Black water coking-preventing impact-resistant shockproof regulating angle valve special for coal chemical industry

An anti-coking, coal chemical technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of short service life, poor action, poor dynamic stability of the valve, etc., to improve the anti-scour ability, improve the movement stability, The effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

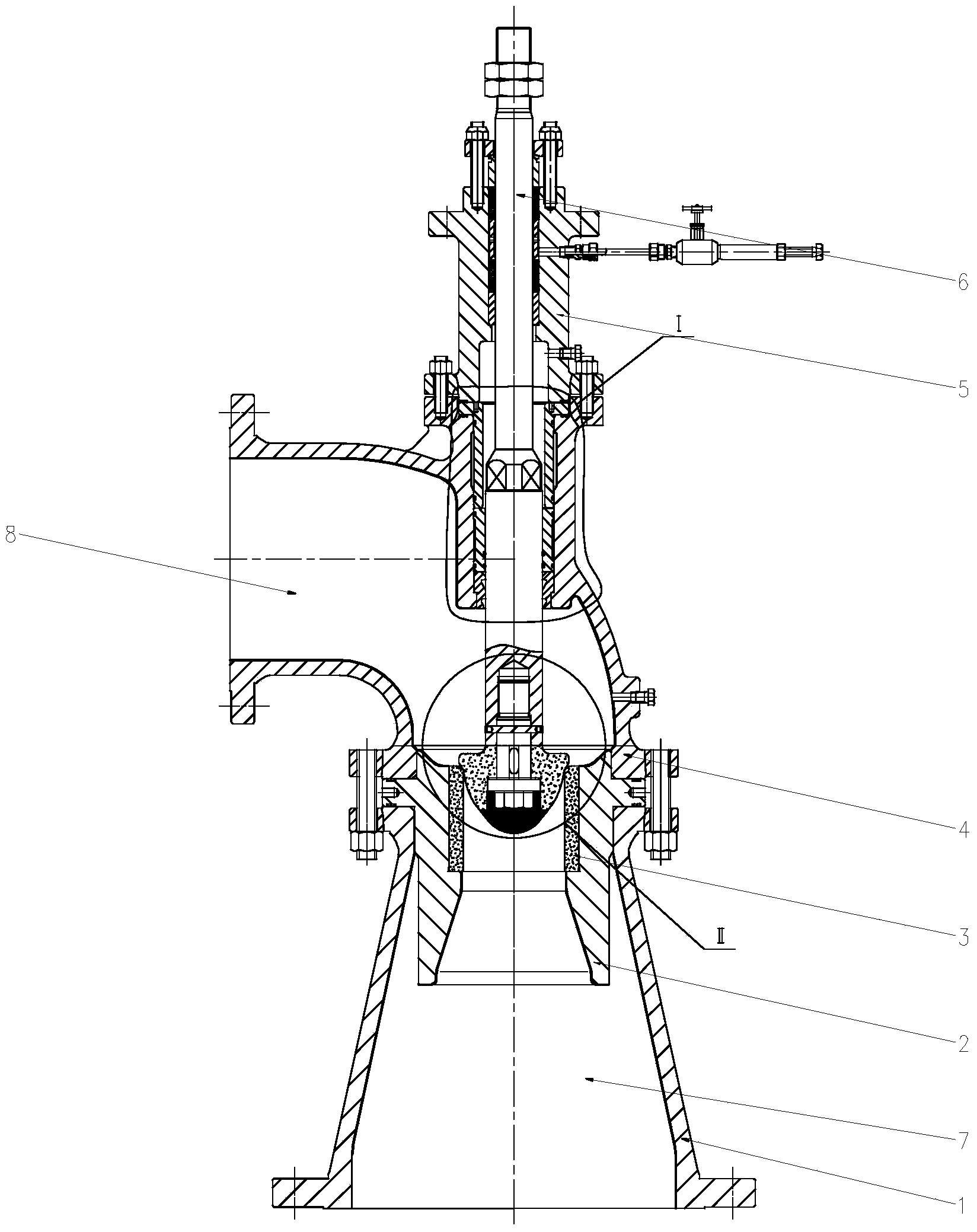

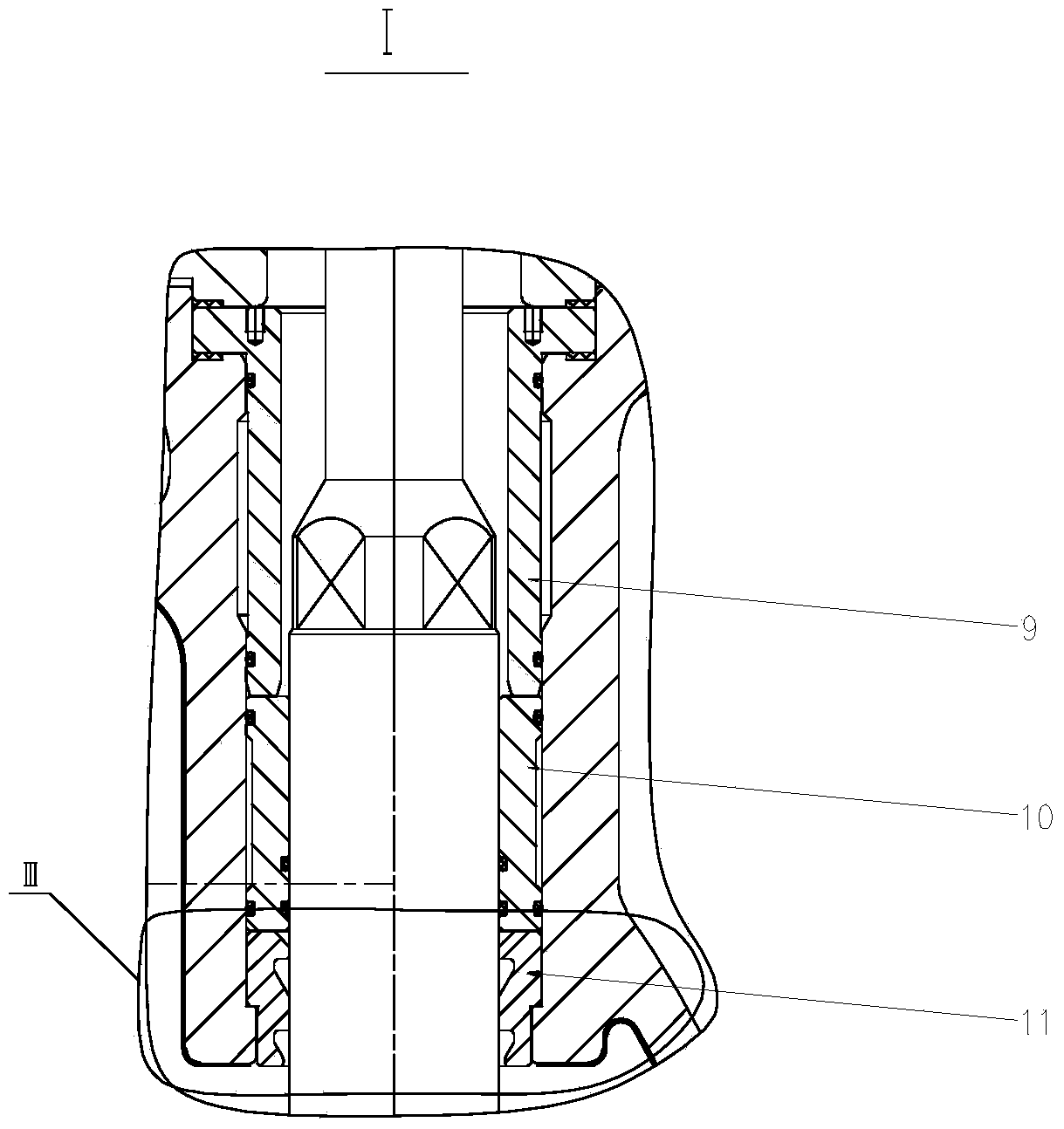

[0027] Such as Figure 1~2 As shown, the present invention mainly includes a diffusion pipe 1 and a valve body 4, the upper end of the valve body 4 is connected to the upper cover 5 by bolts, and the lower end of the valve body 4 is connected to the diffusion pipe 1 by bolts. The valve body 4 is provided with an inlet channel 8, and the diffusion pipe 1 is provided with an outlet channel 7, the inlet channel 8 and the outlet channel 7 are connected to each other, and the inlet channel 8 and the outlet channel 7 are perpendicular to each other. The surfaces of the inlet channel 8 and the outlet channel 7 are provided with tungsten carbide coating. The diffusion tube 1 is a Venturi tube structure.

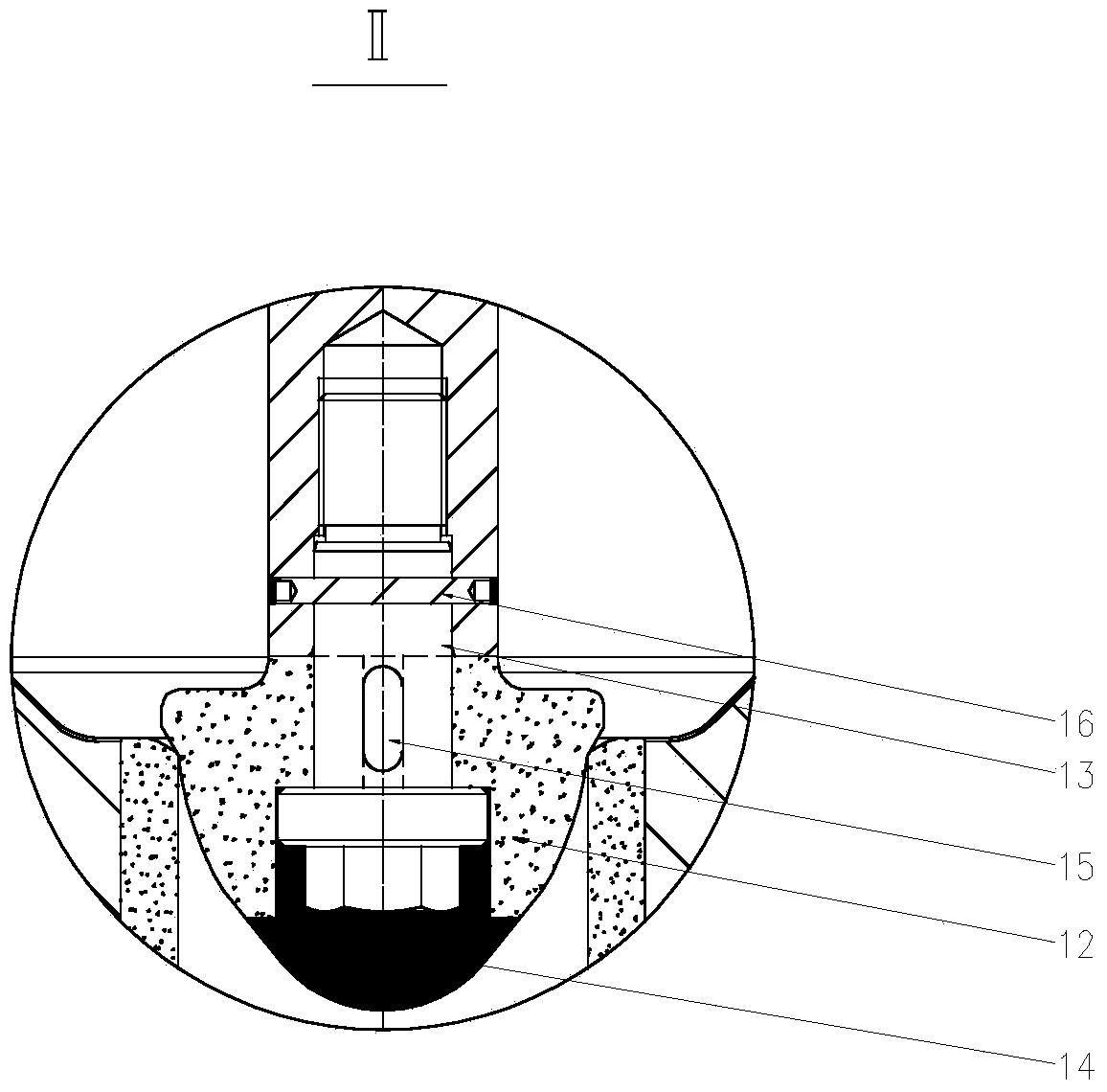

[0028] The outlet channel 7 is provided with a valve seat base 2 , and the valve seat base 2 is clamped by the diffuser pipe 1 and the valve body 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com