Rotating packed bed device with function of regulating and controlling axial liquid distribution

A high-gravity rotating bed and liquid distribution technology, applied in the field of high gravity, can solve problems such as uneven liquid distribution, weakened mass transfer effect, and insufficient utilization of rotor packing, so as to improve mass transfer efficiency and strengthen the gas-liquid mass transfer process , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

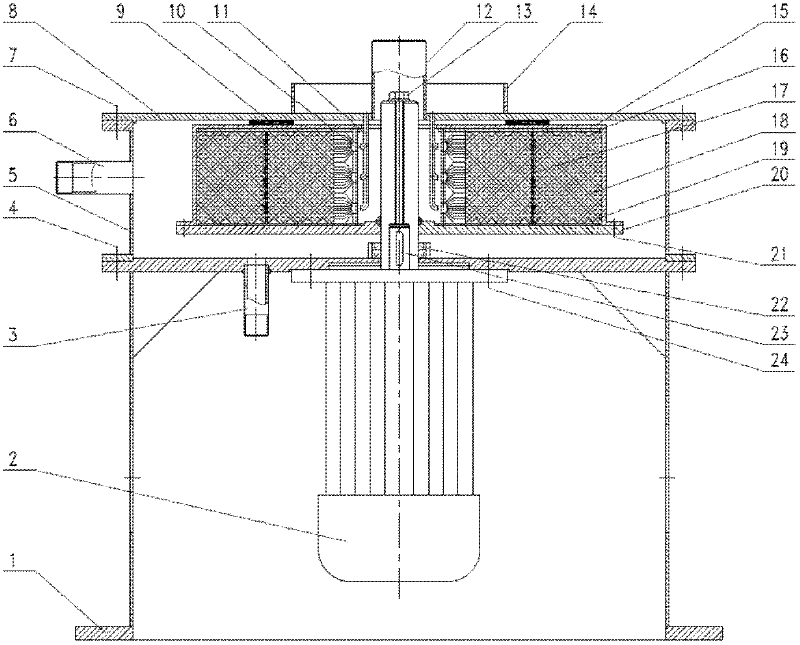

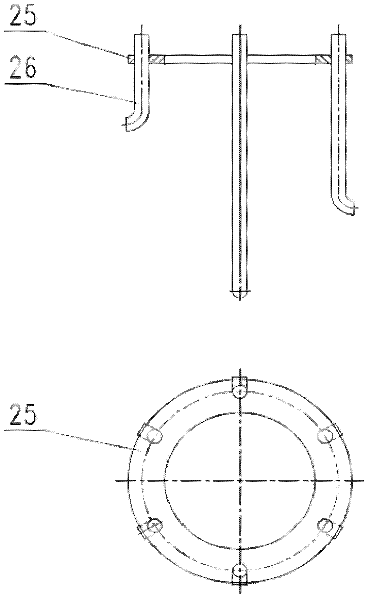

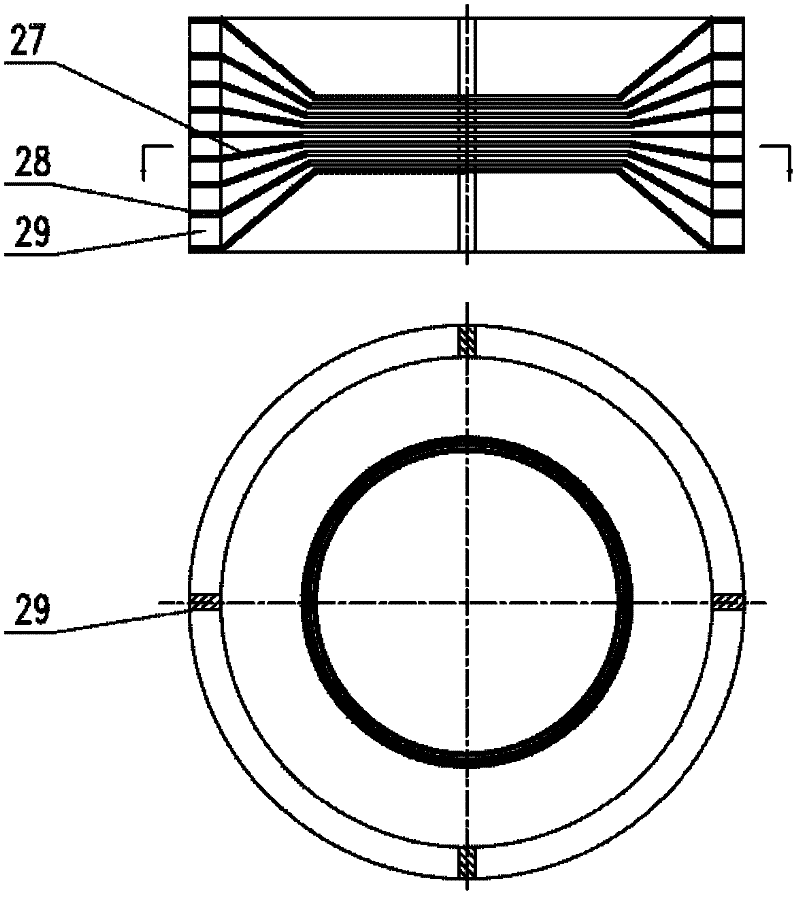

[0025] Such as figure 1 In the single-stage supergravity rotary bed device shown, in the airtight cavity 5 , the shaft of the motor 2 and the turntable 20 are fixed together with bolts 13 , and the motor 2 and the base 1 are fixed together with bolts 24 . The shaft of the motor 2 transmits torque to the shaft of the turntable 20 through the key 23, so that the rotor fixed on the turntable 20 rotates. The rotating bed rotor includes a packing gland 15, a packing core barrel 16, and a point-surface liquid distributor 10 (the schematic diagram is shown in image 3 , the inner part of the distributor is composed of 5 annular cone plates 27 with angles of 0°, 10°, 20°, 30°, and 40°, and a horizontal annular plate 28 is welded on the outside of the annular cone plate. Support plate 29 between plates 28), split cylinder liquid redistributor 17 (the schematic diagram is shown in Figure 4), the upper end surface and the lower end surface of the packing core barrel are provided with ...

Embodiment 2-25

[0030] The process flow and steps are the same as in Example 1, and the process conditions and operating conditions of each embodiment and the corresponding experimental results are shown in Table 1.

[0031] Process conditions and experimental results of each embodiment of table 1

[0032]

Embodiment 26

[0034] Schematic diagram of the structure of the high-gravity two-stage counter-current rotating bed of the present invention is as follows Figure 7 As shown, its structure is the same as figure 1 The structure is basically similar. Liquid flows from the reservoir 48 into the conduit liquid distributor 53 into the point surface liquid distributor 52 . The point surface liquid distributor 52 forces the liquid to distribute evenly in the axial direction of the packing. Under the action of centrifugal force, the liquid passes through the filler 51 and the split-cylindrical liquid redistributor 50, and then is sprayed out from the rotor, and finally is collected by the inner cavity and flows to the next rotor. In the next layer of rotor, the liquid goes through the same process, first flows into the duct type liquid distributor 46, passes through the point surface type liquid distributor 45, packing 42, split cylinder type liquid redistributor 43, and finally flows out from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com