Patents

Literature

349 results about "Axial distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

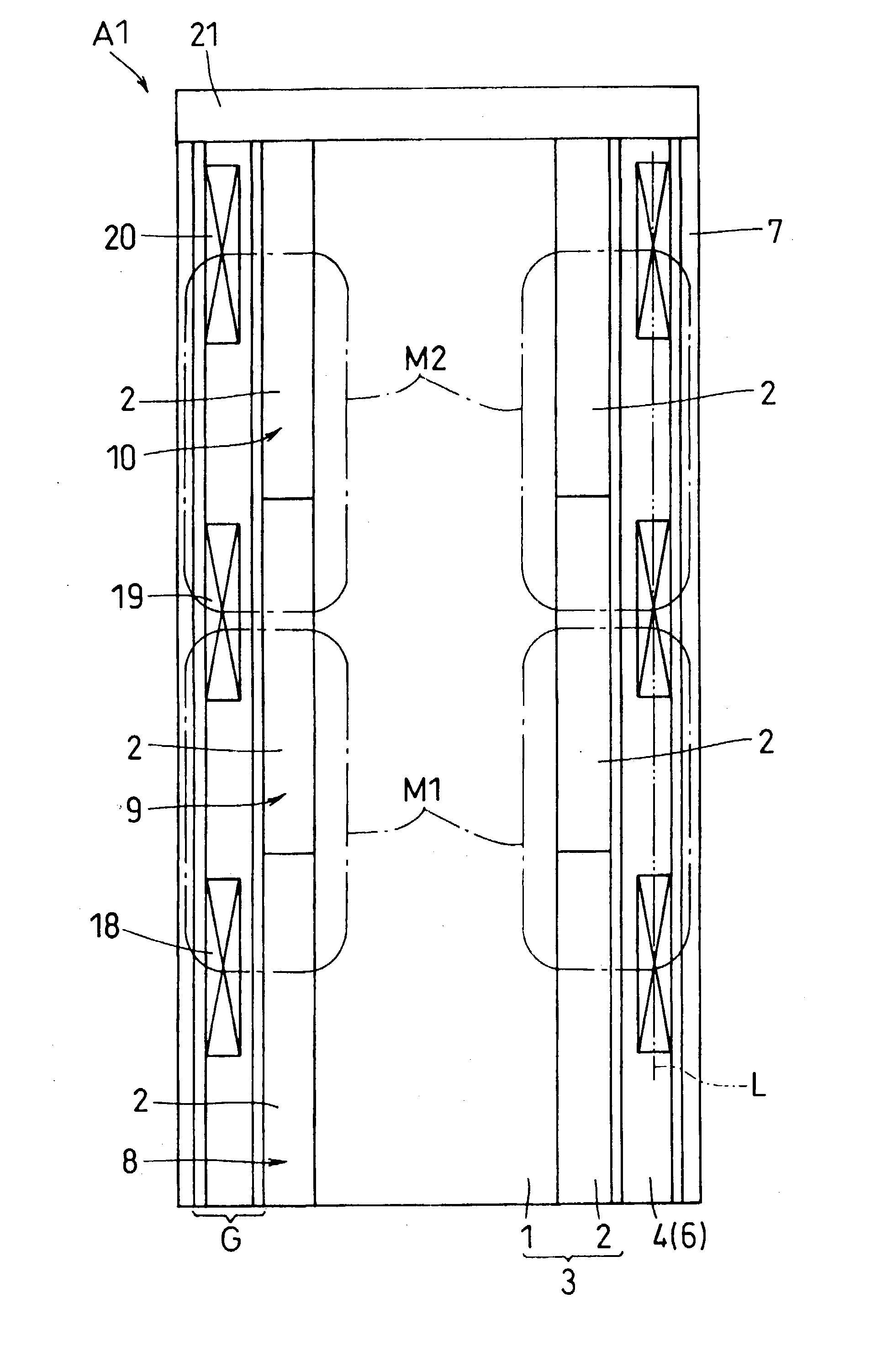

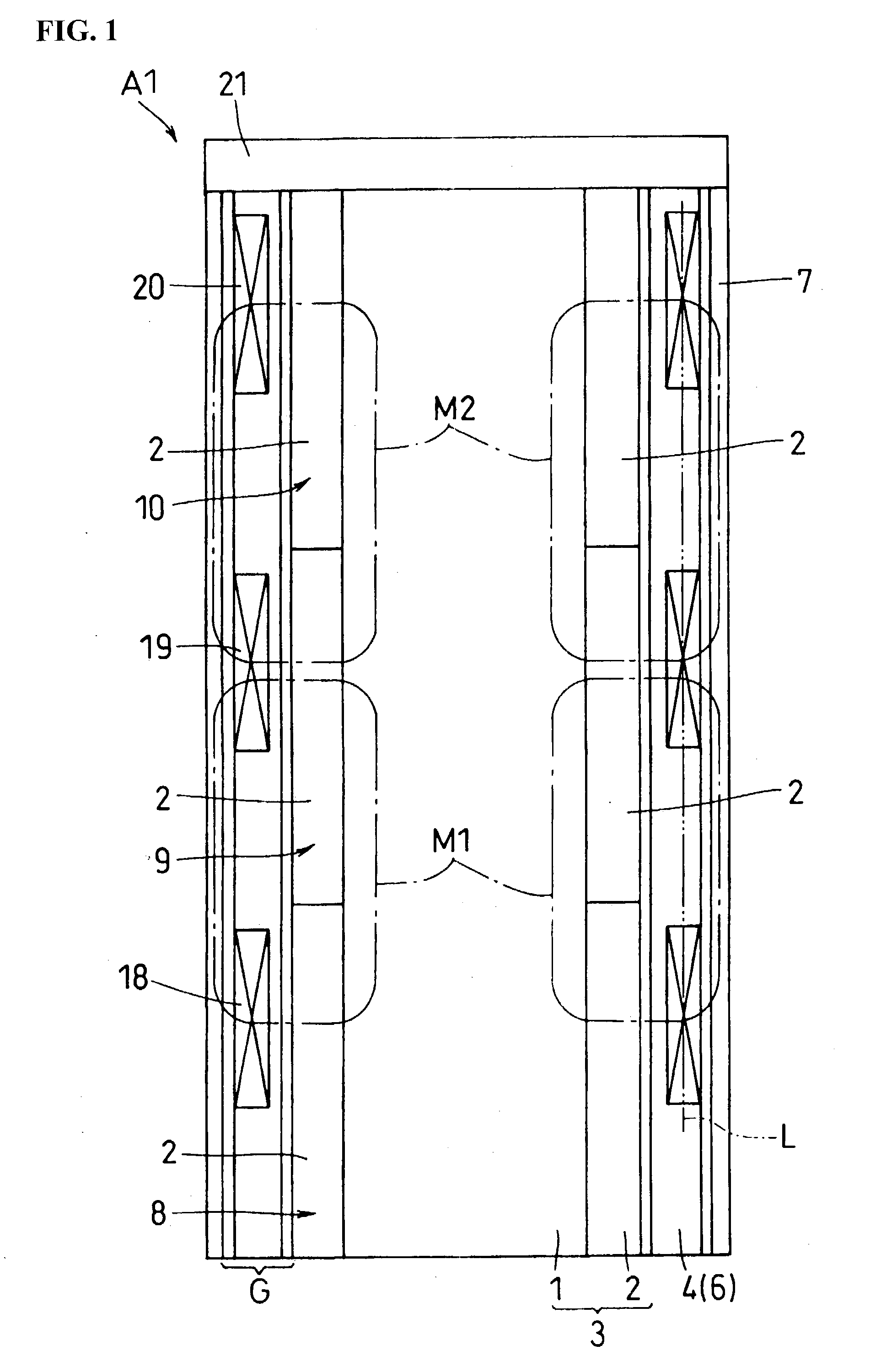

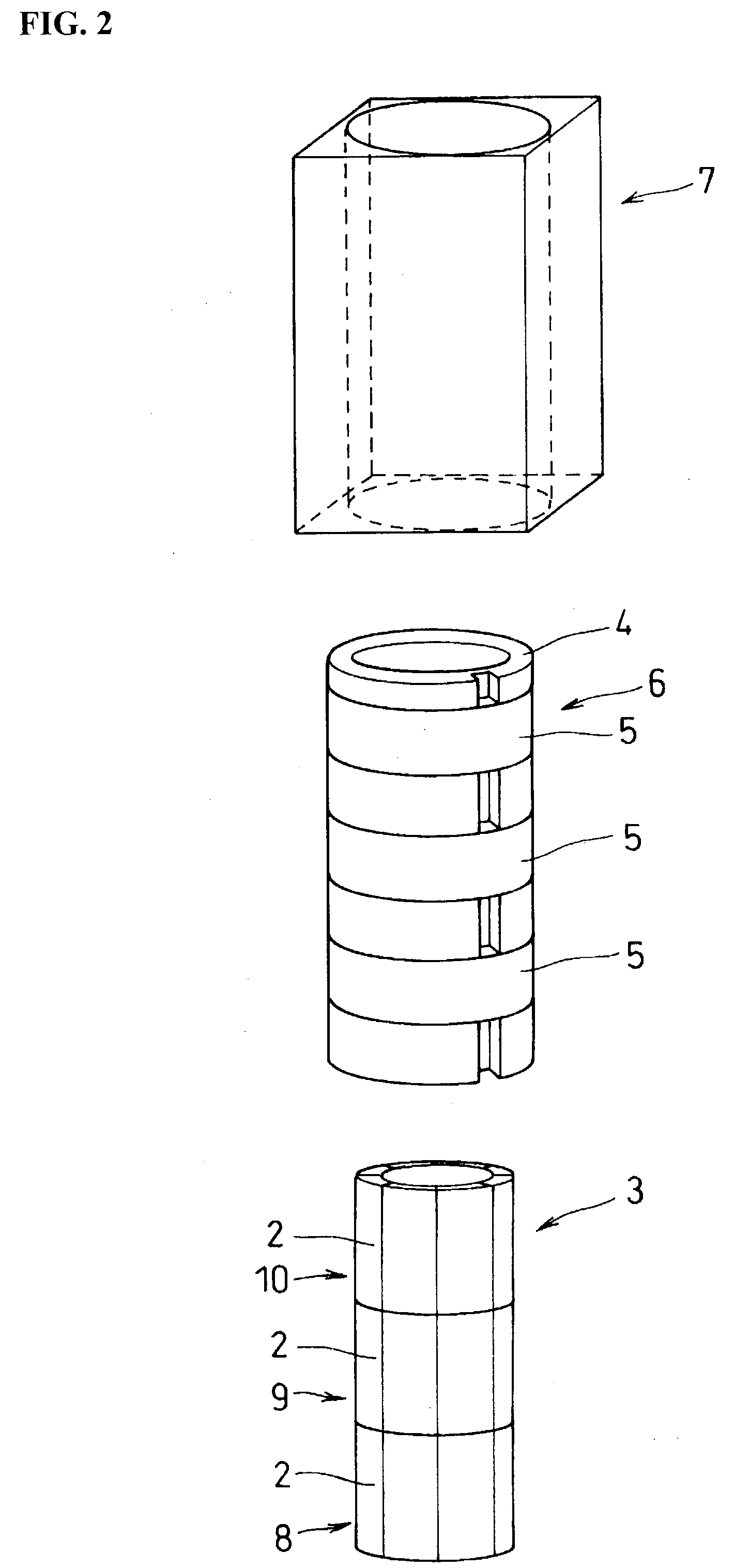

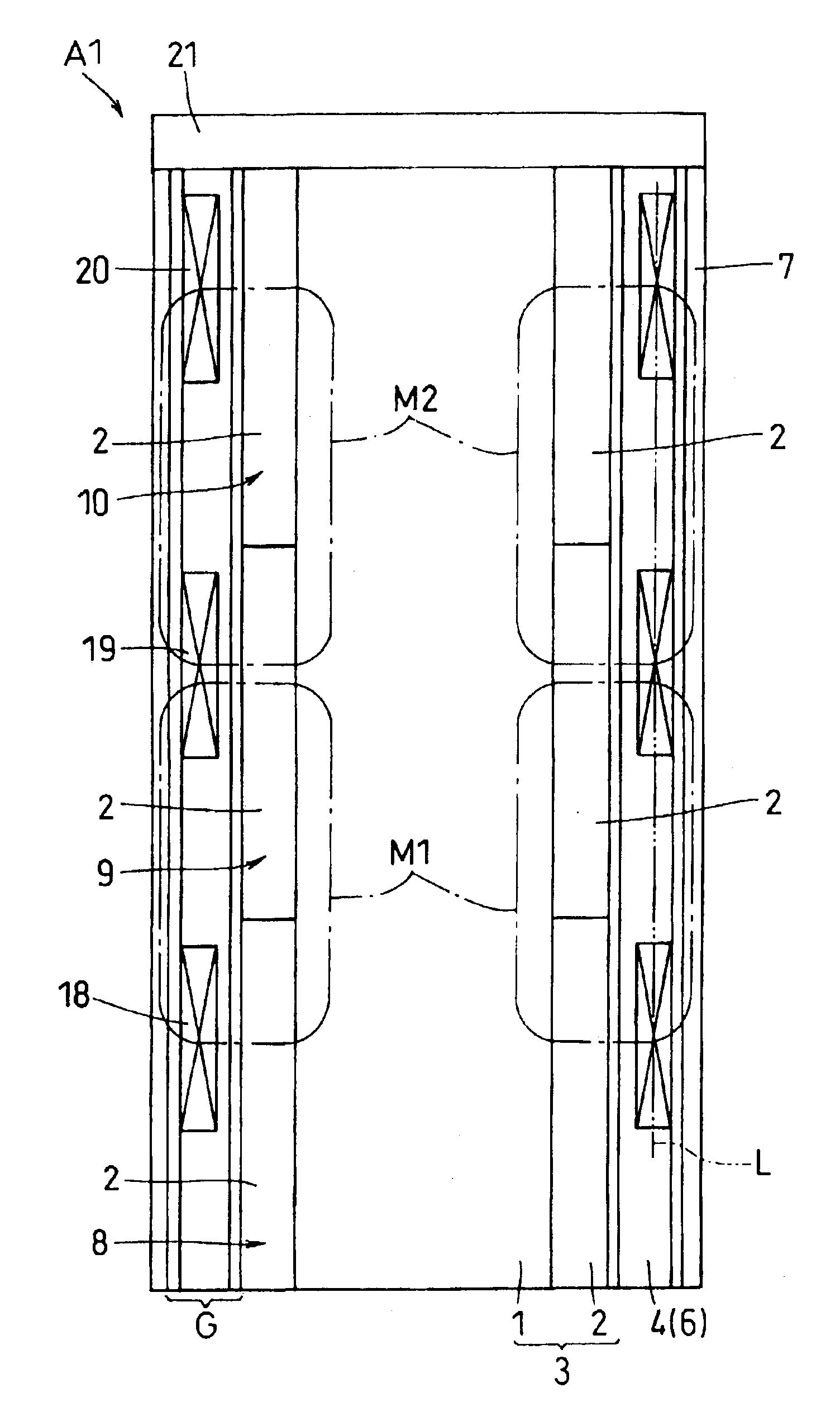

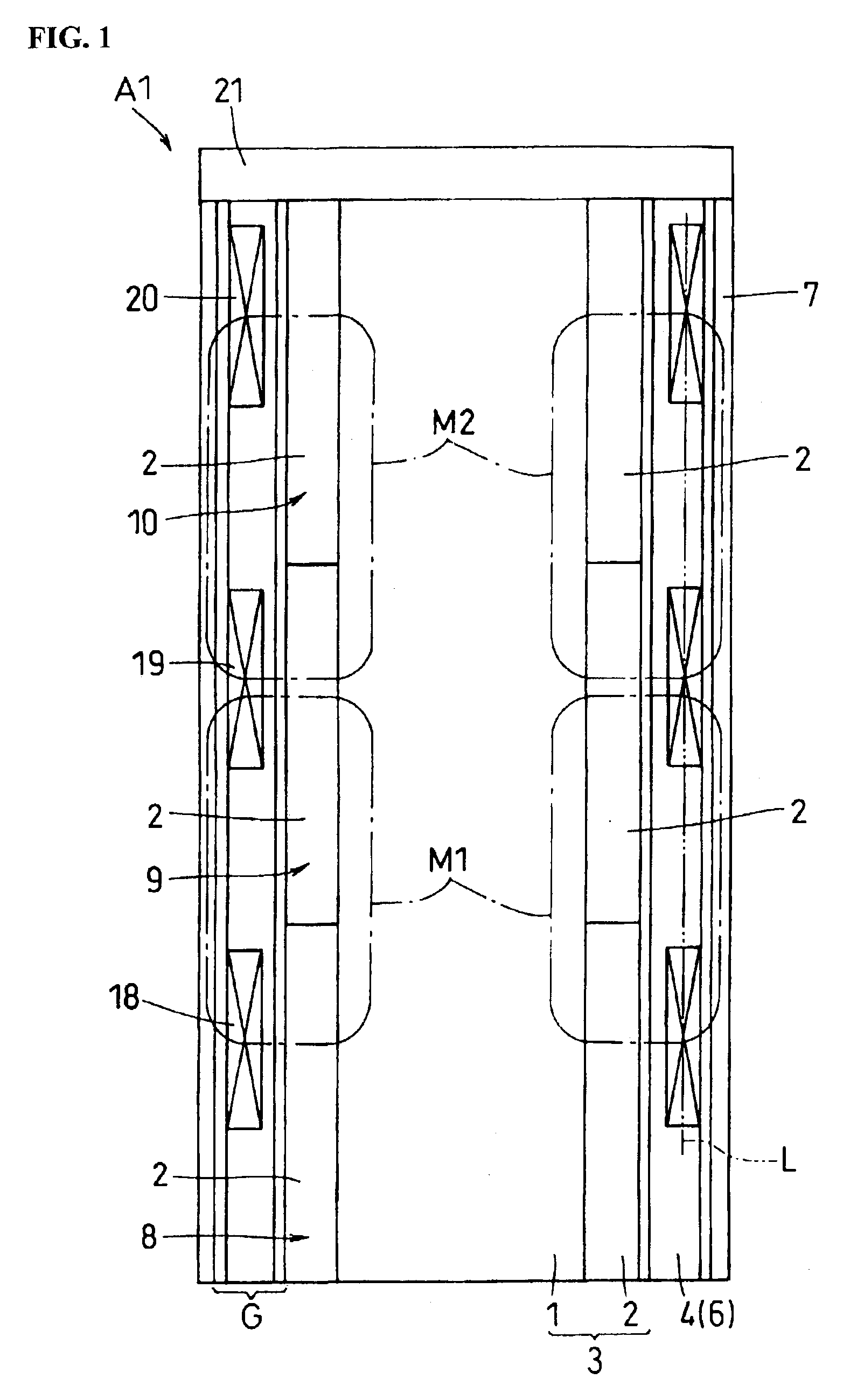

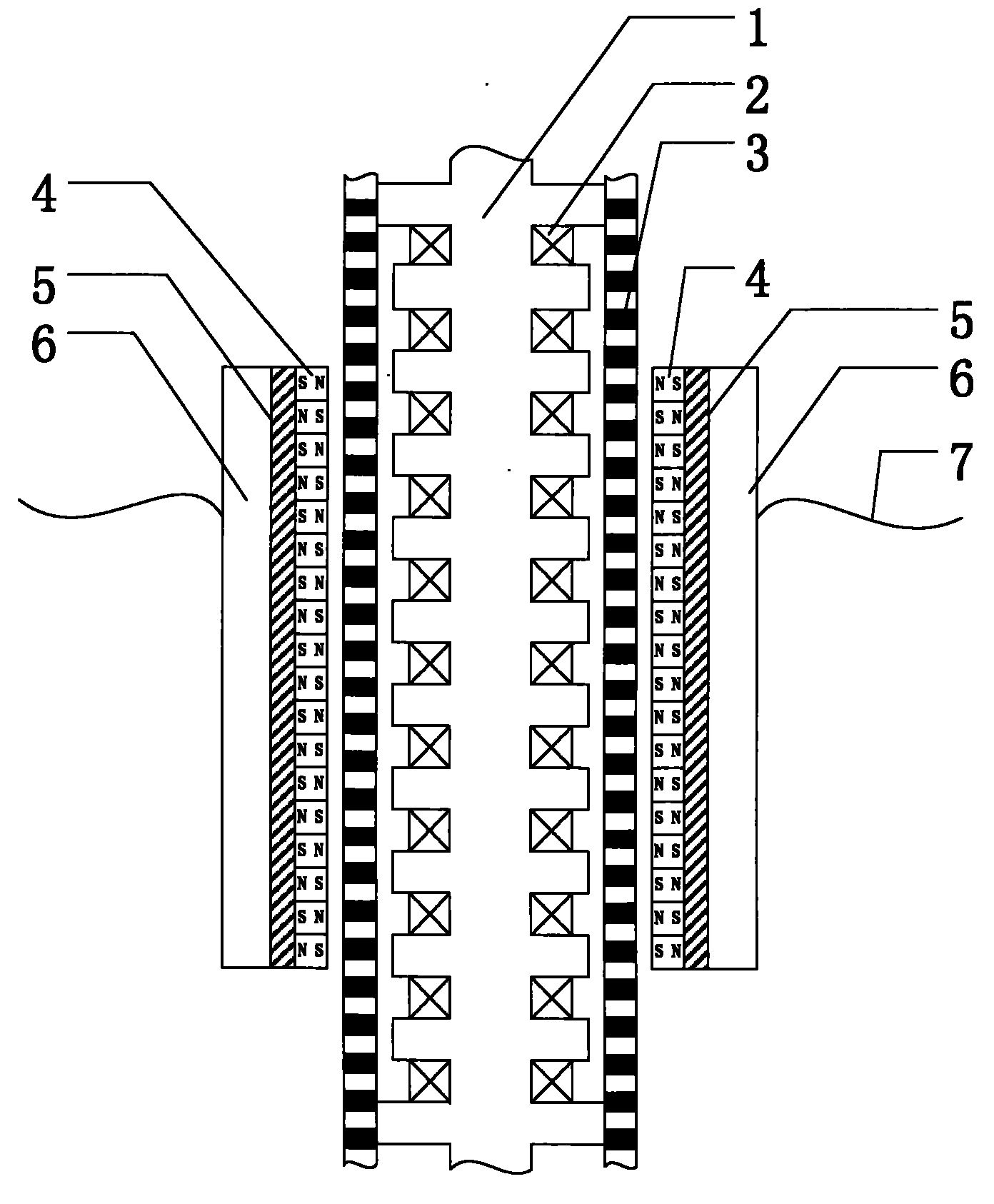

Voice coil linear actuator, apparatus using the actuator, and method for manufacturing the actuator

InactiveUS20030218391A1Reduce resistanceFew coilsElectrical transducersPropulsion systemsMagnetic polesEngineering

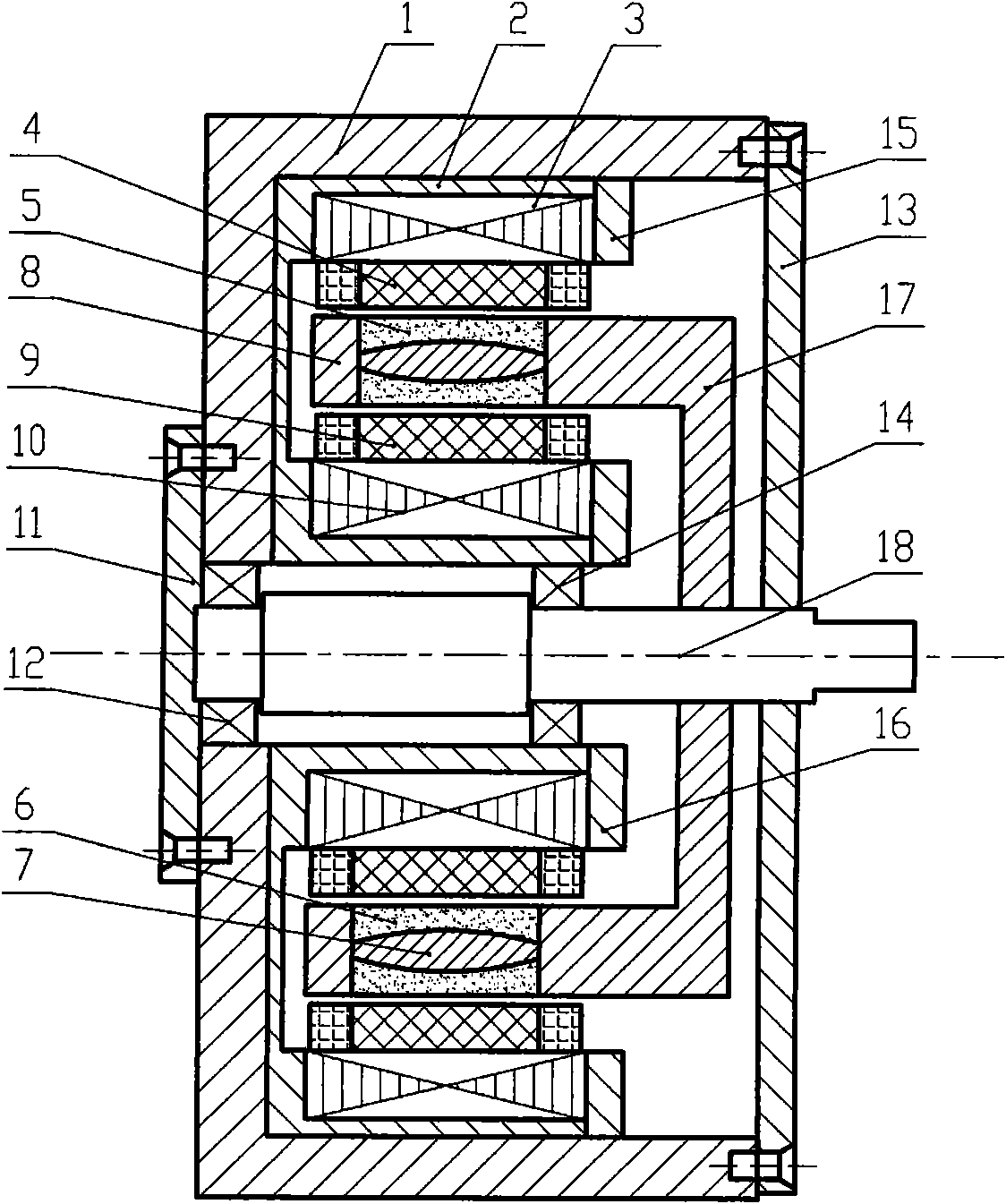

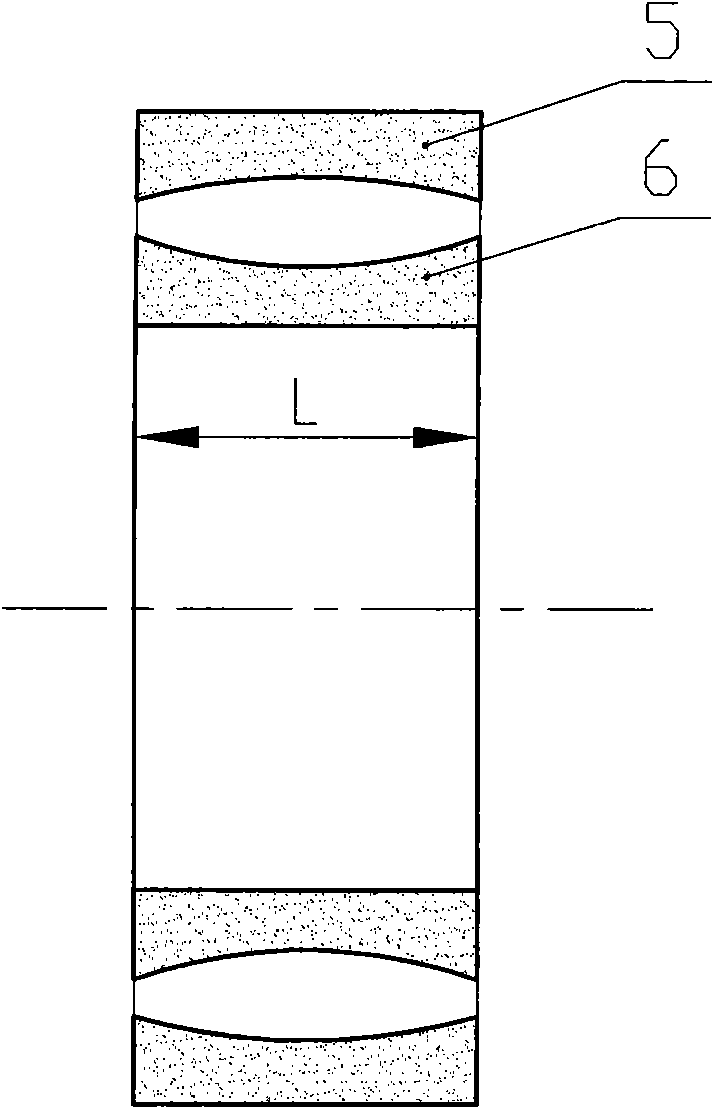

A voice coil linear actuator comprises: an axially-shaped center yoke formed of a ferromagnetic material; an armature coil concentrically disposed so as to move along the axial direction of the center yoke; and a plurality of ring-shaped permanent magnets which have N and S magnetic poles arranged in the radial direction thereof, and are disposed concentrically as to the armature coil. The armature coil has armature coil units distributed in at least three positions in the axial direction, with adjacent pairs of the armature coil units being arranged so that electric current flows through them in opposite directions, respectively. The permanent magnets are distributed in at least three positions in the axial direction at positions facing respective armature coil units in the radial direction. The respective directions of the N magnetic poles of adjacent permanent magnets are arranged facing in opposite directions.

Owner:MURATA MFG CO LTD

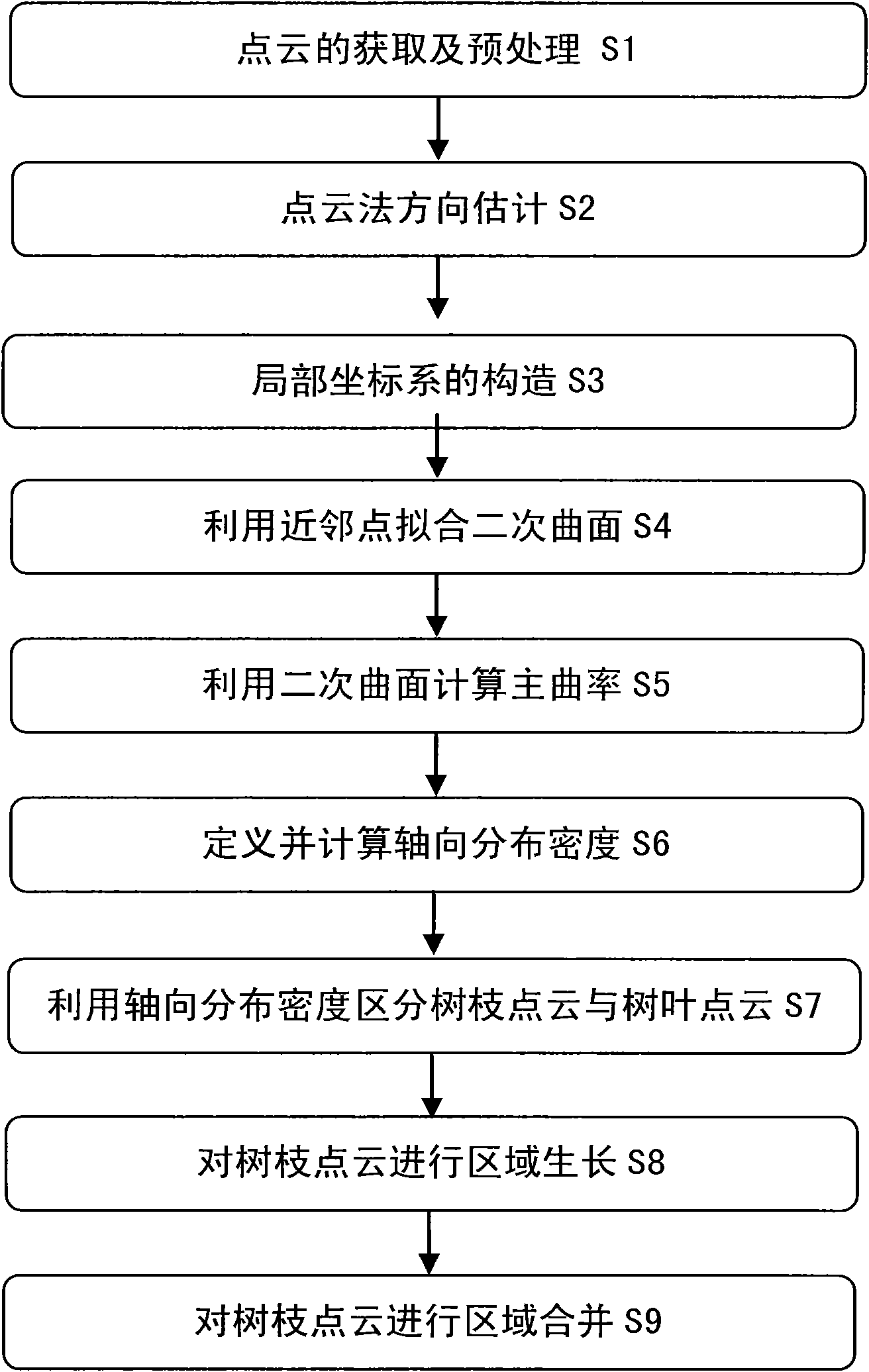

Method for automatically partitioning tree point cloud data

InactiveCN101839701AThe segmentation result is accurateAccurate segmentationUsing optical meansClosest pointPoint cloud

The invention relates to a method for automatically partitioning tree point cloud data. The method comprises the following steps: acquiring and preprocessing point cloud, estimating the direction by a point cloud process, constructing a local coordinate system, fitting a conicoid by using a closest point process, calculating the principal curvature by using the conicoid, defining and calculating the axial distribution density, distinguishing the branch point cloud and the leaf point cloud by using the axial distribution density, carrying out region growing on the branch point cloud, and carrying out region merging on the branch point cloud. By using the tree scanning data of a laser scanner and the estimated principal curvature, the invention partitions the tree scanning point cloud according with the actual organ distribution conditions. The method automatically partitions the tree point cloud scanning data among different organs through the local direction of principal curvature, and has the advantages of simple algorithm and accurate calculation result. The calculation result has important application value in the fields of tree point cloud 3D reconstruction, forest measurement, tree point cloud registration and the like.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Method for controlling isothermal precision formed forging flow line of complicated disk cake forging

ActiveCN101716645AControl streamline distributionImprove mechanical propertiesMetal-working apparatusWheelsAxial distributionMechanical property

The invention discloses a method for controlling an isothermal precision formed forging flow line of a complicated disk cake forging and relates to a method for controlling a flow line of a disk cake forging. The invention aims to lead the forging flow line of the complicated disk cake forging to be distributed along the radial direction or the annular direction to improve the mechanical performance and the fatigue resistance of the complicated disk cake forging in the appointed direction. The method comprises the following main steps of: upsetting blank preparing phase: converting a flow line of an original blank material, which is distributed along the axial direction, into a flow line which is distributed along the annular direction or the radial direction; preforging formation: preparing an obtained cake blank into a preforging, leading the metal allotting amount of all parts of the preforging to be equivalent to a final forging and leading shapes of the preforging and the final forging to be similar; and final forging formation: carrying out final forging formation by two methods of a reverse extrusion deforming way and a radial resistance increase way. The method overcomes the defects of exposure, vortex, cross flowing, and the like of the flow line, which are easy to generate during isothermal precision formation of the complicated disk cake forging, has reasonable flow line distribution and improves the mechanical performance and the fatigue resistance of the disk cake forging.

Owner:HARBIN INST OF TECH

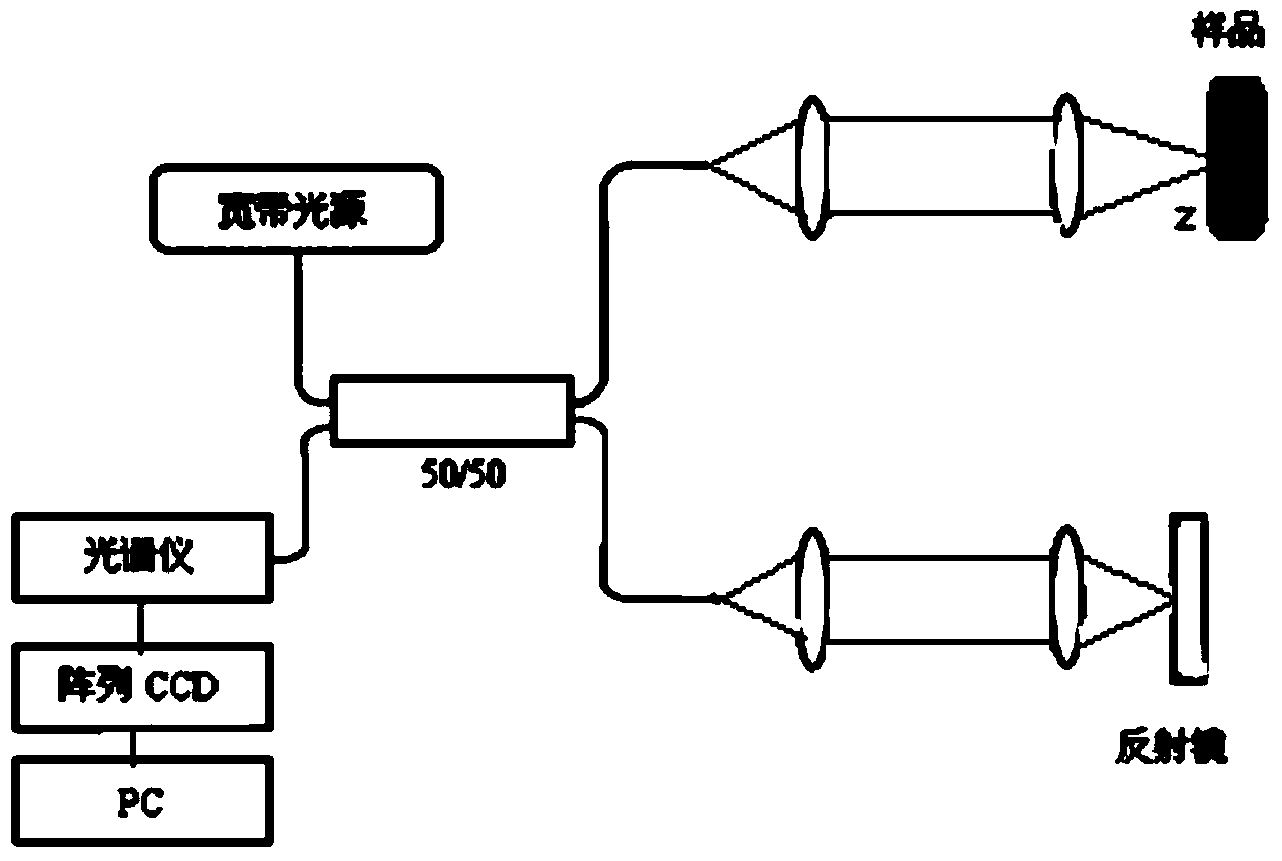

Large size rock quartz optical fibre prefabricated bar manufacturing method

InactiveCN101328012AAvoid secondary pollutionOvercoming issues that limit the manufacture of large size preformsGlass making apparatusVacuum pumpingAcid washing

The invention relates to a method for preparing a large size silica optical fiber perform rod comprising: preparing a large size mandrel by VAD art, inserting the mandrel after the mandrel is extended and the axial distribution of the core-spun is tested into a silica casing, conducting the HF acid washing and pure water cleaning and drying to the mandrel and casing surface before the insertion, then putting the combination of the mandrel and the silica casing into an extending furnace, respectively arranging caudal peduncles of the mindrel and the casing into each clamp, putting the casing and the mindrel into the extending furnace according to respective speed after the extending furnace is warmed up, adjusting the mandrel inserting speed according to the axial distribution of self core-spun, arranging a sealing device on top of the casing caudal peduncle, vacuum pumping the gap between the mandrel and the casing to seal with the outside. The method adopts asynchrony extension method of the mandrel and casing to control the inserting speed of the mandrel, solves the problem that the large fluctuation of the core-spun restricts the production of the large size perform rod, while the vacuum pumping of the gap between the mandrel and the casing to seal with the outside can prevents the secondary pollution during the rotation extension process. The invention discloses a large size silica optical fiber perform rod production method at a high efficiency and low cost.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Superconductive magnetic fluid marine propeller

InactiveCN1629036AShorten speedImprove efficiencyPropulsion power plantsPropulsive elementsPower flowPropeller

This invention relates to a superconduct magnetic liquids ship pushing device, which comprises the superconduct screw tube magnet and rotary magnetic liquids pushing channel, wherein, the superconduct screw tube magnet generates the even axle magnetic field in its central working area. There is located with one round metal electrode in the working round pipe of the magnetic liquids and with the round pipe metal outer cylinder as another electrode. There is a screw flow guiding pads between the metal outer electrode and central round electrode. There are distributed with several radial metal conductive bars and current control parts in the length direction of the screw guiding pad, which are connected to the above two electrodes through the conductive bars.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

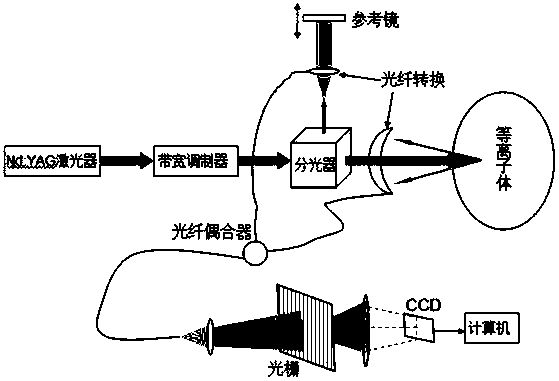

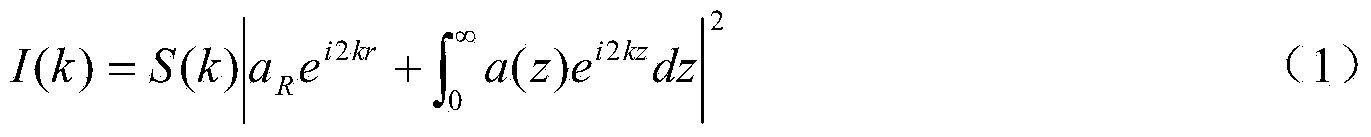

Fusion reactor plasma density and temperature diagnosing method based on Thomson scattering weak coherent technique

InactiveCN104185353AReduced Power RequirementsReduction of background stray light requirementsPlasma techniqueRayleigh scatteringPlasma electron

The invention discloses a fusion reactor plasma density and temperature diagnosing method based on the Thomson scattering weak coherent technique. The method comprises the steps that a broadband low-coherency intense light source is set, a bandwidth modulator is set, a beam splitting system is set, a reference arm is used for generating an optical path difference and a frequency shift signal, the light returned from the reference arm and a detection arm interferes and passes through an optical grating to be divided into interference spectrum signals with different wavelengths to be received by an array CCD, the incident light direction, namely the axial scattering intensity distribution is obtained through the Fourier transform, and the plasma electron density axial distribution information is obtained through rayleigh scattering or raman scattering absolute calibration; the thermal motion rate information of electrons is obtained through the Doppler broadening of a spectral line, and then the plasma electron temperature distribution is obtained; the horizontal movement adjustment is carried out on the length of the reference arm to change the optical path difference changing so as to achieve measurement on the great depth plasma with the depth larger than 1 m. The electron temperature and density of the fusion reactor plasma are measured online through the Thomson back scattering optical coherent chromatographic technique.

Owner:中国人民解放军陆军军官学院

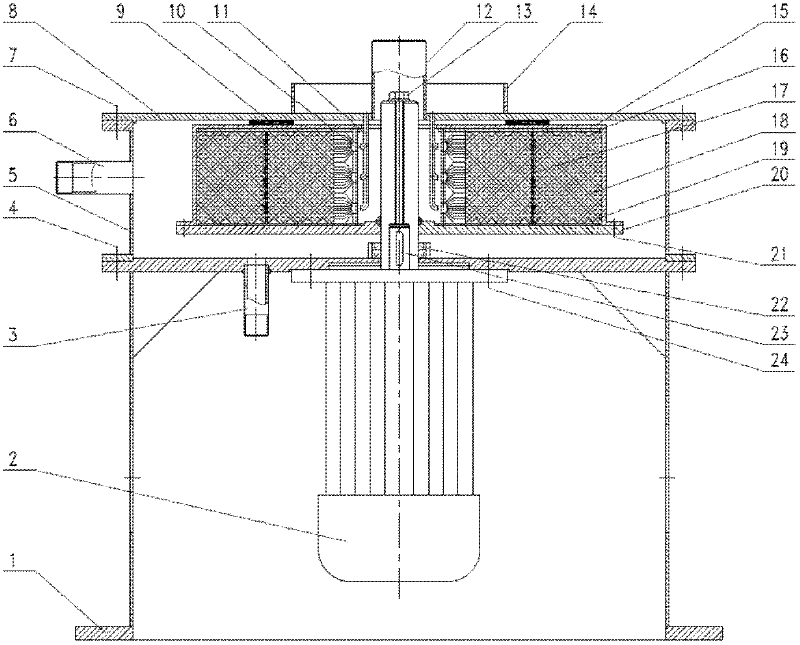

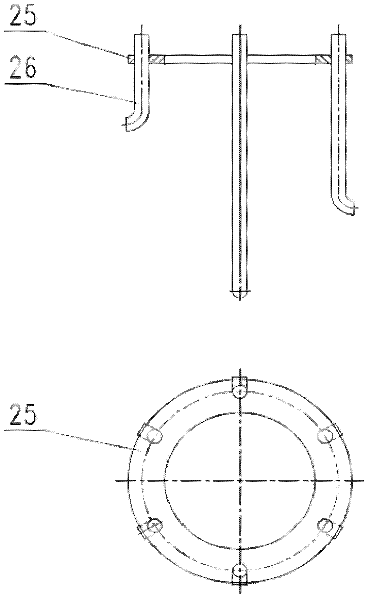

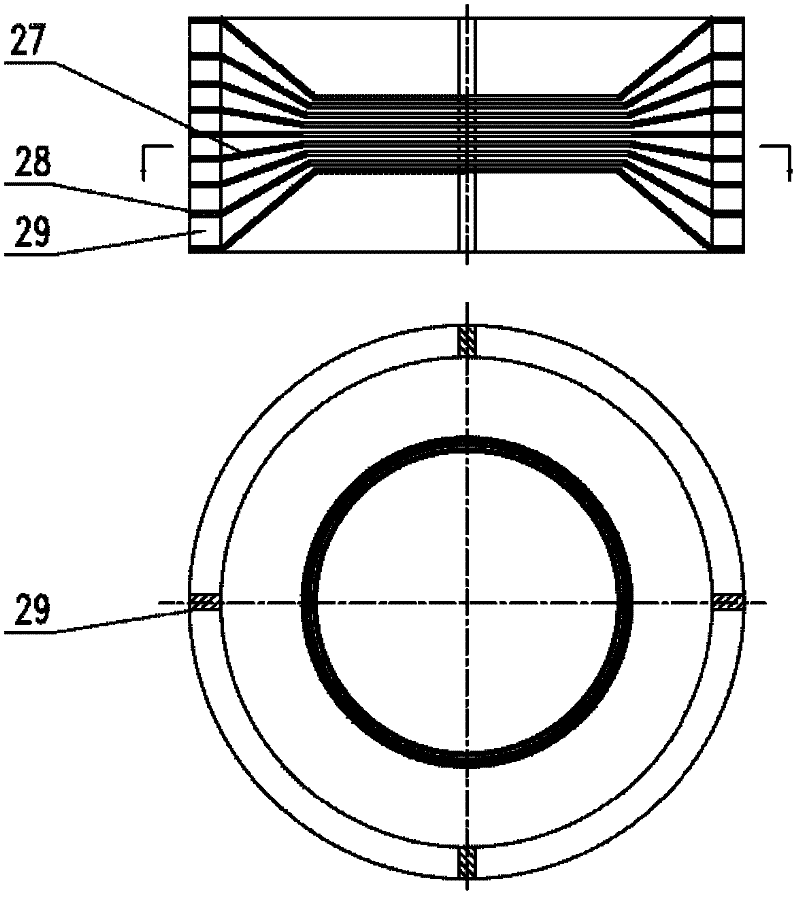

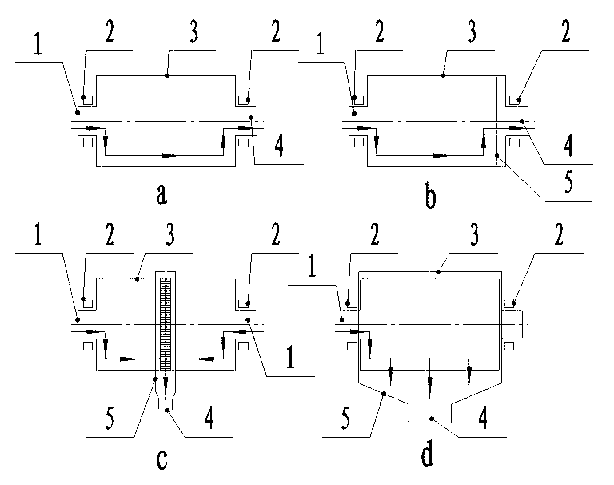

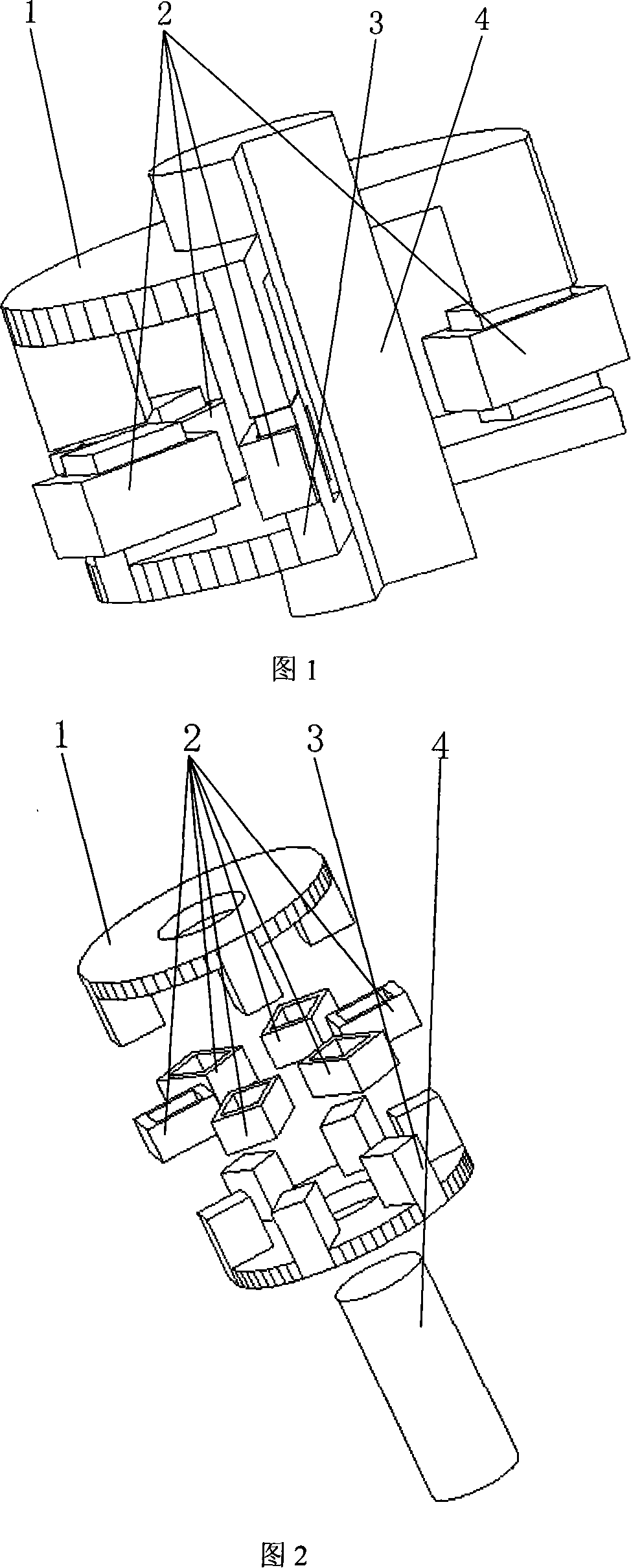

Rotating packed bed device with function of regulating and controlling axial liquid distribution

ActiveCN102247706APromotes even distributionEnhanced gas-liquid mass transfer processDispersed particle separationChemical/physical/physico-chemical stationary reactorsSingle stageHoneycomb

The invention discloses a rotating packed bed device with the function of regulating and controlling axial liquid distribution, and belongs to the technical field of supergravity. The device comprises a closed shell; the center of the shell is provided with a rotating shaft which runs through various shell sections; and a packing layer is arranged in a rotor. The axial uniform distribution of liquid can be realized by regulating and controlling the liquid by internal members such as a honeycomb duct type liquid distributor, a point-plane type liquid distributor, a split cylinder type liquid redistributor, a triangular conical ring and the like under the condition of no pump pressure, so that packing in the rotor is fully utilized, the mass transfer effect is strengthened, and the mass transfer efficiency can be improved by 60 to 70 percent. The internal members for regulating and controlling the axial distribution of the liquid can be used on a single-stage or multi-stage rotating bed, particularly rotors of a multi-stage countercurrent rotating bed except a first-stage rotor.

Owner:BEIJING UNIV OF CHEM TECH

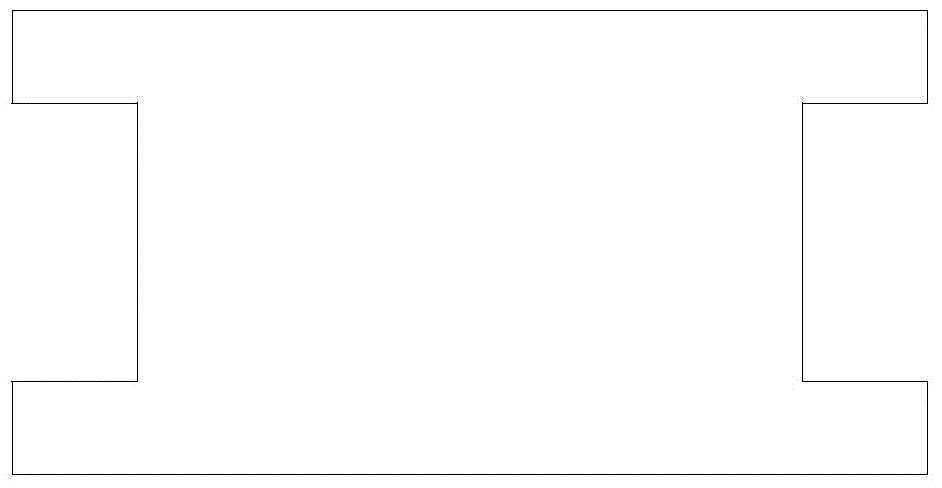

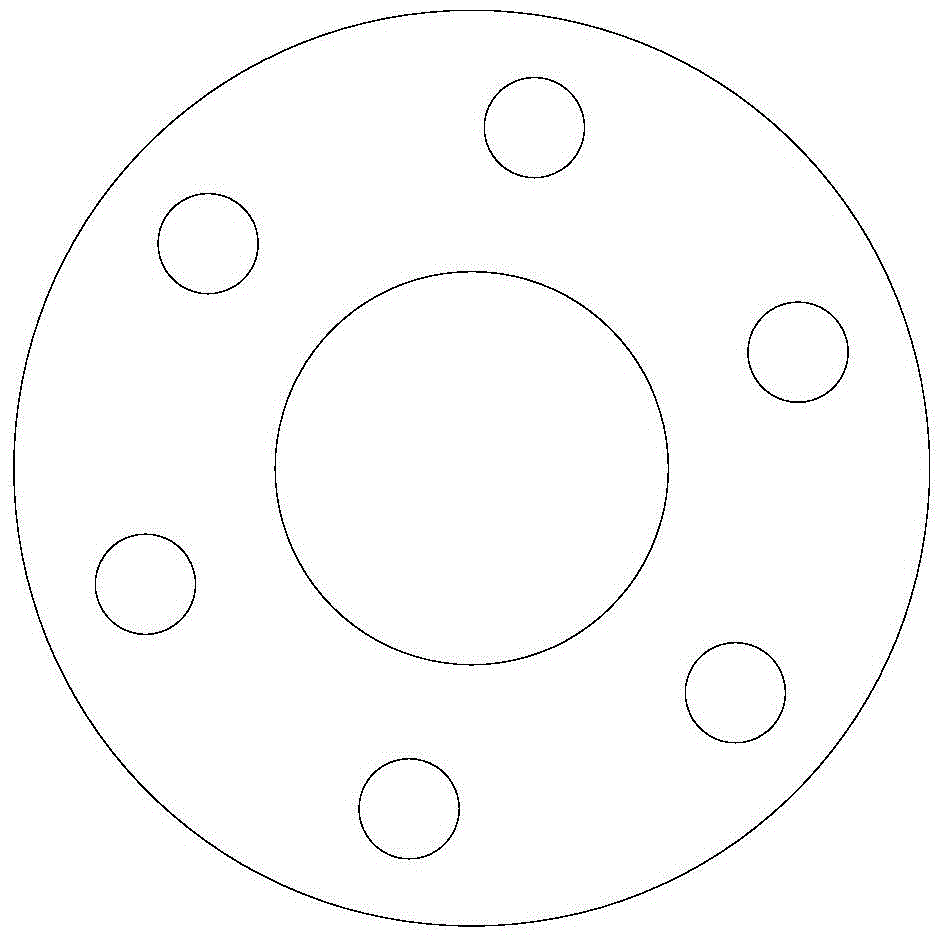

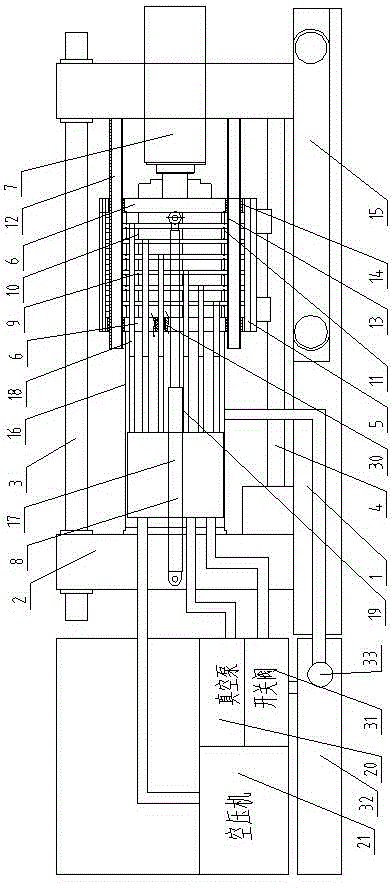

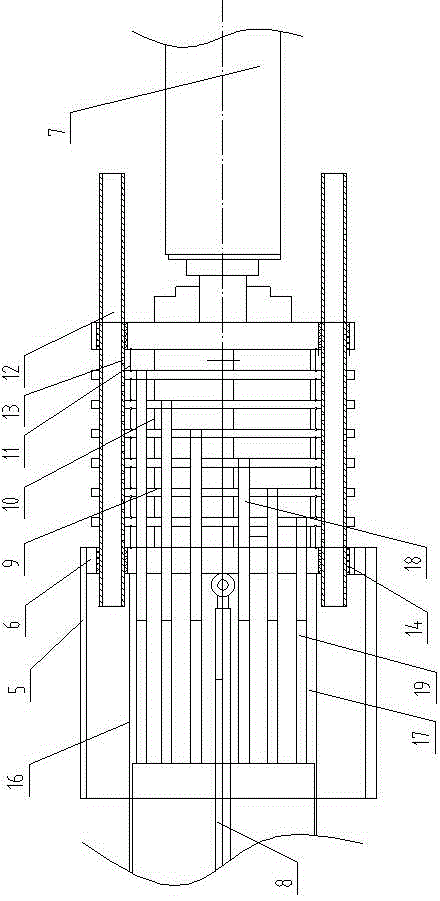

Device for drilling hole in flange on valve

ActiveCN104827078AIncrease productivityGuaranteed machining accuracyFeeding apparatusDriving apparatusHydraulic cylinderAxial distribution

The invention discloses a device for drilling holes in flanges on a valve. The device comprises a drilling mechanism and a clamping mechanism, wherein the drilling mechanism comprises a supporting column and a hydraulic cylinder, the supporting column is distributed along the axial direction of the flanges, a first ferrule and N sliding rods are arranged on the supporting column, N is 1, 2, 3, 4, 5 or 6, the sliding rods are circumferentially distributed by using the supporting column as a center, the sliding rods are arranged in parallel with the surfaces of the flanges, and when N is not equal to 1, an included angle between adjacent sliding rods is 60 or or180 degrees; each sliding rod is provided with a drilling unit, and the drilling unit is slidably connected with the corresponding sliding rod through a sliding block; the first ferrule is hinged to the sliding blocks through the equal-long connecting rods, and the first ferrule is in transmission connection with the hydraulic cylinder; each drilling unit comprises a drill bit and the drilling direction of the drill bit is in parallel with the axial direction of the flanges. The device for drilling holes in the flanges on the valve has the advantages that the processing accuracy is high and the adaptability is good; the sealing performance during connection of the flanges with external pipes is ensured, and the flanges at the two ends of the valve can be automatically drilled.

Owner:华东矿用设备有限公司

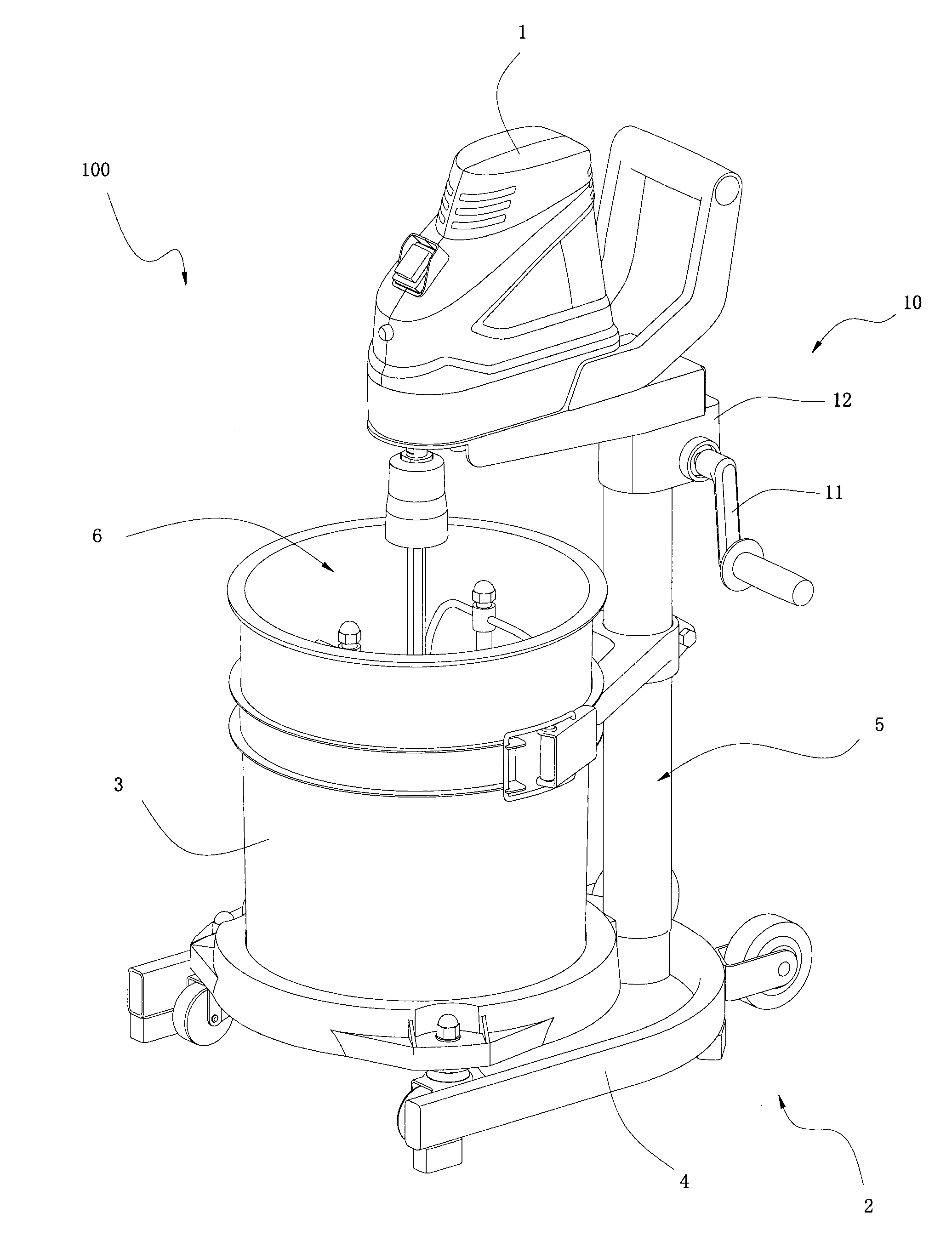

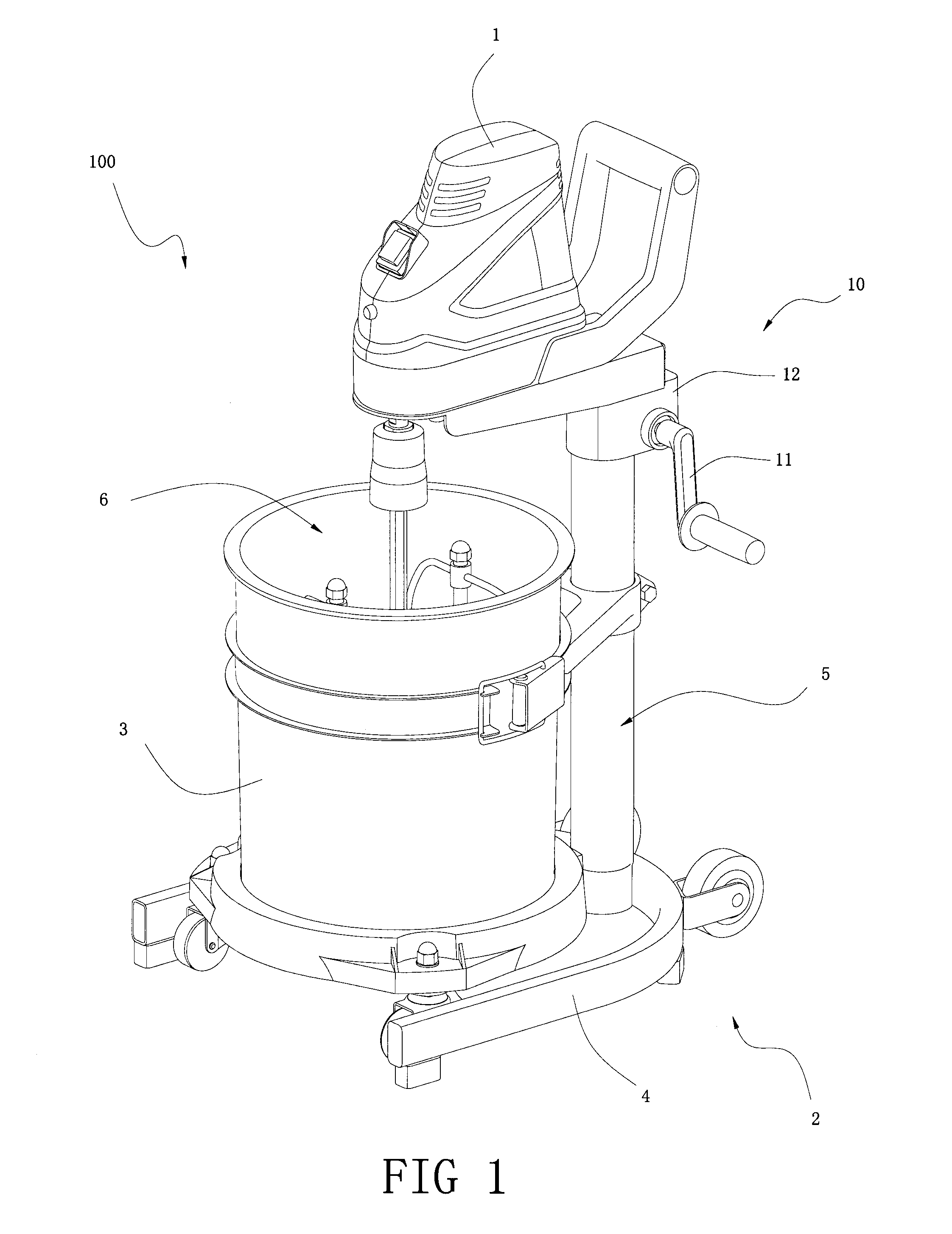

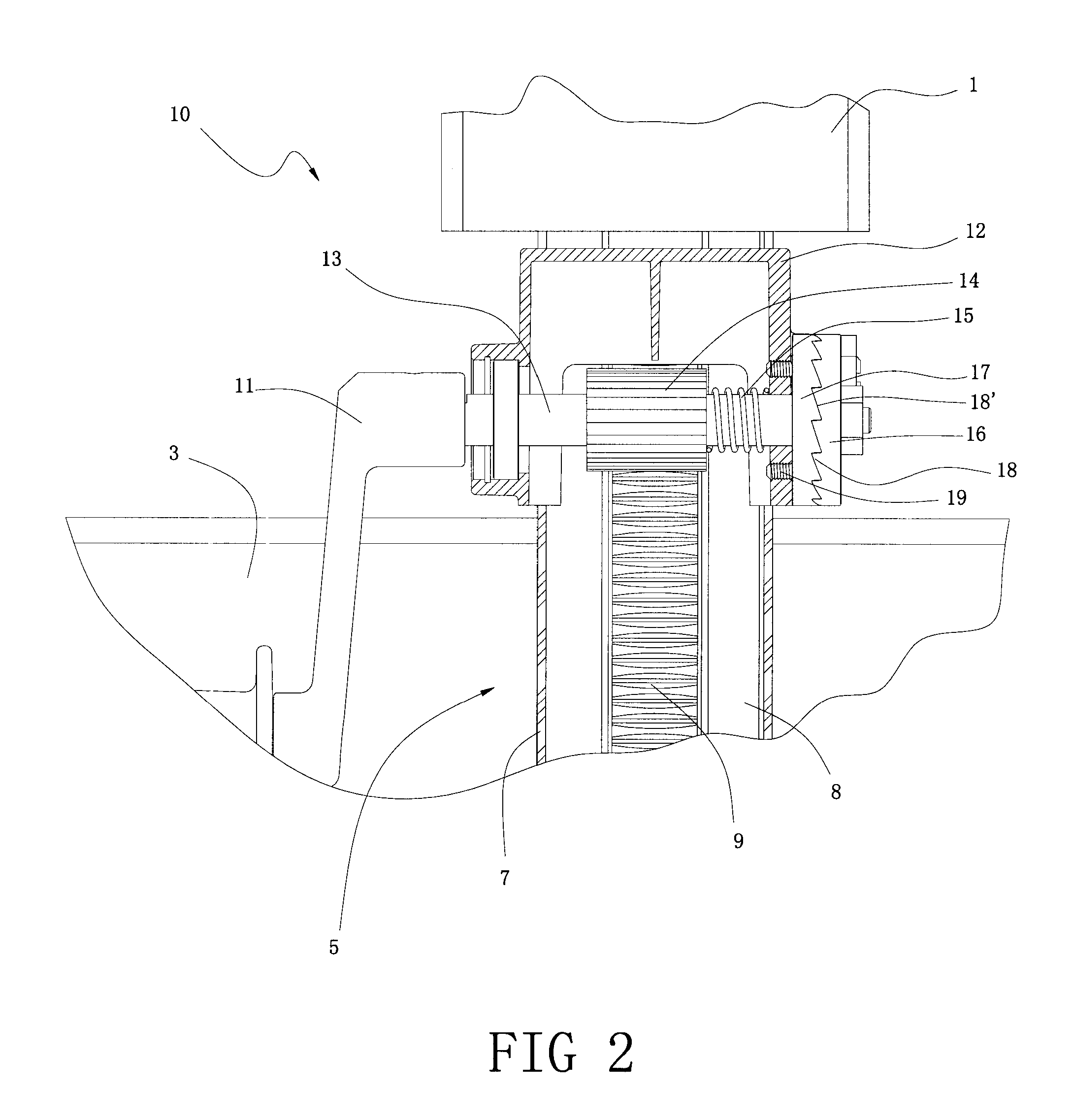

Mixer

InactiveUS20070008816A1Easy to adjustTransportation and packagingRotary stirring mixersEngineeringAxial distribution

To achieve the above-mentioned object, the present invention provides a mixer which comprises a body connecting with a supporting rod, a power system located within the body for driving a mixing paddle to rotate for mixing, and a lifting system for adjusting the location of the body on the supporting rod. The supporting rod comprising a set of teeth distributed on the supporting rod in an axial direction, the lifting system comprising a handle and a gear which is operable with the handle and engaged with the teeth, the body being at a fixed location with respect to the teeth or gear and a lifting system with a lift-locking means having a first member and a second member engaged with each other to limit rotation of the gear.

Owner:NANJING CHERVON IND

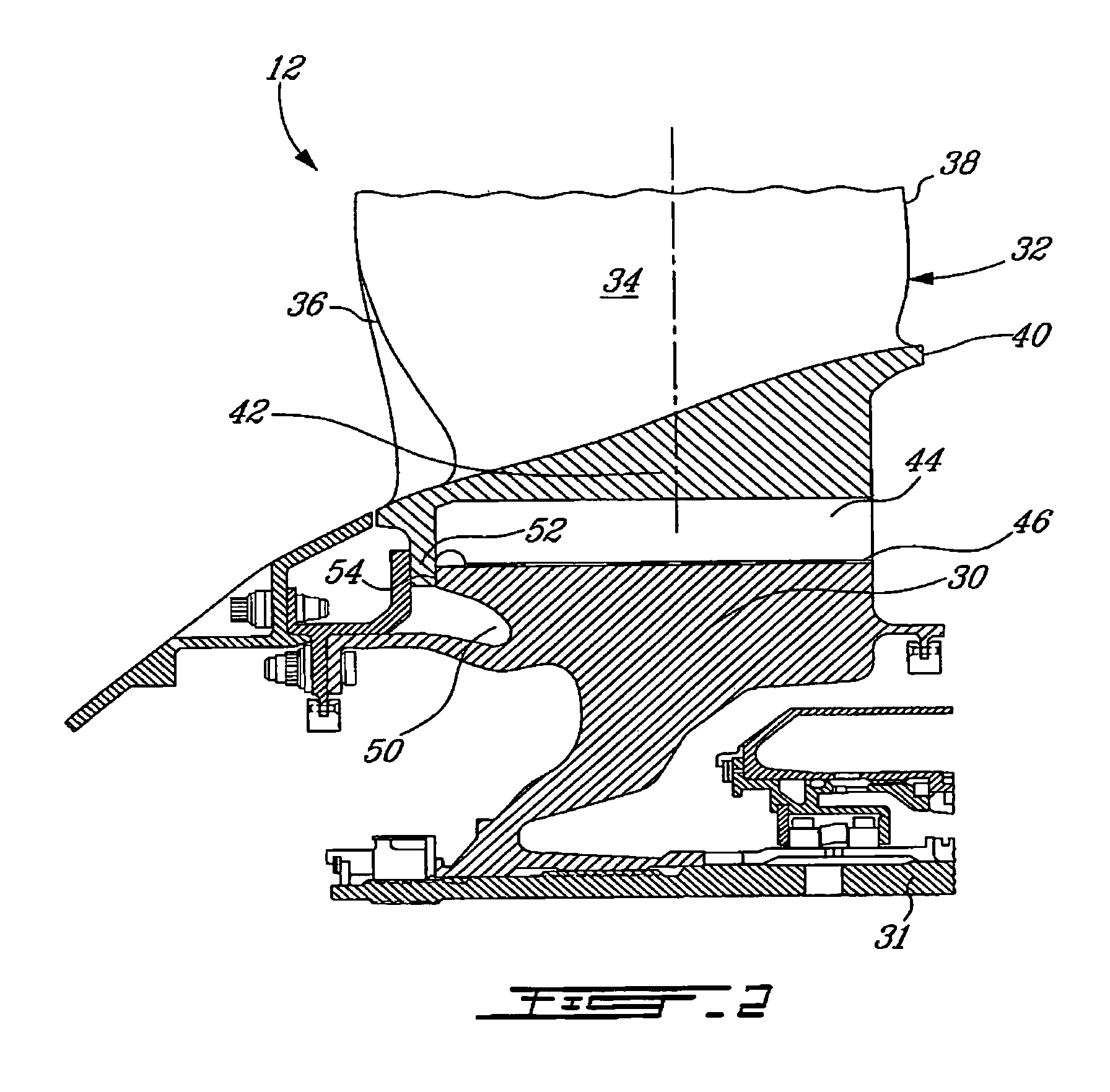

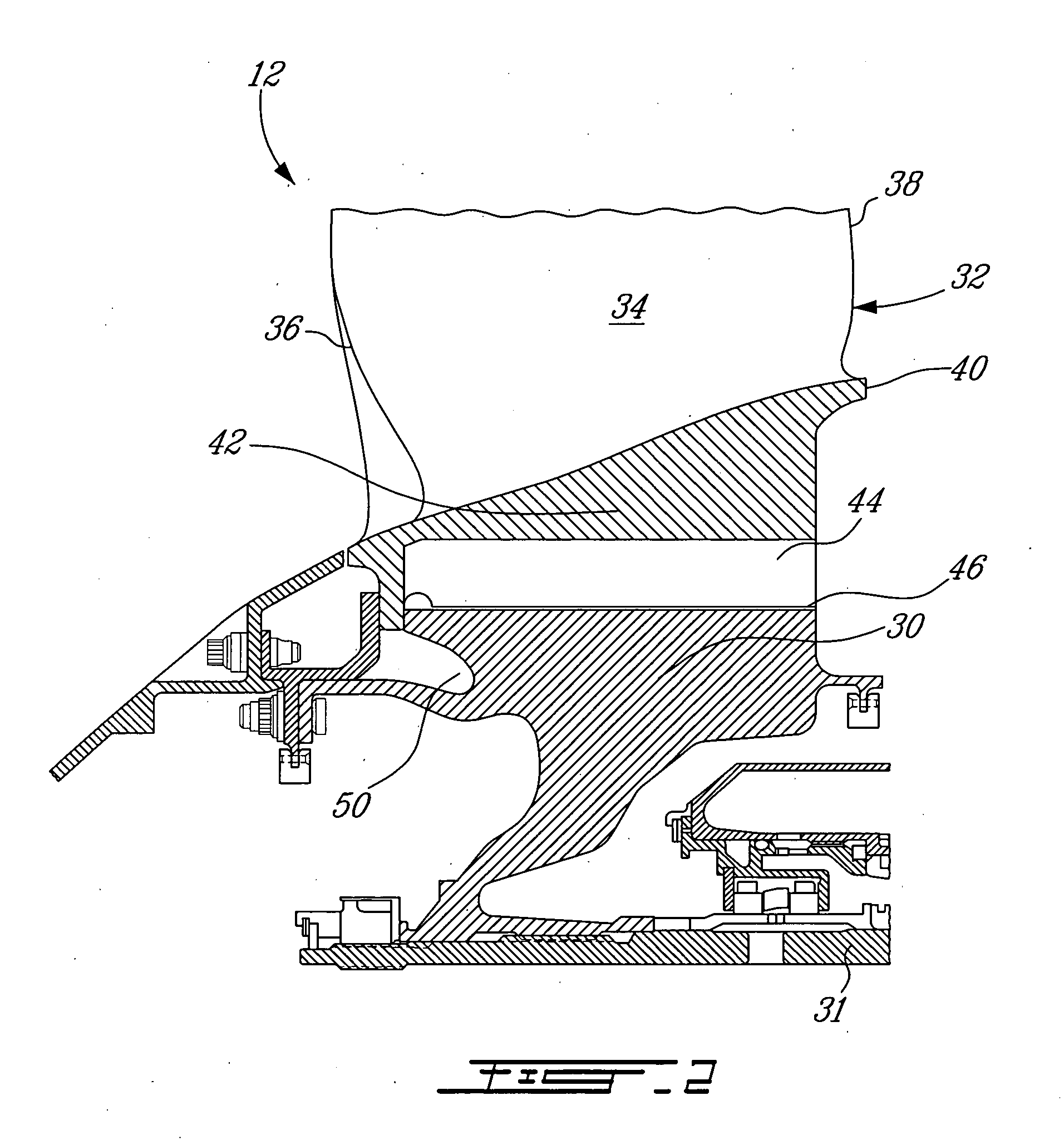

Bladed disk fixing undercut

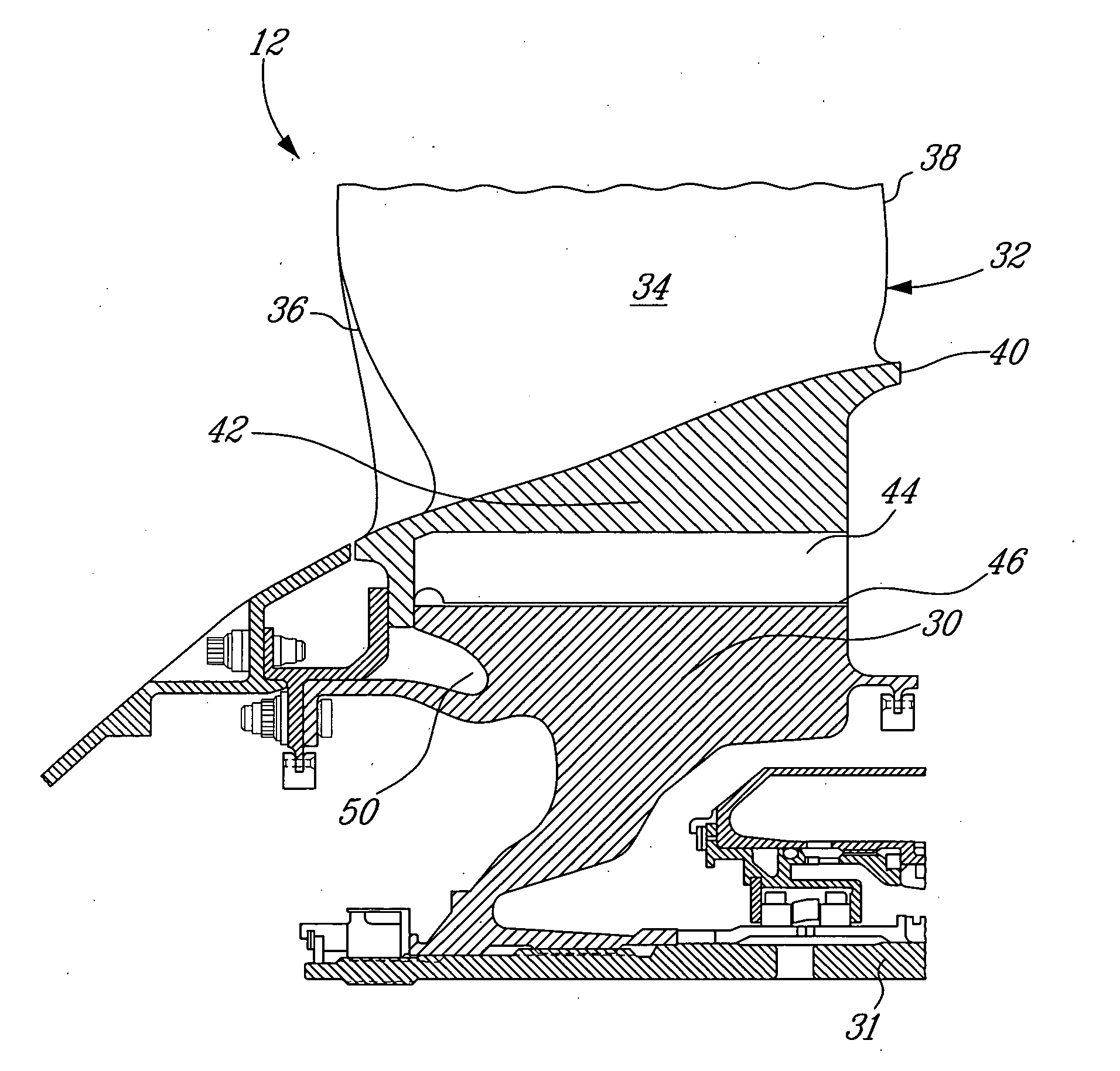

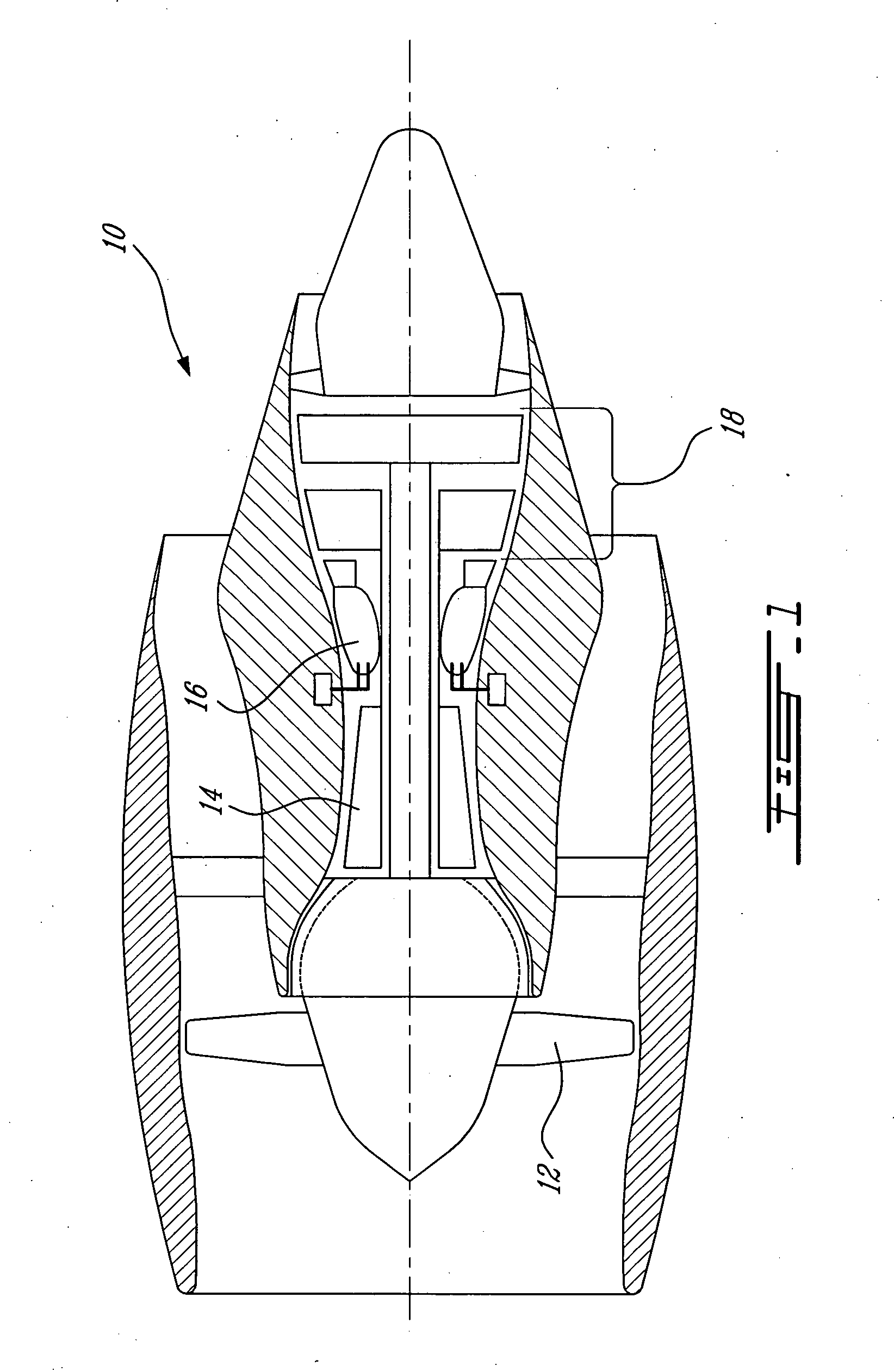

An undercut is provided in a gas turbine engine disk to smooth out an uneven axial distribution of radial stress in the disk. The undercut is defined radially inwardly of the blade attachment slots provided at the periphery of the disk.

Owner:PRATT & WHITNEY CANADA CORP

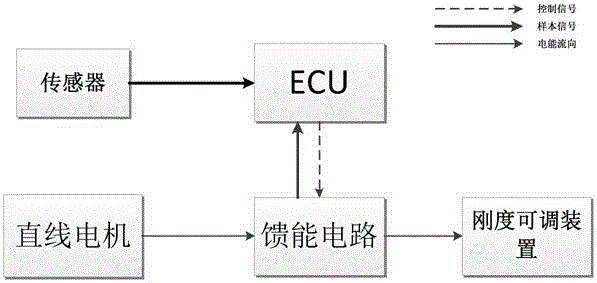

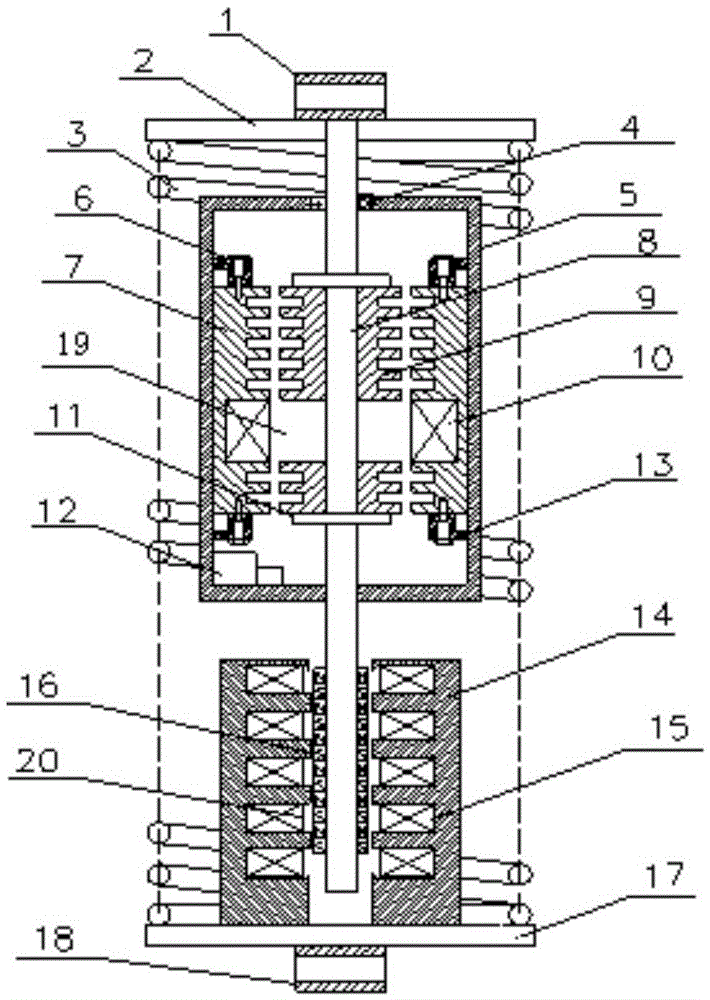

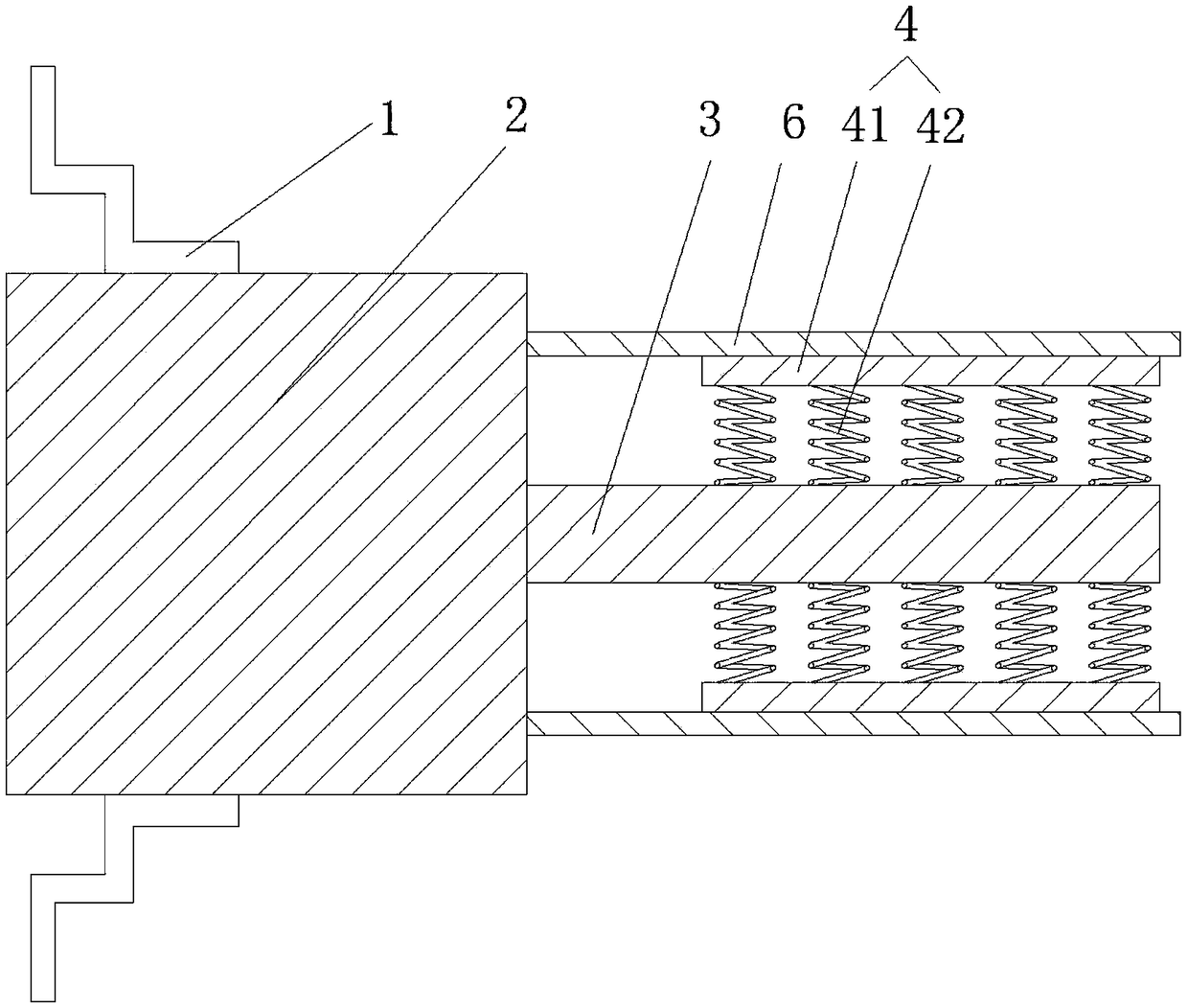

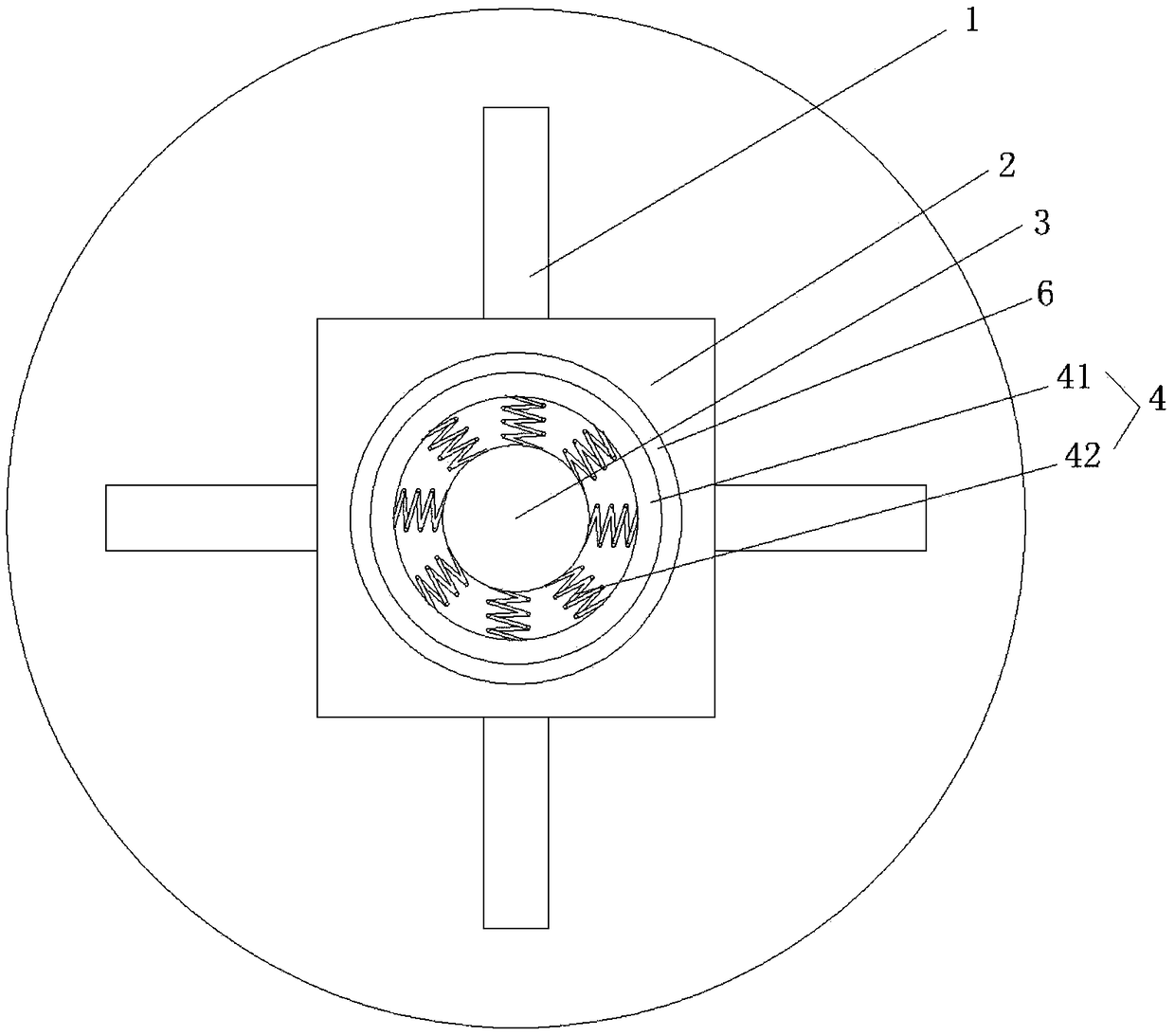

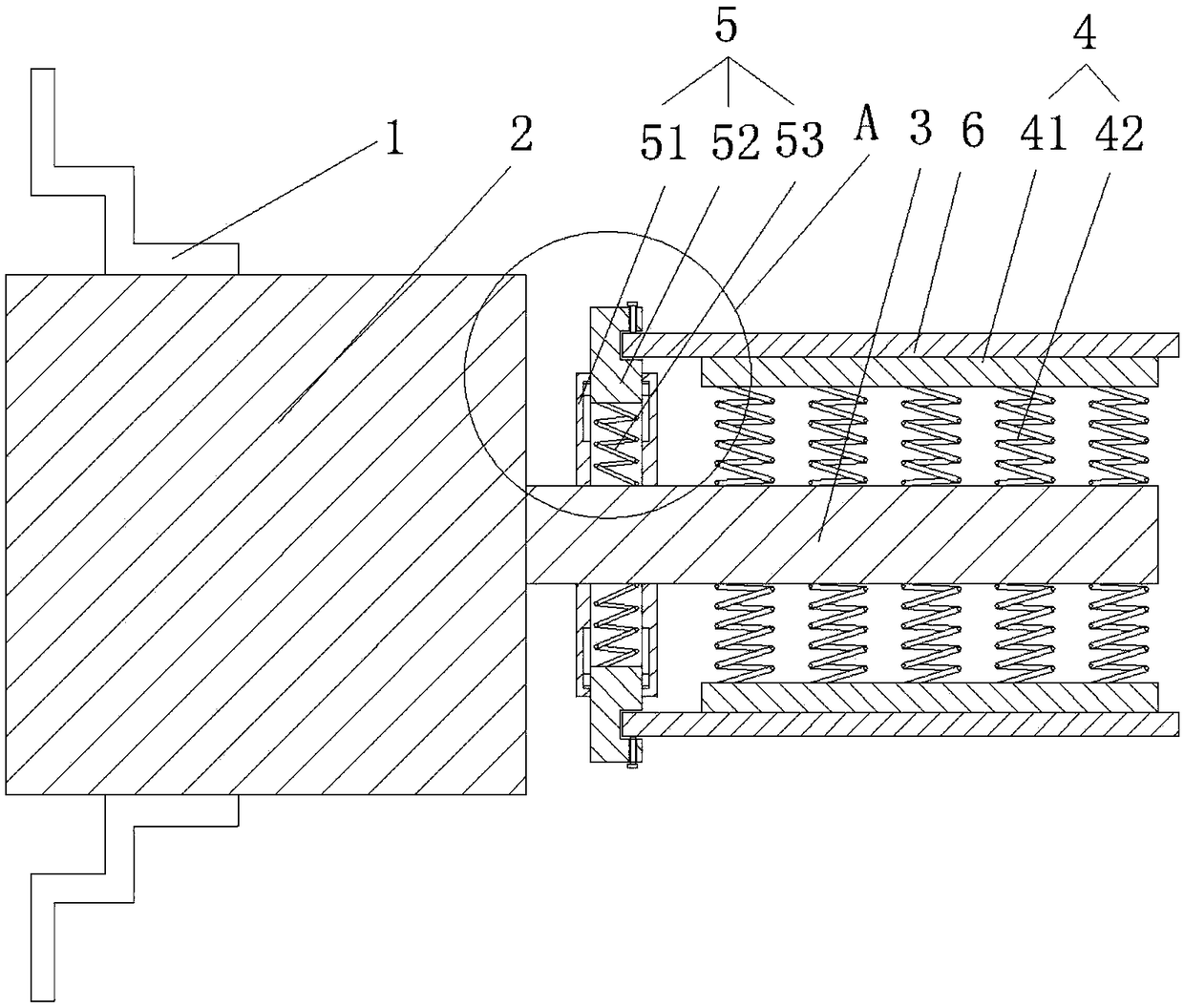

Variable-rigidity semi-active suspension

InactiveCN105584310AAdjustable stiffnessOvercome the disadvantage of not being able to adjust the stiffness of the systemResilient suspensionsSemi activeAxial distribution

The invention provides a variable-rigidity semi-active suspension which comprises an upper connecting ring, a lower connecting ring, an upper spring support, a lower spring support and a rigidity adjusting device. The upper spring support is fixed to the lower end face of the upper connecting ring. The lower spring support is fixed to the upper end face of the lower connecting ring. The rigidity adjusting device comprises a piston rod, a rotor, a stator and a sleeve. The rotor and the stator are located in the sleeve, and the rotor, the stator and the sleeve are coaxial. The piston rod penetrates the centers of the rotor, the stator and the sleeve. The piston rod is fixed to the lower end of the upper connecting ring. The rotor is fixed to the outer wall of the piston rod. The stator is fixed to the inner wall of the sleeve and a magnet exciting coil is fixed to the stator. A gap is reserved between working surfaces of the rotor and the stator and small teeth which are arranged at equal intervals and are equal in width are distributed in the axial directions of the working surfaces. The magnet exciting coil is connected with a controller. By the adoption of the variable-rigidity semi-active suspension, the rigidity and damping can be controlled independently, the smoothness and comfort of a vehicle can be improved, and vibration is attenuated; and when a control part of the suspension fails, the vibration reducing performance of a passive suspension still can be achieved.

Owner:JIANGSU UNIV

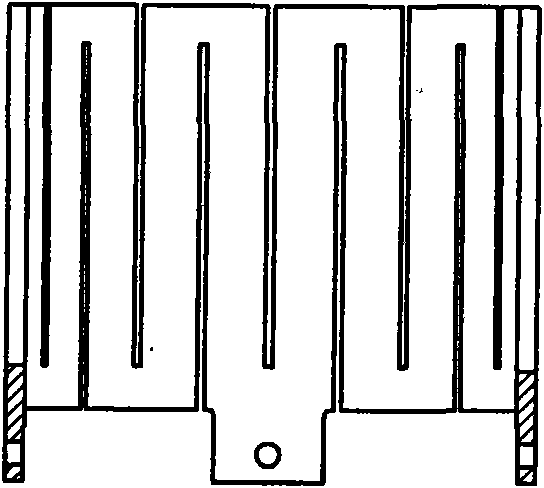

Improved structure of heater of czochralski crystal growing furnace

InactiveCN101580962AReduce manufacturing costIncrease heating powerBy pulling from meltAxial distributionEngineering

The invention relates to a heater device, aiming at providing an improved structure of a graphite heater of a czochralski crystal growing furnace. The heater comprises the ring-shaped graphite heater evenly provided with slots in a crossing way along the axis direction and a thinning heating section arranged on the ring-shaped graphite heater; wherein, the radial cross-sectional area of the thinning heating section is 2 / 3-3 / 4 of that of the rest parts of the heater; the thinning heating section is the part from the bottom of the heater to the height of 1 / 5-1 / 4 of the total height. The invention leads the heating power to be increased at the thinning part of the heater and changes the axial distribution, so as to indirectly form additional bottom heater function at the bottom of the ring-shaped heater, thus achieving the effect of two heaters which are the ring-shaped bottom heater and the bottom heater in the prior art by the structural design of the single graphite heater. Therefore, the invention not only reduces the equipment investment, but also lowers the manufacturing cost of the graphite heater and simplifies the operating procedures.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

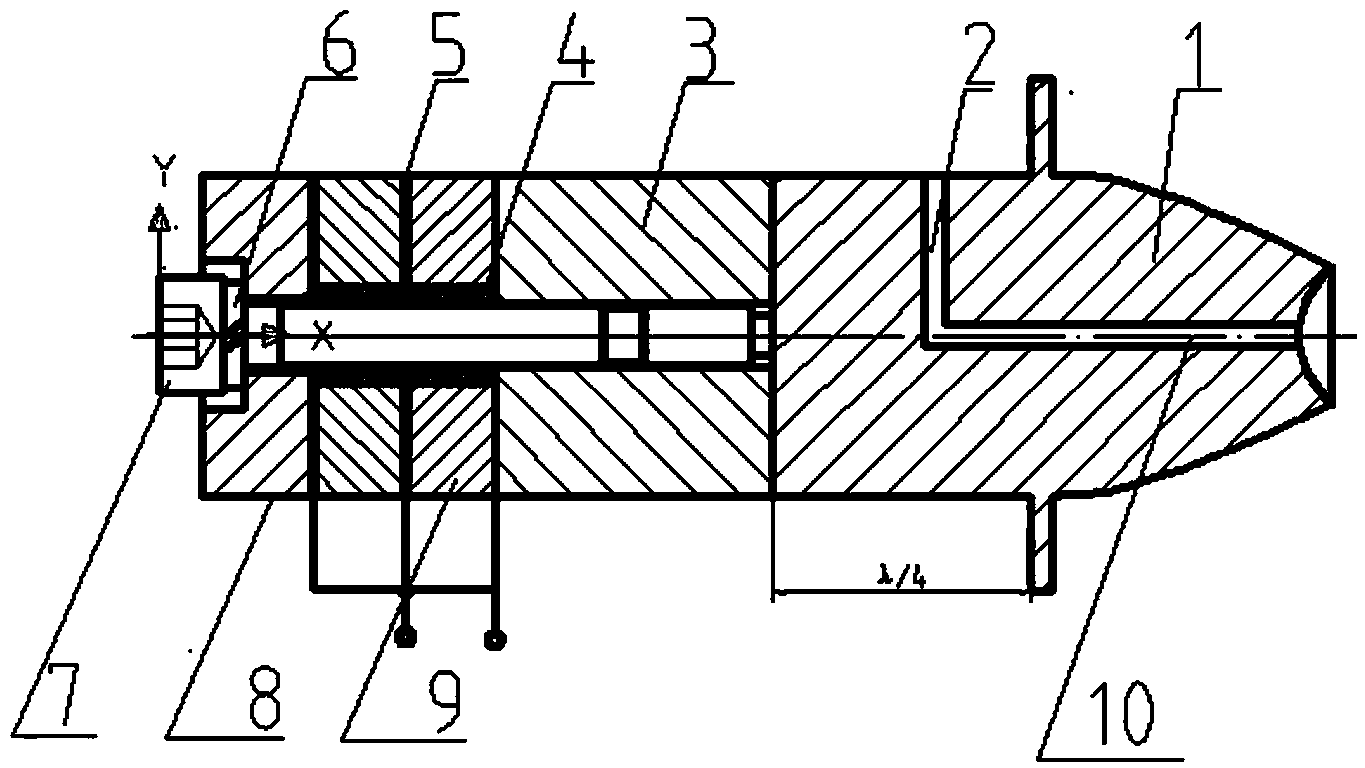

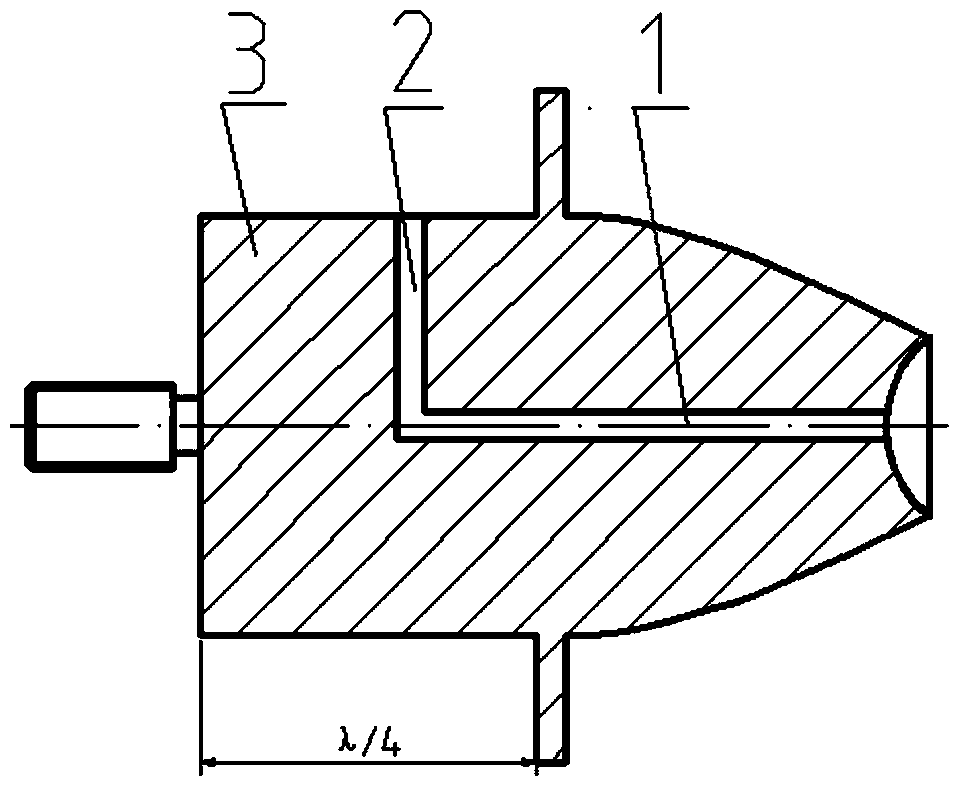

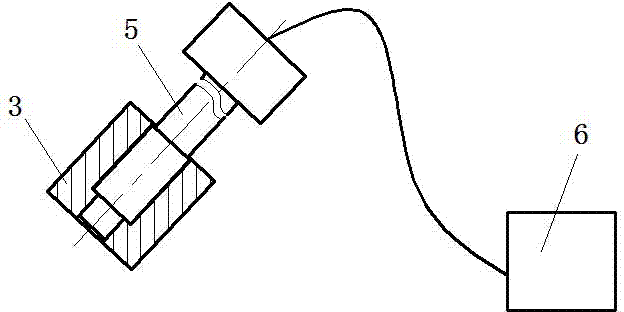

Medium-frequency ultrasonic atomization spray nozzle for Gaussian complex angle and design method of medium-frequency ultrasonic atomization spray nozzle

The invention discloses a design method of a medium-frequency ultrasonic atomization spray nozzle for a Gaussian complex angle and the medium-frequency ultrasonic atomization spray nozzle for the Gaussian complex angle designed according to the method. The design method concretely comprises the following steps that the corresponding cross section variation rule is derived according to the specified requirements of the constant strain, an amplitude-change pole part of the ultrasonic atomization spray nozzle is designed, then, an energy converter part matched with the amplitude-change pole is designed, and finally, the ultrasonic atomization spray nozzle with uniform stress distribution and high vibration amplitude can be obtained. The invention also discloses the medium-frequency ultrasonic atomization spray nozzle for the Gaussian complex angle, and the medium-frequency ultrasonic atomization spray nozzle consists of the energy converter and the amplitude-change pole of the Gaussian complex angle. The stress distribution in the axial direction of the pole is uniform, i.e. no maximum value exists, so greater vibration amplitude can be obtained from the output end along with the shape factor increase of the amplitude-change pole.

Owner:JIANGSU UNIV

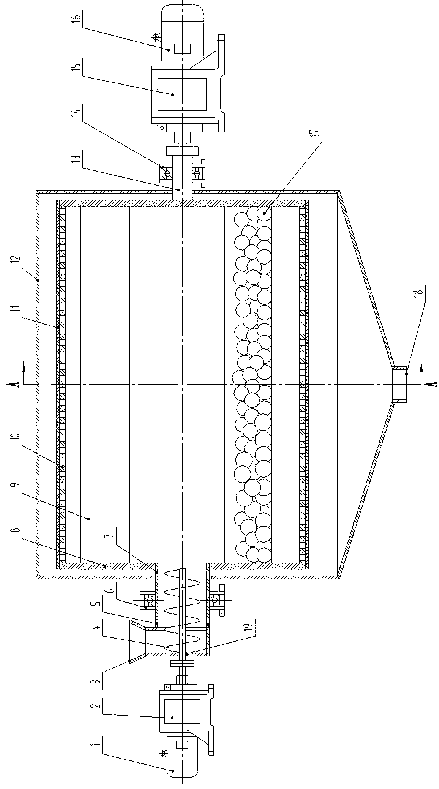

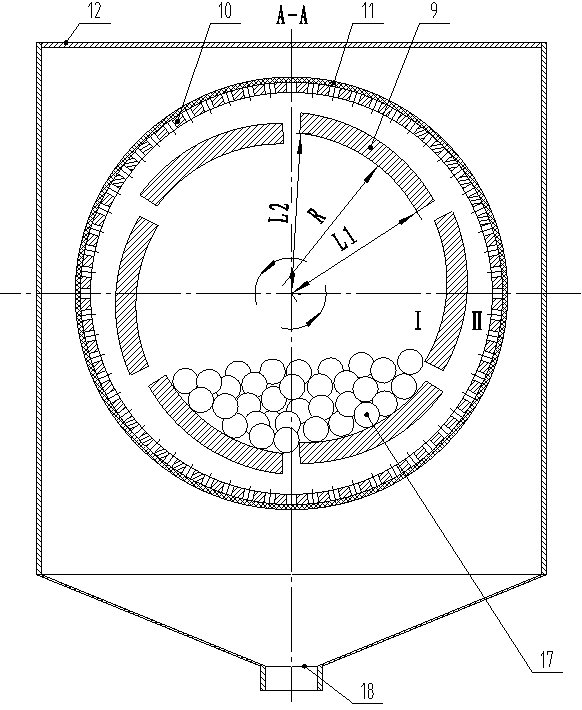

All-radial-direction discharging ball mill

An all-radial-direction discharging ball mill is composed of a main motor, a speed adjusting transmission device of the main motor, a feeding motor, a speed adjusting transmission device of the feeding motor, a feeding and spiral pushing device, a rotary barrel, a screen covered outside the rotary barrel, a lining plate assembly in the barrel, a grinding steel ball in the barrel, a ball mill supporting component and a discharging box. When the ball mill works, materials enter the barrel from a feeding port and are distributed in the barrel along the axial direction fast and evenly under the rotation effect. The materials rotate with the grinding steel ball, are ground and flow in reciprocating mode in a gap among a grinding chamber, a lining plate and the barrel ceaselessly till the materials are ground to be thin enough to penetrate through the steel screen to enter the discharging box. The ball mill works in a radial reciprocating moving mode, the radial discharging motion exists on a barrel wall along all the axial directions of the barrel, namely the ball mill discharges the materials in an all-radial-direction mode. Compared with a traditional ball mill, materials of the ball mill flow to a discharging end from a feeding end slowly, and the ball mill has the advantages of being high in grinding efficiency and material recovery rate.

Owner:王国宁

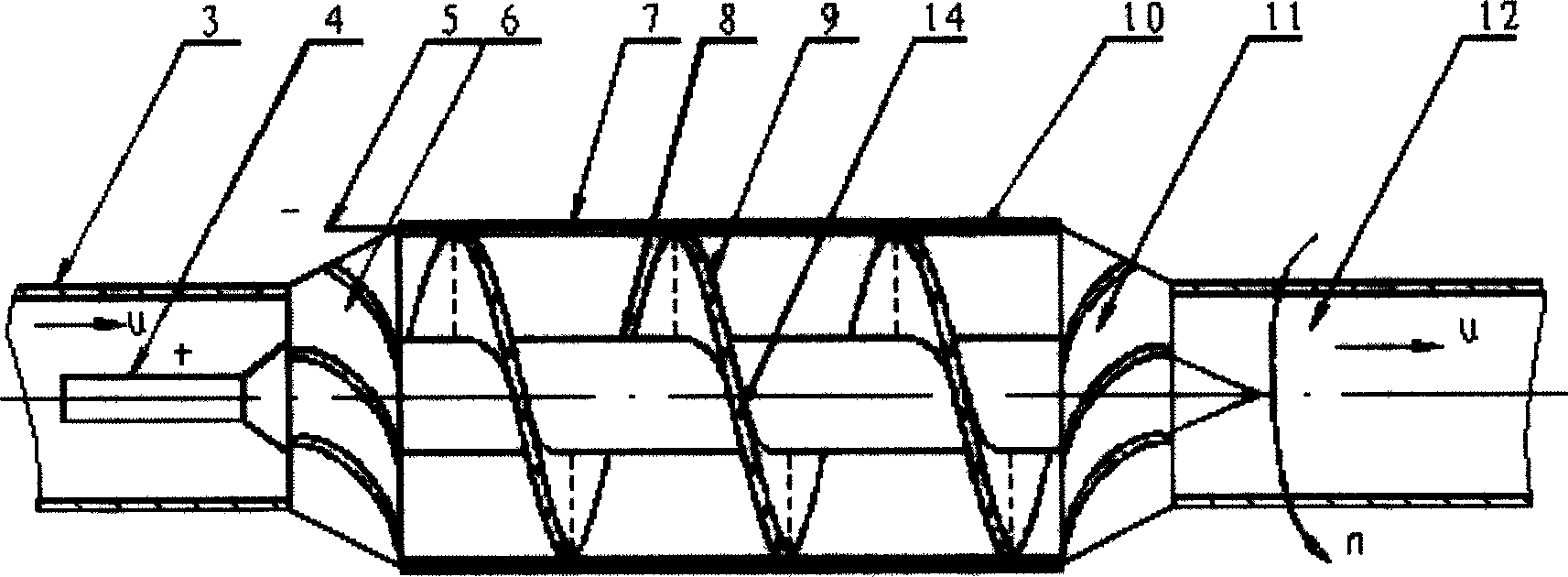

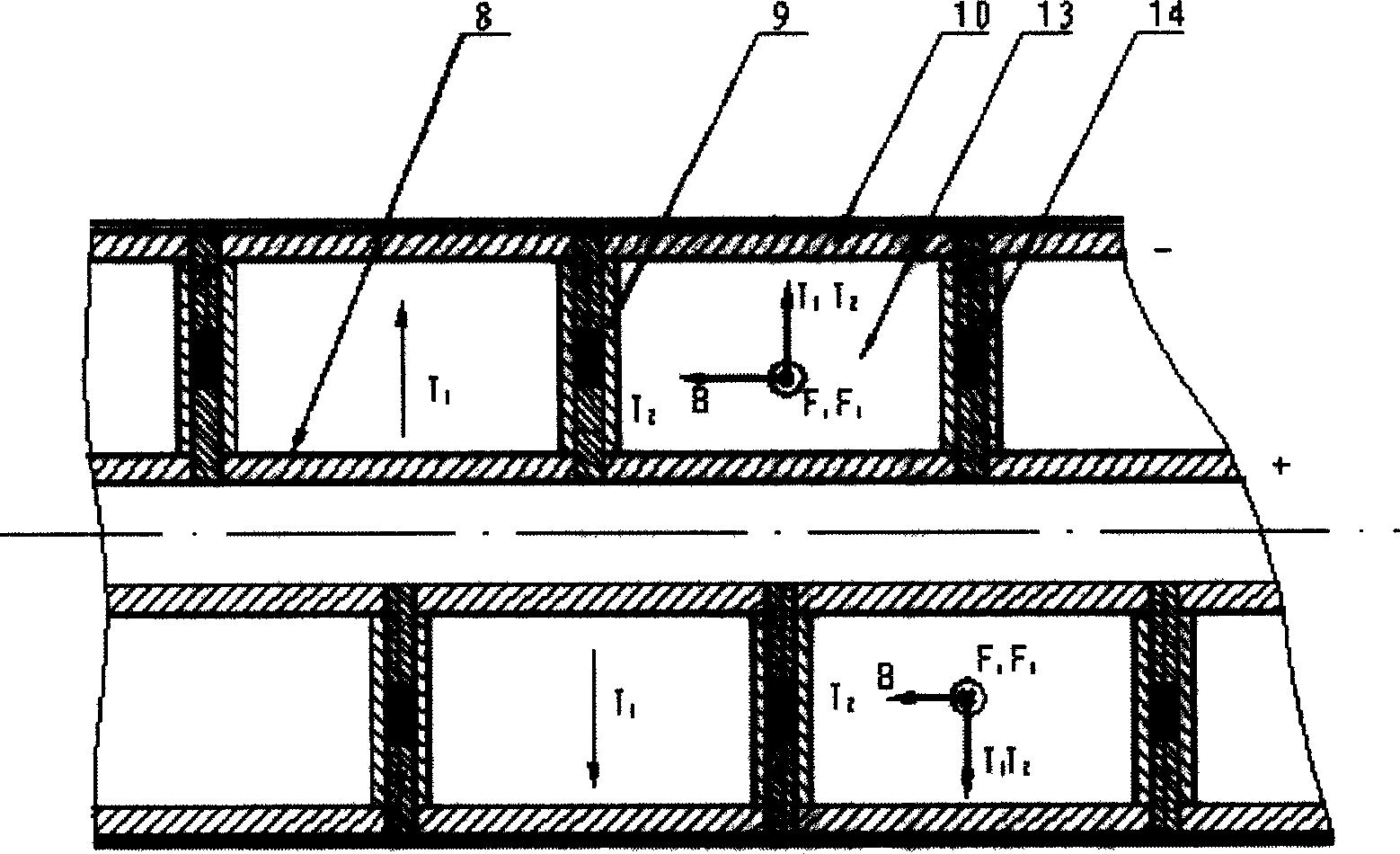

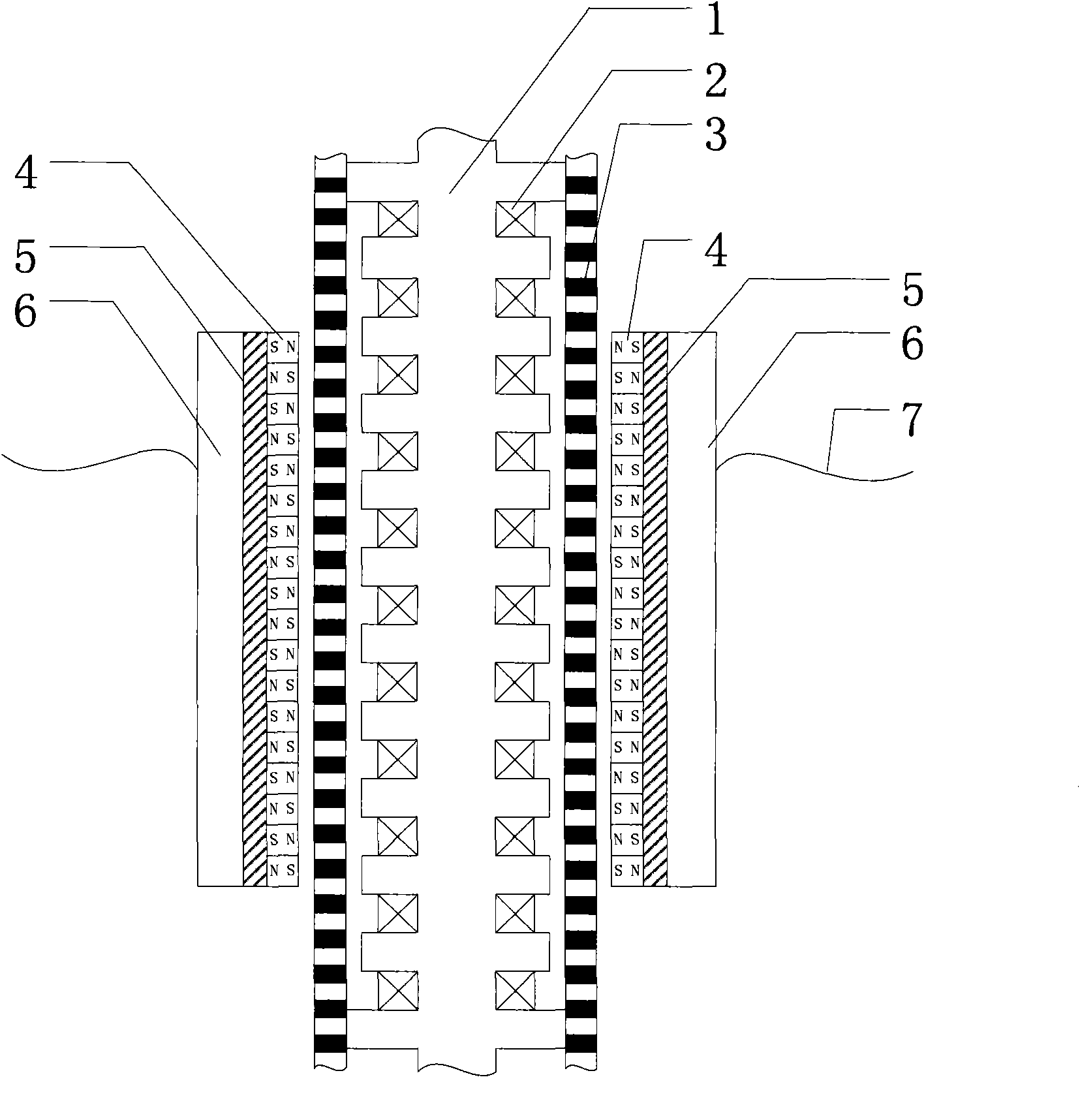

Voice coil linear actuator, apparatus using the actuator, and method for manufacturing the actuator

InactiveUS6856049B2Reduce resistanceIncrease thrustElectrical transducersPropulsion systemsMagnetic polesEngineering

A voice coil linear actuator comprises: an axially-shaped center yoke formed of a ferromagnetic material; an armature coil concentrically disposed so as to move along the axial direction of the center yoke; and a plurality of ring-shaped permanent magnets which have N and S magnetic poles arranged in the radial direction thereof, and are disposed concentrically as to the armature coil. The armature coil has armature coil units distributed in at least three positions in the axial direction, with adjacent pairs of the armature coil units being arranged so that electric current flows through them in opposite directions, respectively. The permanent magnets are distributed in at least three positions in the axial direction at positions facing respective armature coil units in the radial direction. The respective directions of the N magnetic poles of adjacent permanent magnets are arranged facing in opposite directions.

Owner:MURATA MFG CO LTD

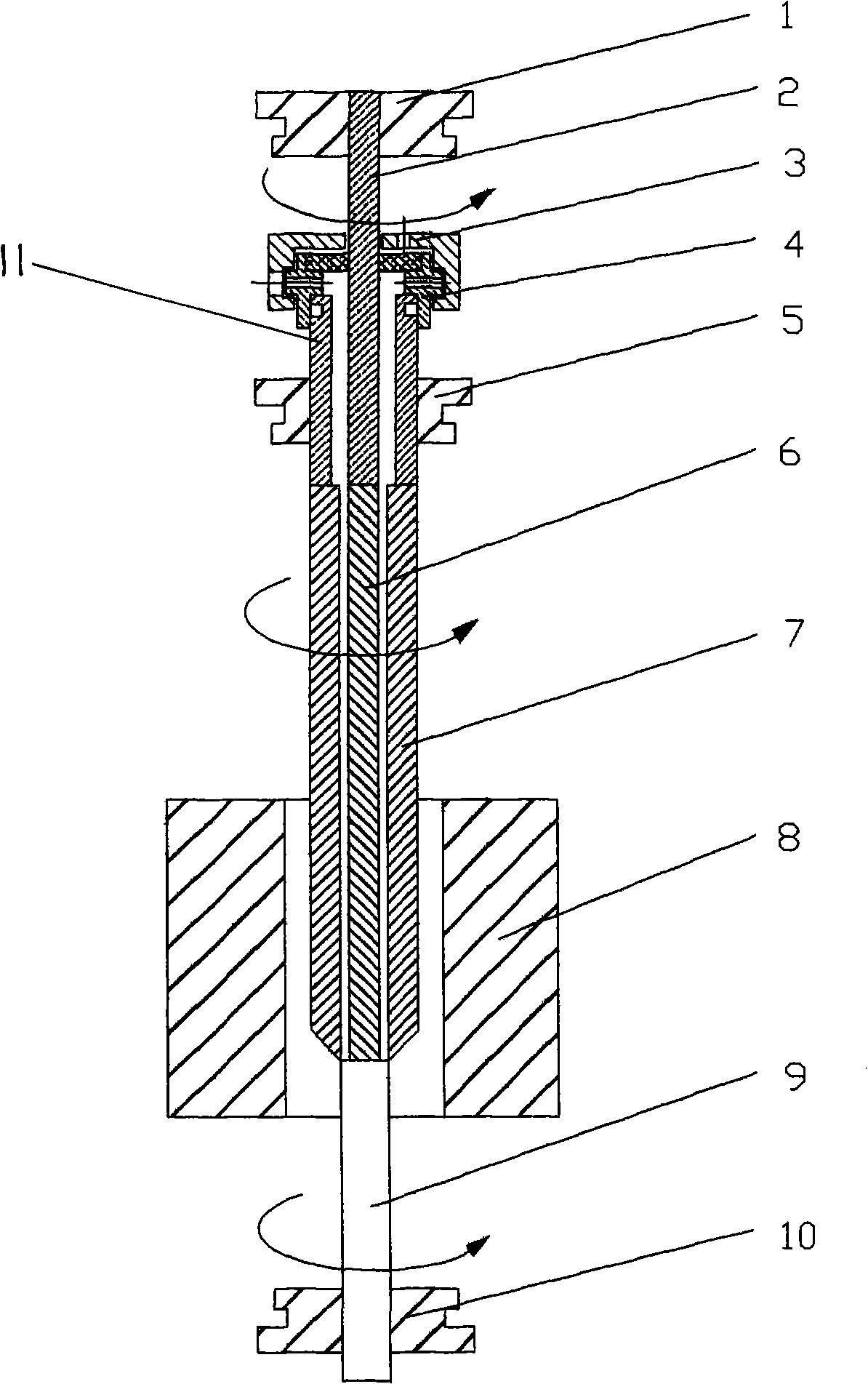

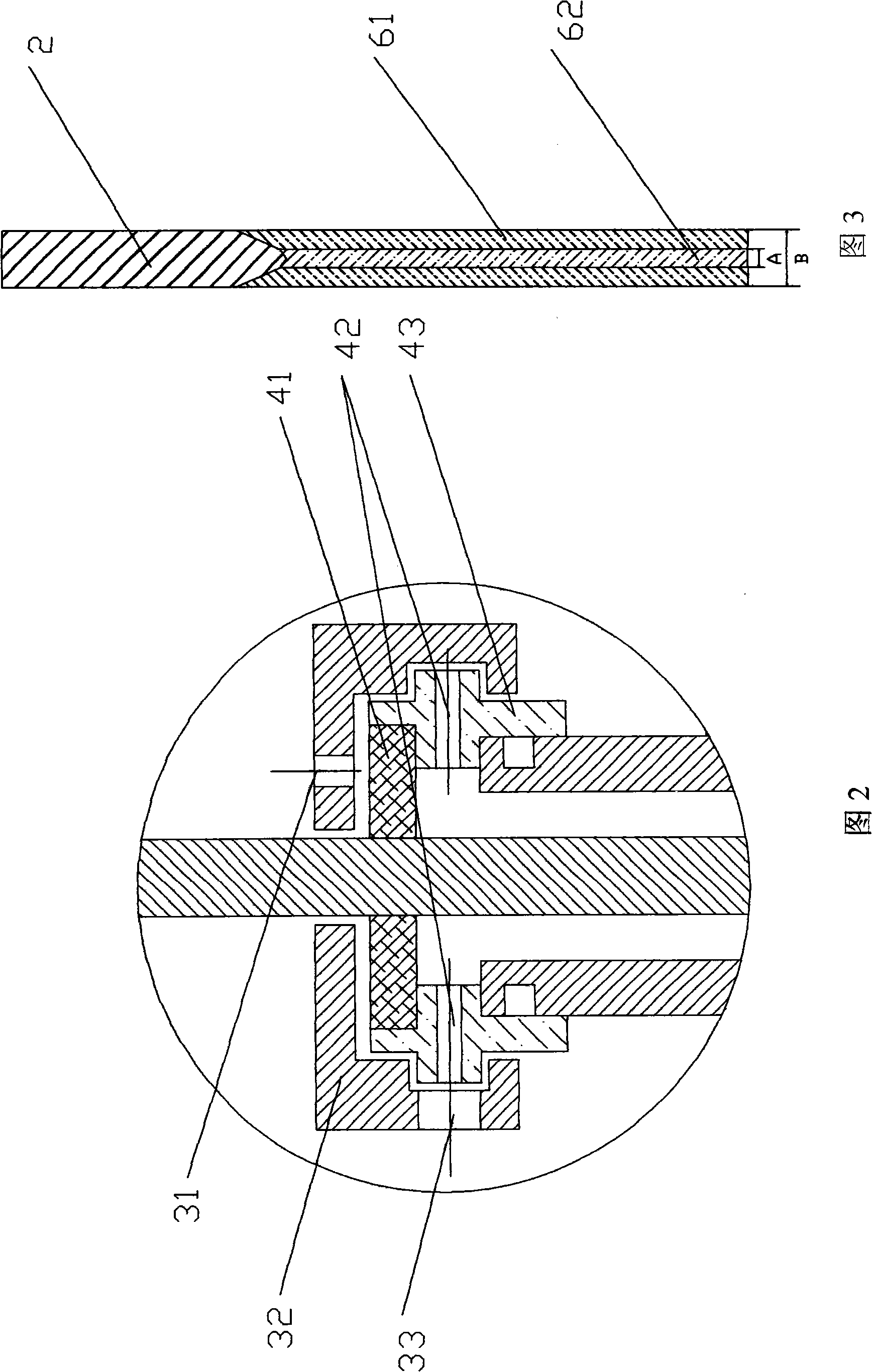

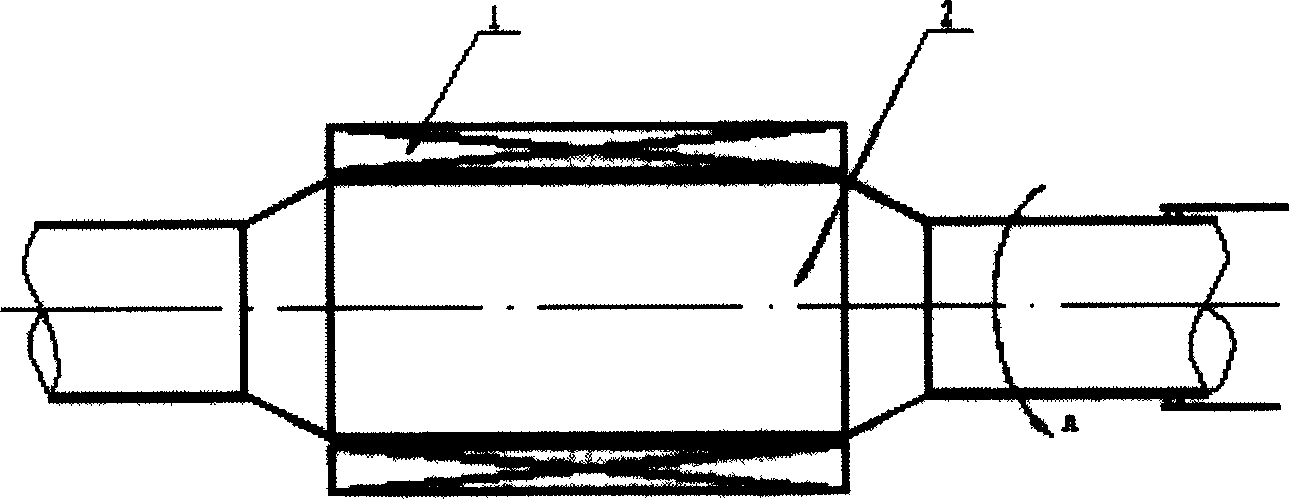

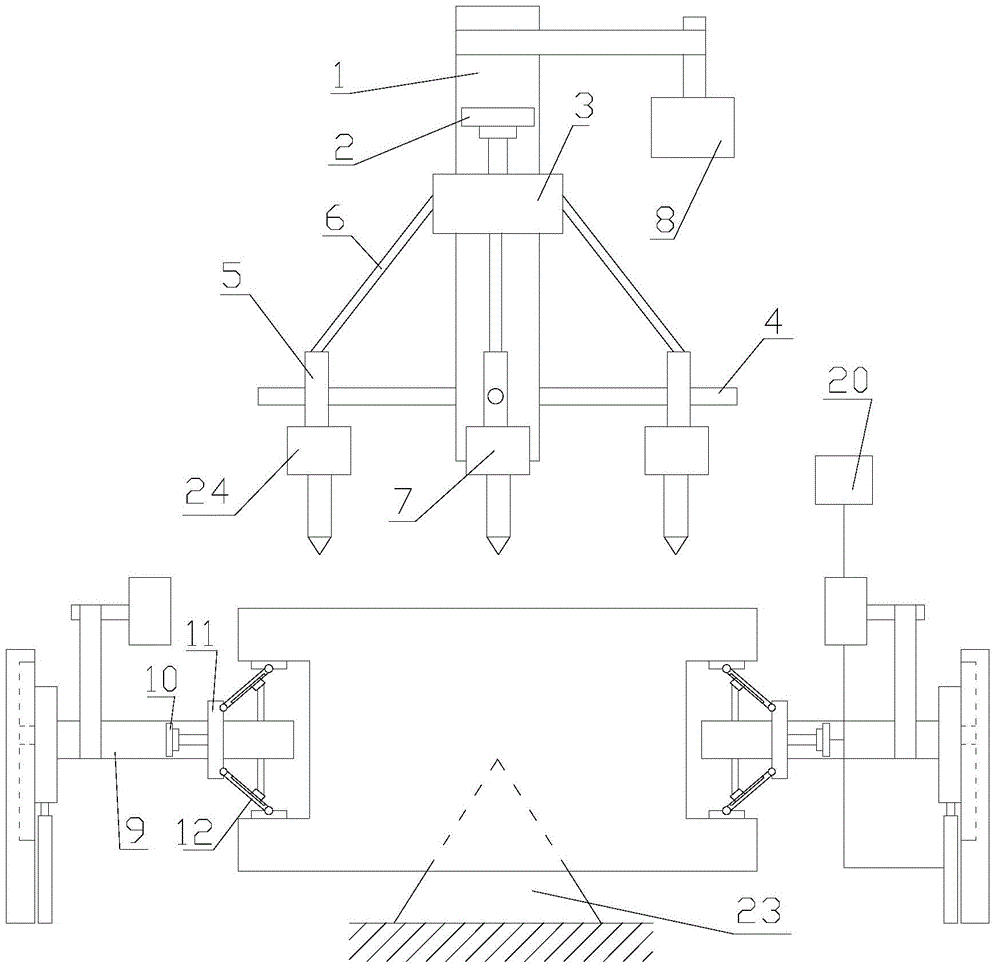

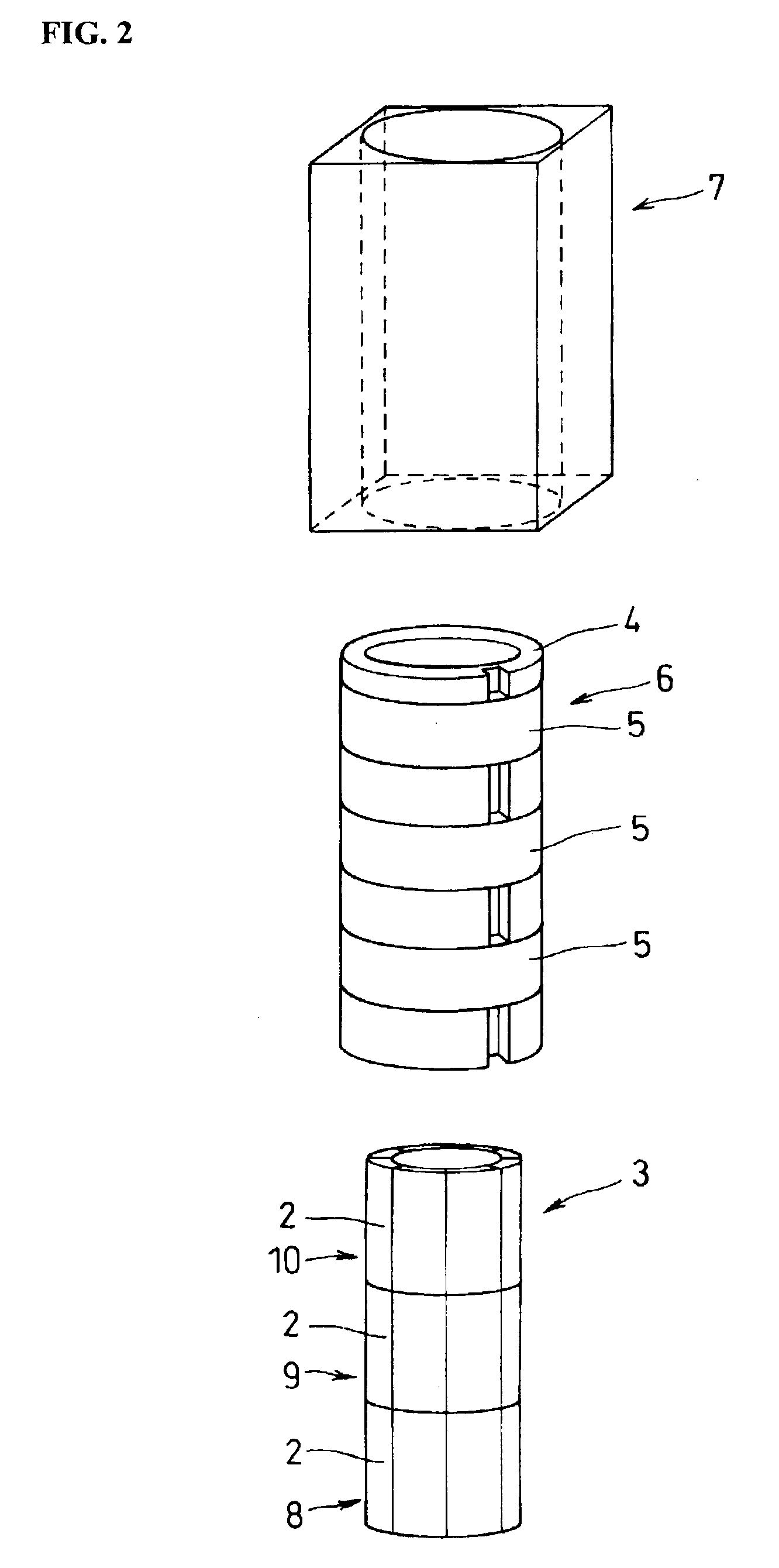

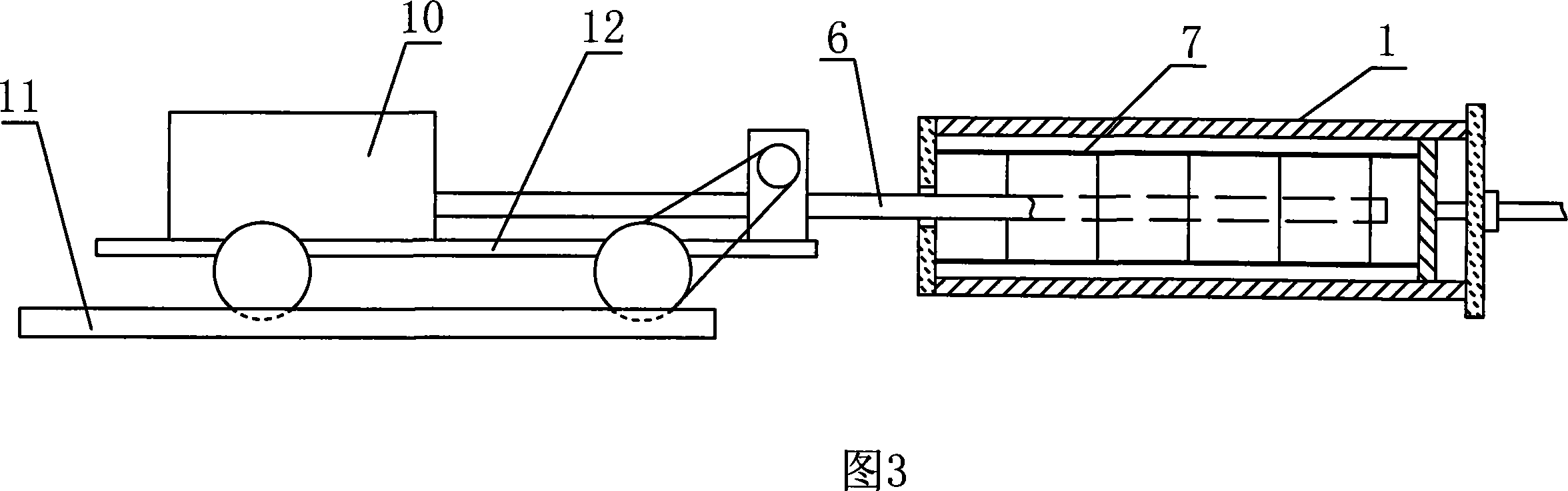

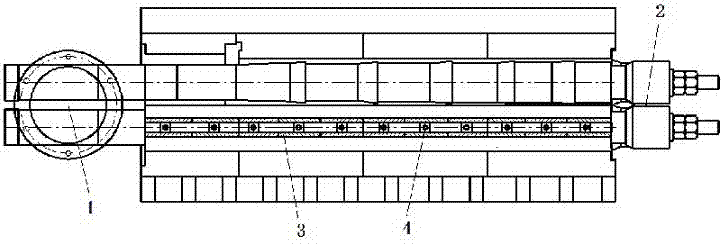

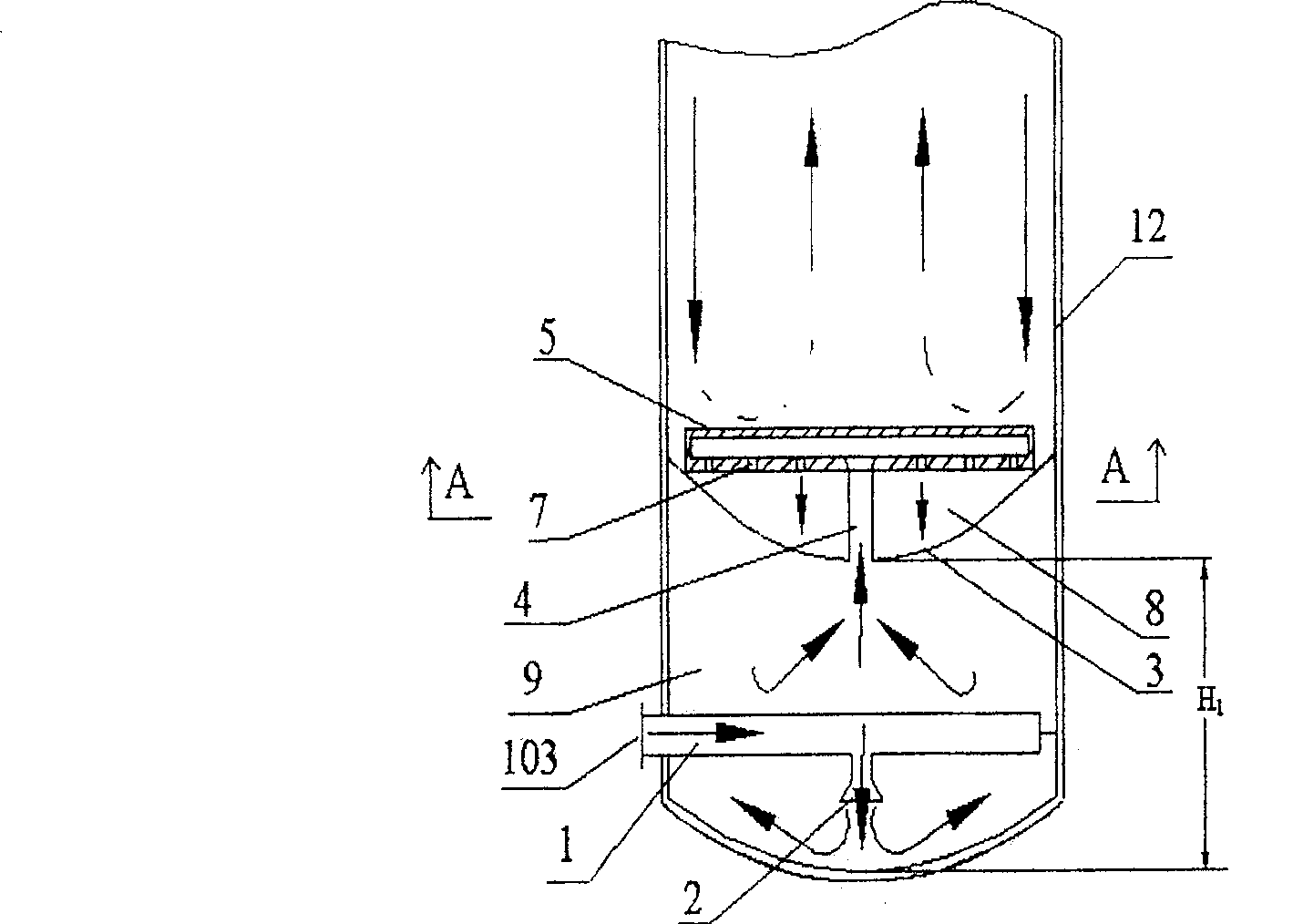

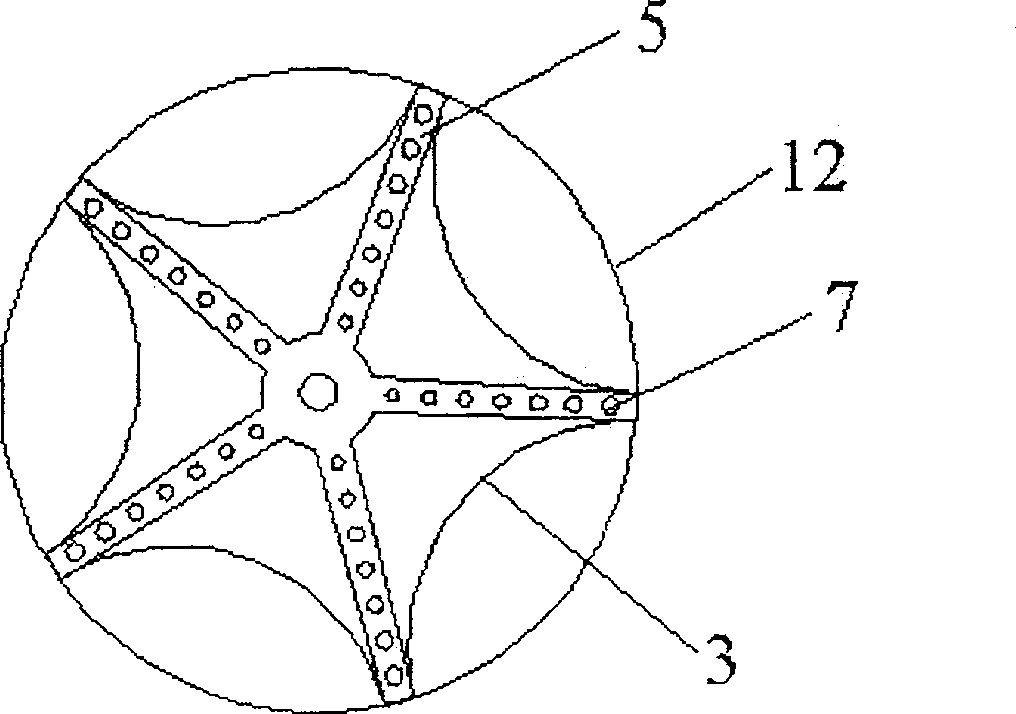

Pipe pile production technology and apparatus for axial distribution after mould combination

ActiveCN101161436AGuaranteed tightnessImprove sealingCeramic shaping apparatusMarine engineeringAxial distribution

The invention relates to a pipe pile production process of a matched die rear axial cloth and production equipment thereof. After the cage of reinforcement is mounted in lower hull die 9 of pipe pile die 1 which is composed of a up hull die 8 and a lower hull die 9 and rotates along the axis, the up hull die 8 and the lower hull die 9 are connected closely. The mixed concrete 5 is poured into the die of the pipe pile through concrete pouring port 3 on one end of the pipe pile die. The pipe pile die is driven to rotate by a drive mechanism 4 to make the concrete shape under the function of centrifugal force. The said pipe pile die is composed of a up hull die and a lower hull die and rotates along the axis. The stretching fixed parts are respectively allocated on the two ends of the pipeline die. The said concrete pouring port is mounted on the stretching fixed part at one end. The said process and production equipment are favourable for increasing the sealing performance of the matched die and uniformity of the cloth to greatly increase the production efficiency of the pipeline and outgoing quality of the pipe line.

Owner:FUJIAN DADI CONCRETE PILE

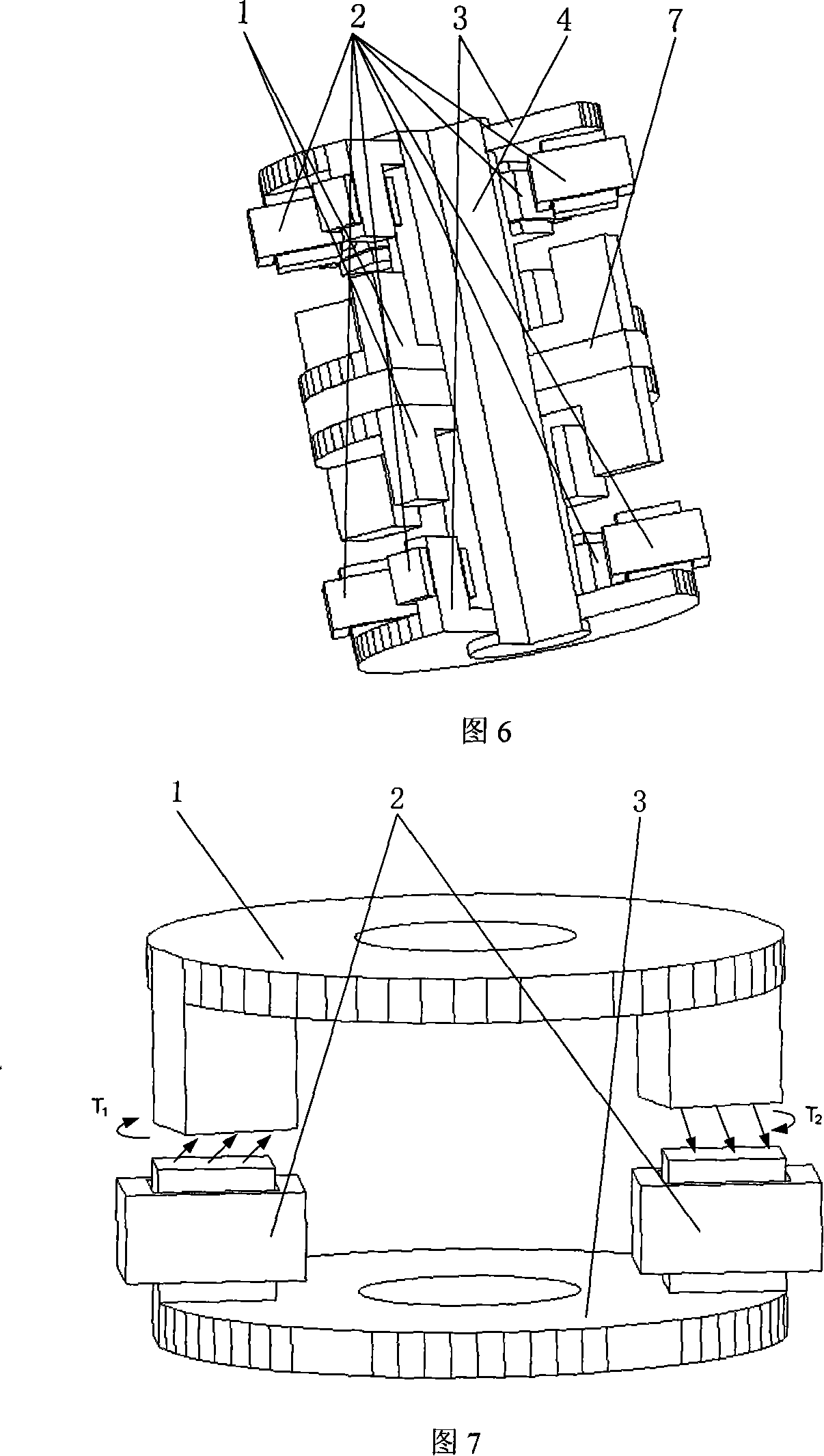

Axial switch reluctance motor

InactiveCN101119039AImprove applicabilityImprove cooling effectElectric machinesMagnetic circuit shape/form/constructionAviationRadial position

The present invention belongs to an electric transmission device filed, which is suitable for the transmission controlling in the special environment such as the electromotive vehicle filed, the food processing, the underwater operation, the nucleus industry, and the aviation field, The present invention consists of a rotor, a winding, a stator and an axis, the rotator and the stator are distributed along the axial direction. The directions of the rotator pole and the stator pole are along the axial direction, and the rotator pole and the stator pole are faced with each other along the axial direction. The pole number of the rotator and the stator can adopt the 6 to 4, 8 to 6, 12 to 8, or 4 to 6, 6 to 8, 8 to 12 and other type of the prior SRM proposal. The rotator and the stator adopt the different rotating axis, the rotator and the rotating axis can be completely separated from the stator. Due to the stator and the rotor has the distance along the axial direction, change the radial position to the axial direction relation, the radial size is decreased, the radial of the rotator is not limited, only need to form the magnetic loop with the stator at the axial direction, the energy transmission manner is changed to the direct axial direction transmission, and beneficial to the heating output of the electromotor, and suitable for using as the electromotor of the electric vehicle wheel.

Owner:JIANGSU UNIV

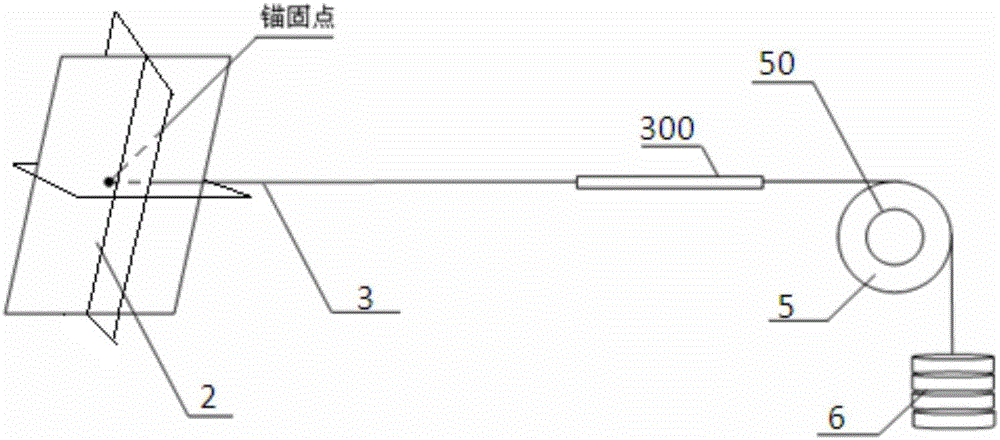

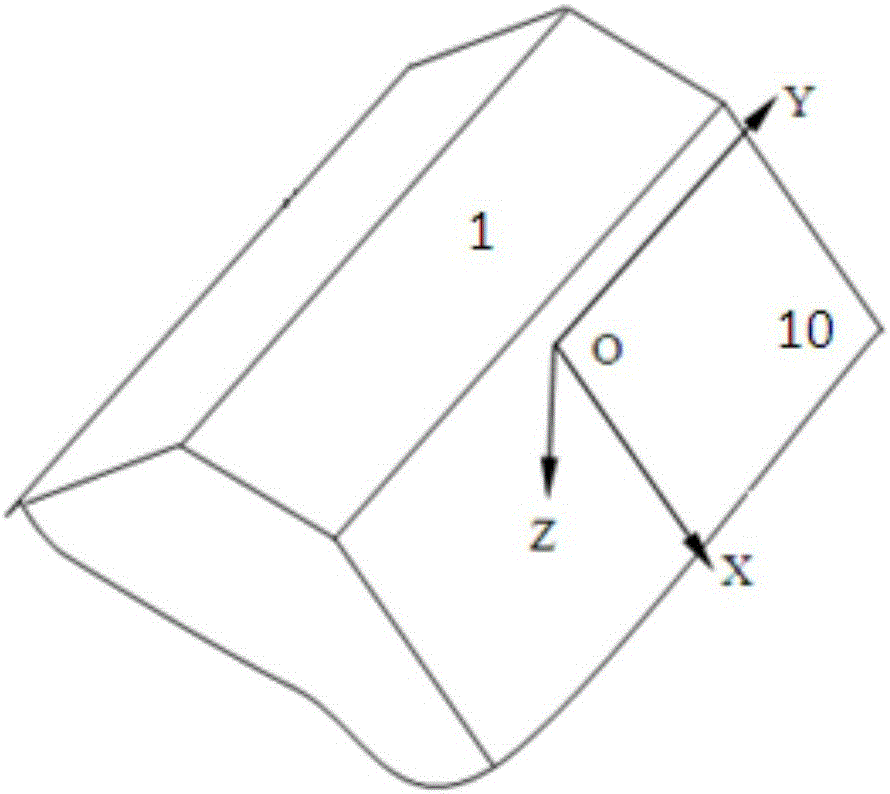

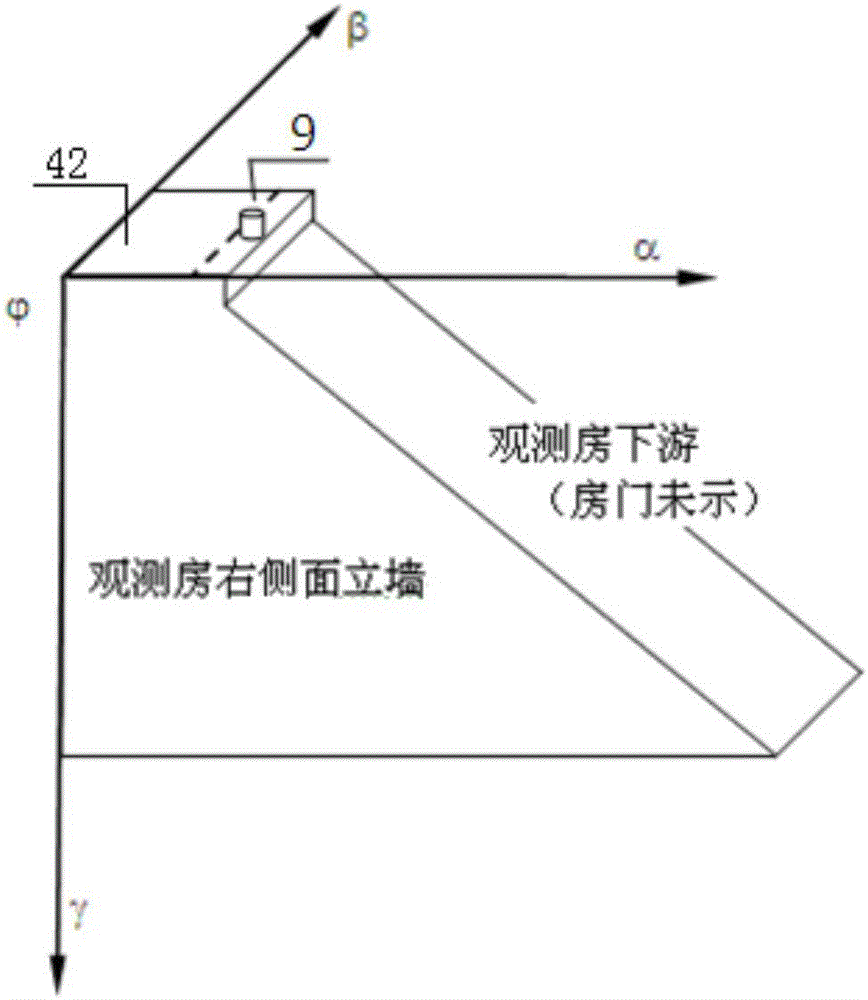

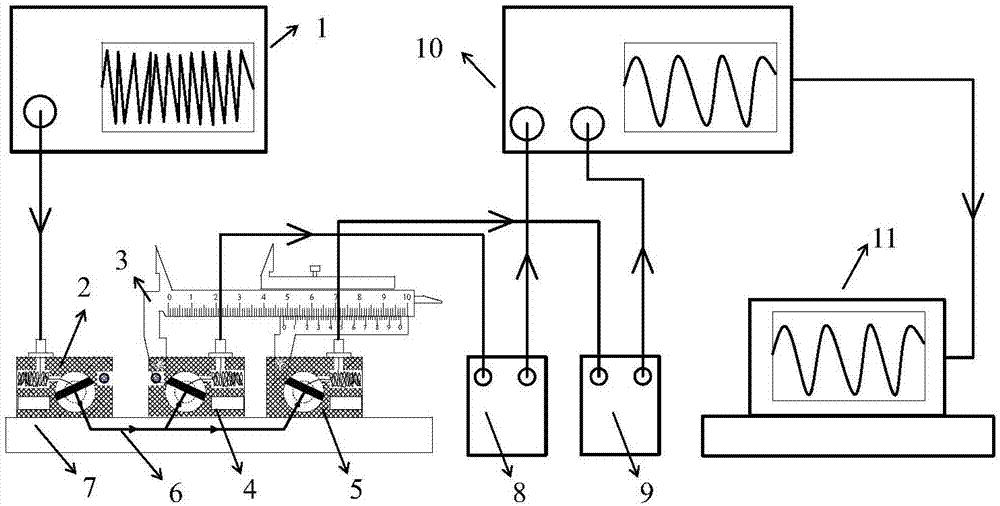

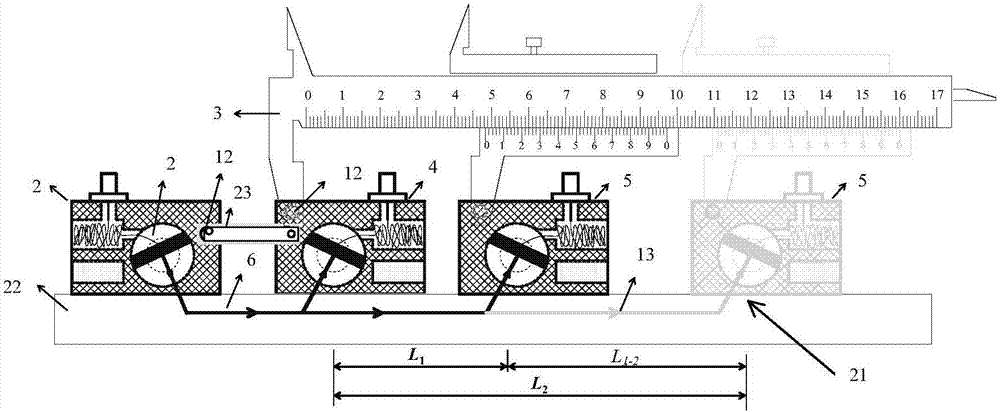

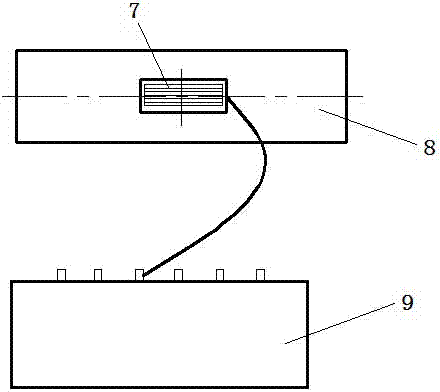

Actual measurement device and method of ultrahigh earth-rock dam internal 3D deformation

ActiveCN106679559AAccurate descriptionAccurate correctionElectrical/magnetic solid deformation measurementSatellite radio beaconingMeasurement deviceEngineering

The invention discloses an actual measurement device and method of ultrahigh earth-rock dam internal 3D deformation. Multi-edged stainless steel plate is buried in some parts that need to be monitored in internal dam, and a vector line body is anchored in the center of the stainless steel plate. The downstream of the line body monitoring facility installs in a wedge-shaped sectional view room inserted in the downstream surface of the dam. A GNSS receiving antenna is installed in the roof and a two-axis inclinometer is installed in four corners of baseboard to acquire 6D shift of the house. The upper wall of the house is reserved for the wide seam for introducing the vector line body that tensions by a fixed pulley and a weight. The angle is measured by the line body orientation measurement device. The line body axial elongation is measured by coaxial swirling potentiometer type displacement meter in a fixed pulley and axial distribution temperature correction is considered. The internal dam 3D deformation can be gained by combining a sensor measurement value and a level-3 coordinate. The device and method has the advantages of high measurement accuracy, good stability and high reliability.

Owner:NANJING AUTOMATION INST OF WATER CONSERVANCY & HYDROLOGY MINIST OF WATER RESOURCES +1

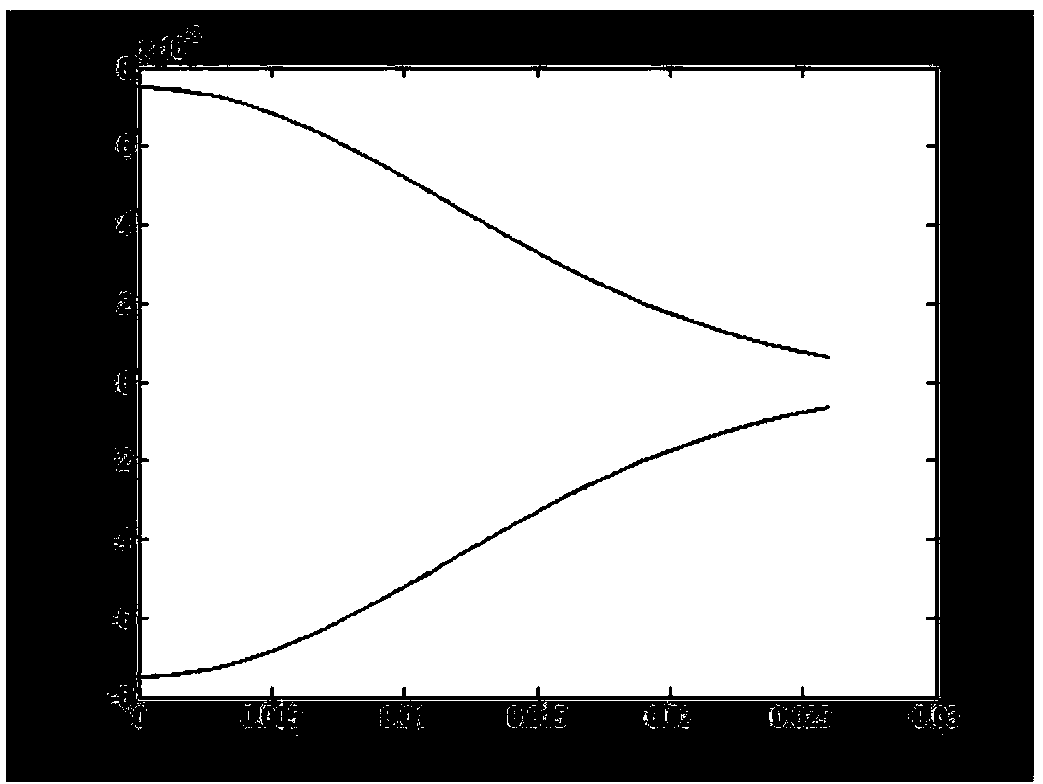

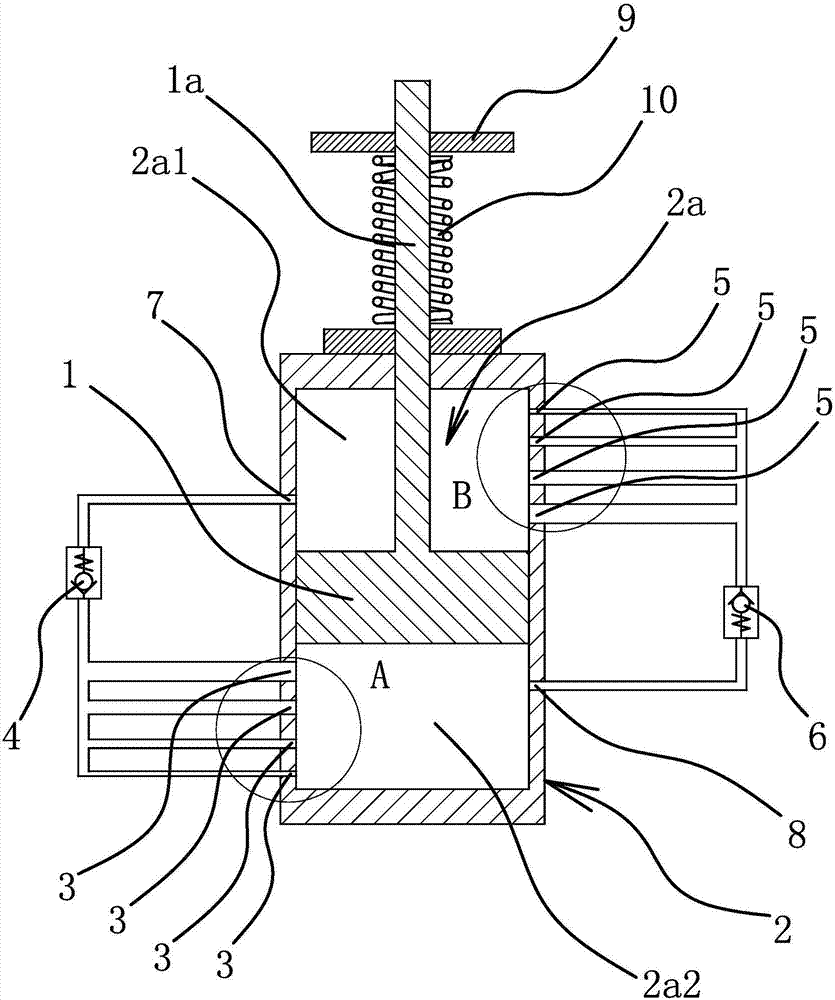

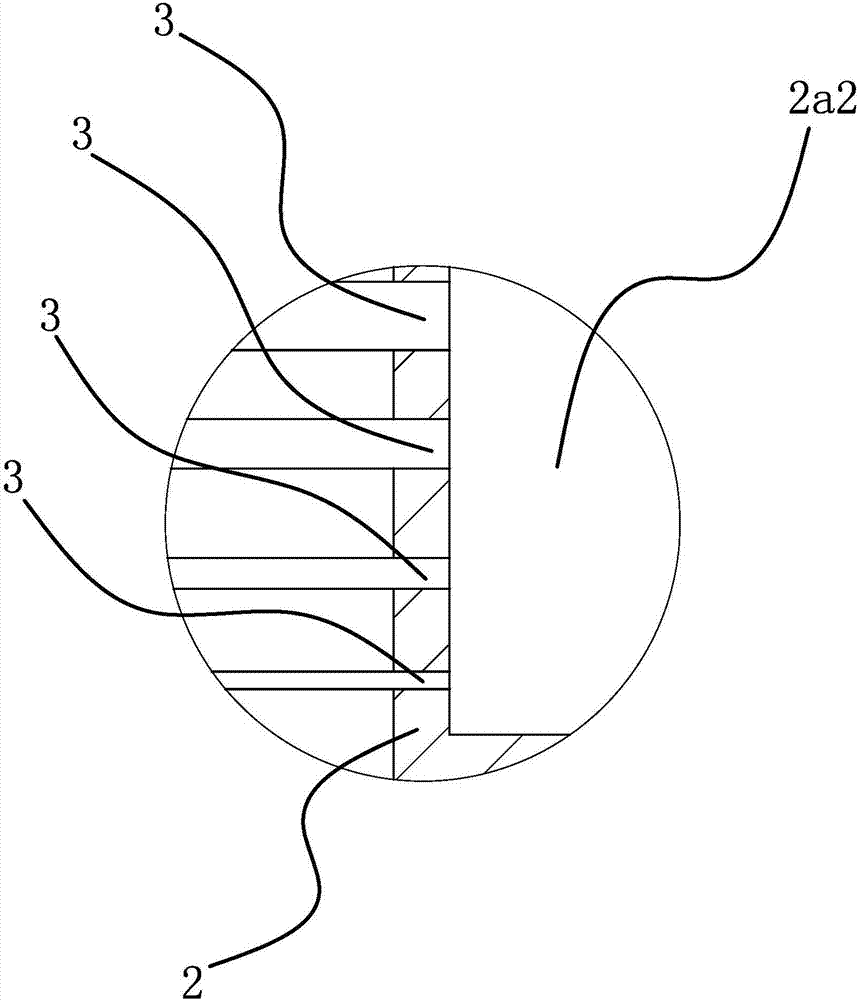

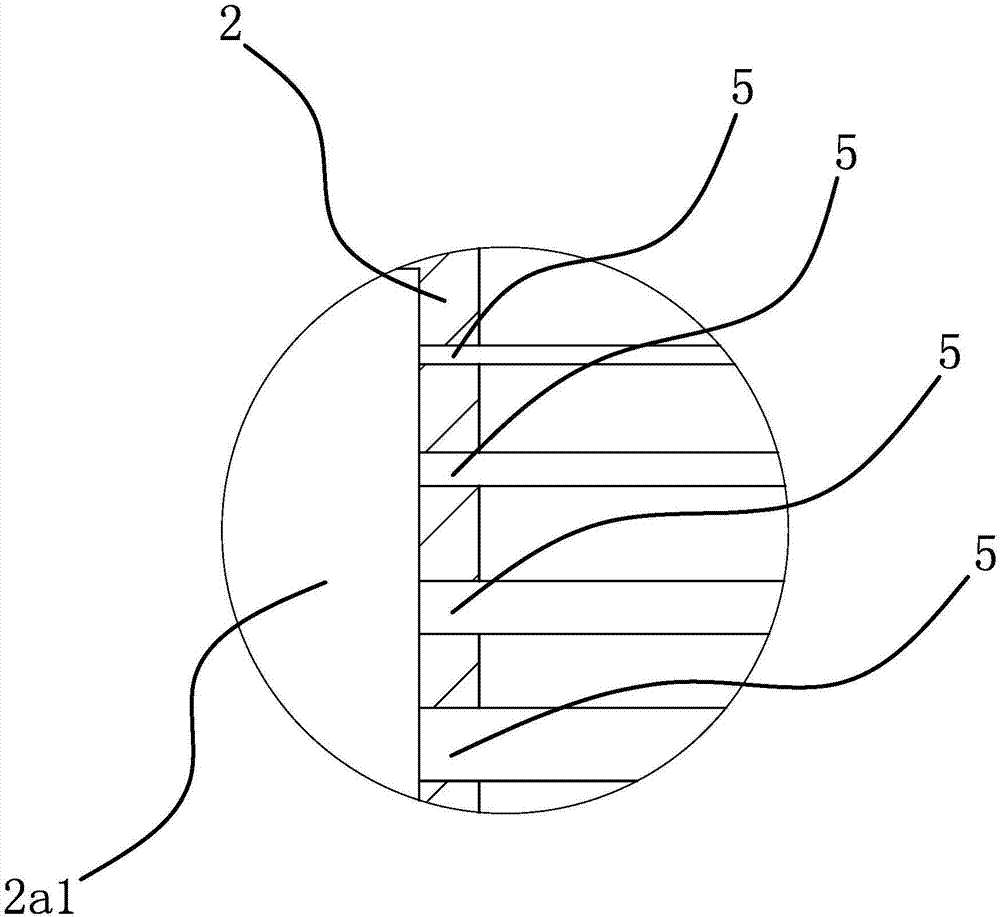

Straight line wave power generator based on magnetic gear

InactiveCN101968025ANo mechanicsNo maintenanceMachines/enginesSafety/regulatory devicesCompound aWave power generation

The invention relates to a straight line wave power generator based on a magnetic gear, solving the defects of large volume, complicated system and low efficiency of a motor used in the wave power generation by compounding a line power generator with the magnetic gear. The invention realizes the integration of the magnetic gear and the line power generator by removing the high-speed side of the traditional magnetic gear. The straight line wave power generator comprises a power generator primary winding and a power generator secondary winding, wherein the power generator primary winding comprises a primary iron core (1), a primary winding (2) and a magnetic adjusting ring (3); the magnetic adjusting ring (3) is distributed between the primary winding (2) and a permanent magnet (4) along the axial direction of a cylinder and fixed on the primary iron core (1), and the primary winding (2) is embedded in a wire slot of the primary iron core (1) which is fixed on the bottom of water; the power generator secondary winding comprises a permanent magnet (4) and a rotor iron core (5); and the low-speed side of the magnetic gear is the permanent magnet (4), and uniformly attached on the surface of the rotor iron core (5) along the axial direction of the cylinder, the rotor iron core (5) is fixed in a floating cylinder (6), and the rotor iron core and the floating cylinder as an integer float on a water level (7).

Owner:SOUTHEAST UNIV

Automatic adjustment vibration reducer

ActiveCN106958619AGood vibration dampingIncrease resistanceSpringsLiquid based dampersVibration amplitudeAuto regulation

The invention provides an automatic adjustment vibration reducer, and belongs to the technical field of automobiles. The automatic adjustment vibration reducer solves the technical problem that in an existing vibration reducer, the magnitude of resistance borne by a main piston cannot be adjusted according to vibration amplitude. The automatic adjustment vibration reducer comprises a main piston, a piston rod, an ascending one-way valve, a descending one-way valve and a hydraulic oil cylinder. A working oil cavity is formed in the hydraulic oil cylinder. The main piston is located in the working oil cavity. The lower end of the piston rod is fixedly connected with the main piston. Multiple lower damping oil holes are formed in the side wall of the lower portion of the hydraulic oil cylinder, and the lower damping oil holes are distributed in the axial direction of the hydraulic oil cylinder. The ascending one-way valve can block all the lower damping oil holes. Multiple upper damping oil holes are formed in the side wall of the upper portion of the hydraulic oil cylinder, and the upper damping oil holes are distributed in the axial direction of the hydraulic oil cylinder. The descending one-way valve can block all the upper damping oil holes. According to the vibration reducer, the magnitude of resistance borne during up-and-down movement of the piston can be adjusted according to the vibration amplitude, and a good vibration reduction effect is achieved.

Owner:TAIZHOU VOCATIONAL & TECHN COLLEGE

Steel member absolute stress distribution detection method based on critical refraction longitudinal waves

ActiveCN107063526AAchieve non-destructive testingSimple methodForce measurementStress distributionMetallurgy

The invention discloses a steel member absolute stress distribution detection method based on critical refraction longitudinal waves. Through calibrating a stress-sound time difference coefficient of the critical refraction longitudinal waves on a sonic path distance of a steel member, a single-emission and double-receiving sensor set is employed to detect the sound propagation time on the corresponding sonic path distance of the in-service steel member, an absolute stress of the steel member is solved, and axial distribution of the absolute stress of the steel member is acquired; the single-emission and double-receiving sensor set comprises an emission sensor and two receiving sensors. The method is advantaged in that damageless detection on axial distribution of the absolute stress of under-construction and well-constructed steel members can be realized, test on a local absolute stress of the in-service steel member can be realized, absolute stress distribution of the in-service steel member can be acquired, and stress distribution of a region of the in-service steel member having relatively large absolute stress gradient can be especially accurately tested.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

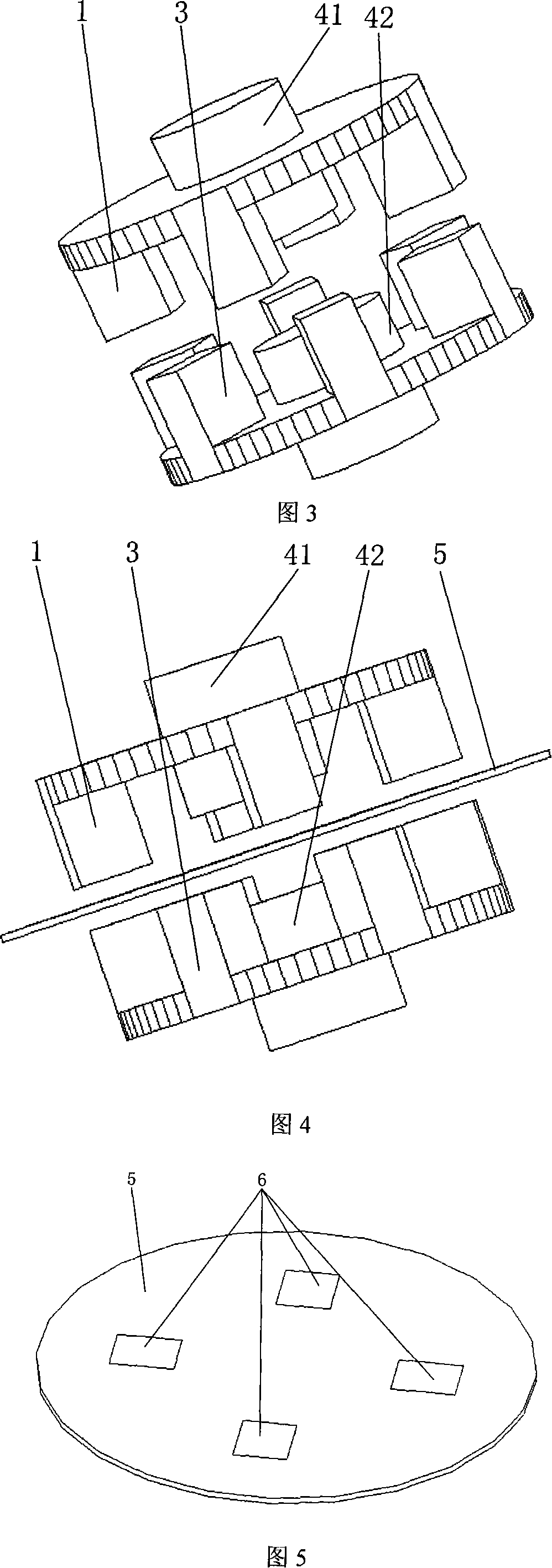

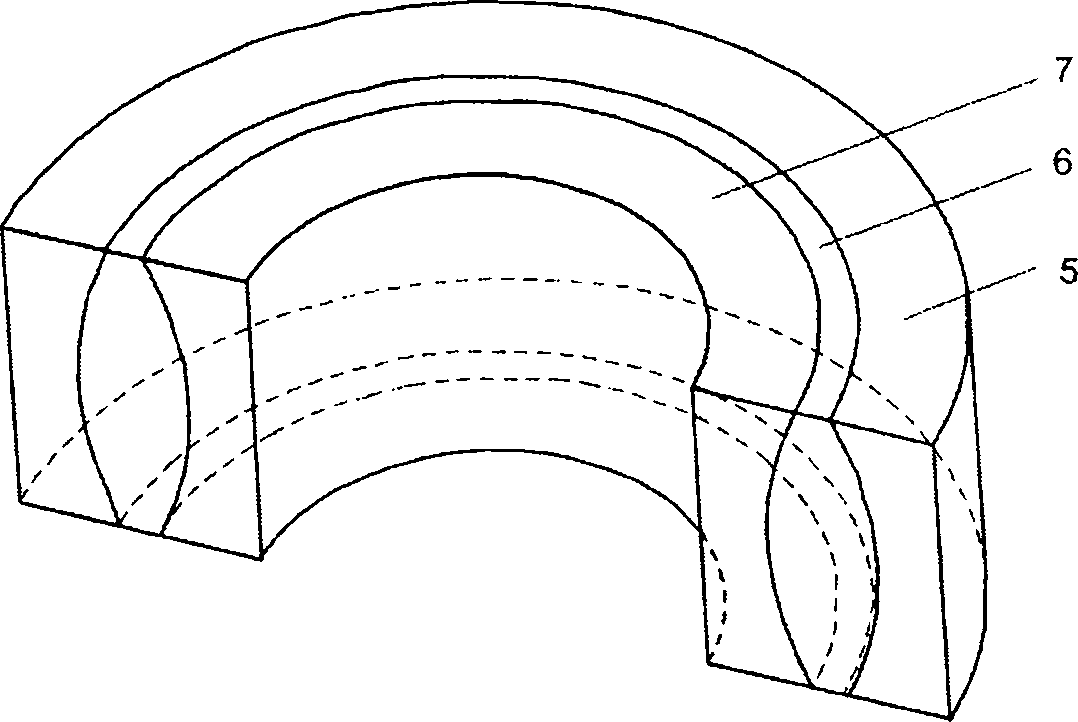

Permanent magnet brushless moment motor with double stators

InactiveCN102035322AMake up for the large equivalent air gapMake up for the serious defect of magnetic flux leakage at the endMagnetic circuit rotating partsMagnetic circuit stationary partsAxial distributionAir gap flux density

The invention discloses a permanent magnet brushless moment motor with double stators, mainly comprising a rotor shaft, an inner stator core, an inner stator cup, an outer stator core, an outer stator cup, a rotor core, rotor inner magnetic steel and rotor outer magnetic steel, wherein the rotor inner magnetic steel and the rotor outer magnetic steel are in a structure with a thin middle part and two thick ends along the axial direction; the rotor inner magnetic steel, the rotor outer magnetic steel and the rotor core jointly form a rotor assembly arranged between the inner stator cup and the outer stator cup; the inner stator cup and the outer stator cup are respectively fixedly connected with the inner stator core and the outer stator core; and the inner stator core and the outer stator core are connected to a main case through sleeves. The unequal thickness design of the rotor inner magnetic steel and the rotor outer magnetic steel in the invention compensates the influence of brow leakage on axial air gap flux density distribution and ensures the uniform axial distribution of the air gap flux density; coils of an inner stator winding and an outer stator winding jointly form the coils of a motor winding, the serial connection turn number of windings of each phase is increased to ensure that the moment coefficient of a motor becomes large, thereby increasing the moment density and reducing the volume of the motor.

Owner:BEIHANG UNIV

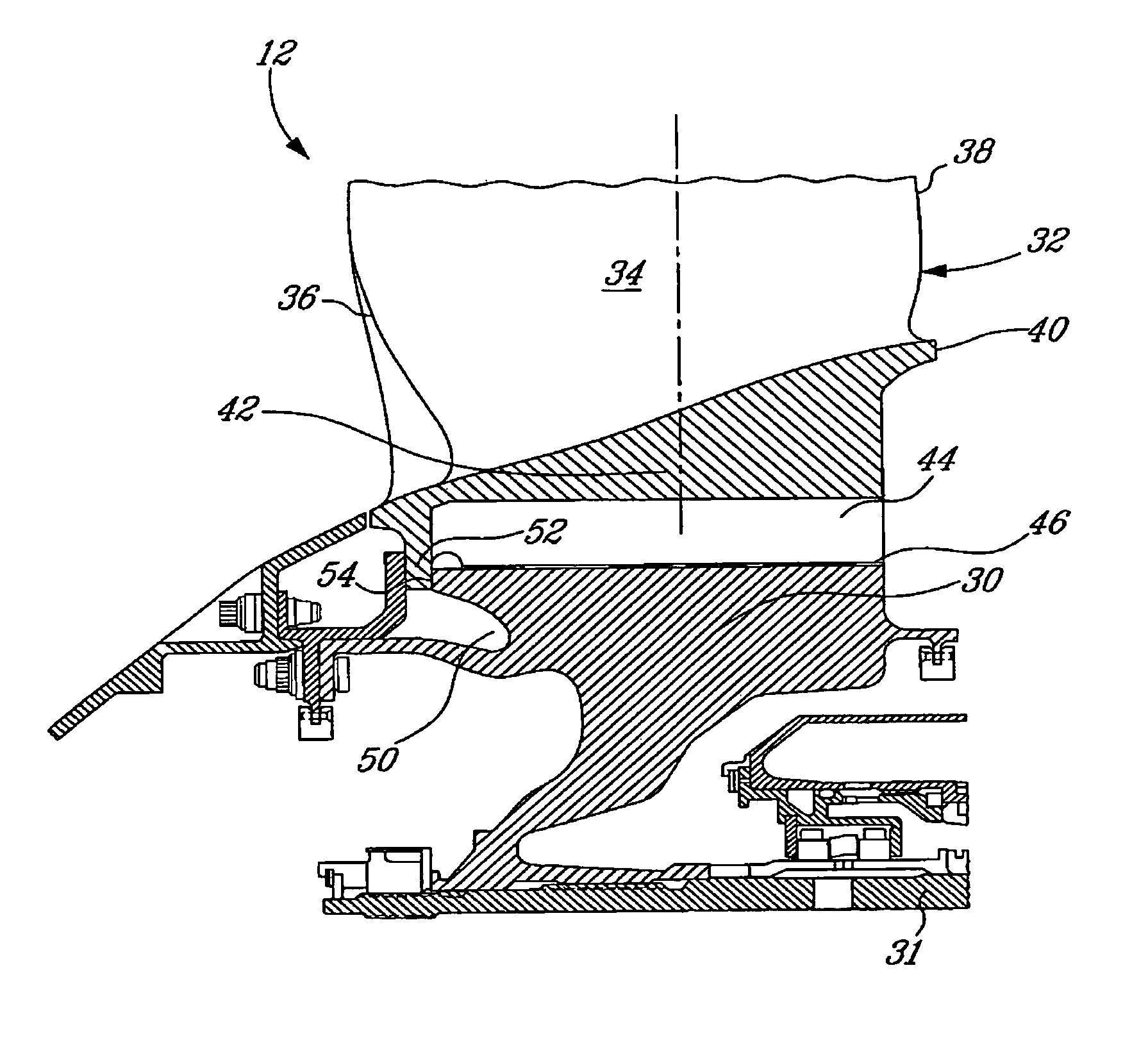

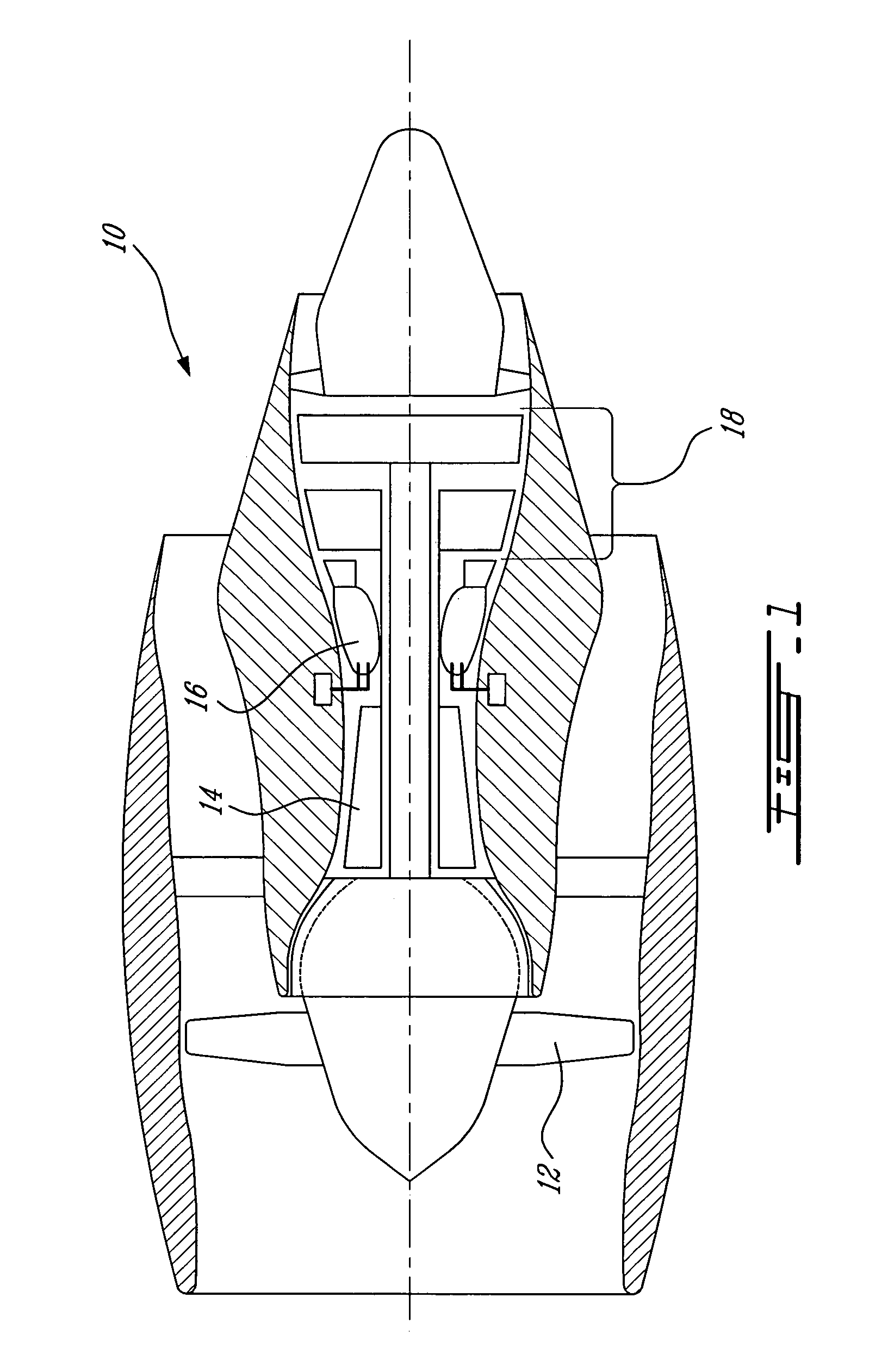

Bladed disk fixing undercut

An undercut is provided in a gas turbine engine disk to smooth out an uneven axial distribution of radial stress in the disk. The undercut is defined radially inwardly of the blade attachment slots provided at the periphery of the disk.

Owner:PRATT & WHITNEY CANADA CORP

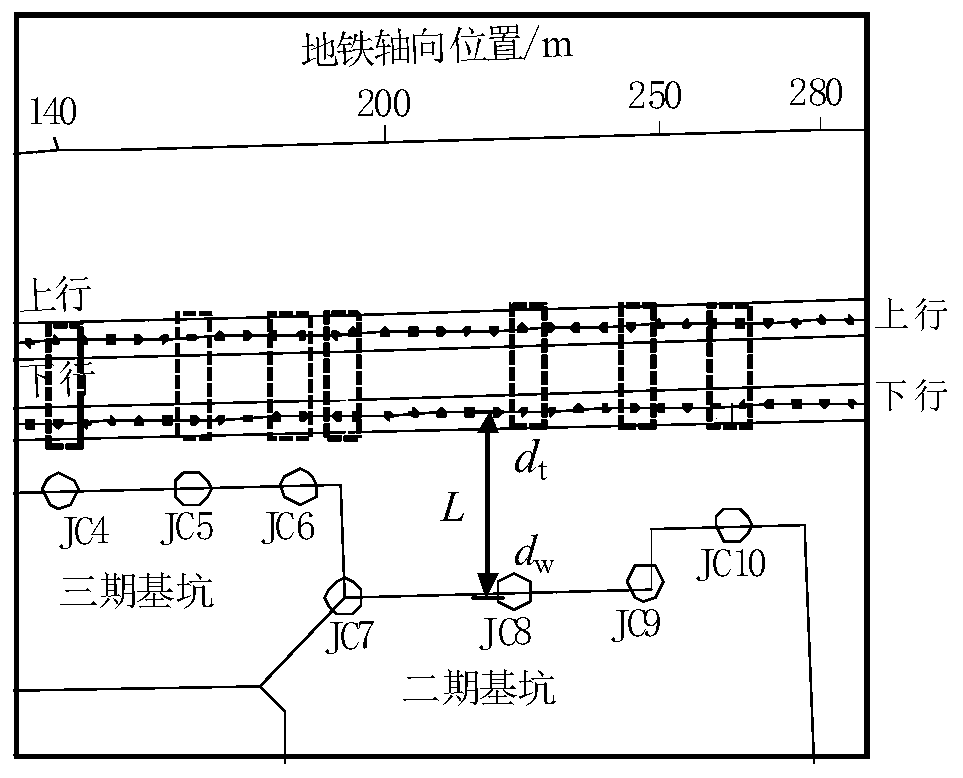

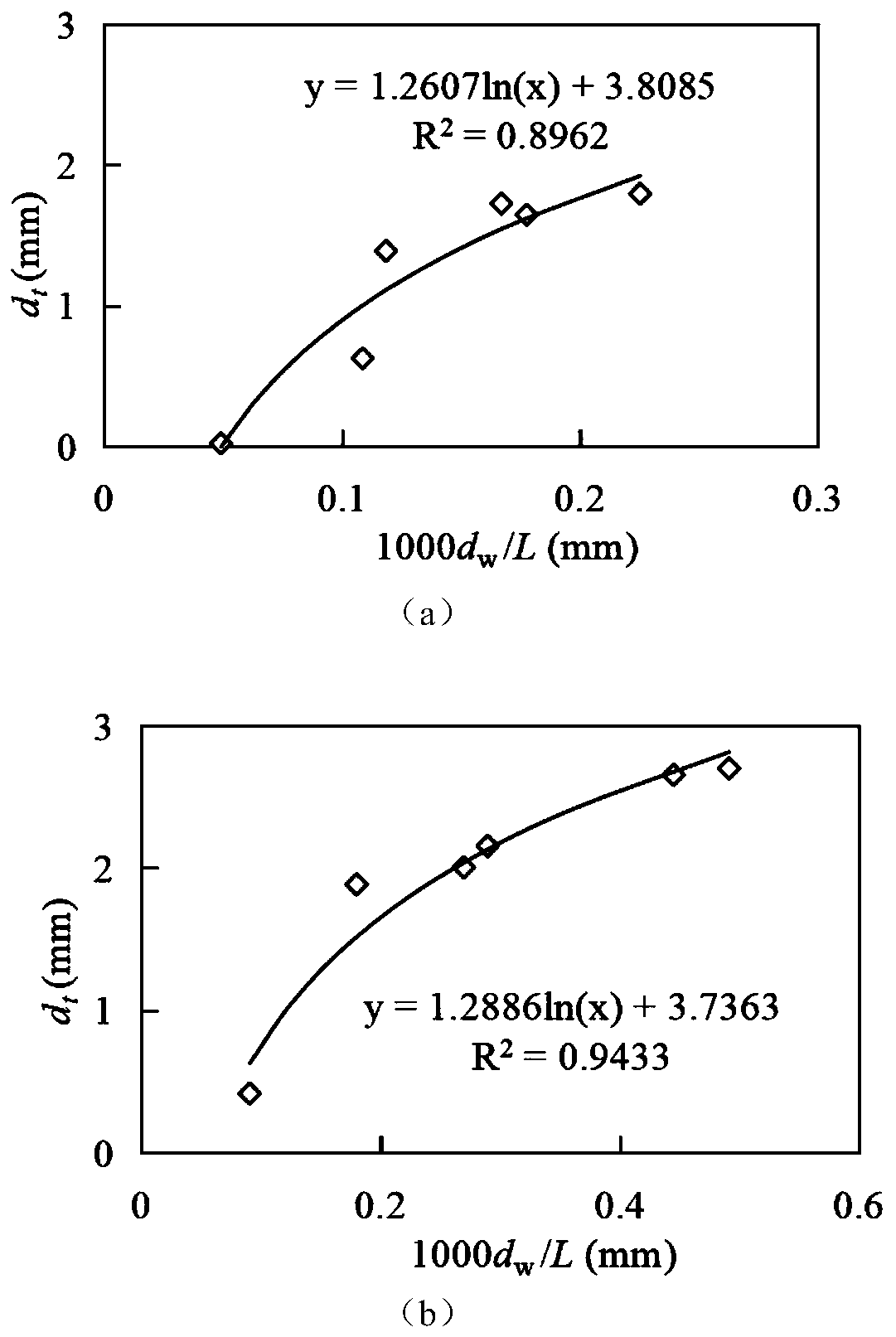

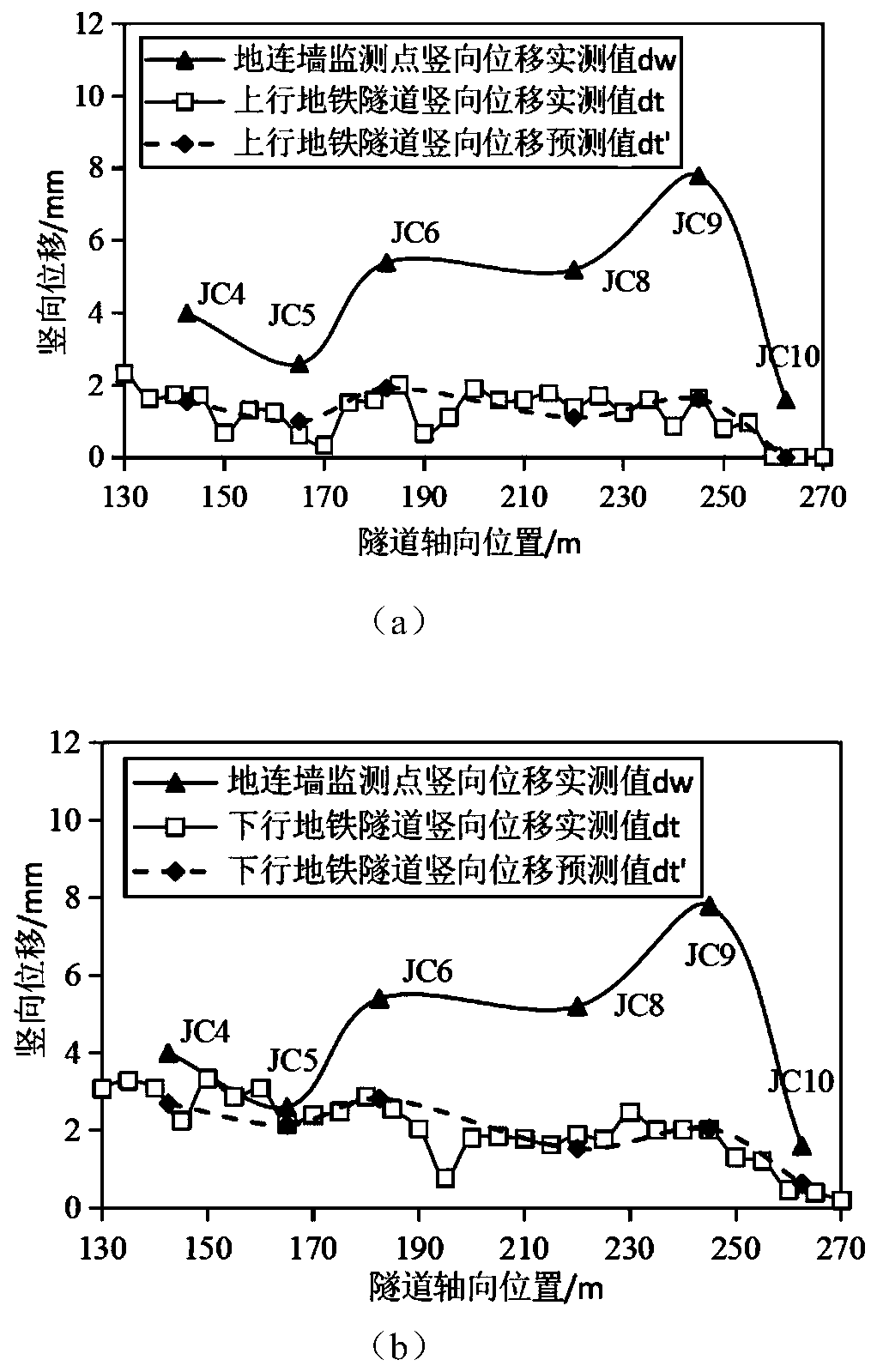

Prediction method for vertical deformation of existing subway tunnel adjacent to foundation pit engineering

PendingCN110727985APredict vertical deformation trendsReduce monitoring costsGeometric CADMonitoring siteAxial distribution

The invention discloses a prediction method for vertical deformation of an existing subway tunnel adjacent to foundation pit engineering. The prediction method comprises: monitoring a foundation pit and a tunnel structure adjacent to the foundation pit laterally, and analyzing vertical displacement characteristics of an enclosure structure and the tunnel structure; recording a cumulative verticaldisplacement measured value of the enclosure structure as dw and a cumulative vertical displacement measured value of the tunnel structure as dt, taking the axial direction of the tunnel as an x-axisdirection, taking the position of a first monitoring point as an x-axis zero point, taking the monitoring data of each monitoring point as a data point, and drawing distribution curves of dw and dt along with the axial position of the tunnel; recording the horizontal distance between the enclosure structure and the adjacent ascending and descending tunnels as L; drawing a relation curve of dt and1000dw / L by considering the influence of L on the deformation correlation of the enclosure structure and the tunnel to obtain dt = Aln (1000dw / L) + B; obtaining dt' of different axial positions of thetunnel by utilizing dt'= Alg (1000dw / L) + B; and drawing a distribution curve of dt and dt' along the axial direction of the tunnel, calculating a prediction error, and evaluating a prediction effect.

Owner:TIANJIN UNIV

Clamping fixture for turning thin-walled pipe

InactiveCN108788856APrevent rotationImprove machining accuracyPositioning apparatusMetal-working holdersEngineeringAxial distribution

The invention provides a clamping fixture for turning a thin-walled pipe, comprising a four-jaw chuck, a fixing block arranged in the four-jaw chuck, a fixing shaft arranged on the fixing block and distributed along the axial direction of the fixing block, and a jacking device arranged in the radial direction of the fixing shaft, wherein the jacking device comprises a jacking barrel coaxial with the fixing shaft, and compression springs connecting the inner wall of the jacking barrel with the outer wall of the fixing shaft, the diameter of the jacking barrel is greater than the diameter of thefixing shaft, the fixing block is a cube, and the axial center line of the fixing block coincides with the axial center line of the fixing shaft and the axial center line of the four-jaw chuck. Through arranging the jacking device, the thin-walled part can be more conveniently jacked better. At the same time, the fixing shaft for being connected with the jacking device is connected with the cubicfixing block, and the four-jaw chuck is used for fixing the fixing block, so that it is ensured that jacking acting force can be applied to the axial direction and the radial direction of the thin-walled part, and the machining precision is improved.

Owner:永春宏达工业设计有限公司

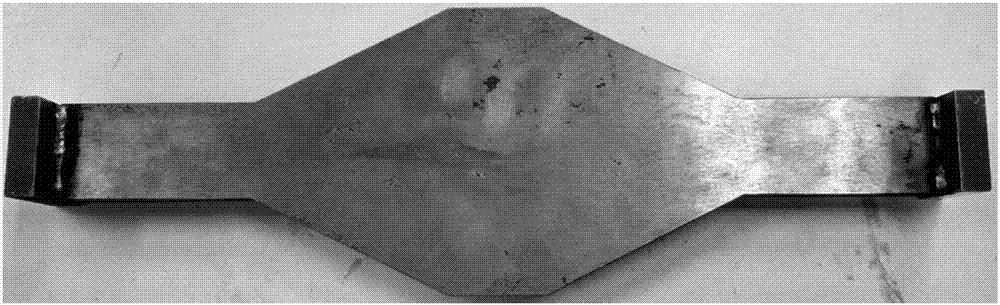

Chamber internal stress test method of screw oil press

ActiveCN104723600ASafe and reliable test method for internal stressEasy to testForce measurementPressesAxial distributionEngineering

The invention discloses a chamber internal stress test method of a screw oil press. The method includes the following steps that 1, a pressing bar on a pressing cage of the screw oil press is selected, and N manholes are drilled in the pressing bar; 2, N upper resistance strain gages and N lower resistance strain gages are attached to the outer wall of an pressing bar and a lower pressing bar adjacent to the pressing bar with the manholes in an up-down mode respectively; 3, pressure sensors are arranged in the manholes respectively; 4, the screw oil press is started to operate, and the strain values of the upper resistance strain gages, the strain values of the lower resistance strain gages and the pressure values of the pressure sensors are recorded and obtained; 5, through a bending calibration experiment, the chamber internal stress values corresponding to the stain values of the upper resistance strain gages and the stain values of the lower resistance strain gages are obtained; 6, averaging is conducted on the stress values of the pressure sensors and the corresponding chamber internal stress values obtained in step 5, and the stress values in the axial distribution direction in a chamber are obtained. The chamber internal stress test method of the screw oil press is safe, reliable, convenient and fast to test and real and accurate in test data and has important actual application value.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Ultra-dry filtering machine and filtrating method thereof

ActiveCN104587717AInfluence intensitySolve the problem of difficult deslimingFiltration separationHydraulic cylinderEngineering

The invention relates to an ultra-dry filtering machine and a filtrating method thereof. The ultra-dry filtering machine comprises a bed body and walls respectively arranged at the left side and the right side of the bed body. According to the invention, a slide track is laterally arranged on the bed body; a cylinder is arranged above the slide track; the bottom of the cylinder is installed on the slide track via a sliding block in a sliding way; pistons are respectively arranged on the left side and the right side in the cylinder; the left piston is connected with the left wall; a first hydraulic cylinder is connected to the right wall of the cylinder; the right piston is connected with a hydraulic rod of the first hydraulic cylinder; multiple filtering plates are axially distributed inside the cylinder; mud-cutting mechanisms are arranged between the filtering plates on two sides and the pistons on corresponding sides and between adjacent filtering plates. According to the invention, a mud-cutting net is arranged between the filtering plates, so as to enlarge gaps between the filtering plates while triggering the mud-cutting net to cut off solids between the filtering plates, thus solving the difficulty of mud removing of the prior art.

Owner:YANGZHOU RONGHENG MACHINERY MFG CO LTD

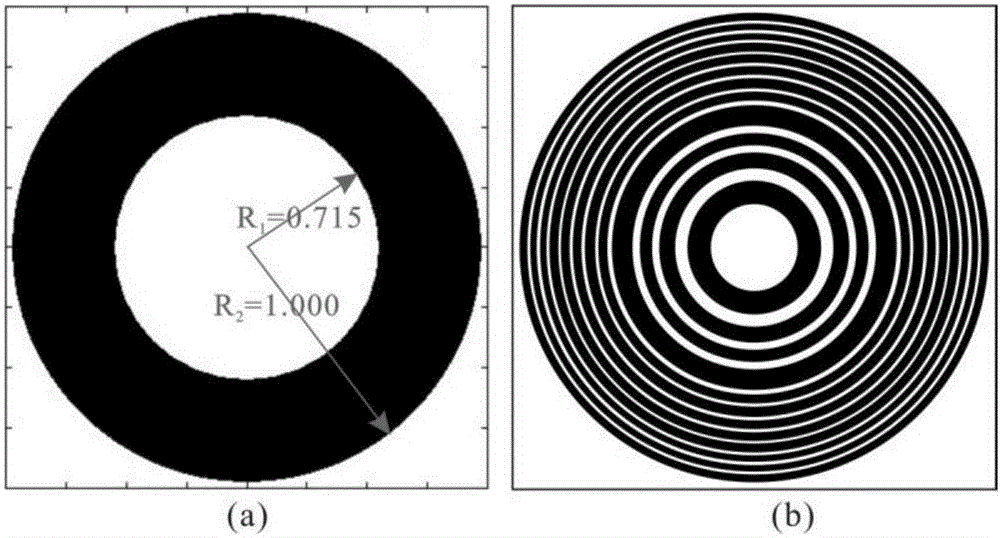

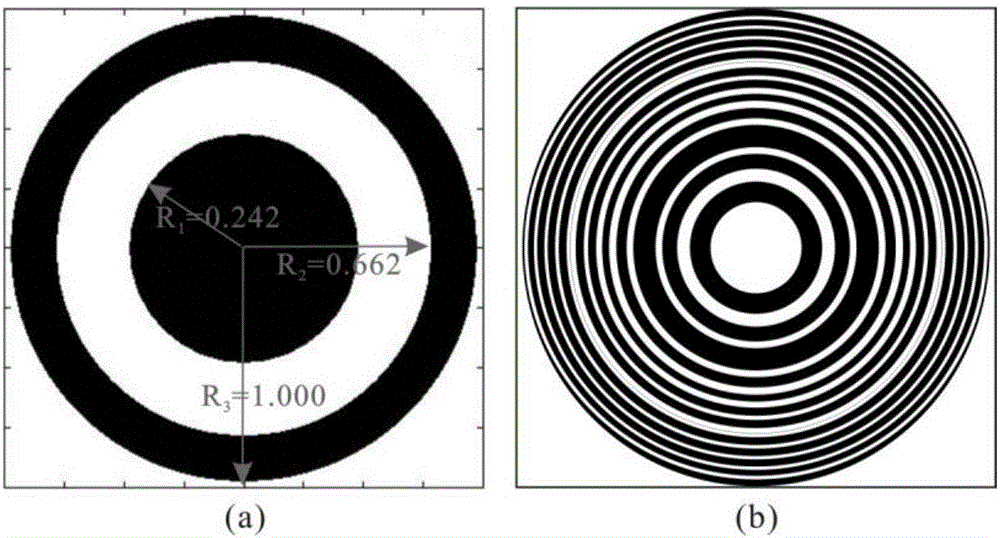

Fresnel-Dammann zone plate

ActiveCN106054295ARealize the effect of focal spot distributionEasy to processDiffraction gratingsWater windowClassical mechanics

The invention provides a Fresnel-Dammann zone plate which is composed of a transparent medium, an opaque metal thin-film and an annular zone structure. The Dammann modulation technology is introduced in the conventional Fresnel zone plate structure. The Fresnel-Dammann zone plate has a series of concentric ring structures so that axial distribution of multiple equal-intensity annular array focal spots can be realized under plane wave illumination without additional focusing lens. The Fresnel-Dammann zone plate is easy to process and reproduce and can be applied to the field of water window wave band, optical imaging and biomedicine.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

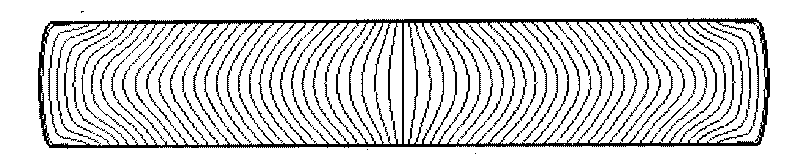

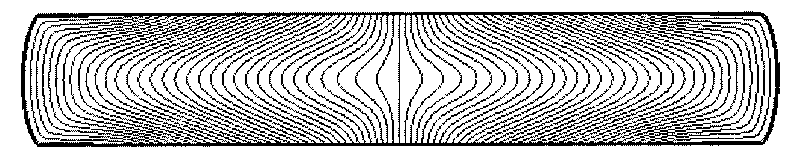

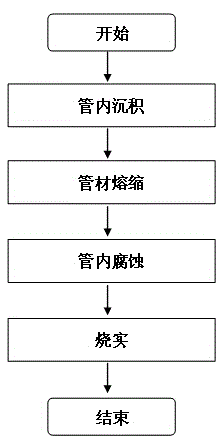

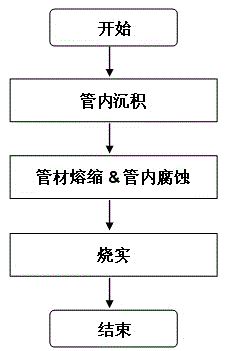

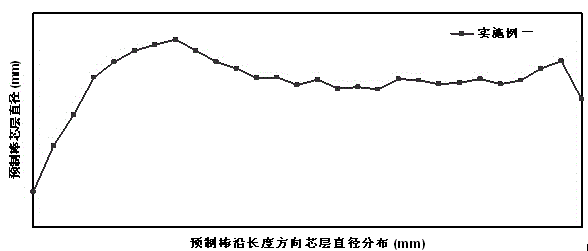

Collapsing manufacture method with improved axial evenness for core rods of optical fiber preforms

InactiveCN104098265AGuaranteed shrinkage qualityImproved core diameter uniformityGlass making apparatusEngineeringAxial distribution

The invention relates to a collapsing manufacture method with improved axial evenness for core rods of optical fiber preforms. The method comprises the following steps: mounting a quartz-doped liner tube on a collapsing lathe, rotating the quartz-doped liner tube, moving a heating furnace jacket from one end of the liner tube to the other end of the liner tube in the axial direction of the liner tube, collapsing the liner tube gradually to realize solid burning. During the collapsing process, the two ends of the liner tube are sealed, and O2 gas is led into the liner tube. The method is characterized in that the axial distribution condition of the sandwich layer diameter of the liner tube after deposition is confirmed before collapsing, and an F-contained corrosive gas is led into the liner tube during the collapsing process of the liner tube to conduct different axial corrosion on the inner wall of the liner tube, or O2 gas and the F-contained corrosive gas are led into the liner tube simultaneously after collapsing and before solid burning to conduct different axial corrosion on the inner wall of the liner tube. The method has the advantages that the effect that different areas in the liner tube are corroded differently is realized by adjusting the flow rate of corrosive mixed gas, and fixed point corrosion is realized, so that the diameter evenness of the core rods of the optical fiber preforms can be improved remarkably. Therefore, optical fiber preparation cost can be reduced; the production efficiency can be improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

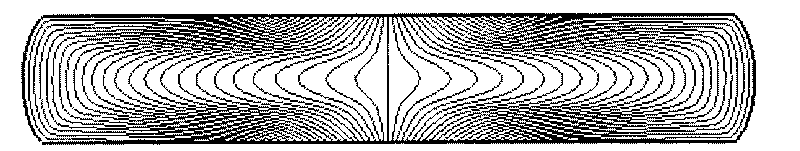

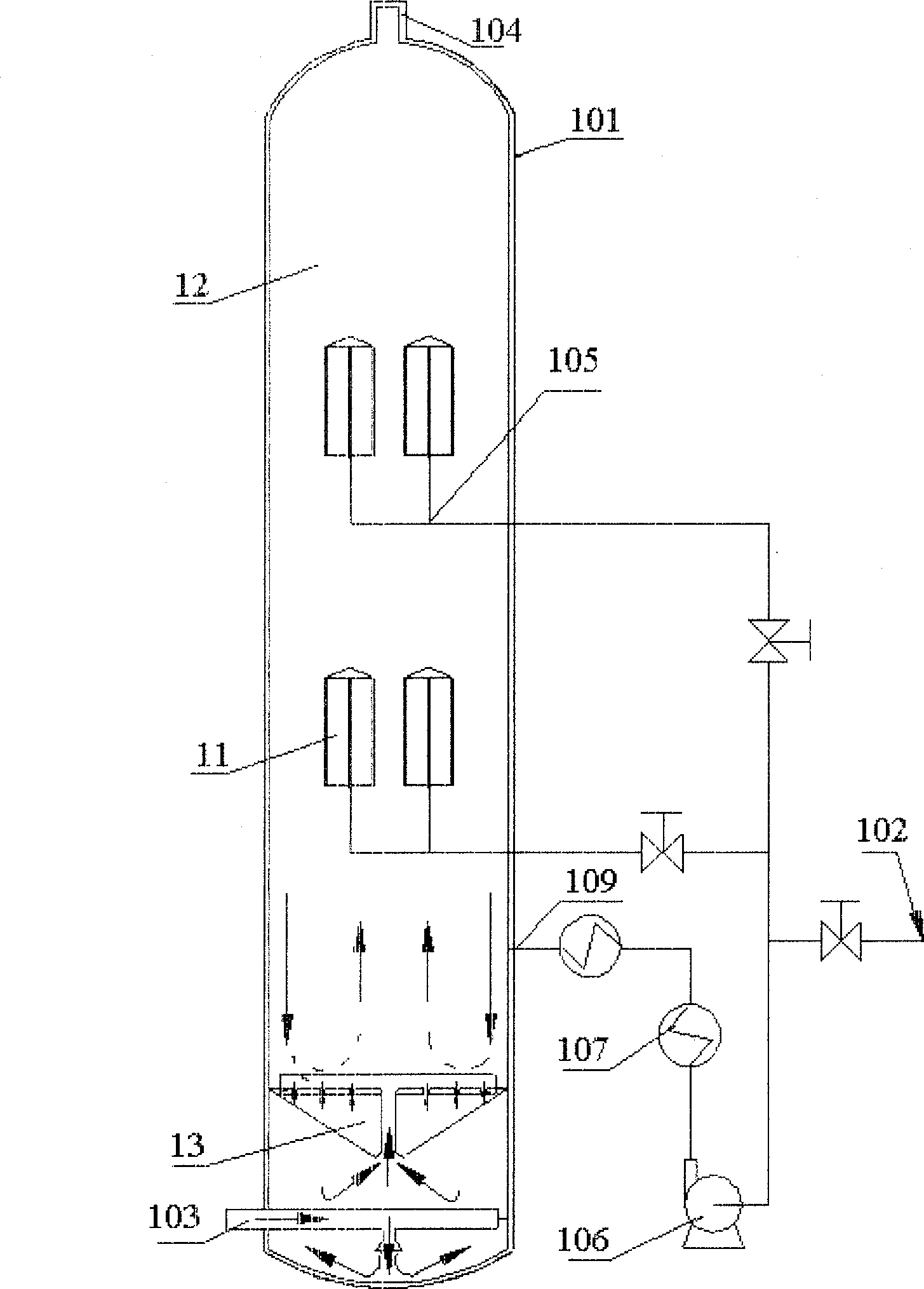

Slurry bubble columun reactor having internal circulation and external heat-exchanging and the application

ActiveCN100512941CAxially distributed evenlyPrevent subsidenceChemical/physical processesLiquid mediumCirculator pump

The invention discloses a slurry bed reaction device with internal circulation and external heat exchange and its application. Comprising a tower-type gas-liquid-solid three-phase slurry bed reactor (12) with a cylindrical shell, a tubular filter (11) vertically arranged in said reactor (12), an orifice gas distributor, a heat exchange device (107) and circulation pump (106). The device of the invention can be used for the reaction of synthesis gas to generate gas or liquid fuel in the presence of catalyst and liquid inert medium. In the present invention, there is an internal gas circulation at the bottom of the reactor, the catalyst is separated on-line inside the reactor, and the fluid carrying effect is used to form internal circulation and external heat exchange inside and outside the reactor, which can effectively prevent the catalyst from settling and promote The catalyst is evenly distributed in the axial direction of the reactor and the temperature distribution in the tower is improved, the space-time yield is high, the reaction heat is conveniently removed, the energy consumption is low, and it is easy to realize large-scale.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com