Variable-wall-thickness flexible gear of harmonic reducer

A harmonic reducer and variable wall thickness technology, used in instruments, belts/chains/gears, portable lifting devices, etc., can solve the complex load of the flexible wheel, increase the fatigue failure of the flexible wheel, and affect the life of the harmonic reducer. and other problems to achieve the effect of reducing the risk of fatigue failure, reducing fatigue stress, and improving the life of the flexible wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

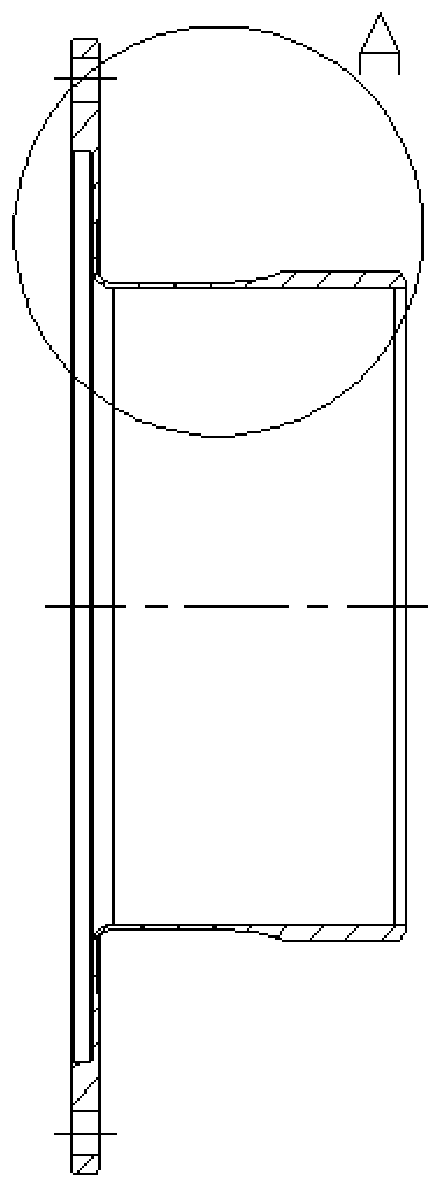

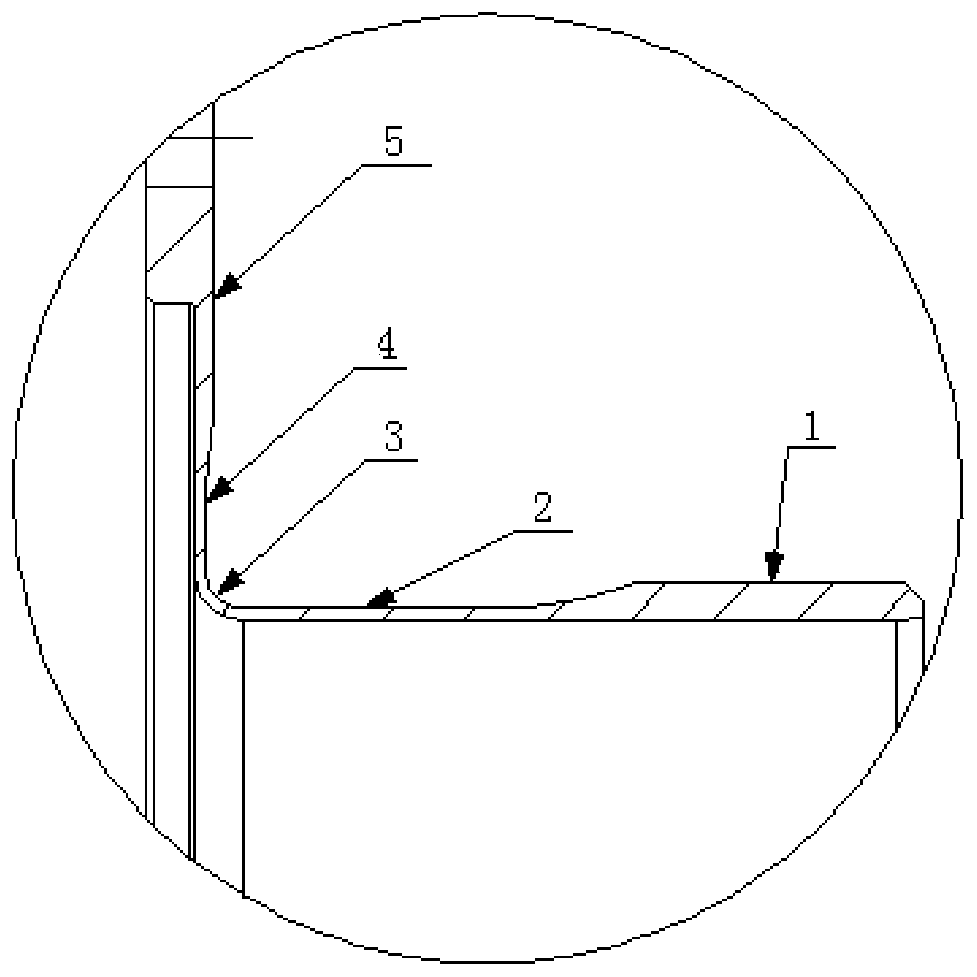

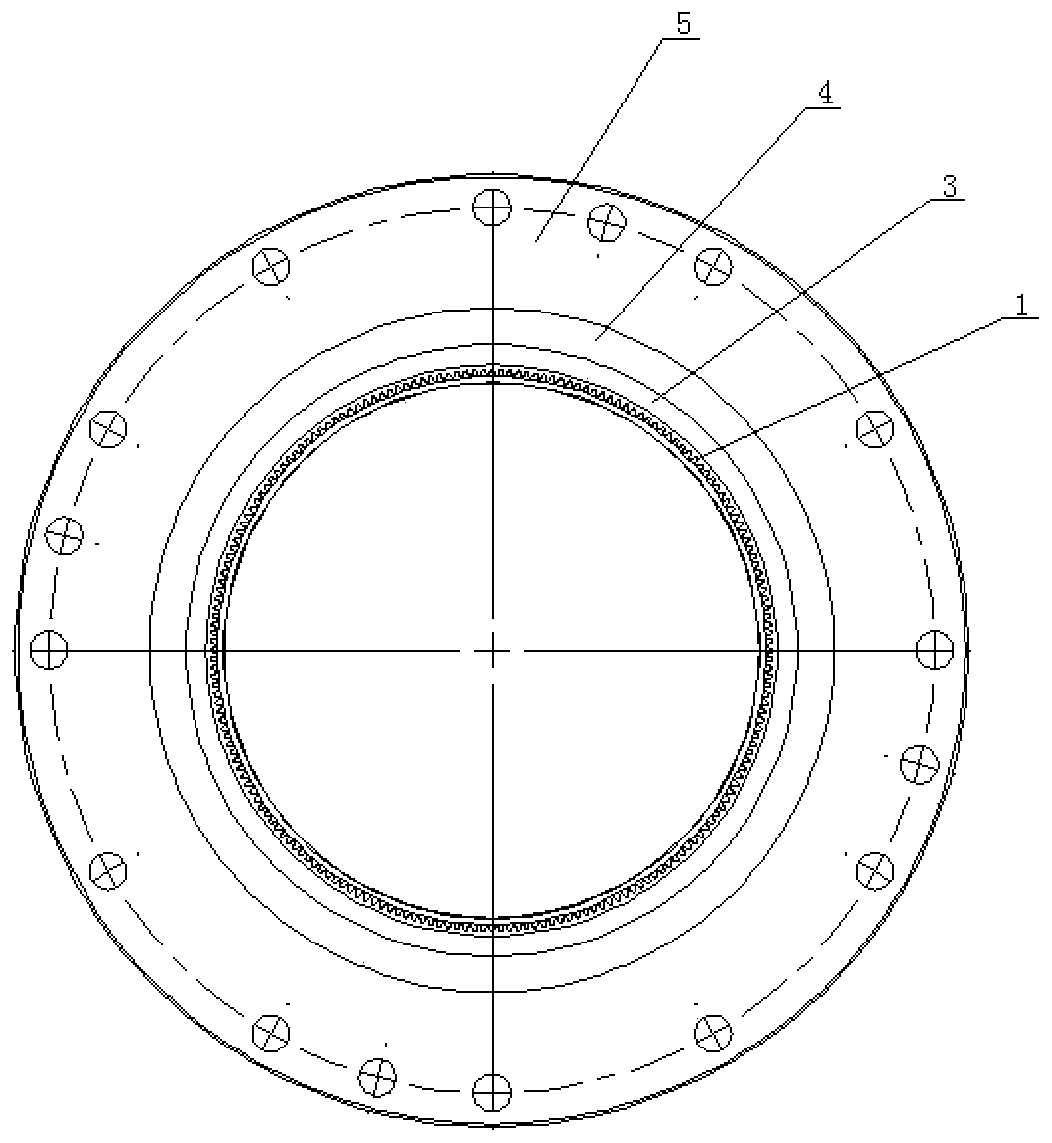

[0016] Such as Figure 1 to Figure 4 As shown: the present invention is integrally formed by a harmonic tooth section 1, a constant wall thickness section 2, a circular arc transition section 3, a variable wall thickness section 4 and a flange section 5, one side of the constant wall thickness section is connected to the One side of the harmonic tooth section is fixedly connected, the other side of the constant wall thickness section is fixedly connected with the inner circle of the variable wall thickness section through the arc transition section, and the outer circle of the variable wall thickness section It is fixedly connected with the inner circle of the flange segment.

[0017] Preferably, the thickness of the section with constant wall thickness is one-third of the thickness of the harmonic gear section.

[0018] Preferably, the thickness of the variable wall thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com