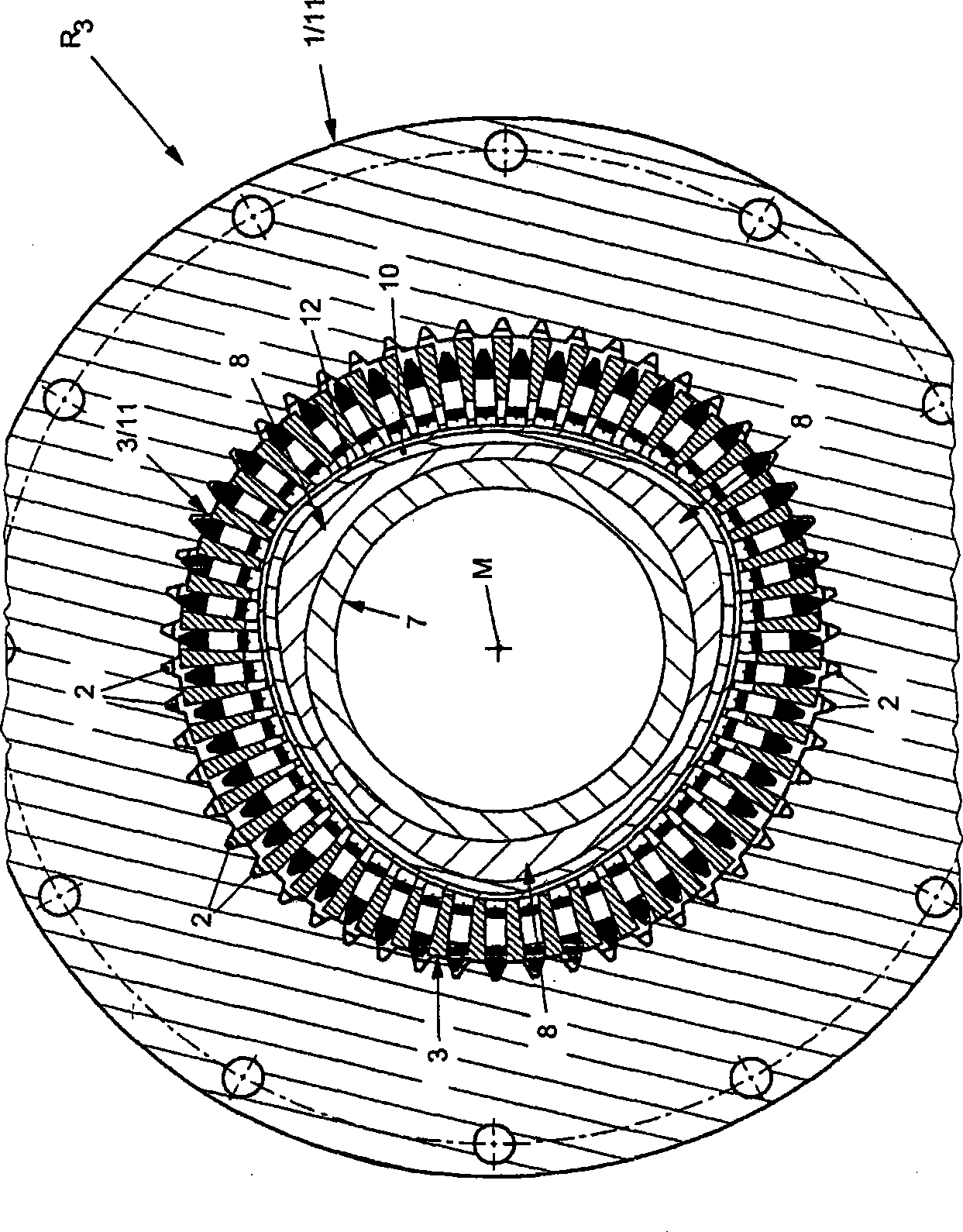

[0059] according to figure 1 , the transmission R configured as a coaxial transmission 1 There is an internal gear 1 with built-in teeth 2 .

[0060] Inside the internal gear 1 is mounted an element 3 in a ring-shaped manner, wherein a plurality of sector gears 5 (Zahnsegment) are mounted in the ring-shaped arrangement of the elements 3, the sector gears 5 being mounted radially side by side and mounted on corresponding guides 4 (Fuehrung). The sector gear 5 is installed in the guide 4 in a reciprocating manner in the radial direction, and is provided with a tooth profile 6 on one end.

[0061] Inside the element 3 that accommodates the sector gear 5 is provided a drive element 7 that is configured as a shaft or a hollow shaft that has a profiler 8 (Profilierung) that has, for example, a profile, a protrusion And it is polygonal or cam-shaped.

[0062] If necessary, a bearing 10 is provided between the outer contour 9 of the shaping device 8 of the drive element 7 and an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com