Impact wrench and method for making same

A sleeve and roll making technology, applied in the field of sleeve and its manufacturing method, can solve the problems of large structural surface, high cost, deformation of processing places, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

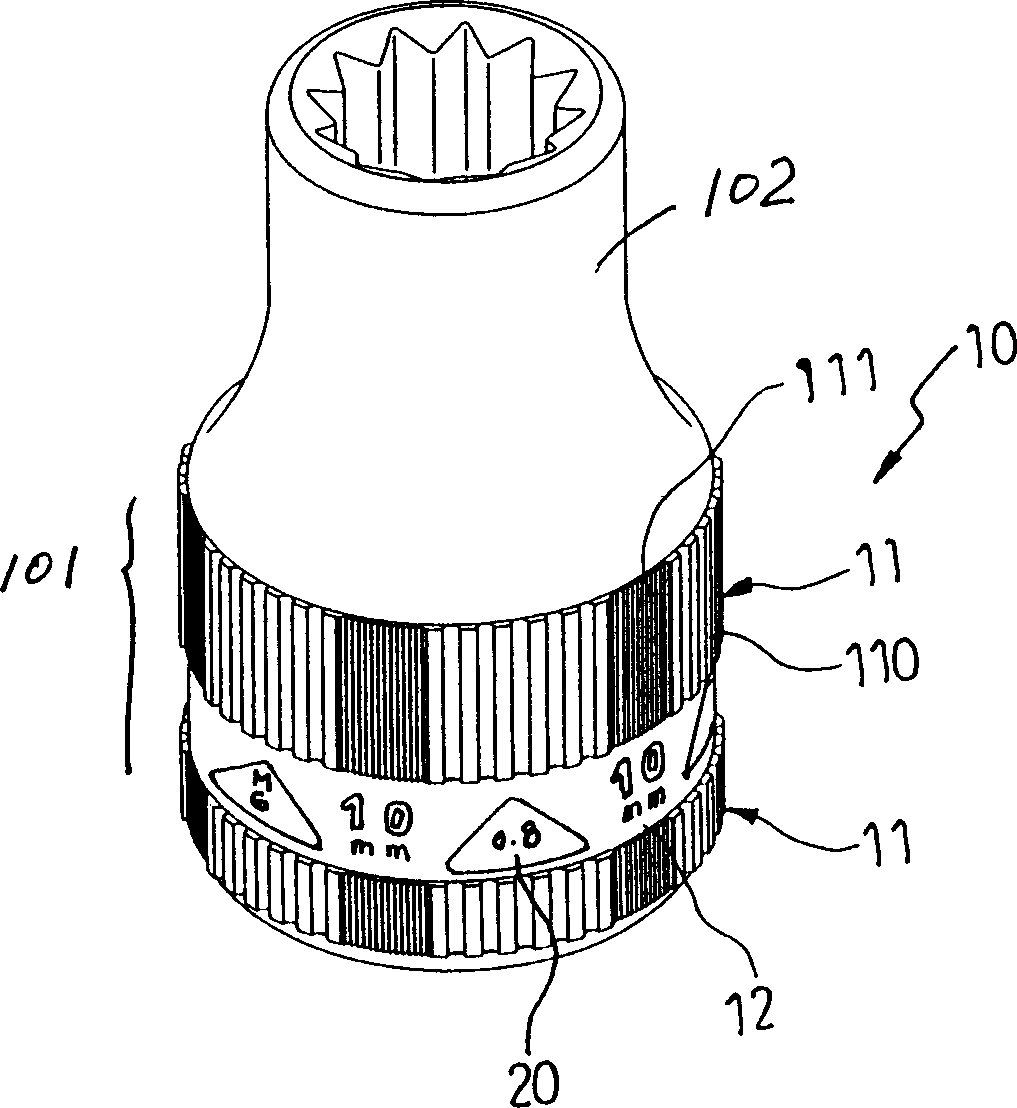

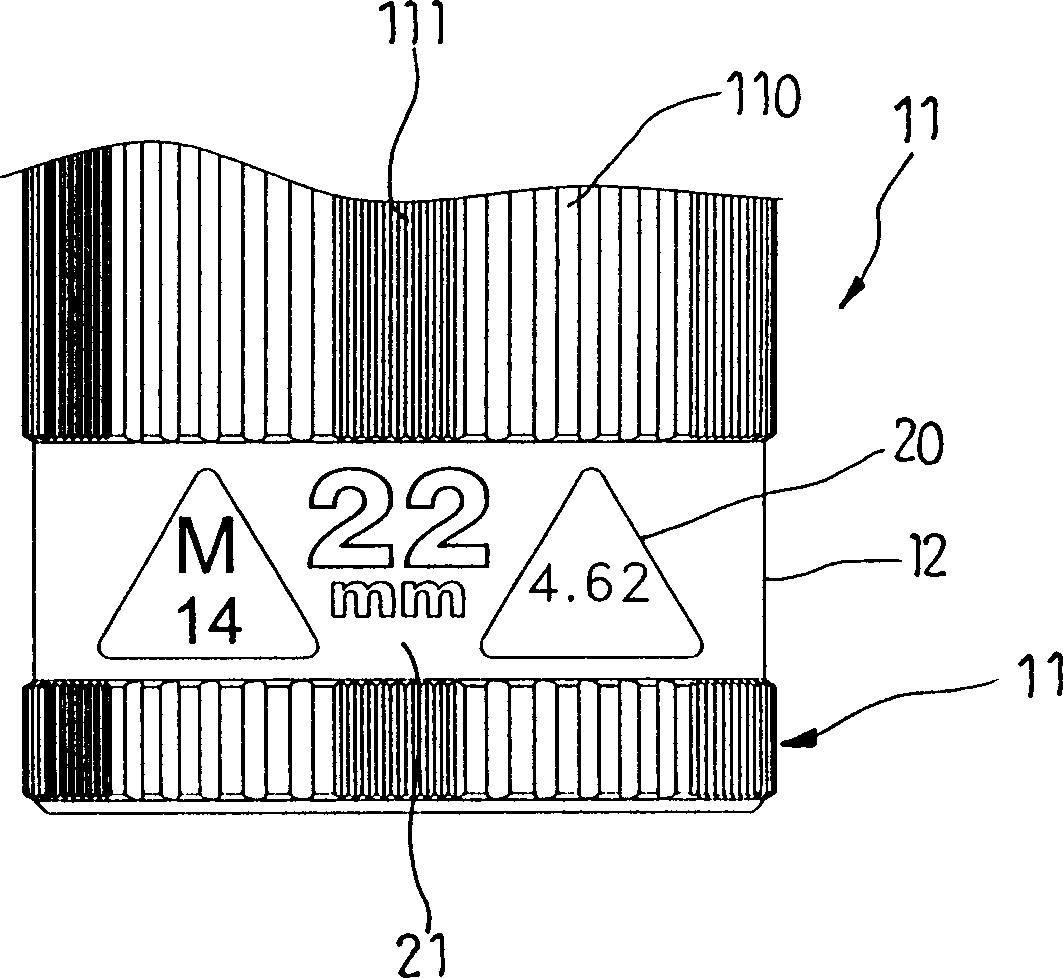

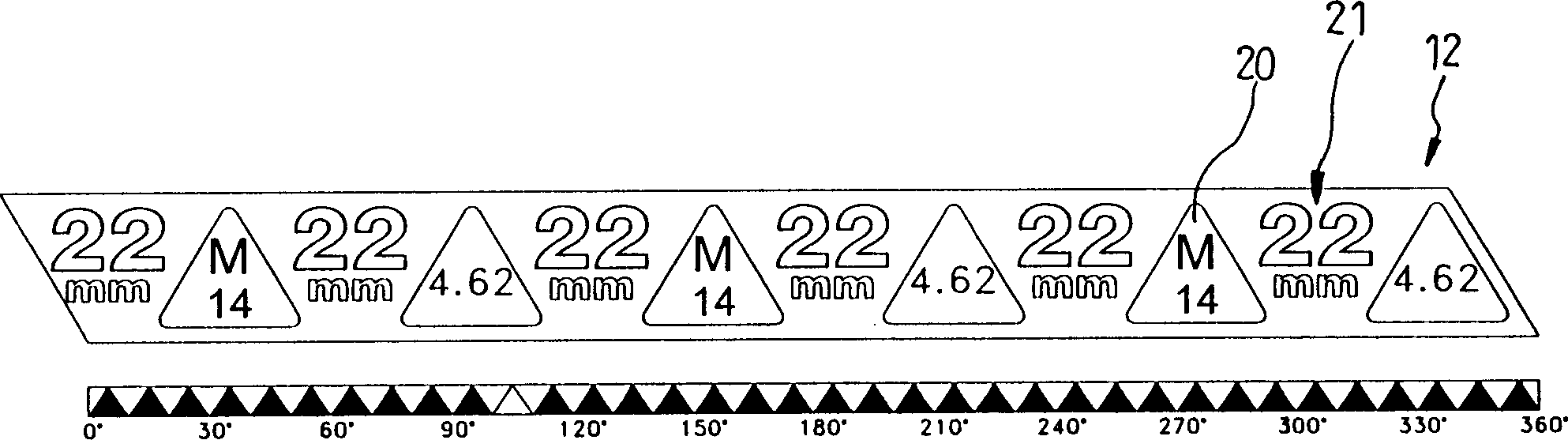

[0035] Please refer to figure 1 As shown, a sleeve of the present invention includes a sleeve body (10), the lower section of the sleeve body includes an isometric body (101), and the upper section can be set as a diameter-reducing section (102). The isometric body of the sleeve body The outer peripheral edge of the body (101) is provided with a detent part (11) and a marking part (12), the detent part (11) is located at both ends, and the detent part (12) is located between the detent parts (11) of the two ends the central section between. The detent part is provided with a continuous tooth-shaped part (110) and a spaced tooth-shaped part (111) with a lower arc surface and different tooth pitches and tooth shapes in equal parts, which can not only increase the aesthetic feeling of the overall appearance , can increase the overall practical performance, and the marking part (12) can be used to roll out a continuous marking body (20) for easy identification.

[0036] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com