Novel bolted fastener for urban rail transit

An urban rail transit and bolt technology, applied in the field of rail transit, can solve the problems of clip withholding loss, failure, breakage and flying out of clip clips, etc., and achieves low vibration amplitude, small deformation, and extended clip fatigue life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

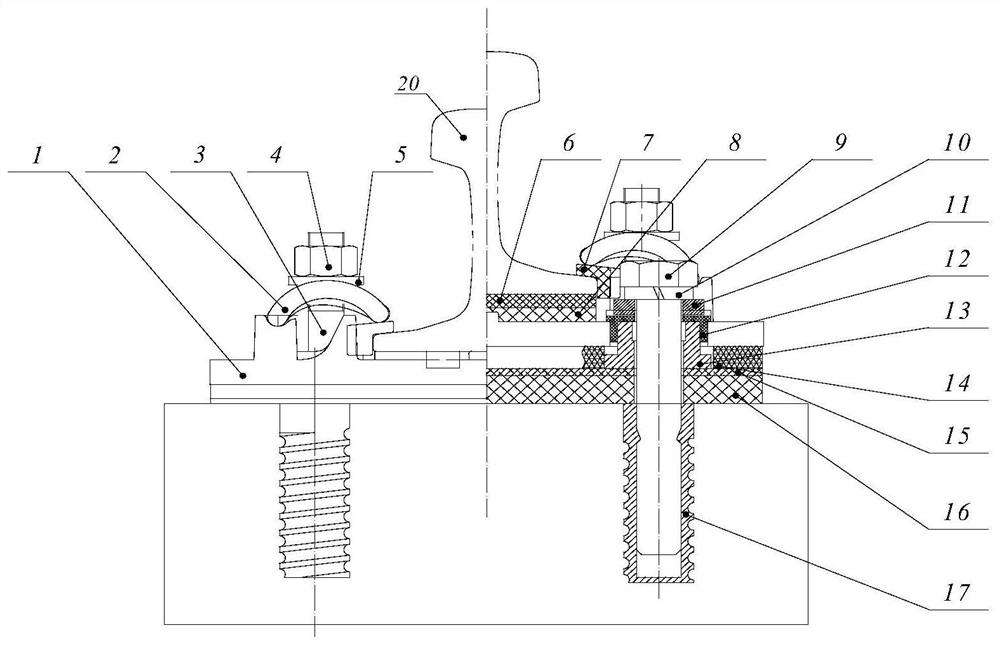

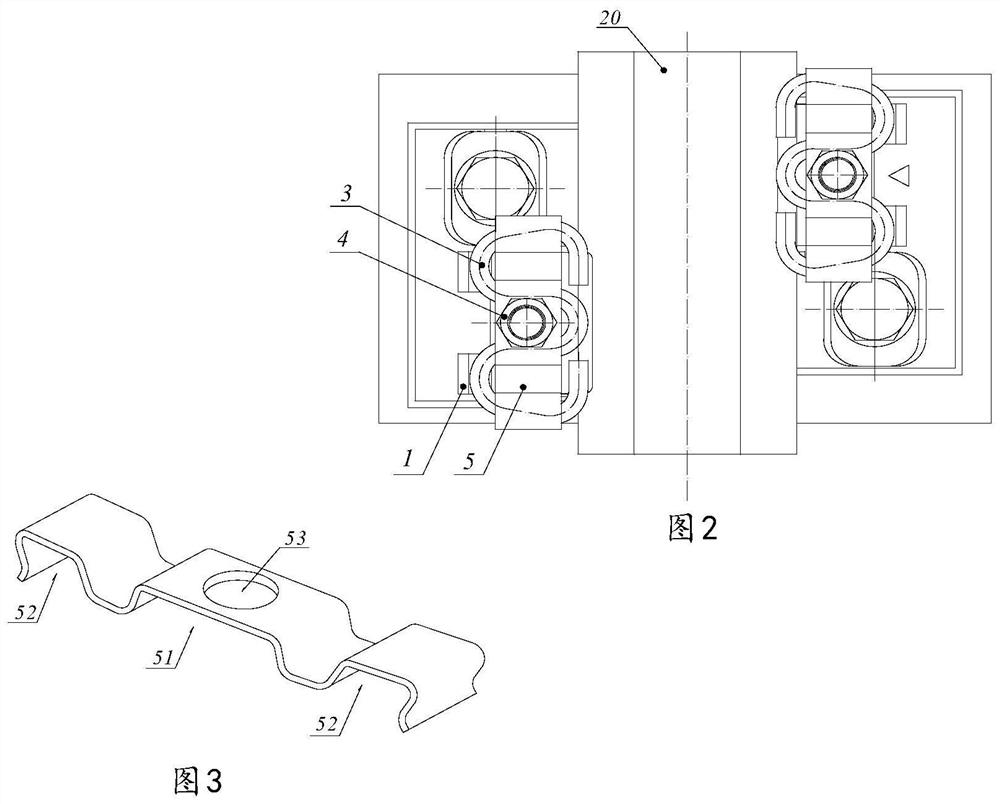

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] refer to figure 1 , figure 2 , a new type of bolted fastener for urban rail transit of the present invention includes an iron backing plate 1, an elastic strip 2, an elastic backing plate 6 under the rail, a T-shaped bolt 3, a lock nut 4, and a special-shaped anti-flying flat washer 5 and insulation gauge block 7. The iron backing plate 1 is installed and fixed on the under-rail foundation by anchor bolts 9, the under-rail elastic backing plate 6 is arranged under the bottom surface of the iron backing plate 1, and the steel rail 20 is located on the iron backing plate 1. The rail 20, the elastic backing plate 6 under the rail, the elastic strip 2, and the iron backing plate 1 can be regarded as the overall structure and vibrate synchronously. The vibration amplitude of the rail and the elastic strip is low, the deformation is small, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com