Sequential-production zipper H-shaped stopper assembling machine

An assembly machine and I-code technology, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of low production efficiency, errors, and different lengths of chain teeth, and achieve a unified chain feeding direction, High production efficiency, continuous and uninterrupted production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

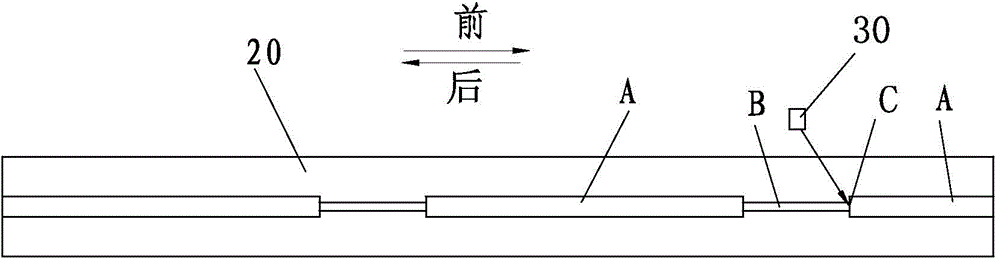

[0025] see figure 1 , the present invention is used to install the I-code 30 on the code-mounted zipper. The chain element segment A and the chain element space segment B are arranged at equal intervals on the chain belt 20. The length of the chain element segment A is designed according to the length of the product. The two chains The chain element segment A is between the tooth space segment B. The upper stop end of the chain element segment A faces, and the lower stop end of the chain element segment A should be installed with the I-code 30 as the bottom stop. The I-code 30 must be close to the chain teeth The back end chain tooth of section A is installed, and when chain belt 20 retreats, can make the rear end chain tooth rear side C of chain element section A offset with I-character code 30.

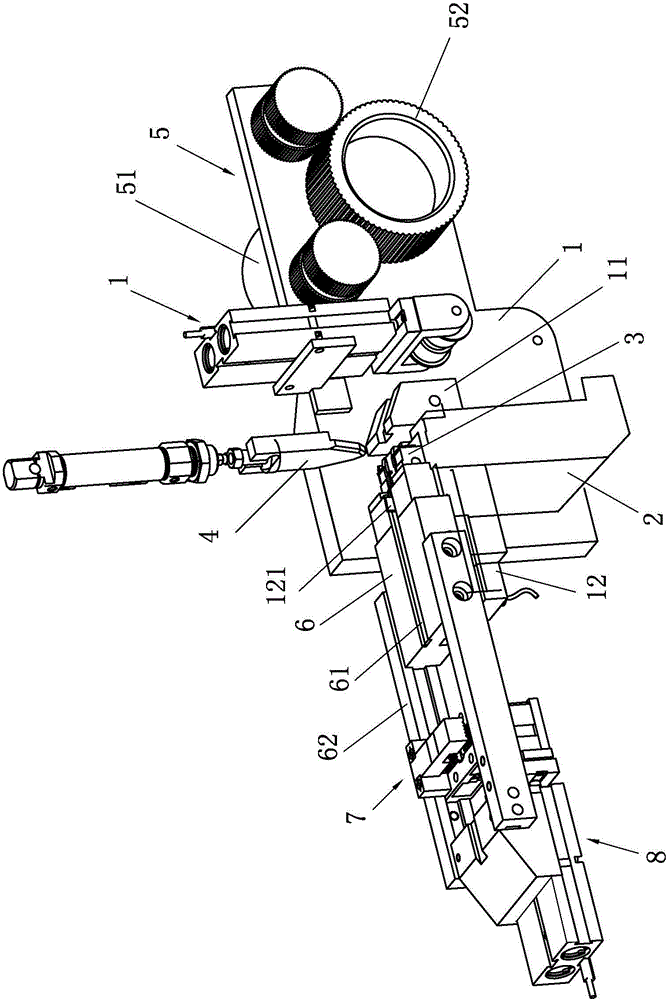

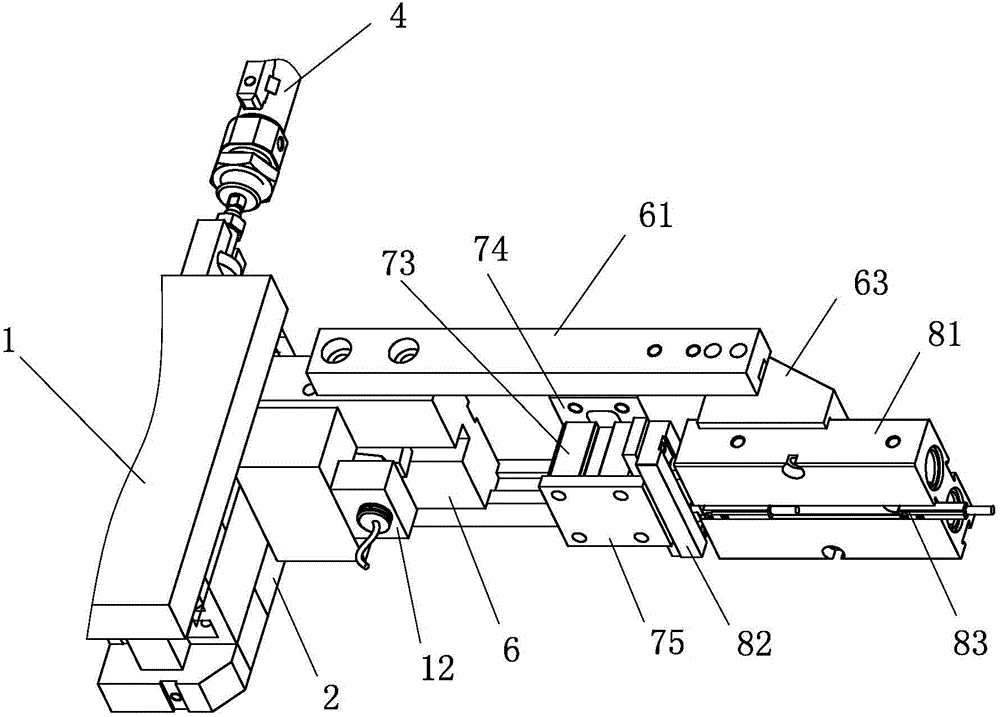

[0026] Such as Figure 2 to Figure 5 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com