Pipe pile production technology and apparatus for axial distribution after mould combination

A technology of production process and production equipment, applied in the field of pipe pile production process and production equipment, can solve the problems of poor sealing performance, uneven distribution, spilled concrete, etc. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Production technology of the present invention comprises:

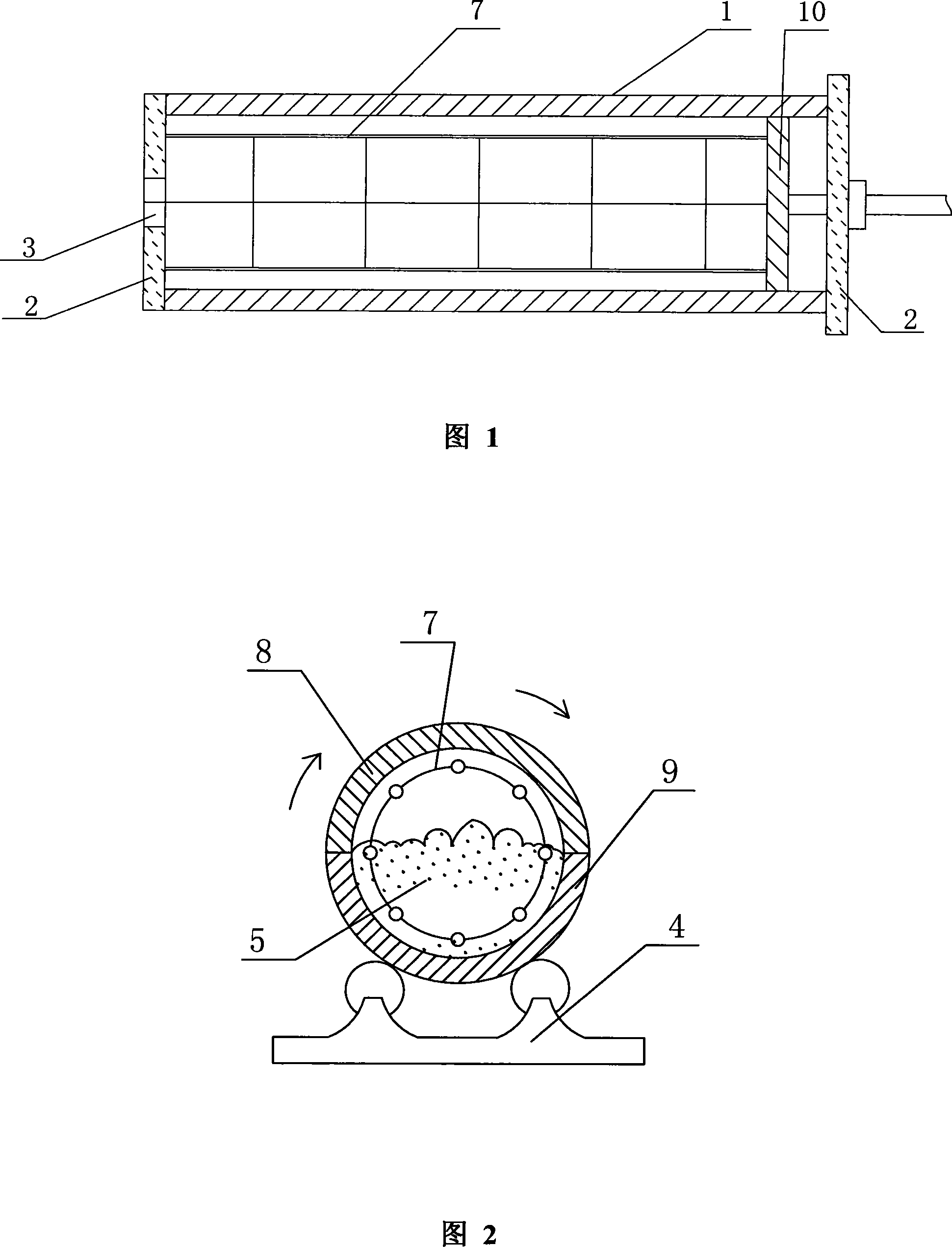

[0016] 1) After setting the reinforcement skeleton 7 in the lower phantom 9 of the pipe pile form 1 which is composed of the upper and lower phantoms 8 and 9 and can rotate along the axis, tighten the upper and lower phantoms;

[0017] 2) pouring ready-mixed concrete material 5 into the pipe pile formwork through the concrete pouring opening 3 on one end of the pipe pile formwork;

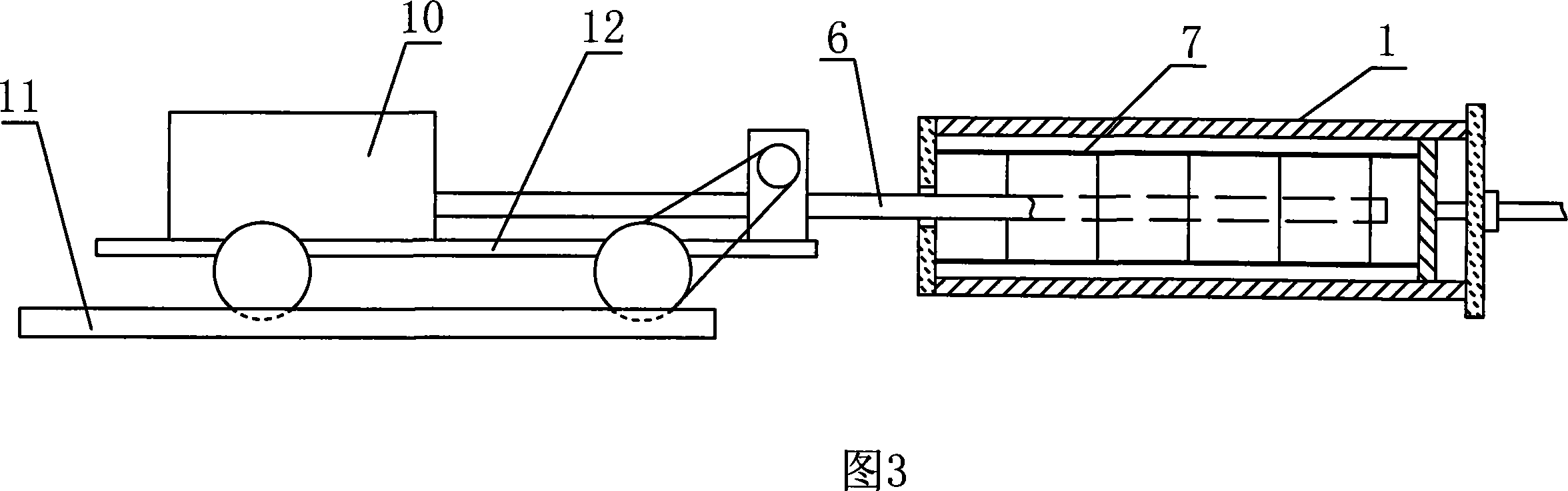

[0018] 3) The pipe pile mold is driven to rotate through the transmission mechanism 4, so that the concrete material is formed under the action of centrifugal force.

[0019] The pipe pile form 1 is composed of upper and lower half phantoms 8 and 9, and can rotate along the horizontal axis. The two ends of the pipe pile form are respectively provided with tensioning fixtures 2, and the concrete pouring opening 3 It is arranged on the tensioning fixture at one end, and the pipe pile formwork is set horizontally, and the ready-mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com