Method for controlling isothermal precision formed forging flow line of complicated disk cake forging

A control method and precision forming technology, applied to vehicle parts, transportation and packaging, wheels, etc., can solve problems such as streamline outcropping, eddy current and through-flow, so as to prevent eddy current or through-flow defects, improve mechanical properties and anti-fatigue performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

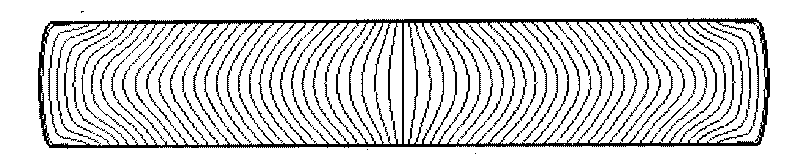

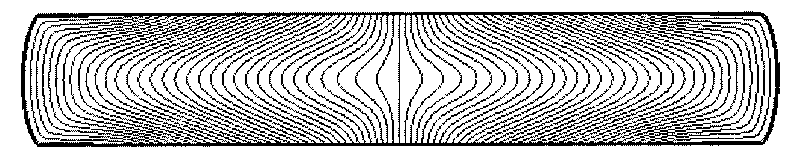

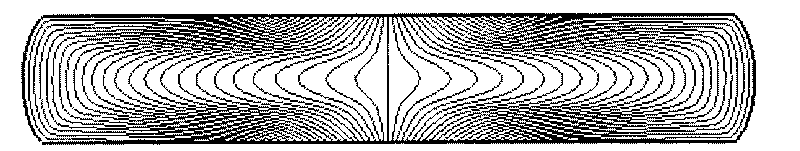

[0018] Specific implementation mode 1: As shown in Figures 1 to 5, the specific process of the forging streamline control method for the isothermal precision forming of complex disc cake forgings described in this implementation mode is as follows:

[0019] A. Upsetting billet making stage: select the original billet according to the geometric dimensions of the pre-designed complex disc cake forging, and change the streamline distributed along the axial direction of the original billet into the streamline distributed along the ring or radial direction ( The original blanks of complex disc cake forgings in isothermal precision forming generally choose bars whose streamlines are distributed along the axial direction):

[0020] The original blank (bar) used to form complex disc cake forgings is heated to a temperature above the recrystallization temperature of the material used and below the melting point, and after heat preservation, it is placed on a flat anvil mold heated to th...

specific Embodiment approach 2

[0030] Specific embodiment two: In step C of this embodiment, the way to increase the radial resistance is: for the forging with a hole in the center, no hole is opened in the center of the original billet or only a small hole with a diameter not greater than 20mm is opened, and the final forging die Center cored to increase the radial resistance at the bore. Prevent or greatly reduce the flow of metal along the radial direction to the center, and avoid the occurrence of flow-through defects. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: In step C of this embodiment, the way to increase the radial resistance is to increase the width and height of the flash bridge when designing the pre-forging, which can increase the flow of metal to the flash in the radial direction. Resistance, reducing the radial flow velocity of the metal, thereby avoiding the generation of flow-through defects. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com